New Cryogels Based on Poly(vinyl alcohol) and a Copolymacrolactone System: I-Synthesis and Characterization

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Method

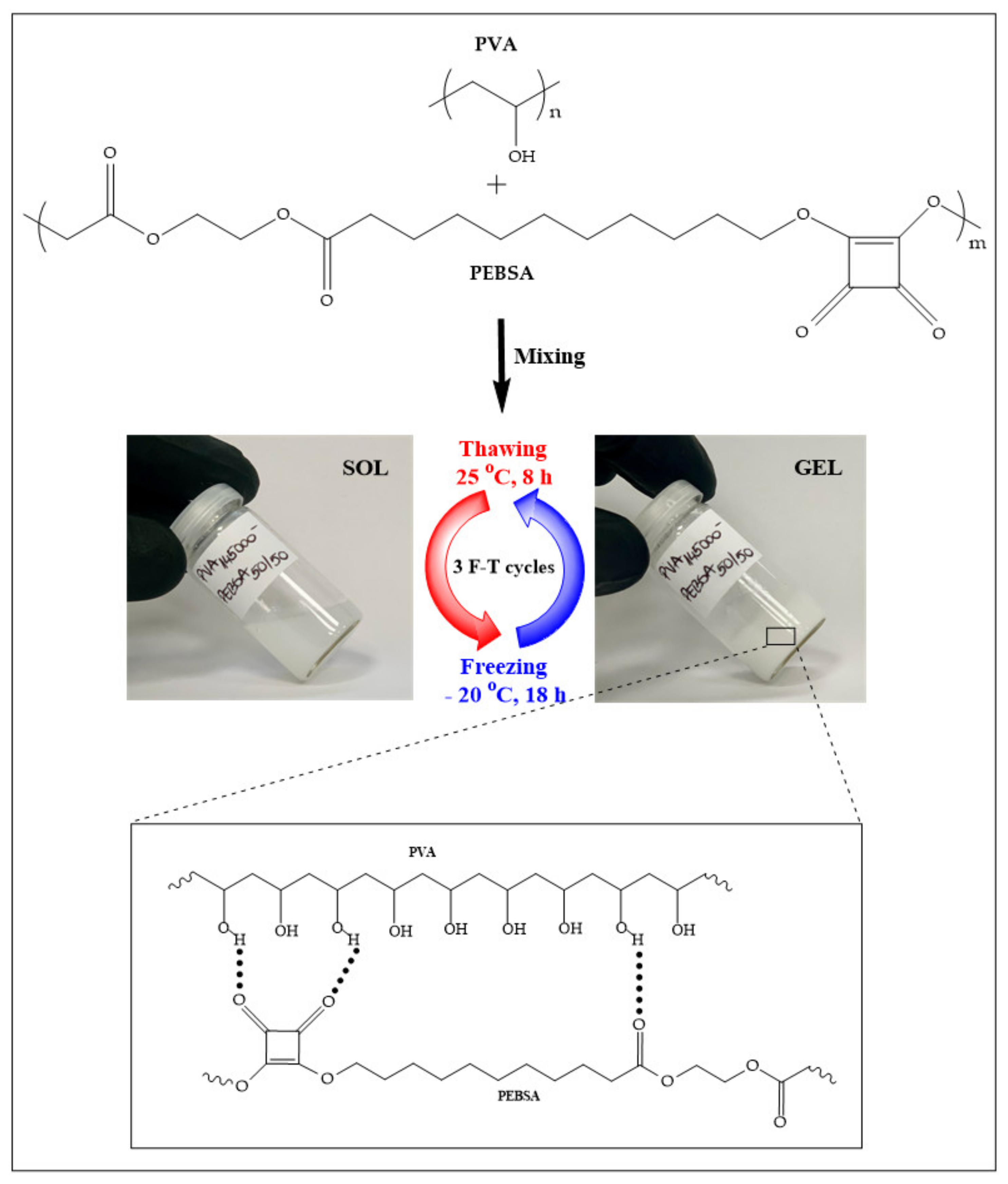

Preparation of Cryogels

2.3. Characterization

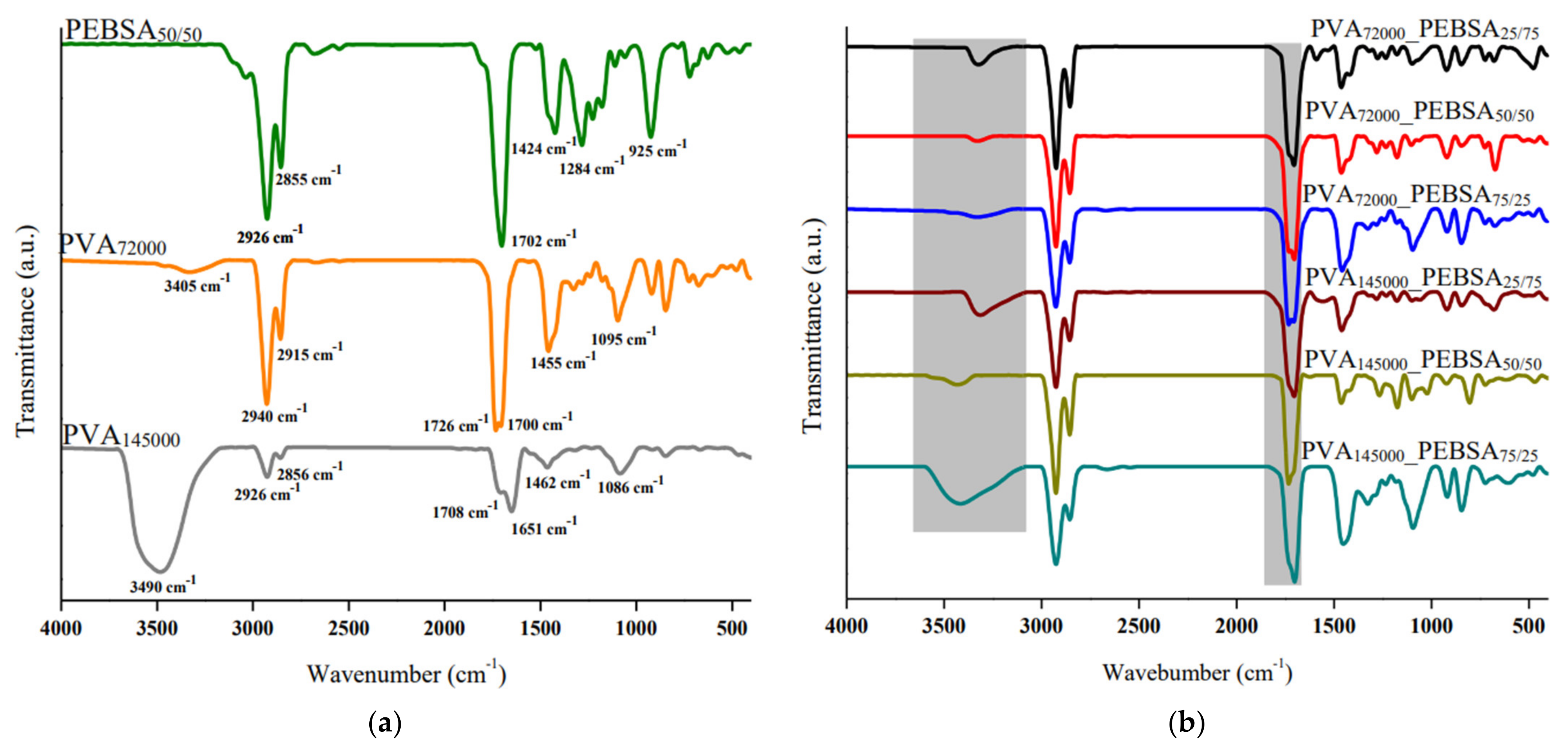

2.3.1. FT-IR

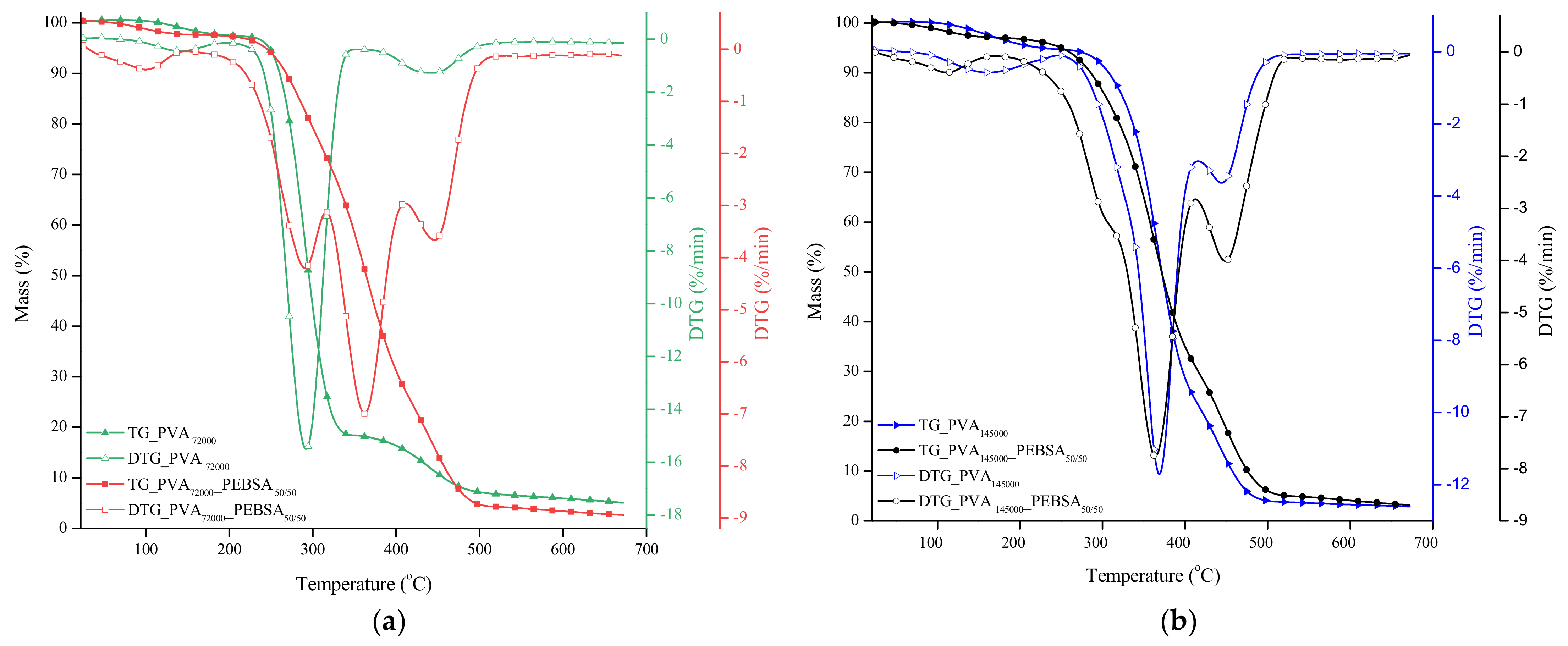

