Pseudocapacitive Effects of Multi-Walled Carbon Nanotubes-Functionalised Spinel Copper Manganese Oxide

Abstract

:1. Introduction

2. Experimental Section and Characterizations

2.1. Materials and Reagents

2.2. Synthetic Procedures

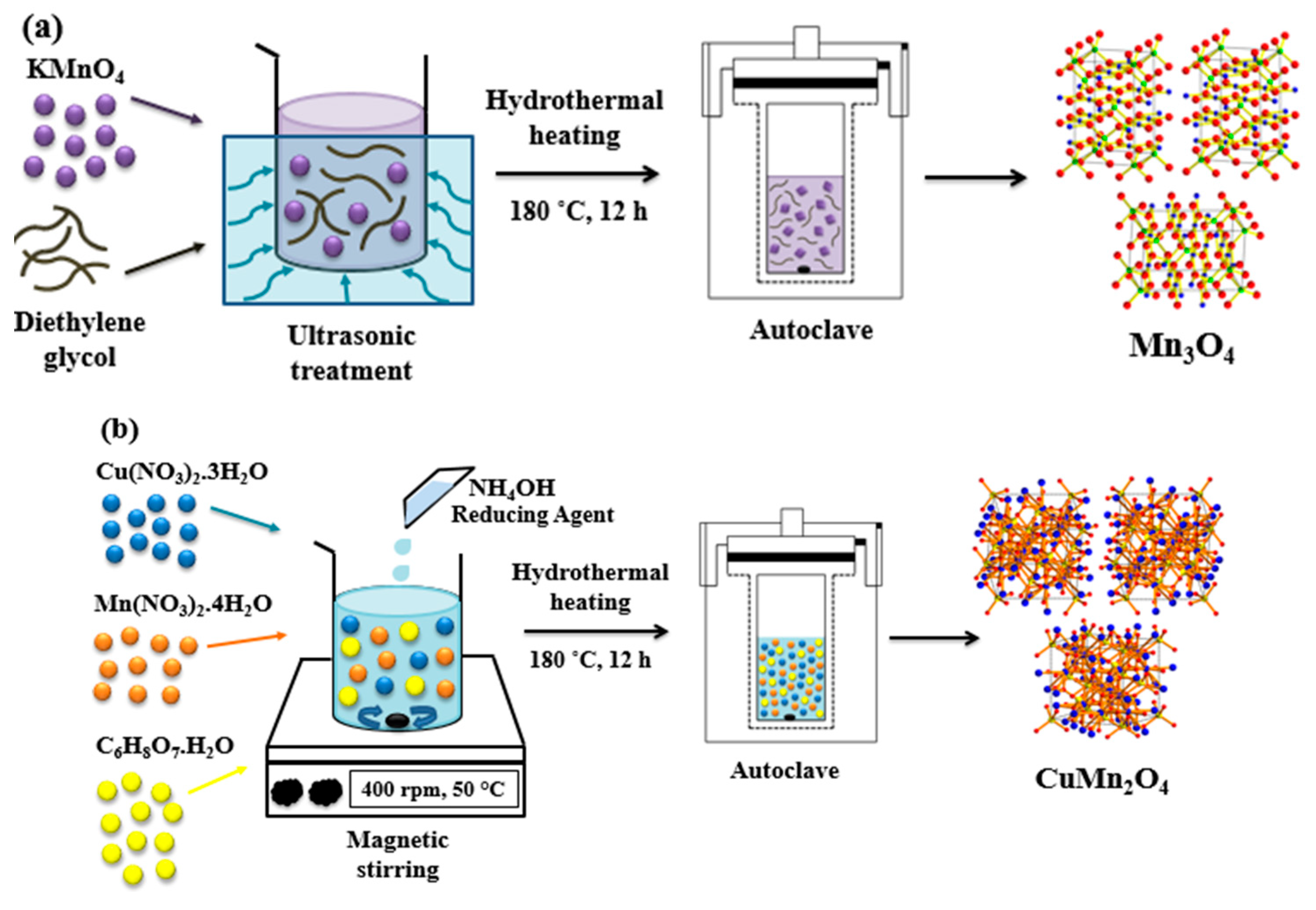

2.2.1. Synthesis of Mn3O4 Electrode Material

2.2.2. Synthesis of CuMn2O4 Nanoparticles

2.2.3. Synthesis of CuMn2O4/MWCNTs

2.3. Material Characterization

2.4. Electrochemical Measurements

3. Results and Discussion

3.1. Scanning Electron Microscopy (SEM)

3.2. High-Resolution Transmission Electron Microscopy (HR-TEM)

3.3. Structural Characterisation

3.4. Electrochemical Characterization

3.4.1. Cyclic Voltammetry (CV)

3.4.2. Electrochemical Impedance Spectroscopy (EIS)

3.4.3. Galvanostatic Charge/Discharge (GCD)

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Chen, Y.; Zhang, X.; Xu, C.; Xu, H. The fabrication of asymmetry supercapacitor based on MWCNTs/MnO2/PPy composites. Electrochim. Acta 2019, 309, 424–431. [Google Scholar] [CrossRef]

- Pratibha, G.; Srinivas, I.; Rao, K.V.; Shanker, A.K.; Raju, B.M.K.; Choudhary, D.K.; Rao, K.S.; Srinivasarao, C.; Maheswari, M. Net global warming potential and greenhouse gas intensity of conventional and conservation agriculture system in rainfed semi-arid tropics of India. Atmos. Environ. 2016, 145, 239–250. [Google Scholar] [CrossRef]

- Zhang, H.; Li, H.; Sun, Z.; Jia, D. One-step hydrothermal synthesis of NiCo2S4 nanoplates/nitrogen-doped mesoporous carbon composites as advanced electrodes for asymmetric supercapacitors. J. Power Sources 2019, 439, 227082. [Google Scholar] [CrossRef]

