Particle Distribution and Heat Transfer of SiO2/Water Nanofluid in the Turbulent Tube Flow

Abstract

:1. Introduction

2. Basic Equations

2.1. Equations for the Nanofluid

2.2. Population Balance Equation for Nanoparticles

2.3. Thermophysical Parameters of the Nanofluid

3. Numerical Method and Verification

3.1. Numerical Method

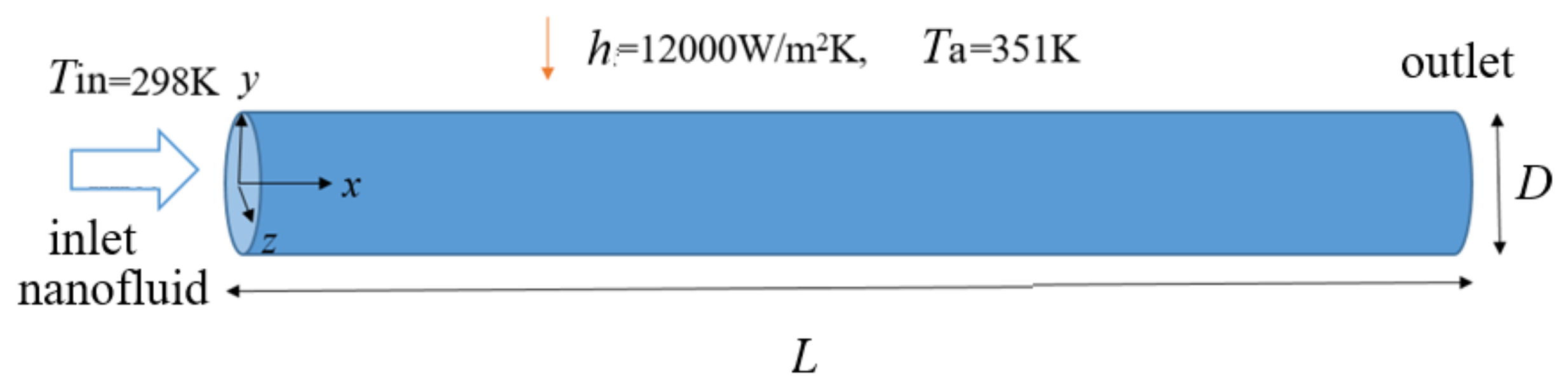

3.2. Boundary Condition

- Inlet

- 2.

- Wall

- 3.

- Outlet

3.3. Parameter Definition

3.4. Main Steps of the Numerical Simulation

- (1)

- Solve Equations (1)–(7) with = 0 to get ui.

- (2)

- Solve Equations (11)–(13) to get m0, m1, and .

- (3)

- Substitute into Equations (14)–(17) to get ρnf, cp,nf, knf, and μnf.

- (4)

- Substitute , ρnf, cp,nf, knf, and μnf into Equations (1)–(7), and solve the equations to get ui, p, and T.

- (5)

- Repeat steps (2) to (4) based on the new flow velocity ui until the difference between the successive results of ui, p, and T is less than a definite value.

- (6)

- Calculate the pressure drop ∆P based on Equation (18), h and Nu based on Equation (19).

