NiB-CrC Coatings Prepared by Magnetron Sputtering Using Composite Ceramic NiCr-BC Target Produced by Detonation Spray Coating

Abstract

:1. Introduction

2. Materials and Methods

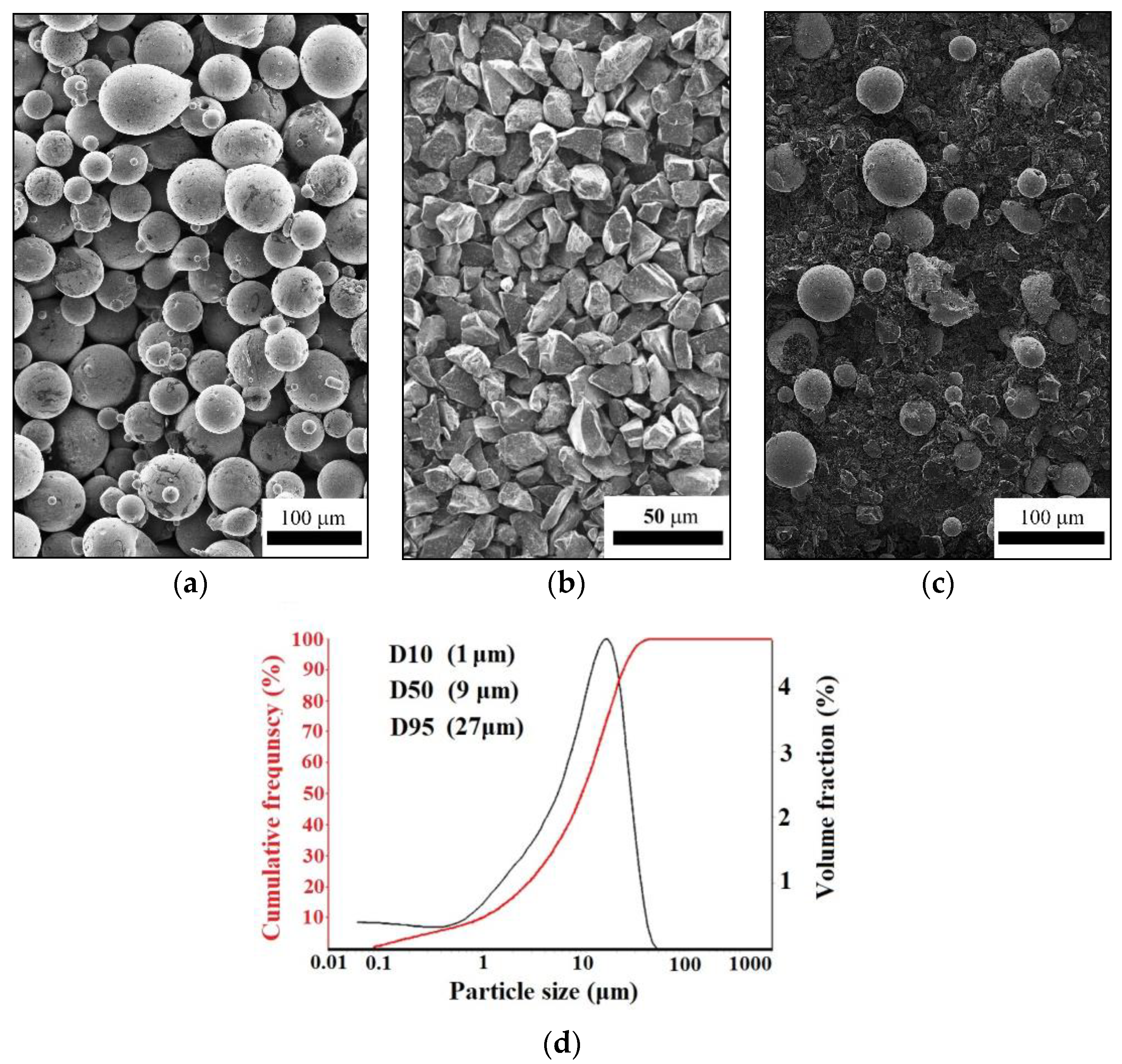

