Competition between Ferroelectric and Ferroelastic Domain Wall Dynamics during Local Switching in Rhombohedral PMN-PT Single Crystals

Abstract

:1. Introduction

2. Experimental Section

2.1. Sample Synthesis and Preparation

2.2. Piezoresponse Force Microscopy and Local Switching

2.3. Finite Element Simulations

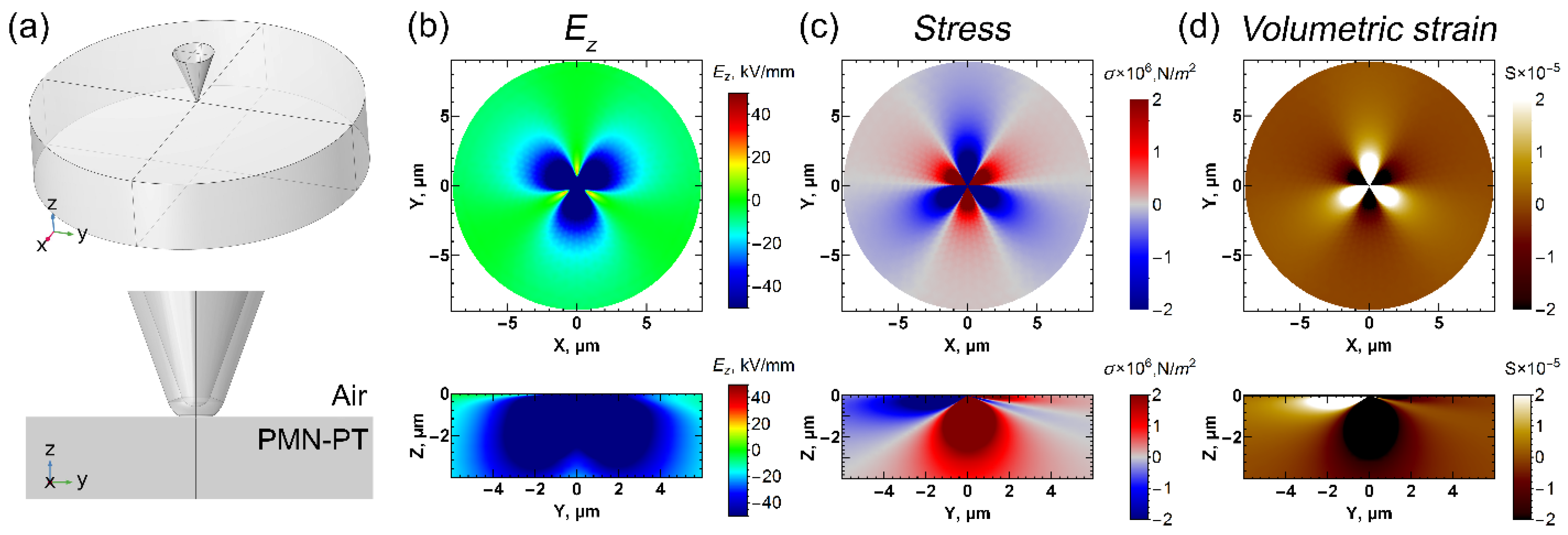

3. Results

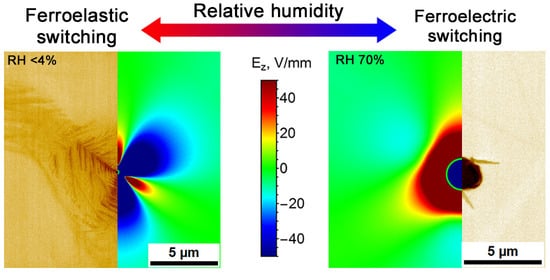

