Processing Effects on the Martensitic Transformation and Related Properties in the Ni55Fe18Nd2Ga25 Ferromagnetic Shape Memory Alloy

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussions

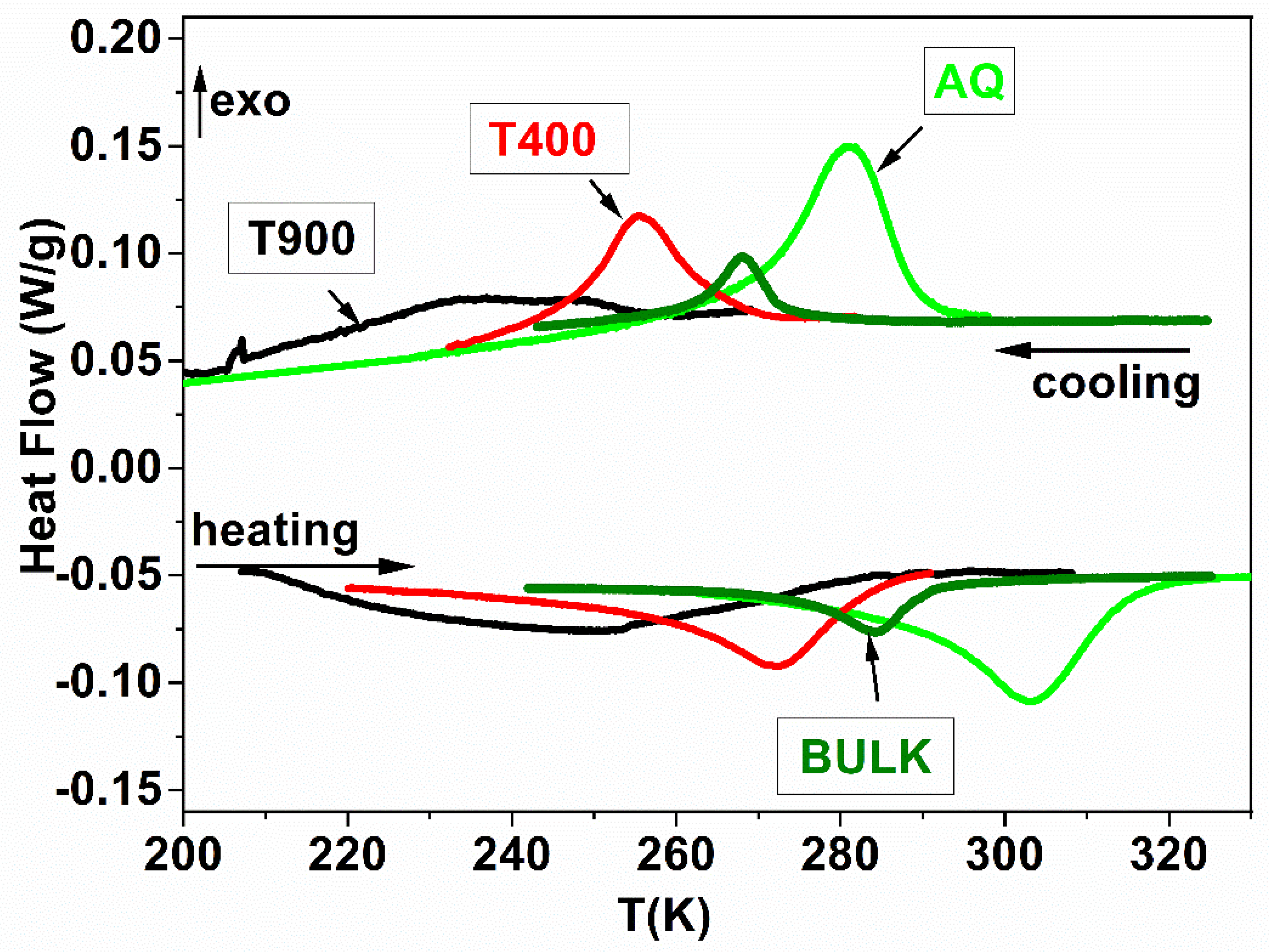

3.1. DSC

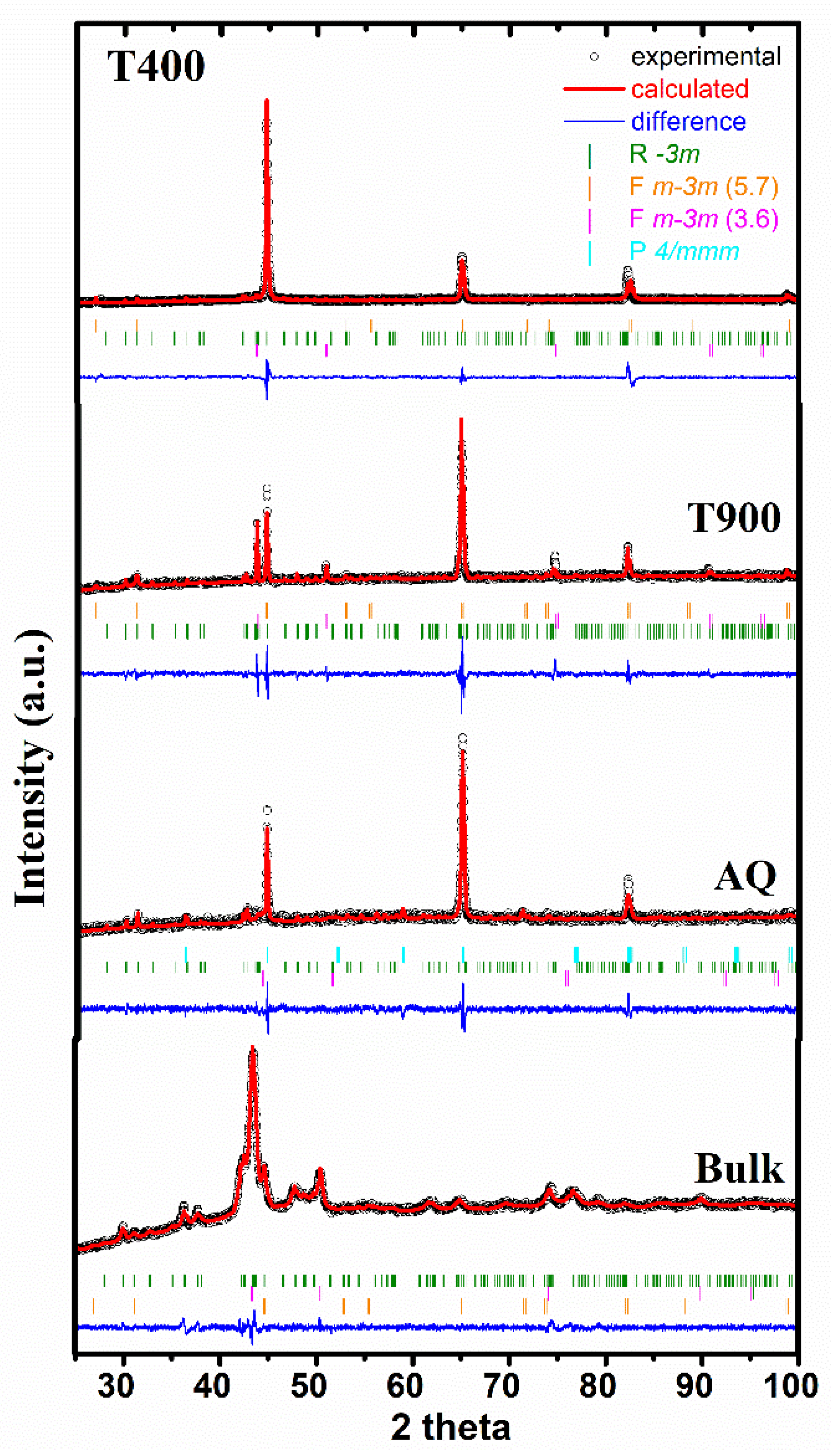

3.2. XRD

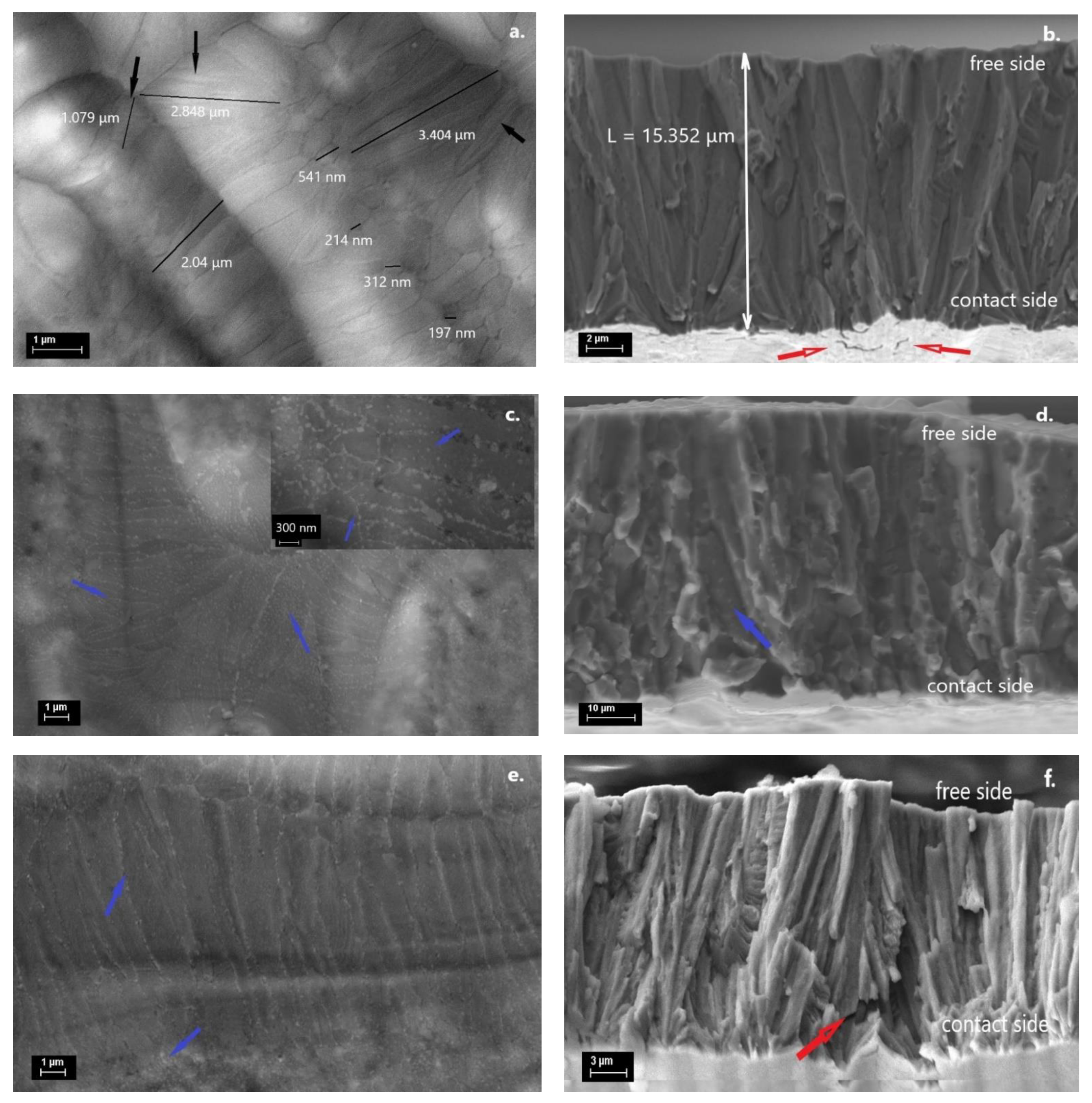

3.3. SEM

