Influence of Laser Process Parameters, Liquid Medium, and External Field on the Synthesis of Colloidal Metal Nanoparticles Using Pulsed Laser Ablation in Liquid: A Review

Abstract

:1. Introduction

| Reference | Metal-Based Nanoparticle | Industry | Applications |

|---|---|---|---|

| Hussain et al. (2021) [39] Hogeweg et al. (2018) [40] Mahmoud et al. (2018) [41] You et al. (2021) [42] | ZnO, SiO2, CuO, Al2O3, TiO2 Fe2O3 | Oil and gas | For enhanced oil recovery (EOR), drilling fluids, wastewater treatment |

| Chellaram et al. (2014) [43] Sahani et al. (2021) [44] Madkour et al. (2021) [45] Tayel et al. (2011) [46] | TiO2, SiO2 ZnO, MgO | Food industry | Food packaging and preservation, additive to improve food texture and colour, contaminant detection; flavouring powders |

| Díez-Pascual (2018) [47] Bhattacharyya et al. (2011) [48] Rodrigues et al. (2019) [49] | ZnO, CuO, Ag2O3, NiO, Bi2O3, MnO2, Al2O3, MgO | Medical | Used in antimicrobial, antibacterial, antifungal treatment |

| Kong et al. (2017) [50] Gu et al. (2020) [51] Adams et al. (2014) [52] | Au, Pt, Pd. TiO, CeO | Pharmaceutical industry | Used as catalyst in drug delivery for anti-cancer, radiotherapy, gene delivery |

| Aliofkhazraei (2016) [53] Ali et al. (2016) [54] Tan et al. (2019) [55] | FeO2, Ag, CdS, GaN, Si, TiO2, Al | Electronic industry | Used in solar cell development, semiconductor devices, ink for 3D printing in electronics |

| Al tuwirqi et al. (2020) [56] Geppert et al. (2021) [57] Jiang et al. (2018) [58] Kalajahi et al. (2020) [59] | Fe2O3, ZnO, | Medical devices | Imaging & bio-analysis, metal nanoparticles doped carbon quantum dots (CQDs) |

| Dinca et al. (2012) [60] Rana et al. (2016) [61] | TiN SiC, Al, Fe2O3, Fe3O4, Cr | Aerospace industry | Nanoparticles as composites, surface coatings for improving the mechanical strength of aircraft structures, data storage media |

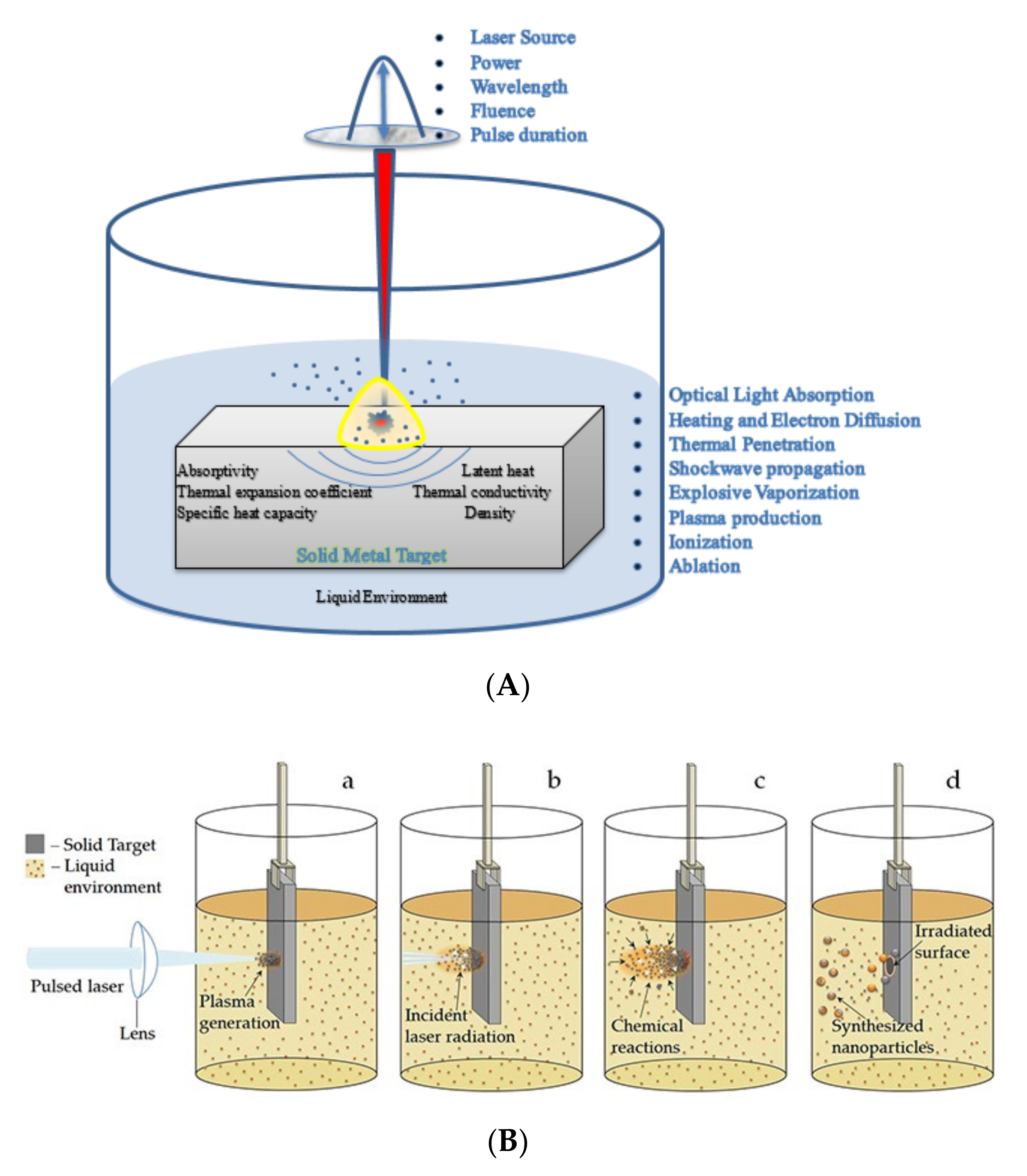

2. Mechanism of the PLAL Process

- The absorption of radiation by the target metal surface electrons and transfer of energy to the lattice;

- Explosive vaporisation and creation of a plasma plume;

- The generation of shockwaves in the solution due to temperature and pressure variations;

- The creation of a cavitation bubble expansion, shrinkage at supersonic speeds, and further diffusion, leading to the ablation of the metal target and release of NPs.