- Akhtar, M.S.; Gul, I.H.; Baig, M.M.; Akram, M.A. Binder-free pseudocapacitive nickel cobalt sulfide/MWCNTs hybrid electrode directly grown on nickel foam for high rate supercapacitors. Mater. Sci. Eng. B 2021, 264, 114898. [Google Scholar] [CrossRef]

- Rajkumar, S.; Elanthamilan, E.; Balaji, T.E.; Sathiyan, A.; Jafneel, N.E.; Merlin, J.P. Recovery of copper oxide nanoparticles from waste SIM cards for supercapacitor electrode material. J. Alloy. Compd. 2020, 849, 156582. [Google Scholar] [CrossRef]

- Ojha, G.P.; Pant, B.; Muthurasu, A.; Chae, S.H.; Park, S.J.; Kim, T.; Kim, H.Y. Three-dimensionally assembled manganese oxide ultrathin nanowires: Prospective electrode material for asymmetric supercapacitors. Energy 2019, 188, 116066. [Google Scholar] [CrossRef]

- Li, B.; Zhang, X.; Dou, J.; Hu, C. Facile synthesis of pseudocapacitive Mn3O4 nanoparticles for high-performance supercapacitor. Ceram. Int. 2019, 45, 16297–16304. [Google Scholar] [CrossRef]

- Zhang, Q.; Gu, D.; Li, H.; Xu, Z.; Sun, H.; Li, J.; Wang, L.; Shen, L. Energy release from RuO2/RuO2 supercapacitors under dynamic discharge conditions. Electrochim. Acta 2021, 367, 137455. [Google Scholar] [CrossRef]

- Pant, B.; Park, M.; Ojha, G.P.; Park, J.; Kuk, Y.S.; Lee, E.J.; Kim, H.Y.; Park, S.J. Carbon nanofibers wrapped with zinc oxide nano-flakes as promising electrode material for supercapacitors. J. Colloid Interface Sci. 2018, 522, 40–47. [Google Scholar] [CrossRef]

- Lang, J.W.; Kong, L.B.; Wu, W.J.; Luo, Y.C.; Kang, L. Facile approach to prepare loose-packed NiO nano-flakes materials for supercapacitors. Chem. Commun. 2008, 35, 4213–4215. [Google Scholar] [CrossRef]