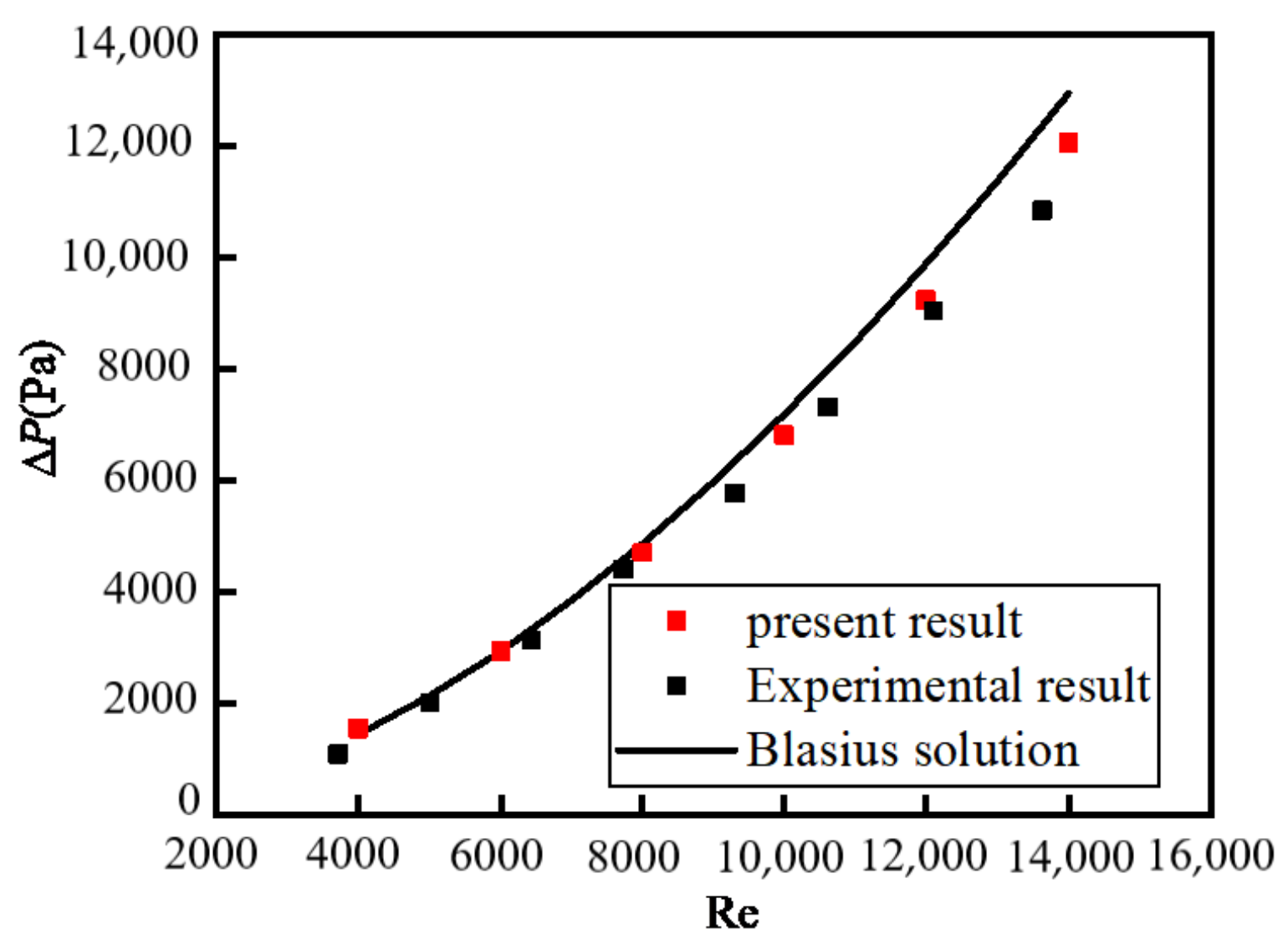

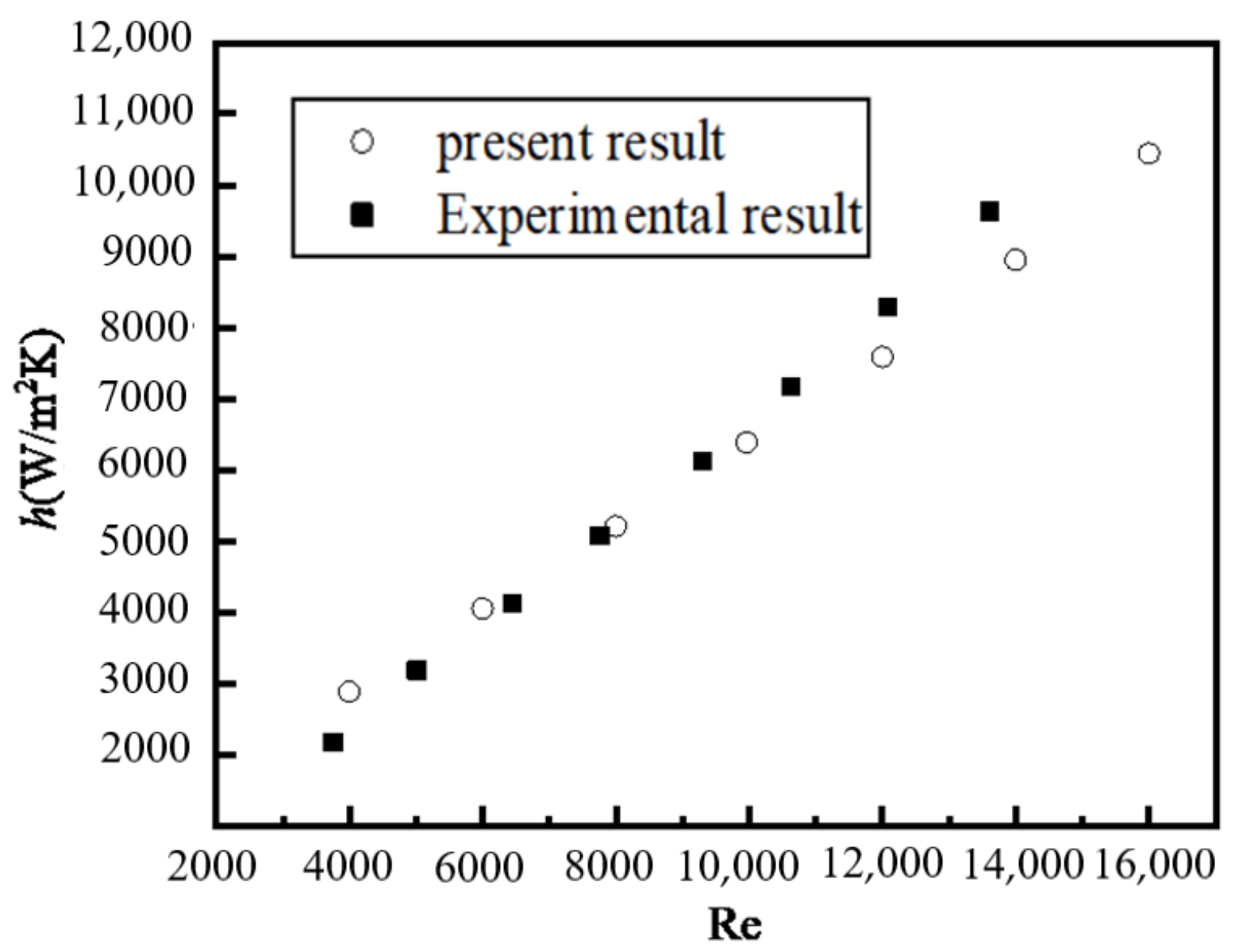

3.5. Grid Independence and Verification of Calculation Methods

4. Results and Discussion

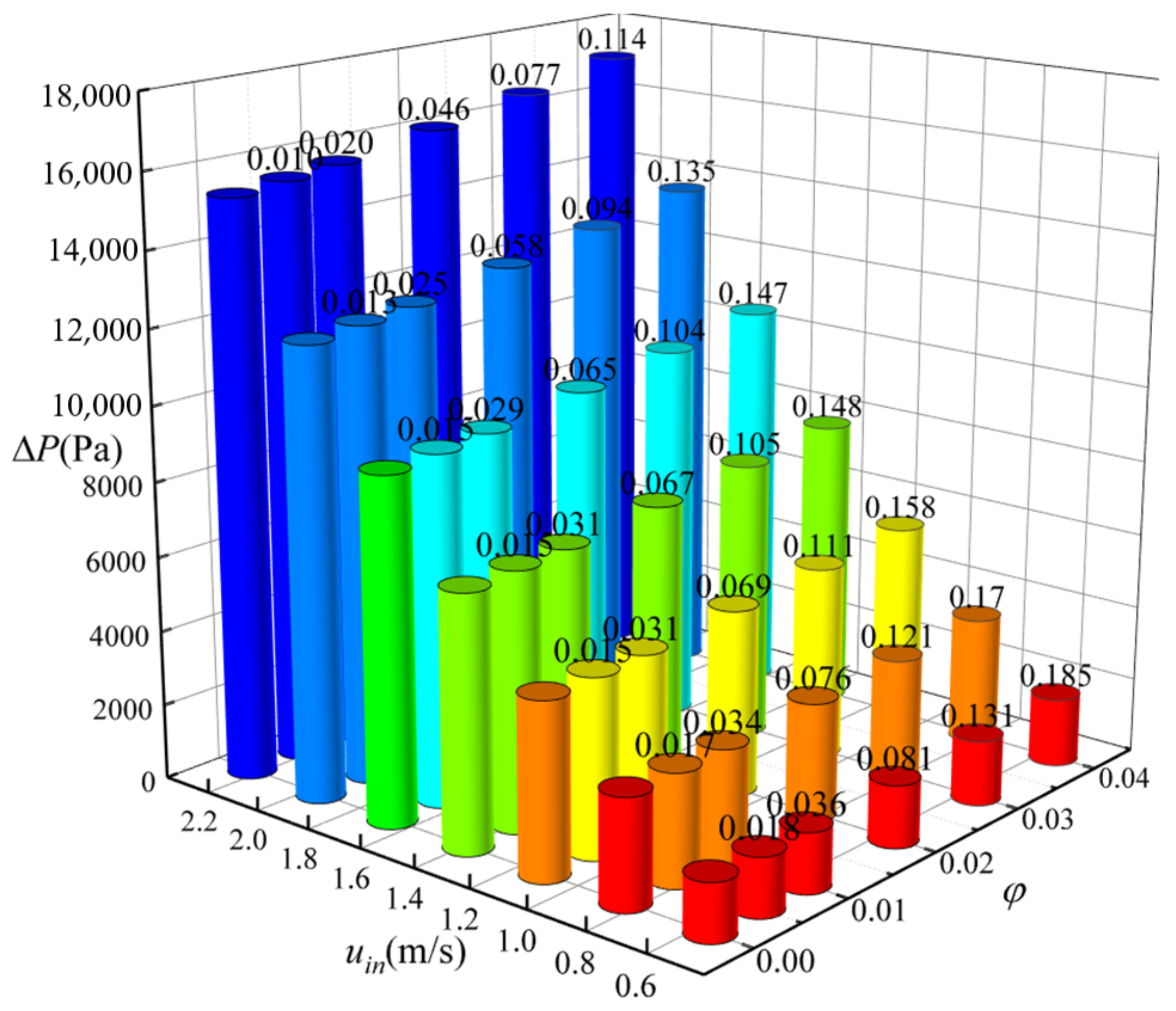

4.1. Pressure Drop

4.2. Particle Distribution

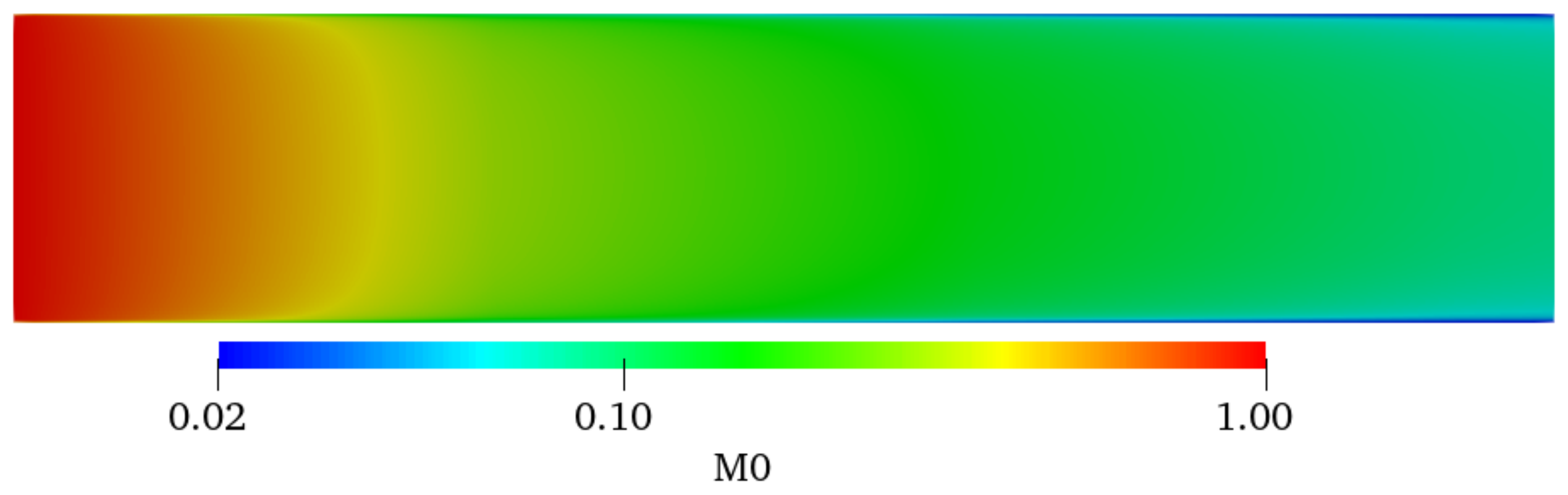

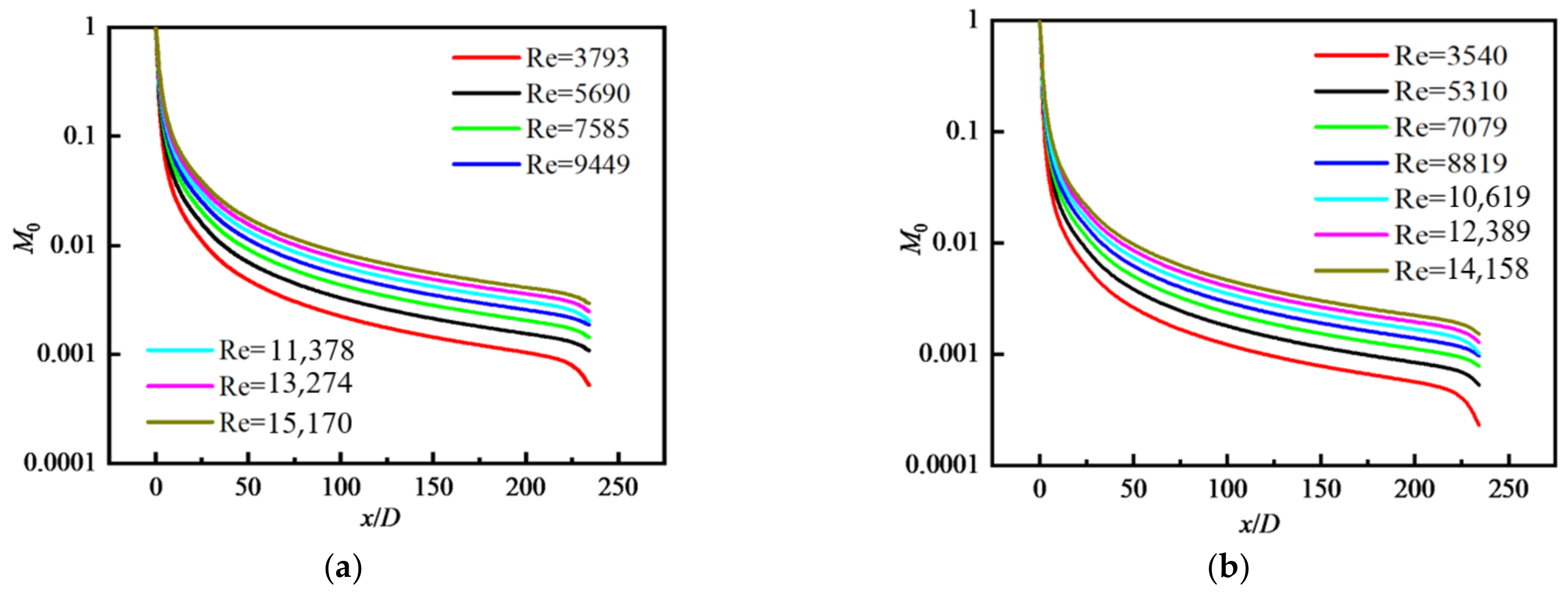

