Subwavelength Quasi-Periodic Array for Infrared Antireflection

Abstract

:1. Introduction

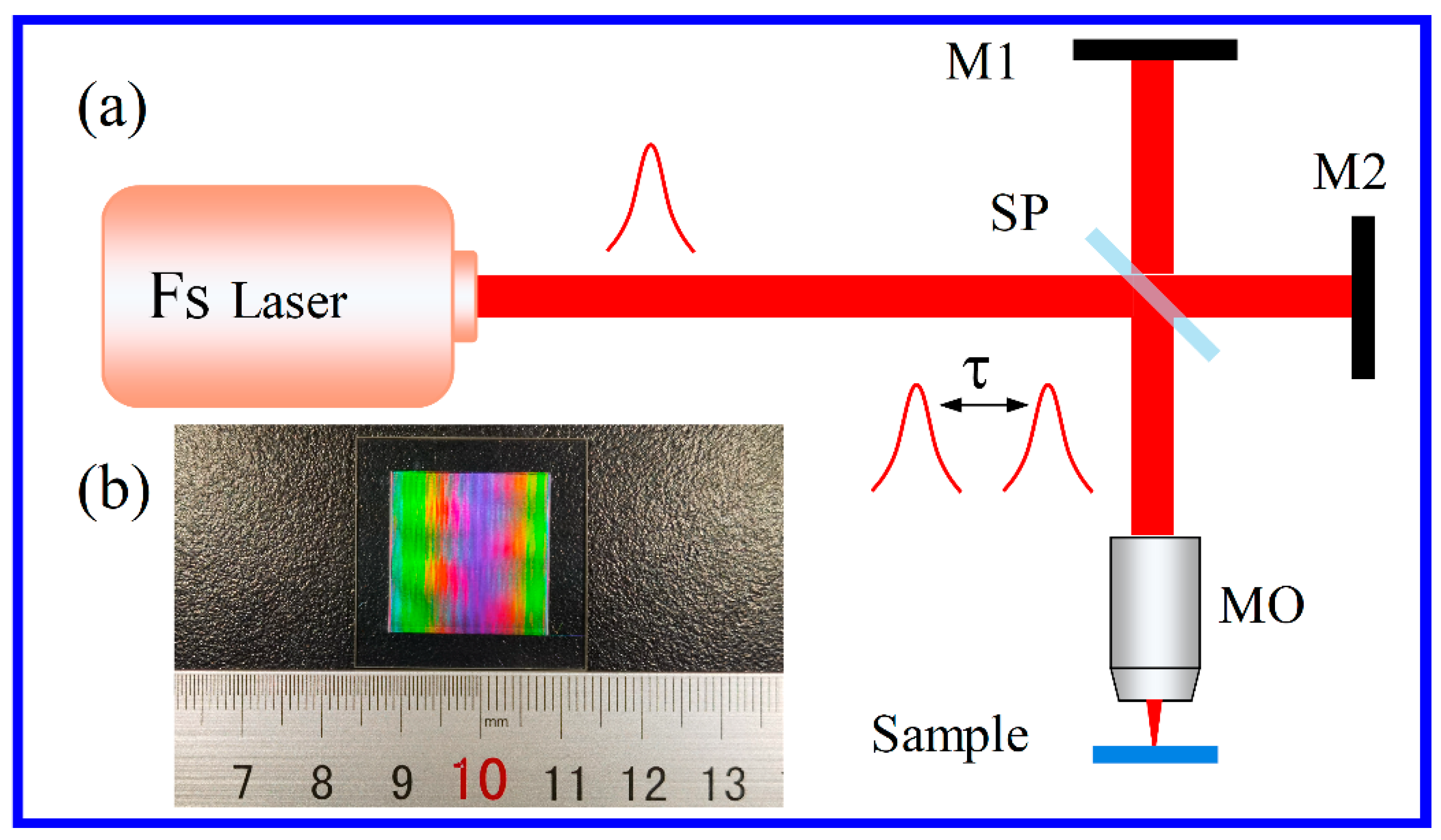

2. Experiment and Simulation

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Bushunov, A.A.; Tarabrin, M.K.; Lazarev, V.A. Review of Surface Modification Technologies for Mid-Infrared Antireflection Microstructures Fabrication. Laser Photon. Rev. 2021, 15, 2000202. [Google Scholar] [CrossRef]

