Ratiometric Upconversion Temperature Sensor Based on Cellulose Fibers Modified with Yttrium Fluoride Nanoparticles

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Instrumentations

2.3. Synthesis of Upconversion Modifier

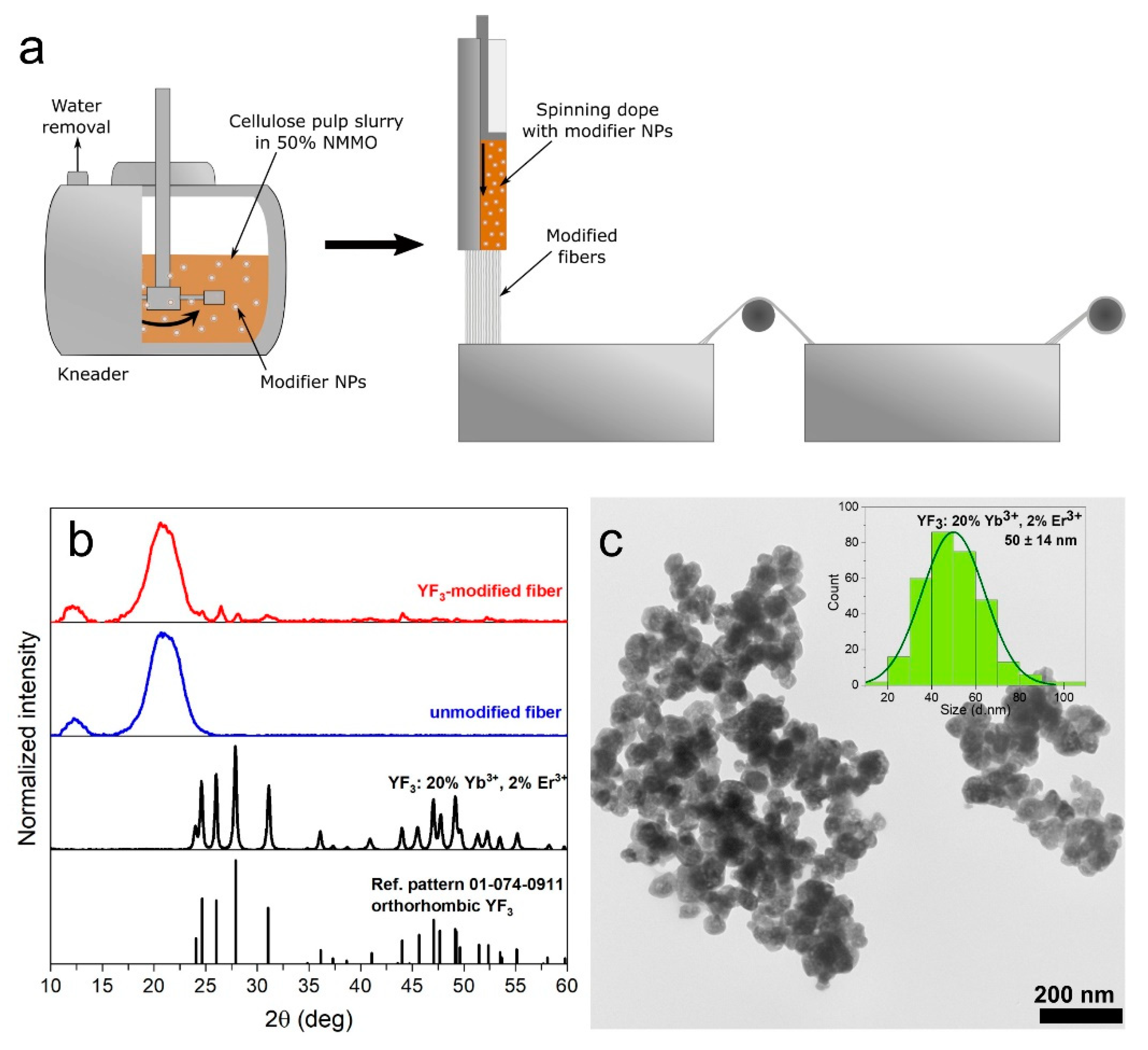

2.4. Preparation of Cellulose Fibers

3. Results

3.1. Structure and Morphology

3.2. Mechanical Properties

3.3. Luminescence Properties

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Amin, A.S. Application of a Triacetylcellulose Membrane with Immobilizated of 5-(2′,4′-Dimethylphenylazo)-6-Hydroxypyrimidine-2,4-Dione for Mercury Determination in Real Samples. Sens. Actuators B Chem. 2015, 221, 1342–1347. [Google Scholar] [CrossRef]

