Measuring Non-Destructively the Total Indium Content and Its Lateral Distribution in Very Thin Single Layers or Quantum Dots Deposited onto Gallium Arsenide Substrates Using Energy-Dispersive X-ray Spectroscopy in a Scanning Electron Microscope

Abstract

:1. Introduction

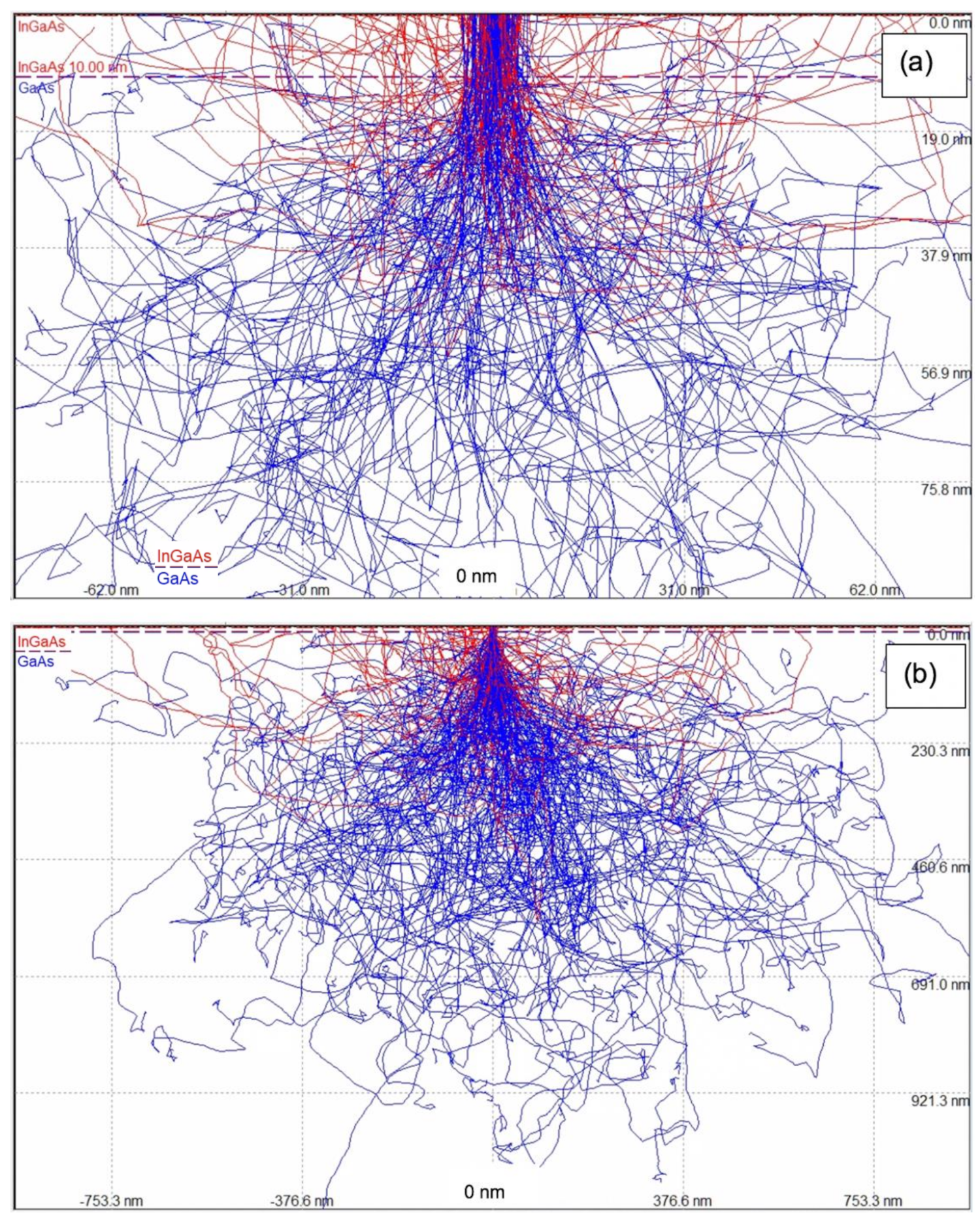

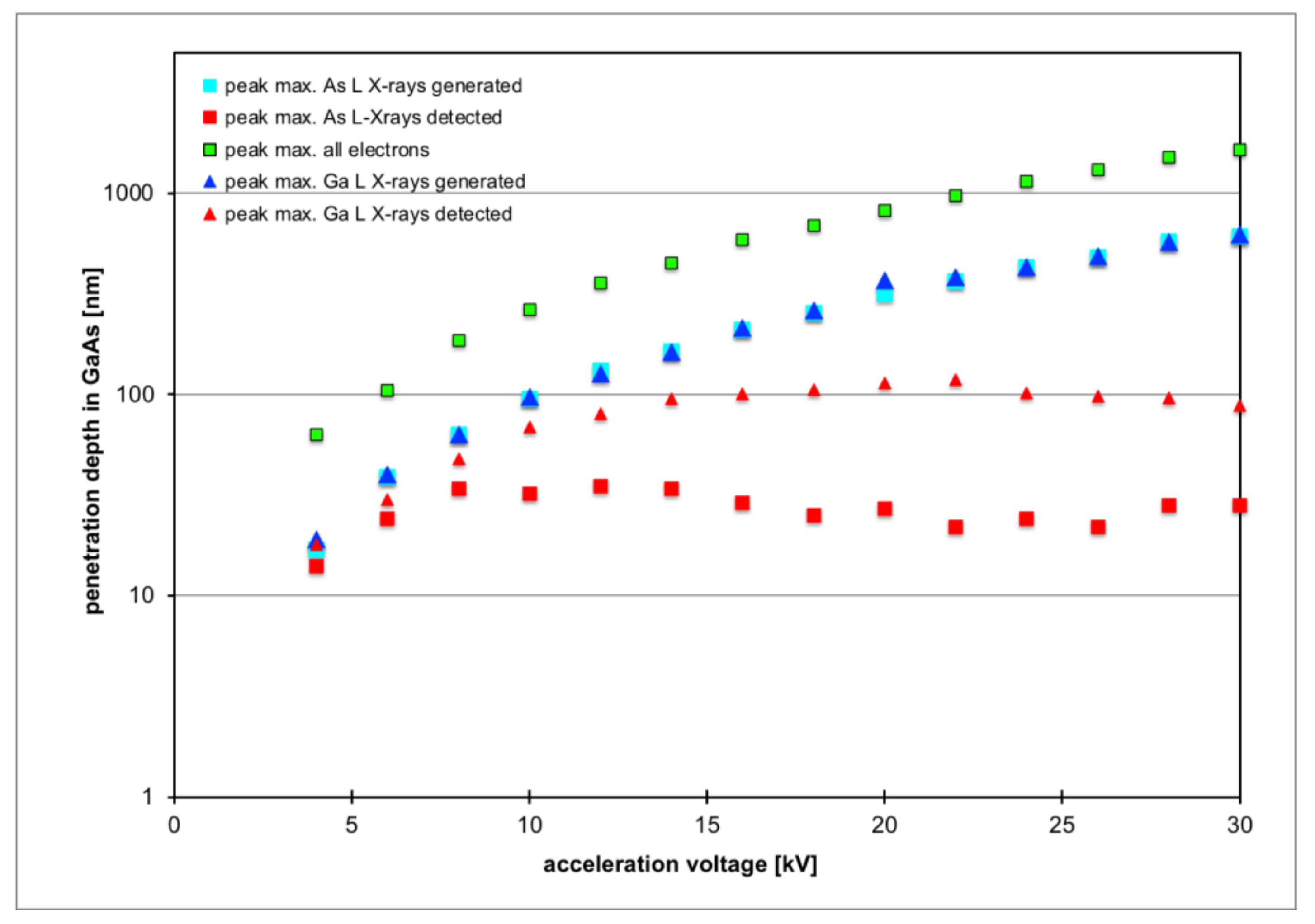

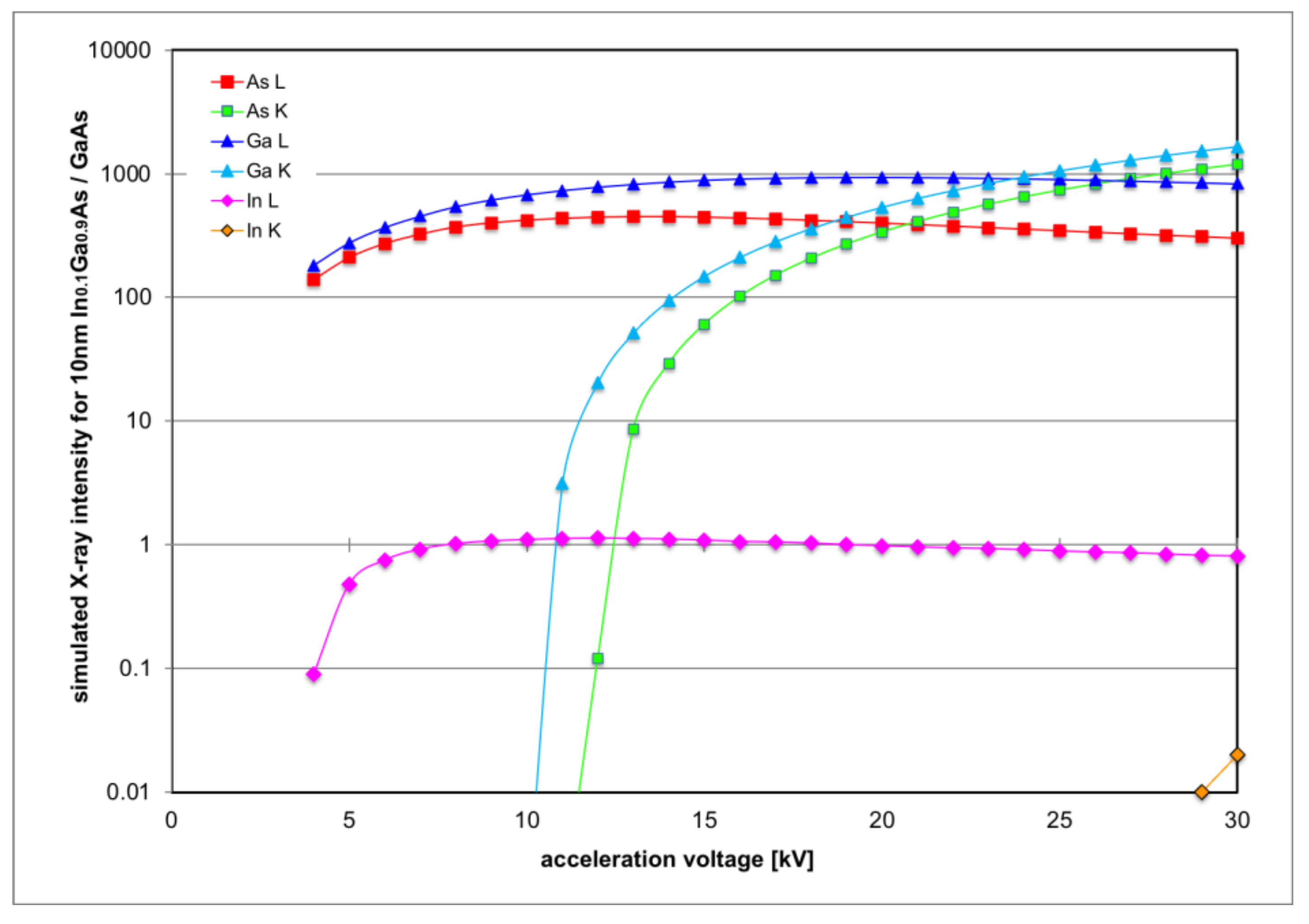

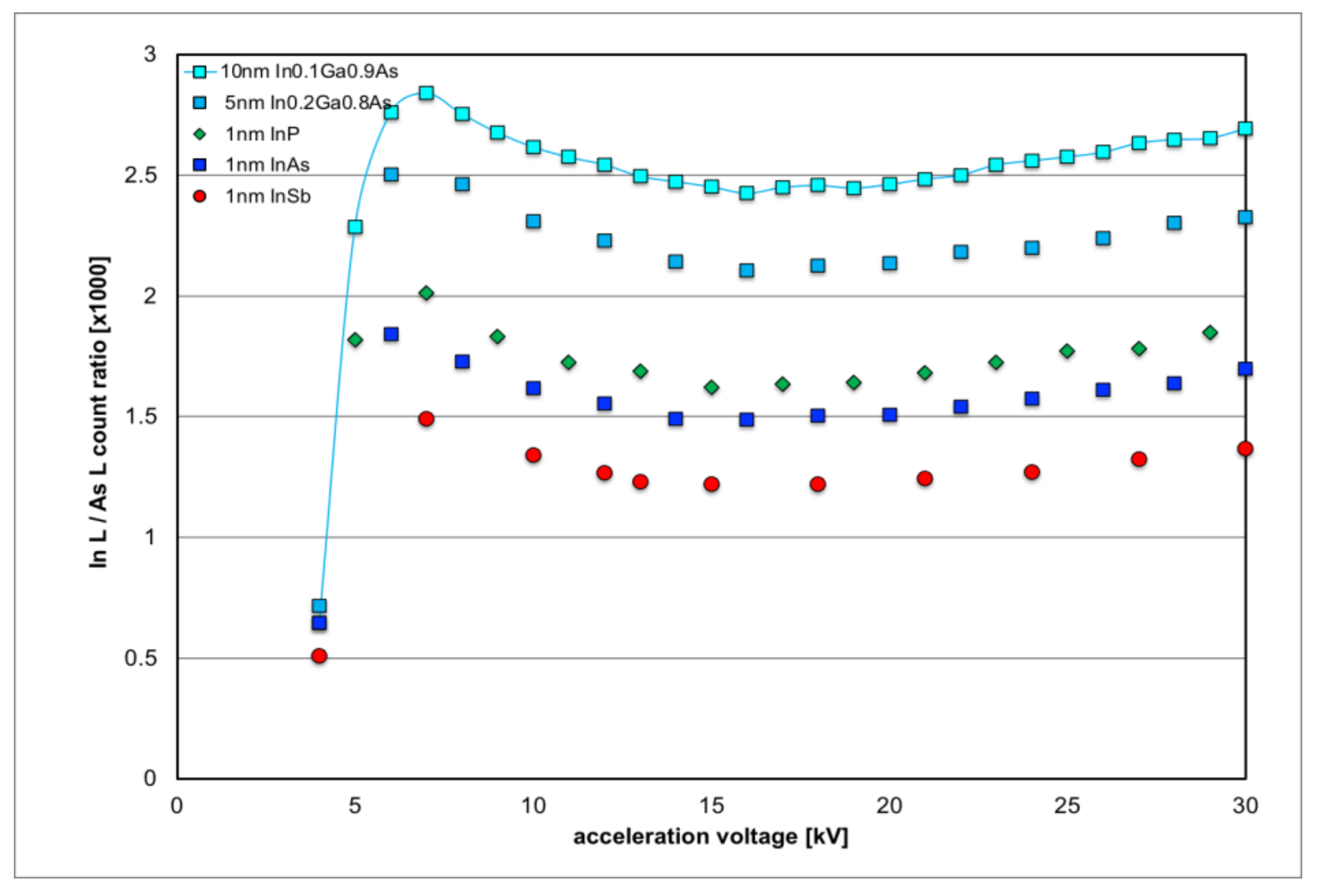

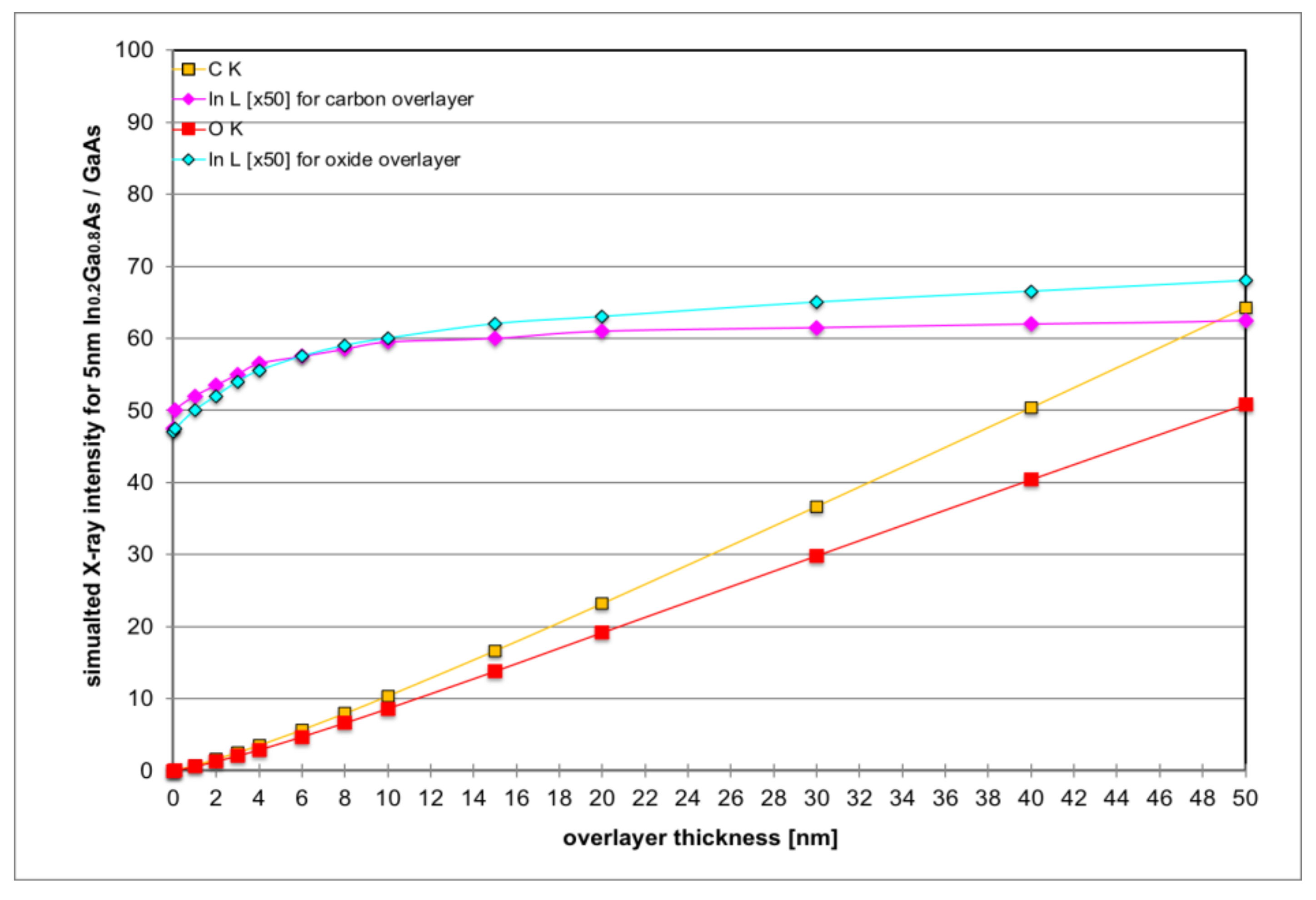

2. Monte Carlo Simulations

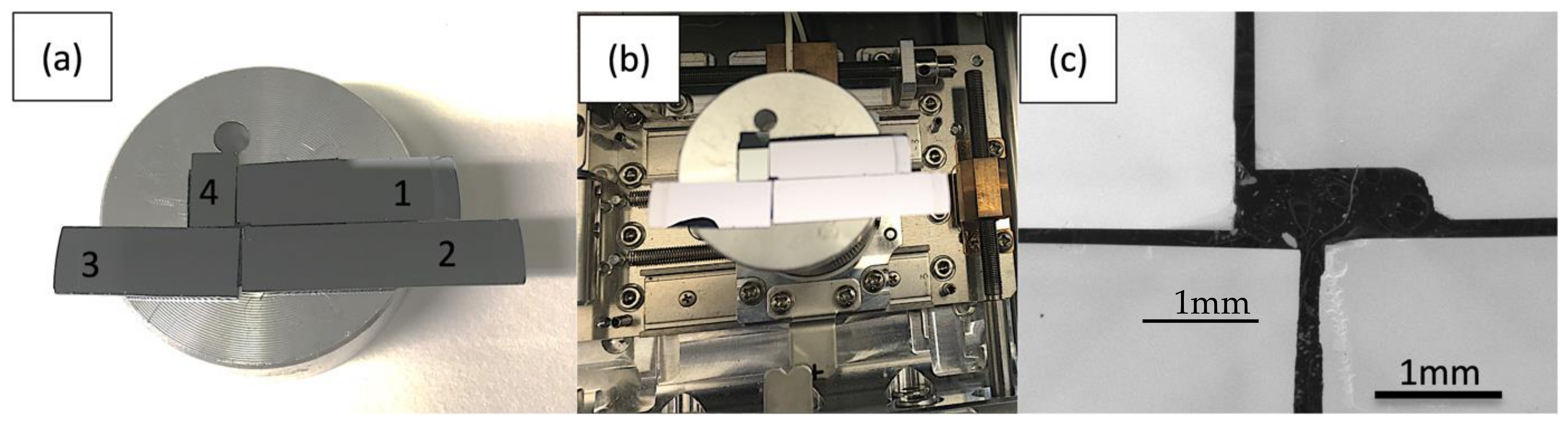

