Influence of Annealing on the Dielectric Properties of Zn-SiO2/Si Nanocomposites Obtained in “Hot” Implantation Conditions

Abstract

:1. Introduction

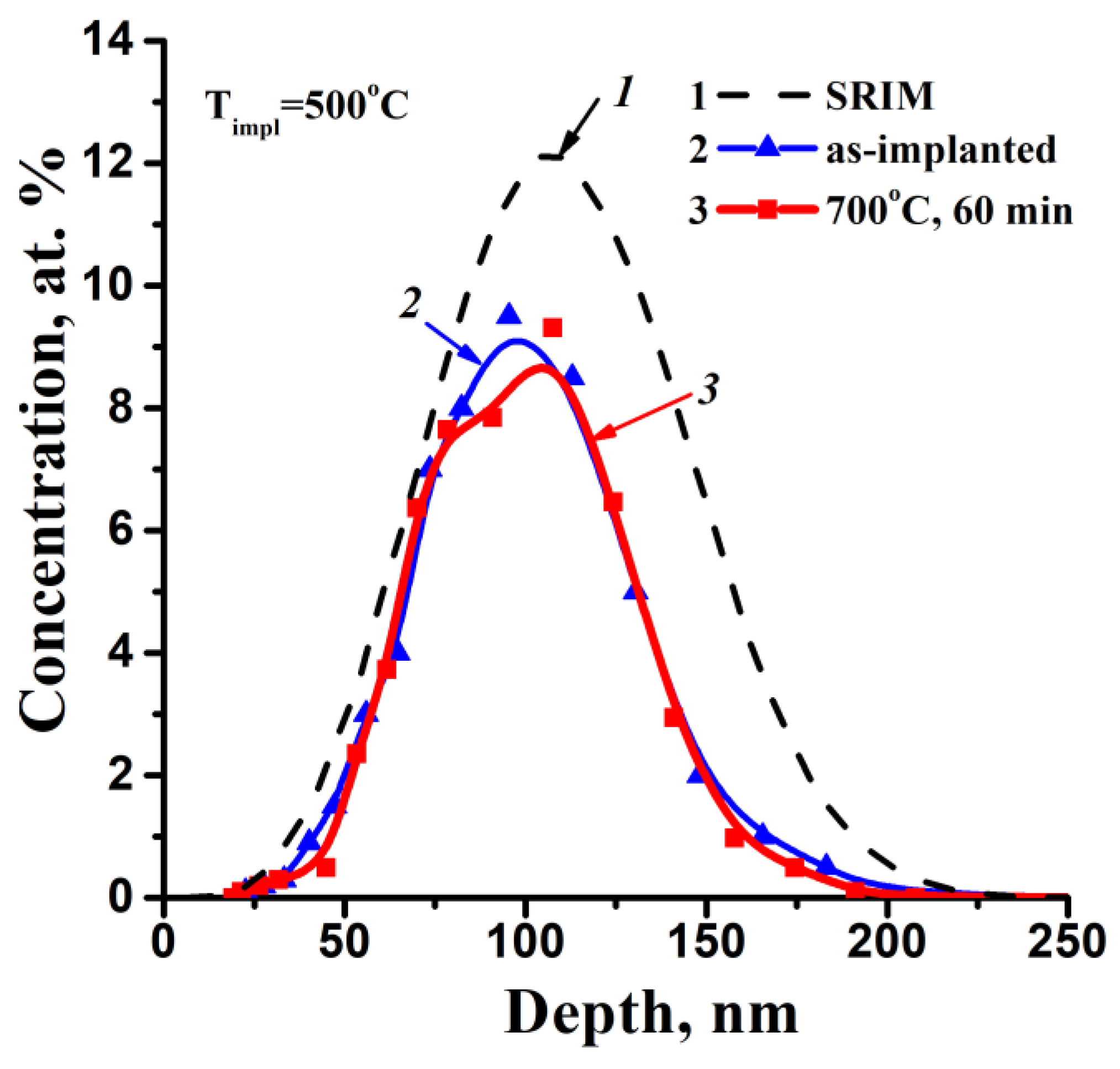

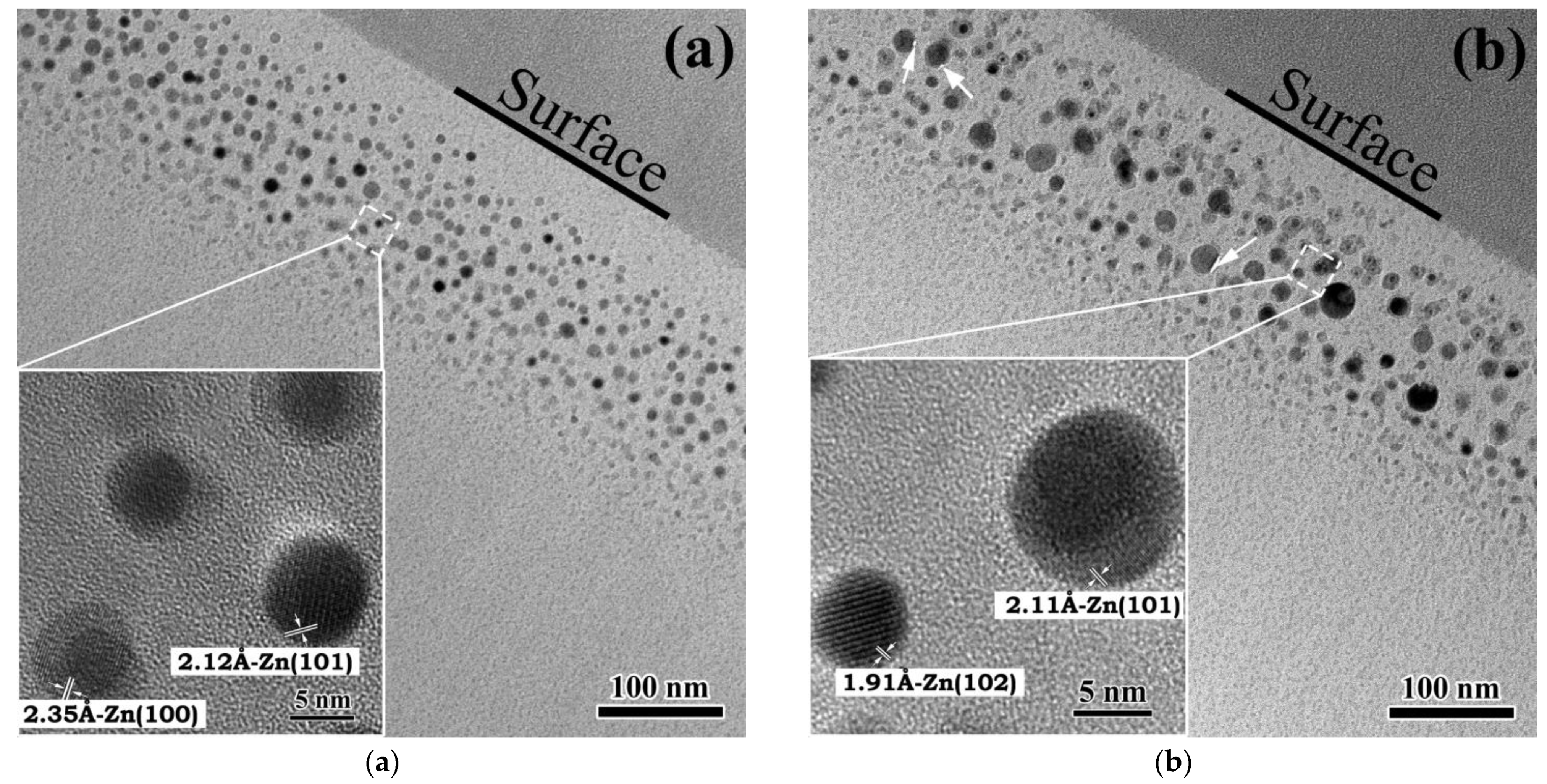

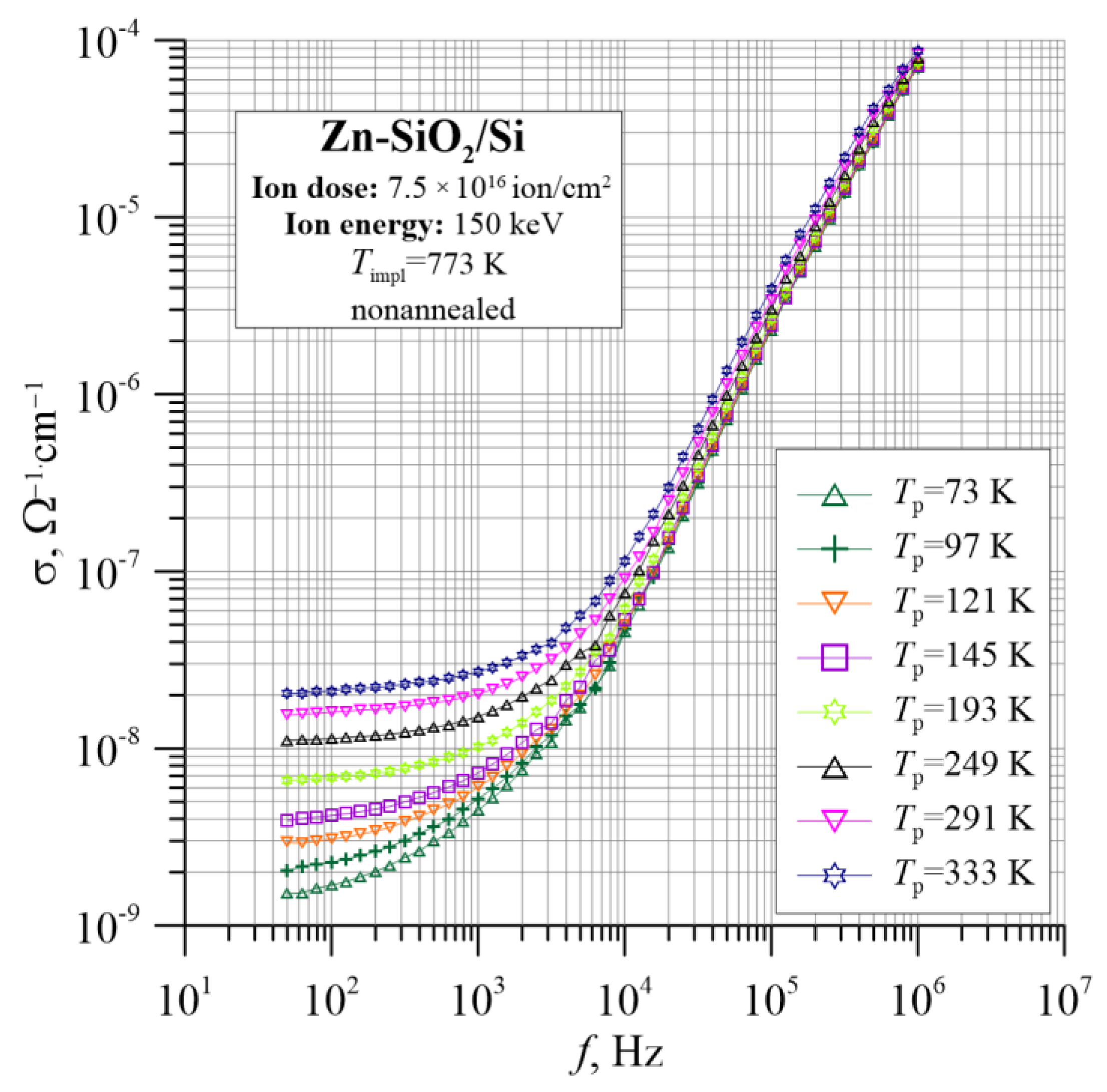

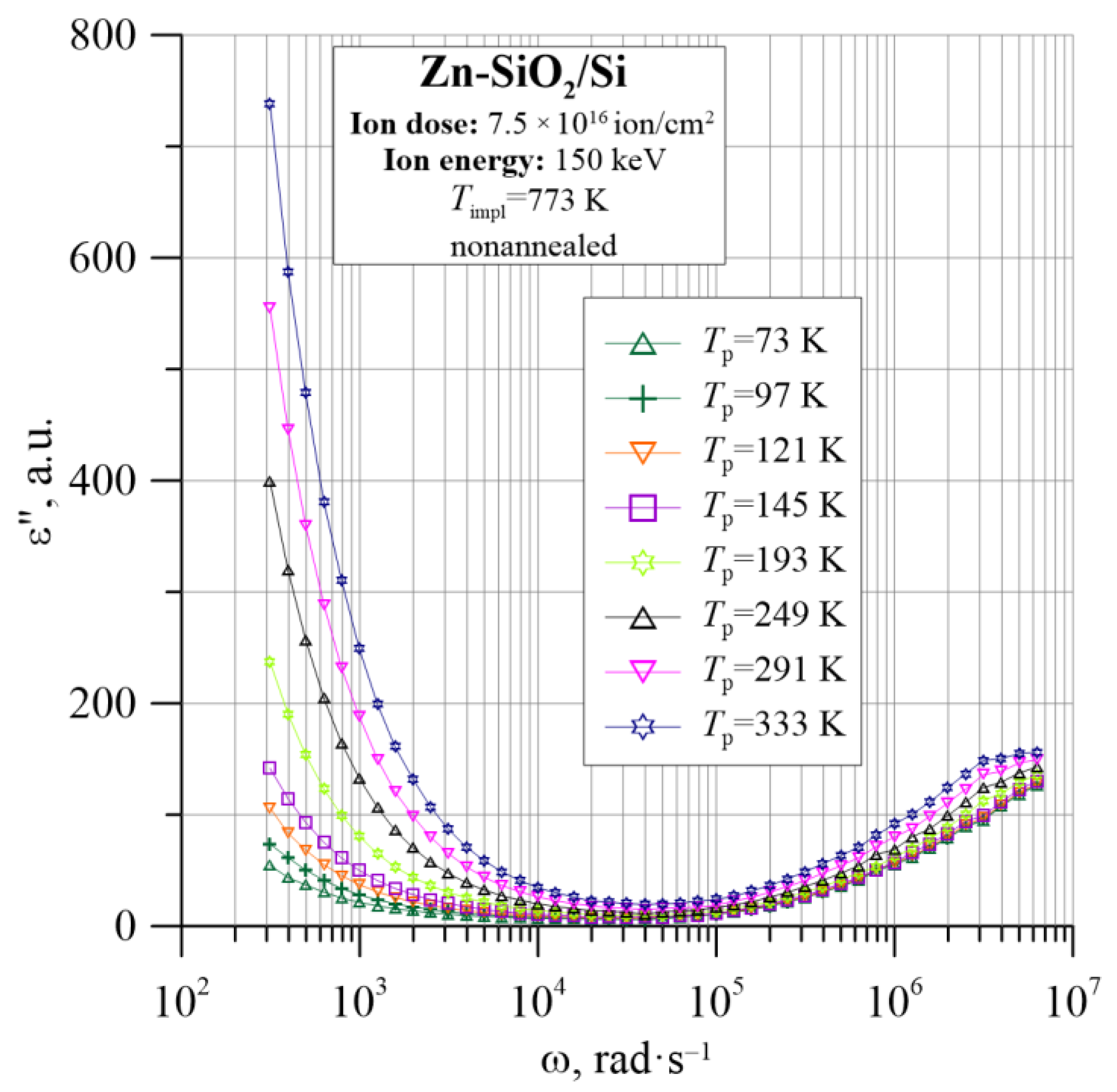

2. Experimental

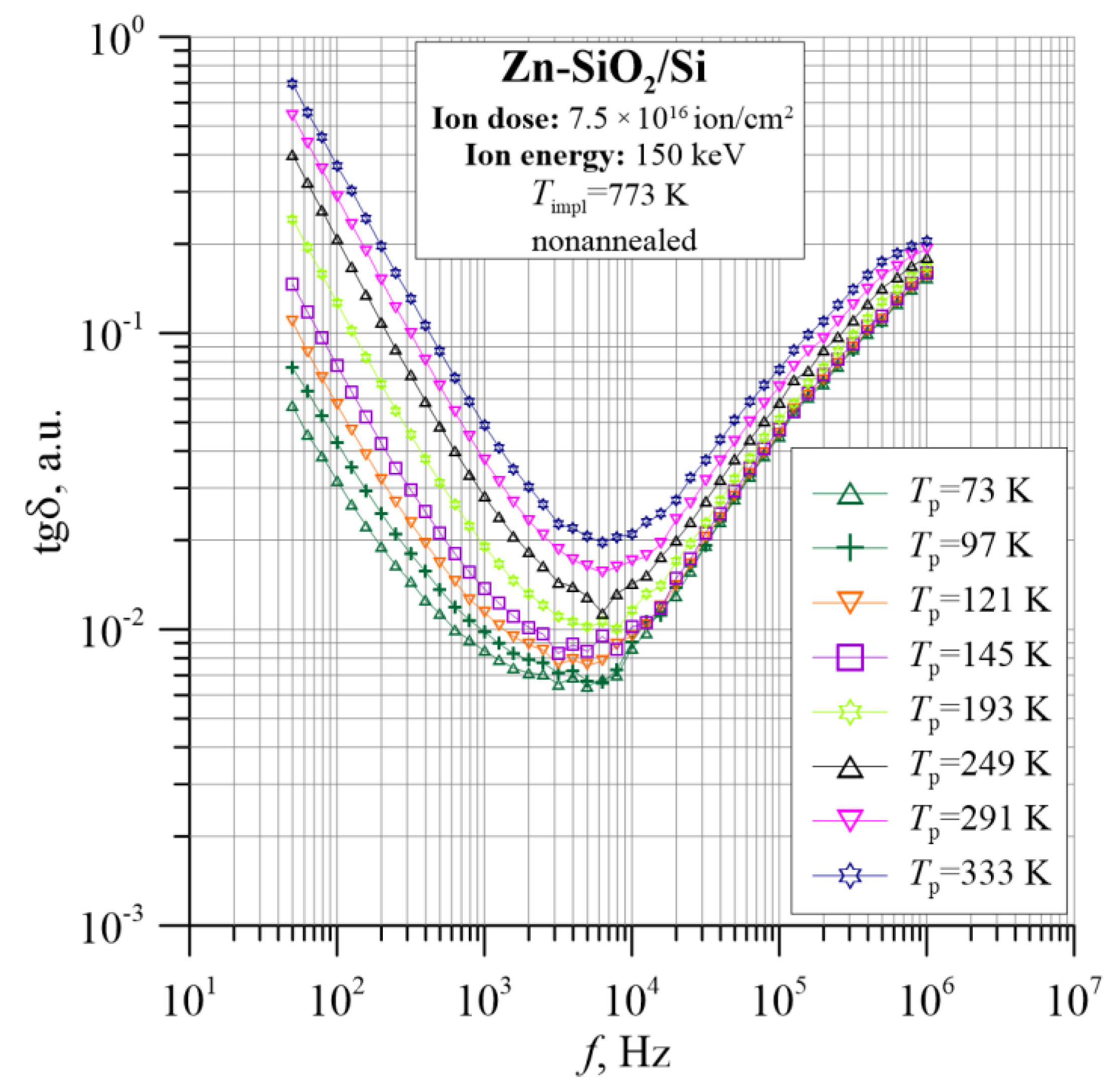

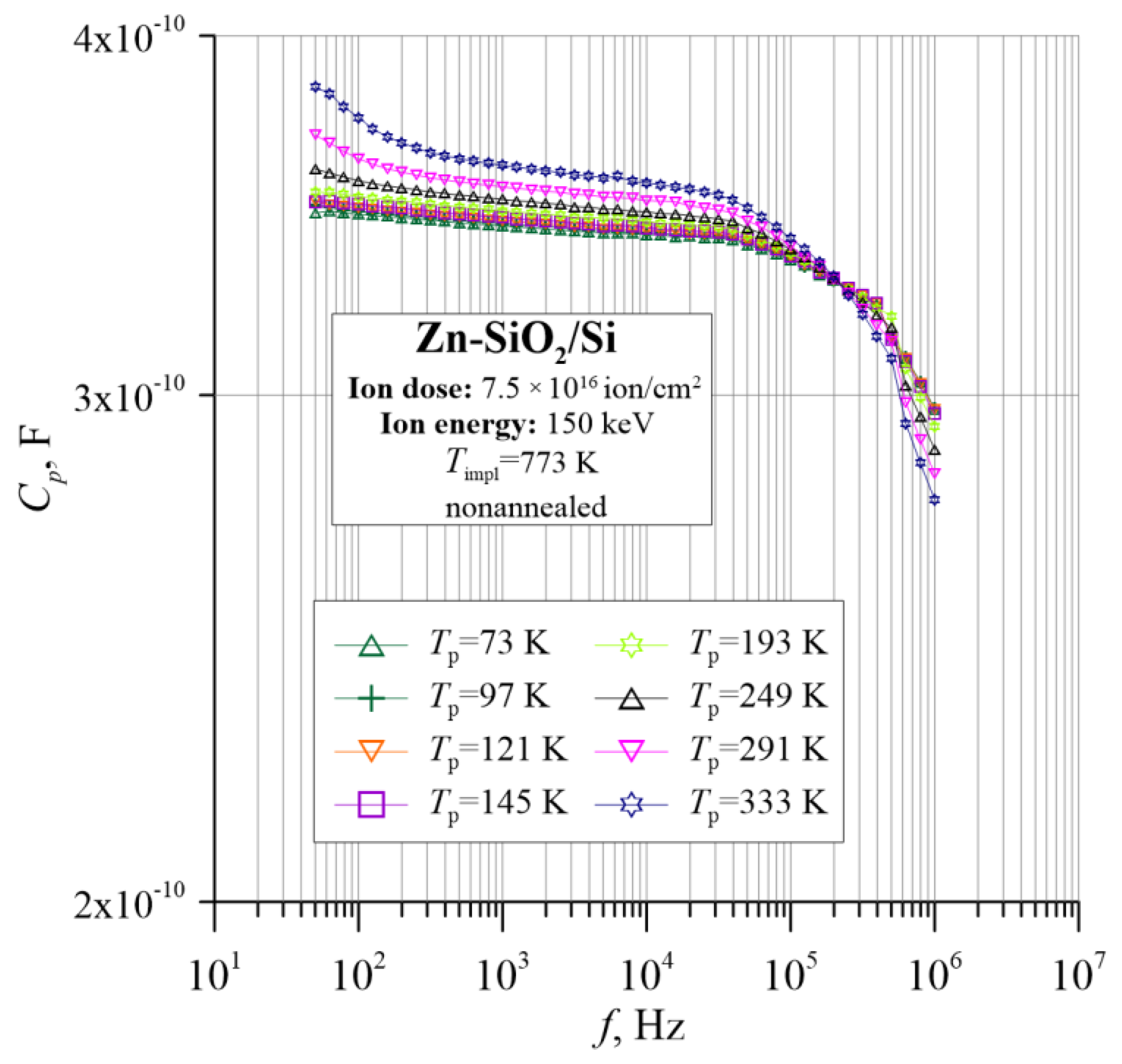

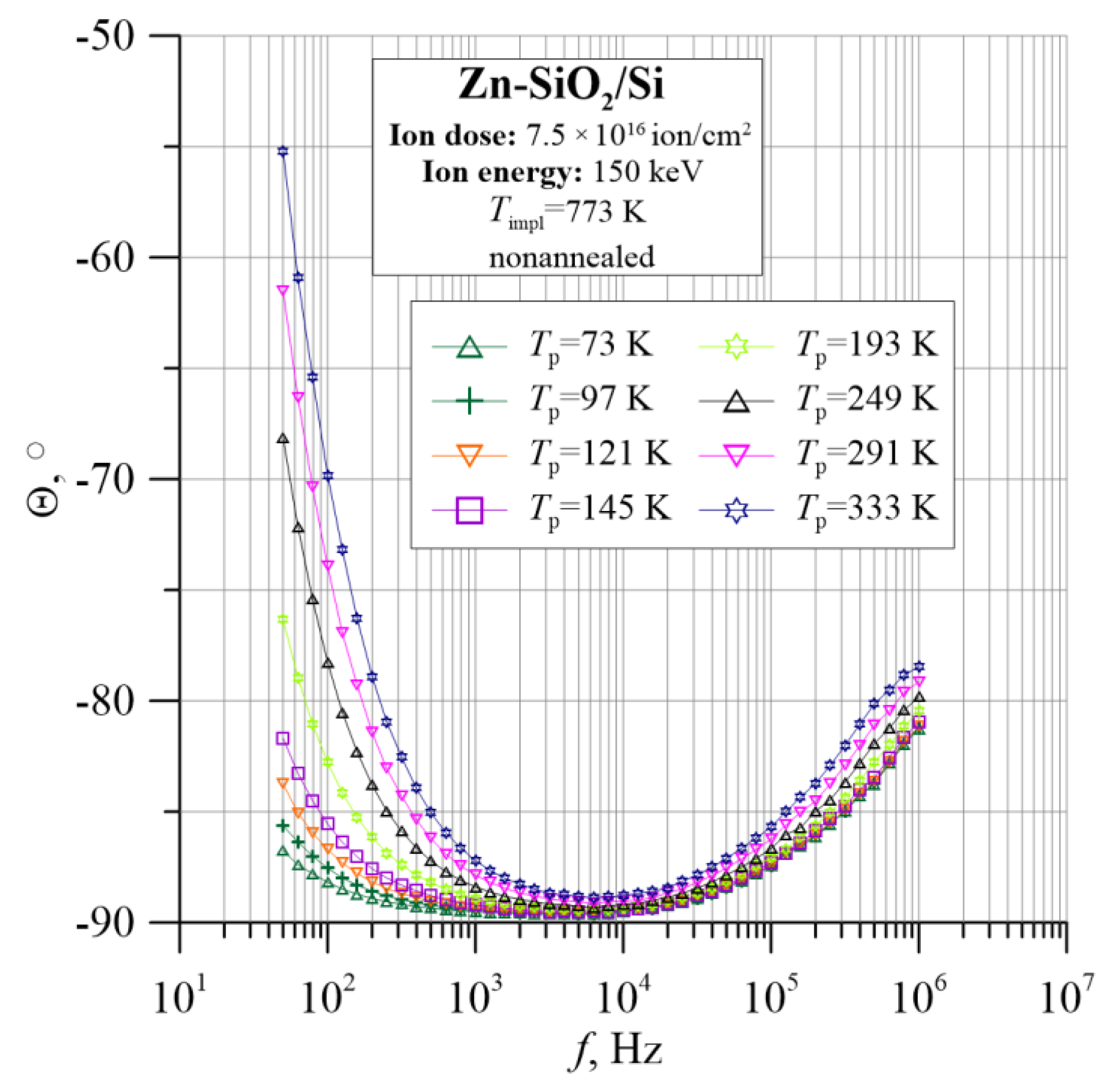

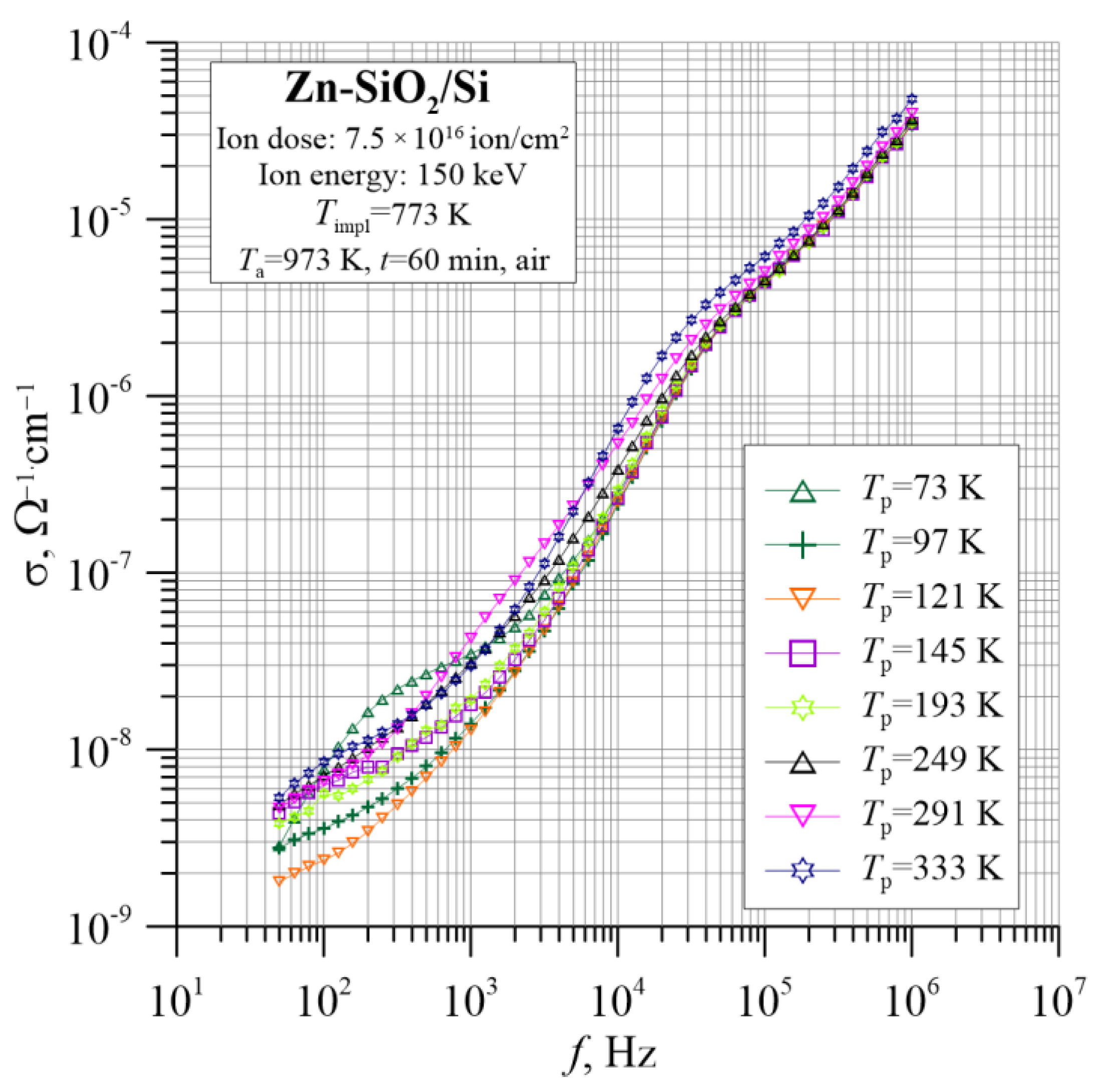

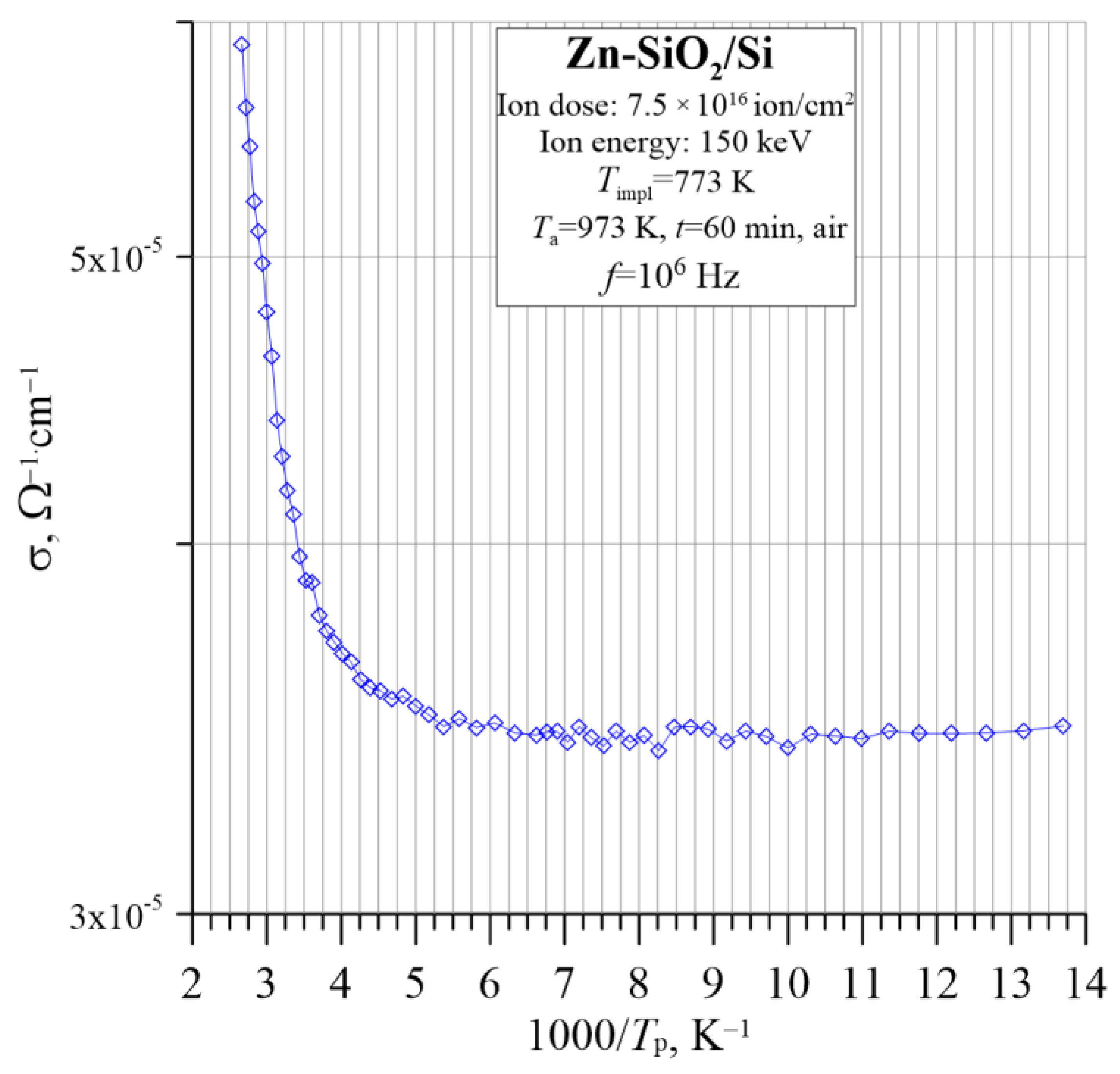

