Electrodeposited Magnetic Nanowires with Radial Modulation of Composition

Abstract

:1. Introduction

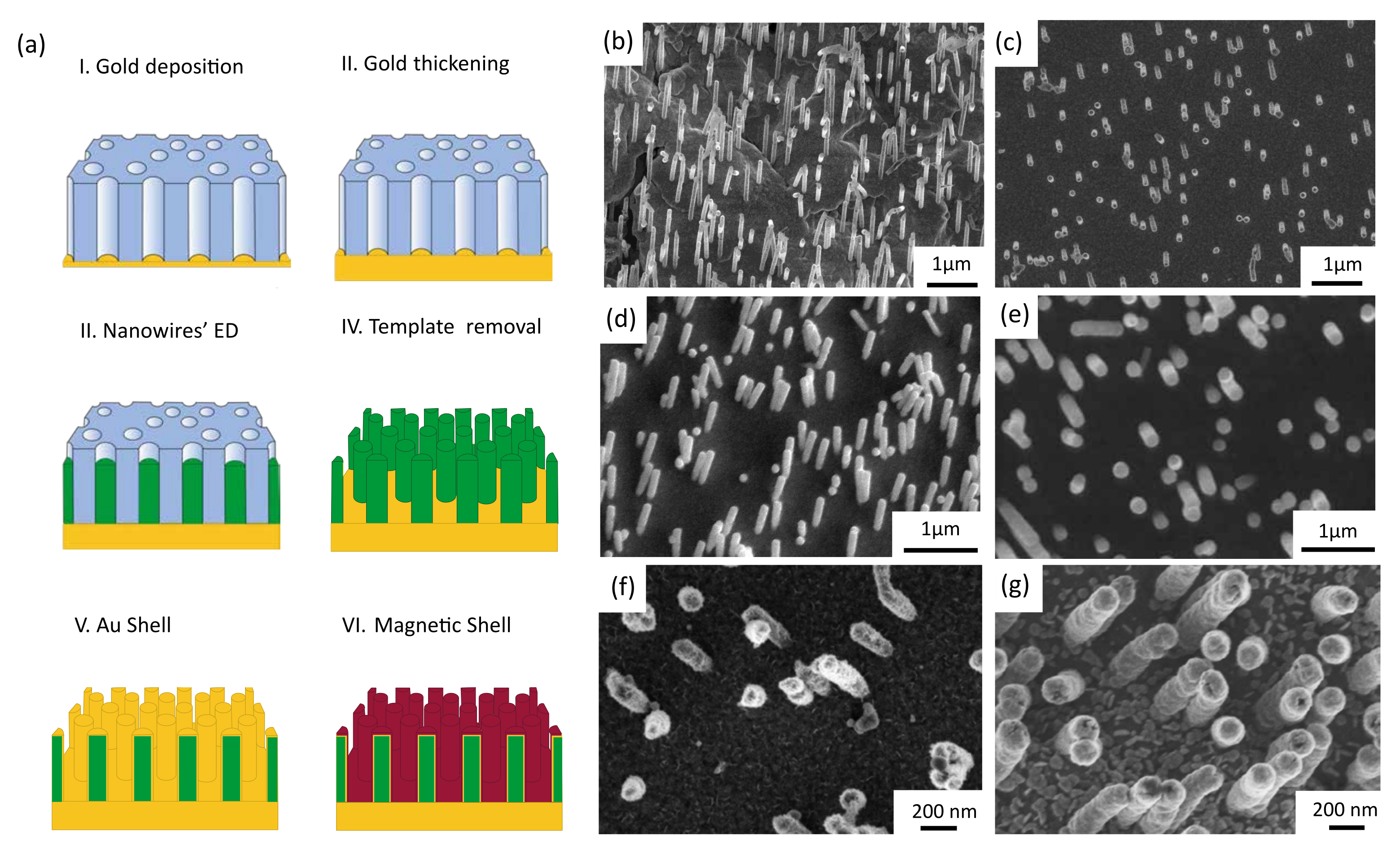

2. Materials and Methods

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Sample Availability

References

- Baibich, M.N.; Broto, J.M.; Fert, A.; Van Dau, F.N.; Petroff, F.; Etienne, P.; Creuzet, G.; Friederich, A.; Chazelas, J. Giant Magnetoresistance of (001)Fe/(001)Cr Magnetic Superlattices. Phys. Rev. Lett. 1988, 61, 2472. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Binasch, G.; Grunberg, P.; Saurenbach, F.; Zinn, W. Enhanced magnetoresistance in layered magnetic structures with antiferromagnetic interlayer exchange. Phys. Rev. B 1989, 39, 4828. [Google Scholar] [CrossRef] [Green Version]

- Fert, A. Nobel Lecture: Origin, development, and future of spintronics. Rev. Mod. Phys. 2008, 80, 1517. [Google Scholar] [CrossRef] [Green Version]

- Duine, R.A.; Lee, K.J.; Parkin, S.S.P.; Stiles, M.D. Synthetic antiferromagnetic spintronics. Nat. Phys. 2018, 14, 217–219. [Google Scholar] [CrossRef]

- Nogués, J.; Schuller, I.K. Exchange bias. J. Magn. Magn. Mater. 1999, 192, 203–232. [Google Scholar] [CrossRef]

- Soumyanarayanan, A.; Reyren, N.; Fert, A.; Panagopoulos, C. Emergent phenomena induced by spin-orbit coupling at surfaces and interfaces. Nature 2016, 539, 509–517. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Jiang, W.; Chen, G.; Liu, K.; Zang, J.; te Velthuis, S.G.E.; Hoffmann, A. Skyrmions in magnetic multilayers. Phys. Rep. 2017, 704, 1–49. [Google Scholar] [CrossRef] [Green Version]