2.3.2. Thermal Analysis

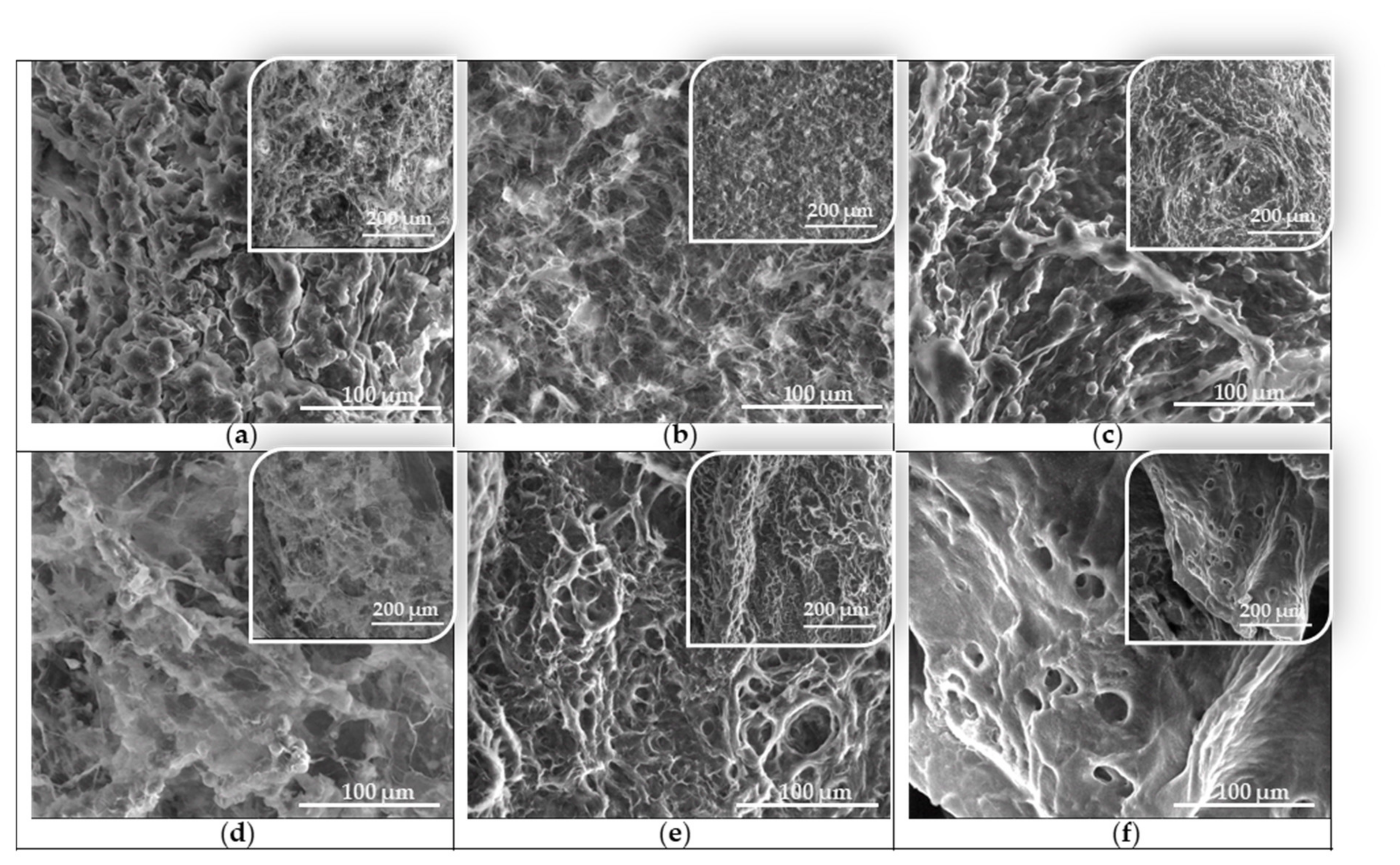

2.3.3. SEM Microscopy

2.3.4. Swelling Studies

3. Results and Discussion

3.1. FT-IR

3.2. Thermal Characterization

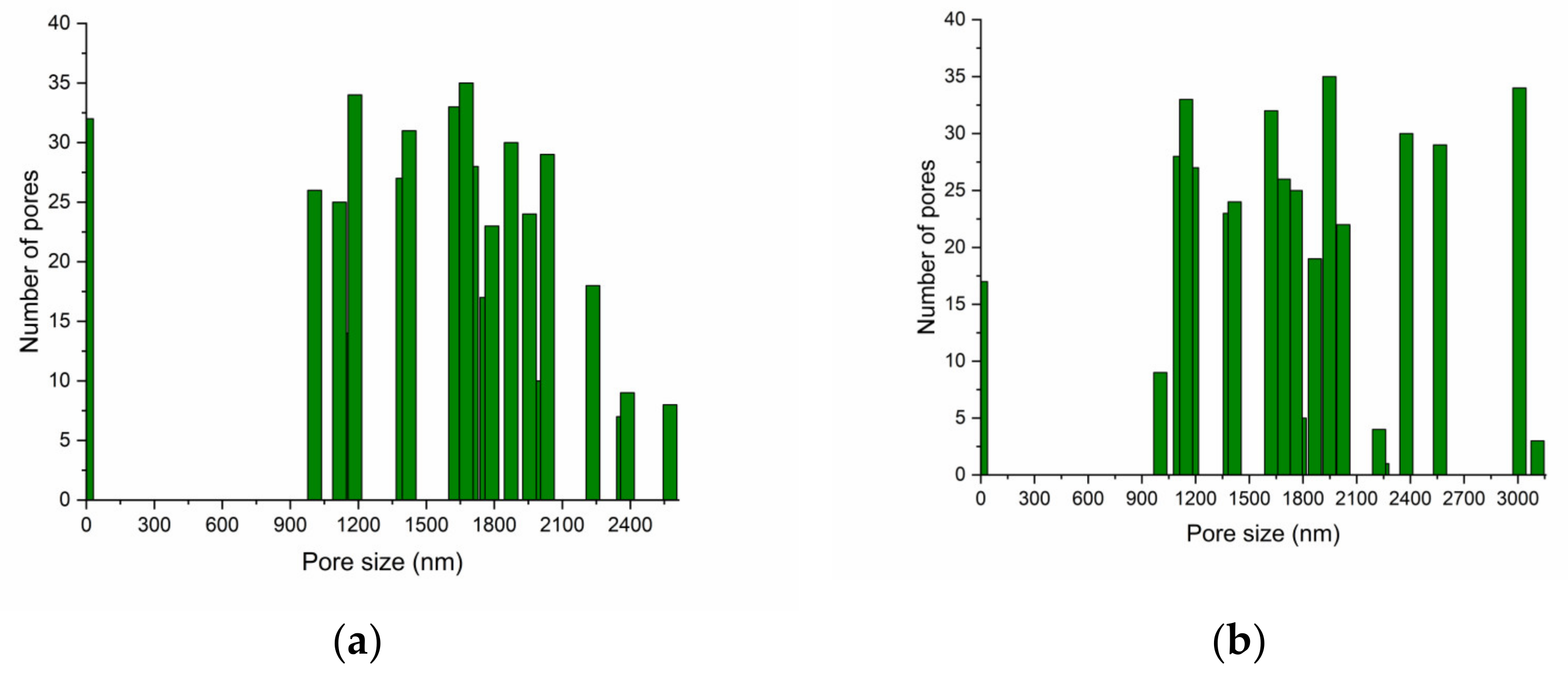

3.3. SEM Studies

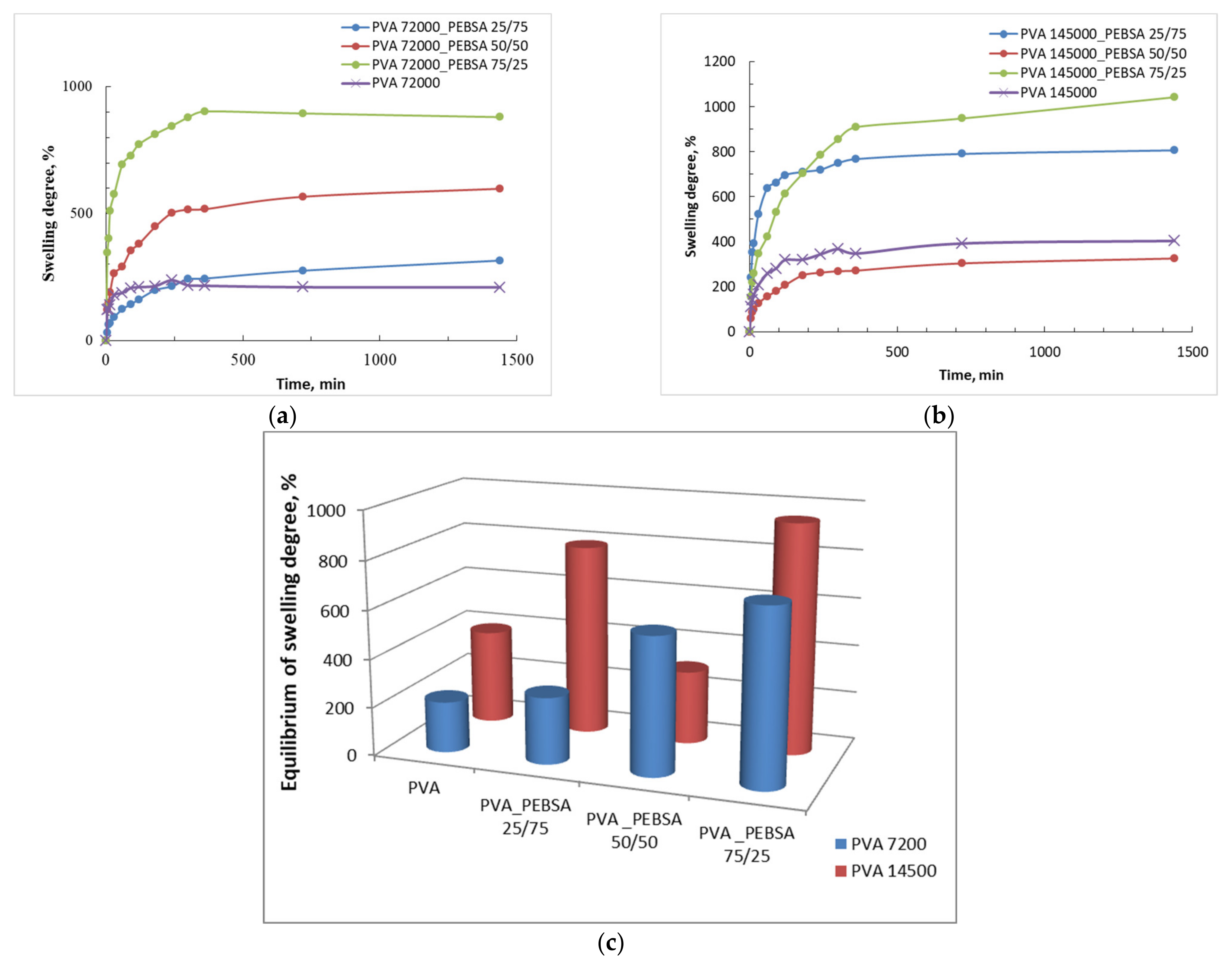

3.4. Degree of Swelling