3. Physical Interactions in the PLAL Process

3.1. Laser–Liquid Interaction

3.2. Radiation Absorption and Energy Transfer to the Lattice

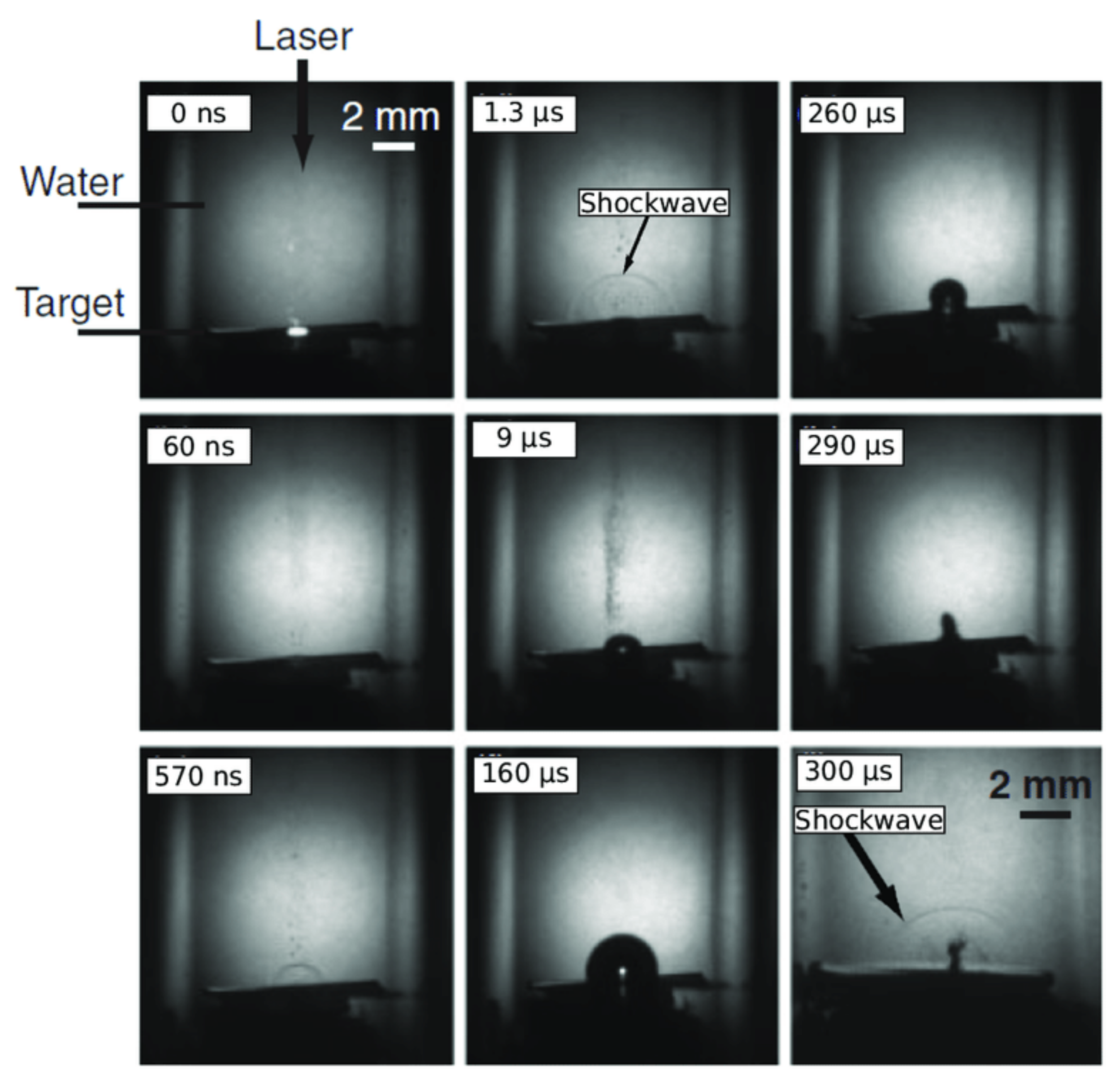

3.3. Cavitation Bubble Dynamics

3.4. NP Formation and Release

4. Laser Parameters Influencing the Ablation and Synthesis of Colloidal NPs

4.1. Source and Wavelength of Laser

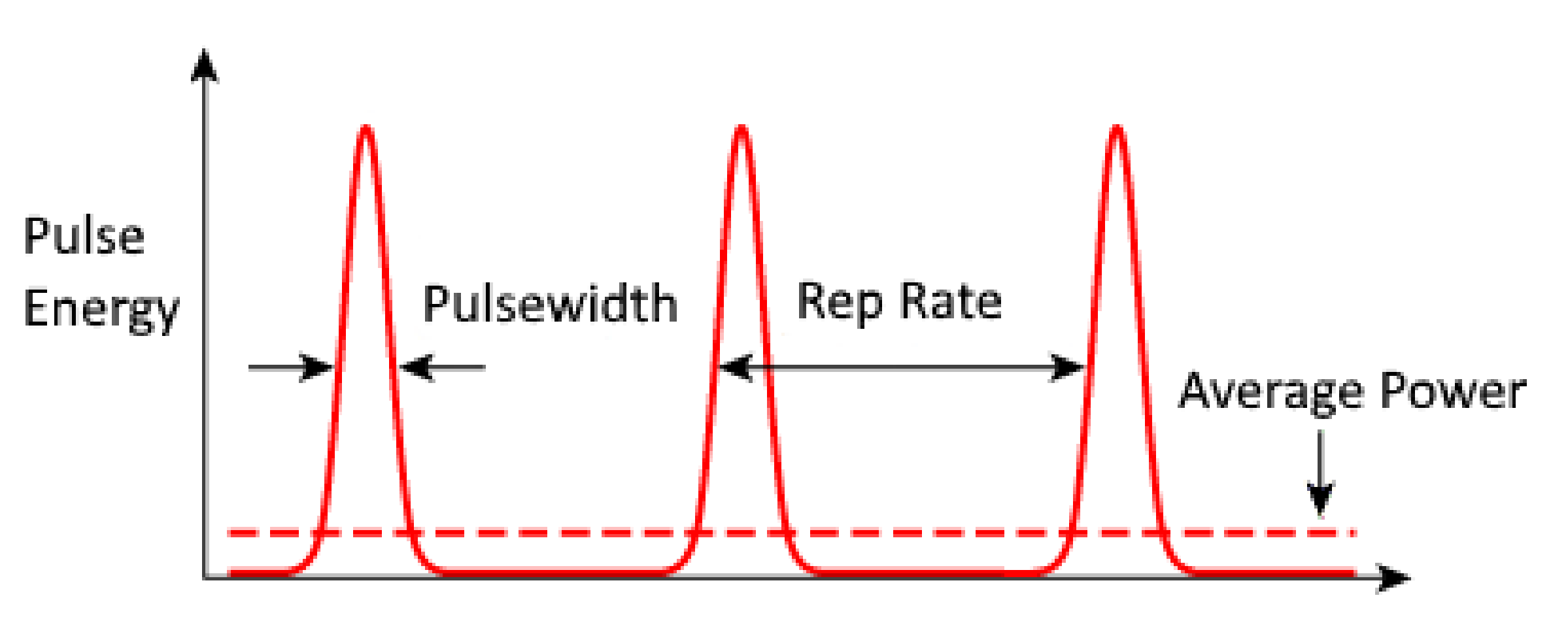

4.2. Pulse Duration (Pulse Width)

4.3. Laser Fluence

4.4. Pulse Repetition Rate (PRR) or Pulse Frequency

5. Effects of a Liquid Environment on the Synthesis of NPs

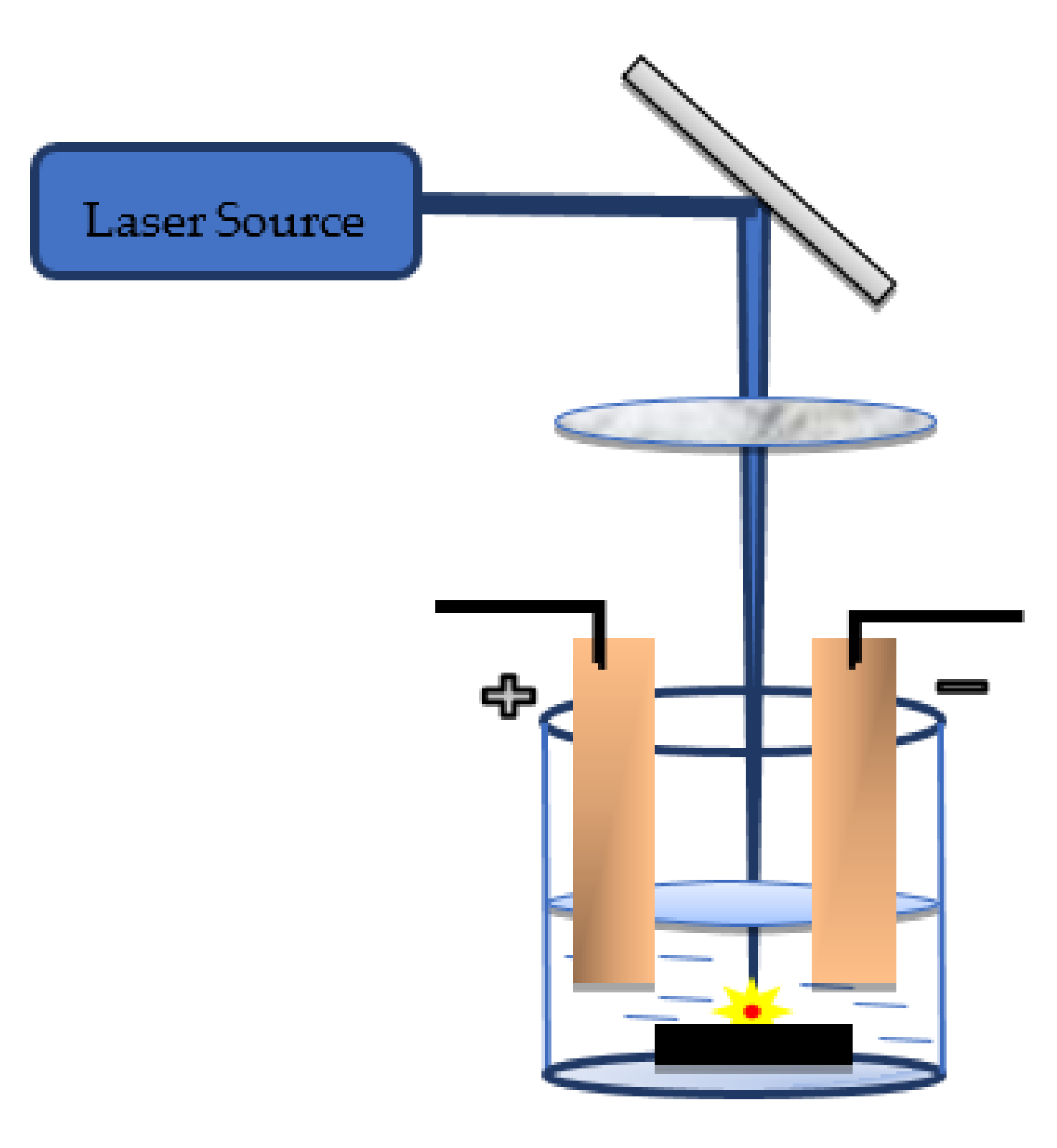

6. Effects of External Field-Assisted Pulsed Laser Ablation

6.1. Electric Field-Assisted PLAL

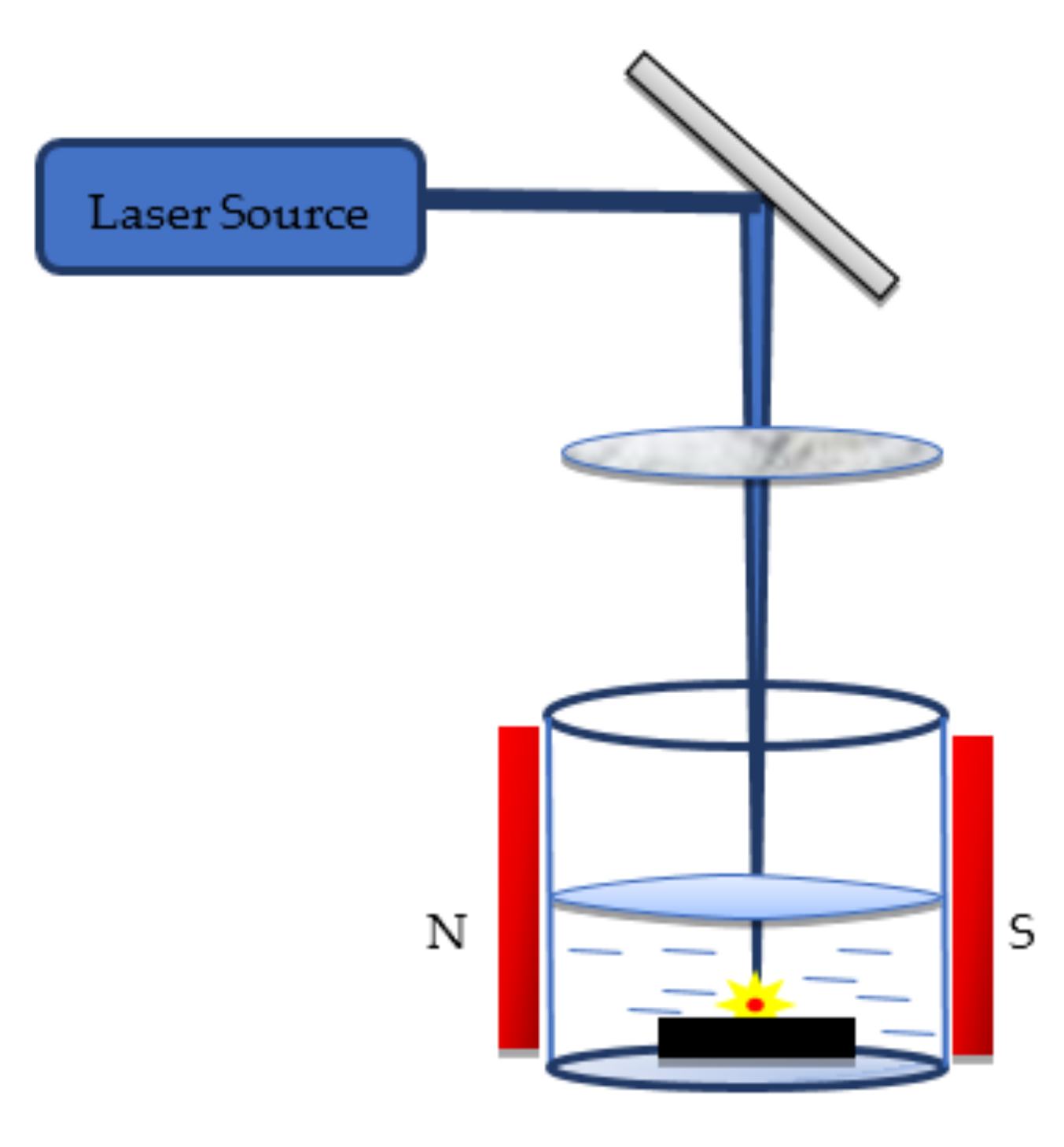

6.2. Magnetic Field-Assisted PLAL

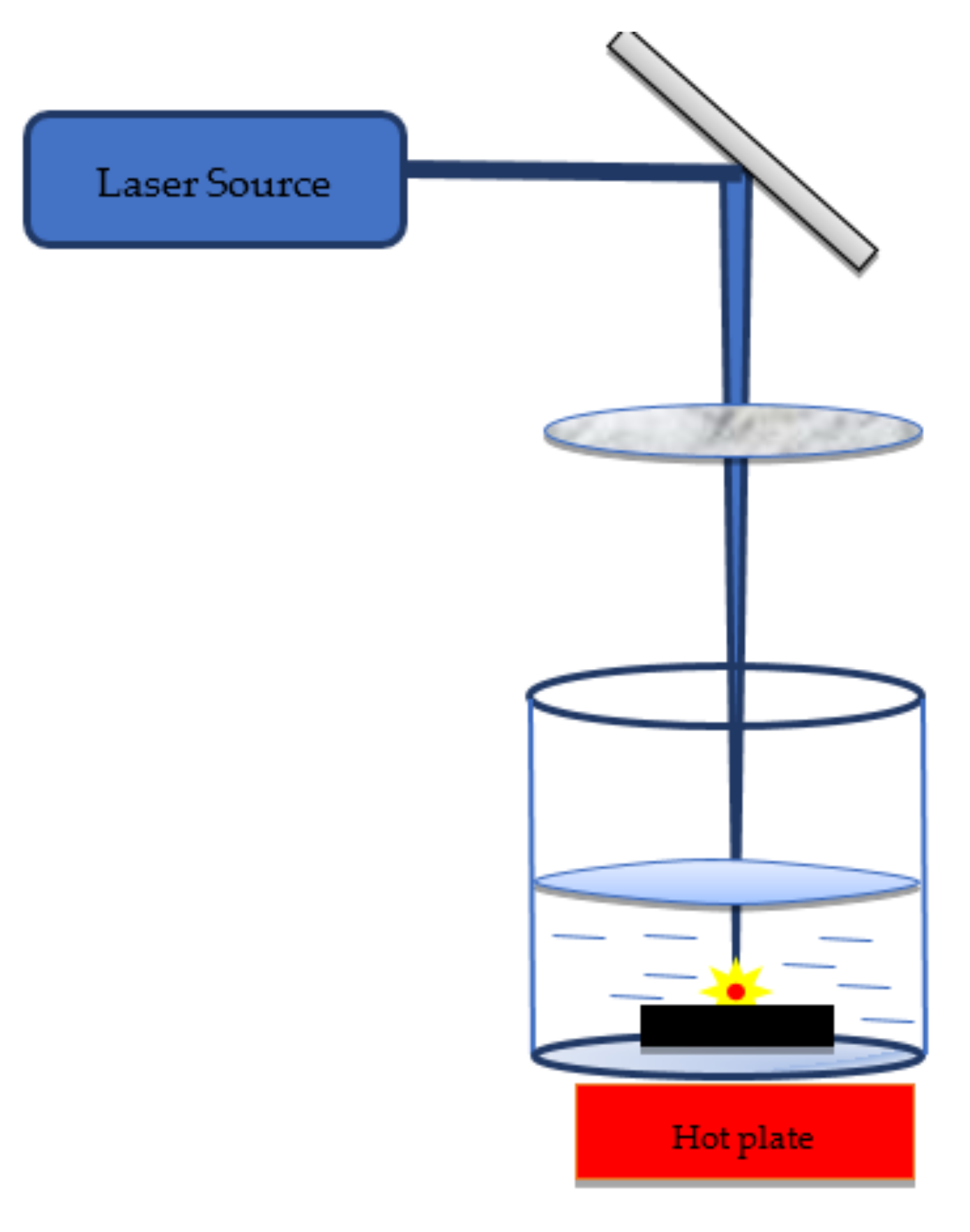

6.3. Temperature Field-Assisted PLAL

7. Bi-Metallic NPs

8. Conclusions

9. Prospects

- (1)

- Laser parameters can be further optimised by considering the effect of material properties that play a major role in the nanostructure formation.

- (2)

- The physiochemical interactions occurring in the PLAL process can be further studied by analysing the thermodynamic process and the chemical reactions between the liquid environment and the ablated NPs.

- (3)

- Further investigations in the effect of ablation angle could be performed because the available literature has focused only on the perpendicular laser beam striking the material target.

- (4)

- Mitigating the toxic effects of colloidal NPs while retaining their most desirable optical properties remains a challenge. Hence, achieving excellent biocompatibility is a prerequisite for the widespread use of colloidal NPs.

- (5)

- Instead of studying PLAL as a standalone technique, further integration with other physical or chemical methods can be performed to help stabilise the colloidal NPs for targeted applications. To the best of our knowledge, studies in this field are limited.

