Controlled Oxidation of Cobalt Nanoparticles to Obtain Co/CoO/Co3O4 Composites with Different Co Content

Abstract

:1. Introduction

2. Materials and Methods

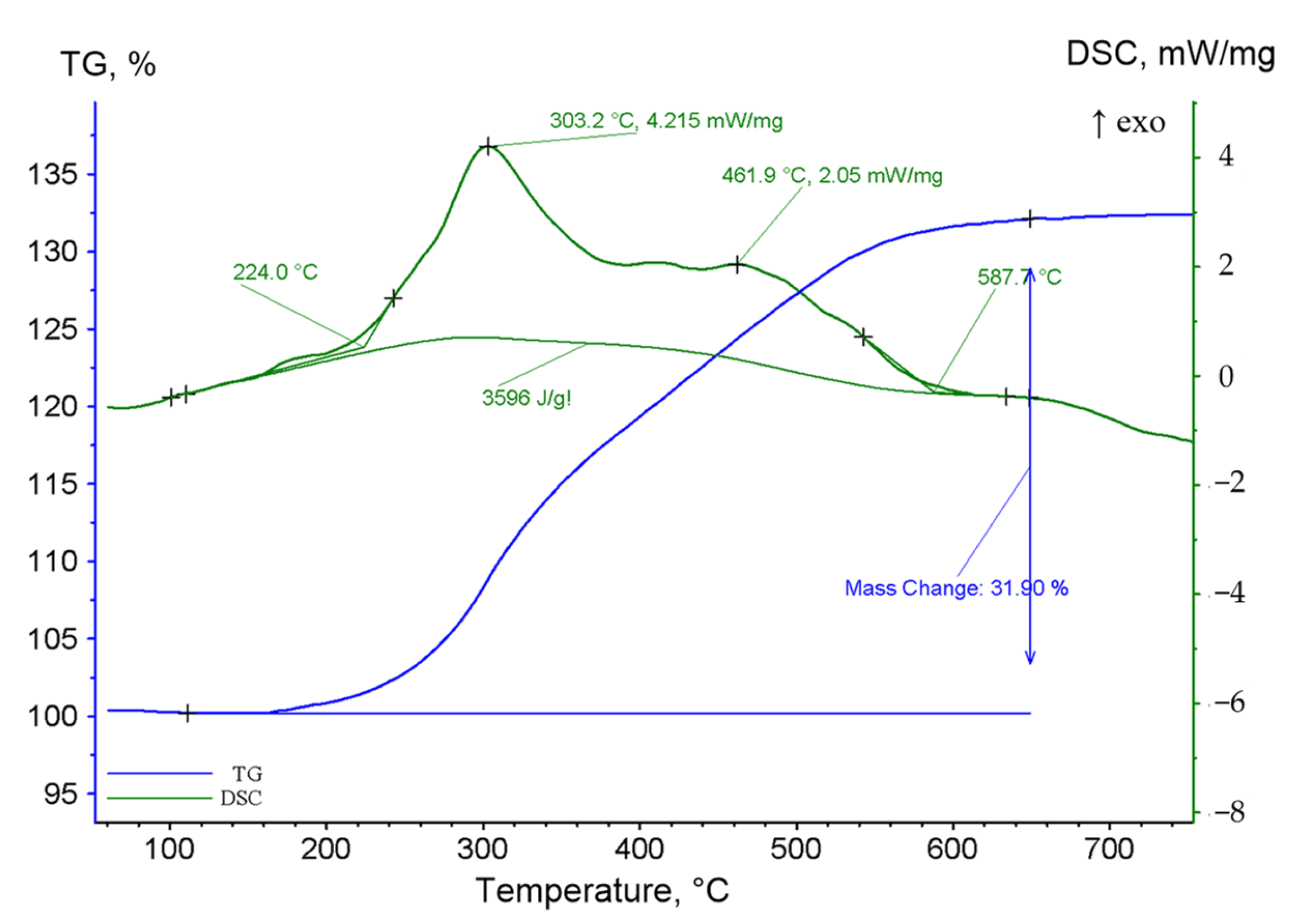

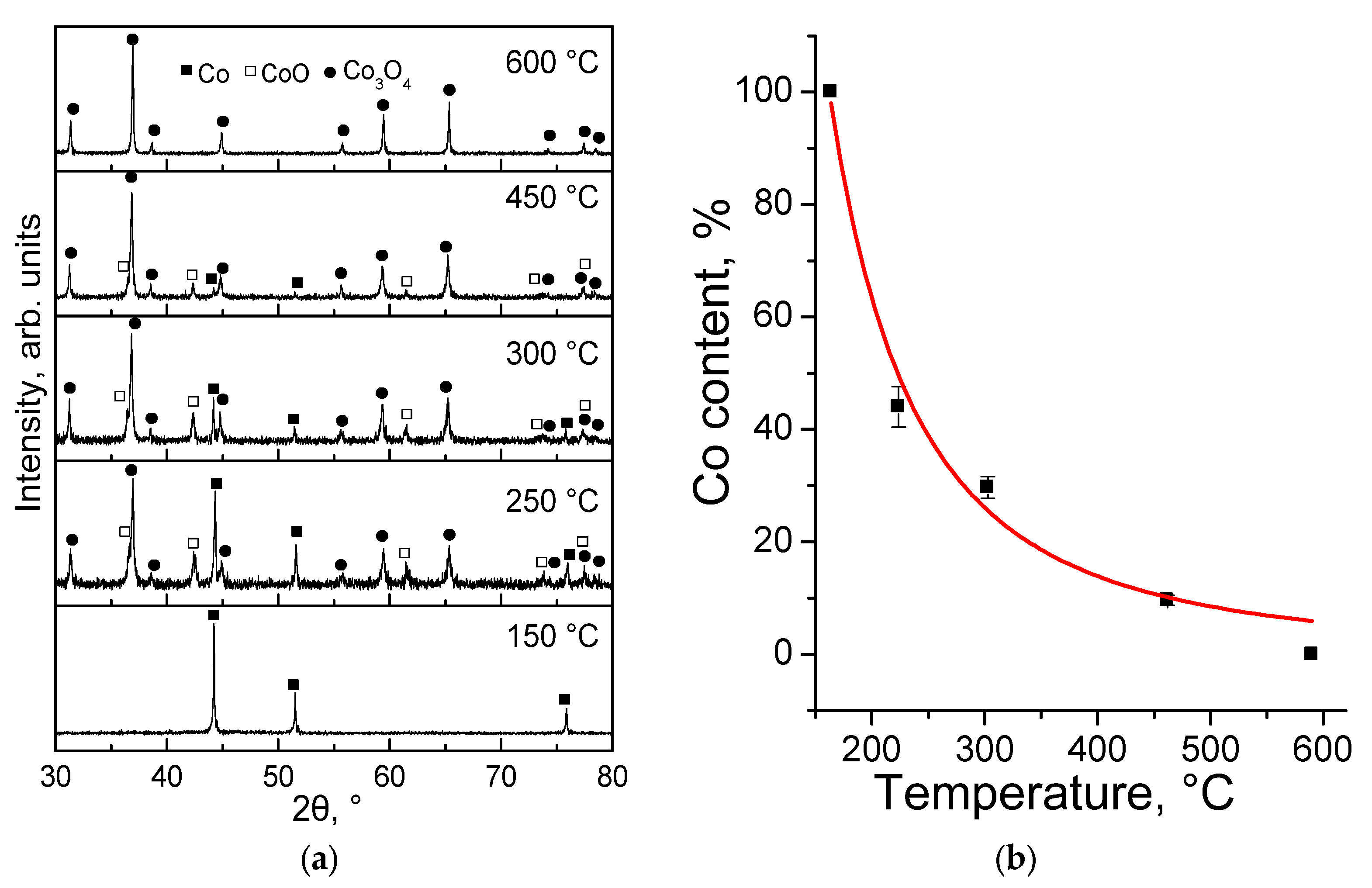

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Faucon, M.P.; Pourret, O.; Lange, B. Element case studies: Cobalt and copper. In Agromining: Farming for Metals; Springer: Cham, Switzerland, 2018; pp. 233–239. [Google Scholar]

- Iravani, S.; Varma, R.S. Sustainable synthesis of cobalt and cobalt oxide nanoparticles and their catalytic and biomedical ap-plications. Green Chem. 2020, 22, 2643–2661. [Google Scholar] [CrossRef]

- Egorova, K.S.; Ananikov, V.P. Toxicity of Metal Compounds: Knowledge and Myths. Organometallics 2017, 36, 4071–4090. [Google Scholar] [CrossRef] [Green Version]