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Xiao, Z.; Li, Q.; Liu, H.; Zhao, Q.; Niu, Y.; Zhao, D. Adhesion Mechanism and Application Progress of Hydrogels. Eur. Polym. J. 2022, 173, 111277. [Google Scholar] [CrossRef]

- Pal, K.; Banthia, A.K.; Majumdar, D.K. Polymeric Hydrogels: Characterization and Biomedical Applications. Des. Monomers Polym. 2009, 12, 197–220. [Google Scholar] [CrossRef] [Green Version]

- Ben Halima, N. Poly(Vinyl Alcohol): Review of Its Promising Applications and Insights into Biodegradation. RSC Adv. 2016, 6, 39823–39832. [Google Scholar] [CrossRef]

- Feng, X.; Hou, X.; Cui, C.; Sun, S.; Sadik, S.; Wu, S.; Zhou, F. Mechanical and Antibacterial Properties of Tannic Acid-Encapsulated Carboxymethyl Chitosan/Polyvinyl Alcohol Hydrogels. Eng. Regen. 2021, 2, 57–62. [Google Scholar] [CrossRef]

- Adelnia, H.; Ensandoost, R.; Shebbrin Moonshi, S.; Gavgani, J.N.; Vasafi, E.I.; Ta, H.T. Freeze/Thawed Polyvinyl Alcohol Hydrogels: Present, Past and Future. Eur. Polym. J. 2022, 164, 110974. [Google Scholar] [CrossRef]

- Chen, Y.; Li, J.; Lu, J.; Ding, M.; Chen, Y. Synthesis and Properties of Poly(Vinyl Alcohol) Hydrogels with High Strength and Toughness. Polym. Test. 2022, 108, 107516. [Google Scholar] [CrossRef]

- Kamoun, E.A.; Kenawy, E.-R.S.; Chen, X. A Review on Polymeric Hydrogel Membranes for Wound Dressing Applications: PVA-Based Hydrogel Dressings. J. Adv. Res. 2017, 8, 217–233. [Google Scholar] [CrossRef] [PubMed]