- (6)

- From this review, we have observed that the liquid environment, material properties, laser parameters, and external field have a combined effect on the size of the obtained NPs and their distribution, morphology, and structure. However, deciding which parameter plays a decisive role in the resultant formation of the desired NPs remains a challenge. Furthermore, we found studies on PLAL [34,67,72,92,98,99,100,101,102,103,104,105,106,107,108,109,110,111] that focused on single-parameter evaluation; however, the area of multiparametric analysis of laser parameters on nanoparticle formation can be explored.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| A | absorbance |

| c | molar concentration |

| l0 | optical path length |

| PLA | pulse laser ablation |

| NPs | nanoparticles |

| DT | thermal diffusivity |

| attenuation coefficient | |

| f | focal length of the lens |

| l | thickness of the liquid layer |

| n | refractive index of liquid |

| r | radius of the laser beam before focus |

| Hv | heat of vaporisation |

| density | |

| CQDS | carbon quantum dots |

| PLAL | pulsed laser ablation in liquid |

| λ | wavelength |

| pulse duration | |

| optical penetration | |

| k | thermal conductivity |

| specific heat capacity of the target material | |

| τe | electron cooling time |

| τp | lattice heating time |

| volumetric heat capacity of electron | |

| electron temperature | |

| C | lattice volumetric heat capacity |

| electron thermal conductivity | |

| electron lattice energy heat transfer coefficient | |

| R | reflectivity of the target material |

| I | laser intensity |

| F | laser fluence |

| Fth | threshold fluence |

| V | scanning speed |

| T | pulse duration |

| S | laser beam spot size |

| E | pulse energy |

| PRR | pulse repetition rate |

| ps | picosecond |

| ns | nanosecond |

| fs | femtosecond |

References

- Cho, E.J.; Holback, H.; Liu, K.C.; Abouelmagd, S.A.; Park, J.; Yeo, Y. Nanoparticle Characterization: State of the Art, Challenges, and Emerging Technologies. Mol. Pharm. 2013, 10, 2093–2110. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Rao, S.V.; Podagatlapalli, G.K.; Hamad, S. Ultrafast Laser Ablation in Liquids for Nanomaterials and Applications. J. Nanosci. Nanotechnol. 2014, 14, 1364–1388. [Google Scholar] [CrossRef] [PubMed]

- Zhou, K.; Zhou, X.; Liu, J.; Huang, Z. Application of magnetic nanoparticles in petroleum industry: A review. J. Pet. Sci. Eng. 2020, 188, 106943. [Google Scholar] [CrossRef]

- Beck, A.; Huang, X.; Artiglia, L.; Zabilskiy, M.; Wang, X.; Rzepka, P.; Palagin, D.; Willinger, M.-G.; Van Bokhoven, J.A. The dynamics of overlayer formation on catalyst nanoparticles and strong metal-support interaction. Nat. Commun. 2020, 11, 1–8. [Google Scholar] [CrossRef]

- Krishnapriya, R.; Nizamudeen, C.; Saini, B.; Mozumder, M.S.; Sharma, R.K.; Mourad, A.-H.I. MOF-derived Co2+-doped TiO2 nanoparticles as photoanodes for dye-sensitized solar cells. Sci. Rep. 2021, 11, 16265. [Google Scholar] [CrossRef]

- Aliev, R.; Gulomov, J.; Abduvohidov, M.; Aliev, S.; Ziyoitdinov, Z.; Yuldasheva, N. Stimulation of Photoactive Absorption of Sunlight in Thin Layers of Silicon Structures by Metal Nanoparticles. Appl. Sol. Energy 2020, 56, 364–370. [Google Scholar] [CrossRef]

- Rahman, M.M.; Karim, M.R.; Alharbi, H.F.; Aldokhayel, B.; Uzzaman, T.; Zahir, H. Cadmium Selenide Quantum Dots for Solar Cell Applications: A Review. Chem. Asian J. 2021, 16, 902–921. [Google Scholar] [CrossRef]

- Hu, X.; Zhang, Y.; Ding, T.; Liu, J.; Zhao, H. Multifunctional Gold Nanoparticles: A Novel Nanomaterial for Various Medical Applications and Biological Activities. Front. Bioeng. Biotechnol. 2020, 8, 990. [Google Scholar] [CrossRef]

- Fiévet, F.; Ammar-Merah, S.; Brayner, R.; Chau, F.; Giraud, M.; Mammeri, F.; Peron, J.; Piquemal, J.-Y.; Sicard, L.; Viau, G. The polyol process: A unique method for easy access to metal nanoparticles with tailored sizes, shapes and compositions. Chem. Soc. Rev. 2018, 47, 5187–5233. [Google Scholar] [CrossRef]

- Tojo, C.; De Dios, M.; Barroso, F. Surfactant Effects on Microemulsion-Based Nanoparticle Synthesis. Materials 2010, 4, 55–72. [Google Scholar] [CrossRef] [Green Version]

- Odularu, A.T. Metal Nanoparticles: Thermal Decomposition, Biomedicinal Applications to Cancer Treatment, and Future Perspectives. Bioinorg. Chem. Appl. 2018, 2018, 9354708. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Yan, K.; Xu, F.; Wei, W.; Yang, C.; Wang, D.; Shi, X. Electrochemical synthesis of chitosan/silver nanoparticles multilayer hydrogel coating with pH-dependent controlled release capability and antibacterial property. Colloids Surf. B Biointerfaces 2021, 202, 111711. [Google Scholar] [CrossRef] [PubMed]

- Arya, S.; Mahajan, P.; Mahajan, S.; Khosla, A.; Datt, R.; Gupta, V.; Young, S.-J.; Oruganti, S.K. Review—Influence of Processing Parameters to Control Morphology and Optical Properties of Sol-Gel Synthesized ZnO Nanoparticles. ECS J. Solid State Sci. Technol. 2021, 10, 023002. [Google Scholar] [CrossRef]

- Zhou, L.; Pan, D.; Guo, Z.; Li, J.; Huang, S.; Song, J. Simple Construction of Amorphous Monometallic Cobalt-Based Selenite Nanoparticles using Ball Milling for Highly Efficient Oxygen Evolution Reaction. ChemCatChem 2021, 13, 2719–2725. [Google Scholar] [CrossRef]

- Nagarajan, V.; Sudan, S.; Sharma, K. Radio Frequency Plasma-Based Synthesis of Metallic Nanoparticles for Biomedical Application. In Emerging Technologies for Nanoparticle Manufacturing; Springer: Cham, Switzerland, 2021; pp. 421–447. [Google Scholar] [CrossRef]

- Ohta, R.; Gerile, N.; Kaga, M.; Kambara, M. Composite Si–Ni nanoparticles produced by plasma spraying physical vapor deposition for negative electrode in Li-ion batteries. Nanotechnology 2021, 32, 265703. [Google Scholar] [CrossRef]

- Chin, C.; Treadwell, L.; Wiley, J. Microwave Synthetic Routes for Shape-Controlled Catalyst Nanoparticles and Nanocomposites. Molecules 2021, 26, 3647. [Google Scholar] [CrossRef]

- Yang, Y.; Johansson, M.; Wiorek, A.; Tarakina, N.V.; Sayed, F.; Mathieu, R.; Soroka, I.L. Gamma-radiation induced synthesis of freestanding nickel nanoparticles. Dalton Trans. 2020, 50, 376–383. [Google Scholar] [CrossRef]

- Salem, S.S.; Fouda, A. Green Synthesis of Metallic Nanoparticles and Their Prospective Biotechnological Applications: An Overview. Biol. Trace Element Res. 2020, 199, 344–370. [Google Scholar] [CrossRef]

- Priyadarshini, E.; Priyadarshini, S.S.; Cousins, B.G.; Pradhan, N. Metal-Fungus interaction: Review on cellular processes underlying heavy metal detoxification and synthesis of metal nanoparticles. Chemosphere 2021, 274, 129976. [Google Scholar] [CrossRef]

- Ammar, H.A.; El Aty, A.A.A.; El Awdan, S.A. Extracellular myco-synthesis of nano-silver using the fermentable yeasts Pichia kudriavzeviiHA-NY2 and Saccharomyces uvarumHA-NY3, and their effective biomedical applications. Bioprocess Biosyst. Eng. 2021, 44, 841–854. [Google Scholar] [CrossRef]

- Li, S.-N.; Wang, R.; Ho, S.-H. Algae-mediated biosystems for metallic nanoparticle production: From synthetic mechanisms to aquatic environmental applications. J. Hazard. Mater. 2021, 420, 126625. [Google Scholar] [CrossRef] [PubMed]

- Srivastava, S.; Usmani, Z.; Atanasov, A.G.; Singh, V.K.; Singh, N.P.; Abdel-Azeem, A.M.; Prasad, R.; Gupta, G.; Sharma, M.; Bhargava, A. Biological Nanofactories: Using Living Forms for Metal Nanoparticle Synthesis. Mini-Reviews Med. Chem. 2021, 21, 245–265. [Google Scholar] [CrossRef] [PubMed]

- Soni, V.; Raizada, P.; Singh, P.; Cuong, H.N.; Rangabhashiyam, S.; Saini, A.; Saini, R.V.; Van Le, Q.; Nadda, A.K.; Le, T.-T.; et al. Sustainable and green trends in using plant extracts for the synthesis of biogenic metal nanoparticles toward environmental and pharmaceutical advances: A review. Environ. Res. 2021, 202, 111622. [Google Scholar] [CrossRef]

- Ijaz, I.; Gilani, E.; Nazir, A.; Bukhari, A. Detail review on chemical, physical and green synthesis, classification, characterizations and applications of nanoparticles. Green Chem. Lett. Rev. 2020, 13, 59–81. [Google Scholar] [CrossRef]

- Gour, A.; Jain, N.K. Advances in green synthesis of nanoparticles. Artif. Cells Nanomed. Biotechnol. 2019, 47, 844–851. [Google Scholar] [CrossRef] [Green Version]

- Hao, J.; Xu, S.; Gao, B.; Pan, L. PL Tunable GaN Nanoparticles Synthesis through Femtosecond Pulsed Laser Ablation in Different Environments. Nanomaterials 2020, 10, 439. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Huang, H.; Lai, J. Mechanism Study of Nanomaterial Synthesis by Pulsed Laser Ablation in Liquid. In Proceedings of the Advanced Laser Processing and Manufacturing II, Beijing, China, 12 November 2018; Volume 10813, p. 1081318. [Google Scholar]

- Patil, P.P.; Phase, D.M.; Kulkarni, S.A.; Ghaisas, S.V.; Kanetkar, S.M.; Ogale, S.B.; Bhide, V.G. Pulsed-laser–induced reactive quenching at liquid-solid interface: Aqueous oxidation of iron. Phys. Rev. Lett. 1987, 58, 238–241. [Google Scholar] [CrossRef] [PubMed]

- Yang, G. Laser ablation in liquids: Applications in the synthesis of nanocrystals. Prog. Mater. Sci. 2007, 52, 648–698. [Google Scholar] [CrossRef]

- Mahdieh, M.; Khosravi, A. Colloidal brass nanoparticles produced by pulsed laser ablation in deionized water and the effect of external electric field on particle size characteristics and ablation rate. Nano-Struct. Nano-Objects 2020, 24, 100580. [Google Scholar] [CrossRef]

- Forsythe, R.C.; Cox, C.P.; Wilsey, M.K.; Müller, A.M. Pulsed Laser in Liquids Made Nanomaterials for Catalysis. Chem. Rev. 2021, 121, 7568–7637. [Google Scholar] [CrossRef]

- Fazio, E.; Gökce, B.; De Giacomo, A.; Meneghetti, M.; Compagnini, G.; Tommasini, M.; Waag, F.; Lucotti, A.; Zanchi, C.G.; Ossi, P.M.; et al. Nanoparticles Engineering by Pulsed Laser Ablation in Liquids: Concepts and Applications. Nanomaterials 2020, 10, 2317. [Google Scholar] [CrossRef] [PubMed]

- Naser, H.; Shanshool, H.M.; Imhan, K.I. Parameters Affecting the Size of Gold Nanoparticles Prepared by Pulsed Laser Ablation in Liquid. Braz. J. Phys. 2021, 51, 878–898. [Google Scholar] [CrossRef]

- Xiao, J.; Liu, P.; Wang, C.; Yang, G. External field-assisted laser ablation in liquid: An efficient strategy for nanocrystal synthesis and nanostructure assembly. Prog. Mater. Sci. 2017, 87, 140–220. [Google Scholar] [CrossRef]

- Zhang, J.; Claverie, J.; Chaker, M.; Ma, D. Colloidal Metal Nanoparticles Prepared by Laser Ablation and their Applications. ChemPhysChem 2017, 18, 986–1006. [Google Scholar] [CrossRef] [PubMed]

- Jaleh, B.; Nasrollahzadeh, M.; Mohazzab, B.F.; Eslamipanah, M.; Sajjadi, M.; Ghafuri, H. State-of-the-Art Technology: Recent Investigations on Laser-Mediated Synthesis of Nanocomposites for Environmental Remediation. Ceram. Int. 2020, 47, 10389–10425. [Google Scholar] [CrossRef]

- Al-Kattan, A.; Grojo, D.; Drouet, C.; Mouskeftaras, A.; Delaporte, P.; Casanova, A.; Robin, J.D.; Magdinier, F.; Alloncle, P.; Constantinescu, C. Short-Pulse Lasers: A Versatile Tool in Creating Novel Nano-/Micro-Structures and Compositional Analysis for Healthcare and Wellbeing Challenges. Nanomaterials 2021, 11, 712. [Google Scholar] [CrossRef]

- Hussain, A.; Emadi, H.; Botchway, K. How nanoparticles have ameliorated the challenges in drilling operations. J. Pet. Sci. Eng. 2020, 197, 107931. [Google Scholar] [CrossRef]

- Hogeweg, A.S.; Hincapie, R.E.; Foedisch, H.; Ganzer, L. Evaluation of Aluminium Oxide and Titanium Dioxide Nanoparticles for EOR Applications. Presented at the SPE Europec Featured at 80th EAGE Conference and Exhibition, Copenhagen, Denmark, 11 June 2018. [Google Scholar]

- Mahmoud, O.; Nasr-El-Din, H.A.; Vryzas, Z.; Kelessidis, V.C. Using Ferric Oxide and Silica Nanoparticles To Develop Modified Calcium Bentonite Drilling Fluids. SPE Drill. Complet. 2017, 33, 12–26. [Google Scholar] [CrossRef]

- You, J.; Wang, L.; Zhao, Y.; Bao, W. A review of amino-functionalized magnetic nanoparticles for water treatment: Features and prospects. J. Clean. Prod. 2020, 281, 124668. [Google Scholar] [CrossRef]

- Chellaram, C.; Murugaboopathi, G.; John, A.; Sivakumar, R.; Ganesan, S.; Krithika, S.; Priya, G. Significance of Nanotechnology in Food Industry. APCBEE Procedia 2014, 8, 109–113. [Google Scholar] [CrossRef] [Green Version]