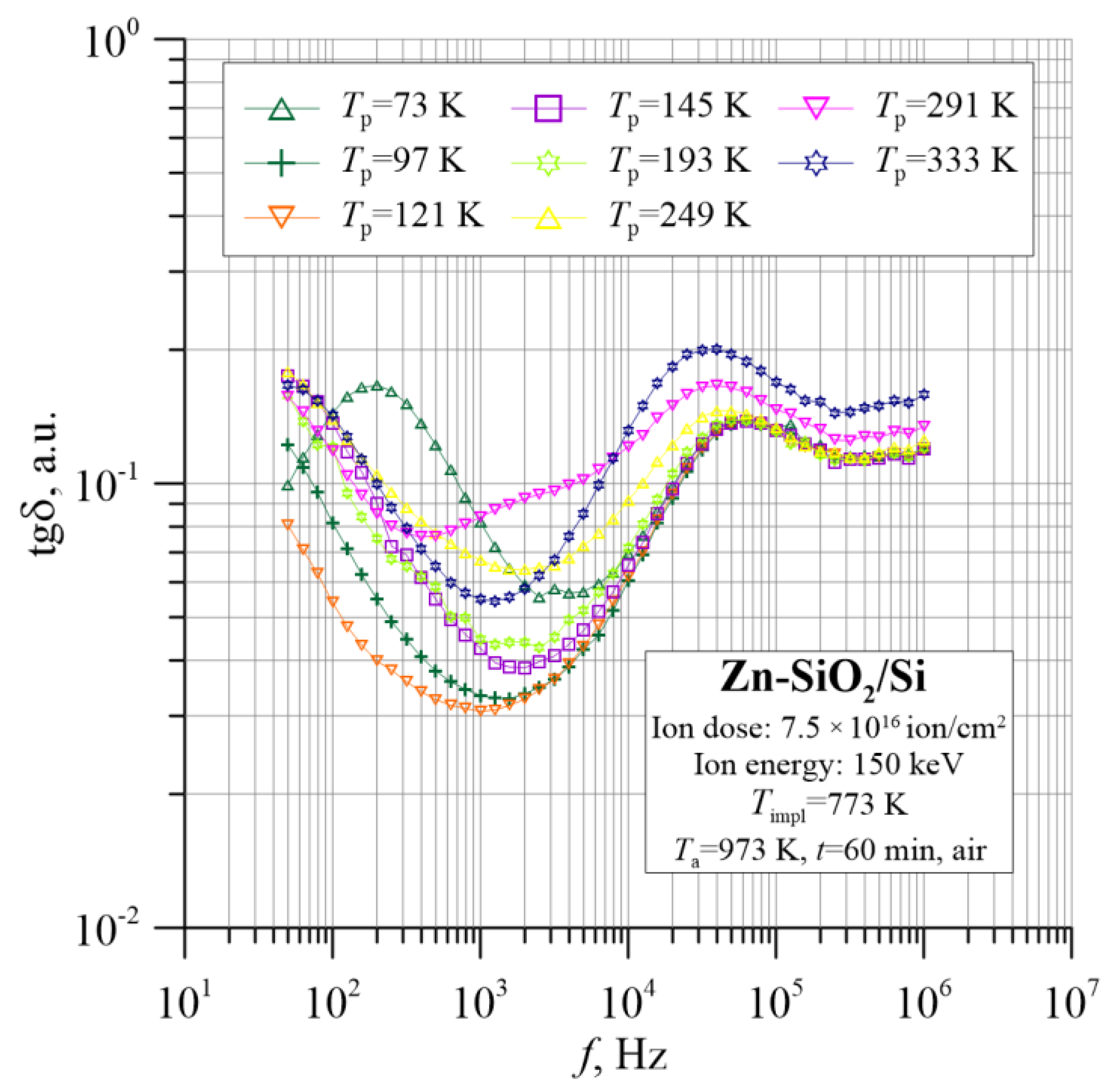

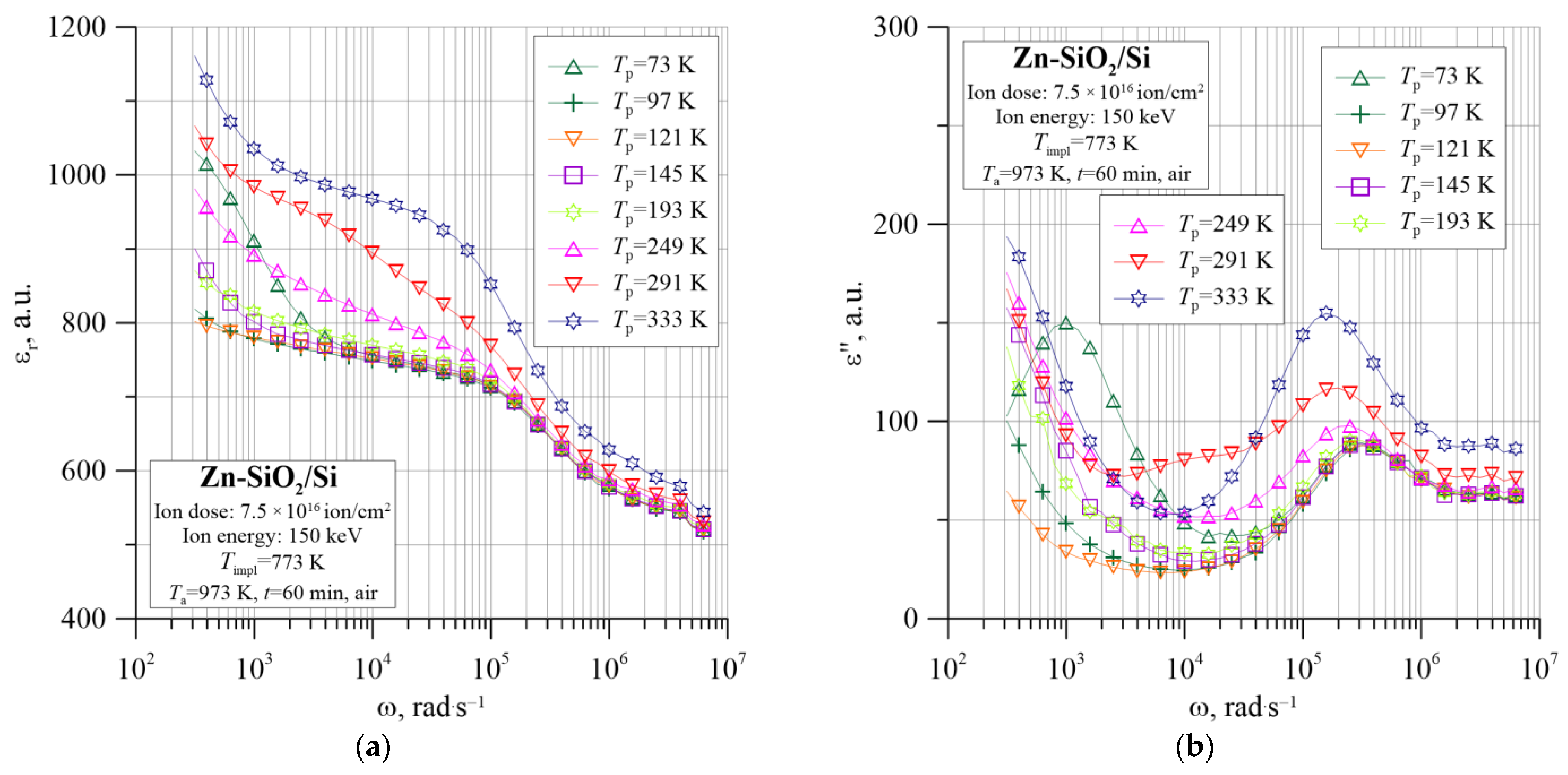

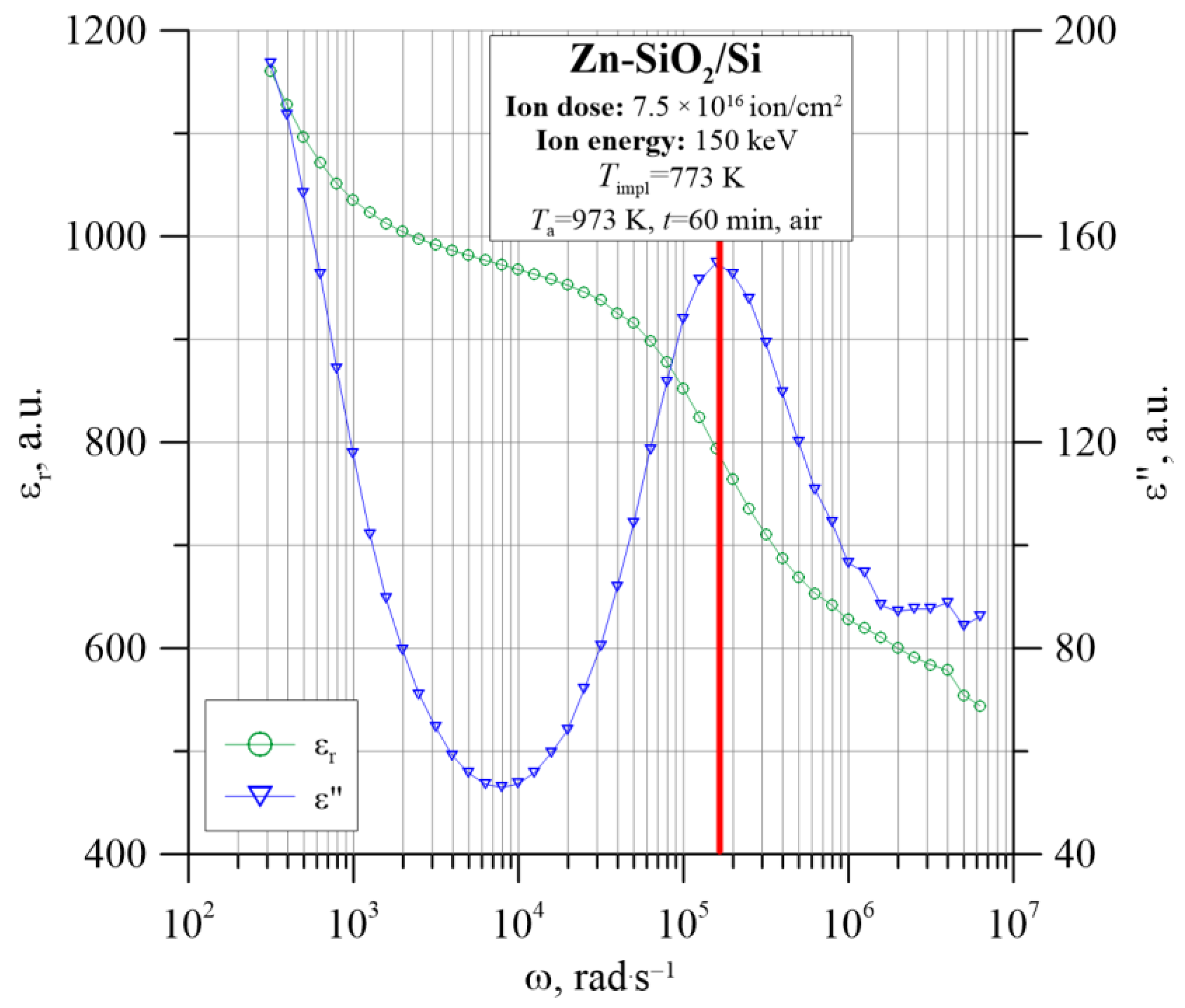

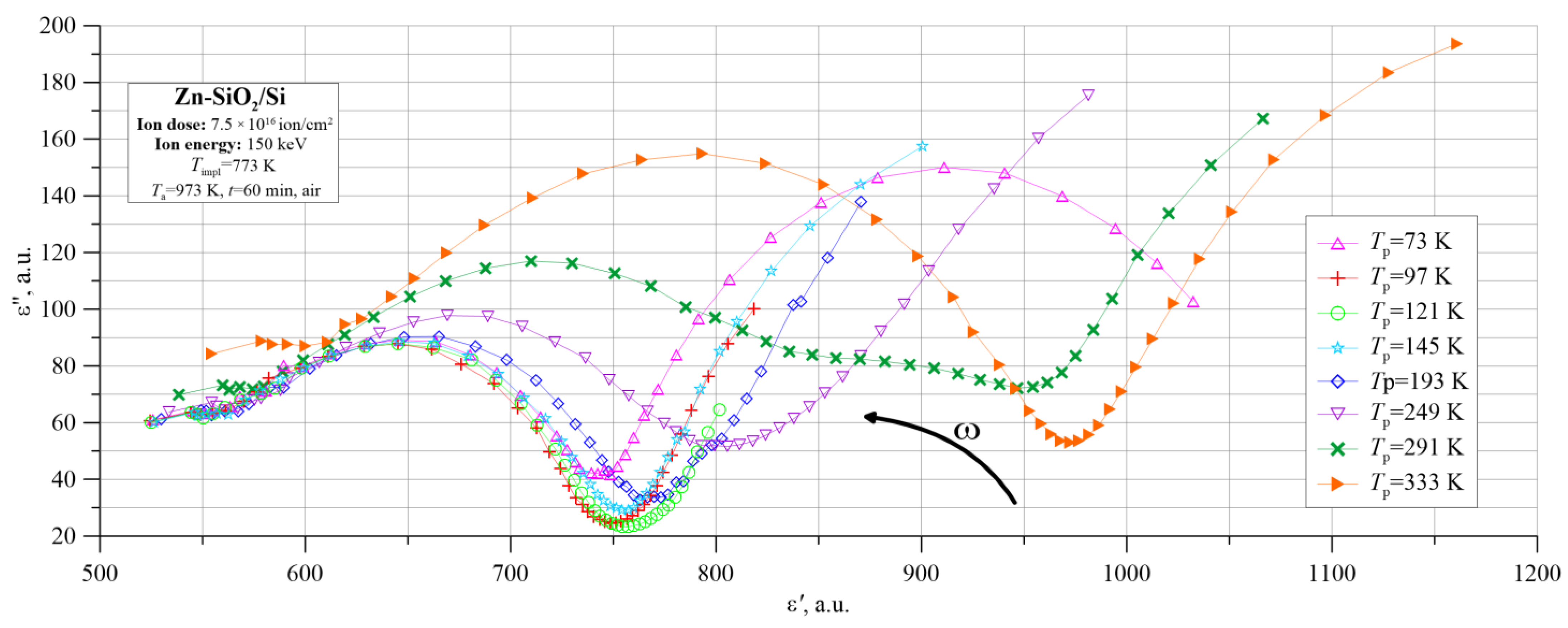

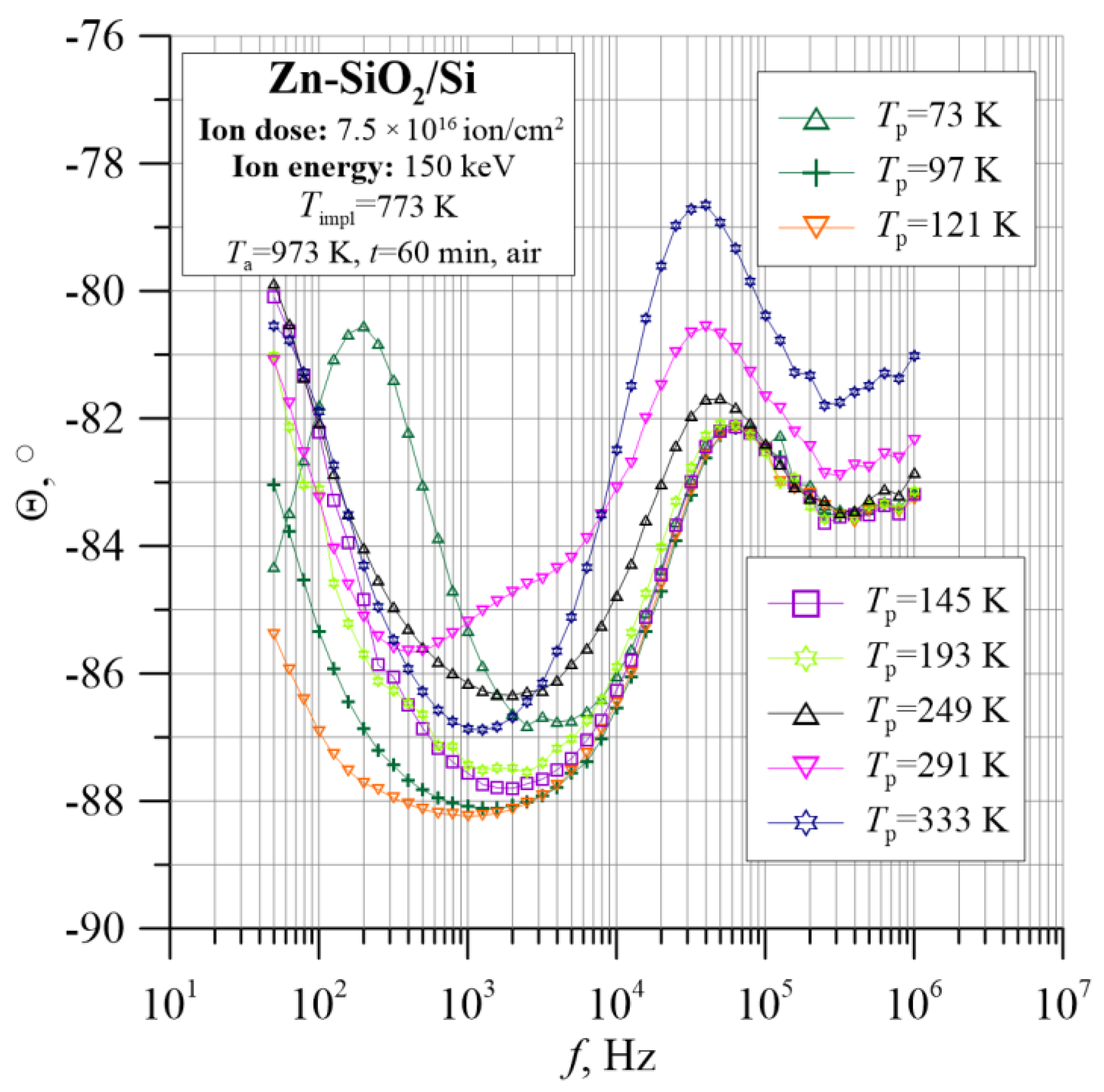

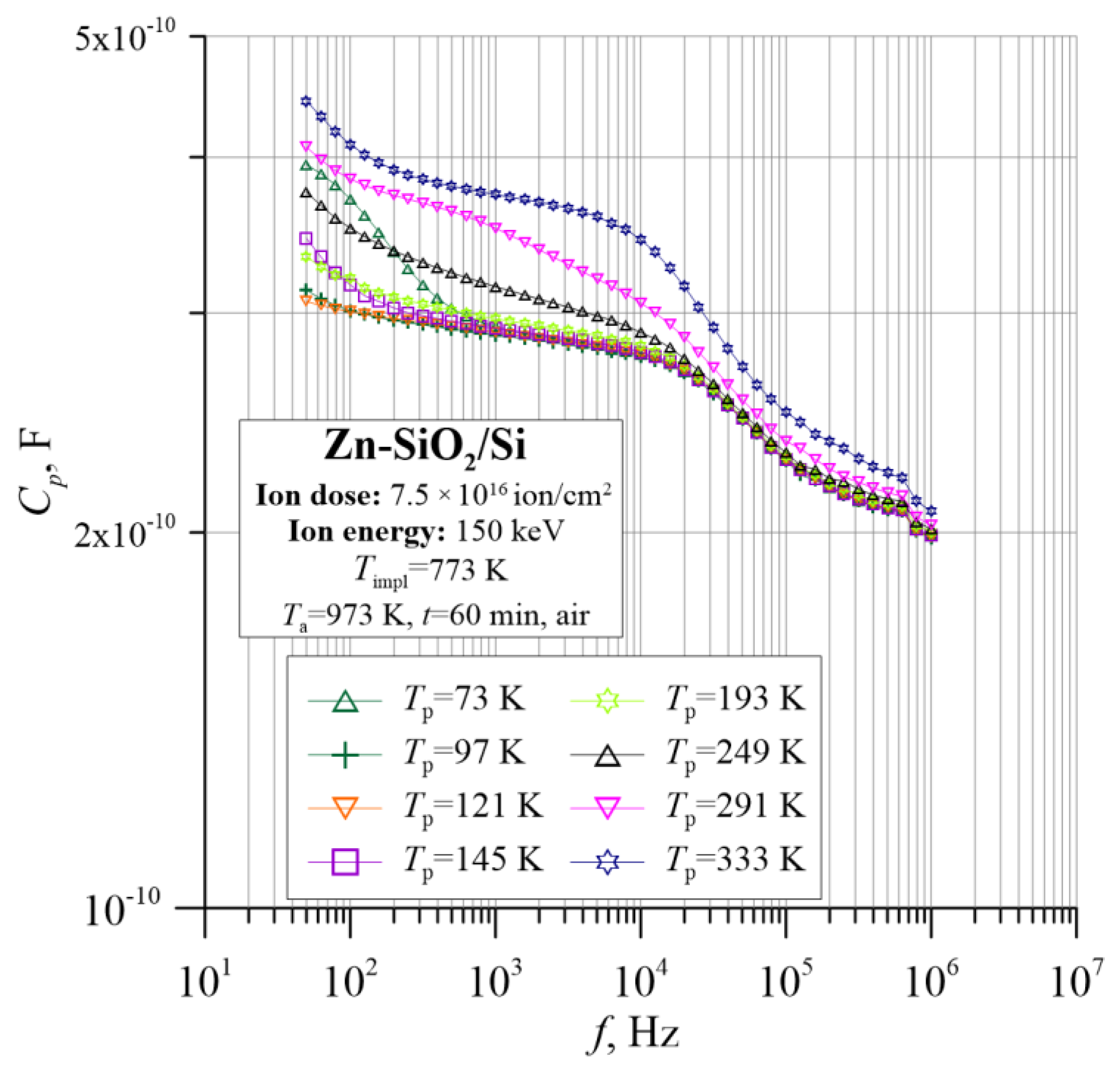

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Meldrum, A.; Boatner, L.A.; White, C.W. Nanocomposites formed by ion implantation: Recent developments and future opportunities. Nucl. Instrum. Methods Phys. Res. Sect. B Beam Interact. Mater. At. 2001, 178, 7–16. [Google Scholar] [CrossRef]