- Jiang, X.; Xia, J.; Luo, X. Simple, Rapid, and Highly Sensitive Colorimetric Sensor Strips from a Porous Cellulose Membrane Stained with Victoria Blue B for Efficient Detection of Trace Cd(II) in Water. ACS Sustain. Chem. Eng. 2020, 8, 5184–5191. [Google Scholar] [CrossRef]

- Li, N.; Yin, J.; Wei, L.; Shen, Q.; Tian, W.; Li, J.; Chen, Y.; Jin, J.; Teng, H.; Zhou, J. Facile Synthesis of Cellulose Acetate Ultrafiltration Membrane with Stimuli-Responsiveness to PH and Temperature Using the Additive of F127-b-PDMAEMA. Chin. J. Chem. 2017, 35, 1109–1116. [Google Scholar] [CrossRef]

- Mahadeva, S.K.; Yun, S.; Kim, J. Flexible Humidity and Temperature Sensor Based on Cellulose–Polypyrrole Nanocomposite. Sens. Actuators A Phys. 2011, 165, 194–199. [Google Scholar] [CrossRef]

- Manjakkal, L.; Franco, F.F.; Pullanchiyodan, A.; González-Jiménez, M.; Dahiya, R. Natural Jute Fibre-Based Supercapacitors and Sensors for Eco-Friendly Energy Autonomous Systems. Adv. Sustain. Syst. 2021, 5, 2000286. [Google Scholar] [CrossRef]

- Fan, J.; Zhang, S.; Li, F.; Yang, Y.; Du, M. Recent Advances in Cellulose-Based Membranes for Their Sensing Applications. Cellulose 2020, 27, 9157–9179. [Google Scholar] [CrossRef]

- Zhang, Z.; Liu, G.; Li, X.; Zhang, S.; Lü, X.; Wang, Y. Design and Synthesis of Fluorescent Nanocelluloses for Sensing and Bioimaging Applications. ChemPlusChem 2020, 85, 487–502. [Google Scholar] [CrossRef]

- Zhu, P.; Liu, Y.; Fang, Z.; Kuang, Y.; Zhang, Y.; Peng, C.; Chen, G. Flexible and Highly Sensitive Humidity Sensor Based on Cellulose Nanofibers and Carbon Nanotube Composite Film. Langmuir 2019, 35, 4834–4842. [Google Scholar] [CrossRef]

- Maddali, H.; Tyryshkin, A.M.; O’Carroll, D.M. Dual-Mode Polymer-Based Temperature Sensor by Dedoping of Electrochemically Doped, Conjugated Polymer Thin Films. ACS Appl. Electron. Mater. 2021, 3, 4718–4725. [Google Scholar] [CrossRef]

- Skwierczyńska, M.; Woźny, P.; Runowski, M.; Kulpiński, P.; Lis, S. Optically Active Plasmonic Cellulose Fibers Based on Au Nanorods for SERS Applications. Carbohydr. Polym. 2022, 279, 119010. [Google Scholar] [CrossRef]

- Wang, G.; Jiang, G.; Zhu, Y.; Cheng, W.; Cao, K.; Zhou, J.; Lei, H.; Xu, G.; Zhao, D. Developing Cellulosic Functional Materials from Multi-Scale Strategy and Applications in Flexible Bioelectronic Devices. Carbohydr. Polym. 2022, 283, 119160. [Google Scholar] [CrossRef] [PubMed]

- Zheng, Y.; Xiao, M.; Jiang, S.; Ding, F.; Wang, J. Coating Fabrics with Gold Nanorods for Colouring, UV-Protection, and Antibacterial Functions. Nanoscale 2013, 5, 788–795. [Google Scholar] [CrossRef] [PubMed]