- Xu, Q.; Li, W.; Ding, L.; Yang, W.; Xiao, H.; Ong, W.-J. Function-driven engineering of 1D carbon nanotubes and 0D carbon dots: Mechanism, properties and applications. Nanoscale 2018, 11, 1475–1504. [Google Scholar] [CrossRef] [PubMed]

- Ansari, S.; Bhor, R.; Pai, K.; Sen, D.; Mazumder, S.; Ghosh, K.; Kolekar, Y.; Ramana, C. Cobalt nanoparticles for biomedical applications: Facile synthesis, physiochemical characterization, cytotoxicity behavior and biocompatibility. Appl. Surf. Sci. 2017, 414, 171–187. [Google Scholar] [CrossRef] [Green Version]

- Waris, A.; Din, M.; Ali, A.; Afridi, S.; Baset, A.; Khan, A.U.; Ali, M. Green fabrication of Co and Co3O4 nanoparticles and their biomedical applications: A review. Open Life Sci. 2021, 16, 14–30. [Google Scholar] [CrossRef]

- Li, W.; Jung, H.; Hoa, N.D.; Kim, D.; Hong, S.-K.; Kim, H. Nanocomposite of cobalt oxide nanocrystals and single-walled carbon nanotubes for a gas sensor application. Sens. Actuators B Chem. 2010, 150, 160–166. [Google Scholar] [CrossRef]

- Avila, A.G.; Barrera, E.C.; Huerta, L.A.; Muhl, S. Cobalt oxide films for solar selective surfaces, obtained by spray pyrolisis. Sol. Energy Mater. Sol. Cells 2004, 82, 269–278. [Google Scholar] [CrossRef]

- Li, W.Y.; Xu, L.N.; Chen, J. Co3O4 Nanomaterials in Lithium-Ion Batteries and Gas Sensors. Adv. Funct. Mater. 2005, 15, 851–857. [Google Scholar] [CrossRef]

- Kumar, R.; Kim, H.J.; Park, S.; Srivastava, A.; Oh, I.K. Graphene-wrapped and cobalt oxide-intercalated hybrid for extremely du-rable super-capacitor with ultrahigh energy and power densities. Carbon 2014, 79, 192–202. [Google Scholar] [CrossRef]

- Baby, T.T.; Sundara, R. A facile synthesis and field emission property investigation of Co3O4 nanoparticles decorated graphene. Mater. Chem. Phys. 2012, 135, 623–627. [Google Scholar] [CrossRef]

- Adekunle, A.S.; Oyekunle, J.A.; Durosinmi, L.M.; Oluwafemi, O.S.; Olayanju, D.S.; Akinola, A.S.; Obisesan, O.R.; Akinyele, O.F.; Ajayeoba, T.A. Potential of cobalt and cobalt oxide nanoparticles as nanocatalyst towards dyes degradation in wastewater. Nano-Struct. Nano-Objects 2019, 21, 100405. [Google Scholar] [CrossRef]

- Have, I.C.T.; Kromwijk, J.J.G.; Monai, M.; Ferri, D.; Sterk, E.B.; Meirer, F.; Weckhuysen, B.M. Uncovering the reaction mechanism behind CoO as active phase for CO2 hydrogenation. Nat. Commun. 2022, 13, 324. [Google Scholar] [CrossRef]

- Liao, L.; Zhang, Q.; Su, Z.; Zhao, Z.; Wang, Y.; Li, Y.; Lu, X.; Wei, D.; Feng, G.; Yu, Q.; et al. Efficient solar water-splitting using a nanocrystalline CoO photocatalyst. Nat. Nanotechnol. 2013, 9, 69–73. [Google Scholar] [CrossRef]

- Ling, T.; Yan, D.Y.; Wang, H.; Jiao, Y.; Hu, Z.; Zheng, Y.; Zheng, L.; Mao, J.; Liu, H.; Du, X.W.; et al. Activating cobalt (II) oxide nanorods for efficient electrocatalysis by strain engineering. Nat. Commun. 2017, 8, 1509. [Google Scholar] [CrossRef] [Green Version]

- Liu, T.; Pang, Y.; Zhu, M.; Kobayashi, S. Microporous Co@ CoO nanoparticles with superior microwave absorption properties. Nanoscale 2014, 6, 2447–2454. [Google Scholar] [CrossRef] [Green Version]

