Combining Azimuthal and Polar Angle Resolved Shadow Mask Deposition and Nanosphere Lithography to Uncover Unique Nano-Crystals

Abstract

:1. Introduction

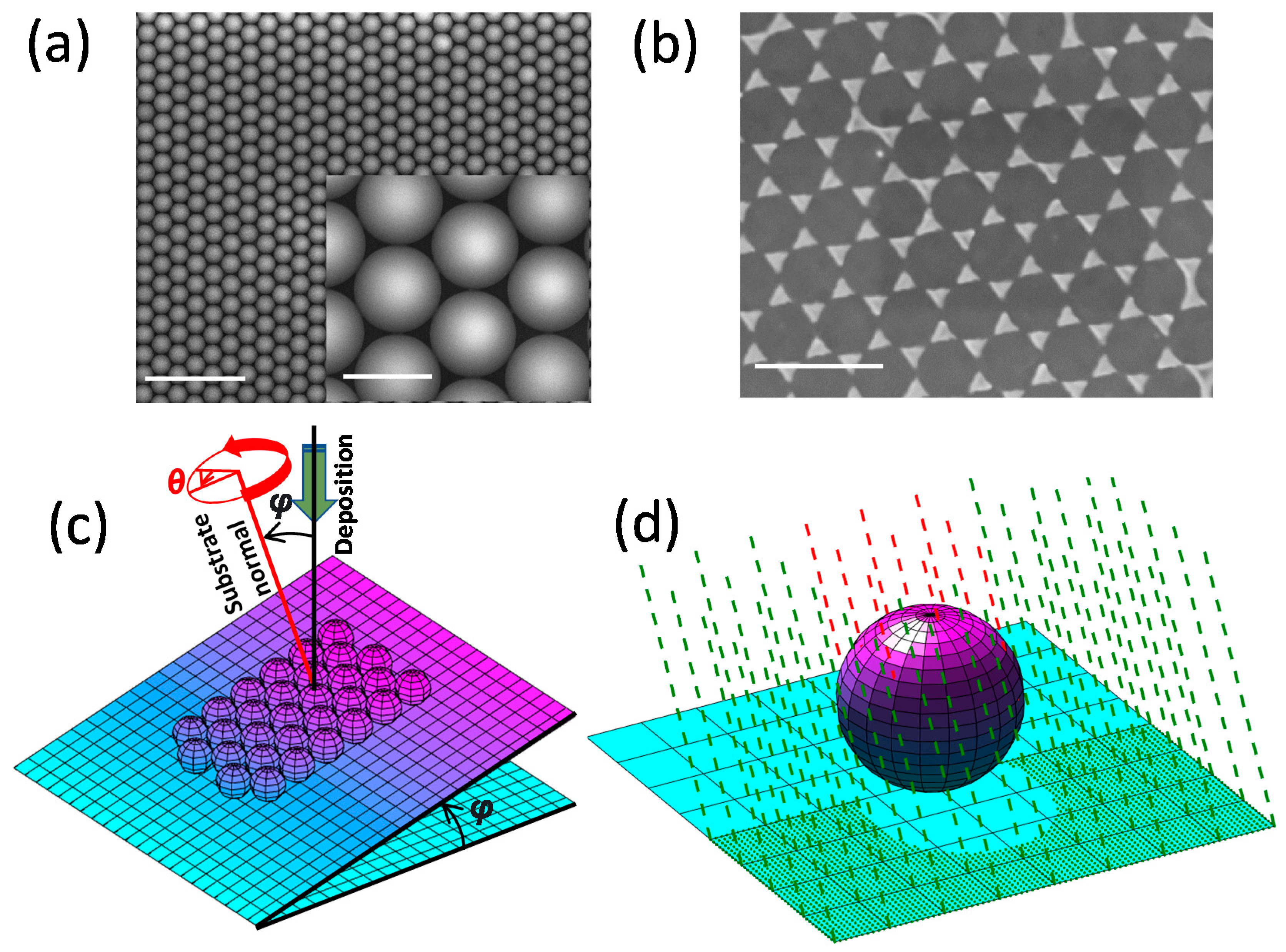

2. Methods

2.1. Experimental

2.2. Simulation

3. Results

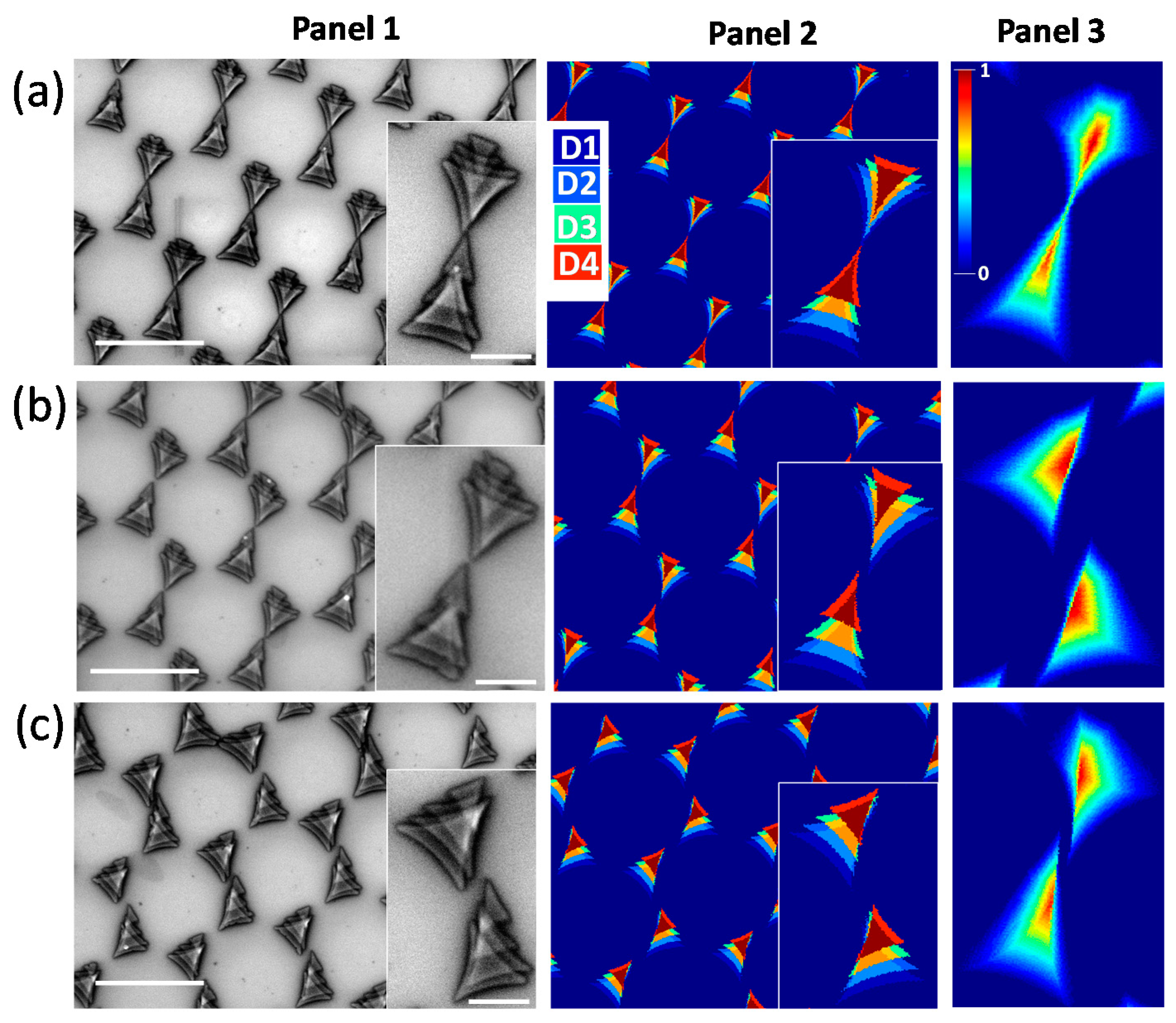

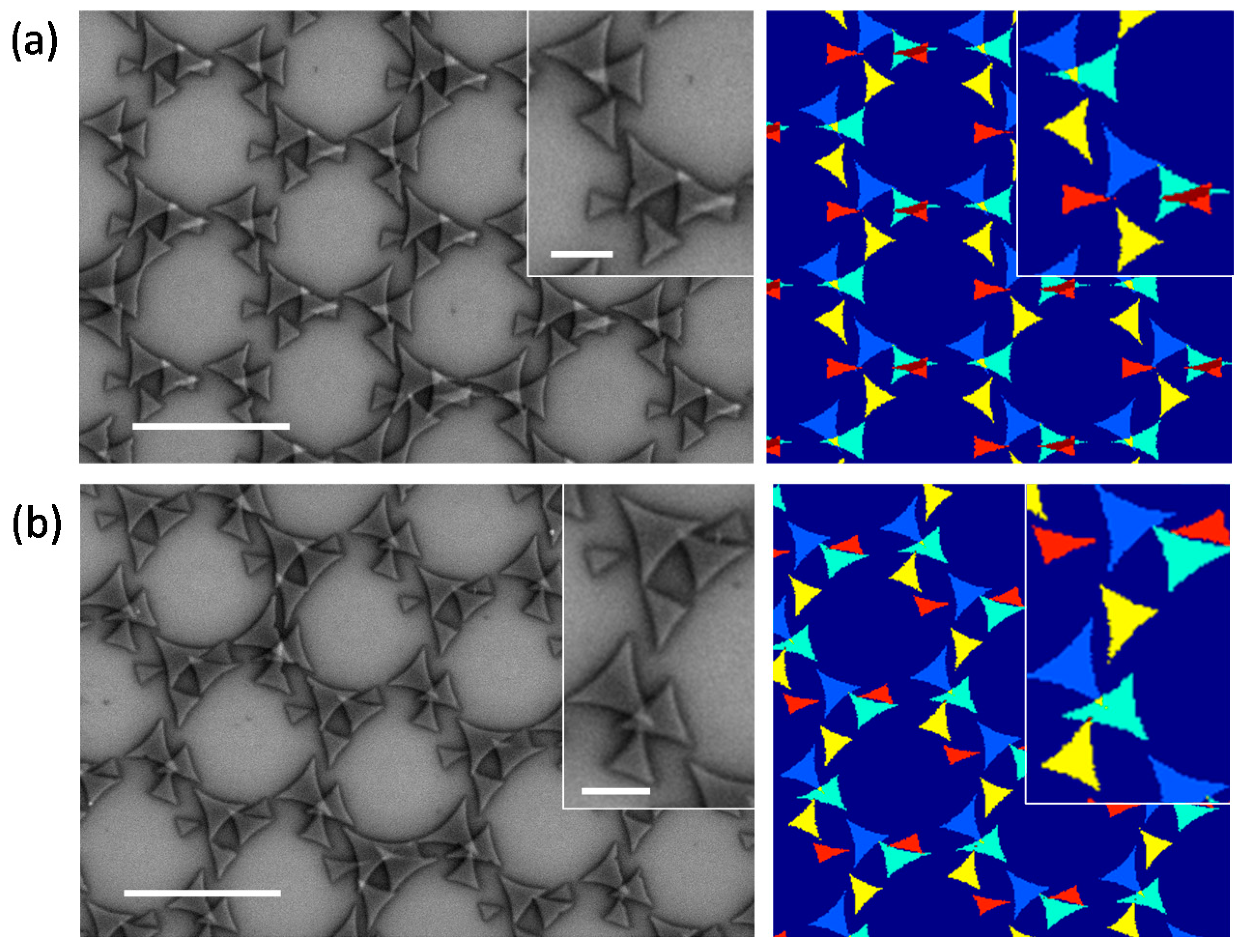

3.1. Variation of Tilt without Azimuthal Rotation

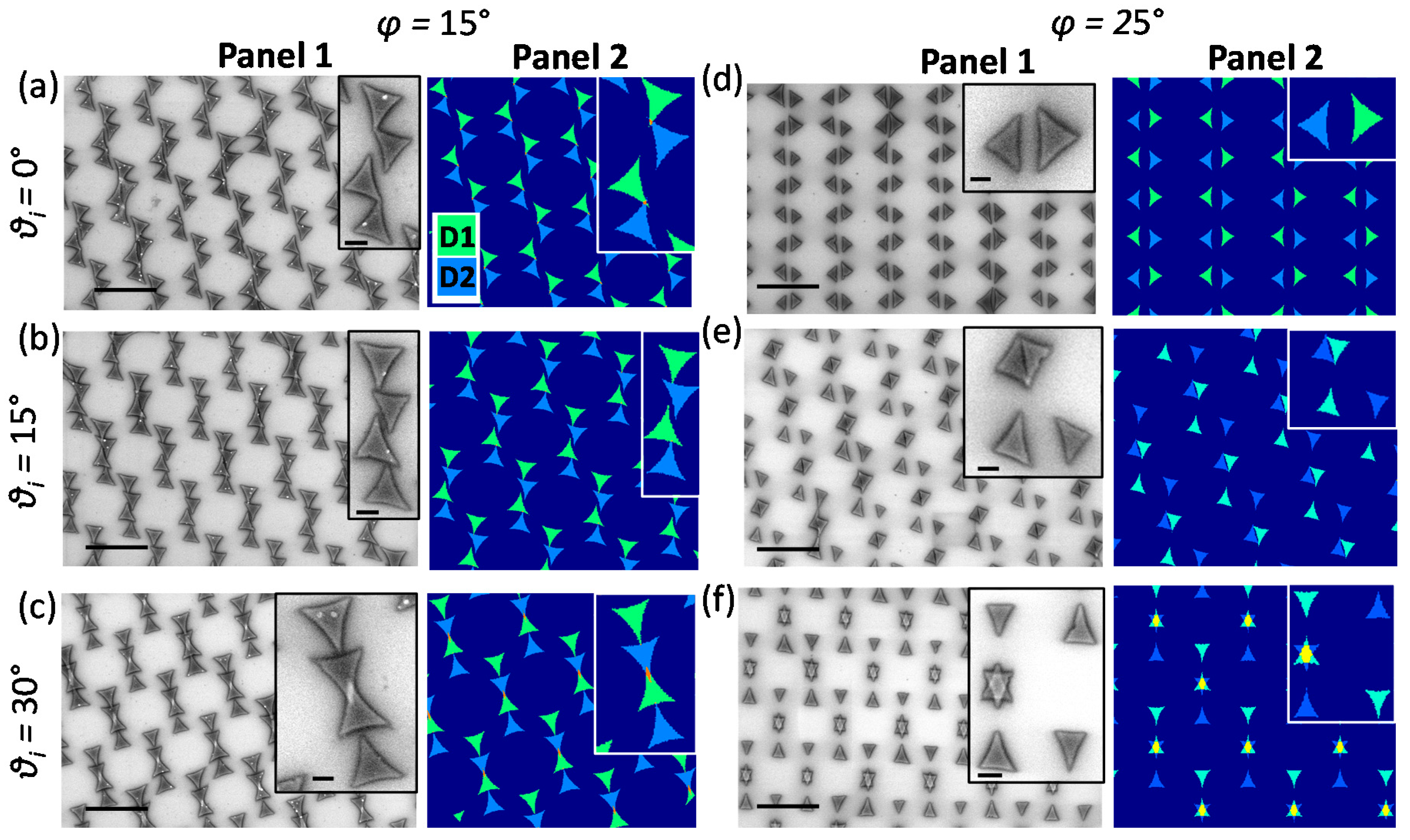

3.2. Variation of Azimuthal Angle at a Constant Tilt

3.2.1. Two-Fold Symmetry

3.2.2. Four-Fold Symmetry

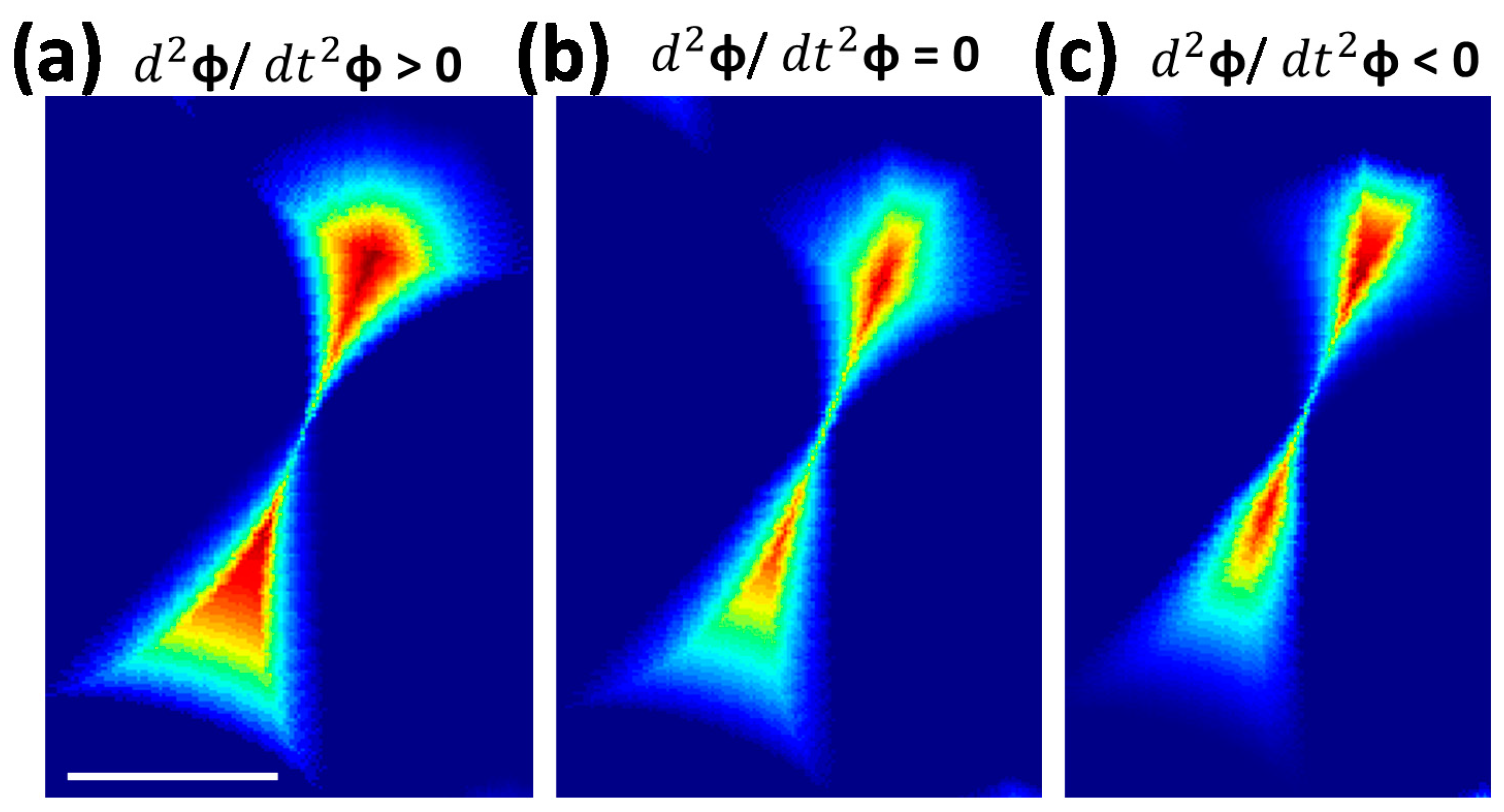

3.3. Simultaneous Variation of Azimuthal Angle Tilt