3. SEM Characterisation

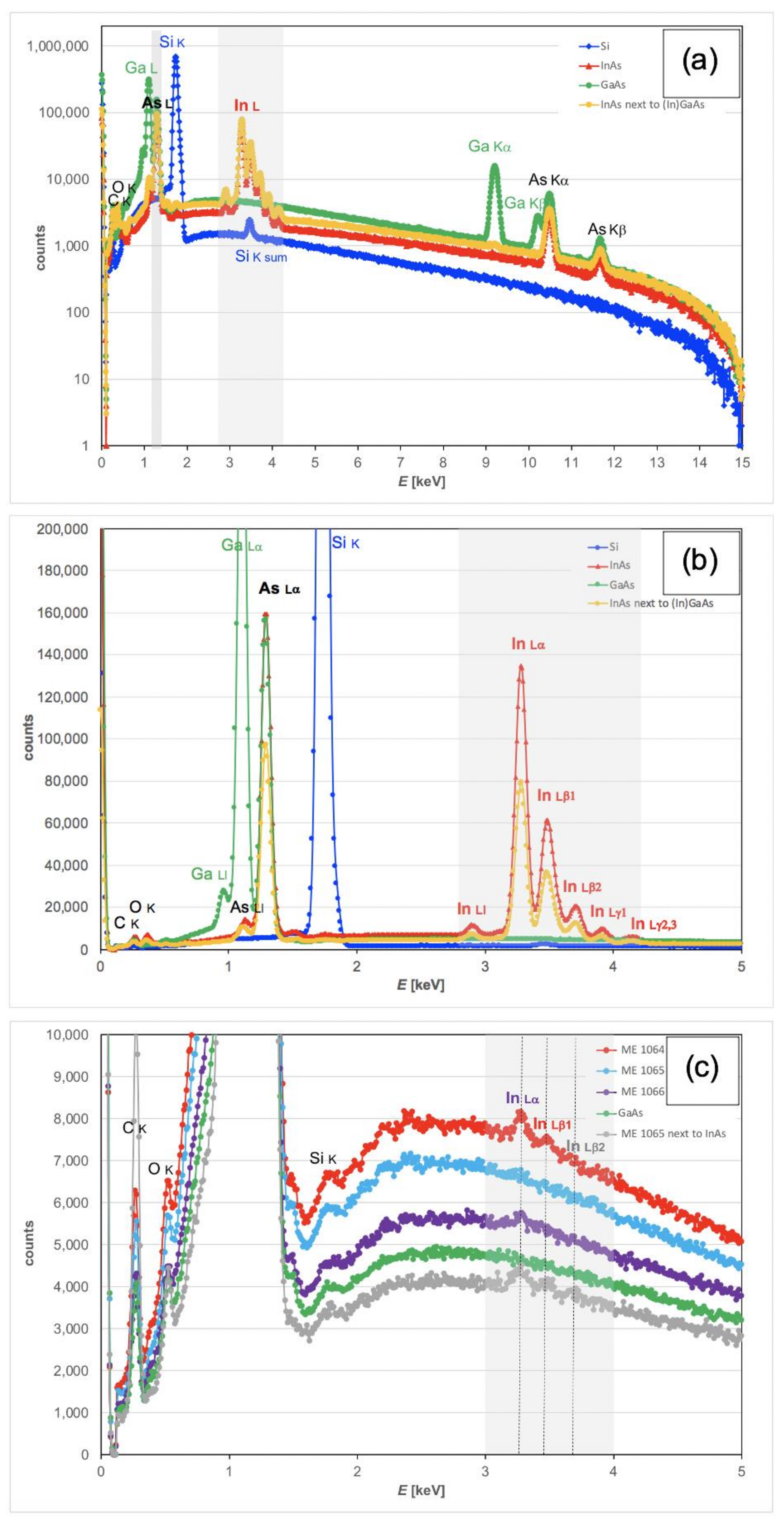

3.1. Energy-Dispersive X-ray (EDX) Spectroscopy

- i.

- It removes detector artefacts, such as sum peaks, escape peaks, offsets due to incomplete charge collection and blur due to line broadening.

- ii.

- It performs continuous bremsstrahlung fitting and background subtraction around these characteristic lines [36].

- iii.

- It fits the peaks of all characteristic X-ray lines detected, including multiple sub-lines.

- iv.

- It quantifies the net counts extracted by internal, standardless calculation of element-number (Z) specific ionisation cross-sections, fluorescence yields and relative X-ray emission rates (Z-effect), absorption (A) and internal fluorescence (F) corrections. This is called standardless peak-to-background (P/B) ZAF quantification [37,38].