- Peng, D.L.; Sumiyama, K.; Hihara, T.; Yamamuro, S.; Konno, T.J. Magnetic properties of monodispersed Co/CoO clusters. Phys. Rev. B 2000, 61, 3103–3109. [Google Scholar] [CrossRef] [Green Version]

- Yan, X.; Tian, L.; He, M.; Chen, X. Three-Dimensional Crystalline/Amorphous Co/Co3O4 Core/Shell Nanosheets as Efficient Electrocatalysts for the Hydrogen Evolution Reaction. Nano Lett. 2015, 15, 6015–6021. [Google Scholar] [CrossRef]

- Zhang, J.; Fu, J.; Zhang, J.; Ma, H.; He, Y.; Li, F.; Xie, E.; Xue, D.; Zhang, H.; Peng, Y. Co@Co3O4 Core–Shell Three-Dimensional Nano-Network for High-Performance Electrochemical Energy Storage. Small 2014, 10, 2618–2624. [Google Scholar] [CrossRef]

- Al-Senani, G.M.; Deraz, N.M.; Abd-Elkader, O.H. Magnetic and characterization studies of CoO/Co3O4 nanocomposite. Processes 2020, 8, 844. [Google Scholar] [CrossRef]

- Yousefi, S.R.; Alshamsi, H.A.; Amiri, O.; Salavati-Niasari, M. Synthesis, characterization and application of Co/Co3O4 nanocomposites as an effective photocatalyst for discoloration of organic dye contaminants in wastewater and antibacterial properties. J. Mol. Liq. 2021, 337, 116405. [Google Scholar] [CrossRef]

- Verelst, M.; Ely, T.O.; Amiens, C.; Snoeck, E.; Lecante, P.; Mosset, A.; Respaud, M.; Broto, J.M.; Chaudret, B. Synthesis and Characterization of CoO, Co3O4, and Mixed Co/CoO Nanoparticules. Chem. Mater. 1999, 11, 2702–2708. [Google Scholar] [CrossRef]

- Pang, M.; Long, G.; Jiang, S.; Ji, Y.; Han, W.; Wang, B.; Liu, X.; Xi, Y.; Wang, D.; Xu, F. Ethanol-assisted solvothermal synthesis of porous nanostructured cobalt oxides (CoO/Co3O4) for high-performance supercapacitors. Chem. Eng. J. 2015, 280, 377–384. [Google Scholar] [CrossRef]

- Wang, D.; Guo, J.; Hu, D.; Xu, Q.; Zhang, L.; Wang, J. Co@Co3O4 Prepared in Situ from Metallic Co as an Efficient Semiconductor Catalyst for Photocatalytic Water Oxidation. ACS Sustain. Chem. Eng. 2018, 6, 8300–8307. [Google Scholar] [CrossRef]

- Şahan, H.; Göktepe, H.; Yıldız, S.; Çaymaz, C.; Patat, Ş. A novel and green synthesis of mixed phase CoO@ Co3O4@ C anode material for lithium ion batteries. Ionics 2019, 25, 447–455. [Google Scholar] [CrossRef]

- Raveau, B.; Seikh, M.M. Charge ordering in cobalt oxides: Impact on structure, magnetic and transport properties. Z. Anorg. Allg. Chem. 2015, 641, 1385–1394. [Google Scholar] [CrossRef]

- Ha, D.-H.; Moreau, L.M.; Honrao, S.; Hennig, R.G.; Robinson, R.D. The Oxidation of Cobalt Nanoparticles into Kirkendall-Hollowed CoO and Co3O4: The Diffusion Mechanisms and Atomic Structural Transformations. J. Phys. Chem. C 2013, 117, 14303–14312. [Google Scholar] [CrossRef]

- Wiedwald, U.; Lindner, J.; Spasova, M.; Frait, Z.; Farle, M. Effect of an oxidic overlayer on the magnetism of Co nanoparticles. Phase Transit. 2005, 78, 85–104. [Google Scholar] [CrossRef]

- Xiang, S.; Dong, L.; Wang, Z.Q.; Han, X.; Daemen, L.L.; Li, J.; Cheng, Y.; Guo, Y.; Liu, X.; Hu, Y.; et al. A unique Co@CoO catalyst for hydro-genolysis of biomass-derived 5-hydroxymethylfurfural to 2, 5-dimethylfuran. Nat. Commun. 2022, 13, 3657. [Google Scholar] [CrossRef] [PubMed]