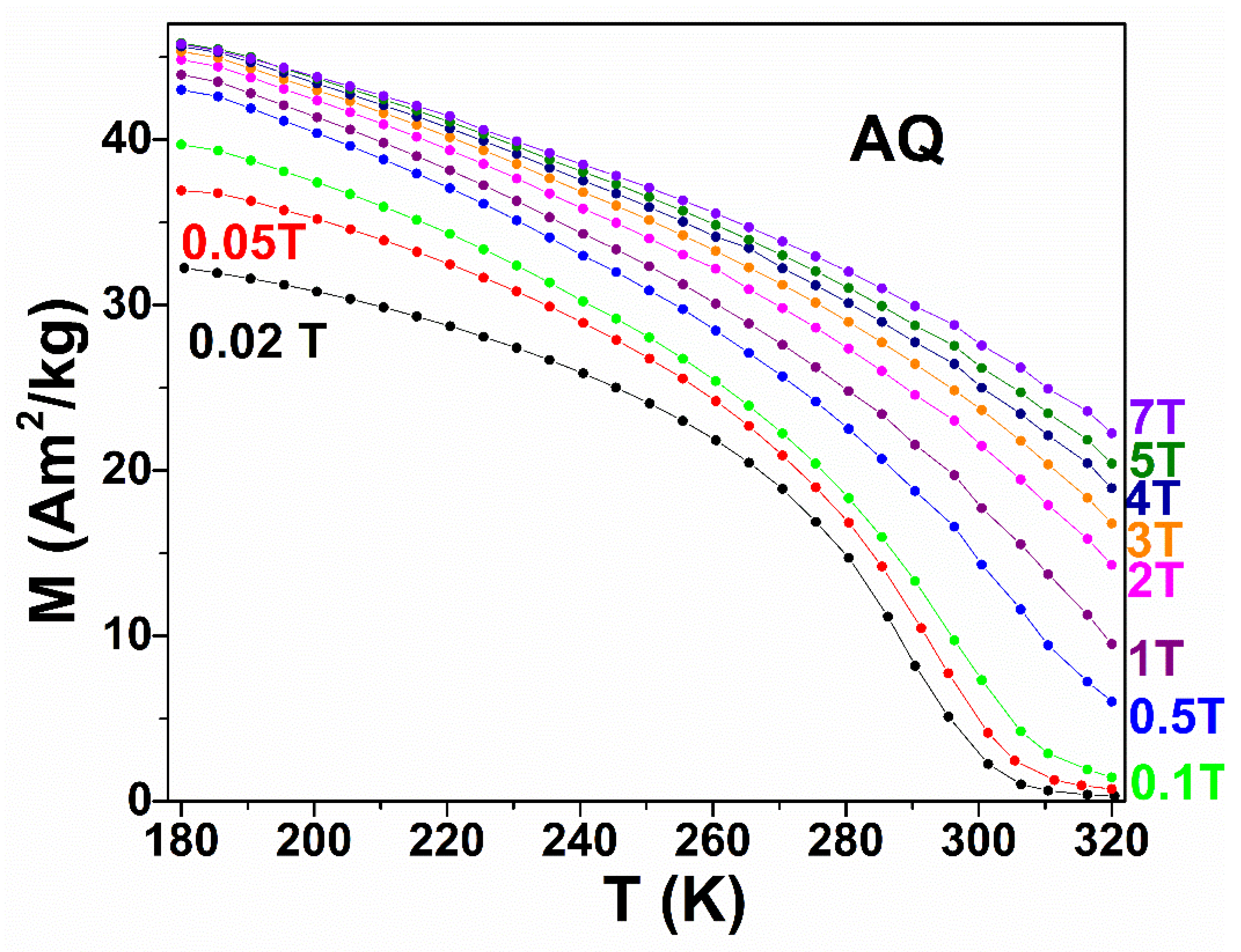

3.4. Magnetic Properties

3.5. Evaluation of Magnetocaloric Effect

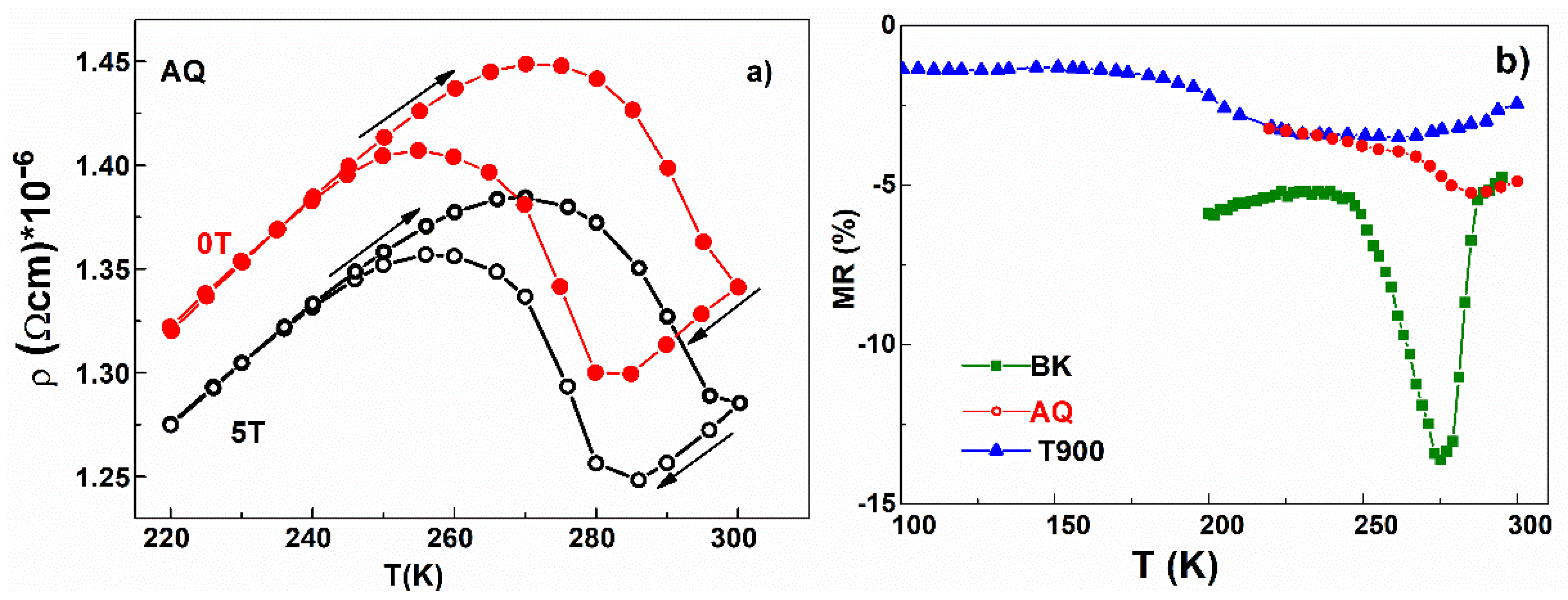

3.6. MR Evaluation from Ac Resistivity (ρ)

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Petrini, L.; Migliavacca, F. Biomedical Applications of Shape Memory Alloys. J. Metall. 2011, 2021, 501483. [Google Scholar] [CrossRef]