- De Julián Fernández, C.; Tagliente, M.A.; Mattei, G.; Sada, C.; Bello, V.; Maurizio, C.; Battaglin, G.; Sangregorio, C.; Gatteschi, D.; Tapfer, L.; et al. Structural and magnetic properties of Fe-Al silica composites prepared by sequential ion implantation. Nucl. Instrum. Methods Phys. Res. Sect. B Beam Interact. Mater. At. 2004, 216, 245–250. [Google Scholar] [CrossRef]

- Liu, Z.; Yang, M.; Chen, T.P.; Liu, Y.; Zhang, H.Y. Dielectric engineering of Ge nanocrystal/SiO2 nanocomposite thin films with Ge ion implantation: Modeling and measurement. Mater. Des. 2015, 83, 713–718. [Google Scholar] [CrossRef]

- Nikolova, L.; Saint-Jacques, R.G.; Dahmoune, C.; Ross, G.G. Si nanoparticle formation in SiO2 by Si ion implantation: Effect of energy and fluence on size distribution and on SiO2 composition. Surf. Coat. Technol. 2009, 203, 2501–2505. [Google Scholar] [CrossRef]

- Avril, L.; Bourgeois, S.; De Lucas, M.M.; Domenichini, B.; Simon, P.; Addou, F.; Boudon, J.; Potin, V.; Imhoff, L. Thermal stability of Au-TiO2 nanocomposite films prepared by direct liquid injection CVD. Vacuum 2015, 122, 314–320. [Google Scholar] [CrossRef]