4.2.1. Distribution of Particle Number Concentration

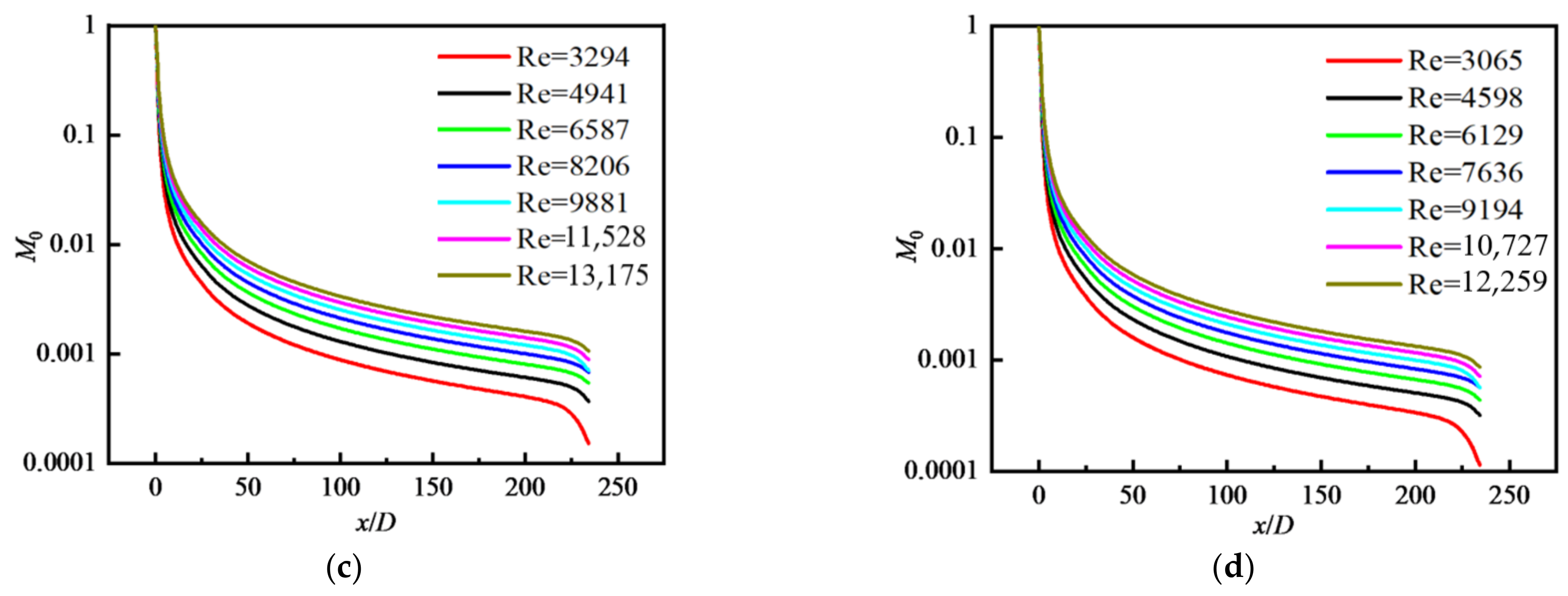

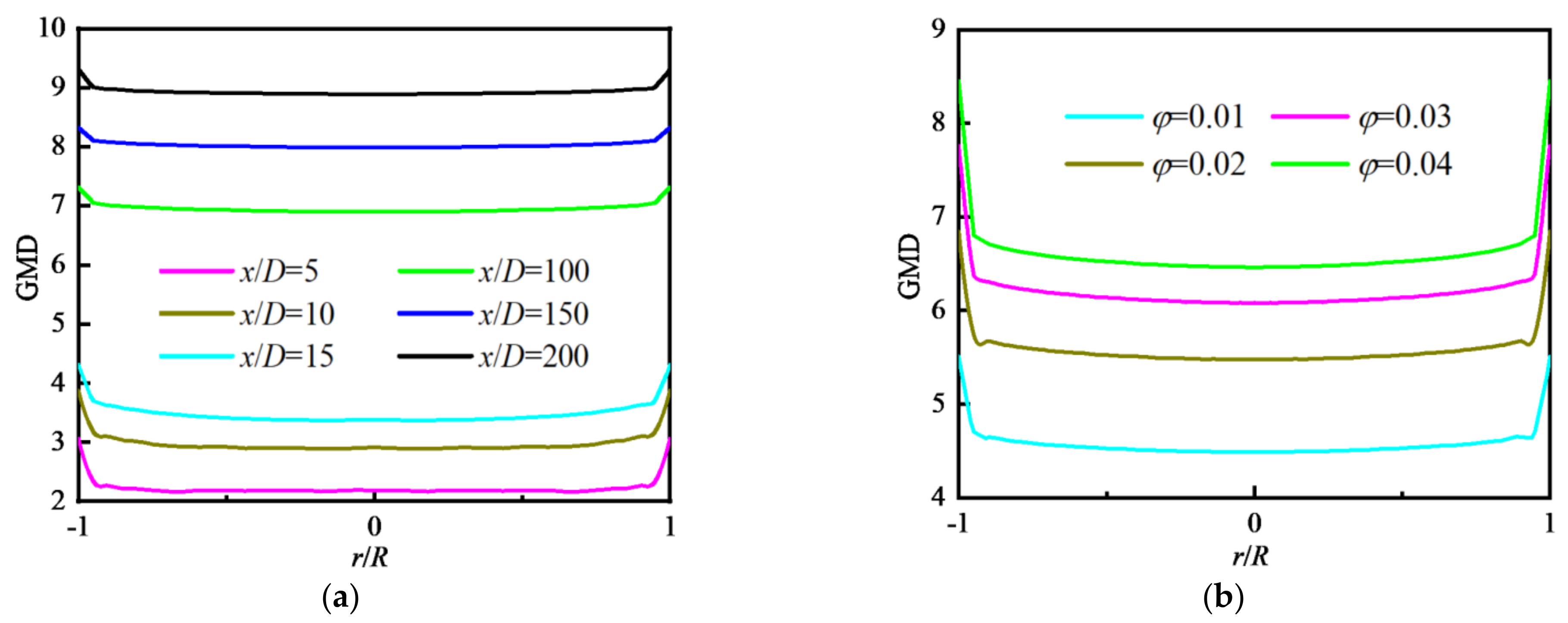

4.2.2. Distribution of Particle Diameter

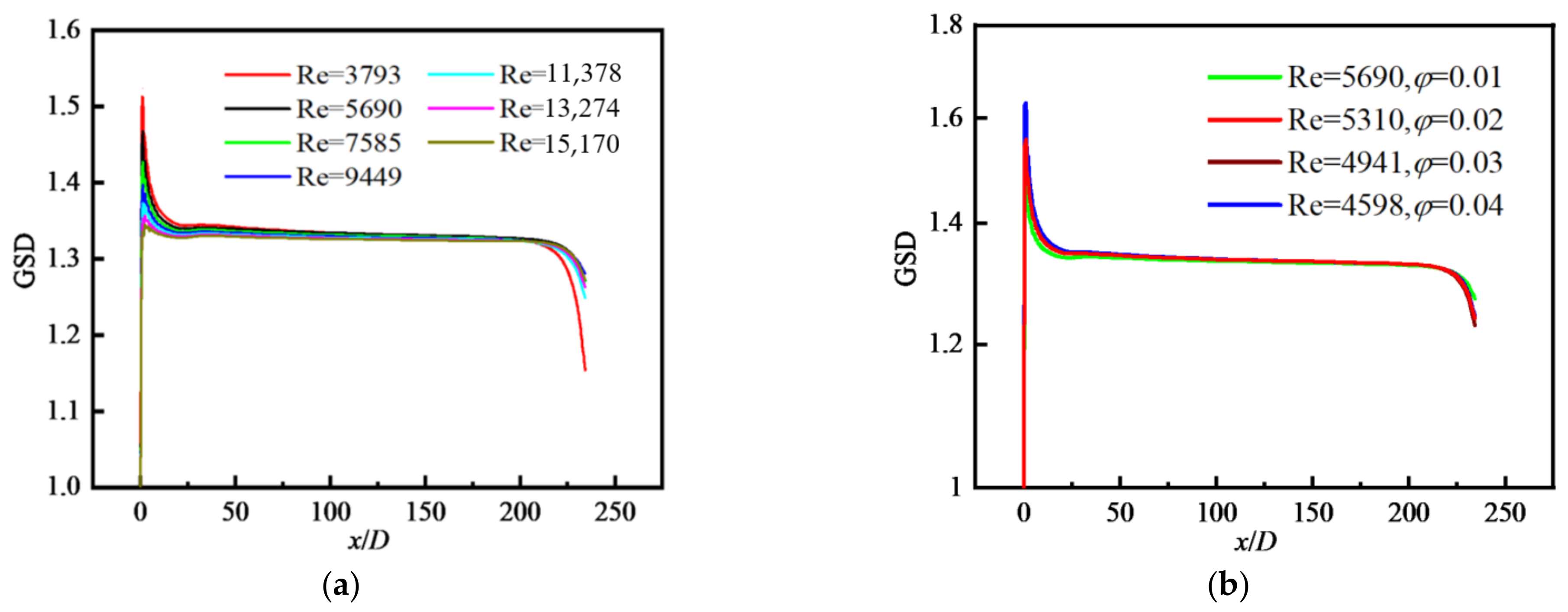

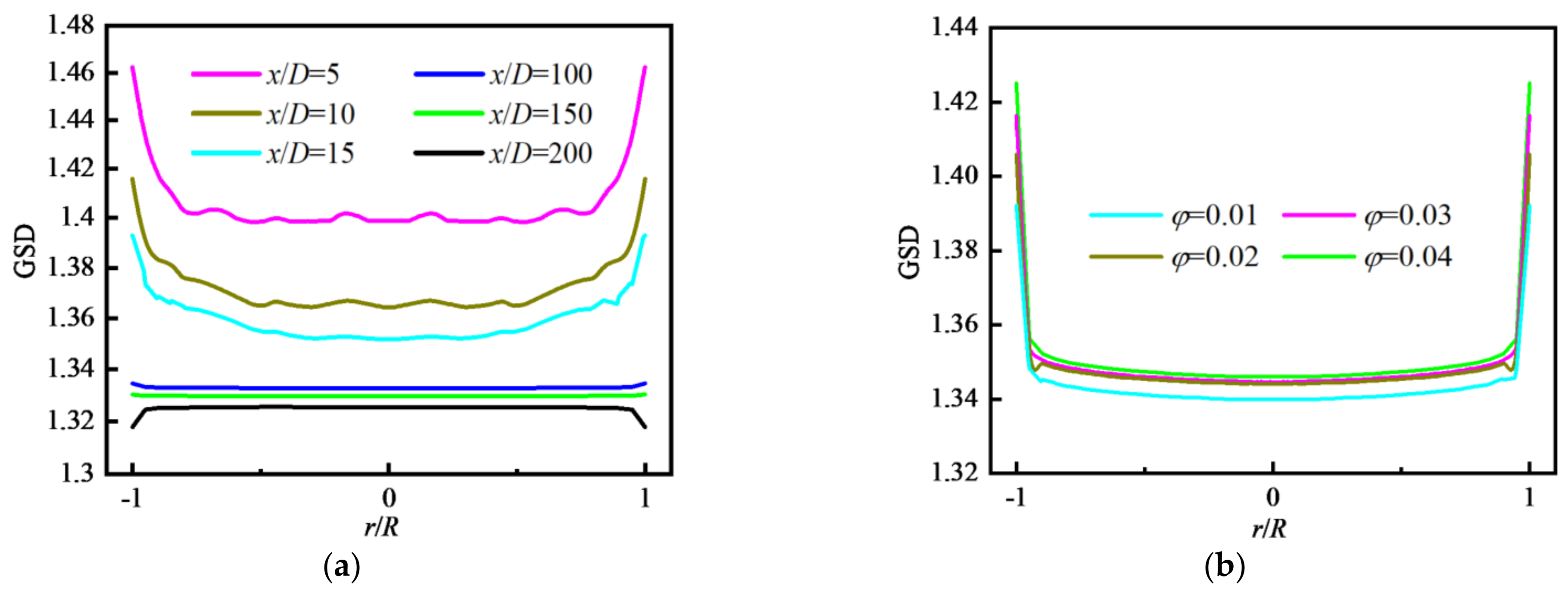

4.2.3. Distribution of Particle Polydispersity