- Morgan, N.B. Medical shape memory alloy applications—The market and its products. Mater. Sci. Eng. A 2004, 378, 16–23. [Google Scholar] [CrossRef]

- Song, G.; Ma, N.; Li, H.-N. Applications of shape memory alloys in civil structures. Eng. Struct. 2006, 28, 1266–1274. [Google Scholar] [CrossRef]

- Nespoli, A.; Besseghini, S.; Pittaccio, S.; Villa, E.; Viscuso, S. The high potential of shape memory alloys in developing miniature mechanicaldevices: A review on shape memory alloy mini-actuators. Sens. Actuators A 2010, 158, 149–160. [Google Scholar] [CrossRef]

- Furuya, Y.; Shimada, H. Shape memory actuators for robotic applications. Mater. Des. 1991, 12, 21–28. [Google Scholar] [CrossRef]

- Van Humbeeck, J. Non-medical applications of shape memory alloys. Mater. Sci. Eng. A 1999, 273–275, 134–148. [Google Scholar] [CrossRef]

- Frolova, L.; Mino, J.; Ryba, T.; Gamcova, J.; Dzubinska, A.; Reiers, M.; Diko, P.; Kavecansky, V.; Milkovic, O.; Kravcak, J. Novel compositions of Heusler-based glass-coated microwires for practical applications using shape memory effect. J Alloys Compd. 2018, 747, 21–25. [Google Scholar] [CrossRef]

- Caputo, M.P.; Berkowitz, A.E.; Armstrong, A.; Müllner, P.; Solomon, C.V. 4D printing of net shape parts made from Ni-Mn-Ga magnetic shape-memory alloys. Addit. Manuf. 2018, 21, 579–588. [Google Scholar] [CrossRef]

- Otsuka, K.; Wayman, C.M. Shape Memory Materials; Cambridge University Press: Cambridge, UK, 1998. [Google Scholar]

- Graf, T.; Felser, C.; Parkin Stuart, S.P. Simple rules for the understanding of Heusler compounds. Prog. Solid State Chem. 2011, 39, 1–50. [Google Scholar] [CrossRef]

- Wollmann, L.; Ajaya, K.N.; Stuart, S.P.P.; Felser, C. Heusler 4.0: Tunable Materials. Annu. Rev. Mater. Res. 2017, 47, 247–270. [Google Scholar] [CrossRef]

- Ullakko, K.; Huang, J.K.; Kantner, C.; O’Handley, R.C.; Kokorin, V.V. Large magnetic-field-induced strains in Ni2MnGa single crystals. Appl. Phys. Lett. 1996, 69, 1966. [Google Scholar] [CrossRef]

- Wuttig, M.; Li, J.; Craciunescu, C. A new ferromagnetic shape memory alloy system. Scr. Mater. 2001, 44, 2393–2397. [Google Scholar] [CrossRef]

- Liu, J.; Xie, H.; Huo, Y.; Zheng, H.; Li, J. Microstructure evolution in CoNiGa shape memory alloys. J Alloys Compd. 2006, 420, 145–157. [Google Scholar] [CrossRef]

- Scheibel, F.; Lauhoff, C.; Riegg, S.; Krooss, P.; Bruder, E.; Adabifiroozjaei, E.; Molina-Luna, L.; Bohm, S.; Chumlyakov, Y.I.; Niendorf, T.; et al. On the Impact of Additive Manufacturing Processes on the Microstructure and Magnetic Properties of Co-Ni-Ga Shape Memory Heusler Alloys. Adv. Eng. Mat. 2022, 2022, 2200069. [Google Scholar] [CrossRef]

- Mishra, A.; Dubey, P.; Chandra, R.; Srivastava, S.K. Observation of large exchange bias field in Mn rich NiMnAl Heusler alloy thin film. J. Mag. Mag. Mat. 2021, 532, 167964. [Google Scholar] [CrossRef]