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Chou Chau, Y.-F.; Chen, K.-H.; Chiang, H.-P.; Lim, C.M.; Huang, H.J.; Lai, C.-H.; Kumara, N. Fabrication and Characterization of a Metallic–Dielectric Nanorod Array by Nanosphere Lithography for Plasmonic Sensing Application. Nanomaterials 2019, 9, 1691. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Li, J.; Hu, Y.; Yu, L.; Li, L.; Ji, D.; Li, L.; Hu, W.; Fuchs, H. Recent Advances of Nanospheres Lithography in Organic Electronics. Small 2021, 17, 2100724. [Google Scholar] [CrossRef] [PubMed]

- Waegner, M. Nanosphere Lithography. In Bio and Nano Packaging Techniques for Electron Devices: Advances in Electronic Device Packaging; Gerlach, G., Wolter, K.-J., Eds.; Springer: Berlin/Heidelberg, 2012; pp. 269–277. ISBN 978-3-642-28522-6. [Google Scholar]

- Fang, X.; Zheng, C.; Yin, Z.; Wang, Z.; Wang, J.; Liu, J.; Luo, D.; Liu, Y.J. Hierarchically Ordered Silicon Metastructures from Improved Self-Assembly-Based Nanosphere Lithography. ACS Appl. Mater. Interfaces 2020, 12, 12345–12352. [Google Scholar] [CrossRef] [PubMed]

- Qiu, T.; Akinoglu, E.M.; Luo, B.; Konarova, M.; Yun, J.-H.; Gentle, I.R.; Wang, L. Nanosphere Lithography: A Versatile Approach to Develop Transparent Conductive Films for Optoelectronic Applications. Adv. Mater. 