- Rana, K.G.; Seeger, R.L.; Ruiz-Gómez, S.; Juge, R.; Zhang, Q.; Bairagi, K.; Pham, V.T.; Belmeguenai, M.; Auffret, S.; Foerster, M.; et al. Imprint from ferromagnetic skyrmions in an antiferromagnet via exchange bias. Appl. Phys. Lett. 2021, 119, 192407. [Google Scholar] [CrossRef]

- Hermosa-Muñoz, J.; Hierro-Rodríguez, A.; Sorrentino, A.; Martín, J.I.; Alvarez-Prado, L.M.; Rehbein, S.; Pereiro, E.; Quirós, C.; Vélez, M.; Ferrer, S. 3D magnetic configuration of ferrimagnetic multilayers with competing interactions visualized by soft X-ray vector tomography. Commun. Phys. 2022, 5, 26. [Google Scholar] [CrossRef]

- Fernandez-Pacheco, A.; Streubel, R.; Fruchart, O.; Hertel, R.; Fischer, P.; Cowburn, R.P. Three-dimensional nanomagnetism. Nat. Commun 2017, 8, 15756. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Streubel, R.; Fischer, P.; Kronast, F.; Kravchuk, V.P.; Sheka, D.D.; Gaididei, Y.; Schmidt, O.G.; Makarov, D. Magnetism in curved geometries. J. Phys. D Appl. Phys. 2016, 49, 363001. [Google Scholar] [CrossRef]

- Piraux, L. Magnetic nanowires. Appl. Sci. 2020, 10, 1832. [Google Scholar] [CrossRef] [Green Version]

- Staňo, M.; Fruchart, O. Magnetic nanowires and nanotubes. In Handbook of Magnetic Materials; Elsevier: Amsterdam, The Netherlands, 2018; Volume 27, pp. 155–267. [Google Scholar]

- Moreno, J.A.; Bran, C.; Vazquez, M.; Kosel, J. Cylindrical magnetic nanowires applications. IEEE Trans. Magn. 2021, 57, 1–17. [Google Scholar] [CrossRef]

- Nunez, A.; Pérez, L.; Abuín, M.; Araujo, J.P.; Proenca, M.P. Magnetic behaviour of multisegmented FeCoCu/Cu electrodeposited nanowires. J. Phys. D Appl. Phys. 2017, 50, 155003. [Google Scholar] [CrossRef]