2.1. Powder Preparation

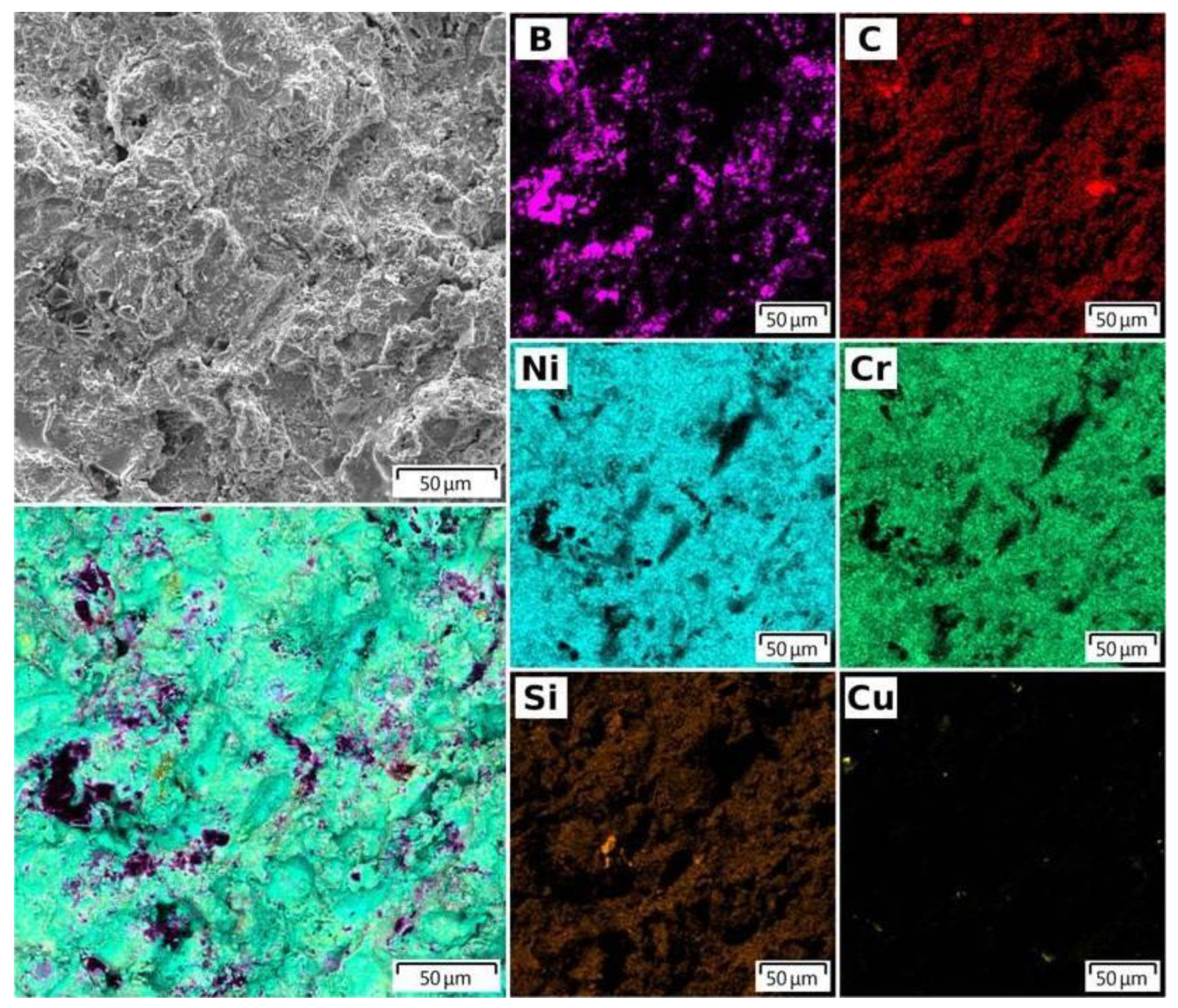

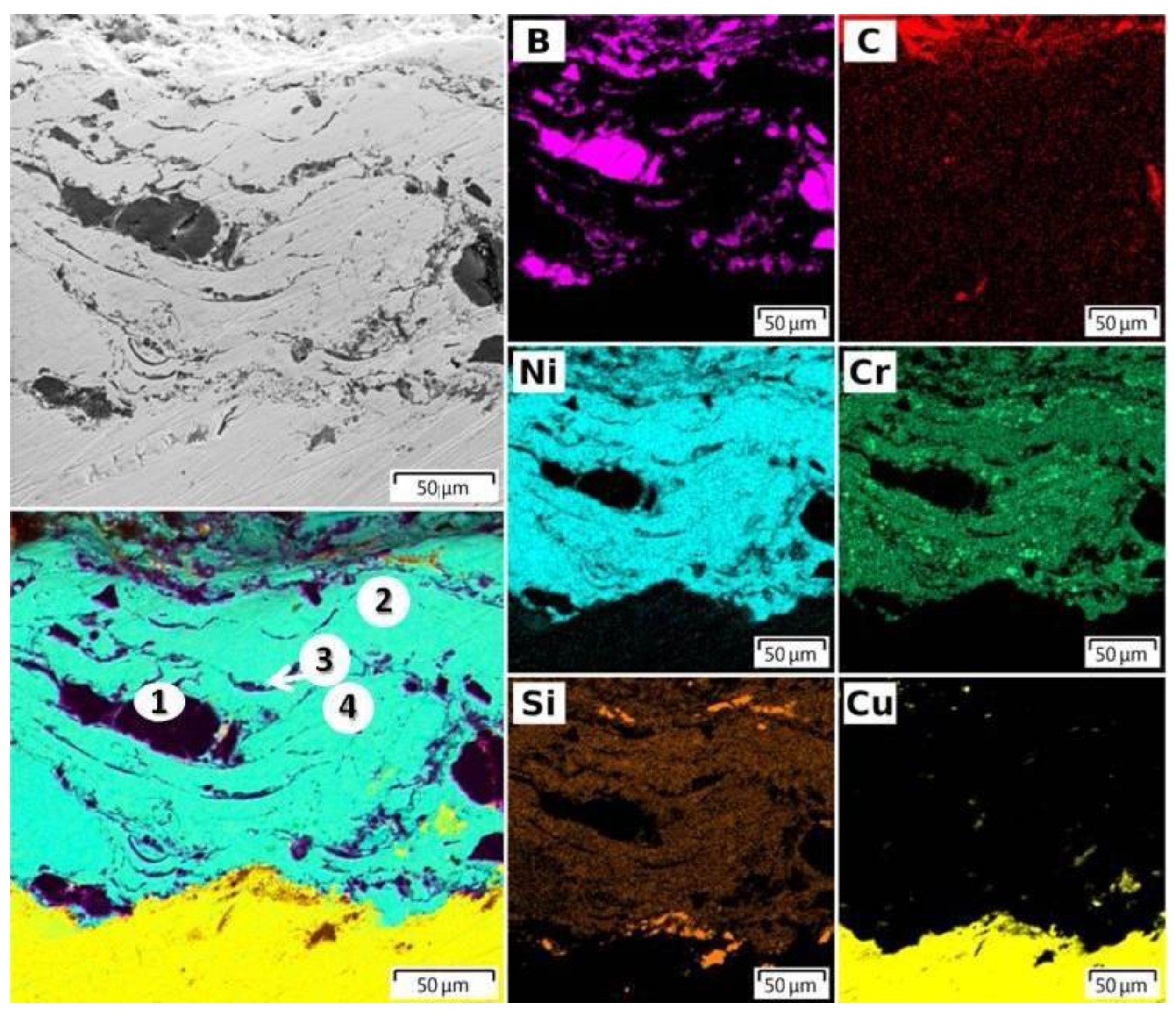

2.2. Metal–Ceramic Composite Target Preparation

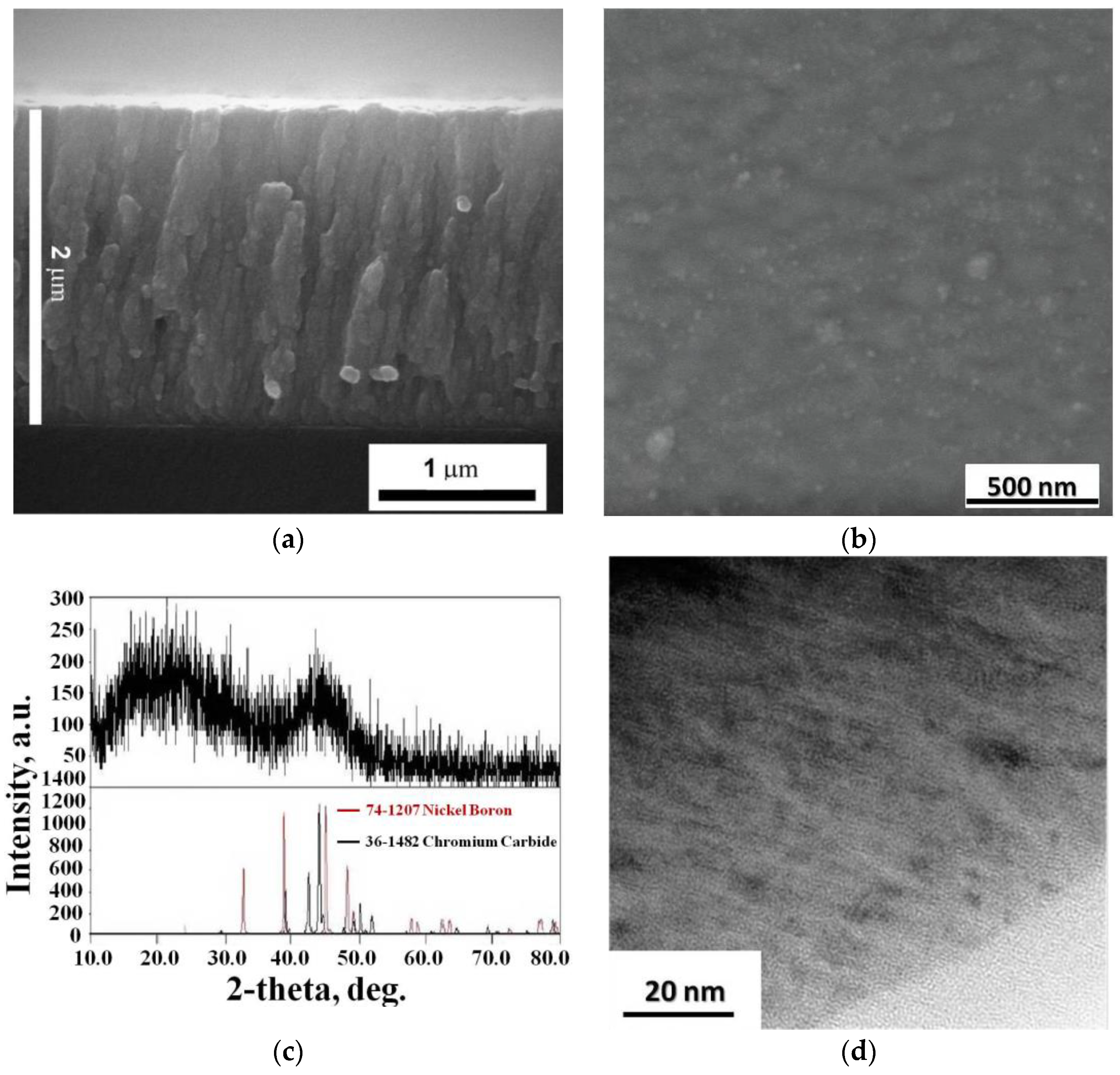

2.3. Boride–Carbide Coating Preparation

3. Results

4. Conclusions

- -

- copper cathode target of equipment for magnetron sputtering in the form of the rotating cylindrical target (100 × 5 mm, Ø 71 mm) was made;