2022, 34, 2103842. [Google Scholar] [CrossRef]

- Winzer, M.; Kleiber, M.; Dix, N.; Wiesendanger, R. Fabrication of Nano-Dot-and Nano-Ring-Arrays by Nanosphere Lithography. Appl. Phys. A 1996, 63, 617–619. [Google Scholar] [CrossRef]

- Semenova, E.; Montoncello, F.; Tacchi, S.; Dürr, G.; Sirotkin, E.; Ahmad, E.; Madami, M.; Gubbiotti, G.; Neusser, S.; Grundler, D. Magnetodynamical Response of Large-Area Close-Packed Arrays of Circular Dots Fabricated by Nanosphere Lithography. Phys. Rev. B 2013, 87, 174432. [Google Scholar] [CrossRef] [Green Version]

- Darvill, D.; Iarossi, M.; Ekeroth, R.M.A.; Hubarevich, A.; Huang, J.-A.; De Angelis, F. Breaking the Symmetry of Nanosphere Lithography with Anisotropic Plasma Etching Induced by Temperature Gradients. Nanoscale Adv. 2021, 3, 359–369. [Google Scholar] [CrossRef]

- Myint, B.; Yap, D.S.F.; Ng, V. Stepwise Nanosphere Lithography: An Alternate Way of Fabricating Nanostructures. Nano Exp. 2020, 1, 020029. [Google Scholar] [CrossRef]

- Zhao, Y.; Chi, Y.; Hong, Y.; Li, Y.; Yang, S.; Yin, J. Twisting for Soft Intelligent Autonomous Robot in Unstructured Environments. Proc. Natl. Acad. Sci. USA 2022, 119, e2200265119. [Google Scholar] [CrossRef]