- Caspani, S.; Moraes, S.; Navas, D.; Proenca, M.P.; Magalhães, R.; Nunes, C.; Araújo, J.P.; Sousa, C.T. The Magnetic Properties of Fe/Cu Multilayered Nanowires: The Role of the Number of Fe Layers and Their Thickness. Nanomaterials 2021, 11, 2729. [Google Scholar] [CrossRef] [PubMed]

- Ruiz-Gomez, S.; Foerster, M.; Aballe, L.; Proenca, M.P.; Lucas, I.; Prieto, J.L.; Mascaraque, A.; de la Figuera, J.; Quesada, A.; Pérez, L. Observation of a topologically protected state in a magnetic domain wall stabilized by a ferromagnetic chemical barrier. Sci. Rep. 2018, 8, 16695. [Google Scholar] [CrossRef] [Green Version]

- Ruiz-Gómez, S.; Fernández-González, C.; Martínez, E.; Raposo, V.; Sorrentino, A.; Foerster, M.; Aballe, L.; Mascaraque, A.; Ferrer, S.; Pérez, L. Helical surface magnetization in nanowires: The role of chirality. Nanoscale 2020, 12, 17880–17885. [Google Scholar] [CrossRef]

- Bran, C.; Berganza, E.; Fernandez-Roldan, J.A.; Palmero, E.M.; Meier, J.; Calle, E.; Jaafar, M.; Foerster, M.; Aballe, L.; Rodriguez, A.F.; et al. Magnetization Ratchet in Cylindrical Nanowires. ACS Nano 2018, 12, 5932–5939. [Google Scholar] [CrossRef] [PubMed]

- Prida, V.M.; Vega, V.; García, J.; Iglesias, L.; Hernando, B.; Minguez-Bacho, I. Electrochemical methods for template-assisted synthesis of nanostructured materials. In Magnetic Nano and Microwires: Design, Synthesis, Properties and Applications; Vázquez, N., Ed.; Elsevier: Amsterdam, The Netherlands, 2015. [Google Scholar]

- Sanz-Hernández, D.; Donnelly, C.; Pérez, L.; Fernández-Pacheco, A. Nanofabrication of three-dimensional magnetic structure. In Nanofabrication: Nanolithography Techniques and Their Applications; de Teresa, J.M., Ed.; IOP Publishing: Bristol, UK, 2020. [Google Scholar]

- Martínez-Banderas, A.I.; Aires, A.; Quintanilla, M.; Holguín-Lerma, J.A.; Lozano-Pedraza, C.; Teran, F.J.; Moreno, J.A.; Perez, J.E.; Ooi, B.S.; Ravasi, T.; et al. Iron-Based Core-Shell Nanowires for Combinatorial Drug Delivery and Photothermal and Magnetic Therapy. ACS Appl. Mater. Interfaces 2019, 11, 43976–43988. [Google Scholar] [CrossRef]

- Cortés-Llanos, B.; Serrano, A.; Muñoz-Noval, A.; Urones-Garrote, E.; del Campo, A.; Marco, J.F.; Ayuso-Sacido, A.; Perez, L. Thermal Route for the Synthesis of Maghemite/Hematite Core/Shell Nanowires. J. Phys. Chem. C 2017, 121, 23158–23165. [Google Scholar] [CrossRef] [Green Version]

- Hopkins, X.; Gill, W.A.; Kringel, R.; Wang, G.; Hass, J.; Acharya, S.; Park, J.; Jeon, I.T.; An, B.H.; Lee, J.S.; et al. Radio frequency-mediated local thermotherapy for destruction of pancreatic tumors using Ni-Au core-shell nanowires. Nanotechnology 2017, 28, 03LT01. [Google Scholar] [CrossRef] [PubMed]

