Preparation and Gas Sensing Properties of Hair-Based Carbon Sheets

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

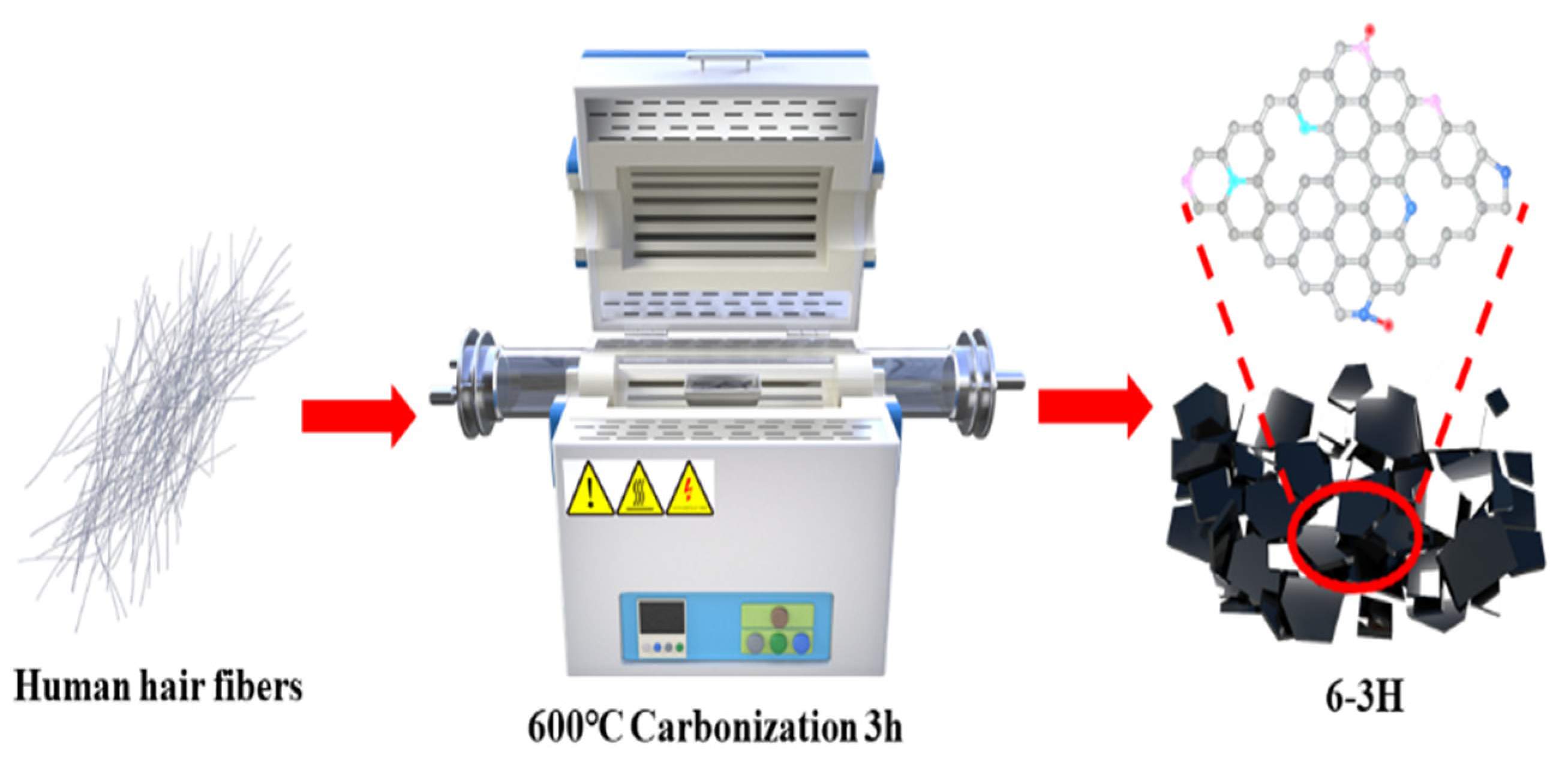

2.2. Sample Preparation

2.3. Sample Characterization

2.4. Preparation and Test of Sensing Chip

3. Results and Discussion