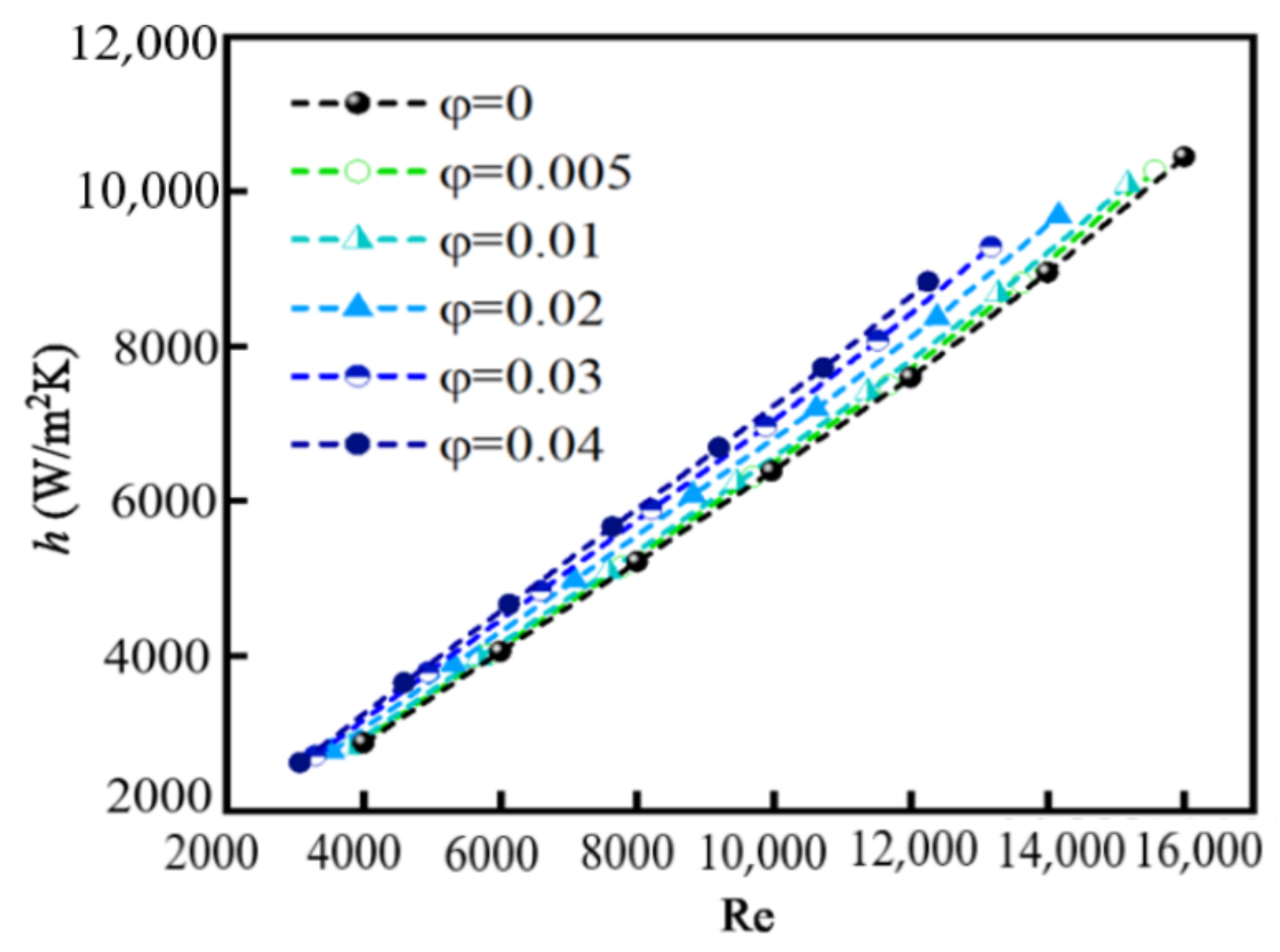

4.3. Convective Heat Transfer

5. Conclusions

- (1)

- ∆P increases significantly after adding nanoparticles and increases with increasing Re. ∆P is proportional to particle volume fraction φ because increased viscosity hinders the motion of the nanofluid and more irregular migration of particles. For a specific φ, the larger the inlet velocity is, the larger the value of ∆P is. When inlet velocity is small, the increase in ∆P caused by adding particles is relatively large. The value of ∆P increases most obviously compared with the case of pure water when the inlet velocity is 0.589 m/s and φ is 0.004.