- Jeon, I.T.; Cho, M.K.; Cho, J.W.; An, B.H.; Wu, J.H.; Kringel, R.; Choi, D.S.; Kim, Y.K. Ni-Au core-shell nanowires: Synthesis, microstructures, biofunctionalization, and the toxicological effects on pancreatic cancer cells. J. Mat. Chem. 2011, 21, 12089. [Google Scholar] [CrossRef]

- Martín-García, L.; Ruiz-Gómez, S.; Abuín, M.; Montaña, Y.; Carmona, N.; Perez, L. Multifunctional core-shell Co-SiO2 nanowires via electrodeposition and sol-gel techniques. RSC Adv. 2015, 5, 97503. [Google Scholar] [CrossRef] [Green Version]

- Szilágyi, I.M.; Nagy, D. Review on one-dimensional nanostructures prepared by electrospinning and atomic layer deposition. J. Phys. Conf. Ser. 2014, 559, 012010. [Google Scholar] [CrossRef]

- Wang, G.; Gao, Z.; Tang, S.; Chen, C.; Duan, F.; Zhao, S.; Lin, S.; Feng, Y.; Zhou, L.; Qin, Y. Microwave absorption properties of carbon nanocoils coated with highly controlled magnetic materials by atomic layer deposition. ACS Nano 2012, 6, 11009–11017. [Google Scholar] [CrossRef]

- Chong, Y.T.; Görlitz, D.; Martens, S.; Yau, M.Y.E.; Allende, S.; Bachmann, J.; Nielsch, K. Multilayered core/shell nanowires displaying two distinct magnetic switching events. Adv. Mater. 2010, 22, 2435–2439. [Google Scholar] [CrossRef] [PubMed]

- Daub, M.; Knez, M.; Goesele, U.; Nielsch, K. Ferromagnetic nanotubes by atomic layer deposition in anodic alumina membranes. J. Appl. Phys. 2007, 101, 09J111. [Google Scholar] [CrossRef]

- Pereiro, E.; Nicolás, J.; Ferrer, S.; Howells, M. A soft X-ray beamline for transmission X-ray microscopy at ALBA. J. Synchrotron Radiat. 2009, 16, 505–512. [Google Scholar] [CrossRef] [PubMed]

- Sorrentino, A.; Nicolás, J.; Valcárcel, R.; Chichón, F.J.; Rosanes, M.; Avila, J.; Tkachuk, A.; Irwin, J.; Ferrer, S.; Pereiro, E. MISTRAL: A transmission soft X-ray microscopy beamline for cryo nano-tomography of biological samples and magnetic domains imaging. J. Synchrotron Radiat. 2015, 22, 1112–1117. [Google Scholar] [CrossRef] [PubMed]

- Domínguez-Bajo, A.; Rodilla, B.L.; Calaresu, I.; Arché-Núñez, A.; González-Mayorga, A.; Scaini, D.; Pérez, L.; Camarero, J.; Miranda, R.; López-Dolado, E.; et al. Interfacing neurons with nanostructured electrodes modulates synaptic circuit features. Adv. Biosyst. 2020, 4, 2000117. [Google Scholar] [CrossRef] [PubMed]

- Mukhtar, A.; Wu, K.; Cao, X.; Gu., I. Cylindrical magnetic nanowires applications. Nanotechnology 2020, 31, 433001. [Google Scholar] [CrossRef] [PubMed]

- Martínez-Banderas, A.I.; Aires, A.; Plaza-García, S.; Colás, L.; Moreno, J.A.; Ravasi, T.; Merzaban, J.S.; Ramos-Cabrer, P.; Cortajarena, A.L.; Kosel, J. Magnetic core-shell nanowires as MRI contrast agents for cell tracking. J. Nanobiotechnol. 2021, 18, 1–12. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Koylan, S.; Tunca, S.; Polat, G.; Durukan, M.B.; Kim, D.; Kalay, Y.E.; Ko, S.H.; Unalan, H.E. Highly stable silver-platinum core-shell nanowires for H2O2 detection. Nanoscale 2021, 13, 13129–13141. [Google Scholar] [CrossRef] [PubMed]