- Kaur, A.; Singh, R.C. Temperature Sensor Based on Exfoliated Graphene Sheets Produced by Microwave Assisted Freezing Induced Volumetric Expansion of Carbonated Water. J. Mater. Sci. Mater. Electron. 2019, 30, 5791–5807. [Google Scholar] [CrossRef]

- Shin, J.; Jeong, B.; Kim, J.; Nam, V.B.; Yoon, Y.; Jung, J.; Hong, S.; Lee, H.; Eom, H.; Yeo, J.; et al. Sensitive Wearable Temperature Sensor with Seamless Monolithic Integration. Adv. Mater. 2020, 32, 1905527. [Google Scholar] [CrossRef] [PubMed]

- Yang, J.; Wei, D.; Tang, L.; Song, X.; Luo, W.; Chu, J.; Gao, T.; Shi, H.; Du, C. Wearable Temperature Sensor Based on Graphene Nanowalls. RSC Adv. 2015, 5, 25609–25615. [Google Scholar] [CrossRef]

- Mikolajek, M.; Martinek, R.; Koziorek, J.; Hejduk, S.; Vitasek, J.; Vanderka, A.; Poboril, R.; Vasinek, V.; Hercik, R. Temperature Measurement Using Optical Fiber Methods: Overview and Evaluation. J. Sens. 2020, 2020, 8831332. [Google Scholar] [CrossRef]

- Moraleda, A.; García, C.; Zaballa, J.; Arrue, J. A Temperature Sensor Based on a Polymer Optical Fiber Macro-Bend. Sensors 2013, 13, 13076–13089. [Google Scholar] [CrossRef] [Green Version]

- Zhang, H.; Zhao, S.; Wang, X.; Ren, X.; Ye, J.; Huang, L.; Xu, S. The Enhanced Photoluminescence and Temperature Sensing Performance in Rare Earth Doped SrMoO4 Phosphors by Aliovalent Doping: From Material Design to Device Applications. J. Mater. Chem. C 2019, 7, 15007–15013. [Google Scholar] [CrossRef]

- Liu, Y.; Peng, W.; Liang, Y.; Zhang, X.; Zhou, X.; Pan, L. Fiber-Optic Mach–Zehnder Interferometric Sensor for High-Sensitivity High Temperature Measurement. Opt. Commun. 2013, 300, 194–198. [Google Scholar] [CrossRef]

- Tapetado, A.; Pinzon, P.J.; Zubia, J.; Vazquez, C. Polymer Optical Fiber Temperature Sensor With Dual-Wavelength Compensation of Power Fluctuations. J. Light. Technol. 2015, 33, 2716–2723. [Google Scholar] [CrossRef] [Green Version]

- Zheng, T.; Runowski, M.; Stopikowska, N.; Skwierczyńska, M.; Lis, S.; Du, P.; Luo, L. Dual-Center Thermochromic Bi2MoO6:Yb3+, Er3+, Tm3+ Phosphors for Ultrasensitive Luminescence Thermometry. J. Alloy. Compd. 2022, 890, 161830. [Google Scholar] [CrossRef]

- Abid; Sehrawat, P.; Julien, C.M.; Islam, S.S. E-Textile Based Wearable Thermometer from WS2 -Quantum Dots. Nanotechnology 2021, 32, 335503. [Google Scholar] [CrossRef]

- Brites, C.D.S.; Millán, A.; Carlos, L.D. Lanthanides in Luminescent Thermometry. In Handbook on the Physics and Chemistry of Rare Earths; Elsevier: Amsterdam, The Netherlands, 2016; Volume 49, pp. 339–427. [Google Scholar]

- Brites, C.D.S.; Balabhadra, S.; Carlos, L.D. Lanthanide-Based Thermometers: At the Cutting-Edge of Luminescence Thermometry. Adv. Opt. Mater. 2019, 7, 1801239. [Google Scholar] [CrossRef] [Green Version]

- Runowski, M. Pressure and Temperature Optical Sensors: Luminescence of Lanthanide-Doped Nanomaterials for Contactless Nanomanometry and Nanothermometry. In Handbook of Nanomaterials in Analytical Chemistry; Elsevier: Amsterdam, The Netherlands, 2020; pp. 227–273. ISBN 9780128166994. [Google Scholar]