- Lazpita, P.; Perez-Checa, A.; Barandiaran, J.M.; Ammerlaan, A.; Zeitler, U.; Chernenko, V. Suppression of martensitic transformation in Ni-Mn-In metamagnetic shape memory alloy under very strong magnetic field. J Alloys Compd. 2021, 874, 159814. [Google Scholar] [CrossRef]

- Zhang, Y.J.; Guo, J.P.; Zhong, M.T.; Xiang, W.W.; Wu, Z.G. Martensitic transformation behaviour and mechanical property of dual-phase Ni-Co-Mn-Sn-Fe ferromagnetic shape memory alloys. J. Mag. Mag. Mat. 2021, 521, 167540. [Google Scholar] [CrossRef]

- Dagdelen, F.; Ozay, C.; Ercan, E.; Emir, G.; Qader, I.N. Change of electrical resistivity during phase transitions in NiMnSn-based shape memory alloy. J. Therm. Anal. Calorim. 2022, 147, 5815–5823. [Google Scholar] [CrossRef]

- Czaja, P.; Przewoznik, J.; Hawelek, L.; Chrobak, A.; Zackiewicz, P.; Maziarz, W. Martensitic transformation, magnetic entropy, and adiabatic temperature changes in bulk and ribbon Ni48Mn39.5Sn12.5−xInx (x = 2, 4, 6) metamagnetic shape memory alloys. J. Mat. Res. 2021, 36, 3317–3328. [Google Scholar] [CrossRef]

- Bonifacich, F.G.; Lambri, O.A.; Perez-Landazabal, J.I.; Recarte, V.; Gargicevich, D.; Zelada, G.I.; Mocellini, R.R.; Sanchez-Alarcos, V.; Marenzana, A.; Plazaola, F. Study of the martensitic transition in Ni-Mn-Sn-Ti ferromagnetic shape memory alloys. Materia Rio J. 2018, 23, 12043. [Google Scholar] [CrossRef]

- Oikawa, K.; Ota, Y.; Ohmori, T.; Tanaka, Y.; Morito, H.; Kainuma, R.; Fukamichi, K.; Ishida, K. Magnetic and martensitic phase transitions in ferromagnetic Ni-Ga-Fe shape memory alloys. Appl. Phys. Lett. 2002, 81, 5201–5203. [Google Scholar] [CrossRef]

- Santamarta, R.; Font, J.; Muntasell, J.; Masdeu, F.; Pons, J.; Cesari, E.; Dutkiewicz, J. Effect of ageing on the martensitic transformation of Ni-Fe-Ga alloys. Scr. Mater. 2006, 54, 1105–1109. [Google Scholar] [CrossRef]

- Alvarado-Hernández, F.; Soto-Parra, D.E.; Ochoa-Gamboa, R.; Castillo-Villa, P.O.; Flores-Zúňiga, H.; Ríos-Jara, D. Thermal and structural study of Ni-Fe-Ga ferromagnetic shape memory alloys. J. Alloys Compd. 2008, 426, 442–445. [Google Scholar] [CrossRef]

- Biswas, A.; Singh, G.; Sarkar, S.K.; Krishnan, M.; Ramamurty, U. Hot deformation behavior of Ni-Fe-Ga-based ferromagnetic shape memory alloy—A study using processing map. Intermetallics 2014, 54, 69–78. [Google Scholar] [CrossRef]

- Pons, J.; Cesari, E.; Seguí, C.; Masdeu, F.; Santamartak, R. Ferromagnetic shape memory alloys: Alternatives to Ni-Mn-Ga. Mater. Sci. Eng. A 2008, 481–482, 57–65. [Google Scholar] [CrossRef]

- Okumura, H.; Uemura, K. Influence of quenching rate on the magnetic and martensitic properties of Ni-Fe-Ga melt-spun ribbons. J. Appl. Phys. 2010, 108, 043910. [Google Scholar] [CrossRef]

- Liu, J.; Scheerbaum, N.; Hinz, D.; Gutfleisch, O. Martensitic transformation and magnetic properties in Ni-Fe-Ga-Co magnetic shape memory alloys. Acta. Mater. 2008, 56, 3177–3186. [Google Scholar] [CrossRef]

- Gao, L.; Gao, Z.Y.; Cai, W.; Zhao, L.C. Effect of rare earth Dy addition on microstructure and martensitic transformation on polycrystalline Ni50Mn29Ga21−xDyx ferromagnetic shape memory alloys. Mater. Sci. Eng. A 2006, 438–440, 1077–1080. [Google Scholar] [CrossRef]

- Gao, L.; Sui, J.H.; Cai, W. Influence of rare earth Gd addition on the structural and magnetic transitions of Ni-Mn-Ga alloys. J. Mag. Mag. Mater. 2008, 320, 63–67. [Google Scholar] [CrossRef]