- -

- NiCr-70B4C coating (thickness ~100–150 μm) without penetrating cracks was obtained on the surface of the cylindrical target cathode by a detonation sputtering complex;

- -

- NiCr-70B4C coating has a lamella-type structure;

- -

- analysis of the surface and cross-section of the NiCr-70B4C coating showed the presence of powder mixture elements (B, C, Ni, Cr, Si) both on the surface and in the volume of the coating;

- -

- cylindrical target cathode with NiCr-70B4C coating was used to obtain a smooth, dense and continuous NiB-Cr7C3 coating on the surface of a 65G steel substrate by magnetron deposition;

- -

- NiB-Cr7C3 coating with a thickness of 2 μm and a quasi-amorphous structure was obtained;

- -

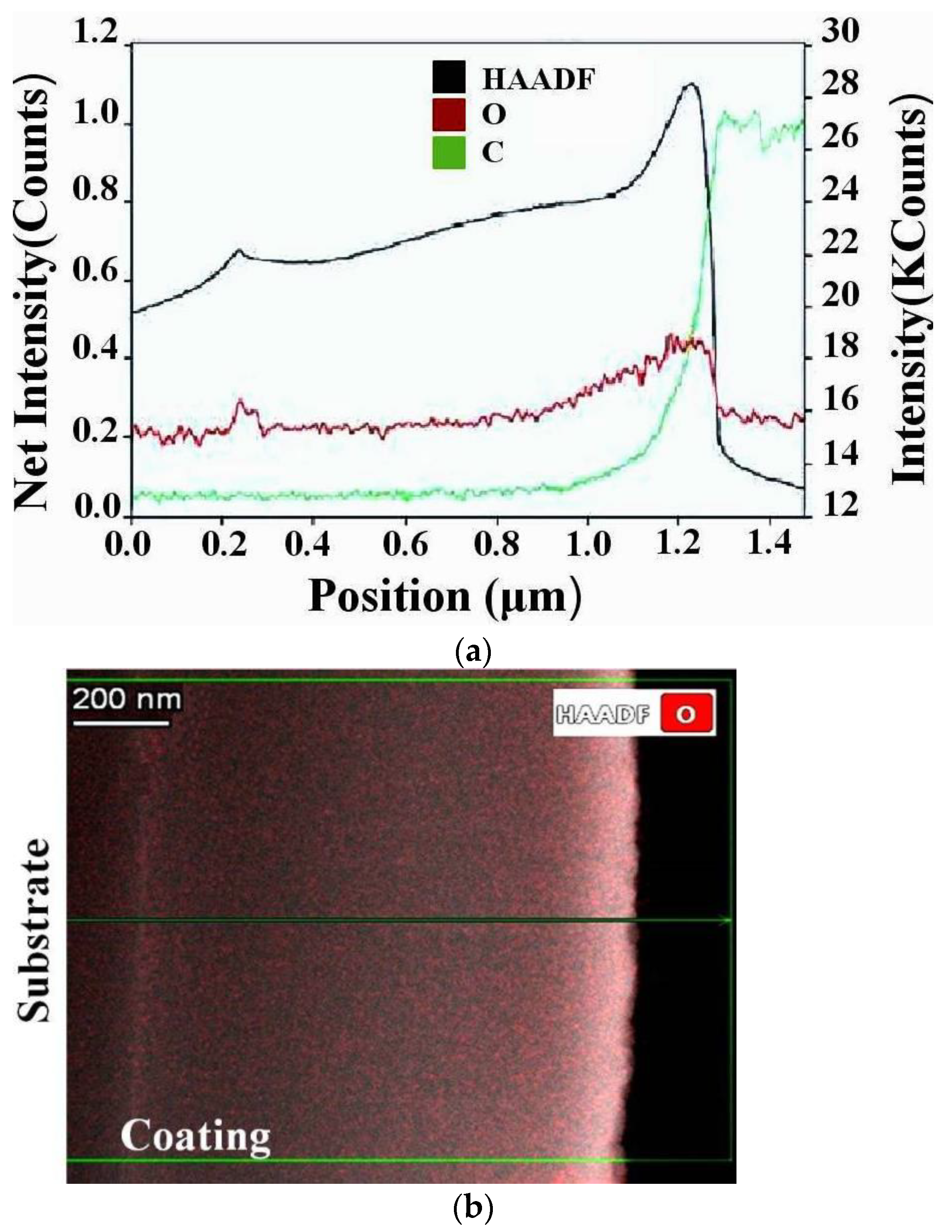

- to study the coating structures and concentration of oxygen and nitrogen impurities across the thickness of the coating, a sample of steel 65G with a NiCr-70B4C coating 1 μm thick was made;