- Runowski, M.; Woźny, P.; Martín, I.R. Optical Pressure Sensing in Vacuum and High-Pressure Ranges Using Lanthanide-Based Luminescent Thermometer–Manometer. J. Mater. Chem. C 2021, 9, 4643–4651. [Google Scholar] [CrossRef]

- Stopikowska, N.; Runowski, M.; Skwierczyńska, M.; Lis, S. Improving Performance of Luminescent Nanothermometers Based on Non-Thermally and Thermally Coupled Levels of Lanthanides by Modulating Laser Power. Nanoscale 2021, 13, 14139–14146. [Google Scholar] [CrossRef]

- Suo, H.; Zhao, X.; Zhang, Z.; Wang, Y.; Sun, J.; Jin, M.; Guo, C. Rational Design of Ratiometric Luminescence Thermometry Based on Thermally Coupled Levels for Bioapplications. Laser Photon. Rev. 2021, 15, 2000319. [Google Scholar] [CrossRef]

- Brites, C.D.S.; Fiaczyk, K.; Ramalho, J.F.C.B.; Sójka, M.; Carlos, L.D.; Zych, E. Widening the Temperature Range of Luminescent Thermometers through the Intra- and Interconfigurational Transitions of Pr3+. Adv. Opt. Mater. 2018, 6, 1701318. [Google Scholar] [CrossRef]

- Manzani, D.; Petruci, J.F.D.S.; Nigoghossian, K.; Cardoso, A.A.; Ribeiro, S.J.L. A Portable Luminescent Thermometer Based on Green Up-Conversion Emission of Er3+/Yb3+ Co-Doped Tellurite Glass. Sci. Rep. 2017, 7, 41596. [Google Scholar] [CrossRef]

- Wang, Q.; Liao, M.; Lin, Q.; Xiong, M.; Mu, Z.; Wu, F. A Review on Fluorescence Intensity Ratio Thermometer Based on Rare-Earth and Transition Metal Ions Doped Inorganic Luminescent Materials. J. Alloys Compd. 2021, 850, 156744. [Google Scholar] [CrossRef]

- Jaque, D.; Vetrone, F. Luminescence Nanothermometry. Nanoscale 2012, 4, 4301. [Google Scholar] [CrossRef]

- Zhu, K.; Zhou, H.; Qiu, J.; Wang, L.-G.; Ye, L. Optical Temperature Sensing Characteristics of Sm3+ Doped YAG Single Crystal Fiber Based on Luminescence Emission. J. Alloy. Compd. 2022, 890, 161844. [Google Scholar] [CrossRef]

- Luo, Y.; Zhang, L.; Liu, Y.; Heydari, E.; Chen, L.; Bai, G. Designing Dual-mode Luminescence in Er3+ Doped Y2WO6 Microparticles for Anticounterfeiting and Temperature Measurement. J. Am. Ceram. Soc. 2022, 105, 1375–1385. [Google Scholar] [CrossRef]

- Guo, J.; Zhou, B.; Yang, C.; Dai, Q.; Kong, L. Stretchable and Temperature-Sensitive Polymer Optical Fibers for Wearable Health Monitoring. Adv. Funct. Mater. 2019, 29, 1902898. [Google Scholar] [CrossRef]

- Suo, H.; Hu, F.; Zhao, X.; Zhang, Z.; Li, T.; Duan, C.; Yin, M.; Guo, C. All-in-One Thermometer-Heater up-Converting Platform YF3: Yb3+, Tm3+ Operating in the First Biological Window. J. Mater. Chem. C 2017, 5, 1501–1507. [Google Scholar] [CrossRef]

- Suo, H.; Zhao, X.; Zhang, Z.; Li, T.; Goldys, E.M.; Guo, C. Constructing Multiform Morphologies of YF: Er3+/Yb3+ up-Conversion Nano/Micro-Crystals towards Sub-Tissue Thermometry. Chem. Eng. J. 2017, 313, 65–73. [Google Scholar] [CrossRef]

- Pudovkin, M.S.; Ginkel, A.K.; Lukinova, E.V. Temperature Sensitivity of Nd3+, Yb3+:YF3 Ratiometric Luminescent Thermometers at Different Yb3+ Concentration. Opt. Mater. 2021, 119, 111328. [Google Scholar] [CrossRef]