- Sahani, S.; Sharma, Y.C. Advancements in applications of nanotechnology in global food industry. Food Chem. 2020, 342, 128318. [Google Scholar] [CrossRef]

- Madkour, L.H. A Review: Metal Nanoparticles and Their Safety Processing in Functional Foods. J. Chem. Sci. Chem. Eng. 2021, 1, 18–36. [Google Scholar]

- Tayel, A.A.; El-Tras, W.F.; Moussa, S.H.; El-Baz, A.F.; Mahrous, H.; Salem, M.F.; Brimer, L. Antibacterial action of zinc oxide nanoparticles against foodborne pathogens. J. Food Saf. 2011, 31, 211–218. [Google Scholar] [CrossRef]

- Díez-Pascual, A.M. Antibacterial Activity of Nanomaterials. Nanomaterials 2018, 8, 359. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Bhattacharyya, A.; Datta, P.S.; Chaudhuri, P.; Barik, B.R. Nanotechnology-A New Frontier for Food Security in Socio Economic Development. In Proceedings of the Disaster Risk Vulnerablity Conference, Kerala, India, 12–14 March 2011; pp. 116–120. [Google Scholar]

- Sambur, J.B.; Chen, P. Approaches to Single-Nanoparticle Catalysis. Annu. Rev. Phys. Chem. 2014, 65, 395–422. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kong, F.-Y.; Zhang, J.-W.; Li, R.-F.; Wang, Z.-X.; Wang, W.-J.; Wang, W. Unique Roles of Gold Nanoparticles in Drug Delivery, Targeting and Imaging Applications. Molecules 2017, 22, 1445. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Gu, T.; Chen, T.; Cheng, L.; Li, X.; Han, G.; Liu, Z. Mesoporous silica decorated with platinum nanoparticles for drug delivery and synergistic electrodynamic-chemotherapy. Nano Res. 2020, 13, 2209–2215. [Google Scholar] [CrossRef]

- Adams, C.P.; Walker, K.A.; Obare, S.O.; Docherty, K.M. Size-Dependent Antimicrobial Effects of Novel Palladium Nanoparticles. PLoS ONE 2014, 9, e85981. [Google Scholar] [CrossRef] [Green Version]

- Aliofkhazraei, M. Handbook of Nanoparticles; Springer: Cham, Switzerland, 2016; ISBN 3319153382. [Google Scholar]

- Ali, A.; Zafar, H.; Zia, M.; ul Haq, I.; Phull, A.R.; Ali, J.S.; Hussain, A. Synthesis, characterization, applications, and challenges of iron oxide nanoparticles. Nanotechnol. Sci. Appl. 2016, 9, 49–67. [Google Scholar] [CrossRef] [Green Version]

- Tan, H.W.; An, J.; Chua, C.K.; Tran, T. Metallic Nanoparticle Inks for 3D Printing of Electronics. Adv. Electron. Mater. 2019, 5. [Google Scholar] [CrossRef]

- Altuwirqi, R.M.; Baatiyah, B.; Nugali, E.; Hashim, Z.; Al-Jawhari, H. Synthesis and Characterization of Aluminum Nanoparticles Prepared in Vinegar Using a Pulsed Laser Ablation Technique. J. Nanomater. 2020, 2020, 1–5. [Google Scholar] [CrossRef] [Green Version]

- Geppert, M.; Himly, M. Iron Oxide Nanoparticles in Bioimaging—An Immune Perspective. Front. Immunol. 2021, 12, 2366. [Google Scholar] [CrossRef] [PubMed]

- Jiang, J.; Pi, J.; Cai, J. The Advancing of Zinc Oxide Nanoparticles for Biomedical Applications. Bioinorg. Chem. Appl. 2018, 2018, 1062562. [Google Scholar] [CrossRef] [PubMed]

- Kalajahi, S.T.; Rasekh, B.; Yazdian, F.; Neshati, J.; Taghavi, L. Green mitigation of microbial corrosion by copper nanoparticles doped carbon quantum dots nanohybrid. Environ. Sci. Pollut. Res. 2020, 27, 40537–40551. [Google Scholar] [CrossRef] [PubMed]

- Dinca, I.; Ban, C.; Stefan, A.; Pelin, G. Nanocomposites as Advanced Materials for Aerospace Industry. INCAS Bull. 2012, 4, 73. [Google Scholar]

- Rana, S.; Fangueiro, R. Advanced Composites in Aerospace Engineering. In Advanced Composite Materials for Aerospace Engineering; Elsevier: Amsterdam, The Netherlands, 2016; pp. 1–15. [Google Scholar]

- Mansoureh, G.; Parisa, V. Synthesis of Metal Nanoparticles Using Laser Ablation Technique. In Emerging Applications of Nanoparticles and Architecture Nanostructures; Elsevier: Amsterdam, The Netherlands, 2018; pp. 575–596. [Google Scholar]

- Altuwirqi, R.M.; Albakri, A.S.; Al-Jawhari, H.; Ganash, E.A. Green synthesis of copper oxide nanoparticles by pulsed laser ablation in spinach leaves extract. Optik 2020, 219, 165280. [Google Scholar] [CrossRef]

- Du, H.; Castaing, V.; Guo, D.; Viana, B. Rare-earths doped-nanoparticles prepared by pulsed laser ablation in liquids. Ceram. Int. 2020, 46, 26299–26308. [Google Scholar] [CrossRef]

- Cui, L.; Ren, X.; Wang, J.; Sun, M. Synthesis of homogeneous carbon quantum dots by ultrafast dual-beam pulsed laser ablation for bioimaging. Mater. Today Nano 2020, 12, 100091. [Google Scholar] [CrossRef]

- Zhang, D.; Li, Z.; Sugioka, K. Laser ablation in liquids for nanomaterial synthesis: Diversities of targets and liquids. J. Phys. Photonics 2021, 3, 042002. [Google Scholar] [CrossRef]

- Shabalina, A.V.; Svetlichnyi, V.A.; Kulinich, S.A. Green laser ablation-based synthesis of functional nanomaterials for generation, storage and detection of hydrogen. Curr. Opin. Green Sustain. Chem. 2021, 31, 100566. [Google Scholar] [CrossRef]

- Reichenberger, S.; Marzun, G.; Muhler, M.; Barcikowski, S. Perspective of Surfactant-Free Colloidal Nanoparticles in Heterogeneous Catalysis. ChemCatChem 2019, 11, 4489–4518. [Google Scholar] [CrossRef]

- Cadot, G.; Axinte, D.; Billingham, J. Continuous trench, pulsed laser ablation for micro-machining applications. Int. J. Mach. Tools Manuf. 2016, 107, 8–20. [Google Scholar] [CrossRef] [Green Version]

- Dittrich, S.; Streubel, R.; McDonnell, C.; Huber, H.P.; Barcikowski, S.; Gökce, B. Comparison of the productivity and ablation efficiency of different laser classes for laser ablation of gold in water and air. Appl. Phys. A 2019, 125, 432. [Google Scholar] [CrossRef]

- Neddersen, J.; Chumanov, G.; Cotton, T.M. Laser Ablation of Metals: A New Method for Preparing SERS Active Colloids. Appl. Spectrosc. 1993, 47, 1959–1964. [Google Scholar] [CrossRef]

- DellʼAglio, M.; Gaudiuso, R.; de Pascale, O.; de Giacomo, A. Mechanisms and Processes of Pulsed Laser Ablation in Liquids during Nanoparticle Production. Appl. Surf. Sci. 2015, 348, 4–9. [Google Scholar] [CrossRef]

- Sadrolhosseini, A.R.; Mahdi, M.A.; Alizadeh, F.; Rashid, S.A. Laser Ablation Technique for Synthesis of Metal Nanoparticle in Liquid. In Laser Technology and its Applications; IntechOpen: London, UK, 2019. [Google Scholar] [CrossRef] [Green Version]

- Svetlichnyi, V.A.; Shabalina, A.V.; Lapin, I.N.; Goncharova, D.A. Metal Oxide Nanoparticle Preparation by Pulsed Laser Ablation of Metallic Targets in Liquid. In Applications of Laser Ablation—Thin Film Deposition, Nanomaterial Synthesis and Surface Modification; InTech: Rijeka, Croatia, 2016. [Google Scholar] [CrossRef] [Green Version]

- Hahn, A.; Barcikowski, S.; Chichkov, B.N. Influences on Nanoparticle Production during Pulsed Laser Ablation. Pulse 2008, 40, 50. [Google Scholar] [CrossRef]

- Menéndez-Manjón, A.; Wagener, P.; Barcikowski, S. Transfer-Matrix Method for Efficient Ablation by Pulsed Laser Ablation and Nanoparticle Generation in Liquids. J. Phys. Chem. C 2011, 115, 5108–5114. [Google Scholar] [CrossRef]

- Sulaiman, S.A.; Ismail, A.K.A.A.; Azman, M.N.F.N. Scattering Effects in Laser Attenuation System for Measurement of Droplet Number Density. Energy Procedia 2014, 50, 79–86. [Google Scholar] [CrossRef] [Green Version]

- Seely, J.F. Quantum Theory of Inverse Bremsstrahlung Absorption and Pair Production. In Laser Interaction and Related Plasma Phenomena; Springer: Boston, MA, USA, 1974; pp. 835–847. [Google Scholar] [CrossRef]

- Sasaki, K.; Takada, N. Liquid-phase laser ablation. Pure Appl. Chem. 2010, 82, 1317–1327. [Google Scholar] [CrossRef]

- Chichkov, B.N.; Momma, C.; Nolte, S.; von Alvensleben, F.; Tünnermann, A. Femtosecond, picosecond and nanosecond laser ablation of solids. Appl. Phys. A 1996, 63, 109–115. [Google Scholar] [CrossRef]

- Tsuji, T.; Okazaki, Y.; Tsuboi, Y.; Tsuji, M. Nanosecond time-resolved observations of laser ablation of silver in water. Jpn. J. Appl. Phys. 2007, 46, 1533. [Google Scholar] [CrossRef]

- Huang, H.; Lai, J.; Lu, J.; Li, Z. Pulsed laser ablation of bulk target and particle products in liquid for nanomaterial fabrication. AIP Adv. 2019, 9, 015307. [Google Scholar] [CrossRef]

- Senegačnik, M.; Kunimoto, K.; Yamaguchi, S.; Kimura, K.; Sakka, T.; Gregorčič, P. Dynamics of laser-induced cavitation bubble during expansion over sharp-edge geometry submerged in liquid—An inside view by diffuse illumination. Ultrason. Sonochemistry 2021, 73, 105460. [Google Scholar] [CrossRef]

- Reich, S.; Schönfeld, P.; Wagener, P.; Letzel, A.; Ibrahimkutty, S.; Gökce, B.; Barcikowski, S.; Menzel, A.; Rolo, T.D.S.; Plech, A. Pulsed laser ablation in liquids: Impact of the bubble dynamics on particle formation. J. Colloid Interface Sci. 2017, 489, 106–113. [Google Scholar] [CrossRef] [PubMed]

- Nguyen, T.T.P.; Tanabe-Yamagishi, R.; Ito, Y. Impact of liquid layer thickness on the dynamics of nano- to sub-microsecond phenomena of nanosecond pulsed laser ablation in liquid. Appl. Surf. Sci. 2018, 470, 250–258. [Google Scholar] [CrossRef]

- Torrisi, L.; Torrisi, A. Laser Ablation Parameters Influencing Gold Nanoparticle Synthesis in Water. Radiat. Eff. Defects Solids 2018, 173, 729–739. [Google Scholar] [CrossRef]

- Shih, C.-Y.; Streubel, R.; Heberle, J.; Letzel, A.; Shugaev, M.V.; Wu, C.; Schmidt, M.; Gökce, B.; Barcikowski, S.; Zhigilei, L.V. Two mechanisms of nanoparticle generation in picosecond laser ablation in liquids: The origin of the bimodal size distribution. Nanoscale 2018, 10, 6900–6910. [Google Scholar] [CrossRef] [Green Version]

- Letzel, A.; Santoro, M.; Frohleiks, J.; Ziefuß, A.R.; Reich, S.; Plech, A.; Fazio, E.; Neri, F.; Barcikowski, S.; Gökce, B. How the re-irradiation of a single ablation spot affects cavitation bubble dynamics and nanoparticles properties in laser ablation in liquids. Appl. Surf. Sci. 2018, 473, 828–837. [Google Scholar] [CrossRef]

- Taccogna, F.; Dell’Aglio, M.; Rutigliano, M.; Valenza, G.; De Giacomo, A. On the growth mechanism of nanoparticles in plasma during pulsed laser ablation in liquids. Plasma Sources Sci. Technol. 2017, 26, 045002. [Google Scholar] [CrossRef]

- De Giacomo, A.; Dell’Aglio, M.; Santagata, A.; Gaudiuso, R.; De Pascale, O.; Wagener, P.; Messina, G.C.; Compagnini, G.; Barcikowski, S. Cavitation dynamics of laser ablation of bulk and wire-shaped metals in water during nanoparticles production. Phys. Chem. Chem. Phys. 2012, 15, 3083–3092. [Google Scholar] [CrossRef]

- Wang, C.X.; Liu, P.; Cui, H.; Yang, G.W. Nucleation and growth kinetics of nanocrystals formed upon pulsed-laser ablation in liquid. Appl. Phys. Lett. 2005, 87, 201913. [Google Scholar] [CrossRef]

- Barberio, M.; Antici, P. In situ study of nucleation and aggregation phases for nanoparticles grown by laser-driven methods. Sci. Rep. 2017, 7, srep41372. [Google Scholar] [CrossRef] [PubMed]

- Taccogna, F. Nucleation and growth of nanoparticles in a plasma by laser ablation in liquid. J. Plasma Phys. 2015, 81. [Google Scholar] [CrossRef]

- Perez-Lopez, C.A.; Perez-Taborda, J.A.; Riascos, H.; Avila, A. The influence of pulsed laser ablation in liquids parameters on the synthesis of ZnO nanoparticles. J. Phys. Conf. Ser. 2020, 1541, 012019. [Google Scholar] [CrossRef]