- -

- the average concentration of oxygen in the coating reaches 5 at. %;

- -

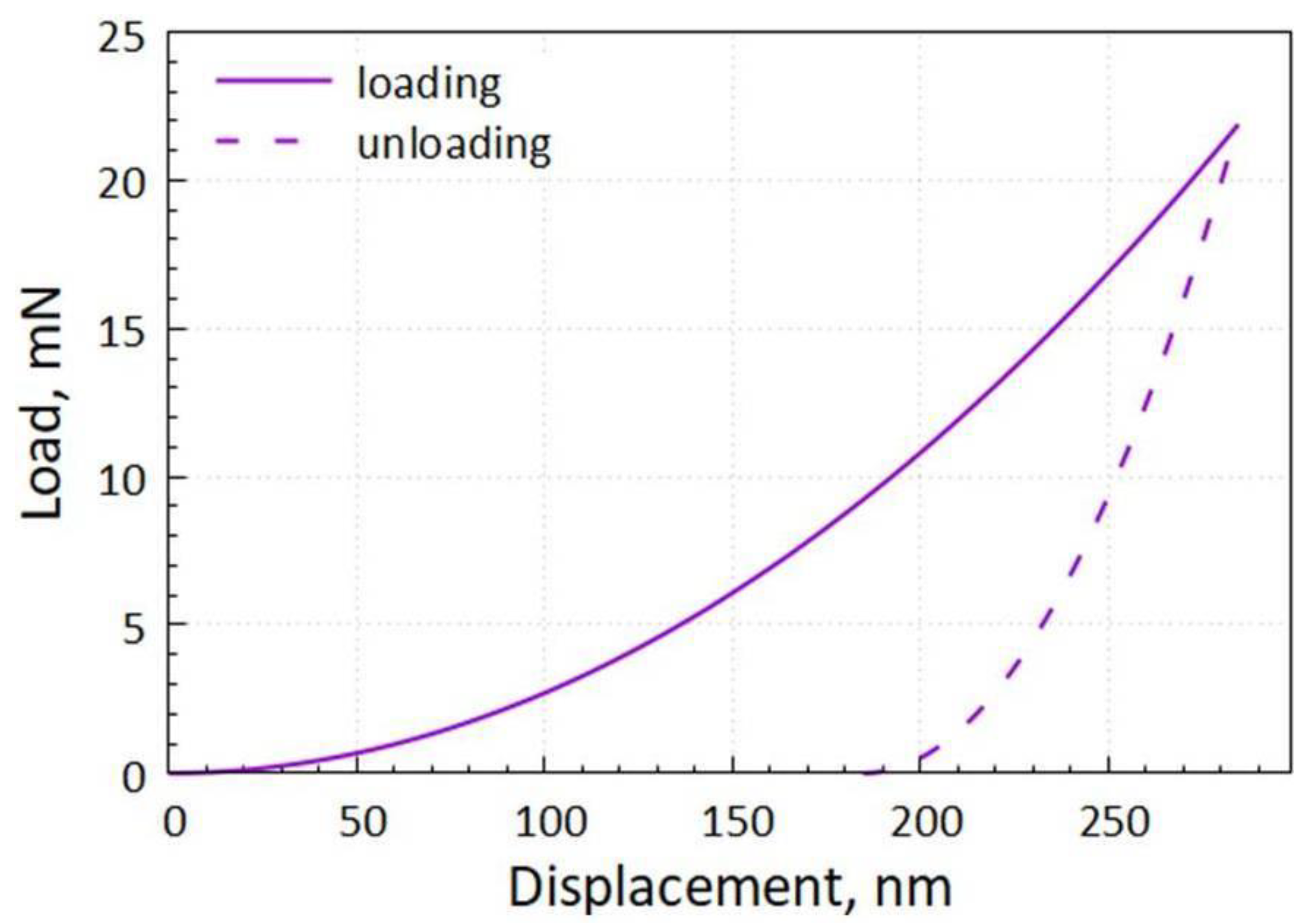

- the microhardness of the coating at an indentation depth of 0.25 μm (12.5% of the coating thickness) and at an indentation load of 21.86 mN is not less than 10 GPa;