- Runowski, M.; Woźny, P.; Martín, I.R.; Lavín, V.; Lis, S. Praseodymium Doped YF3:Pr3+ Nanoparticles as Optical Thermometer Based on Luminescence Intensity Ratio (LIR)—Studies in Visible and NIR Range. J. Lumin. 2019, 214, 116571. [Google Scholar] [CrossRef]

- Gong, J.; Li, J.; Xu, J.; Xiang, Z.; Mo, L. Research on Cellulose Nanocrystals Produced from Cellulose Sources with Various Polymorphs. RSC Adv. 2017, 7, 33486–33493. [Google Scholar] [CrossRef] [Green Version]

- Gupta, P.K.; Uniyal, V.; Naithani, S. Polymorphic Transformation of Cellulose I to Cellulose II by Alkali Pretreatment and Urea as an Additive. Carbohydr. Polym. 2013, 94, 843–849. [Google Scholar] [CrossRef]

- Öztürk, H.B.; Potthast, A.; Rosenau, T.; Abu-Rous, M.; MacNaughtan, B.; Schuster, K.C.; Mitchell, J.R.; Bechtold, T. Changes in the Intra- and Inter-Fibrillar Structure of Lyocell (TENCEL®) Fibers Caused by NaOH Treatment. Cellulose 2009, 16, 37–52. [Google Scholar] [CrossRef]

- Runowski, M.; Shyichuk, A.; Tymiński, A.; Grzyb, T.; Lavín, V.; Lis, S. Multifunctional Optical Sensors for Nanomanometry and Nanothermometry: High-Pressure and High-Temperature Upconversion Luminescence of Lanthanide-Doped Phosphates—LaPO4/YPO4:Yb3+ –Tm3+. ACS Appl. Mater. Interfaces 2018, 10, 17269–17279. [Google Scholar] [CrossRef] [PubMed]

- Martins, J.C.; Bastos, A.R.N.; Ferreira, R.A.S.; Wang, X.; Chen, G.; Carlos, L.D. Primary Luminescent Nanothermometers for Temperature Measurements Reliability Assessment. Adv. Photonics Res. 2021, 2, 2000169. [Google Scholar] [CrossRef]

- Balabhadra, S.; Debasu, M.L.; Brites, C.D.S.; Ferreira, R.A.S.; Carlos, L.D. Upconverting Nanoparticles Working as Primary Thermometers in Different Media. J. Phys. Chem. C 2017, 121, 13962–13968. [Google Scholar] [CrossRef]

- Liu, W.; Wang, X.; Zhu, Q.; Li, X.; Sun, X.; Li, J.-G. Upconversion Luminescence and Favorable Temperature Sensing Performance of Eulytite-Type Sr3Y(PO4)3: Yb3+/Ln3+ Phosphors (Ln=Ho, Er, Tm). Sci. Technol. Adv. Mater. 2019, 20, 949–963. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ngo, T.T.; Cabello-Olmo, E.; Arroyo, E.; Becerro, A.I.; Ocaña, M.; Lozano, G.; Míguez, H. Highly Versatile Upconverting Oxyfluoride-Based Nanophosphor Films. ACS Appl. Mater. Interfaces 2021, 13, 30051–30060. [Google Scholar] [CrossRef] [PubMed]

- Chai, G.; Dong, G.; Qiu, J.; Zhang, Q.; Yang, Z. Phase Transformation and Intense 2.7 Μm Emission from Er3+ Doped YF3/YOF Submicron-Crystals. Sci. Rep. 2013, 3, 1598. [Google Scholar] [CrossRef] [Green Version]

- Carrillo, F.; Colom, X.; Suñol, J.; Saurina, J. Structural FTIR Analysis and Thermal Characterisation of Lyocell and Viscose-Type Fibres. Eur. Polym. J. 2004, 40, 2229–2234. [Google Scholar] [CrossRef]

- Tan, W.; Ren, Y.; Xiao, M.; Guo, Y.; Liu, Y.; Zhang, J.; Zhou, X.; Liu, X. Enhancing the Flame Retardancy of Lyocell Fabric Finished with an Efficient, Halogen-Free Flame Retardant. RSC Adv. 2021, 11, 34926–34937. [Google Scholar] [CrossRef]