- Dang, A.; Wang, Y.; Zhang, H.; Panatdasirisuk, W.; Xia, Y.; Wang, Z.; Jariwala, D.; Li, T.; Yang, S. Electrospun Gold Nanoprism/Poly (vinyl alcohol) Nanofibers for Flexible and Free-Standing Surface-Enhanced Raman Scattering Substrates. ACS Appl. Nano Mater. 2022, 5, 6650–6658. [Google Scholar] [CrossRef]

- Chirumamilla, M.; Toma, A.; Gopalakrishnan, A.; Das, G.; Zaccaria, R.P.; Krahne, R.; Rondanina, E.; Leoncini, M.; Liberale, C.; De Angelis, F. 3D Nanostar Dimers with a Sub-10-nm Gap for Single-/Few-Molecule Surface-Enhanced Raman Scattering. Adv. Mater. 2014, 26, 2353–2358. [Google Scholar] [CrossRef] [PubMed]

- Langer, J.; Jimenez de Aberasturi, D.; Aizpurua, J.; Alvarez-Puebla, R.A.; Auguié, B.; Baumberg, J.J.; Bazan, G.C.; Bell, S.E.J.; Boisen, A.; Brolo, A.G.; et al. Present and Future of Surface-Enhanced Raman Scattering. ACS Nano 2020, 14, 28–117. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Cecchini, M.P.; Turek, V.A.; Paget, J.; Kornyshev, A.A.; Edel, J.B. Self-Assembled Nanoparticle Arrays for Multiphase Trace Analyte Detection. Nat. Mater. 2013, 12, 165–171. [Google Scholar] [CrossRef] [Green Version]

- Das, G.; Mecarini, F.; Gentile, F.; De Angelis, F.; Mohan Kumar, H.G.; Candeloro, P.; Liberale, C.; Cuda, G.; Di Fabrizio, E. Nano-patterned SERS substrate: Application for protein analysis vs. temperature. Biosens. Bioelectron. 2009, 24, 1693–1699. [Google Scholar] [CrossRef]

- Mahato, B.; Choudhury, S.; Mandal, R.; Barman, S.; Otani, Y.; Barman, A. Tunable Configurational Anisotropy In Collective Magnetization Dynamics of Ni80Fe20 Nanodot Arrays With Varying Dot Shapes. J. Appl. Phys. 2015, 117, 213909. [Google Scholar] [CrossRef] [Green Version]

- Imperia, P.; Kandulski, W.; Kosiorek, A.; Głaczyńska, H.; Maletta, H.; Giersig, M. Magnetic Anisotropy Study of Triangular-Shaped Co Nanostructures. J. Magn. Magn. Mater. 2008, 320, 2682–2687. [Google Scholar] [CrossRef]

- Donnelly, C.; Finizio, S.; Gliga, S.; Holler, M.; Hrabec, A.; Odstrčil, M.; Mayr, S.; Scagnoli, V.; Heyderman, L.J.; Guizar-Sicairos, M.; et al. Time-Resolved Imaging of Three-Dimensional Nanoscale Magnetization Dynamics. Nat. Nanotechnol. 2020, 15, 356–360. [Google Scholar] [CrossRef] [PubMed]

- Caso, D.; Aliev, F.G. Edge Spin Wave Transmission Through a Vertex Domain Wall in Triangular Dots. SN Appl. Sci. 2022, 4, 188. [Google Scholar] [CrossRef]

- da Silva, J.; Guerra, Y.; Padrón-Hernández, E. Simulations of FMR for Study the Shape Anisotropy in Square Hollow Nanopillars. J. Magn. Magn. Mater. 2022, 544, 168642. [Google Scholar] [CrossRef]

- Jin, C.; Li, S.; Zhang, H.; Wang, R.; Wang, J.; Lian, R.; Gong, P.; Shi, X. Spin-Wave Modes of Elliptical Skyrmions in Magnetic Nanodots. New J. Phys. 2022, 24, 043005. [Google Scholar] [CrossRef]

- Hicks, E.M.; Zhang, X.; Zou, S.; Lyandres, O.; Spears, K.G.; Schatz, G.C.; Van Duyne, R.P. Plasmonic Properties of Film over Nanowell Surfaces Fabricated by Nanosphere Lithography. J. Phys. Chem. B 2005, 109, 22351–22358. [Google Scholar] [CrossRef] [PubMed]

- Jensen, T.R.; Malinsky, M.D.; Haynes, C.L.; Van Duyne, R.P. Nanosphere Lithography: Tunable Localized Surface Plasmon Resonance Spectra of Silver Nanoparticles. J. Phys. Chem. B 2000, 104, 10549–10556. [Google Scholar] [CrossRef]