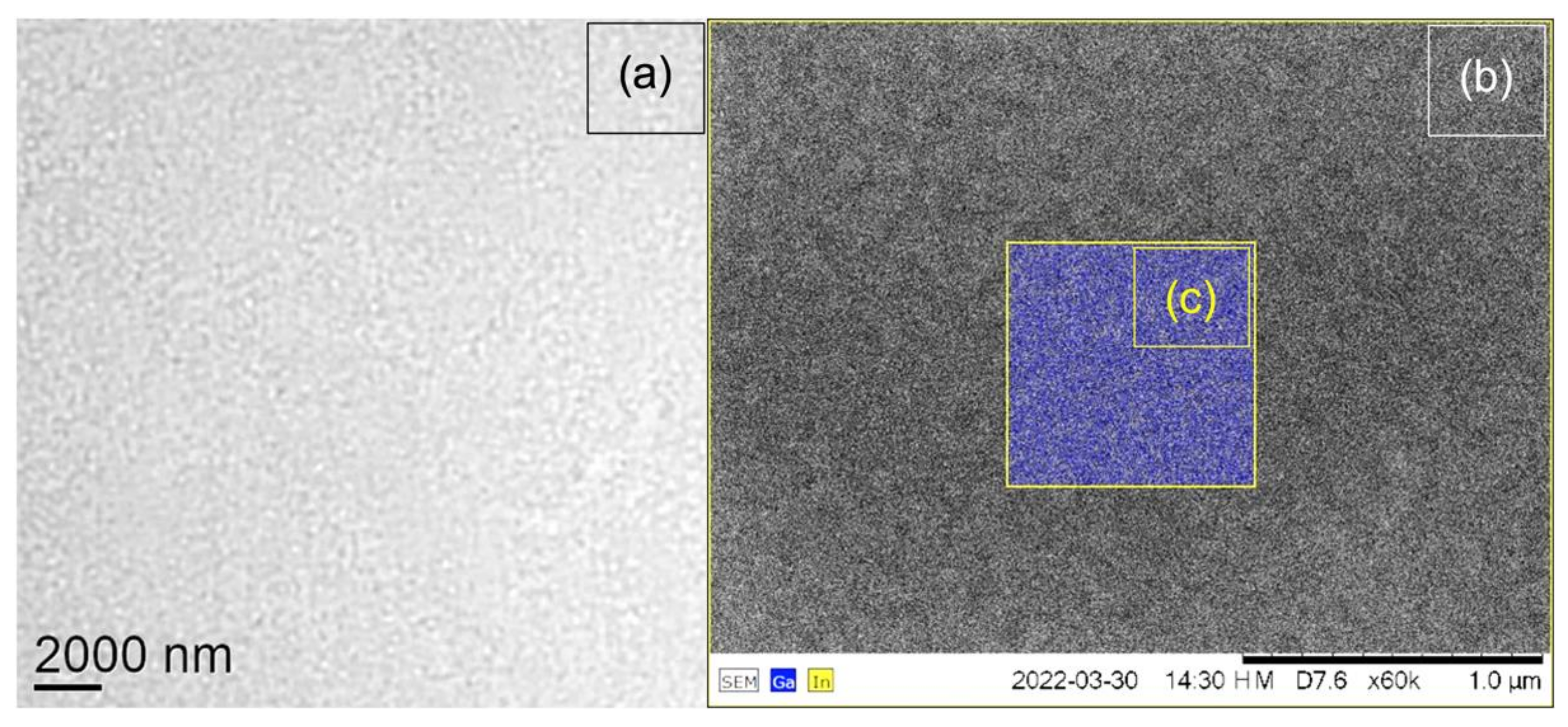

3.2. EDX Mapping

4. Discussion

5. Conclusions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Brandt, O.; Tapfer, L.; Ploog, K.; Bierwolf, R.; Hohenstein, M.; Philipp, F.; Lage, H.; Heberle, A. InAs quantum dots in a single-crystal GaAs matrix. Phys. Rev. B 1991, 44, 8043–8053. [Google Scholar] [CrossRef] [PubMed]

- Leonard, D.; Fafard, S.; Pond, K.; Zhang, Y.H.; Merz, J.L.; Petroff, P.M. Structural and optical properties of self-assembled InGaAs quantum dots. J. Vac. Sci. Technol. B 1994, 12, 2516–2520. [Google Scholar] [CrossRef]

- Yoffe, A.D. Semiconductor quantum dots and related systems: Electronic, optical, luminescence and related properties of low dimensional systems. Adv. Phys. 2001, 50, 1–208. [Google Scholar] [CrossRef]

- Joyce, P.B.; Krzyzewski, T.J.; Bell, G.R.; Jones, T.S.; Malik, S.; Childs, D.; Murray, R. Effect of growth rate on the size, composition, and optical properties of InAs/GaAs quantum dots grown by molecular beam epitaxy. Phys. Rev. B 2000, 62, 10891–10895. [Google Scholar] [CrossRef]

- Ledentsov, N.N.; Ustinov, V.M.; Egorov, A.Y.; Zhukov, A.E.; Maksimov, M.V.; Tabatadze, I.G.; Kopev, P.S. Optical properties of heterostructures with InGaAs-GaAs quantum clusters. Semiconductors 1994, 28, 832–834. [Google Scholar]

- Gerard, J.M.; Genin, J.B.; Lefebvre, J.; Moison, J.M.; Lebouche, N.; Berthe, F. Optical investigation of the self-organised growth of InAs/GaAs quantum boxes. J. Crystal Growth 1995, 150, 351–356. [Google Scholar] [CrossRef]

- Walther, T.; Cullis, A.G.; Norris, D.J.; Hopkinson, M. The nature of islanding in the InGaAs/GaAs epitaxial system. In Proceedings of the MRS Fall Meeting, 27 November–1 December 2000, Boston, MA, USA. Mat. Res. Soc. Symp. Proc. 2001, 648, P. 12.6.1-6. [Google Scholar]

- Walther, T.; Cullis, A.G.; Norris, D.J.; Hopkinson, M. How InGaAs islands form on GaAs substrates: The missing link in et explanation of the Stranski-Krastanow transition. In Proceedings of the 12th Microscopy of Semiconducting Materials Conference, 25–29 March 2001, Oxford, UK. Inst. Phys. Conf. Ser. 2001, 169, 85–88. [Google Scholar]

- Walther, T.; Cullis, A.G.; Norris, D.J.; Hopkinson, M. Nature of the Stranski-Krastanow transition during epitaxy of InGaAs on GaAs. Phys. Rev. Lett. 2001, 86, 2381–2384. [Google Scholar] [CrossRef]

- Theeten, J.; Hottier, F. On the role of chlorine in the vapour phase epitaxy of (100)GaAs as evidenced by leed and rheed. Surf. Sci. 1976, 58, 583–589. [Google Scholar] [CrossRef]

- Theeten, J.B. Real-time and spectroscopic ellipsometry of film growth: Application to multilayer systems in plasma and CVD processing of semiconductors. Surf. Sci. 1998, 96, 293–295. [Google Scholar]

- Arthur, J.R. The use of scanning Auger microscopy in molecular beam epitaxy of GaAs and GaP. J. Vac. Sci. Technol. 1973, 10, 136–139. [Google Scholar] [CrossRef]

- Murrell, A.J.; Wee, A.T.S.; Fairbrother, D.H.; Singh, N.K.; Foord, J.S. Surface chemical processes in metal organic molecular-beam epitaxy; Ga deposition from triethylgallium on GaAs(100). J. Appl. Phys. 1990, 68, 4053. [Google Scholar] [CrossRef]

- Schwartz, G.P.; Gualtieri, G.J.; Kammlott, G.W.; Schwartz, B. An X-ray photoelectron spectroscopy study of native oxides on GaAs. J. Electrochem. Soc. 1979, 126, 1737–1749. [Google Scholar] [CrossRef]

- Ploog, K. Surface studies during molecular beam epitaxy of gallium arsenide. J. Vac. Sci. Technol. 1979, 16, 838–846. [Google Scholar] [CrossRef]