- Xu, J.; Gao, L.; Cao, J.; Wang, W.; Chen, Z. Preparation and electrochemical capacitance of cobalt oxide (Co3O4) nanotubes as supercapacitor material. Electrochim. Acta 2010, 56, 732–736. [Google Scholar] [CrossRef]

- Wang, Z.; Fang, J.; Hao, Y.; Chen, C.; Zhang, D. High-performance Mn3O4 nanomaterials synthesized via a new two-step hydrothermal method in asymmetric supercapacitors. Mater. Sci. Semiond. Process. 2021, 130, 105823. [Google Scholar] [CrossRef]

- Ren, H.; Zhang, L.; Zhang, J.; Miao, T.; Yuan, R.; Chen, W.; Wang, Z.; Yang, J.; Zhao, B. Na+ pre-intercalated Na0.11MnO2 on three-dimensional graphene as cathode for aqueous zinc ion hybrid supercapacitor with high energy density. Carbon 2022, 198, 46–56. [Google Scholar] [CrossRef]

- Saha, S.; Roy, A.; Ray, A.; Das, T.; Nandi, M.; Ghosh, B.; Das, S. Effect of particle morphology on the electrochemical performance of hydrothermally synthesized NiMn2O4. Electrochim. Acta 2020, 353, 136515. [Google Scholar] [CrossRef]

- Yun, H.; Zhou, X.; Zhu, H.; Zhang, M. One-dimensional zinc-manganate oxide hollow nanostructures with enhanced supercapacitor performance. J. Colloid Interface Sci. 2021, 585, 138–147. [Google Scholar] [CrossRef] [PubMed]

- Kanaujiya, N.; Kumar, N.; Singh, M.; Sharma, Y.; Varma, G.D. CoMn2O4 Nanoparticles Decorated on 2D MoS2 Frame: A Synergetic Energy Storage Composite Material for Practical Supercapacitor Applications. J. Energy Storage 2021, 35, 102302. [Google Scholar] [CrossRef]

- Saravanakumar, B.; Lakshmi, S.M.; Ravi, G.; Ganesh, V.; Sakunthala, A.; Yuvakkumar, R. Electrochemical properties of rice-like copper manganese oxide (CuMn2O4) nanoparticles for pseudocapacitor applications. J. Alloys Compd. 2017, 723, 115–122. [Google Scholar] [CrossRef]

- Kang, L.; Hung, C.; Zhang, J.; Zhang, M.; Zhang, N.; He, Y.; Luo, C.; Wang, C.; Zhou, X.; Wu, X. A new strategy for synthesis of hierarchical MnO2-Mn3O4 nanocomposite via reduction-induced exfoliation of MnO2 nanowires and its application in high-performance asymmetric supercapacitor. Compos. B. Eng. 2019, 178, 107501. [Google Scholar] [CrossRef]

- Hsu, H.L.; Miah, M.; Saha, S.K.; Chen, J.H.; Chen, L.C.; Hsu, S.Y. Three-dimensional bundle-like multiwalled carbon nanotubes composite for supercapacitor electrode application. Mater. Today Chem. 2021, 22, 100569. [Google Scholar] [CrossRef]

- Ali, G.A.M.; Megiel, E.; Romanski, J.; Algarni, H.; Chong, K.F. A wide potential window symmetric supercapacitor by TEMPO functionalized MWCNTs. J. Mol. Liq. 2018, 271, 31–39. [Google Scholar] [CrossRef]

- Shakir, I. High Performance Flexible pseudocapacitors based on nano-architectured spinel nickel cobaltite anchored multiwall carbon nanotubes. Electrochim. Acta 2014, 132, 490–495. [Google Scholar] [CrossRef]

- Geng, L.; Xu, S.; Liu, J.; Guo, A.; Hou, F. Effects of CNT-film pretreatment on the characteristics of nico2o4/cnt core-shell hybrids as electrode material for electrochemistry capacitor. Electroanalysis 2017, 29, 778–786. [Google Scholar] [CrossRef]