- -

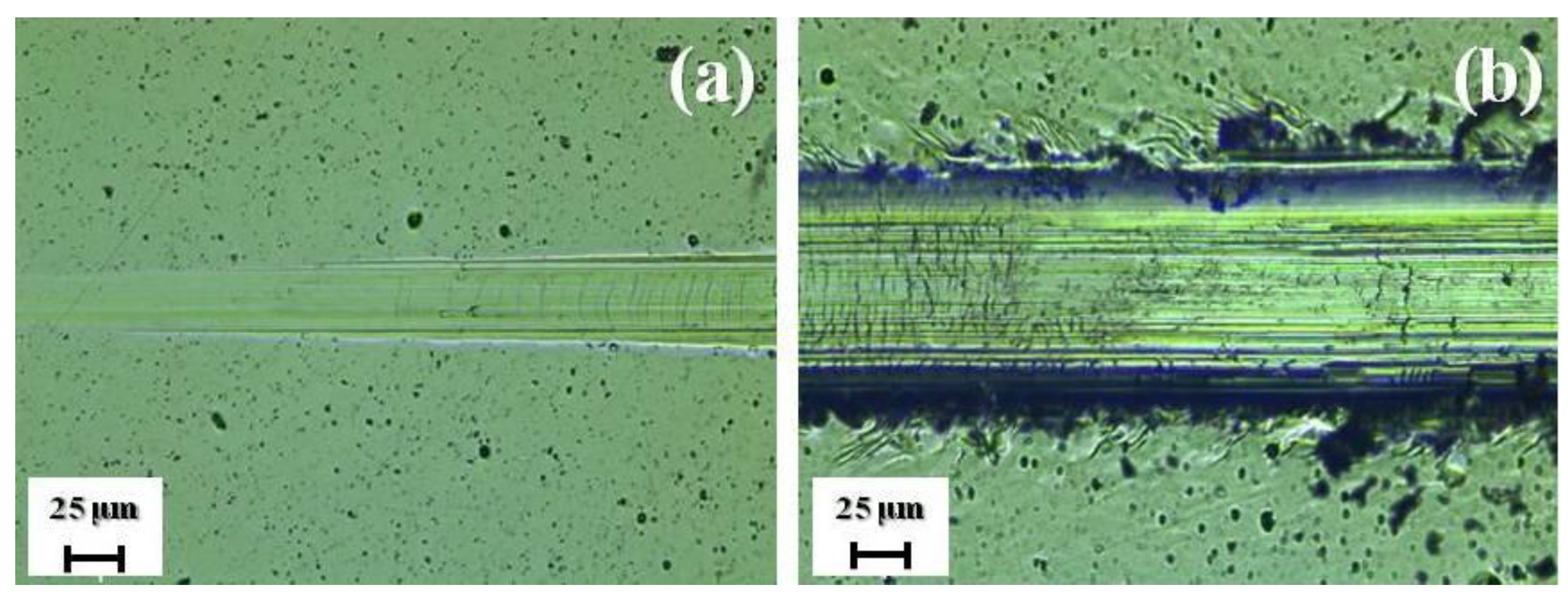

- the adhesion fracture load exceeds 16 N with plastic and uniform nature of wear.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Kosminska, Y.O.; Kornyushchenko, G.S.; Gannych, Y.V.; Perekrestov, V.I. Fabrication and physical properties of coatings belonging to W, Ta, Hf, Ti, Mo, Cr, Al and C based multicomponent systems. J. Superhard Mater. 2020, 42, 388–395. [Google Scholar] [CrossRef]

- Sheu, H.H.; Tzeng, Y.C.; Syu, J.H. Study of the strengthening mechanism of electrodeposited Ni-B thin films with ultra-low boron content. Mater. Lett. 2019, 238, 275–277. [Google Scholar] [CrossRef]

- Yildiz, R.A.; Genel, K.; Gulmez, T. Effect of electroless Ni-B and Ni-WB coatings on the corrosion-fatigue behavior of 7075 Al alloy. Int. J. Fatigue 2021, 144, 106040. [Google Scholar] [CrossRef]

- Kiryukhantsev-Korneev, P.V.; Sytchenko, A.D.; Gorshkov, V.A.; Loginov, P.A.; Sheveyko, A.N.; Nozhkina, A.V.; Levashov, E.A. Complex study of protective Cr3C2–NiAl coatings deposited by vacuum electro-spark alloying, pulsed cathodic arc evaporation, magnetron sputtering, and hybrid technology. Ceram. Int. 2022, 48, 10921–10931. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhang, S.; He, Y.; Li, H.; He, T.; Fan, Y.; Zhang, H. Mechanical properties and corrosion resistance of pulse electrodeposited Ni-B/B4C composite coatings. Surf. Coat. Technol. 2021, 421, 127458. [Google Scholar] [CrossRef]

- Lu, H.; Shang, J.; Jia, X.; Li, Y.; Li, F.; Li, J.; Nie, Y. Erosion and corrosion behavior of shrouded plasma sprayed Cr3C2-NiCr coating. Surf. Coat. Technol. 2020, 388, 125534. [Google Scholar] [CrossRef]

- Wang, Y.W.; Sun, X.W.; Wang, L.; Yang, Y.; Ren, X.X.; Ma, Y.D.; Dong, Y.C. Microstructure and properties of CrB2-Cr3C2 composite coatings prepared by plasma spraying. Surf. Coat. Technol. 2021, 425, 127693. [Google Scholar] [CrossRef]

- Kumar, D.D.; Kumar, N.; Kalaiselvam, S.; Radhika, R.; Rabel, A.M.; Jayavel, R. Tribo-mechanical properties of reactive magnetron sputtered transition metal carbide coatings. Tribol. Int. 2017, 114, 234–244. [Google Scholar] [CrossRef]

- Zhao, D.; Jiang, X.; Wang, Y.; Duan, W.; Wang, L. Microstructure evolution, wear and corrosion resistance of CrC nanocomposite coatings in seawater. Appl. Surf. Sci. 2018, 457, 914–924. [Google Scholar] [CrossRef]