- Choudhury, K.; Singh, R.; Kumar, P.; Ranjan, M.; Srivastava, A.; Kumar, A. Effect of confined geometry on the size distribution of nanoparticles produced by laser ablation in liquid medium. Nano-Struct. Nano-Objects 2019, 17, 129–137. [Google Scholar] [CrossRef] [Green Version]

- Dowding, C. Laser Ablation. In Advances in Laser Materials Processing; Elsevier: Amsterdam, The Netherlands, 2010; pp. 575–628. [Google Scholar]

- Walsh, B.M. Nonlinear mixing of Nd:YAG lasers; harmonic and sum frequency generation. Opt. Mater. 2017, 65, 2–7. [Google Scholar] [CrossRef]

- Zhou, J.; Christov, I.; Taft, G.; Huang, C.-P.; Murnane, M.M.; Kapteyn, H. Pulse evolution in a broad-bandwidth Ti:sapphire laser. Opt. Lett. 1994, 19, 1149–1151. [Google Scholar] [CrossRef]

- Preuss, S.; Demchuk, A.; Stuke, M. Sub-Picosecond UV Laser Ablation of Metals. Appl. Phys. A 1995, 61, 33–37. [Google Scholar] [CrossRef]

- Ready, J.F. Industrial Applications of Lasers; Elsevier: Amsterdam, The Netherlands, 1997. [Google Scholar]

- Mortazavi, S.Z.; Parvin, P.; Reyhani, A.; Golikand, A.N.; Mirershadi, S. Effect of Laser Wavelength at IR (1064 nm) and UV (193 nm) on the Structural Formation of Palladium Nanoparticles in Deionized Water. J. Phys. Chem. C 2011, 115, 5049–5057. [Google Scholar] [CrossRef]

- Schwenke, A.; Wagener, P.; Nolte, S.; Barcikowski, S. Influence of processing time on nanoparticle generation during picosecond-pulsed fundamental and second harmonic laser ablation of metals in tetrahydrofuran. Appl. Phys. A 2011, 104, 77–82. [Google Scholar] [CrossRef] [Green Version]

- Kim, J.; Reddy, D.A.; Ma, R.; Kim, T.K. The influence of laser wavelength and fluence on palladium nanoparticles produced by pulsed laser ablation in deionized water. Solid State Sci. 2014, 37, 96–102. [Google Scholar] [CrossRef]

- Baladi, A.; Mamoory, R.S. Effect of Laser Wavelength and Ablation Time on Pulsed Laser Ablation Synthesis of Al Nanoparticles in Ethanol. Int. J. Mod. Phys. Conf. Ser. 2012, 5, 58–65. [Google Scholar] [CrossRef]

- Torrisi, L.; Gammino, S.; Andò, L.; Nassisi, V.; Doria, D.; Pedone, A. Comparison of nanosecond laser ablation at 1064 and 308 nm wavelength. Appl. Surf. Sci. 2003, 210, 262–273. [Google Scholar] [CrossRef]

- Solati, E.; Dejam, L.; Dorranian, D. Effect of laser pulse energy and wavelength on the structure, morphology and optical properties of ZnO nanoparticles. Opt. Laser Technol. 2014, 58, 26–32. [Google Scholar] [CrossRef]

- Solati, E.; Vaghri, E.; Dorranian, D. Effects of wavelength and fluence on the graphene nanosheets produced by pulsed laser ablation. Appl. Phys. A 2018, 124, 749. [Google Scholar] [CrossRef]

- Zhang, K.; Ivanov, D.S.; Ganeev, R.A.; Boltaev, G.S.; Krishnendu, P.S.; Singh, S.C.; Garcia, M.E.; Zavestovskaya, I.N.; Guo, C. Pulse Duration and Wavelength Effects of Laser Ablation on the Oxidation, Hydrolysis, and Aging of Aluminum Nanoparticles in Water. Nanomaterials 2019, 9, 767. [Google Scholar] [CrossRef] [Green Version]

- Sakka, T.; Masai, S.; Fukami, K.; Ogata, Y.H. Spectral profile of atomic emission lines and effects of pulse duration on laser ablation in liquid. Spectrochim. Acta Part B At. Spectrosc. 2009, 64, 981–985. [Google Scholar] [CrossRef] [Green Version]

- Shih, C.-Y.; Shugaev, M.V.; Wu, C.; Zhigilei, L.V. The Effect of Pulse Duration on Nanoparticle Generation in Pulsed Laser Ablation in Liquids: Insights from Large-Scale Atomistic Simulations. Phys. Chem. Chem. Phys. 2020, 22, 7077–7099. [Google Scholar] [CrossRef]

- Kabashin, A.V.; Meunier, M. Synthesis of colloidal nanoparticles during femtosecond laser ablation of gold in water. J. Appl. Phys. 2003, 94, 7941. [Google Scholar] [CrossRef] [Green Version]

- Jeon, J.-W.; Yoon, S.; Choi, H.W.; Kim, J.; Farson, D.; Cho, S.-H. The Effect of Laser Pulse Widths on Laser—Ag Nanoparticle Interaction: Femto- to Nanosecond Lasers. Appl. Sci. 2018, 8, 112. [Google Scholar] [CrossRef] [Green Version]

- Abbasi, M.; Dorranian, D. Effect of laser fluence on the characteristics of Al nanoparticles produced by laser ablation in deionized water. Opt. Spectrosc. 2015, 118, 472–481. [Google Scholar] [CrossRef]

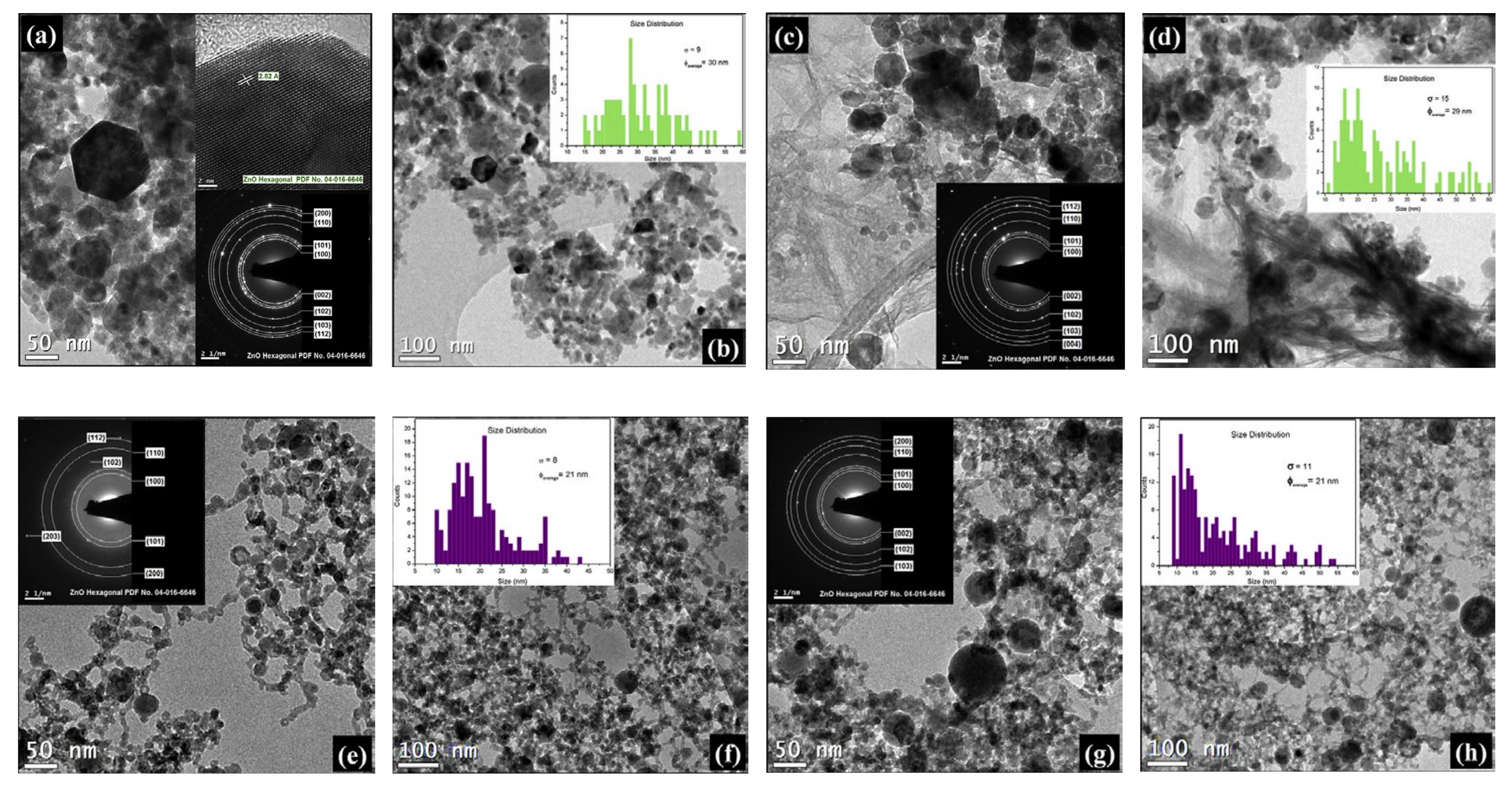

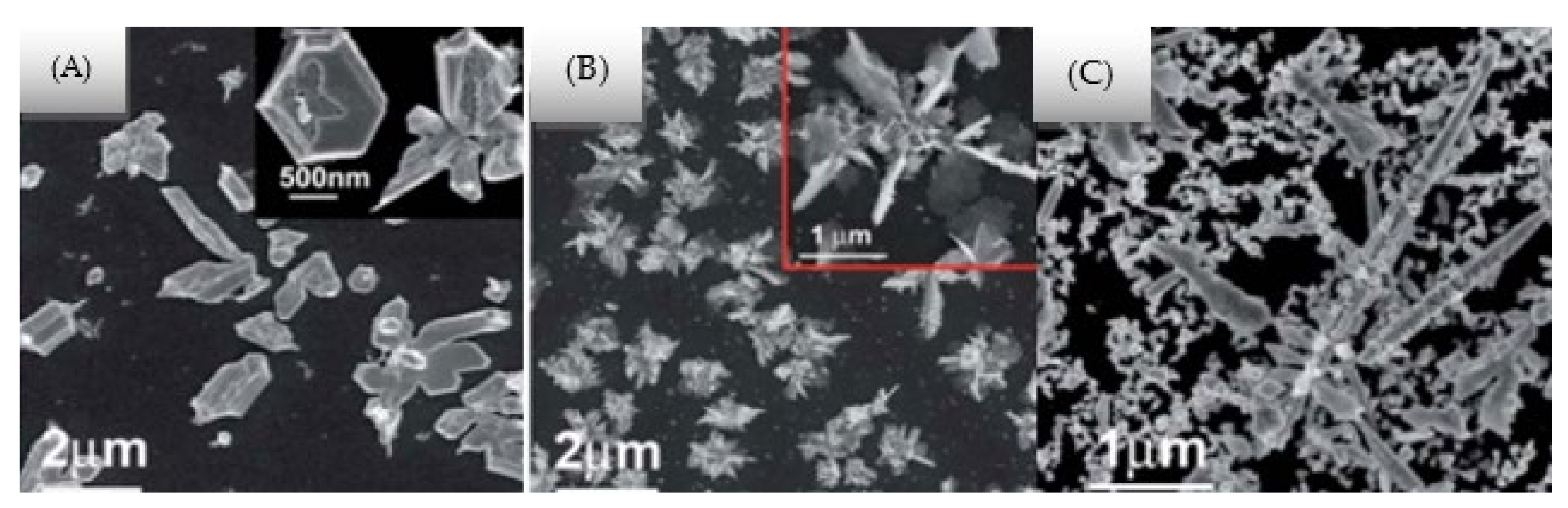

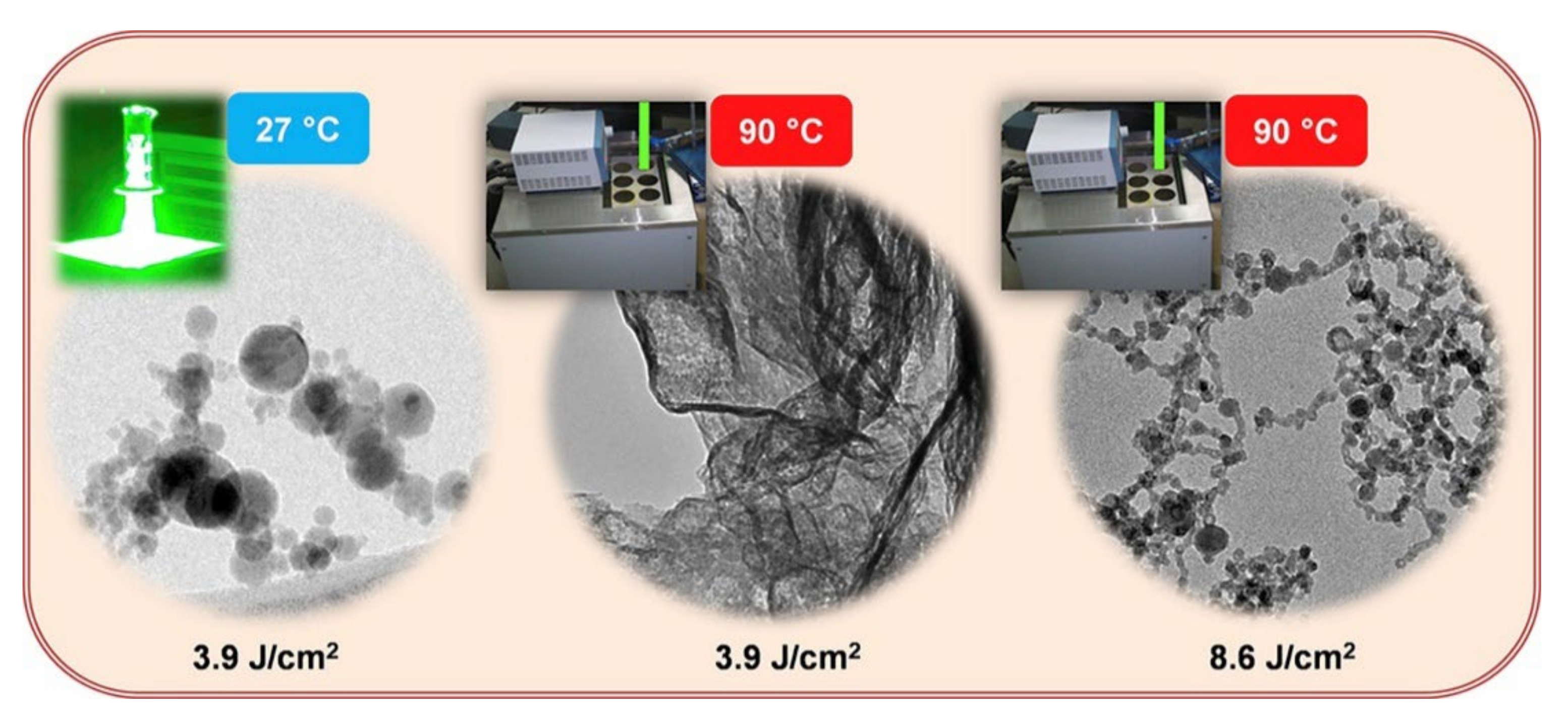

- Guillén, G.G.; Palma, M.I.M.; Krishnan, B.; Avellaneda, D.; Castillo, G.; Das Roy, T.; Shaji, S. Structure and morphologies of ZnO nanoparticles synthesized by pulsed laser ablation in liquid: Effects of temperature and energy fluence. Mater. Chem. Phys. 2015, 162, 561–570. [Google Scholar] [CrossRef]