- Phuangmali, I.; Seadan, M.; Khankrua, R.; Suttiruengwong, S. Reactive Compatibilization of Poly(Hydroxybutyrate-Co-Hydroxyvalerate)/Polyvinyl Alcohol Blends. Polym. Plast. Technol. Mater. 2021, 60, 1461–1473. [Google Scholar] [CrossRef]

- Massarelli, E.; Silva, D.; Pimenta, A.F.R.; Fernandes, A.I.; Mata, J.L.G.; Armês, H.; Salema-Oom, M.; Saramago, B.; Serro, A.P. Polyvinyl Alcohol/Chitosan Wound Dressings Loaded with Antiseptics. Int. J. Pharm. 2021, 593, 120110. [Google Scholar] [CrossRef] [PubMed]

- Gahlawat, P.; Sen, C.; Das, M. Effect of Molecular Weight of Polyvinyl Alcohol on Properties of Starch Film Cross-Linked with Glutaraldehyde. J. Agric. Eng. Food Technol. 2015, 2, 12–16. [Google Scholar]

- Chiriac, A.P.; Rusu, A.G.; Nita, L.E.; Macsim, A.-M.; Tudorachi, N.; Rosca, I.; Stoica, I.; Tampu, D.; Aflori, M.; Doroftei, F. Synthesis of Poly(Ethylene Brassylate-Co-Squaric Acid) as Potential Essential Oil Carrier. Pharmaceutics 2021, 13, 477. [Google Scholar] [CrossRef] [PubMed]

- Chiriac, A.P.; Asandulesa, M.; Stoica, I.; Tudorachi, N.; Rusu, A.G.; Nita, L.E.; Chiriac, V.M.; Timpu, D. Comparative Study on the Properties of a Bio-Based Copolymacrolactone System. Polym. Test. 2022, 109, 107555. [Google Scholar] [CrossRef]

- Chiriac, A.P.; Stoleru, E.; Rosca, I.; Serban, A.; Nita, L.E.; Rusu, A.G.; Ghilan, A.; Macsim, A.-M.; Mititelu-Tartau, L. Development of a New Polymer Network System Carrier of Essential Oils. Biomed. Pharmacother. 2022, 149, 112919. [Google Scholar] [CrossRef]

- Futama, H.; Tanaka, H. The Thermal Decomposition of Polyvinyl Alcohol Using Mass Spectrometer. J. Phys. Soc. Jpn. 1957, 12, 433. [Google Scholar] [CrossRef]

- Peng, Z.; Kong, L. A Thermal Degradation Mechanism of Polyvinyl Alcohol/Silica Nanocomposites. Polym. Degrad. Stab. 2007, 92, 1061–1071. [Google Scholar] [CrossRef]

- Rajesha Shetty, G.; Lakshmeesha Rao, B. Preparation and Characterization of Silk Fibroin-Polyvinyl Alcohol (PVA) Blend Films for Food Packaging Materials. Mater. Today Proc. 2022, 55, 194–200. [Google Scholar] [CrossRef]

- Shirbin, S.J.; Karimi, F.; Chan, N.J.-A.; Heath, D.E.; Qiao, G.G. Macroporous Hydrogels Composed Entirely of Synthetic Polypeptides: Biocompatible and Enzyme Biodegradable 3D Cellular Scaffolds. Biomacromolecules 2016, 17, 2981–2991. [Google Scholar] [CrossRef] [PubMed]

| Sample * | PVA/PEBSA Ratio | Notation | Observations ** | Photographs of PVA/PEBSA Cryogels |

|---|---|---|---|---|

| PVA72000_PEBSA25/75 | 3/1 | PVA72000_PEBSA25/75_3/1 | Compact and opalescent gel |  |

| 2/1 | PVA72000_PEBSA25/75_2/1 | Compact gel | ||

| 1/1 | PVA72000_PEBSA25/75_1/1 | Compact and strong gel | ||

| PVA145000_PEBSA25/75 | 3/1 | PVA145000_PEBSA25/75_3/1 | Compact and opalescent gel |  |