- Zhao, J.; Zhang, C.; Braun, P.V.; Giessen, H. Large-Area Low-Cost Plasmonic Nanostructures in the NIR for Fano Resonant Sensing. Adv. Mater. 2012, 24, OP247–OP252. [Google Scholar] [CrossRef] [PubMed]

- Rahaman, M.; Moras, S.; He, L.; Madeira, T.I.; Zahn, D.R. Fine-Tuning of Localized Surface Plasmon Resonance of Metal Nanostructures from Near-Infrared to Blue Prepared by Nanosphere Lithography. J. Appl. Phys. 2020, 128, 233104. [Google Scholar] [CrossRef]

- Lu, Y.-C.; Hsueh, C.-H. Fabrication of Periodic Ag Tetrahedral Nanopyramids via H2O2-Assisted Nanosphere Lithography for Plasmonic Applications. Colloids Surf. A Physicochem. Eng. Asp. 2021, 628, 127278. [Google Scholar] [CrossRef]

- Tiberto, P.; Barrera, G.; Celegato, F.; Conta, G.; Coisson, M.; Vinai, F.; Albertini, F. Ni80Fe20 Nanodisks by Nanosphere Lithography for Biomedical Applications. J. Appl. Phys. 2015, 117, 17B304. [Google Scholar] [CrossRef] [Green Version]

- Montoncello, F.; Tacchi, S.; Giovannini, L.; Madami, M.; Gubbiotti, G.; Carlotti, G.; Sirotkin, E.; Ahmad, E.; Ogrin, F.; Kruglyak, V. Asymmetry of Spin Wave Dispersions in a Hexagonal Magnonic Crystal. Appl. Phys. Lett. 2013, 102, 202411. [Google Scholar] [CrossRef]

- Manzin, A.; Barrera, G.; Celegato, F.; Coïsson, M.; Tiberto, P. Influence of Lattice Defects on the Ferromagnetic Resonance Behaviour of 2D Magnonic Crystals. Sci. Rep. 2016, 6, 22004. [Google Scholar] [CrossRef] [Green Version]

- Krupiński, M.; Zabila, Y.; Marszalek, M. Nanopatterned Thin Films with Perpendicular Magnetic Anisotropy–Structure and Magnetism. In Modern Magnetic and Spintronic Materials; Springer: New York, NY, USA, 2020; pp. 47–71. ISBN 978-94-024-2034-0. [Google Scholar]

- Dai, Z.; Li, Y.; Duan, G.; Jia, L.; Cai, W. Phase Diagram, Design of Monolayer Binary Colloidal Crystals, and Their Fabrication Based on Ethanol-Assisted Self-Assembly at the Air/Water Interface. ACS Nano 2012, 6, 6706–6716. [Google Scholar] [CrossRef]

- Burtsev, V.; Marchuk, V.; Kugaevskiy, A.; Guselnikova, O.; Elashnikov, R.; Miliutina, E.; Postnikov, P.; Svorcik, V.; Lyutakov, O. Hydrophilic/Hydrophobic Surface Modification Impact on Colloid Lithography: Schottky-Like Defects, Dislocation, and Ideal Distribution. Appl. Surf. Sci. 2018, 433, 443–448. [Google Scholar] [CrossRef]

- Chen, L.; He, X.; Liu, H.; Qian, L.; Kim, S.H. Water Adsorption on Hydrophilic and Hydrophobic Surfaces of Silicon. J. Phys. Chem. C 2018, 122, 11385–11391. [Google Scholar] [CrossRef]