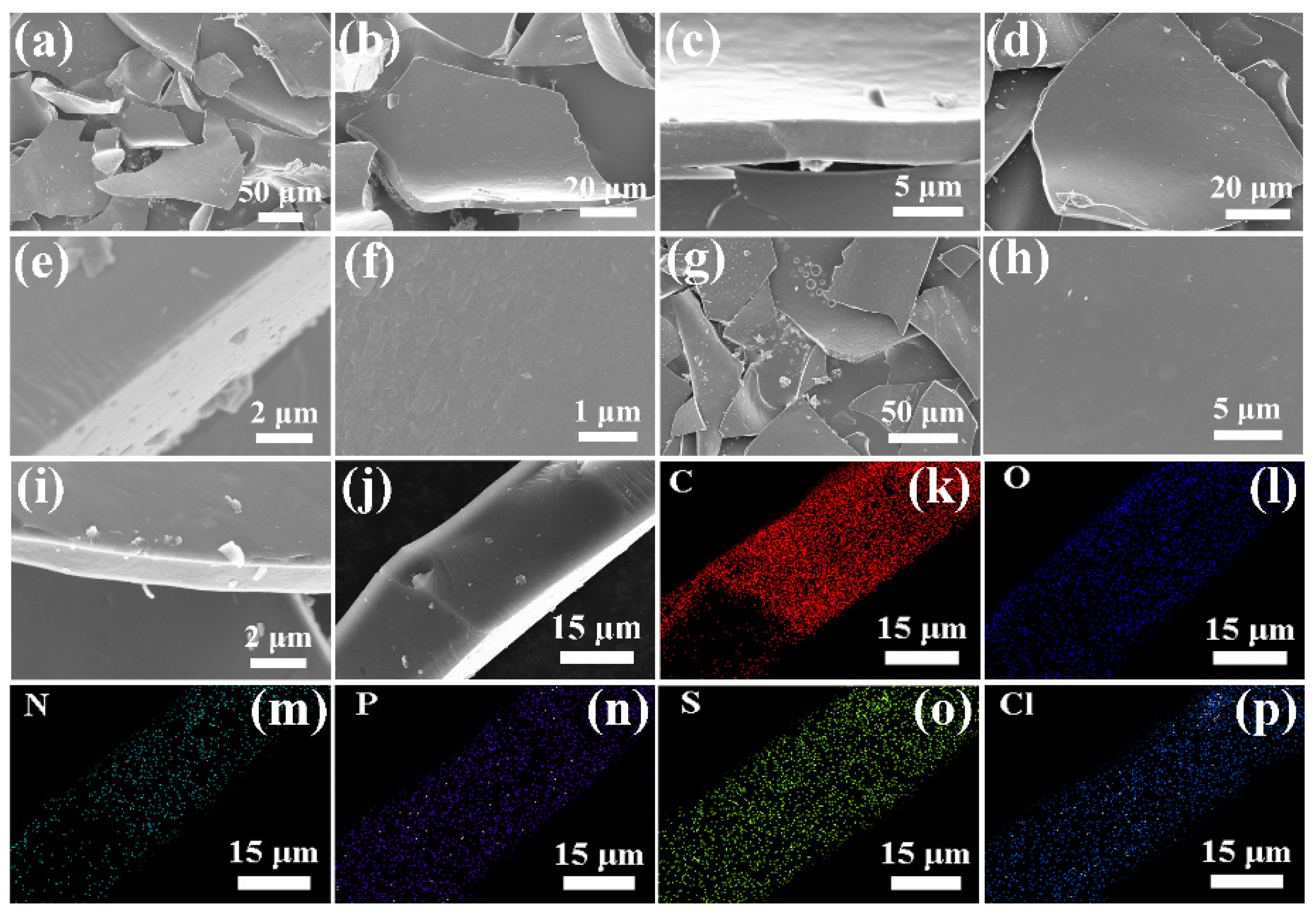

3.1. Morphologies and Microstructures

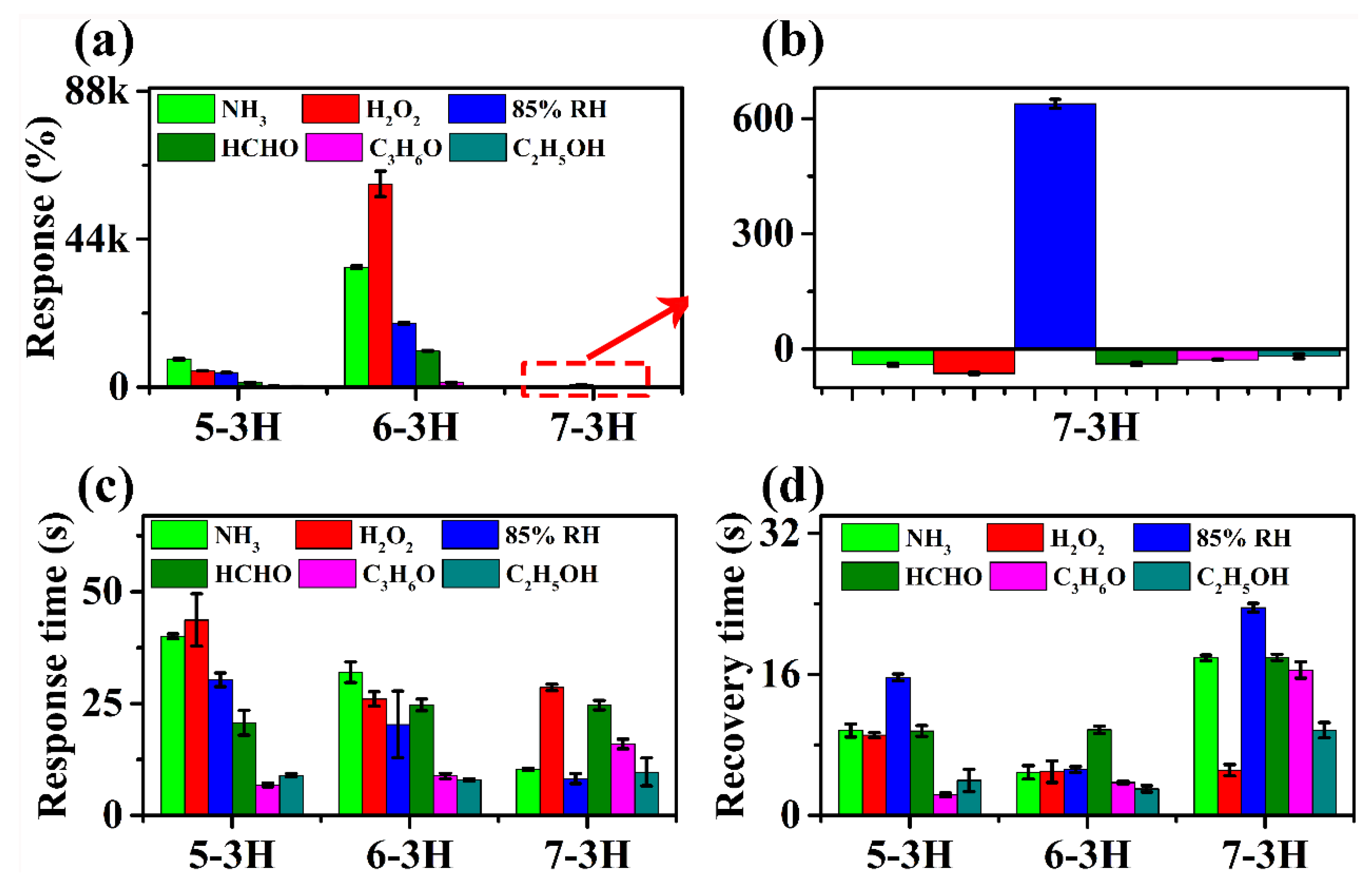

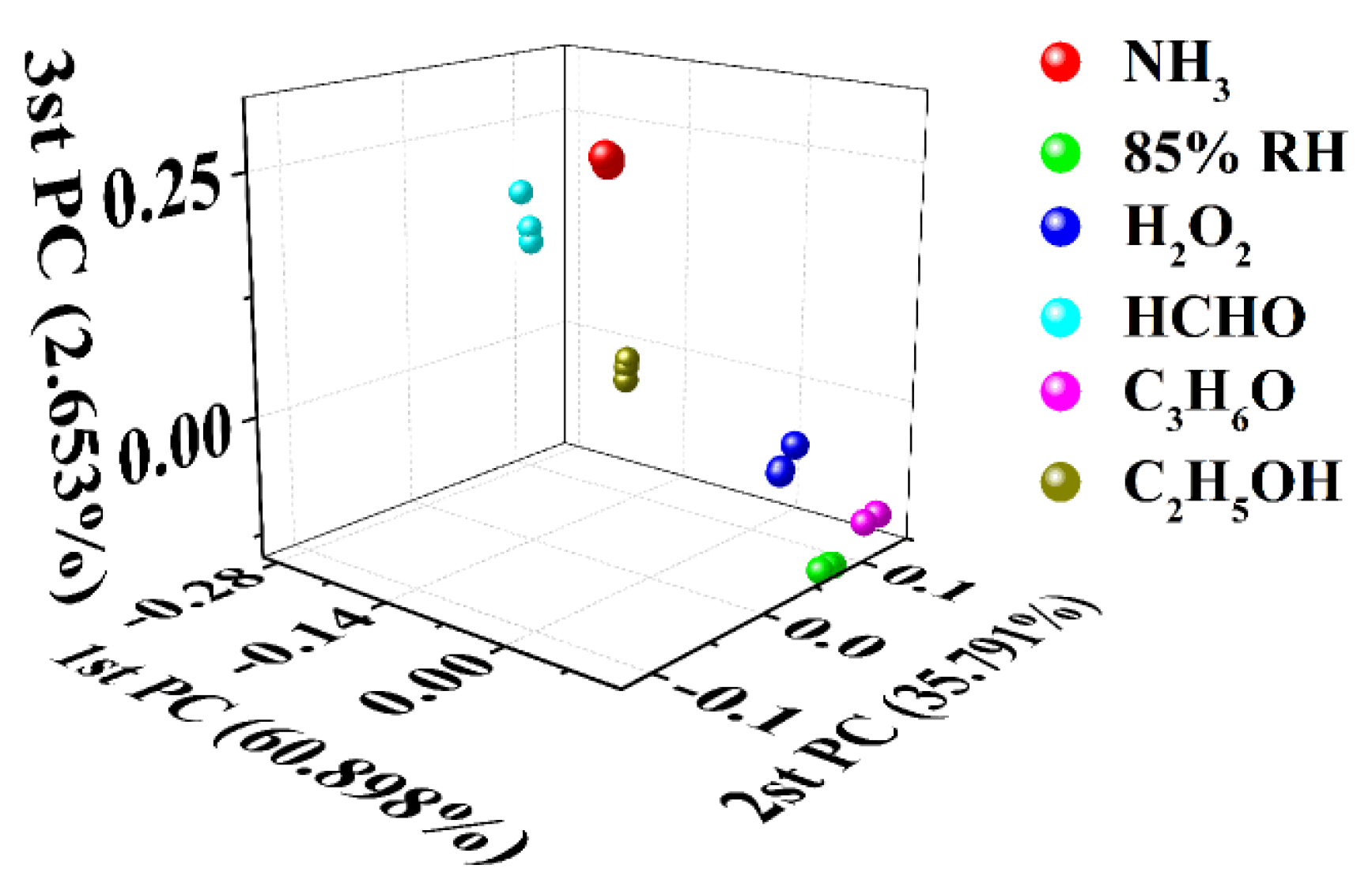

3.2. Gas sensing Performances of 5−3H, 6−3H, and 7−3H

3.3. Limit of Detection and Possible Sensing Mechanisms of WCF−MoS2

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Minkin, R.M. The Gluten-Free Revolution: Absolutely Everything You Need To Know About Losing the Wheat, Reclaiming Your Health, and Eating Happily Ever After. Libr. J. 2015, 140, 124. [Google Scholar]

- Popov, A.A.; Yang, S.; Dunsch, L. Endohedral fullerenes. Chem. Rev. 2013, 113, 5989–6113. [Google Scholar] [CrossRef]

- Dresselhaus, M.S.; Dresselhaus, G.; Rao, A.M.; Eklund, P.C. Optical properties of C60 and related materials. Synth. Met. 1996, 78, 313–325. [Google Scholar] [CrossRef]