- Ge, F.; Bai, L.; Wu, W.; Cao, L.; Wang, X.; Ma, Y.; Han, S.; Wang, H.; An, X.; Wang, H.; et al. The controllable growth of CoBaTiO3 nanocomposite epitaxial film by laser molecular beam epitaxy. J. Cryst. Growth 2010, 312, 2489–2493. [Google Scholar] [CrossRef]

- Xie, J.; Yao, M.; Gao, W.; Su, Z.; Yao, X. Significantly enhanced dielectric constant and energy density in Au/Al2O3 nanocomposite thin films. J. Alloys Compd. 2019, 772, 324–331. [Google Scholar] [CrossRef]

- Lambert, M.; May, A.; Akkan, C.K.; Agarwal, N.; Aktas, O.C. Ag-Al2O3 optical nanocomposites with narrow particle size distribution prepared by pulsed laser deposition. Mater. Lett. 2014, 137, 405–408. [Google Scholar] [CrossRef]

- Salvadori, M.C.; Teixeira, F.S.; Sgubin, L.G.; Cattani, M.; Brown, I.G. Surface modification by metal ion implantation forming metallic nanoparticles in an insulating matrix. Appl. Surf. Sci. 2014, 310, 158–163. [Google Scholar] [CrossRef]

- Amekura, H.; Kono, K.; Takeda, Y.; Kishimoto, N. Cupric oxide nanoparticles in SiO2 fabricated by copper-ion implantation combined with thermal oxidation. Appl. Phys. Lett. 2005, 87, 153105. [Google Scholar] [CrossRef]

- Zhang, X.J.; Wang, Y.H.; Chen, H.J.; Zheng, L.R. Local structure study of the Ni nanoparticles embedded in SiO2 by ion implantation. J. Alloys Compd. 2016, 654, 176–179. [Google Scholar] [CrossRef]

- Carles, R.; Farcǎu, C.; Bonafos, C.; Benassayag, G.; Pécassou, B.; Zwick, A. The synthesis of single layers of Ag nanocrystals by ultra-low-energy ion implantation for large-scale plasmonic structures. Nanotechnology 2009, 20, 355305. [Google Scholar] [CrossRef]