- Haram, N.; Ahmad, N. Effect of laser fluence on the size of copper oxide nanoparticles produced by the ablation of Cu target in double distilled water. Appl. Phys. A 2012, 111, 1131–1137. [Google Scholar] [CrossRef]

- Amendola, V.; Meneghetti, M. Controlled size manipulation of free gold nanoparticles by laser irradiation and their facile bioconjugation. J. Mater. Chem. 2007, 17, 4705–4710. [Google Scholar] [CrossRef]

- Pyatenko, A.; Wang, H.; Koshizaki, N.; Tsuji, T. Mechanism of pulse laser interaction with colloidal nanoparticles. Laser Photon Rev. 2013, 7, 596–604. [Google Scholar] [CrossRef]

- Tsuji, T.; Yahata, T.; Yasutomo, M.; Igawa, K.; Tsuji, M.; Ishikawa, Y.; Koshizaki, N. Preparation and investigation of the formation mechanism of submicron-sized spherical particles of gold using laser ablation and laser irradiation in liquids. Phys. Chem. Chem. Phys. 2012, 15, 3099–3107. [Google Scholar] [CrossRef]

- Aghdam, H.D.; Azadi, H.; Esmaeilzadeh, M.; Bellah, S.M.; Malekfar, R. Ablation time and laser fluence impacts on the composition, morphology and optical properties of copper oxide nanoparticles. Opt. Mater. 2019, 91, 433–438. [Google Scholar] [CrossRef]

- Xu, B.; Song, R.G.; Wang, C. Effect of Laser Fluence on Silver Nanoparticles Colloid. Adv. Mater. Res. 2012, 415, 747–750. [Google Scholar]

- Mozaffari, H.; Mahdieh, M.H. Synthesis of colloidal aluminum nanoparticles by nanosecond pulsed laser and the effect of external electric field and laser fluence on ablation rate. Opt. Laser Technol. 2020, 126, 106083. [Google Scholar] [CrossRef]

- Al-Douri, Y.; Al-Samarai, R.A.; Abdulateef, S.; Abu Odeh, A.; Badi, N.; Voon, C. Nanosecond pulsed laser ablation to synthesize GaO colloidal nanoparticles: Optical and structural properties. Optik 2018, 178, 337–342. [Google Scholar] [CrossRef]

- Waag, F.; Streubel, R.; Gökce, B.; Barcikowski, S. Synthesis of gold, platinum, and gold-platinum alloy nanoparticle colloids with high-power megahertz-repetition-rate lasers: The importance of the beam guidance method. Appl. Nanosci. 2021, 11, 1303–1312. [Google Scholar] [CrossRef]

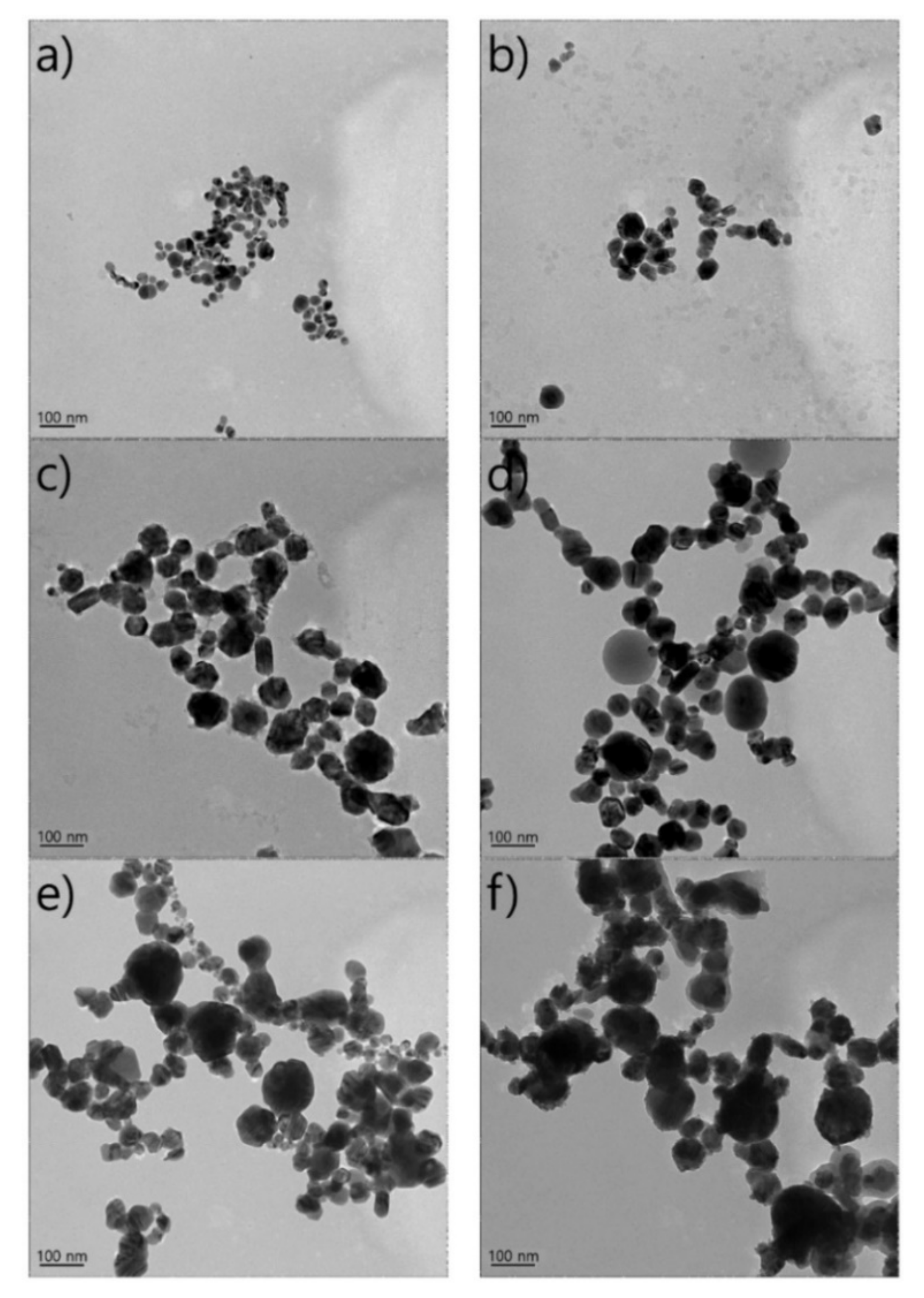

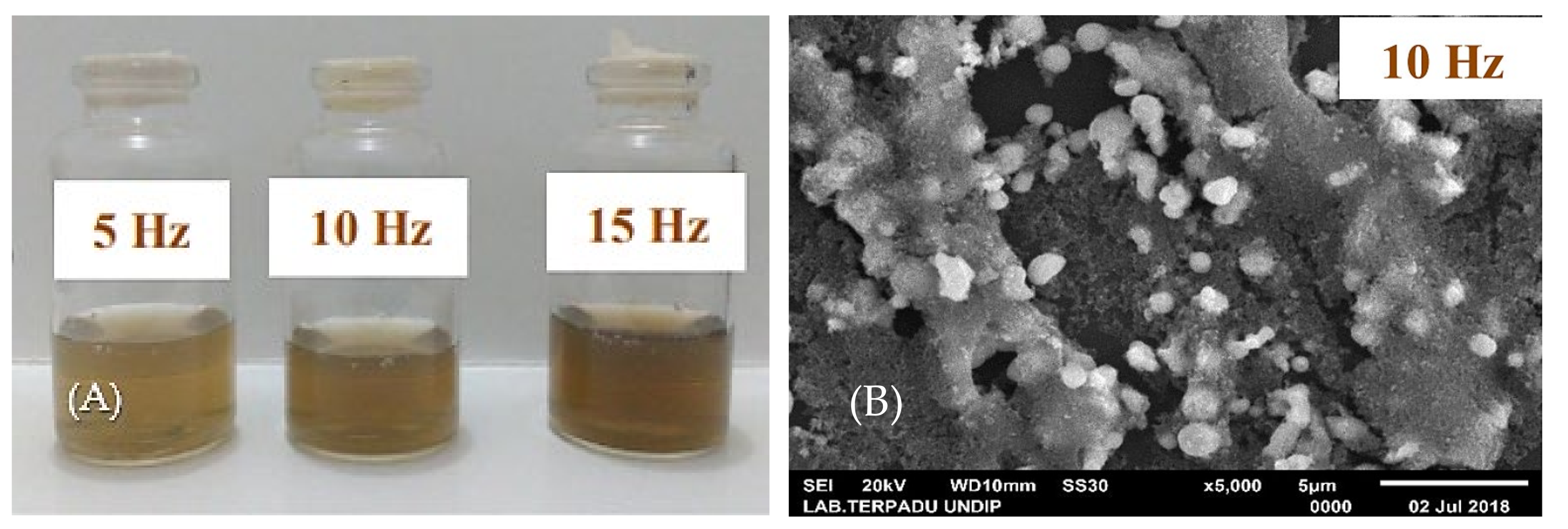

- Sa’Adah, F.; Miskiyah, R.Z.; Hikmantiyah, N.; Khumaeni, A. Effect of laser repetition rate in the synthesis of colloidal zinc nanoparticles by pulse laser ablation method. J. Phys. Conf. Ser. 2019, 1153, 012069. [Google Scholar] [CrossRef]

- Valverde-Alva, M.A.; García-Fernández, T.; Esparza-Alegría, E.; Villagrán-Muniz, M.; Sánchez-Aké, C.; Castañeda-Guzmán, R.; de la Mora, M.B.; Márquez-Herrera, C.E.; Llamazares, J.L.S. Laser Ablation Efficiency during the Production of Ag Nanoparticles in Ethanol at a Low Pulse Repetition Rate (1–10 Hz). Laser Phys. Lett. 2016, 13, 106002. [Google Scholar] [CrossRef]

- Nikolov, A.S.; Balchev, I.I.; Nedyalkov, N.N.; Kostadinov, I.K.; Karashanova, D.B.; Atanasova, G.B. Influence of the laser pulse repetition rate and scanning speed on the morphology of Ag nanostructures fabricated by pulsed laser ablation of solid target in water. Appl. Phys. A 2017, 123, 719. [Google Scholar] [CrossRef]

- Ganjali, M.; Vahdatkhah, P.; Marashi, S. Synthesis of Ni Nanoparticles by Pulsed Laser Ablation Method in Liquid Phase. Procedia Mater. Sci. 2015, 11, 359–363. [Google Scholar] [CrossRef] [Green Version]

- Elfaham, M.M.; Okil, M.; Mostafa, A.M. Fabrication of magnesium metallic nanoparticles by liquid-assisted laser ablation. J. Opt. Soc. Am. B 2020, 37, 2620. [Google Scholar] [CrossRef]

- Menazea, A. Femtosecond laser ablation-assisted synthesis of silver nanoparticles in organic and inorganic liquids medium and their antibacterial efficiency. Radiat. Phys. Chem. 2019, 168, 108616. [Google Scholar] [CrossRef]

- Mostafa, A.; Yousef, S.A.; Eisa, W.; Ewaida, M.A.; Al Ashkar, E. Synthesis of cadmium oxide nanoparticles by pulsed laser ablation in liquid environment. Optik 2017, 144, 679–684. [Google Scholar] [CrossRef]

- Altowyan, A.S.; Mostafa, A.M.; Ahmed, H.A. Effect of liquid media and laser energy on the preparation of Ag nanoparticles and their nanocomposites with Au nanoparticles via laser ablation for optoelectronic applications. Optik 2021, 241, 167217. [Google Scholar] [CrossRef]

- Alluhaybi, H.; Ghoshal, S.; Shamsuri, W.W.; Alsobhi, B.; Salim, A.A.; Krishnan, G. Pulsed laser ablation in liquid assisted growth of gold nanoparticles: Evaluation of structural and optical features. Nano-Struct. Nano-Objects 2019, 19, 100355. [Google Scholar] [CrossRef]