- Li, G.; Li, Y.; Liu, H.; Guo, Y.; Li, Y.; Zhu, D. Architecture of graphdiyne nanoscale films. Chem. Commun. 2010, 46, 3256–3258. [Google Scholar] [CrossRef]

- Yin, X.-F.; Zhang, Q.; Chen, Z.Y.; Wang, H.F.; Li, X.; Wang, H.X.; Li, H.X.; Kang, C.M.; Chu, S.; Li, K.F.; et al. NLRP3 in human glioma is correlated with increased WHO grade, and regulates cellular proliferation, apoptosis and metastasis via epithelial-mesenchymal transition and the PTEN/AKT signaling pathway. Int. J. Oncol. 2018, 53, 973–986. [Google Scholar] [CrossRef] [Green Version]

- Su, D.S.; Perathoner, S.; Centi, G. Nanocarbons for the development of advanced catalysts. Chem. Rev. 2013, 113, 5782–5816. [Google Scholar] [CrossRef]

- Mao, J.; Locozzia, J.; Huang, J.; Meng, K.; Lai, Y.; Lin, Z. Graphene aerogels for efficient energy storage and conversion. Energy Environ. Sci. 2018, 11, 772–799. [Google Scholar] [CrossRef]

- Yu, X.; Cheng, H.; Zhang, M.; Zhao, Y.; Qu, Y.; Shi, G. Graphene-based smart materials. Nat. Rev. Mater. 2017, 2, 1–13. [Google Scholar] [CrossRef]

- Lam, S.S.; Liew, R.K.; Lim, X.Y.; Ani, F.N.; Jusoh, A. Fruit waste as feedstock for recovery by pyrolysis technique. Int. Biodeterior. Biodegrad. 2016, 113, 325–333. [Google Scholar] [CrossRef]

- Sun, Q.; Wu, Z.; Cao, B.; Chen, X.; Zhang, C.; Shaymurat, T.; Duan, H.; Zhang, J.; Zhang, M. Gas sensing performance of biomass carbon materials promoted by nitrogen doping and pn junction. Appl. Surf. Sci. 2022, 592, 153254. [Google Scholar] [CrossRef]

- Cao, S.; Cao, S.; Sun, Q.; Zhang, W.; Beysen, S.; Wang, S.; Shaymurat, T.; Zhang, M.; Duan, H. Gas sensing properties of cotton-based carbon fibers and ZnO/carbon fibers regulated by changing carbonization temperatures. Sens. Actuators B Chem. 2021, 337, 129818. [Google Scholar] [CrossRef]

- Jiang, L.; Sheng, L.; Fan, Z. Biomass-derived carbon materials with structural diversities and their applications in energy storage. Sci. China Mater. 2018, 61, 133–158. [Google Scholar] [CrossRef] [Green Version]

- Xia, Y.; Wu, Z.; Qin, Z.; Chen, F.; Lv, C.; Zhang, M.; Shaymurat, T.; Duan, H. Wool-Based Carbon Fiber/MoS2 Composite Prepared by Low-Temperature Catalytic Hydrothermal Method and Its Application in the Field of Gas Sensors. Nanomaterials 2022, 12, 1105. [Google Scholar] [CrossRef]

- Wang, Y.; Zhang, M.; Shen, X.; Wang, H.; Wang, H.; Xia, K.; Yin, Z.; Zhang, Y. Biomass-derived carbon materials: Controllable preparation and versatile applications. Small 2021, 17, 2008079. [Google Scholar] [CrossRef] [PubMed]

- Kim, H.-J.; Lee, J.-H. Highly sensitive and selective gas sensors using p-type oxide semiconductors: Overview. Sens. Actuators B Chem. 2014, 192, 607–627. [Google Scholar] [CrossRef]

- Wu, Z.; Zhou, C.; Zu, B.; Li, Y.; Dou, X. Contactless and rapid discrimination of improvised explosives realized by Mn2+ doping tailored ZnS nanocrystals. Adv. Funct. Mater. 2016, 26, 4578–4586. [Google Scholar] [CrossRef]