- (2)

- M0 decreases along the flow direction. M0 near the wall is decreased to the original 2% and decreased by about 90% in the central area. For a fixed φ, with the increase in Re, M0 increases and the reduction rate of M0 along the flow direction decreases. M0 decreases with increasing φ and is the largest in the inlet area, and gradually decreases along the flow direction. M0 in the core area basically presents a uniform distribution. GMD increases with increasing φ, but with decreasing Re because the larger the Re is, the smaller the possibility of particle collision and coagulation is. GMD is the minimum in the inlet area and gradually increases along the flow direction, and basically presents a uniform distribution in the core area. GSD increases sharply at the inlet and decreases in the inlet area, and then remains almost unchanged in the whole tube, finally decreasing rapidly again at the outlet. The effects of Re and φ on the variation in GSD along the flow direction are insignificant. In the inlet area, GSD decreases along the flow direction, and is unevenly distributed and fluctuated along the radial direction. Downstream, GSD changes little along the flow direction and presents a uniform distribution along the radial direction. φ has little effect on GSD except for the case of φ = 0.01.

- (3)

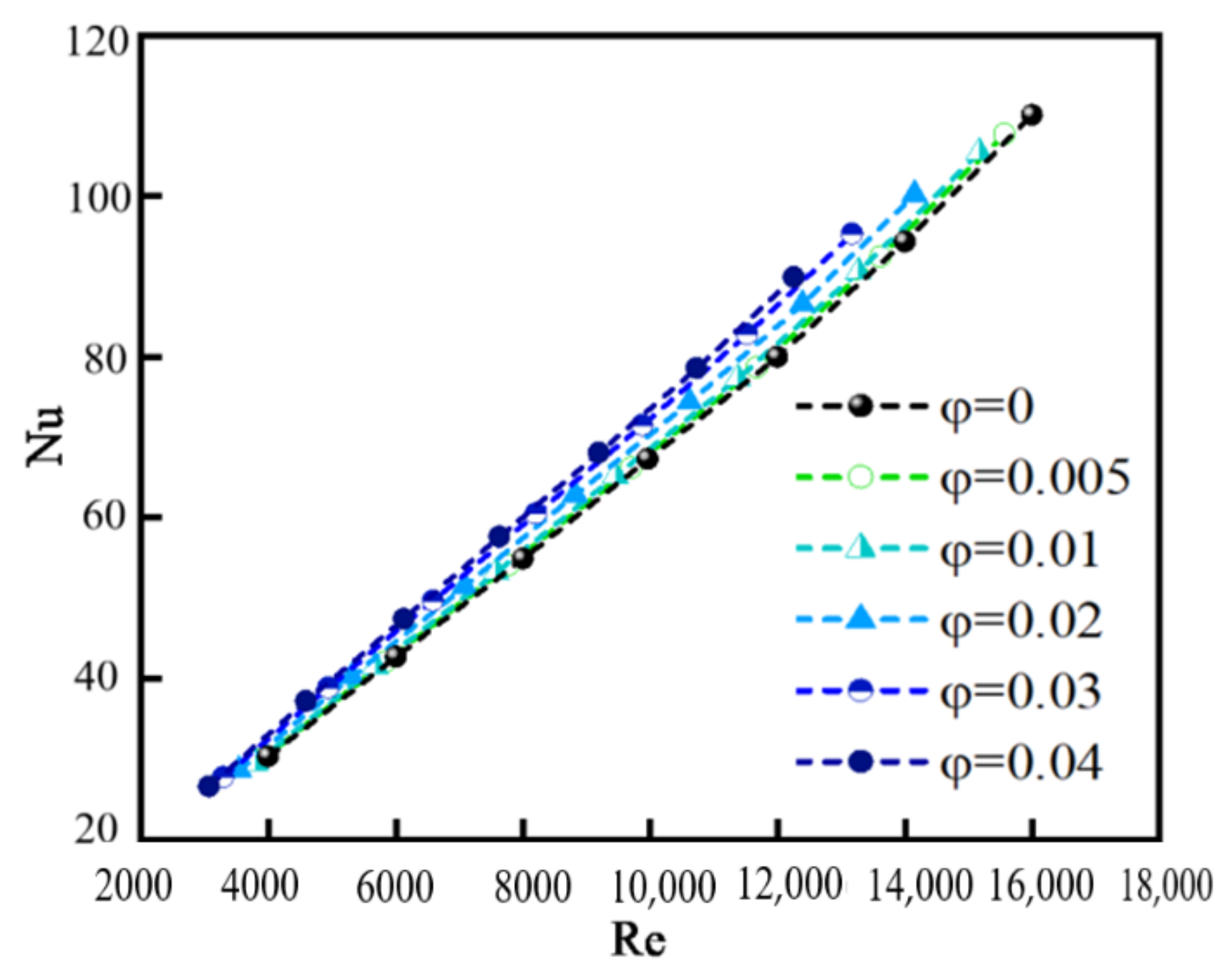

- h and Nu are larger for nanofluids than that for pure water, and increase with the increase in φ. However, the variation in φ from 0.005 to 0.04 has little effect on h and Nu because of particle coagulation. The values of h and Nu increase nearly linearly when Re changes from 3000 to 16,000 because the disordered movement of particles caused by the turbulent flow is more obvious at high Re, and a greater amount of heat is carried by a faster moving fluid at high Re than a slower moving fluid at low Re.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| A | cross-sectional area of the tube |

| cp,nf | nanofluid specific heat capacity |

| df | equivalent diameter |

| dp | particle diameter |

| D | tube diameter |

| DB | Brownian diffusion coefficient |

| Dk | effective diffusion of k |

| Dω | effective diffusion of ω |

| E | total energy |

| G | turbulent kinetic energy generation rate |

| h | convective heat transfer coefficient |

| k | turbulent kinetic energy |

| kB | Boltzmann constant |

| knf | nanofluid thermal conductivity |

| L | tube length |

| mk | moment |

| M | molecular weight of the base fluid |

| n | particle size distribution function |

| NA | Avogadro constant |

| Rij | Reynolds stress |

| S | measure of the strain rate tensor |

| Sk | internal source term of k |

| Sω | internal source term of ω |

| t | time |

| T | nanofluid temperature |

| ui | nanofluid velocity |

| v | particle volume |

| β | particle coagulation kernel function |

| μ | dynamic viscosity |

| μnf | nanofluid dynamic viscosity |

| μt | turbulent dynamical viscosity |

| ρ | density |

| ρnf | nanofluid density |

| νt | turbulent diffusion coefficient |

| φ | volume fraction of nanoparticles |

| ω | turbulent dissipation rate |

References

- Almertejy, A.; Rashid, M.M.; Ali, N.; Almurtaji, S. Application of nanofluids in gas turbine and intercoolers—A comprehensive review. Nanomaterials 2022, 12, 338. [Google Scholar] [CrossRef] [PubMed]