- Zuñiga-Ibarra, V.; Shaji, S.; Krishnan, B.; Johny, J.; Kanakkillam, S.S.; Avellaneda, D.; Martinez, J.A.; Das Roy, T.; Delgado, N.A.R. Synthesis and characterization of black TiO2 nanoparticles by pulsed laser irradiation in liquid. Appl. Surf. Sci. 2019, 483, 156–164. [Google Scholar] [CrossRef]

- Mendivil, M.; Krishnan, B.; Castillo, G.; Shaji, S. Synthesis and properties of palladium nanoparticles by pulsed laser ablation in liquid. Appl. Surf. Sci. 2015, 348, 45–53. [Google Scholar] [CrossRef]

- Kupracz, P.; Coy, E.; Grochowska, K.; Karczewski, J.; Rysz, J.; Siuzdak, K. The pulsed laser ablation synthesis of colloidal iron oxide nanoparticles for the enhancement of TiO2 nanotubes photo-activity. Appl. Surf. Sci. 2020, 530, 147097. [Google Scholar] [CrossRef]

- Goncharova, D.A.; Kharlamova, T.S.; Lapin, I.N.; Svetlichnyi, V.A. Chemical and Morphological Evolution of Copper Nanoparticles Obtained by Pulsed Laser Ablation in Liquid. J. Phys. Chem. C 2019, 123, 21731–21742. [Google Scholar] [CrossRef]

- Riahi, A.; Khamlich, S.; Balghouthi, M.; Khamliche, T.; Doyle, T.B.; Dimassi, W.; Guizani, A.; Maaza, M. Study of thermal conductivity of synthesized Al2O3-water nanofluid by pulsed laser ablation in liquid. J. Mol. Liq. 2020, 304, 112694. [Google Scholar] [CrossRef]

- Al-Nassar, S.I.; Hussein, F.I.; Adel, M.K. The effect of laser pulse energy on ZnO nanoparticles formation by liquid phase pulsed laser ablation. J. Mater. Res. Technol. 2019, 8, 4026–4031. [Google Scholar] [CrossRef]

- Kanitz, A.; Hoppius, J.S.; Sanz, M.D.M.; Maicas, M.; Ostendorf, A.; Gurevich, E.L. Synthesis of Magnetic Nanoparticles by Ultrashort Pulsed Laser Ablation of Iron in Different Liquids. ChemPhysChem 2017, 18, 1155–1164. [Google Scholar] [CrossRef]

- Gondal, M.A.; Fasasi, T.A.; Baig, U.; Mekki, A. Effects of Oxidizing Media on the Composition, Morphology and Optical Properties of Colloidal Zirconium Oxide Nanoparticles Synthesized via Pulsed Laser Ablation in Liquid Technique. J. Nanosci. Nanotechnol. 2018, 18, 4030–4039. [Google Scholar] [CrossRef]

- Tsuji, T.; Thang, D.-H.; Okazaki, Y.; Nakanishi, M.; Tsuboi, Y.; Tsuji, M. Preparation of silver nanoparticles by laser ablation in polyvinylpyrrolidone solutions. Appl. Surf. Sci. 2008, 254, 5224–5230. [Google Scholar] [CrossRef]

- Begildayeva, T.; Chinnadurai, D.; Lee, S.J.; Yu, Y.; Song, J.K.; Choi, M.Y. Implementation of novel pulsed laser ablation strategy to control the morphological growth and enrich the electrochemically active sites of multifunctional Ni–CuO electrocatalyst. J. Alloys Compd. 2022, 901, 163446. [Google Scholar] [CrossRef]

- Sylvestre, J.-P.; Kabashin, A.V.; Sacher, E.; Meunier, M.; Luong, J.H.T. Stabilization and Size Control of Gold Nanoparticles during Laser Ablation in Aqueous Cyclodextrins. J. Am. Chem. Soc. 2004, 126, 7176–7177. [Google Scholar] [CrossRef] [PubMed]

- Šišková, K.; Vlčková, B.; Turpin, A.P.Y.; Fayet, C. Ion-Specific Effects on Laser Ablation of Silver in Aqueous Electrolyte Solutions. J. Phys. Chem. C 2008, 112, 4435–4443. [Google Scholar] [CrossRef]

- Amendola, V.; Meneghetti, M.; Granozzi, G.; Agnoli, S.; Polizzi, S.; Riello, P.; Boscaini, A.; Anselmi, C.; Fracasso, G.; Colombatti, M.; et al. Top-down synthesis of multifunctional iron oxide nanoparticles for macrophage labelling and manipulation. J. Mater. Chem. 2011, 21, 3803–3813. [Google Scholar] [CrossRef]

- Elahi, N.; Kamali, M.; Baghersad, M.H. Recent biomedical applications of gold nanoparticles: A review. Talanta 2018, 184, 537–556. [Google Scholar] [CrossRef]

- Gavrilenko, E.A.; Goncharova, D.A.; Lapin, I.N.; Nemoykina, A.L.; Svetlichnyi, V.A.; Aljulaih, A.A.; Mintcheva, N.; Kulinich, S.A. Comparative Study of Physicochemical and Antibacterial Properties of ZnO Nanoparticles Prepared by Laser Ablation of Zn Target in Water and Air. Materials 2019, 12, 186. [Google Scholar] [CrossRef] [Green Version]

- He, C.; Sasaki, T.; Usui, H.; Shimizu, Y.; Koshizaki, N. Fabrication of ZnO Nanoparticles by Pulsed Laser Ablation in Aqueous Media and PH-Dependent Particle Size: An Approach to Study the Mechanism of Enhanced Green Photoluminescence. J. Photochem. Photobiol. A Chem. 2007, 191, 66–73. [Google Scholar] [CrossRef]

- Bajaj, G.; Soni, R.K. Effect of liquid medium on size and shape of nanoparticles prepared by pulsed laser ablation of tin. Appl. Phys. A 2009, 97, 481–487. [Google Scholar] [CrossRef]

- Tsuji, T.; Hamagami, T.; Kawamura, T.; Yamaki, J.; Tsuji, M. Laser ablation of cobalt and cobalt oxides in liquids: Influence of solvent on composition of prepared nanoparticles. Appl. Surf. Sci. 2005, 243, 214–219. [Google Scholar] [CrossRef]

- Tilaki, R.M.; Zad, A.I.; Mahdavi, S.M. The effect of liquid environment on size and aggregation of gold nanoparticles prepared by pulsed laser ablation. J. Nanoparticle Res. 2006, 9, 853–860. [Google Scholar] [CrossRef]

- Budiati, I.M.; Sa’Adah, F.; Rifani, N.D.; Khumaeni, A. Effect of solvent in the synthesis of colloidal copper nanoparticles by pulse laser ablation method. AIP Conf. Proc. 2019, 2202, 020003. [Google Scholar] [CrossRef]

- Lee, S.J.; Theerthagiri, J.; Choi, M.Y. Time-Resolved Dynamics of Laser-Induced Cavitation Bubbles During Production of Ni Nanoparticles via Pulsed Laser Ablation in Different Solvents and Their Electrocatalytic Activity for Determination of Toxic Nitroaromatics. Chem. Eng. J. 2021, 427, 130970. [Google Scholar] [CrossRef]

- Solati, E.; Aghazadeh, Z.; Dorranian, D. Effects of Liquid Ablation Environment on the Characteristics of TiO2 Nanoparticles. J. Clust. Sci. 2019, 31, 961–969. [Google Scholar] [CrossRef]

- Moura, C.; Pereira, R.; Andritschky, M.; Lopes, A.; de Freitas Grilo, J.P.; Nascimento, R.M.D.; Silva, F. Effects of laser fluence and liquid media on preparation of small Ag nanoparticles by laser ablation in liquid. Opt. Laser Technol. 2017, 97, 20–28. [Google Scholar] [CrossRef]

- Lasemi, N.; Pacher, U.; Zhigilei, L.; Miguel, O.B.; Lahoz, R.; Kautek, W. Pulsed laser ablation and incubation of nickel, iron and tungsten in liquids and air. Appl. Surf. Sci. 2018, 433, 772–779. [Google Scholar] [CrossRef] [Green Version]

- Ali, N.; Bashir, S.; Begum, N.; Rafique, M.S.; Husinsky, W. Effect of Liquid Environment on the Titanium Surface Modification by Laser Ablation. Appl. Surf. Sci. 2017, 405, 298–307. [Google Scholar] [CrossRef]

- Lee, S.H.; Jung, H.J.; Theerthagiri, J.; Kim, T.H.; Choi, M.Y. Selective synthesis of Au and graphitic carbon-encapsulated Au (Au@GC) nanoparticles by pulsed laser ablation in solvents: Catalytic Au and acid-resistant Au@GC nanoparticles. Appl. Surf. Sci. 2019, 506, 145006. [Google Scholar] [CrossRef]

- Nikov, R.G.; Nedyalkov, N.N.; Atanasov, P.A.; Karashanova, D.B. Laser-assisted fabrication and size distribution modification of colloidal gold nanostructures by nanosecond laser ablation in different liquids. Appl. Phys. A 2017, 123, 490. [Google Scholar] [CrossRef]

- Hirtle, S.; Terekhin, P.N.; Schäfer, M.; Kang, Y.; Ashok, S.; L’huillier, J.A.; Rethfeld, B. Influence of an external electric field on the energy dissipation at the initial stage of laser ablation. Opt. Eng. 2021, 61, 21003. [Google Scholar] [CrossRef]

- Spadaro, S.; Bonsignore, M.; Fazio, E.; Cimino, F.; Speciale, A.; Trombetta, D.; Barreca, F.; Saija, A.; Neri, F. Molybdenum oxide nanocolloids prepared by an external field-assisted laser ablation in water. EPJ Web Conf. 2018, 167, 04009. [Google Scholar] [CrossRef] [Green Version]

- Ismail, R.A.; Fadhil, F.A. Effect of electric field on the properties of bismuth oxide nanoparticles prepared by laser ablation in water. J. Mater. Sci. Mater. Electron. 2014, 25, 1435–1440. [Google Scholar] [CrossRef]

- Liu, P.; Wang, C.X.; Chen, X.Y.; Yang, G.W. Controllable Fabrication and Cathodoluminescence Performance of High-index Facets GeO2 Micro- and Nanocubes and Spindles upon Electrical-field-assisted Laser Ablation in Liquid. J. Phys. Chem. C 2008, 112, 13450–13456. [Google Scholar] [CrossRef]

- Al-Haddad, R.M.S.; Hamid, M.K.; Jumaa, T. Electric Field Effect on the Synthesis of Nanogold Particles by PLAL. Int. J. Chem. Nat. Sci. 2015, 3, 269–274. [Google Scholar]

- Moniri, S.; Hantehzadeh, M.R.; Ghoranneviss, M.; Asadabad, M.A. Study of the optical and structural properties of Pt nanoparticles prepared by laser ablation as a function of the applied electric field. Appl. Phys. A 2017, 123, 684. [Google Scholar] [CrossRef]

- Sapkota, D.; Li, Y.; Musaev, O.R.; Wrobel, J.M.; Kruger, M.B. Effect of electric fields on tin nanoparticles prepared by laser ablation in water. J. Laser Appl. 2017, 29, 012002. [Google Scholar] [CrossRef]

- Mahdieh, M.H.; Mozaffari, H. Characteristics of colloidal aluminum nanoparticles prepared by nanosecond pulsed laser ablation in deionized water in presence of parallel external electric field. Phys. Lett. A 2017, 381, 3314–3323. [Google Scholar] [CrossRef]

- Liu, P.; Yang, S.; Fang, M.; Luo, X.; Cai, W. Complex nanostructures synthesized from nanoparticle colloids under an external electric field. Nanoscale 2011, 3, 3933–3940. [Google Scholar] [CrossRef]

- Safa, M.; Dorranian, D.; Masoudi, A.A.; Matin, L.F. Influence of transverse magnetic field on the properties of laser ablation produced nickel oxide nanoparticles. Phys. Scr. 2020, 96, 025804. [Google Scholar] [CrossRef]

- Ghaem, E.N.; Dorranian, D.; Sari, A.H. External magnetic field effects on the characteristics of cobalt nanoparticles prepared by pulsed laser ablation. Opt. Quantum Electron. 2021, 53, 1–14. [Google Scholar] [CrossRef]

- Abbas, A.K.; Ibrahim, I.M.; Naser, D.K. The Effect of Electric and Magnetic Field on Silver Nanoparticles Prepared by Pulse Laser Ablation. Int. J. Sci. Eng. Res. 2016, 7, 976–980. [Google Scholar]

- Kim, K.K.; Roy, M.; Kwon, H.; Song, J.K.; Park, S.M. Laser ablation dynamics in liquid phase: The effects of magnetic field and electrolyte. J. Appl. Phys. 2015, 117, 074302. [Google Scholar] [CrossRef]

- Ismail, R.A.; Sulaiman, G.M.; Abdulrahman, S.A. Preparation of iron oxide nanoparticles by laser ablation in DMF under effect of external magnetic field. Int. J. Mod. Phys. B 2016, 30, 1650094. [Google Scholar] [CrossRef]

- Serkov, A.A.; Rakov, I.I.; Simakin, A.V.; Kuzmin, P.G.; Shafeev, G.A.; Mikhailova, G.N.; Antonova, L.K.; Troitskii, A.V.; Kuzmin, G.P. Influence of external magnetic field on laser-induced gold nanoparticles fragmentation. Appl. Phys. Lett. 2016, 109, 053107. [Google Scholar] [CrossRef]

- Nikov, R.; Nedyalkov, N.; Karashanova, D. Laser ablation of Ni in the presence of external magnetic field: Selection of microsized particles. Appl. Surf. Sci. 2020, 518, 146211. [Google Scholar] [CrossRef]