- Zhang, X.; Sui, J.; Yu, Z.; Cai, W. Structure and shape memory effect in a Ni54Mn25Ga20Gd1 alloy with a high transformation temperature. J. Alloys Compd. 2011, 509, 8032–8037. [Google Scholar] [CrossRef]

- Sui, J.; Zhang, X.; Gao, L.; Cai, W. Microstructure, phase transformation and mechanical properties of Ni-Mn-Ga-Y magnetic shape memory alloys. J. Alloys Compd. 2011, 509, 8692–8699. [Google Scholar] [CrossRef]

- Tsuchiya, K.; Tsutsumi, A.; Ohtsuka, H.; Umemoto, M. Modification of Ni-Mn-Ga ferromagnetic shape memory alloy by addition of rare earth elements. Mater. Sci. Eng. A 2004, 378, 370–376. [Google Scholar] [CrossRef]

- Rama Rao, N.V.; Gopalan, R.; Manivel Raja, M.; Chandrasekaran, V.; Suresh, K.G. Mössbauer studies on structural ordering and magnetic properties of melt-spun Ni-Fe-Ga ribbons. Appl. Phys. Lett. 2008, 93, 202503. [Google Scholar]

- Pecharsky, V.K.; Gschneidner, K.A., Jr. Giant Magnetocaloric Effect in Gd5(Si2Ge2). Phys. Rev. Lett. 1997, 78, 4494. [Google Scholar] [CrossRef]

- Qian, J.F.; Liu, E.K.; Feng, L.; Zhu, W.; Li, G.J.; Wang, W.H.; Wu, G.H.; Du, Z.W.; Fu, X. Unusual magnetic anisotropy in the ferromagnetic shape-memory alloy Ni50Fe23Ga27. Appl. Phys. Lett. 2011, 99, 252504. [Google Scholar]

- Hamilton, R.F.; Efstathiou, C.; Sehitoglu, H.; Chumlyakov, Y. Thermal and stress-induced martensitic transformations in NiFeGa single crystals under tension and compression. Scr. Mat. 2006, 54, 465–469. [Google Scholar] [CrossRef]

- Chernenko, V.A.; Barandiarán, J.M.; L’Vov, V.A.; Gutiérrez, J.; Lázpita, P.; Orue, I. Temperature dependent magnetostrains in polycrystalline magnetic shape memory Heusler alloys. J Alloys Compd. 2013, 577, S305–S308. [Google Scholar] [CrossRef]

- Khovaylo, V.V.; Buchelnikov, V.D.; Kainuma, R.; Koledov, V.V.; Ohtsuka, M.; Shavrov, V.G. Phase transitions in Ni2+xMn1−xGa with a high Ni excess. Phys. Rev. B 2005, 72, 224408. [Google Scholar] [CrossRef] [Green Version]

- Tolea, F.; Crisan, A.D.; Sofronie, M.; Tolea, M.; Valeanu, M. Magnetic and Martensitic transformations in the bulk and melt spun ribbons of Ni57−xNdxFe18Ga25 Ferromagnetic Shape Memory Alloys. Mater. Today Proc. 2015, 2S, S875–S878. [Google Scholar]

- Picornell, C.; Pons, J.; Cesari, E.; Dutkiewicz, J. Thermal characteristics of Ni-Fe-Ga-Mn and Ni-Fe-Ga-Co ferromagnetic shape memory alloys. Intermetallics 2008, 16, 751–757. [Google Scholar] [CrossRef]

- Tolea, F.; Sofronie, M.; Crisan, A.D.; Enculescu, M.; Kuncser, V.; Valeanu, M. Effect of thermal treatments on the structural and magnetic transitions in melt-spun Ni-Fe-Ga-(Co) ribbons. J. Alloys Compd. 2015, 650, 664–670. [Google Scholar] [CrossRef]

- Albertini, F.; Besseghini, S.; Paoluzi, A.; Pareti, L.; Pasquale, M.; Passaretti, F.; Sasso, C.P.; Stantero, A.; Villa, E. Structural, magnetic and anisotropic properties of Ni2MnGa melt-spun ribbons. J. Mag. Mag. Mater. 2002, 1421, 242–245. [Google Scholar] [CrossRef]

- Liu, Y.; Zhang, X.; Xing, D.; Shen, H.; Chen, D.; Liu, J.; Sun, J. Magnetocaloric effect (MCE) in melt-extracted Ni-Mn-Ga-Fe Heusler microwires. J. Alloys Compd. 2014, 616, 184–188. [Google Scholar] [CrossRef]