- Chamkha, A.; Selimefendigil, F. Forced convection of pulsating nanofluid flow over a backward facing step with various particle shapes. Energies 2018, 11, 3068. [Google Scholar] [CrossRef]

- Manca, O.; Nardini, S.; Ricci, D. A numerical study of nanofluid forced convection in ribbed channels. Appl. Therm. Eng. 2012, 37, 280–292. [Google Scholar] [CrossRef]

- Sundar, L.S.; Kumar, N.T.R.; Naik, M.T.; Sharma, K.V. Effect of full length twisted tape inserts on heat transfer and friction factor enhancement with Fe3O4 magnetic nanofluid inside a plain tube: An experimental study. Int. J. Heat Mass Transf. 2012, 55, 2761–2768. [Google Scholar] [CrossRef]

- Zhu, L.L.; Awais, M.; Javed, H.M.A.; Mustafa, M.S.; Tlili, I.; Khan, S.U.; Shadloo, M.S. Photo-catalytic pretreatment of biomass for anaerobic digestion using visible light and Nickle oxide (NiOx) nanoparticles prepared by sol gel method. Renew. Energy 2020, 154, 128–135. [Google Scholar] [CrossRef]

- Ramesh, G.K.; Roopa, G.S.; Shehzad, S.A.; Khan, S.U. Interaction of Al2O3-Ag and Al2O3-Cu hybrid nanoparticles with water on convectively heated moving material. Multidiscip. Model. Mater. Struct. 2020, 16, 1651–1667. [Google Scholar] [CrossRef]

- Ali, H.M. In tube convection heat transfer enhancement: SiO2 aqua based nanofluids. J. Mol. Liq. 2020, 308, 113031. [Google Scholar] [CrossRef]

- Hejazian, M.; Moraveji, M.K.; Beheshti, A. Comparative study of Euler and mixture models for turbulent flow of Al2O3 nanofluid inside a horizontal tube. Int. Commun. Heat Mass Transf. 2014, 52, 152–158. [Google Scholar] [CrossRef]

- Liu, F.; Cai, Y.; Wang, L.Q.; Zhao, J. Effects of nanoparticle shapes on laminar forced convective heat transfer in curved ducts using two-phase model. Int. J. Heat Mass Transf. 2018, 116, 292–305. [Google Scholar] [CrossRef]

- Hemmat Esfe, M.; Saedodin, S. Turbulent forced convection heat transfer and thermophysical properties of Mgo–water nanofluid with consideration of different nanoparticles diameter, an empirical study. J. Therm. Anal. Calorim. 2015, 119, 1205–1213. [Google Scholar] [CrossRef]

- Keblinski, P.; Phillpot, S.R.; Choi, S.U.S.; Eastman, J.A. Mechanisms of heat flow in suspensions of nano-sized particles (nanofluids). Int. J. Heat Mass Transf. 2002, 45, 855–863. [Google Scholar] [CrossRef]

- Bahiraei, M. A numerical study of heat transfer characteristics of CuO–water nanofluid by Euler–Lagrange approach. J. Therm. Anal. Calorim. 2016, 123, 1591–1599. [Google Scholar] [CrossRef]

- Heyhat, M.M.; Kowsary, F. Effect of particle migration on flow and convective heat transfer of nanofluids flowing through a circular pipe. J. Heat Transf. 2010, 132, 062401. [Google Scholar] [CrossRef]

- Lin, J.Z.; Xia, Y.; Ku, X.K. Pressure drop and heat transfer of nanofluid in turbulent pipe flow considering particle coagulation and breakage. J. Heat Transf. 2014, 136, 111701. [Google Scholar] [CrossRef]

- Lin, J.Z.; Xia, Y.; Ku, X.K. Flow and heat transfer characteristics of nanofluids containing rod-like particles in a turbulent pipe flow. Int. J. Heat Mass Transf. 2016, 93, 57–66. [Google Scholar] [CrossRef]

- Zhang, P.; Lin, J.Z.; Ku, X. Friction factor and heat transfer of nanofluid in the turbulent flow through a 90° bend. J. Hydrodyn. 2021, 33, 1105–1118. [Google Scholar] [CrossRef]

- Calvino, U.; Vallejo, J.P.; Buschmann, M.H.; Fernandez-Seara, J.; Lugo, L. Analysis of heat transfer characteristics of a gnp aqueous nanofluid through a double-tube heat exchanger. Nanomaterials 2021, 11, 844. [Google Scholar] [CrossRef] [PubMed]

- Alam, M.S.; Nahar, B.; Gafur, M.A.; Seong, G.; Hossain, M.Z. Forced convective heat transfer coefficient measurement of low concentration nanorods ZnO–ethylene glycol nanofluids in laminar flow. Nanomaterials 2022, 12, 1568. [Google Scholar] [CrossRef]

- Jamshed, W.; Nasir, N.A.A.M.; Isa, S.S.P.M.; Safdar, R.; Shahzad, F.; Nisar, K.S.; Eid, M.R.; Abdel-Aty, A.H.; Yahia, I.S. Thermal growth in solar water pump using Prandtl-Eyring hybrid nanofluid: A solar energy application. Sci. Rep. 2021, 11, 18704. [Google Scholar] [CrossRef] [PubMed]

- Shahzad, M.; Abdel-Aty, A.H.; Attia, R.A.M.; Khoshnaw, S.H.A.; Aldila, D.; Ali, M.; Sultan, F. Dynamics models for identifying the key transmission parameters of the COVID-19 disease. Alex. Eng. J. 2021, 60, 757–765. [Google Scholar] [CrossRef]

- Abdullah; Ahmad, S.; Owyed, S.; Abdel-Aty, A.H.; Mahmoud, E.E.; Shah, K.; Alrabaiah, H. Mathematical analysis of COVID-19 via new mathematical model. Chaos Solitons Fractals 2021, 143, 110585. [Google Scholar] [CrossRef]

- Sheikholeslami, M.; Jafaryar, M.; Shafee, A.; Li, Z.X.; Haq, R.U. Heat transfer of nanoparticles employing innovative turbulator considering entropy generation. Int. J. Heat Mass Transf. 2019, 136, 1233–1240. [Google Scholar] [CrossRef]

- Sheikholeslami, M.; Jafaryar, M.; Shafee, A.; Li, Z.X. Nanofluid turbulent convective flow in a circular duct with helical turbulators considering CuO nanoparticles. Int. J. Heat Mass Transf. 2018, 124, 980–989. [Google Scholar] [CrossRef]

- Menter, F.R.; Kuntz, M.; Langtry, R. Ten Years of Industrial Experience with the SST Turbulence Model. In Turbulence, Heat and Mass Transfer 4; Begell House Inc.: Danbury, CT, USA, 2003. [Google Scholar]