- Ma, H.; Jiao, H.; Feng, C.; Lian, Z.; Li, H.; Feng, L. Reduction of the Fresnel Reflection Effect in the Hybrid PBF-PMF Resonator for RFOG. J. Light. Technol. 2021, 39, 7502–7508. [Google Scholar] [CrossRef]

- Tsai, T.-Y.; Lee, Z.-C.; Tsao, H.-X.; Lin, S.-T. Minimization of Fresnel reflection by anti-reflection fiber Bragg grating inscribed at the fiber ends. Opt. Express 2019, 27, 11510–11515. [Google Scholar] [CrossRef] [PubMed]

- Fossi, A.P.; Ferrec, Y.; Roux, N.; D’Almeida, O.; Guerineau, N.; Sauer, H. Miniature and cooled hyperspectral camera for outdoor surveillance applications in the mid-infrared. Opt. Lett. 2016, 41, 1901–1904. [Google Scholar] [CrossRef] [Green Version]

- Hayashi, J.G.; Mousavi, S.M.A.; Ventura, A.; Poletti, F. Numerical modeling of a hybrid hollow-core fiber for enhanced mid-infrared guidance. Opt. Express 2021, 29, 17042–17052. [Google Scholar] [CrossRef]

- Pfeiffer, K.; Dewald, W.; Szeghalmi, A. Antireflection coating with consistent near-neutral color on complex-shaped substrates prepared by ALD. Opt. Lett. 2019, 44, 3270–3273. [Google Scholar] [CrossRef]

- Ma, C.; Wang, L.; Fan, X.; Liu, J. Broadband antireflection and hydrophobic CaF2 film prepared with magnetron sputtering. Appl. Surf. Sci. 2021, 560, 149924. [Google Scholar] [CrossRef]

- Chan, L.W.; E Morse, D.; Gordon, M.J. Moth eye-inspired anti-reflective surfaces for improved IR optical systems & visible LEDs fabricated with colloidal lithography and etching. Bioinspir. Biomim. 2018, 13, 041001. [Google Scholar]

- Wang, Z.; Ding, H.; Liu, D.; Xu, C.; Li, B.; Niu, S.; Li, J.; Liu, L.; Zhao, J.; Zhang, J.; et al. Large-Scale Bio-Inspired Flexible Antireflective Film with Scale-Insensitivity Arrays. ACS Appl. Mater. Interfaces 2021, 13, 23103–23112. [Google Scholar] [CrossRef]

- Ye, X.; Jiang, X.-D.; Huang, J.; Sun, L.-X.; Geng, F.; Yi, Z.; Zu, X.-T.; Wu, W.-D.; Zheng, W. Subwavelength structures for high power laser antireflection application on fused silica by one-step reactive ion etching. Opt. Lasers Eng. 2016, 78, 48–54. [Google Scholar] [CrossRef]

- Kim, M.; Yi, S.; Kim, J.D.; Yin, X.; Li, J.; Bong, J.; Liu, D.; Liu, S.-C.; Kvit, A.; Zhou, W.; et al. Enhanced Performance of Ge Photodiodes via Monolithic Antireflection Texturing and α-Ge Self-Passivation by Inverse Metal-Assisted Chemical Etching. ACS Nano 2018, 12, 6748–6755. [Google Scholar] [CrossRef] [PubMed]

- Bacon-Brown, D.A.; Braun, P.V. Tunable Antireflection Coating to Remove Index-Matching Requirement for Interference Lithography. Adv. Opt. Mater. 2018, 6, 1701049. [Google Scholar] [CrossRef]

- Sun, J.; Wang, X.; Wu, J.; Jiang, C.; Shen, J.; Cooper, M.A.; Zheng, X.; Liu, Y.; Yang, Z.; Wu, D. Biomimetic Moth-eye Nanofabrication: Enhanced Antireflection with Superior Self-cleaning Characteristic. Sci. Rep. 2018, 8, 5438. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Tarabrin, M.K.; Bushunov, A.A.; Teslenko, A.A.; Sakharova, T.; Hinkel, J.; Usenov, I.; Döhler, T.; Geißler, U.; Artyushenko, V.; Lazarev, V.A. Fabrication of an antireflection microstructure on AgClBr polycrystalline fiber by single pulse femtosecond laser ablation. Opt. Mater. Express 2021, 11, 487–496. [Google Scholar] [CrossRef]