- Moreno, J.A.; Khan, M.A.; Ivanov, Y.P.; Lopatin, S.; Holguín-Lerma, J.A.; Marinaro, G.; Ooi, B.S.; Idriss, H.; Kosel, J. Growth of Ordered Iron Oxide Nanowires for Photo-electrochemical Water Oxidation. ACS Appl. Energy Mater. 2019, 12, 8473–8480. [Google Scholar] [CrossRef]

- Perez, J.E.; Bajaber, B.; Alsharif, N.; Martínez-Banderas, A.I.; Patel, N.; Sharip, A.; Fabrizio, E.D.; Merzaban, J.; Kosel, J. Modulated nanowire scaffold for highly efficient differentiation of mesenchymal stem cells. J. Nanobiotechnol. 2022, 20, 282. [Google Scholar] [CrossRef] [PubMed]

- Domínguez-Bajo, A.; Rosa, J.M.; González-Mayorga, A.; Rodilla, B.L.; Arché-Núnez, A.; Benayas, E.; Ocón, P.; Pérez, L.; Camarero, J.; Miranda, R.; et al. Nanostructured gold electrodes promote neural maturation and network connectivity. Biomaterials 2021, 279, 121186. [Google Scholar] [CrossRef] [PubMed]

- Zan, G.; Wu, T.; Zhu, F.; He, P.; Cheng, Y.; Chai, S.; Wang, Y.; Huang, X.; Zhang, W.; Wan, Y.; et al. A biomimetic conductive super-foldable material. Matter 2021, 4, 3232–3247. [Google Scholar] [CrossRef]

- Zan, G.; Wu, T.; Zhang, Z.; Li, J.; Zhou, J.; Zhu, F.; Chen, H.; Wen, M.; Yang, X.; Peng, X.; et al. Bioinspired Nanocomposites with Self-Adaptive Stress Dispersion for Super-Foldable Electrodes. Adv. Sci. 2022, 9, 2103714. [Google Scholar] [CrossRef]

- Zan, G.; Wu, T.; Dong, W.; Tu, T.; Xu, R.; Chen, X.; Wu, Y.W.Q. Two-Level Biomimetic Designs Enable Intelligent Stress Dispersion for Super-Foldable C/NiS Nanofiber Free-Standing Electrodel. Adv. Fiber Mater. 2022; in press. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fernández-González, C.; Guedeja-Marrón, A.; Rodilla, B.L.; Arché-Nuñez, A.; Corcuera, R.; Lucas, I.; González, M.T.; Varela, M.; de la Presa, P.; Aballe, L.; et al. Electrodeposited Magnetic Nanowires with Radial Modulation of Composition. Nanomaterials 2022, 12, 2565. https://doi.org/10.3390/nano12152565

Fernández-González C, Guedeja-Marrón A, Rodilla BL, Arché-Nuñez A, Corcuera R, Lucas I, González MT, Varela M, de la Presa P, Aballe L, et al. Electrodeposited Magnetic Nanowires with Radial Modulation of Composition. Nanomaterials. 2022; 12(15):2565. https://doi.org/10.3390/nano12152565

Chicago/Turabian StyleFernández-González, Claudia, Alejandra Guedeja-Marrón, Beatriz L. Rodilla, Ana Arché-Nuñez, Rubén Corcuera, Irene Lucas, María Teresa González, Maria Varela, Patricia de la Presa, Lucía Aballe, and et al. 2022. "Electrodeposited Magnetic Nanowires with Radial Modulation of Composition" Nanomaterials 12, no. 15: 2565. https://doi.org/10.3390/nano12152565

APA StyleFernández-González, C., Guedeja-Marrón, A., Rodilla, B. L., Arché-Nuñez, A., Corcuera, R., Lucas, I., González, M. T., Varela, M., de la Presa, P., Aballe, L., Pérez, L., & Ruiz-Gómez, S. (2022). Electrodeposited Magnetic Nanowires with Radial Modulation of Composition. Nanomaterials, 12(15), 2565. https://doi.org/10.3390/nano12152565