- Ramkrishna, D. Population Balances: Theory and Applications to Particulate Systems in Engineering; Academic Press: San Diego, CA, USA, 2000. [Google Scholar]

- Li, D.; Li, Z.; Gao, Z. Quadrature-based moment methods for the population balance equation: An algorithm review. Chin. J. Chem. Eng. 2019, 27, 483–500. [Google Scholar] [CrossRef]

- Hulburt, H.M.; Katz, S. Some problems in particle technology: A statistical mechanical formulation. Chem. Eng. Sci. 1964, 19, 555–574. [Google Scholar] [CrossRef]

- Yu, M.; Lin, J.Z. Binary homogeneous nucleation and growth of water-sulfuric acid nanoparticles using a TEMOM model. Int. J. Heat Mass Transf. 2010, 53, 635–644. [Google Scholar] [CrossRef]

- Yu, M.; Lin, J.Z.; Chan, T. A new moment method for solving the coagulation equation for particles in Brownian motion. Aerosol Sci. Technol. 2008, 42, 705–713. [Google Scholar] [CrossRef]

- Das, S.; Khan, M.A.A.; Mahmoud, E.E.; Abdel-Aty, A.H.; Abualnaja, K.M.; Shaikh, A.A. A production inventory model with partial trade credit policy and reliability. Alex. Eng. J. 2021, 60, 1325–1338. [Google Scholar] [CrossRef]

- Owyed, S.; Abdou, M.A.; Abdel-Aty, A.H.; Ibraheem, A.A.; Nekhili, R.; Baleanu, D. New optical soliton solutions of space- time fractional nonlinear dynamics of microtubules via three integration schemes. J. Intell. Fuzzy Syst. 2020, 38, 2859–2866. [Google Scholar] [CrossRef]

- Yu, M.; Lin, J.Z.; Jin, H.H.; Jiang, Y. The verification of the Taylor-expansion moment method for the nanoparticle coagulation in the entire size regime due to Brownian motion. J. Nanopart. Res. 2011, 13, 2007–2020. [Google Scholar] [CrossRef]

- Teng, T.; Hung, Y. Estimation and experimental study of the density and specific heat for alumina nanofluid. J. Exp. Nanosci. 2014, 9, 707–718. [Google Scholar] [CrossRef]

- Corcione, M. Empirical correlating equations for predicting the effective thermal conductivity and dynamic viscosity of nanofluids. Energy Convers. Manag. 2011, 52, 789–793. [Google Scholar] [CrossRef]

- Timofeeva, E.V.; Gavrilov, A.N.; McCloskey, J.M.; Tolmachev, Y.V.; Sprunt, S.; Lopatina, L.M.; Selinger, J.V. Thermal conductivity and particle agglomeration in alumina nanofluids: Experiment and theory. Phys. Rev. E 2007, 76, 61203. [Google Scholar] [CrossRef] [PubMed]

- Khedkar, R.S.; Shrivastava, N.; Sonawane, S.S.; Wasewar, K.L. Experimental investigations and theoretical determination of thermal conductivity and viscosity of TiO2–ethylene glycol nanofluid. Int. Commun. Heat Mass Transf. 2016, 73, 54–61. [Google Scholar] [CrossRef]

- Meriläinen, A.; Seppälä, A.; Saari, K.; Seitsonen, J.; Ruokolainen, J.; Puisto, S.; Rostedt, N.; Ala-Nissila, T. Influence of particle size and shape on turbulent heat transfer characteristics and pressure losses in water-based nanofluids. Int. J. Heat Mass Transf. 2013, 61, 439–448. [Google Scholar] [CrossRef]

- Corcione, M. Heat transfer features of buoyancy-driven nanofluids inside rectangular enclosures differentially heated at the sidewalls. Int. J. Therm. Sci. 2010, 49, 1536–1546. [Google Scholar] [CrossRef]

- Prasher, R.; Phelan, P.E.; Bhattacharya, P. Effect of aggregation kinetics on the thermal conductivity of nanoscale colloidal solutions (nanofluid). Nano Lett. 2006, 6, 1529–1534. [Google Scholar] [CrossRef]

- Lee, K.W.; Lee, Y.J.; Han, D.S. The Log-Normal size distribution theory for Brownian coagulation in the low Knudsen number regime. J. Colloid Interface Sci. 1997, 188, 486–492. [Google Scholar] [CrossRef]

| Constant | αk1 | αk2 | αω1 | αω2 | β1 | β2 | γ1 | γ2 | β* | a1 | b1 | c1 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Value | 0.85 | 1.0 | 0.5 | 0.856 | 0.075 | 0.0828 | 5/9 | 0.44 | 0.09 | 0.31 | 1.0 | 10.0 |

| Thermo-Physical Properties | ρ (kg/m3) | μ (kg/m∙s) | Thermal Conductivity k (W/m∙K) | Specific Heat Capacity cp(J/kg∙K) |

|---|---|---|---|---|

| Water | 997.048 | 0.00089 | 0.6072 | 4182 |

| SiO2 (65 nm) | 2200 | \ | 1.38 | 733 |

| Volume Fraction φ | Pr | ||||

|---|---|---|---|---|---|

| 0 (base fluid) | 997.048 | 4182 | 0.00089 | 6.13 | 0.6027 |

| 0.005 | 1003.06 | 4144 | 0.00092 | 6.25 | 0.6099 |

| 0.01 | 1009.07 | 4107 | 0.00095 | 6.38 | 0.6126 |

| 0.02 | 1021.11 | 4033 | 0.00103 | 6.70 | 0.6181 |

| 0.03 | 1033.14 | 3962 | 0.00112 | 7.09 | 0.6236 |

| 0.04 | 1047.17 | 3892 | 0.00122 | 7.65 | 0.6292 |

| Number of Cells | Node (a × b × c) | ∆P (Pa) | hmean(W/m2K) | |

|---|---|---|---|---|

| Grid 1 | 864,000 | 12 × 9 × 1500 | 4673.6 | 5478.9 |

| Grid 2 | 2,400,000 | 20 × 15 × 1500 | 4679.8 | 5188.42 |

| Grid 3 | 3,456,000 | 24 × 18 × 1500 | 4706.6 | 5185.44 |

| Grid 4 | 240,000 | 20 × 15 × 150 | 4688.9 | 5211.87 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shi, R.; Lin, J.; Yang, H. Particle Distribution and Heat Transfer of SiO2/Water Nanofluid in the Turbulent Tube Flow. Nanomaterials 2022, 12, 2803. https://doi.org/10.3390/nano12162803

Shi R, Lin J, Yang H. Particle Distribution and Heat Transfer of SiO2/Water Nanofluid in the Turbulent Tube Flow. Nanomaterials. 2022; 12(16):2803. https://doi.org/10.3390/nano12162803

Chicago/Turabian StyleShi, Ruifang, Jianzhong Lin, and Hailin Yang. 2022. "Particle Distribution and Heat Transfer of SiO2/Water Nanofluid in the Turbulent Tube Flow" Nanomaterials 12, no. 16: 2803. https://doi.org/10.3390/nano12162803

APA StyleShi, R., Lin, J., & Yang, H. (2022). Particle Distribution and Heat Transfer of SiO2/Water Nanofluid in the Turbulent Tube Flow. Nanomaterials, 12(16), 2803. https://doi.org/10.3390/nano12162803