- Recarte, V.; Pérez-Landazábal, J.I.; Gomez-Polo, C.; Cesari, E.; Dutkiewicz, J. Magnetocaloric effect in Ni-Fe-Ga shape memory alloys. Appl. Phys. Lett. 2006, 88, 132503. [Google Scholar]

- Sarkar, S.K.; Biswas, A.; Babu, P.D.; Kaushik, S.D.; Srivastava, A.; Siruguri, V.; Krishnan, M. Effect of partial substitution of Fe by Mn in Ni55Fe19Ga26 on its microstructure and magnetic properties. J. Alloys Compd. 2014, 586, 515–523. [Google Scholar] [CrossRef]

- Pal, D.; Mandal, K. Magnetocaloric effect and magnetoresistance of Ni-Fe-Ga alloys. J. Phys. D Appl. Phys. 2010, 43, 455002. [Google Scholar] [CrossRef]

- Barandiarán, J.M.; Chernenko, V.A.; Lázpita, P.; Gutiérrez, J.; Feuchtwanger, J. Effect of martensitic transformation and magnetic field on transport properties of Ni-Mn-Ga and Ni-Fe-Ga Heusler alloys. Phys. Rev. B 2009, 80, 104404. [Google Scholar] [CrossRef]

- Srivastava, V.K.; Chatterjee, R.; O’Handley, R.C. Effect of twin boundaries on electrical transport in Ni-Mn-Ga single crystal. Appl. Phys. Lett. 2006, 89, 222107. [Google Scholar] [CrossRef]

| Sample | Ms (K) | Mf (K) | As (K) | Af (K) | T0 (K) | TCM (K) | TCA (K) | ΔSm (J/kgK) |

|---|---|---|---|---|---|---|---|---|

| Bulk | 274 | 262.6 | 275.6 | 290 | 282 | 300 | 291 | −4.58 |

| AQ | 291 | 269 | 290 | 318 | 304.5 | 290 | 282.6 | −5.4 |

| T400 | 267 | 246 | 261 | 285 | 276 | 296 | 291.6 | −3.2 |

| T900 | 258 | 204 | 210 | 281 | 269.5 | 275 | 271 | −3.4 |

| Sample | Phase | a (Å) | c (Å) | V (Å3) | Dp (nm) |

|---|---|---|---|---|---|

| Bulk | Fm-3m | 5.747 (1) | - | 189.8 | - |

| Fm-3m | 3.618 (9) | - | 47.4 | - | |

| R-3m | 8.565 (1) | 12.476 (1) | 792.6 | - | |

| AQ | P 4/mmm | 2.481 (1) | 3.515 (9) | 21.6 | 43.3 |

| Fm-3m | 3.549 (9) | - | 44.7 | 21.4 | |

| R-3m | 8.557 (4) | 12.425 (9) | 788 | 125.1 | |

| T400 | Fm-3m | 5.729 (2) | - | 188.1 | 84.6 |

| Fm-3m | 3.590 (6) | - | 46.3 | 139.9 | |

| R-3m | 8.563 (1) | 12.449 (9) | 790.6 | 147.5 | |

| T900 | Fm-3m | 5.744 (9) | - | 189.6 | 121.7 |

| Fm-3m | 3.590 (2) | - | 46.3 | 82.2 | |

| R-3m | 8.560 (1) | 12.459 (2) | 790.6 | 131.3 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sofronie, M.; Popescu, B.; Enculescu, M.; Tolea, M.; Tolea, F. Processing Effects on the Martensitic Transformation and Related Properties in the Ni55Fe18Nd2Ga25 Ferromagnetic Shape Memory Alloy. Nanomaterials 2022, 12, 3667. https://doi.org/10.3390/nano12203667

Sofronie M, Popescu B, Enculescu M, Tolea M, Tolea F. Processing Effects on the Martensitic Transformation and Related Properties in the Ni55Fe18Nd2Ga25 Ferromagnetic Shape Memory Alloy. Nanomaterials. 2022; 12(20):3667. https://doi.org/10.3390/nano12203667

Chicago/Turabian StyleSofronie, Mihaela, Bogdan Popescu, Monica Enculescu, Mugurel Tolea, and Felicia Tolea. 2022. "Processing Effects on the Martensitic Transformation and Related Properties in the Ni55Fe18Nd2Ga25 Ferromagnetic Shape Memory Alloy" Nanomaterials 12, no. 20: 3667. https://doi.org/10.3390/nano12203667

APA StyleSofronie, M., Popescu, B., Enculescu, M., Tolea, M., & Tolea, F. (2022). Processing Effects on the Martensitic Transformation and Related Properties in the Ni55Fe18Nd2Ga25 Ferromagnetic Shape Memory Alloy. Nanomaterials, 12(20), 3667. https://doi.org/10.3390/nano12203667