- Aruchamy, K.; Nagaraj, R.; Manohara, H.M.; Nidhi, M.R.; Mondal, D.; Ghosh, D.; Nataraj, S.K. One-step green route synthesis of spinel ZnMn2O4 nanoparticles decorated on MWCNTs as a novel electrode material for supercapacitor. Mater. Sci. Eng. B 2020, 252, 114481. [Google Scholar] [CrossRef]

- Mondal, C.; Ghosh, D.; Aditya, T.; Sasmal, A.K.; Pal, T. Mn3O4 nanoparticles anchored to multiwall carbon nanotubes: A distinctive synergism for high-performance supercapacitors. New J. Chem. 2015, 39, 8373–8380. [Google Scholar] [CrossRef]

- Sun, G.; Ren, H.; Shi, Z.; Zhang, L.; Wang, Z.; Zhan, K.; Yan, Y.; Yang, J.; Zhao, B. V2O5/vertically-aligned carbon nanotubes as negative electrode for asymmetric supercapacitor in neutral aqueous electrolyte. J. Colloid Interface Sci. 2021, 588, 847–856. [Google Scholar] [CrossRef]

- Peng, W.; Su, Z.; Wang, J.; Li, S.; Chen, K.; Song, N.; Luo, S.; Xie, A. MnCoOx-multi-walled carbon nanotubes composite with ultra-high specific capacitance for supercapacitors. J. Energy Storage 2022, 51, 104519. [Google Scholar] [CrossRef]

- Shi, Z.; Sun, G.; Yuan, R.; Chen, W.; Wang, Z.; Zhang, L.; Zhan, K.; Zhu, M.; Yang, J.; Zhao, B. Scalable fabrication of NiCo2O4/reduced graphene oxide composites by ultrasonic spray as binder-free electrodes for supercapacitors with ultralong lifetime. J. Mater. Sci. Technol. 2022, 99, 260–269. [Google Scholar] [CrossRef]

- Li, L.; Jiang, G.; Ma, J. CuMn2O4/graphene nanosheets as excellent anode for lithium-ion battery. Mater. Res. Bull. 2018, 104, 53–59. [Google Scholar] [CrossRef]

- Pal, B.; Yang, S.; Ramesh, S.; Thangadurai, V.; Jose, R. Electrolyte selection for supercapacitive devices: A critical review. Nanoscale Adv. 2019, 1, 3807–3835. [Google Scholar] [CrossRef] [Green Version]

- Sezer, N.; Koc, M. Oxidative acid treatment of carbon nanotubes. Surf. Interfaces 2019, 14, 1–8. [Google Scholar] [CrossRef]

- Li, T.; Guo, C.; Sun, B.; Li, T.; Li, Y.; Hou, L.; Wei, Y. Well-shaped Mn3O4 tetragonal bipyramids with good performance for lithium ion batteries. J. Mater Chem. A 2015, 3, 7248–7254. [Google Scholar] [CrossRef]

- Kavil, J.; Anjana, P.M.; Joshy, D.; Babu, A.; Raj, G.; Periyat, P.; Rakhi, R.B. g-C3N4/CuO and g-C3N4/Co3O4 nanohybrid structures as efficient electrode materials in symmetric supercapacitors. RSC Adv. 2019, 9, 38430–38437. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Abel, M.J.; Pramothkumar, A.; Senthikumar, N.; Jothivenkatachalam, K.; Inbaraj, P.F.H.; Prince, J.J. Flake-like CuMn2O4 nanoparticles synthesized via co-precipitation method for photocatalytic activity. Phys. B Condens. Matter 2019, 572, 117–124. [Google Scholar]

- Wan, X.; Tang, N.; Xie, Q.; Zhao, S.; Zhou, C.; Dai, Y.; Yang, Y. A CuMn2O4 spinel oxide as a superior catalyst for the aerobic oxidation of 5-hydroxymethylfurfural toward 2,5-furandicarboxylic acid in aqueous solvent. Catal. Sci. Technol. 2021, 11, 1497–1509. [Google Scholar] [CrossRef]