- Feng, L.; Li, Y.; Sun, L.; Mi, H.; Ren, X.; Zhang, P. Heterostructured CoO-Co3O4 nanoparticles anchored on nitro-gen-doped hollow carbon spheres as cathode catalysts for Li-O2 batteries. Nanoscale 2019, 11, 14769–14776. [Google Scholar] [CrossRef] [PubMed]

- Yılmaz, F.; Lee, D.-J.; Song, J.-W.; Hong, H.-S.; Son, H.-T.; Yoon, J.-S.; Hong, S.-J. Fabrication of cobalt nano-particles by pulsed wire evaporation method in nitrogen atmosphere. Powder Technol. 2013, 235, 1047–1052. [Google Scholar] [CrossRef]

- Kotov, Y.A. Electric Explosion of Wires as a Method for Preparation of Nanopowders. J. Nanoparticle Res. 2003, 5, 539–550. [Google Scholar] [CrossRef]

- Lerner, M.I.; Glazkova, E.A.; Lozhkomoev, A.S.; Svarovskaya, N.V.; Bakina, O.V.; Pervikov, A.V.; Psakhie, S.G. Synthesis of Al nanoparticles and Al/AlN composite nanoparticles byelectrical explosion of aluminum wires in argon and nitrogen. Powder Technol. 2016, 295, 307–314. [Google Scholar] [CrossRef]

- Pervikov, A.V. Structural and phase transformations in zinc and brass wires under heating with high-density current pulse. Phys. Plasmas 2016, 23, 060701. [Google Scholar] [CrossRef]

- Veselovskiy, R.V.; Dubinya, N.V.; Ponomarev, A.V.; Fokin, I.V.; Patonin, A.V.; Pasenko, A.M.; Fetisova, A.M.; Matveev, M.A.; Afinogenova, N.A.; Rud’Ko, D.V.; et al. Shared Research Facilities “Petrophysics, Geomechanics and Paleomagnetism” of the Schmidt Institute of Physics of the Earth Ras. Geodyn. Tectonophys. 2022, 13. [Google Scholar] [CrossRef]

- Yin, Y.; Rioux, R.M.; Erdonmez, C.K.; Hughes, S.; Somorjai, G.A.; Alivisatos, A.P. Formation of hollow nanocrystals through the nanoscale Kirkendall effect. Science 2004, 304, 711–714. [Google Scholar] [CrossRef] [Green Version]

- Wang, C.M.; Baer, D.R.; Thomas, L.E.; Amonette, J.E.; Antony, J.; Qiang, Y.; Duscher, G. Void formation during early stages of passivation: Initial oxidation of iron nanoparticles at room temperature. J. Appl. Phys. 2005, 98, 094308. [Google Scholar] [CrossRef]

- Chernavskii, P.A.; Pankina, G.V.; Zaikovskii, V.I.; Peskov, N.V.; Afanasiev, P. Formation of hollow spheres upon oxidation of supported cobalt nanoparticles. J. Phys. Chem. C 2008, 112, 9573–9578. [Google Scholar] [CrossRef]

- Srikala, D.; Singh, V.N.; Banerjee, A.; Mehta, B.R.; Patnaik, S. Control of magnetism in cobalt nanoparticles by ox-ygen passivation. J. Phys. Chem. C 2008, 112, 13882–13885. [Google Scholar] [CrossRef]

- Srivastava, A.K.; Madhavi, S.; Menon, M.; Ramanujan, R.V. Synthesis of Co/Co3O4 Nanocomposite Particles Rele-vant to Magnetic Field Processing. J. Nanosci. Nanotechnol. 2010, 10, 6580–6585. [Google Scholar] [CrossRef]

- Guo, B.; Xu, Y.; Zhou, S. Morphology dependence of low temperatures exchange bias Co/CoO core-shell nanoparticles/spheres by eco-friendly solvothermal route. AIP Adv. 2018, 8, 115115. [Google Scholar] [CrossRef] [Green Version]