- Musaev, O.R.; Sutter, E.A.; Wrobel, J.M.; Kruger, M.B. The effect of magnetic fields on the products of laser ablation. Appl. Phys. A 2016, 122, 95. [Google Scholar] [CrossRef]

- Al-Dahash, G.; Obaid, N.M.; Majeed, H.A. The Effect of Liquid Environment and Magnetic Field on Optical Properties of Pt Nanoparticles Colloidal Prepared by Pulsed Laser Ablation. Int. J. Chem. Tech. Res. 2016, 9, 118–130. [Google Scholar]

- Solati, E.; Dorranian, D. Effect of temperature on the characteristics of ZnO nanoparticles produced by laser ablation in water. Bull. Mater. Sci. 2016, 39, 1677–1684. [Google Scholar] [CrossRef] [Green Version]

- Solati, E.; Dorranian, D. Estimation of Lattice Strain in ZnO Nanoparticles Produced by Laser Ablation at Different Temperatures. J. Appl. Spectrosc. 2017, 84, 490–497. [Google Scholar] [CrossRef]

- Haram, N.; Ahmad, N. Formation of Gold and Silver Nanochains and Nanonetworks by Liquid Assisted Laser Ablation at Elevated Temperature. J. Clust. Sci. 2014, 26, 713–725. [Google Scholar] [CrossRef]

- Menéndez-Manjón, A.; Chichkov, B.N.; Barcikowski, S. Influence of Water Temperature on the Hydrodynamic Diameter of Gold Nanoparticles from Laser Ablation. J. Phys. Chem. C 2010, 114, 2499–2504. [Google Scholar] [CrossRef]

- Hong, M.H.; Ng, K.Y.; Xie, Q.; Shi, L.P.; Chong, T.C. Pulsed laser ablation in a cooled liquid environment. Appl. Phys. A 2008, 93, 153–157. [Google Scholar] [CrossRef]

- Mintcheva, N.; Yamaguchi, S.; Kulinich, S.A. Hybrid TiO2-ZnO Nanomaterials Prepared Using Laser Ablation in Liquid. Materials 2020, 13, 719. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Baig, U.; Khan, A.; Gondal, M.A.; Dastageer, M.A.; Falath, W.S. Laser Induced Anchoring of Nickel Oxide Nanoparticles on Polymeric Graphitic Carbon Nitride Sheets Using Pulsed Laser Ablation for Efficient Water Splitting under Visible Light. Nanomaterials 2020, 10, 1098. [Google Scholar] [CrossRef]

- Imbrogno, A.; Pandiyan, R.; Barberio, M.; Macario, A.; Bonanno, A.; El Khakani, M.A. Pulsed-laser-ablation based nanodecoration of multi-wall-carbon nanotubes by Co–Ni nanoparticles for dye-sensitized solar cell counter electrode applications. Mater. Renew. Sustain. Energy 2017, 6, 11. [Google Scholar] [CrossRef]

- Kotha, R.; Fernandes, G.; Nikam, A.N.; Kulkarni, S.; Pandey, A.; Pandey, S.; Mutalik, S. Surface engineered bimetallic nanoparticles based therapeutic and imaging platform: Recent advancements and future perspective. Mater. Sci. Technol. 2020, 36, 1729–1748. [Google Scholar] [CrossRef]

- Al-Douri, Y.; Abdulateef, S.; Abu Odeh, A.; Voon, C.; Badi, N. GaNO colloidal nanoparticles synthesis by nanosecond pulsed laser ablation: Laser fluence dependent optical absorption and structural properties. Powder Technol. 2017, 320, 457–461. [Google Scholar] [CrossRef]

- Wagener, P.; Jakobi, J.; Rehbock, C.; Chakravadhanula, V.S.K.; Thede, C.; Wiedwald, U.; Bartsch, M.; Kienle, L.; Barcikowski, S. Solvent-surface interactions control the phase structure in laser-generated iron-gold core-shell nanoparticles. Sci. Rep. 2016, 6, 23352. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Neumeister, A.; Jakobi, J.; Rehbock, C.; Moysig, J.; Barcikowski, S. Monophasic ligand-free alloy nanoparticle synthesis determinants during pulsed laser ablation of bulk alloy and consolidated microparticles in water. Phys. Chem. Chem. Phys. 2014, 16, 23671–23678. [Google Scholar] [CrossRef] [Green Version]

- Sharifi, T.; Dorranian, D.; Torkamany, M. Optimisation of GaAs nanocrystals synthesis by laser ablation in water. J. Exp. Nanosci. 2013, 8, 808–817. [Google Scholar] [CrossRef]

- Roston, A.H.M.; Isahak, W.N.R.W.; Mohamad, A.B. Preparation of Aluminium Alloy Metal Nanoparticles by Liquid Pulsed-Laser Ablation. Indian J. Sci. Technol. 2016, 9, 21. [Google Scholar] [CrossRef] [Green Version]

- Subhan, A.; Mourad, A.-H.I.; Das, S. Pulsed Laser Synthesis of Bi-Metallic Nanoparticles for Biomedical Applications: A Review. In Proceedings of the Advances in Science and Engineering Technology International Conferences (ASET), Dubai, United Arab Emirates, 21–24 February 2022. [Google Scholar]

- Benabid, F.; Kharchi, N.; Zouai, F.; Mourad, A.-H.I.; Benachour, D. Impact of co-mixing technique and surface modification of ZnO nanoparticles using stearic acid on their dispersion into HDPE to produce HDPE/ZnO nanocomposites. Polym. Polym. Compos. 2019, 27, 389–399. [Google Scholar] [CrossRef]

- Mohamed, F.H.; Mourad, A.-H.I.; Barton, D.C. UV irradiation and aging effects on nanoscale mechanical properties of ultra high molecular weight polyethylene for biomedical implants. Plast. Rubber Compos. 2008, 37, 346–352. [Google Scholar] [CrossRef]

- Zahoor, A.; Mourad, A.-H.I. Recent Developments in Processing and Characterization of Metal Foam. In Proceedings of the ASME International Mechanical Engineering Congress and Exposition, Virtual, Online, 1–5 November 2021; Volume 85574, p. V003T03. [Google Scholar]

- Subhan, A.; Zahoor, A.; Mourad, A.-H.I. Advances in manufacturing techniques of cladding steel pipes using corrosion-resistant alloy material for offshore oil and gas pipelines. In Proceedings of the 2022 Advances in Science and Engineering Technology International Conferences (ASET), Dubai, United Arab Emirates, 21–24 February 2022; pp. 1–6. [Google Scholar] [CrossRef]

- Zahoor, A.; Mourad, A.-H.I.; Khan, S.H. Production of open cell Nickel-based metal foam from polyurethane template. In Proceedings of the 2022 Advances in Science and Engineering Technology International Conferences (ASET), Dubai, United Arab Emirates, 21–24 February 2022; pp. 1–6. [Google Scholar]

| Reference | Studied Metal/Metal Oxide Nanoparticle | Laser Parameters | Characteristic Investigated | Remarks |

|---|---|---|---|---|

| Alwa et al. [125] | Ag NPs | Laser wavelength (355 nm, 532 nm) Laser fluence (38.2, 76.4, 144.6 J/cm2) | Stability and size distribution | Spherical nanostructure NP size increased with wavelength broader size distribution with increased fluence |

| Ganjali et al. [127] | Ni NPs | Laser fluence per pulse (50, 100, 150 mJ) | Structural, optical, antibacterial property | Energy bandgap changed with fluence. Enhanced antibacterial activity by reducing particle size |

| El Faham et al. [128] | Mg NPs | Laser wavelength (1064 nm) Pulse duration: 7 ns PRR: 10 Hz Ablation time: 10–30 min | Spectral line intensities, plasma parameters | An increase in ablation time leads to a blue shift in absorption, particle size reduction (20–30 nm) |

| Menazea et al. [129] | Ag NPs | Laser wavelength (800 nm) Pulse width: 40 fs Power 1 mJ PRR: 1 KHz Ablation time: 15 min | Antibacterial efficiency, structural & optical properties | Spherical-shaped NPs, uniform size distribution |

| Mostafa et al. [130] | CdO NPs | Pulse duration: 7 ns Energy per pulse: 80 mJ | Stability, morphology | Crystalline and spherical NPs of size 47 nm |

| Altowyan et al. [131] | Au-Ag NPs | Pulse duration: 7 ns Energy per pulse: 50, 150, 250 mJ | Effect of laser energy on nanostructure | (Au)Core-(Ag)shell nanostructure formation. Ag-Shell thickness increased with laser energy |

| Alluhaybi et al. [132] | Au NPs | Laser wavelength: 1064 nm Pulse width: 8 ns Fluence: 7.28, 17.03, 21.55 and 23.96 J/cm2 | Structural, morphological, optical properties | Generation of spherical NPs (7–30 nm) An increase in ablation energy yielded a blue shift in absorbance, smaller particles (30.1 to 7.5 nm) |

| Ibarra et al. [133] | TiO2 | Laser wavelength: 532 nm Pulse width: 10 ns Fluence: 0.65 J/cm2 Irradiation time: 45, 60, 75, 90 min | Optical properties, energy bandgap | The shift of diffraction peaks and bigger spherical nanoparticles with an increase in irradiation time, phase change of TiO2 |

| Mendivil et al. [134] | Pd NPs | Laser wavelength: 1064 nm Pulse width: 10 ns Fluence: 40.5–8 J/cm2 Irradiation time: 45, 60, 75, 90 min | Morphology, nanostructure, the effect of fluence on size of nanoparticles | Spherical morphology, cubic crystalline nanostructure. Average diameter increased with reduction in fluence (17 ± 6 nm for 40.5 J/cm2. 24 ± 7 nm for 18 J/cm2 27 ± 9 nm for 8 J/cm2) |

| Kupracz et al. [135] | Fe based NPs | Laser wavelength: 1064 nm Pulse width:6 ns PRR: 10 Hz Fluence: 9–21 J/cm2 Irradiation time: 2–32 min | Stability, composition | An increase in fluence incrementally changes the NP diameter. Longer irradiation and storage lead to agglomeration |

| Goncharova et al. [136] | Cu NPs | Laser wavelength: 1064 nm Pulse width: 7 ns PRR: 20 Hz | Structure, morphology, stability, composition | Cubic-shaped NPs formed initially, 10–50-nm size range, nanoribbons formed after 2 weeks |

| Altuwirqi et al. [56] | Al NPs | Laser wavelength: 532 nm Ablation time: 15 min PRR: 10 Hz Pulse width: 6 ns | Structure, morphology | Spherical morphology, core-shell nanostructure formation Average diameter: 12 ± 9 nm |

| Riahi et al. [137] | Al NPs | Laser wavelength: 1064 nm Ablation time: 15 min PRR: 10 Hz Pulse width: 6–7 ns | Thermal conductivity, optical properties | Increased thermal conductivity of nanofluid. Change in nanoparticle concentration |

| Nassar et al. [138] | Zn NPs | Laser wavelength: 800 nm Ablation time: 10 min PRR: 1 KHz Pulse width: 130 fs | Effect of pulse energy (0.05 mJ, 1.11 mJ, 1.15 mJ) on NP size and distribution | NP size increases with pulse energy Higher absorption |

| Reference | Liquid Medium | Study | Formed Nanostructure, Morphology | Research Outcome |

|---|---|---|---|---|

| Lee et al. [153] | Methanol, DIW, hexane, acetonitrile | Cavitation bubble dynamics of Ni NPs | FCC/HCP, Pure FCC and spherical-shaped NPs | Bubble lifetime and crystal structure depends on liquid media |

| Solati et al. [154] | Distilled water, acetone, CTAB | Effect of liquid environment on the properties of TiO2 | Polycrystalline, spherical-shaped NPs | Distilled water produces smaller, narrow size distribution, better adhesion than other solvents |

| Moura et al. [155] | DDW, acetone and ethanol | Study characteristics of Ag NPs | Spherical NPs | Liquid media play a major role in the mean size and size distribution. Acetone and ethanol resulted in low productivity but a bigger NP size. |

| Lasemi et al. [156] | Distilled water, ethanol, butanol, iso-propanol | Study the development of Ni, Fe and W NPs | Not reported | Ni showed more incubation than other metals. |

| Ali et al. [157] | DIW, propanol | Study the characteristics, mechanical and structural surface changes in Ti NPs | Nanocones, -globules in DIW Dendritic, globular in propanol | Ablation mass and nanostructure formation and bubble confinement are dictated by the liquid medium |

| Lee et al. [158] | DIW, methanol, hexane, acetonitrile | Study chemical reactivity of Au, Au-GC NPs in various solvents | Spherical, agglomerated chains and polycrystalline nanostructure | The enhanced catalytic activity of Au NPs |

| Nikov et al. [159] | Chloroform, toluene and ethanol | Study on the effect of optical properties and size distribution in different solvents for Au NPs | Spherical and spheroidal morphology, elongated nanostructures | Mean size distribution influenced by the liquid medium |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Subhan, A.; Mourad, A.-H.I.; Al-Douri, Y. Influence of Laser Process Parameters, Liquid Medium, and External Field on the Synthesis of Colloidal Metal Nanoparticles Using Pulsed Laser Ablation in Liquid: A Review. Nanomaterials 2022, 12, 2144. https://doi.org/10.3390/nano12132144

Subhan A, Mourad A-HI, Al-Douri Y. Influence of Laser Process Parameters, Liquid Medium, and External Field on the Synthesis of Colloidal Metal Nanoparticles Using Pulsed Laser Ablation in Liquid: A Review. Nanomaterials. 2022; 12(13):2144. https://doi.org/10.3390/nano12132144

Chicago/Turabian StyleSubhan, Abdul, Abdel-Hamid Ismail Mourad, and Yarub Al-Douri. 2022. "Influence of Laser Process Parameters, Liquid Medium, and External Field on the Synthesis of Colloidal Metal Nanoparticles Using Pulsed Laser Ablation in Liquid: A Review" Nanomaterials 12, no. 13: 2144. https://doi.org/10.3390/nano12132144