- Ndipingwi, M.M.; Ikpo, C.O.; Hlongwa, N.W.; Myalo, Z.; Ross, N.; Masikini, M.; John, S.V.; Baker, P.G.; Roos, W.D.; Iwuoha, E.I. Orthorhombic Nanostructured Li2MnSiO4/Al2O3 Supercapattery Electrode with Efficient Lithium-Ion Migratory Pathway. Batter. Supercaps 2018, 1, 223–235. [Google Scholar] [CrossRef]

- Gao, F.; Qin, S.H.; Zhang, Y.H.; Gu, J.F.; Qu, J.Y. Highly efficient formation of Mn3O4-graphene oxide hybrid aerogels for use as the cathode material of high performance lithium ion batteries. New Carbon Mater. 2020, 35, 121–130. [Google Scholar] [CrossRef]

- Ismail, F.M.; Ramadan, M.; Abdellah, A.M.; Ismail, I.; Allam, N.K. Mesoporous spinel manganese zinc ferrite for high-performance supercapacitors. J. Electroanal. Chem 2018, 817, 111–117. [Google Scholar] [CrossRef]

- Hlongwa, N.W.; Ikpo, C.O.; Ndipingwi, M.M.; Nolly, C.; Raleie, N.; Dywili, N.; Iwuoha, E.I. Graphene-functionalised olivine lithium manganese phosphate derivatives for high performance lithium-ion capacitors. Electroanalysis 2020, 32, 2812–2826. [Google Scholar] [CrossRef]

- Zhang, L.; Guo, Y.; Shen, K.; Huo, J.; Liu, Y.; Guo, S. Ion-matching porous carbons with ultra-high surface area and superior energy storage performance for supercapacitors. J. Mater. Chem. A 2019, 7, 9163–9172. [Google Scholar] [CrossRef]

- Brolly, C.; Parnell, J.; Bowden, S. Raman spectroscopy: Caution when interpreting organic carbon from oxidising environments. Planet. Space Sci. 2016, 121, 53–59. [Google Scholar] [CrossRef] [Green Version]

- Rahmanifar, M.S.; Hemmati, M.; Noori, A.; I-Kady, M.F.E.; Mousavi, M.F.; Kaner, R.B. Asymmetric supercapacitors: An alternative to activated carbon negative electrodes based on earth abundant elements. Mater. Today Energy 2019, 12, 26–36. [Google Scholar] [CrossRef]

- Nguyen, N.V.; Tran, T.V.; Luong, S.T.; Pham, T.M.; Nguyen, K.V.; Vu, T.D.; Nguyen, H.S.; To, N.V. Facile synthesis of a NiCo2O4 nanoparticles mesoporous carbon composite as electrode materials for supercapacitor. ChemistrySelect 2020, 5, 7060–7068. [Google Scholar] [CrossRef]

- Gu, Y.; Wu, J.; Wang, X.; Liu, W.; Yan, S. Producing “Symbiotic” Reduced Graphene Oxide/Mn3O4 Nanocomposites Directly from converting Graphite for High-Performance Supercapacitor Electrodes. ACS Omega 2020, 5, 18975–18986. [Google Scholar] [CrossRef]

- Noori, A.; El-Kady, M.F.; Rahmanifar, M.S.; Kaner, R.B.; Mousavi, M.F. Towards establishing standard performance metrics for batteries, supercapacitors and beyond. Chem. Soc. Rev. 2019, 5, 1272–1341. [Google Scholar] [CrossRef]

- Li, J.; Tang, Z.; Zhang, Z. Layered hydrogen titanate nanowires with novel lithium intercalation properties. Chem. Mater. 2005, 17, 5848–5855. [Google Scholar] [CrossRef]

- Wang, Y.; Song, Y.; Xia, Y. Electrochemical capacitors: Mechanism, materials, systems, characterization and applications. Chem. Soc. Rev. 2016, 45, 5925–5950. [Google Scholar] [CrossRef]