- Lu, H.; Zhao, X.S. Biomass-derived carbon electrode materials for supercapacitors. Sustain. Energy Fuels 2017, 1, 1265–1281. [Google Scholar] [CrossRef]

- Zhao, X.; Zhu, J.; Liang, L.; Li, C.; Liao, J.; Xing, W. Biomass-derived N-doped carbon and its application in electrocatalysis. Appl. Catal. B Environ. 2014, 154, 177–182. [Google Scholar] [CrossRef]

- Zhou, X.; Wang, P.; Zhang, Y.; Wang, L.; Zhang, L.; Zhang, L.; Xu, L.; Liu, L. Biomass based nitrogen-doped structure-tunable versatile porous carbon materials. J. Mater. Chem. A 2017, 5, 12958–12968. [Google Scholar] [CrossRef]

- Sun, Q.; Wu, Z.; Qin, Z.; Chen, X.; Zhang, C.; Cao, B.; Duan, H.; Zhang, J. A dog nose-inspired high-performance NH3 gas sensor of biomass carbon materials with a pleated structure derived from rose tea. J. Mater. Chem. A 2022, 10, 14326–14335. [Google Scholar] [CrossRef]

- Altuntaş, D.B.; Aslan, S.; Akyol, Y.; Nevruzoglu, V. Synthesis of new carbon material produced from human hair and its evaluation as electrochemical supercapacitor. Energy Sources Part A Recovery Util. Environ. Eff. 2020, 42, 2346–2356. [Google Scholar] [CrossRef]

- Baltenneck, F.; Bernard, B.A.; Garson, J.C.; Engström, P.; Riekel, C.; Leroy, F.; Franbourg, A.; Doucet, J. Study of the keratinization process in human hair follicle by X-ray microdiffraction. Cell. Mol. Biol. 2000, 46, 1017–1024. [Google Scholar]

- Hearle, J.W.S. A critical review of the structural mechanics of wool and hair fibres. Int. J. Biol. Macromol. 2000, 27, 123–138. [Google Scholar] [CrossRef]

- Lee, L.D.; Baden, H.P. Chemistry and composition of the keratins. Int. J. Dermatol. 1975, 14, 161–171. [Google Scholar] [CrossRef]

- Pramanick, B.; Cadenas, L.B.; Kim, D.M.; Lee, W.; Shim, Y.B.; Martinez-Chapa, S.O.; Madou, M.J.; Hwang, H. Human hair-derived hollow carbon microfibers for electrochemical sensing. Carbon 2016, 107, 872–877. [Google Scholar] [CrossRef]

- Li, Y.B.; Liu, H.H.; Wang, X.C.; Zhang, X.X. Fabrication and performance of wool keratin–functionalized graphene oxide composite fibers. Mater. Today Sustain. 2019, 3, 100006. [Google Scholar] [CrossRef]

- Hou, X.; Ren, P.G.; Dai, Z.; Guo, Z.; Zhang, Z.; Sun, A.; He, W.; Ren, F.; Jin, Y. N–O Codoped Carbon Nanofibers Decorated with Graphene for High-Performance Supercapacitors. Energy Technol. 2021, 9, 2100743. [Google Scholar] [CrossRef]

- Lin, Q.; Hao, S.; Hu, W.; Wang, M.; Zang, Z.; Zhu, L.; Du, J.; Tang, X. Human hair keratin for physically transient resistive switching memory devices. J. Mater. Chem. C 2019, 7, 3315–3321. [Google Scholar] [CrossRef]

- Parajuli, S.; Miao, W. Sensitive determination of triacetone triperoxide explosives using electrogenerated chemiluminescence. Anal. Chem. 2013, 85, 8008–8015. [Google Scholar] [CrossRef]

- Sun, Q.; Wu, Z.; Duan, H.; Jia, D. Detection of triacetone triperoxide (TATP) precursors with an array of sensors based on MoS2/RGO composites. Sensors 2019, 19, 1281. [Google Scholar] [CrossRef] [Green Version]

- Wu, Z.; Zhang, M.; Cao, S.; Wang, L.; Qin, Z.; Zhong, F.; Duan, H. Flexible all-biomass gas sensor based on doped carbon quantum dots/nonwoven cotton with discriminative function. Cellulose 2022, 29, 5817–5832. [Google Scholar] [CrossRef]