- Freitas, R.A. Nanomedicine, Volume I: Basic Capabilities; Landes Bioscience: Austin, TX, USA, 1999; Volume I, ISBN 1-57059-645-X. [Google Scholar]

- Sadasivuni, K.K.; Kafy, A.; Kim, H.-C.; Ko, H.-U.; Mun, S.; Kim, J. Reduced Graphene Oxide Filled Cellulose Films for Flexible Temperature Sensor Application. Synth. Met. 2015, 206, 154–161. [Google Scholar] [CrossRef]

- Yi, H.; Lee, S.-H.; Kim, D.; Jeong, H.E.; Jeong, C. Colorimetric Sensor Based on Hydroxypropyl Cellulose for Wide Temperature Sensing Range. Sensors 2022, 22, 886. [Google Scholar] [CrossRef]

- Wei, Y.; Qian, Y.; Zhu, P.; Xiang, L.; Lei, C.; Qiu, G.; Wang, C.; Liu, Y.; Liu, Y.; Chen, G. Nanocellulose-Templated Carbon Nanotube Enhanced Conductive Organohydrogel for Highly-Sensitive Strain and Temperature Sensors. Cellulose 2022, 29, 3829–3844. [Google Scholar] [CrossRef]

| Unmodified Cellulose Fibers | YF3-Modified Cellulose Fibers | |

|---|---|---|

| Elastic modulus [cN/tex] | 1218 | 1519 |

| Tenacity [cN/tex] | 28.7 | 26.2 |

| Elongation at break [%] | 9.4 | 8.0 |

| Linear density [tex] | 0.3264 | 1.450 |

| Material | Type of Sensor | Sensing Range [K] | ΔT [K] | Sr, [% K−1] | Susceptible to EMI | Ref. |

|---|---|---|---|---|---|---|

| YF3-modified cellulose fibers | Ratiometric UC | 298–362 | 0.09 (at 298 K) | 1.23 (at 289 K) | No | This work |

| Cellulose-PPy nanocomposite | Capacitive | 288–323 | n.d. | n.d. | Yes | [4] |

| PEDOT-PSS-SWCNT coated jute fibers | Resistive | 297–308 | n.d. | 0.23 | Yes | [5] |

| WS2-QDs/RGO coated cotton fabric | Resistive | 77–398 | 0.01 (0.06 human trial) | 0.56 (298-396 K) | Yes | [22] |

| Cellulose/RGO composite films | Capacitive | 298–353 | n.d | n.d | Yes | [52] |

| HPC-ethylene glycol | Colorimetric | 253–298 | 2 | n.a. | No | [53] |

| CNF/CNT nanohybrid | Resistive | 303–353 | n.d. | 1.081 | Yes | [54] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Skwierczyńska, M.; Stopikowska, N.; Kulpiński, P.; Kłonowska, M.; Lis, S.; Runowski, M. Ratiometric Upconversion Temperature Sensor Based on Cellulose Fibers Modified with Yttrium Fluoride Nanoparticles. Nanomaterials 2022, 12, 1926. https://doi.org/10.3390/nano12111926

Skwierczyńska M, Stopikowska N, Kulpiński P, Kłonowska M, Lis S, Runowski M. Ratiometric Upconversion Temperature Sensor Based on Cellulose Fibers Modified with Yttrium Fluoride Nanoparticles. Nanomaterials. 2022; 12(11):1926. https://doi.org/10.3390/nano12111926

Chicago/Turabian StyleSkwierczyńska, Małgorzata, Natalia Stopikowska, Piotr Kulpiński, Magdalena Kłonowska, Stefan Lis, and Marcin Runowski. 2022. "Ratiometric Upconversion Temperature Sensor Based on Cellulose Fibers Modified with Yttrium Fluoride Nanoparticles" Nanomaterials 12, no. 11: 1926. https://doi.org/10.3390/nano12111926

APA StyleSkwierczyńska, M., Stopikowska, N., Kulpiński, P., Kłonowska, M., Lis, S., & Runowski, M. (2022). Ratiometric Upconversion Temperature Sensor Based on Cellulose Fibers Modified with Yttrium Fluoride Nanoparticles. Nanomaterials, 12(11), 1926. https://doi.org/10.3390/nano12111926