- Vadiyar, M.M.; Bhise, S.C.; Patil, S.K.; Kolekar, S.S.; Chang, J.Y.; Ghule, A.V. comparative study of individual and mixed aqueous electrolytes with ZnFe2O4 nano-flakes thin film as an electrode for supercapacitor application. ChemistrySelect 2016, 1, 959–966. [Google Scholar] [CrossRef]

- Misnon, I.I.; Aziz, R.A.; Zain, N.K.M.; Vidhyadharan, B.; Krishnan, S.G.; Jose, R. High performance MnO2 nanoflower electrode and the relationship between solvated ion size and specific capacitance in highly conductive electrolytes. Mater. Res. Bull. 2014, 57, 221–230. [Google Scholar] [CrossRef] [Green Version]

- Balamurugan, J.; Nguyen, T.T.; Aravindan, V.; Kim, N.H.; Lee, J.H. Flexible solid-state asymmetric supercapacitors based on nitrogen-doped graphene encapsulated ternary metal-nitrides with ultralong cycle life. Adv. Funct. Mater. 2018, 28, 1804663. [Google Scholar] [CrossRef]

- Cao, L.; Tang, G.; Mei, J.; Liu, H. Construct hierarchical electrode with NixCo3-xS4 nanosheet coated on NiCo2O4 nanowire arrays grown on carbon fiber paper for high-performance asymmetric supercapacitors. J. Power Sources 2017, 359, 262–269. [Google Scholar] [CrossRef]

- Qu, Z.; Shi, M.; Wu, H.; Liu, Y.; Jiang, J.; Yan, C. An efficient binder-free electrode with multiple carbonized channels wrapped by NiCo2O4 nanosheets for high-performance capacitive energy storage. J. Power Sources 2019, 410–411, 179–187. [Google Scholar] [CrossRef]

- Liu, C.; Yu, Z.; Neff, D.; Zhamu, A.; Jang, B.Z. Graphene-based supercapacitor with an ultrahigh energy density. Nano Lett. 2010, 10, 4863–4868. [Google Scholar] [CrossRef] [PubMed]

- Krishnamoorthy, K.; Pazhamalai, P.; Sahoo, S.; Kim, S.J. Titanium carbide sheet based high performance wire type solid state supercapacitors. J. Mater. Chem. A 2017, 5, 5726–5736. [Google Scholar] [CrossRef]

- Chhetri, K.; Tiwari, A.; Dahal, B.; Ojha, G.; Mukhiya, T.; Lee, M.; Kim, T.; Chae, S.; Muthurasu, A.; Kim, H. A ZIF-8-derived nanoporous carbon nanocomposite wrapped with Co3O4-polyaniline as an efficient electrode material for an asymmetric supercapacitor. J. Electroanal. Chem. 2020, 856, 113670. [Google Scholar] [CrossRef]

- Rajkumar, S.; Elanthamilan, E.; Merlin, J.P.; Sathiyan, A. Enhanced electrochemical behavior of FeCo2O4/PANI electrode material for supercapacitors. J. Alloys Compd. 2021, 874, 159876. [Google Scholar] [CrossRef]

- Mandal, D.; Routh, P.; Mahato, A.K.; Nandi, K. Electrochemically modified graphite paper as an advanced electrode substrate for supercapacitor application. J. Mater. Chem. A 2019, 7, 17547–17560. [Google Scholar] [CrossRef]

- Pazhamalai, P.; Krishnamoorthy, K.; Sahoo, S.; Kim, S.J. Two-dimensional molybdenum diselenide nanosheets as a novel electrode material for symmetric supercapacitors using organic electrolyte. Electrochim. Acta 2019, 295, 591–598. [Google Scholar] [CrossRef]

- Kulandaivalu, S.; Hussein, M.Z.; Jaafar, A.M.; Abdah, M.A.A.M.; Azman, N.H.N.; Sulaiman, Y. A simple strategy to prepare a layer-by-layer assembled composite of Ni-Co LDHs on polypyrrole/rGO for a high specific capacitance supercapacitor. RSC Adv. 2019, 9, 40479–40486. [Google Scholar] [CrossRef] [Green Version]