- Verma, A.L.; Saxena, S.; Saini, G.S.S.; Gaur, V.; Jain, V.K. Hydrogen peroxide vapor sensor using metal-phthalocyanine functionalized carbon nanotubes. Thin Solid Film. 2011, 519, 8144–8148. [Google Scholar] [CrossRef]

- Lu, Y.; Meyyappan, M.; Li, J. Trace Detection of Hydrogen Peroxide Vapor Using a Carbon-Nanotube-Based Chemical Sensor. Small 2011, 7, 1714–1718. [Google Scholar] [CrossRef]

- Adamyan, Z.N.; Sayunts, A.G.; Khachaturyan, E.A.; Araqelyan, V.M.; Aroutiounian, V.M.; Joost, B. Study of Hydrogen Peroxide Vapors Sensors Based on Carbon Nanotubes Coated with Tin Oxide Nanoparticles. J. Contemp. Phys. (Armen. Acad. Sci.) 2019, 54, 57–64. [Google Scholar] [CrossRef]

- Lee, D.-J.; Choi, S.-W.; Byun, Y.T. Room temperature monitoring of hydrogen peroxide vapor using platinum nanoparticles-decorated single-walled carbon nanotube networks. Sens. Actuators B Chem. 2018, 256, 744–750. [Google Scholar] [CrossRef]

- Näther, N.; Henkel, H.; Schneider, A.; Schöning, M.J. Investigation of different catalytically active and passive materials for realising a hydrogen peroxide gas sensor. Phys. Status Solidi 2009, 206, 449–454. [Google Scholar] [CrossRef]

- Qian, W.; Sun, F.; Xu, Y.; Qiu, L.; Liu, C.; Wang, S.; Yan, F. Human hair-derived carbon flakes for electrochemical supercapacitors. Energy Environ. Sci. 2014, 7, 379–386. [Google Scholar] [CrossRef]

- Yamazoe, N.; Shimanoe, K. Theory of power laws for semiconductor gas sensors. Sens. Actuators B Chem. 2008, 128, 566–573. [Google Scholar] [CrossRef]

- Korotcenkov, G. Metal oxides for solid-state gas sensors: What determines our choice? Mater. Sci. Eng. B 2007, 139, 1–23. [Google Scholar] [CrossRef]

| Sensing Methods | Concentration (ppm) | Response (%) | Res/Rec Time (s) | LoD (ppm) | Ref |

|---|---|---|---|---|---|

| MoS2/RGO−3 | 50 | 373 | 8.7/2.1 | 0.65 | [30] |

| CQDs/PCFT | 100 | 12,000 | 10/2.5 | 0.057 | [31] |

| CoPc−f−MWNTs | 34% H2O2 (aq) vapor | 3.8 | 2/3 | -- | [32] |

| SWCNTs | 100 | ~1.97 | ~20/18 | 25 | [33] |

| MWCNTs/SnO2 | 17.5 | ~59,500 | 210/342 | -- | [34] |

| Pt−SWCNTs | 60.6 | 50 | ~240/-- | 0.027 | [35] |

| 6−3H | 6 | 760 | 8.6/2 | 0.83 | Present work |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, Z.; Xia, Y.; Liu, L.; Sun, Q.; Sun, J.; Zhong, F.; Zhang, M.; Duan, H. Preparation and Gas Sensing Properties of Hair-Based Carbon Sheets. Nanomaterials 2022, 12, 3512. https://doi.org/10.3390/nano12193512

Wu Z, Xia Y, Liu L, Sun Q, Sun J, Zhong F, Zhang M, Duan H. Preparation and Gas Sensing Properties of Hair-Based Carbon Sheets. Nanomaterials. 2022; 12(19):3512. https://doi.org/10.3390/nano12193512

Chicago/Turabian StyleWu, Zhaofeng, Yidan Xia, Lixiang Liu, Qihua Sun, Jun Sun, Furu Zhong, Min Zhang, and Haiming Duan. 2022. "Preparation and Gas Sensing Properties of Hair-Based Carbon Sheets" Nanomaterials 12, no. 19: 3512. https://doi.org/10.3390/nano12193512