- Kowalczyk, S.P.; Schaffer, W.J.; Kraut, E.A.; Grant, R.W. Determination of the InAs-GaA(100) heterojunction band discontinuities by x-ray photoelectron spectroscopy (XPS). J. Vac. Sci. Technol. 1982, 20, 705–708. [Google Scholar] [CrossRef]

- Hamann, D.M.; Bardgett, D.; Cordova, D.L.M.; Maynard, L.A.; Hadland, E.C.; Lygo, A.C.; Wood, S.R.; Esters, M.; Johnson, D.C. Sub-monolayer accuracy in determining the number of atoms per unit area in ultrathin films using X-ray fluorescence. Chem. Mater. 2018, 30, 6209–6216. [Google Scholar] [CrossRef]

- Braun, W.; Ploog, K.H. Real-time surface composition and roughness analysis in MBE using RHEED-induced X-ray fluorescence. J. Cryst. Growth 2003, 251, 68–72. [Google Scholar] [CrossRef]

- Nowak, S.H.; Bjeoumikhov, A.; von Borany, J.; Buchriegler, J.; Munnik, F.; Petric, M.; Renno, A.D.; Radtke, M.; Reinholz, U.; Scharf, O.; et al. Examples of XRF and PIXE imaging with few microns resolution using SLcam, a color X-ray camera. X-ray Spectrom. 2015, 44, 135–140. [Google Scholar] [CrossRef]

- Joy, D.C. Monte Carlo Modeling for Electron Microscopy and Microanalysis; Oxford University Press: New York, NY, USA, 1995. [Google Scholar]

- Pouchou, J.L.; Pichoir, F. Surface film X-ray microanalysis. Scanning 1990, 12, 212–224. [Google Scholar] [CrossRef]

- Pouchou, J.L.; Pichoir, F. Electron probe X-ray microanalysis applied to thin surface films and stratified specimens. Scanning Microsc. 1993, 1993 (Suppl. 7), 167–189. [Google Scholar]

- Möller, A.; Weinbruch, S.; Stadermann, F.J.; Ortner, H.M.; Balogh, A.G.; Hahn, H. Accuracy of film thickness determination in electron probe microanalysis. Mikrochim. Acta 1995, 119, 41–47. [Google Scholar] [CrossRef]

- Matthews, M.B.; Buse, B.; Kearns, S.L. Electron probe microanalysis through coated oxidized surfaces. Microsc. Microanal. 2019, 25, 1112–1129. [Google Scholar] [CrossRef] [PubMed]

- Staub, P.F. The low energy X-ray spectrometry techniques as applied to semiconductors. Microsc. Microanal. 2006, 12, 340–346. [Google Scholar] [CrossRef] [PubMed]

- Walther, T. Measurement of nanometre-scale gate oxide thicknesses by energy-dispersive X-ray spectroscopy in a scanning electron microscope combined with Monte Carlo simulations. Nanomaterials 2021, 11, 2117. [Google Scholar] [CrossRef]

- Goldstein, J.I.; Costley, J.L.; Lorimer, G.W.; Reed, S.J.B. Quantitative X-ray analysis in the electron microscope. In: Proc. Anal. Electr. Microsc., Chicago, USA. Scanning Electron Microsc. 1977, 1, 315–324. [Google Scholar]

- Drouin, D.; Couture, A.R.; Joly, D.; Tastet, X.; Aimez, Y.; Gauvin, R. CASINO v2.42.—A fast and easy-to-use modeling tool for scanning electron microscopy and microanalysis users. Scanning 2007, 29, 92–101. [Google Scholar] [CrossRef]

- Yuan, Y.; Demers, H.; Rudinsky, S.; Gauvin, R. Secondary fluorescence correction for characteristic and Bremsstrahlung X-rays using Monte Carlo X-ray depth distributions applied to bulk and multilayer materials. Microsc. Microanal. 2019, 25, 92–104. [Google Scholar] [CrossRef]

- Joy, D.C.; Newbury, D.E.; Myklebust, R.L. The role of fast secondary electrons in degrading spatial resolution in the analytical electron microscope. J. Microsc. 1982, 128, RP1-2. [Google Scholar] [CrossRef]

- Joy, D.C. Secondary electrons and the spatial resolution of EDS analysis. In Analytical Electron Microscopy; Williams, D.B., Joy, D.C., Eds.; San Francisco Press: San Francisco, CA, USA, 1984; pp. 43–46. [Google Scholar]

- Walther, T. A study of compositional variations in semiconductor heterostructures by transmission electron microscopy. Ph.D. Thesis, University of Cambridge, Cambridge, UK, December 1996. [Google Scholar]

- Griffiths, A.J.V.; Walther, T. Quantification of carbon contamination under electron beam irradiation in a scanning transmission electron microscope and its suppression by plasma cleaning. J. Phys. Conf. Ser. 2010, 241, 012017. [Google Scholar] [CrossRef]

- Wooley, J.C.; Blazey, K.W. Reflectivity spectra of GaSb–InSb and GaAs–InAs alloys. J. Phys. Chem. Solids 1964, 25, 713–716. [Google Scholar] [CrossRef]

- Jones, C.E. Determination of alloy composition in the GaAs–InAs system by reflectivity. Appl. Spectrosc. 1966, 20, 161–163. [Google Scholar] [CrossRef]

- Wendt, M.; Schmidt, A. Improved reproducibility of energy-dispersive X-ray microanalysis by normalization to the background. Phys. Stat. Sol. A 1978, 46, 179–183. [Google Scholar] [CrossRef]

- Small, J.A.; Leigh, S.D.; Newbury, D.E.; Myklebust, R.L. Modeling of the bremsstrahlung radiation produced in pure- element targets by 10–40 keV electrons. J. Appl. Phys. 1987, 61, 459–469. [Google Scholar] [CrossRef]

- Introduction to EDS Analysis. Available online: http://www.bruker.com/quantax-eds-for-sem (accessed on 1 June 2022).