- Xu, L.; Wang, S.; Zhang, X.; He, T.; Lu, F.; Li, H.; Ye, J. A facile method of preparing LiMnPO4/reduced graphene oxide aerogel as cathodic material for aqueous lithium-ion hybrid supercapacitors. Appl. Surf. Sci. 2018, 428, 977–985. [Google Scholar] [CrossRef]

- Li, X.; Ding, R.; Yi, L.; Shi, W.; Xu, Q.; Liu, E. Mesoporous Ni-P@NiCo2O4 composite materials for high performance aqueous asymmetric supercapacitors. Electrochim. Acta 2016, 222, 1169–1175. [Google Scholar] [CrossRef]

- Mariappan, V.K.; Krishnamoorthy, K.; Pazhamalai, P.; Sahoo, S.; Nardekar, S.S.; Kim, S.J. Nanostructured tenary metal chalcogenide-based binder-free electrodes for high energy density asymmetric supercapacitors. Nano Energy 2019, 57, 307–316. [Google Scholar] [CrossRef]

- Li, Y.; Tang, F.; Wang, R.; Wang, C.; Liu, J. A novel dual-ion hybrid supercapacitor based on NiCo2O4 nanowire cathode and MoO2-C nanofilm anode. ACS Appl. Mater. Interfaces 2016, 8, 30232–30238. [Google Scholar] [CrossRef] [PubMed]

- Luo, Y.; Zhang, H.; Guo, D.; Ma, J.; Li, Q.; Chen, L.; Wang, T. Porous NiCo2O4-reduced graphene oxide (rGO) composite with superior capacitance retention for supercapacitors. Electrochim. Acta 2014, 132, 332–337. [Google Scholar] [CrossRef]

- Iqbal, N.; Wang, X.; Babar, A.A.; Yu, J.; Ding, B. Highly flexible NiCo2O4/CNTs doped carbon nanofibers for CO2 adsorption and supercapacitor electrodes. J. Colloid Interface Sci. 2016, 476, 87–93. [Google Scholar] [CrossRef] [PubMed]

- Mazinani, B.; Kazazi, M.; Mobarhan, G.; Shokouhimehr, M. The combination synthesis of Ag-doped MnCo2O4 nanoparticles for supercapacitor applications. JOM 2019, 71, 8. [Google Scholar] [CrossRef]

- Xuan, H.; Xu, Y.; Zhang, Y.; Li, H.; Han, P.; Du, Y. One-step combustion synthesis of porous CNTs/C/NiMoO4 composites for high-performance asymmetric supercapacitors. J. Alloys Compd. 2018, 745, 135–146. [Google Scholar] [CrossRef]

- Krishnaveni, M.; Wu, J.J.; Anandan, S.; Ashokkumar, M. Facile synthesis of SnO2 nanoparticle intercalacted unzipped multi-walled carbon nanotubes via an ultrasound-assisted route for symmetric supercapacitor devices. Sustain. Energy Fuels 2020, 4, 5120–5131. [Google Scholar] [CrossRef]

- Chhetri, K.; Dahal, B.; Tiwari, A.; Mukhiya, T.; Muthurasu, A.; Kim, T.; Kim, H.; Kim, H.Y. Integrated hybrid of graphitic carbon-encapsulated CuxO on multilayered mesoporous carbon from copper MOFs and polyaniline for asymmetric supercapacitor and oxygen reduction reactions. Carbon 2021, 179, 89–99. [Google Scholar] [CrossRef]

- Zhong, C.; Deng, Y.; Hu, W.; Qiao, J.; Zhang, L.; Zhang, J. A review of electrolyte materials and compositions for electrochemical supercapacitors. Chem. Soc. Rev. 2015, 44, 7484–7539. [Google Scholar] [CrossRef]

- Yuan, A.; Zhang, Q. A novel hybrid manganese dioxide/activated carbon supercapacitor using lithium hydroxide electrolyte. Electrochem. Commun. 2006, 8, 1173–1178. [Google Scholar] [CrossRef]

- Manickam, M.; Singh, P.; Issa, T.B.; Thurgate, S.; Marco, R.D. Lithium insertion into manganese dioxide electrode in MnO2/Zn aqueous battery: Part I. A preliminary study. J. Power Sources 2004, 130, 254–259. [Google Scholar] [CrossRef]