- Kiryukhantsev-Korneev, P.V.; Sheveyko, A.N.; Vorotilo, S.A.; Levashov, E.A. Wear-resistant Ti–Al–Ni–C–N coatings produced by magnetron sputtering of SHS-targets in the DC and HIPIMS modes. Ceram. Int. 2020, 46, 1775–1783. [Google Scholar] [CrossRef]

- Kiryukhantsev-Korneev, F.V.; Kuptsov, K.A.; Sheveiko, A.N.; Levashov, E.A.; Shtansky, D.V. Wear-resistant Ti-Al-Si-CN coatings produced by magnetron sputtering of SHS targets. Russ. J. Non-Ferr. Met. 2013, 54, 330–335. [Google Scholar] [CrossRef]

- Kiryukhantsev-Korneev, P.V.; Sheveyko, A.N.; Kuptsov, K.A.; Novikov, A.V.; Shtansky, D.V. Ti-Cr-BN coatings prepared by pulsed cathodic-arc evaporation of ceramic TiCrB target produced by SHS. Prot. Met. Phys. Chem. Surf. 2013, 49, 677–681. [Google Scholar] [CrossRef]

- Kiryukhantsev-Korneev, P.V.; Iatsyuk, I.V.; Shvindina, N.V.; Levashov, E.A.; Shtansky, D.V. Comparative investigation of structure, mechanical properties, and oxidation resistance of Mo-Si-B and Mo-Al-Si-B coatings. Corros. Sci. 2017, 123, 319–327. [Google Scholar] [CrossRef]

- Kiryukhantsev-Korneev, P.V. Pulsed Magnetron Sputtering of Ceramic SHS Targets as a Promising Technique for Deposition of Multifunctional Coatings. Prot. Met. Phys. Chem. Surf. 2020, 56, 343–357. [Google Scholar] [CrossRef]

- Vasyliev, V.V.; Luchaninov, A.A.; Reshetnyak, E.N.; Strel’nitskij, V.E.; Tolmacheva, G.N.; Pribytkov, G.A.; Gurskikh, A.V.; Krinitcyn, M.G. Application of powder cathodes for Ti-Si-N coatings deposition from the filtered vacuum-arc plasma. Int. J. Surf. Sci. Eng. 2015, 13, 148–163. (In Russian) [Google Scholar]

- Kolisnichenko, O.V.; Tyurin, Y.N.; Tovbin, R. Efficiency of process of coating spraying using multichamber detonation unit. Paton Weld. J. 2017, 10, 18–23. [Google Scholar] [CrossRef]

- Tyurin, Y.N.; Pohrebniak, O.D. Method and Device for Detonation Film Deposition. UA Patent 83831, 26 August 2008. (In Ukrainian). [Google Scholar]

- Kovaleva, M.; Sirota, V.; Goncharov, I.; Novikov, V.; Yapryntsev, M.; Vagina, O.; Pavlenko, I.; Tyurin, Y.; Mogucheva, A. Kinetics investigation of the formation of a gas-resistant glass-forming layer during the oxidation of ZrB2-MoSi2-Y2O3-Al coatings in the air atmosphere. Coatings 2021, 11, 1018. [Google Scholar] [CrossRef]

- Endo, T.; Obayashi, R.; Tajiri, T.; Kimura, K.; Morohashi, Y.; Johzaki, T.; Mizunari, S. Thermal spray using a high-frequency pulse detonation combustor operated in the liquid-purge mode. J. Therm. Spray Technol. 2016, 25, 494–508. [Google Scholar] [CrossRef]

- Wang, Q.; Sun, Q.; Zhang, M.X.; Niu, W.J.; Tang, C.B.; Wang, K.S.; Wang, L. The influence of cold and detonation thermal spraying processes on the microstructure and properties of Al-based composite coatings on Mg alloy. Surf. Coat. Technol. 2018, 352, 627–633. [Google Scholar] [CrossRef]

- Markashova, L.I.; Tyurin, Y.N.; Kolisnichenko, O.V.; Berdnikova, E.N.; Kushnareva, O.S.; Polovetsky, E.V.; Titkov, E.P. Effect of structure on properties of Al2O3 and Al (or Ti) mechanical mixture coatings produced by multi-chamber detonation spraying method. Paton Weld. J. 2017, 9, 27–32. [Google Scholar] [CrossRef]

- Kovaleva, M.; Prozorova, M.; Arseenko, M.; Tyurin, Y.; Kolisnichenko, O.; Yapryntsev, M.; Sirota, V. Zircon-based ceramic coatings formed by a new multi-chamber gas-dynamic accelerator. Coatings 2017, 7, 142. [Google Scholar] [CrossRef]

- Kovaleva, M.; Goncharov, I.; Novikov, V.; Yapryntsev, M.; Vagina, O.; Pavlenko, I.; Sirota, V.; Tyurin, Y.; Kolisnichenko, O. Effect of heat treatment on the microstructure and phase composition of ZrB2–MoSi2 coating. Coatings 2019, 9, 779. [Google Scholar] [CrossRef] [Green Version]