- Walther, T.; Nutter, J.; Reithmaier, J.P.; Pavelescu, E.M. X-ray mapping in a scanning transmission electron microscope of InGaAs quantum dots with embedded fractional monolayers of aluminium. Semicond. Sci. Technol. 2020, 35, 084001. [Google Scholar] [CrossRef]

- Walther, T.; England, J. Investigation of boron implantation into silicon by quantitative energy-filtered transmission electron microscopy. In Proceedings of the 17th International Conf. on Microscopy of Semiconducting Materials, 4–7 April 2011, Cambridge, UK. J. Phys. Conf. Ser. 2011, 326, 012053. [Google Scholar]

- QUANTAX micro-XRF. Available online: https://www.bruker.com/en/products-and-solutions/elemental-analyzers/eds-wds-ebsd-SEM-Micro-XRF/quantax-micro-xrf.html (accessed on 22 June 2022).

- Mu, S. Minimum Detection Limit and Silicon Nitride Window. Available online: https://edaxblog.com/2021/04/08/minimum-detection-limit-and-silicon-nitride-window/ (accessed on 1 June 2022).

- Walther, T. A comparison of transmission electron microscopy methods to measure wetting layer thicknesses to sub-monolayer precision. In Proceedings of the EMAG2007, Glasgow, UK, 3–7 September 2007. [Google Scholar]

- Walther, T.; Hopkinson, M.; Daneu, N.; Recnik, A.; Ohno, Y.; Inoue, K.; Yonenaga, I. How to best measure atomic segregation to grain boundaries by analytical transmission electron microscopy. J. Mater. Sci. 2014, 49, 3898–3908. [Google Scholar] [CrossRef]

- Walther, T. Accurate measurement of atomic segregation to grain boundaries or to planar faults by analytical transmission electron microscopy. Phys. Stat. Sol. C 2015, 12, 310–313. [Google Scholar] [CrossRef] [Green Version]

- Christien, F.; Risch, P. Cross-sectional measurement of grain boundary segregation using WDS. Ultramicroscopy 2016, 170, 107–112. [Google Scholar] [CrossRef]

| Layer Material | Density | Band- | Lattice | # In Atoms/nm3 | ||

|---|---|---|---|---|---|---|

| [g/cm3] | gap [eV] | Constant [pm] | Strain State Compared | Relaxed | Fully Strained | |

| @300K | @300K | to GaAs | ||||

| GaAs | 5.32 | 1.42 | 565.3 | 22.14 | – | |

| In0.1Ga0.9As | 5.34 | 1.27 | 569.4 | 21.67 | 21.84 | |

| In0.2Ga0.8As | 5.38 | 1.13 | 573.4 | 21.21 | 21.55 | |

| InP | 4.81 | 1.344 | 586.87 | 19.79 | 20.64 | |

| InAs | 5.68 | 0.354 | 605.83 | 17.99 | 19.48 | |

| InSb | 5.77 | 0.17 | 647.9 | 14.71 | 17.32 | |

| Bulk Sample | BSE Coeff. | As X-rays | Ga X-rays | In X-rays | ||||

|---|---|---|---|---|---|---|---|---|

| Line Type | L | K | L | K | L | K | ||

| GaAs | 0.329 | 444.93 | 60.95 | 897.14 | 148.88 | - | - | |

| InAs | 0.361 | 419.02 | 50.79 | - | - | 603.52 | 0 | |

| # | Growth Number | Substrate | Top Layer | Nom. InAs Equiv. ML | InL [Counts] | AsL [Counts] | InL/AsL | Measured Thickness [InAs Equiv. ML] |

|---|---|---|---|---|---|---|---|---|

| 1 | ME1065 | GaAs | In0.2Ga0.8As | 1.4 | 1112 | 2,106,681 | 0.000528 | 0.9 ± 0.6 |

| 2 | ME1066 | GaAs | In0.2Ga0.8As | 3.5 | 5239 | 1,696,135 | 0.003083 | 5.1 ± 0.7 |

| 3 | ME1064 | GaAs | In0.2Ga0.8As | 7.0 | 12,380 | 2,392,187 | 0.005175 | 8.6 ± 0.6 |

| 4 | – | InAs | – | – | 2,342,596 | 1,463,727 | 1.60 | – |

| 5 | – | GaAs | – | 0 | 596 | 1,459,337 | 0.000408 | 0.7 ± 0.8 |

| 6 | AF9151 | GaAs | InAs | 1.5 | 3787 | 2,279,822 | 0.001661 | 2.7 ± 0.8 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Walther, T. Measuring Non-Destructively the Total Indium Content and Its Lateral Distribution in Very Thin Single Layers or Quantum Dots Deposited onto Gallium Arsenide Substrates Using Energy-Dispersive X-ray Spectroscopy in a Scanning Electron Microscope. Nanomaterials 2022, 12, 2220. https://doi.org/10.3390/nano12132220

Walther T. Measuring Non-Destructively the Total Indium Content and Its Lateral Distribution in Very Thin Single Layers or Quantum Dots Deposited onto Gallium Arsenide Substrates Using Energy-Dispersive X-ray Spectroscopy in a Scanning Electron Microscope. Nanomaterials. 2022; 12(13):2220. https://doi.org/10.3390/nano12132220

Chicago/Turabian StyleWalther, Thomas. 2022. "Measuring Non-Destructively the Total Indium Content and Its Lateral Distribution in Very Thin Single Layers or Quantum Dots Deposited onto Gallium Arsenide Substrates Using Energy-Dispersive X-ray Spectroscopy in a Scanning Electron Microscope" Nanomaterials 12, no. 13: 2220. https://doi.org/10.3390/nano12132220