- Inamdar, A.I.; Kim, Y.S.; Pawar, S.M.; Kim, J.H.; Im, H.; Kim, H. Chemically grown, porous, nickel oxide thin-film for electrochemical supercapacitors. J. Power Sources 2011, 196, 2393–2397. [Google Scholar] [CrossRef]

| Electrode Material | D (nm) | d (nm) | a (nm) | c (nm) |

|---|---|---|---|---|

| Mn3O4 | 74.04 | 0.20 | 0.58 | 0.95 |

| CuMn2O4 | 77.94 | 0.27 | 0.94 | |

| CuMn2O4/MWCNTs | 51.26 | 0.23 | 0.77 |

| Electrode Material | Rs (Ω) | Cdl (F) | Rct (Ω) | Zw (Ω s−1/2) | τ (s rad−1) | (°) |

|---|---|---|---|---|---|---|

| Mn3O4 | 0.98 | 2.58 × 10−3 | 1.29 | 4.98 | 4.62 × 10−3 | 46 |

| CuMn2O4 | 0.45 | 4.64 × 10−3 | 0.83 | 2.86 | 3.83 × 10−3 | 55 |

| CuMn2O4/MWCNTs | 0.36 | 7.93 × 10−3 | 0.63 | 0.86 | 3.34 × 10−3 | 64 |

| Electrode Material | Rs (Ω) | Cdl (F) | Rct (Ω) | Zw (Ω s−1/2) | τ (s rad−1) | (°) |

|---|---|---|---|---|---|---|

| Mn3O4 | 0.36 | 3.16 × 10−3 | 0.52 | 0.38 | 3.77 × 10−3 | 37 |

| CuMn2O4 | 0.31 | 5.66 × 10−3 | 0.48 | 0.33 | 2.69 × 10−3 | 45 |

| CuMn2O4/MWCNTs | 0.25 | 7.87 × 10−3 | 0.35 | 0.30 | 1.63 × 10−3 | 71 |

| Electrode Material | Electrolyte | Csp (F g−1) | Reference |

|---|---|---|---|

| CuMn2O4/MWCNTs | 3 M LiOH | 1652.9 | This work |

| LiMnPO4/rGO | 1 M LiOH | 464.5 | [59] |

| Ni–P/NiCo2O4 | 0.7 M LiOH | 1240 | [60] |

| Cu3SbS4/Ni–5 | 1 M LiOH | 835.2 | [61] |

| NiCo2O4//MoO2-C | 1 M LiOH | 94.9 | [62] |

| NiCo2O4/rGO | 2 M KOH | 777.1 | [63] |

| NiCo2O4/CNTs | 1 M KOH | 220 | [64] |

| MnCo2O4/Ag NPs | 6 M KOH | 942 | [65] |

| CNTs/C/NiMoO4 | 2 M KOH | 1037 | [66] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nolly, C.; Ikpo, C.O.; Ndipingwi, M.M.; Ekwere, P.; Iwuoha, E.I. Pseudocapacitive Effects of Multi-Walled Carbon Nanotubes-Functionalised Spinel Copper Manganese Oxide. Nanomaterials 2022, 12, 3514. https://doi.org/10.3390/nano12193514

Nolly C, Ikpo CO, Ndipingwi MM, Ekwere P, Iwuoha EI. Pseudocapacitive Effects of Multi-Walled Carbon Nanotubes-Functionalised Spinel Copper Manganese Oxide. Nanomaterials. 2022; 12(19):3514. https://doi.org/10.3390/nano12193514

Chicago/Turabian StyleNolly, Christopher, Chinwe O. Ikpo, Miranda M. Ndipingwi, Precious Ekwere, and Emmanuel I. Iwuoha. 2022. "Pseudocapacitive Effects of Multi-Walled Carbon Nanotubes-Functionalised Spinel Copper Manganese Oxide" Nanomaterials 12, no. 19: 3514. https://doi.org/10.3390/nano12193514