- Vasilik, N.; Tyurin, Y.; Kolisnichenko, O. Method for Gas-Dynamic Detonating Speedup of Powders and Device for Its Implementation. RU Patent 2,506,341, 11 July 2012. [Google Scholar]

- Kovaleva, M.; Tyurin, Y.; Vasilik, N.; Kolisnichenko, O.; Prozorova, M.; Arseenko, M.; Danshina, E. Deposition and Characterization of Al2O3 Coatings by Multi-chamber Gas-dynamic Accelerator. Surf. Coat. Technol. 2013, 232, 719–725. [Google Scholar] [CrossRef]

- Šímová, V.; Vlček, J.; Zuzjaková, Š.; Houška, J.; Shen, Y.; Jiang, J.; Peřina, V. Magnetron sputtered Hf-B-Si-C-N films with controlled electrical conductivity and optical transparency, and with ultrahigh oxidation resistance. Thin Solid Films 2018, 653, 333–340. [Google Scholar] [CrossRef]

- Chang, C.L.; Huang, C.S.; Jao, J.Y. Microstructural, mechanical and wear properties of Cr-Al-B-N coatings deposited by DC reactive magnetron co-sputtering. Surf. Coat. Technol. 2011, 205, 2730–2737. [Google Scholar] [CrossRef]

- Debnárová, S.; Souček, P.; Buršíková, V.; Hans, M.; Holzapfel, D.M.; Mráz, S.; Vašina, P. Phase formation, thermal stability and mechanical properties of Nb-BC coatings prepared by combinatorial magnetron sputtering. Surf. Coat. Technol. 2022, 433, 128137. [Google Scholar] [CrossRef]

- Smyrnova, K.V.; Pogrebnjak, A.D.; Beresnev, V.M.; Litovchenko, S.V.; Borba-Pogrebnjak, S.O.; Manokhin, A.S.; Klimenko, S.A.; Zhollybekov, B.; Kupchishin, A.I.; Kravchenko, Y.O.; et al. Microstructure and physical-mechanical properties of (TiAlSiY)N nanostructured coatings under different energy conditions. Met. Mater. Int. 2018, 24, 1024–1035. [Google Scholar] [CrossRef]

| Barrel Length, mm | Barrel Diameter, mm | Deposition Distance, mm | Powder Feed Rate, g/h | Flow Rate of Fuel Mixture Components, m3/h | ||

|---|---|---|---|---|---|---|

| Oxygen | Propane | Air | ||||

| 500 | 16 | 60 | 700 | * 187/ ** 190 | * 41/ ** 41 | * 94/ ** 82 |

| Parameters | Meaning | |

|---|---|---|

| Leaking | 0.06 cm3/min | |

| Operating pressure | 0.17 Pa | |

| Working gas | Ar (99.999% purity) | |

| Total argon flow in the chamber | 78 sccm * | |

| Current/Voltage | ||

| Target | NiCr-B4C | 2 A/506 V |

| Carbon | 0.8 A/489 V | |

| Frequency | 18 kHz | |

| Cathode material | NiCr-B4C Carbon (99.999% purity) | |

| Bias | 1 A/40 V | |

| Magnetron–sample distance | 70 mm | |

| Deposition time | 50 min | |

| Point | Element Composition, wt% | |||||

|---|---|---|---|---|---|---|

| B | C | Ni | Cr | Si | Cu | |

| 1 | 75.49 | 23.73 | 0.34 | 0.08 | 0.13 | - |

| 2 | - | 7.90 | 72.96 | 10.88 | 4.04 | - |

| 3 | 54.68 | 20.05 | 15.14 | 2.59 | 0.82 | 2.64 |

| 4 | - | 8.23 | 57.53 | 20.52 | 2.99 | 6.30 |

| Element composition, wt% | B | C | O | Al | Si | Ca | Cr | Fe | Ni |

| 11.89 | 8.64 | 1.09 | 0.16 | 3.52 | 0.22 | 12.50 | 3.39 | 58.60 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sirota, V.; Zaitsev, S.; Prokhorenkov, D.; Limarenko, M.; Skiba, A.; Kovaleva, M. NiB-CrC Coatings Prepared by Magnetron Sputtering Using Composite Ceramic NiCr-BC Target Produced by Detonation Spray Coating. Nanomaterials 2022, 12, 3584. https://doi.org/10.3390/nano12203584

Sirota V, Zaitsev S, Prokhorenkov D, Limarenko M, Skiba A, Kovaleva M. NiB-CrC Coatings Prepared by Magnetron Sputtering Using Composite Ceramic NiCr-BC Target Produced by Detonation Spray Coating. Nanomaterials. 2022; 12(20):3584. https://doi.org/10.3390/nano12203584

Chicago/Turabian StyleSirota, Viacheslav, Sergei Zaitsev, Dmitriy Prokhorenkov, Mihail Limarenko, Andrey Skiba, and Marina Kovaleva. 2022. "NiB-CrC Coatings Prepared by Magnetron Sputtering Using Composite Ceramic NiCr-BC Target Produced by Detonation Spray Coating" Nanomaterials 12, no. 20: 3584. https://doi.org/10.3390/nano12203584