- Hagner, M.; Sulzer, P.; Liehl, A.; Cimander, M.; Kempf, H.; Bitzer, A.; Herter, A.; Leitenstorfer, A. Ultrabroadband suppression of mid-infrared reflection losses of a layered semiconductor by nanopatterning with a focused ion beam. Opt. Express 2021, 29, 33632–33641. [Google Scholar] [CrossRef]

- Bushunov, A.A.; Tarabrin, M.K.; Lazarev, V.A.; Karasik, V.E.; Korostelin, Y.V.; Frolov, M.P.; Skasyrsky, Y.K.; Kozlovsky, V.I. Fabrication of anti-reflective microstructures on chalcogenide crystals by femtosecond laser ablation. Opt. Mater. Express 2019, 9, 1689–1697. [Google Scholar] [CrossRef]

- Zhang, F.; Wang, H.; Wang, C.; Zhao, Y.; Duan, J. Direct femtosecond laser writing of inverted array for broadband antireflection in the far-infrared. Opt. Lasers Eng. 2020, 129, 106062. [Google Scholar] [CrossRef]

- Bushunov, A.A.; Teslenko, A.A.; Tarabrin, M.K.; Lazarev, V.A.; Isaenko, L.I.; Eliseev, A.P.; Lobanov, S.I. Fabrication of antireflection microstructures on the surface of GaSe crystal by single-pulse femtosecond laser ablation. Opt. Lett. 2020, 45, 5994–5997. [Google Scholar] [CrossRef]

- Li, X.; Li, M.; Liu, H.; Guo, Y. Fabrication of an Anti-Reflective Microstructure on ZnS by Femtosecond Laser Bessel Beams. Molecules 2021, 26, 4278. [Google Scholar] [CrossRef]

- Li, Q.-K.; Cao, J.-J.; Yu, Y.; Wang, L.; Sun, Y.-L.; Chen, Q.-D.; Sun, H. Fabrication of an anti-reflective microstructure on sapphire by femtosecond laser direct writing. Opt. Lett. 2017, 42, 543–546. [Google Scholar] [CrossRef] [Green Version]

- Zhang, F.; Duan, J.; Zhou, X.; Wang, C. Broadband and wide-angle antireflective subwavelength microstructures on zinc sulfide fabricated by femtosecond laser parallel multi-beam. Opt. Express 2018, 26, 34016–34030. [Google Scholar] [CrossRef] [PubMed]

- Wang, H.; Zhang, F.; Wang, C.; Duan, J. Broadband antireflective subwavelength structures for infrared detection. Opt. Laser Technol. 2022, 149, 107931. [Google Scholar] [CrossRef]

- Jiang, L.; Wang, A.; Li, B.; Cui, T.; Lu, Y.-F. Electrons dynamics control by shaping femtosecond laser pulses in micro/nanofabrication: Modeling, method, measurement and application. Light. Sci. Appl. 2018, 7, 17134. [Google Scholar] [CrossRef] [Green Version]

- Ding, K.; Wang, C.; Li, S.; Zhang, X.; Lin, N.; Duan, J. Large-area cactus-like micro-/nanostructures with anti-reflection and superhydrophobicity fabricated by femtosecond laser and thermal treatment. Surface Interfaces 2022, 33, 102292. [Google Scholar] [CrossRef]

- Tec-Yam, S.; Rojas, J.; Rejón, V.; Oliva, A. High quality antireflective ZnS thin films prepared by chemical bath deposition. Mater. Chem. Phys. 2012, 136, 386–393. [Google Scholar] [CrossRef]

- Zhang, F.; Wang, C.; Yin, K.; Dong, X.R.; Song, Y.X.; Tian, Y.X.; Duan, J.A. Quasi-periodic concave microlens array for liquid refractive index sensing fabricated by femtosecond laser assisted with chemical etching. Sci. Rep. 2018, 8, 2419. [Google Scholar] [CrossRef] [Green Version]