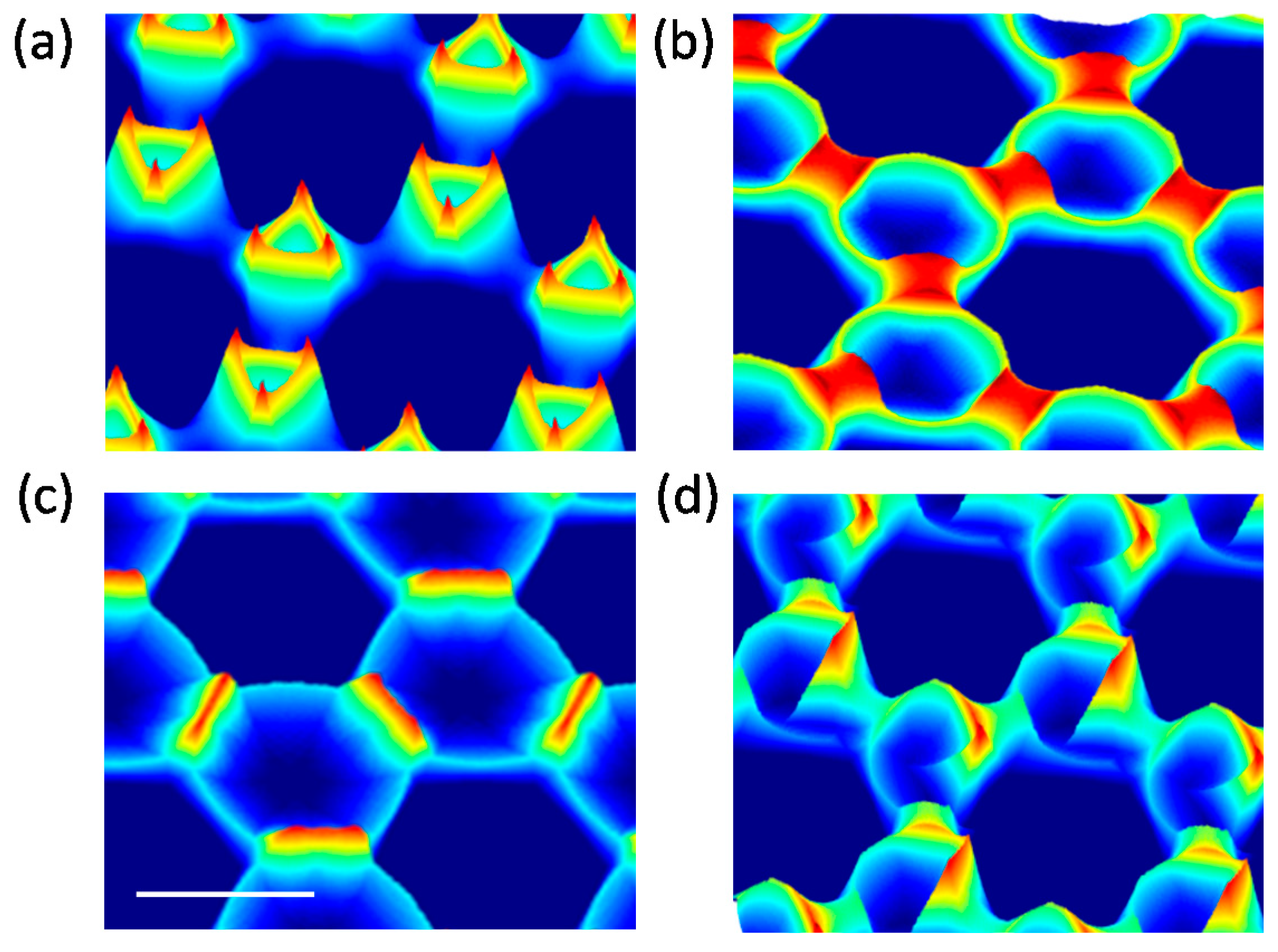

| Figure | Method | θ | φ |

|---|---|---|---|

| Figure 5a | Experiment | 15, 105, 195, 285° | 25° |

| Figure 5b | Simulation | 15, 195° | 25° |

| Figure 5c | Simulation | 105, 285° | 25° |

| Figure 5d | Simulation | 15, 105, 195, 285° | 25° |

| Figure 5e | Experiment | 355, 85, 175, 265° | 25° |

| Figure 5f | Simulation | 355, 175° | 25° |

| Figure 5g | Simulation | 85, 265° | 25° |

| Figure 5h | Simulation | 355, 85, 175, 265° | 25° |

| Figure 5i | Experiment | 0, 90° | 25° |

| Figure 5j | Simulation | 0, 90° | 25° |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ganguly, A.; Das, G. Combining Azimuthal and Polar Angle Resolved Shadow Mask Deposition and Nanosphere Lithography to Uncover Unique Nano-Crystals. Nanomaterials 2022, 12, 3464. https://doi.org/10.3390/nano12193464

Ganguly A, Das G. Combining Azimuthal and Polar Angle Resolved Shadow Mask Deposition and Nanosphere Lithography to Uncover Unique Nano-Crystals. Nanomaterials. 2022; 12(19):3464. https://doi.org/10.3390/nano12193464

Chicago/Turabian StyleGanguly, Arnab, and Gobind Das. 2022. "Combining Azimuthal and Polar Angle Resolved Shadow Mask Deposition and Nanosphere Lithography to Uncover Unique Nano-Crystals" Nanomaterials 12, no. 19: 3464. https://doi.org/10.3390/nano12193464

APA StyleGanguly, A., & Das, G. (2022). Combining Azimuthal and Polar Angle Resolved Shadow Mask Deposition and Nanosphere Lithography to Uncover Unique Nano-Crystals. Nanomaterials, 12(19), 3464. https://doi.org/10.3390/nano12193464