- Xie, X.; Ni, C.; Lin, Z.; Wu, D.; Sun, X.; Zhang, Y.; Wang, B.; Du, W. Phase and morphology evolution of high dielectric CoO/Co3O4 particles with Co3O4 nanoneedles on surface for excellent microwave absorption application. Chem. Eng. J. 2020, 396, 125205. [Google Scholar] [CrossRef]

| Sample | The Amount of Substance in the Samples, % | ||

|---|---|---|---|

| Co | CoO | Co3O4 | |

| Co | 100 | 0 | 0 |

| Co/CoO/Co3O4 (250 °C) | 44.0 ± 3.6 | 14.7 ± 1.1 | 41.3 ± 2.9 |

| Co/CoO/Co3O4 (300 °C) | 27.9 ± 1.9 | 12.1 ± 0.8 | 60.0 ± 4.2 |

| Co/CoO/Co3O4 (450 °C) | 9.6 ± 0.9 | 10.2 ± 0.6 | 80.2 ± 4.4 |

| Co3O4 | 0 | 0 | 100 |

| Sample | Hc, Oe | Ms, emu/g | Mr, emu/g |

|---|---|---|---|

| Co | 225 ± 11.1 | 90 ± 3.6 | 64 ± 3.4 |

| Co/CoO/Co3O4 (250 °C) | 81 ± 5.9 | 29 ± 2.3 | 5 ± 3.4 |

| Co/CoO/Co3O4 (300 °C) | 45 ± 3.2 | 19 ± 2.1 | 1.7 ± 3.4 |

| Co/CoO/Co3O4 (450 °C) | 54 ± 2.9 | 7.9 ± 0.7 | 0.8 ± 3.4 |

| Co3O4 | 51 ± 2.7 | 1.1 ± 0.1 | 0.1 ± 3.4 |

| Composition of Particles | Hc, Oe | Ms, emu/g | Mr, emu/g | Reference |

|---|---|---|---|---|

| Co/CoO | 600.5 | 115.5 | - | [15] |

| CoO/Co3O4 | 0.2734 | 3.450 | 85.032 | [20] |

| Co/Co3O4 | 373 | 127.8 | - | [21] |

| Co/CoO | - | 18 | - | [22] |

| Co/Co3O4 | - | 59.8 | - | [39] |

| Co/CoO | - | 34.6 | - | [39] |

| Co/Co3O4 | 46.9 | 67.7 | - | [40] |

| Co/CoO | - | 100.6–74.6 | - | [41] |

| Co/CoO/Co3O4 | 198.3–327.3 | 67.0–24.7 | - | [42] |

| CoO/Co3O4 | 330.8 | 5.8 | - | [42] |

| Co/CoO/Co3O4 | 81–54 | 29–7.9 | 5–0.8 | In this work |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lozhkomoev, A.S.; Pervikov, A.V.; Kazantsev, S.O.; Suliz, K.V.; Veselovskiy, R.V.; Miller, A.A.; Lerner, M.I. Controlled Oxidation of Cobalt Nanoparticles to Obtain Co/CoO/Co3O4 Composites with Different Co Content. Nanomaterials 2022, 12, 2523. https://doi.org/10.3390/nano12152523

Lozhkomoev AS, Pervikov AV, Kazantsev SO, Suliz KV, Veselovskiy RV, Miller AA, Lerner MI. Controlled Oxidation of Cobalt Nanoparticles to Obtain Co/CoO/Co3O4 Composites with Different Co Content. Nanomaterials. 2022; 12(15):2523. https://doi.org/10.3390/nano12152523

Chicago/Turabian StyleLozhkomoev, Aleksandr S., Alexander V. Pervikov, Sergey O. Kazantsev, Konstantin V. Suliz, Roman V. Veselovskiy, Andrey A. Miller, and Marat I. Lerner. 2022. "Controlled Oxidation of Cobalt Nanoparticles to Obtain Co/CoO/Co3O4 Composites with Different Co Content" Nanomaterials 12, no. 15: 2523. https://doi.org/10.3390/nano12152523

APA StyleLozhkomoev, A. S., Pervikov, A. V., Kazantsev, S. O., Suliz, K. V., Veselovskiy, R. V., Miller, A. A., & Lerner, M. I. (2022). Controlled Oxidation of Cobalt Nanoparticles to Obtain Co/CoO/Co3O4 Composites with Different Co Content. Nanomaterials, 12(15), 2523. https://doi.org/10.3390/nano12152523