- Liu, F.; Jiao, H.; Zhang, J.; Yin, B.; Liu, H.; Ji, Y.; Wang, Z.; Cheng, X. High performance ZnS antireflection sub-wavelength structures with HfO2 protective film for infrared optical windows. Opt. Express 2021, 29, 31058–31067. [Google Scholar] [CrossRef]

- Li, X.; Li, C.; Jiang, L.; Shi, X.; Zhang, N.; Lu, Y. Ablation area quasiperiodic oscillations in semiconductors with femtosecond laser double-pulse delay. Opt. Lett. 2014, 39, 2382–2385. [Google Scholar] [CrossRef]

- Wang, L.; Xu, B.-B.; Chen, Q.-D.; Ma, Z.-C.; Zhang, R.; Liu, Q.-X.; Sun, H.-B. Maskless laser tailoring of conical pillar arrays for antireflective biomimetic surfaces. Opt. Lett. 2011, 36, 3305–3307. [Google Scholar] [CrossRef] [Green Version]

- Zhang, F.; Wang, C.; Yin, K.; Dong, X.; Song, Y.; Tian, Y.; Duan, J. Underwater giant enhancement of broadband diffraction efficiency of surface diffraction gratings fabricated by femtosecond laser. J. Appl. Phys. 2017, 121, 243102. [Google Scholar] [CrossRef]

- Geints, Y.E.; Mokrousova, D.; Pushkarev, D.; Rizaev, G.; Seleznev, L.; Geints, I.Y.; Ionin, A.; Zemlyanov, A. Energy limit for linear-to-nonlinear femtosecond laser pulse focusing in air. Opt. Laser Technol. 2021, 143, 107377. [Google Scholar] [CrossRef]

- Lin, Z.; Ji, L.; Hong, M. Enhancement of femtosecond laser-induced surface ablation via temporal overlapping double-pulse irradiation. Photon. Res. 2020, 8, 271–278. [Google Scholar] [CrossRef]

- Zhang, Y.; Zou, G.; Liu, L.; Zhao, Y.; Liang, Q.; Wu, A.; Zhou, Y.N. Time-dependent wettability of nano-patterned surfaces fabricated by femtosecond laser with high efficiency. Appl. Surf. Sci. 2016, 389, 554–559. [Google Scholar] [CrossRef]

- Feng, H.; Dong, J.; Wu, X.; Yang, F.; Ma, L.; Liu, X.; Liu, Q. Ultra-large local field enhancement effect of isolated thick triangular silver nanoplates on a silicon substrate in the green waveband. Opt. Lett. 2020, 45, 2099–2102. [Google Scholar] [CrossRef]

- Hu, Y.; Liang, C.; Sun, X.; Zheng, J.; Duan, J.; Zhuang, X. Enhancement of the Conductivity and Uniformity of Silver Nanowire Flexible Transparent Conductive Films by Femtosecond Laser-Induced Nanowelding. Nanomaterials 2019, 9, 673. [Google Scholar] [CrossRef] [PubMed]

| Sample | Period | Processing Time | MPC Enhancement |

|---|---|---|---|

| SQA | 3.5 µm | 50 min | 46.1% |

| ASS | 3.8 µm | 2.8 h | 32.3% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, H.; Zhang, F.; Duan, J. Subwavelength Quasi-Periodic Array for Infrared Antireflection. Nanomaterials 2022, 12, 3520. https://doi.org/10.3390/nano12193520

Wang H, Zhang F, Duan J. Subwavelength Quasi-Periodic Array for Infrared Antireflection. Nanomaterials. 2022; 12(19):3520. https://doi.org/10.3390/nano12193520

Chicago/Turabian StyleWang, Haoran, Fan Zhang, and Ji’an Duan. 2022. "Subwavelength Quasi-Periodic Array for Infrared Antireflection" Nanomaterials 12, no. 19: 3520. https://doi.org/10.3390/nano12193520

APA StyleWang, H., Zhang, F., & Duan, J. (2022). Subwavelength Quasi-Periodic Array for Infrared Antireflection. Nanomaterials, 12(19), 3520. https://doi.org/10.3390/nano12193520