| 2/1 | PVA145000_PEBSA25/75_2/1 | Compact gel | ||

| 1/1 | PVA145000_PEBSA25/75_1/1 | Compact and strong gel | ||

| PVA72000_PEBSA50/50 | 3/1 | PVA72000_PEBSA50/50_3/1 | Compact and opalescent gel |  |

| 2/1 | PVA72000_PEBSA50/50_2/1 | Compact gel | ||

| 1/1 | PVA72000_PEBSA50/50_1/1 | Compact and strong gel | ||

| PVA145000_PEBSA50/50 | 3/1 | PVA145000_PEBSA50/50_3/1 | Compact and opalescent gel |  |

| 2/1 | PVA145000_PEBSA50/50_2/1 | Compact gel | ||

| 1/1 | PVA145000_PEBSA50/50_1/1 | Compact and strong gel | ||

| PVA72000_PEBSA75/25 | 3/1 | PVA72000_PEBSA75/25_3/1 | Compact and opalescent gel |  |

| 2/1 | PVA72000_PEBSA75/25_2/1 | Compact gel | ||

| 1/1 | PVA72000_PEBSA75/25_1/1 | Compact and strong gel | ||

| PVA145000_PEBSA 75/25 | 3/1 | PVA145000_PEBSA75/25_3/1 | Compact and opalescent gel |  |

| 2/1 | PVA145000_PEBSA75/25_2/1 | Compact gel | ||

| 1/1 | PVA145000_PEBSA75/25_1/1 | Compact and strong gel |

| Sample | Degradation Stage | Tonset (°C) | Tpeak (°C) | W (%) | Residue (%) | T10 (°C) | T20 (°C) |

|---|---|---|---|---|---|---|---|

| PVA72000 | I | 90 | 140 | 2.55 | 5.05 | 260 | 273 |

| II | 248 | 293 | 79.5 | ||||

| III | 397 | 442 | 12.9 | ||||

| PVA145000 | I | 89 | 162 | 5.27 | 2.88 | 309 | 336 |

| II | 290 | 370 | 70.01 | ||||

| III | 423 | 445 | 21.84 | ||||

| PVA72000_PEBSA50/50 | I | 38 | 105 | 2.76 | 2.63 | 268 | 296 |

| II | 235 | 293 | 25.8 | ||||

| III | 328 | 365 | 45.63 | ||||

| IV | 422 | 449 | 23.53 | ||||

| PVA145000_PEBSA50/50 | I | 32 | 117 | 2.94 | 3.17 | 286 | 319 |

| II | 267 | 305 | 16.63 | ||||

| III | 330 | 365 | 49.85 | ||||

| IV | 421 | 449 | 27.41 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Crețu, B.-E.-B.; Nita, L.E.; Șerban, A.-M.; Rusu, A.G.; Doroftei, F.; Chiriac, A.P. New Cryogels Based on Poly(vinyl alcohol) and a Copolymacrolactone System: I-Synthesis and Characterization. Nanomaterials 2022, 12, 2420. https://doi.org/10.3390/nano12142420

Crețu B-E-B, Nita LE, Șerban A-M, Rusu AG, Doroftei F, Chiriac AP. New Cryogels Based on Poly(vinyl alcohol) and a Copolymacrolactone System: I-Synthesis and Characterization. Nanomaterials. 2022; 12(14):2420. https://doi.org/10.3390/nano12142420

Chicago/Turabian StyleCrețu, Bianca-Elena-Beatrice, Loredana Elena Nita, Alexandru-Mihail Șerban, Alina Gabriela Rusu, Florica Doroftei, and Aurica P. Chiriac. 2022. "New Cryogels Based on Poly(vinyl alcohol) and a Copolymacrolactone System: I-Synthesis and Characterization" Nanomaterials 12, no. 14: 2420. https://doi.org/10.3390/nano12142420

APA StyleCrețu, B.-E.-B., Nita, L. E., Șerban, A.-M., Rusu, A. G., Doroftei, F., & Chiriac, A. P. (2022). New Cryogels Based on Poly(vinyl alcohol) and a Copolymacrolactone System: I-Synthesis and Characterization. Nanomaterials, 12(14), 2420. https://doi.org/10.3390/nano12142420