- Kumar, P.; Ahmad, B.; Chand, F.; Asokan, K. Magnetic and electronic structures of Co ion implanted CeO2 thin films. Appl. Surf. Sci. 2018, 452, 217–222. [Google Scholar] [CrossRef]

- Salh, R.; Kourkoutis, L.F.; Zamoryanskaya, M.V.; Schmidt, B.; Fitting, H.J. Ion implantation and cluster formation in silica. Superlattices Microstruct. 2009, 45, 362–368. [Google Scholar] [CrossRef]

- Spirin, R.E.; Salvadori, M.C.; Teixeira, F.S.; Sgubin, L.G.; Cattani, M.; Brown, I.G. Nanocomposite formed by titanium ion implantation into alumina. J. Appl. Phys. 2014, 116, 184306. [Google Scholar] [CrossRef]

- Bachiller-Perea, D.; Debelle, A.; Thomé, L.; Behar, M. Damage accumulation in MgO irradiated with MeV Au ions at elevated temperatures. J. Nucl. Mater. 2016, 478, 268–274. [Google Scholar] [CrossRef]

- Singh, J.P.; Lim, W.C.; Lee, J.; Song, J.; Lee, I.J.; Chae, K.H. Surface and local electronic structure modification of MgO film using Zn and Fe ion implantation. Appl. Surf. Sci. 2018, 432, 132–139. [Google Scholar] [CrossRef]

- Stepanov, A.L. Ion synthesis and nonlinear optical properties of metal nanoparticles. In ICONO 2010: International Conference on Coherent and Nonlinear Optics; Fabre, C., Zadkov, V., Drabovich, K., Eds.; SPIE: Bellingham, WA, USA, 2010; Volume 7993, p. 8. [Google Scholar]

- Shen, Y.; He, W.; Zhang, D.; Zhang, X.; Xue, Y.; Liu, C. Creation of nanoparticles and luminescence in Al2O3 crystal by Zn ion implantation. J. Lumin. 2011, 131, 2725–2729. [Google Scholar] [CrossRef]

- Zatsepin, D.A.; Zatsepin, A.F.; Boukhvalov, D.W.; Kurmaev, E.Z.; Pchelkina, Z.V.; Gavrilov, N.V. Electronic structure and photoluminescence properties of Zn-ion implanted silica glass before and after thermal annealing. J. Non-Cryst. Solids 2016, 432, 183–188. [Google Scholar] [CrossRef] [Green Version]

- Gefle, O.S.; Lebedev, S.M.; Pokholkov, Y.P.; Tkachenko, S.N.; Volokhin, V.A.; Cherkashina, E.I. Study of dielectric relaxation spectra of composite materials by the dielectric spectroscopy method. In Proceedings of the 2005 International Symposium on Electrical Insulating Materials, Kitakyushu, Japan, 5–9 June 2005; pp. 85–87. [Google Scholar]

- Zukowski, P.; Koltunowicz, T.N.; Czarnacka, K.; Fedotov, A.K.; Tyschenko, I.E. Carrier transport and dielectric permittivity of SiO2 films containing ion-beam synthesized InSb nanocrystals. J. Alloys Compd. 2020, 846, 156482. [Google Scholar] [CrossRef]

- Koltunowicz, T.N.; Zukowski, P.; Czarnacka, K.; Bondariev, V.; Boiko, O.; Svito, I.A.; Fedotov, A.K. Dielectric properties of nanocomposite (Cu)x(SiO2)(100−x) produced by ion-beam sputtering. J. Alloys Compd. 2015, 652, 444–449. [Google Scholar] [CrossRef]

- Zukowski, P.; Kołtunowicz, T.; Partyka, J.; Fedotova, Y.A.; Larkin, A.V. Electrical properties of nanostructures (CoFeZr)x + (Al2O3)1−x with use of alternating current. Vacuum 2009, 83, S275–S279. [Google Scholar] [CrossRef]

- Zhukowski, P.; Kołtunowicz, T.N.; Fedotova, J.A.; Larkin, A.V. An effect of annealing on electric properties of nanocomposites (CoFeZr)x(Al2O3)1−x produced by magnetron sputtering in the atmosphere of argon and oxygen beyond the percolation threshold. Prz. Elektrotech. 2010, 86, 157–159. [Google Scholar]

- Koltunowicz, T.N.; Zhukowski, P.; Bondariev, V.; Saad, A.; Fedotova, J.A.; Fedotov, A.K.; Milosavljević, M.; Kasiuk, J.V. Enhancement of negative capacitance effect in (CoFeZr)x(CaF2)(100−x) nanocomposite films deposited by ion beam sputtering in argon and oxygen atmosphere. J. Alloys Compd. 2015, 615, S361–S365. [Google Scholar] [CrossRef]

- Koltunowicz, T.N. Inductive type properties of FeCoZr–CaF2 and FeCoZr–PZT nanocomposites. J. Mater. Sci.-Mater. Electron. 2015, 26, 6450–6457. [Google Scholar] [CrossRef] [Green Version]

- Koltunowicz, T.N.; Zukowski, P.; Boiko, O.; Saad, A.; Fedotova, J.A.; Fedotov, A.K.; Larkin, A.V.; Kasiuk, J. AC Hopping Conductance in Nanocomposite Films with Ferromagnetic Alloy Nanoparticles in a PbZrTiO3 Matrix. J. Electron. Mater. 2015, 44, 2260–2268. [Google Scholar] [CrossRef] [Green Version]

- Koltunowicz, T.N. Dielectric Properties of (CoFeZr)(x)(PZT)(100−x) Nanocomposites Produced with a Beam of Argon and Oxygen Ions. Acta Phys. Pol. A 2014, 125, 1412–1414. [Google Scholar] [CrossRef]

- Svito, I.; Fedotov, A.K.; Koltunowicz, T.N.; Zukowski, P.; Kalinin, Y.; Sitnikov, A.; Czarnacka, K.; Saad, A. Hopping of electron transport in granular Cux(SiO2)1−x nanocomposite films deposited by ion-beam sputtering. J. Alloys Compd. 2015, 615, S371–S374. [Google Scholar] [CrossRef]

- Mayer, M. SIMNRA User’s Guide; Max-Planck-Institute fur Plasmaphysik: Garching, Germany, 1997. [Google Scholar]

- Koltunowicz, T.N. Measurement Station for Frequency Dielectric Spectroscopy of Nanocomposites and Semiconductors. J. Appl. Spectrosc. 2015, 82, 653–658. [Google Scholar] [CrossRef]

- Biersack, J.P.; Ziegler, J.F. The Stopping and Range of Ions in Solids; Springer: Berlin, Germany, 1982. [Google Scholar]

- Zukowski, P.; Kołtunowicz, T.; Partyka, J.; Fedotova, Y.A.; Larkin, A.V. Hopping conductivity of metal-dielectric nanocomposites produced by means of magnetron sputtering with the application of oxygen and argon ions. Vacuum 2009, 83, S280–S283. [Google Scholar] [CrossRef]

- Abeles, B.; Sheng, P.; Coutts, M.D.; Arie, Y. Structural and electrical properties of granular metal films. Adv. Phys. 1975, 24, 407–461. [Google Scholar] [CrossRef]

- Sankar, S.; Berkowitz, A.E.; Smith, D.J. Spin-dependent transport of Co-SiO2 granular films approaching percolation. Phys. Rev. B-Condens. Matter Mater. Phys. 2000, 64, 14273. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kołtunowicz, T.N.; Czarnacka, K.; Gałaszkiewicz, P.; Komarov, F.F.; Makhavikou, M.A.; Milchanin, O.V. Influence of Annealing on the Dielectric Properties of Zn-SiO2/Si Nanocomposites Obtained in “Hot” Implantation Conditions. Nanomaterials 2022, 12, 3449. https://doi.org/10.3390/nano12193449

Kołtunowicz TN, Czarnacka K, Gałaszkiewicz P, Komarov FF, Makhavikou MA, Milchanin OV. Influence of Annealing on the Dielectric Properties of Zn-SiO2/Si Nanocomposites Obtained in “Hot” Implantation Conditions. Nanomaterials. 2022; 12(19):3449. https://doi.org/10.3390/nano12193449

Chicago/Turabian StyleKołtunowicz, Tomasz N., Karolina Czarnacka, Piotr Gałaszkiewicz, Fadei F. Komarov, Maxim A. Makhavikou, and Oleg V. Milchanin. 2022. "Influence of Annealing on the Dielectric Properties of Zn-SiO2/Si Nanocomposites Obtained in “Hot” Implantation Conditions" Nanomaterials 12, no. 19: 3449. https://doi.org/10.3390/nano12193449