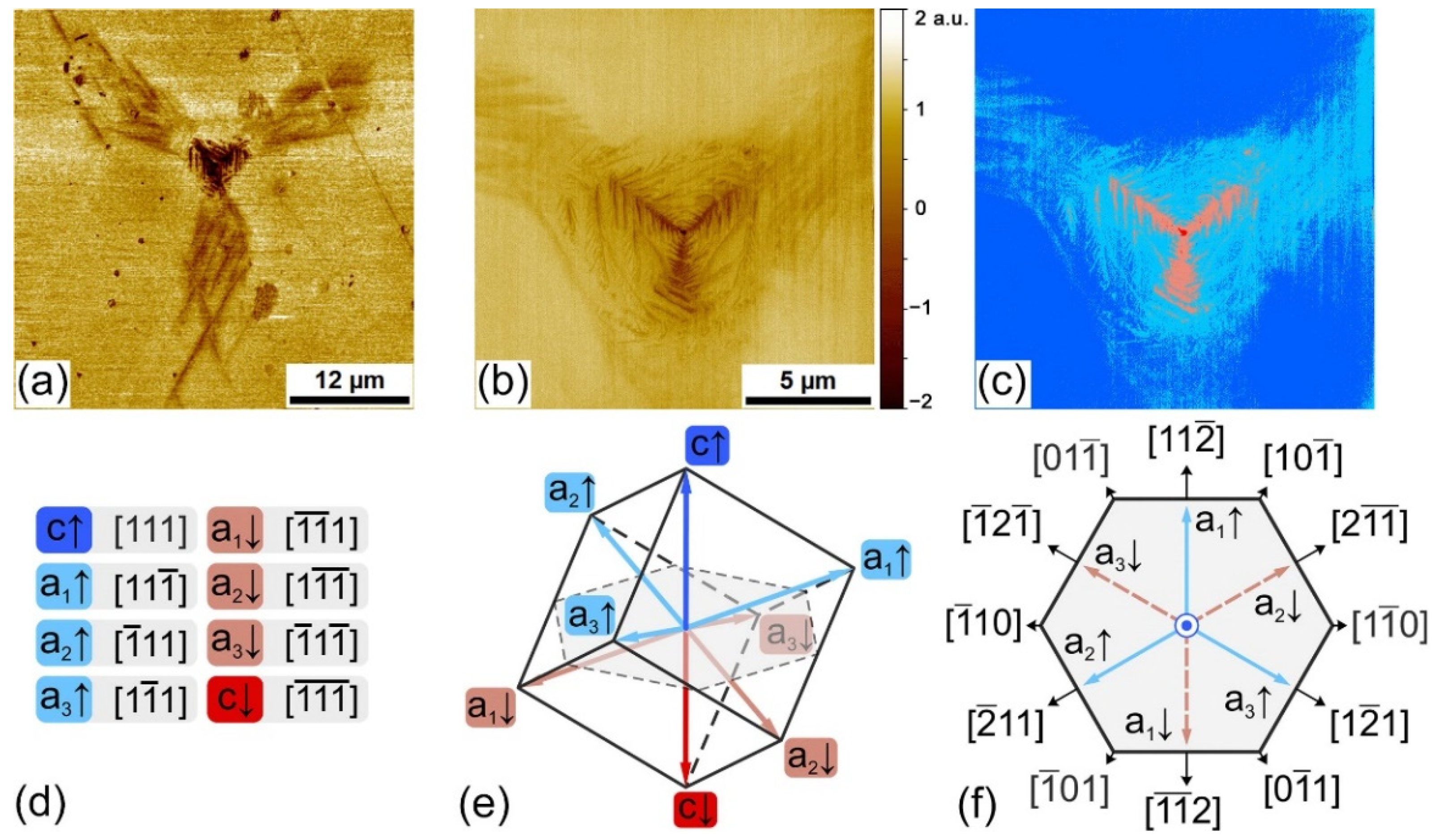

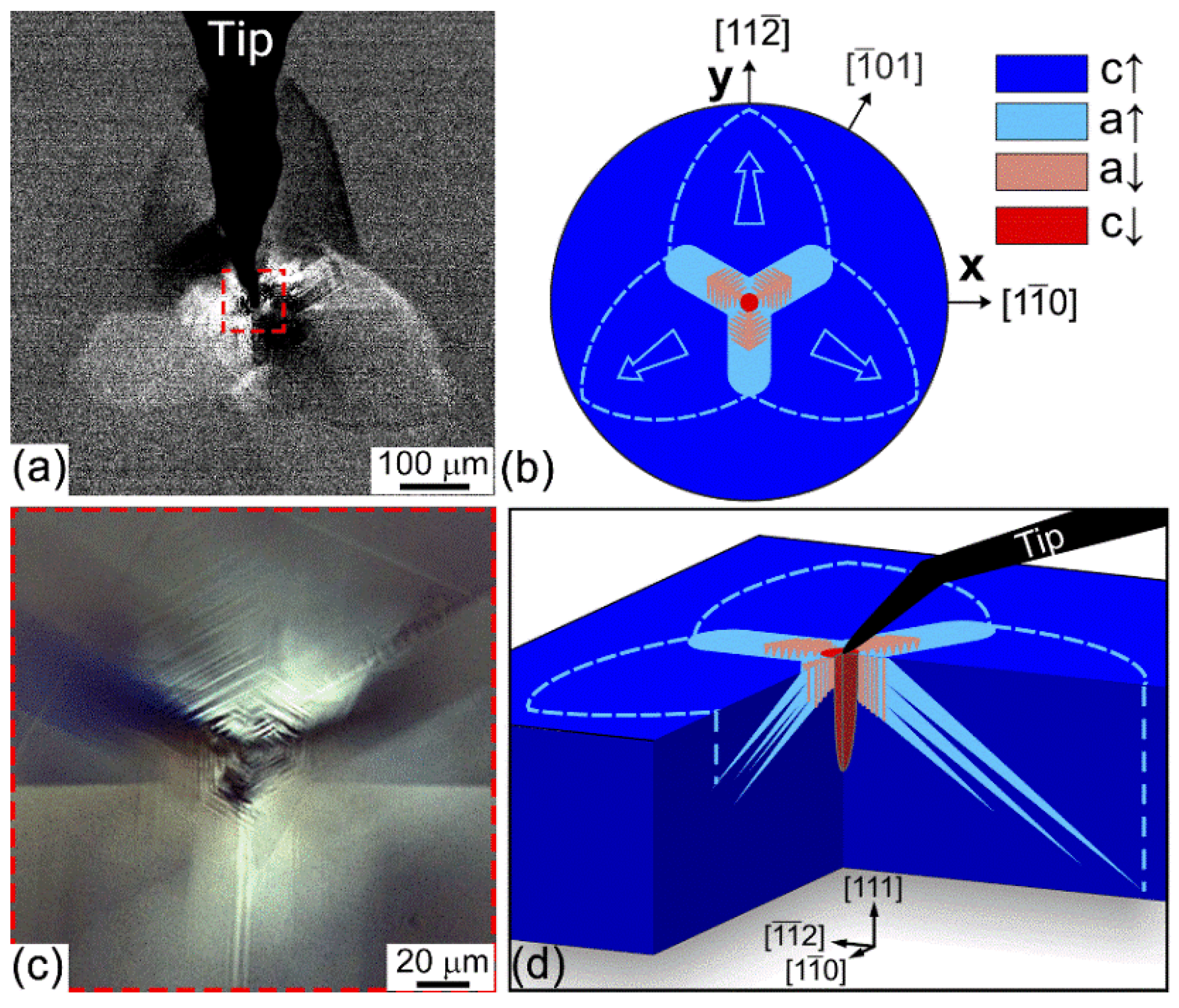

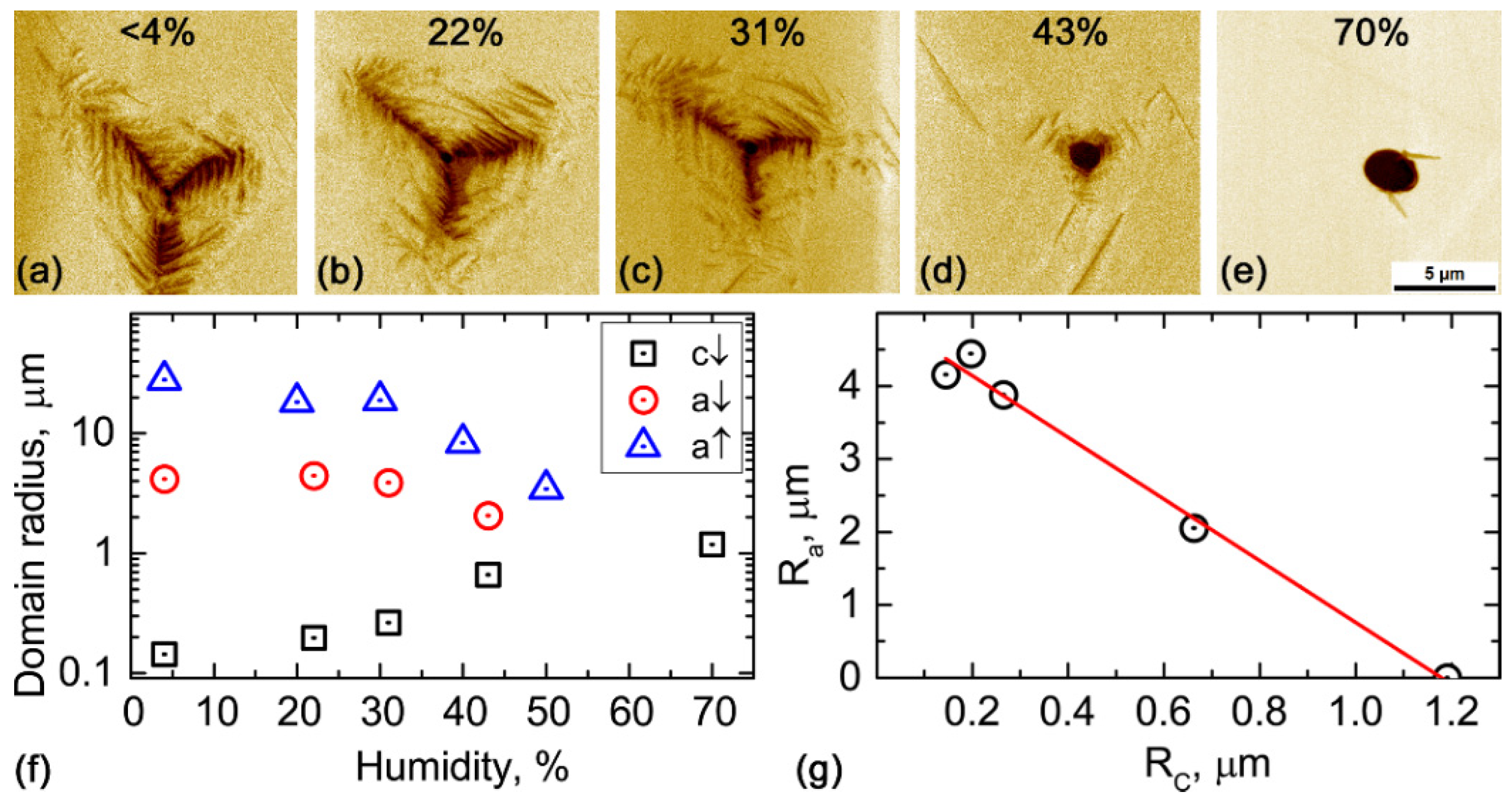

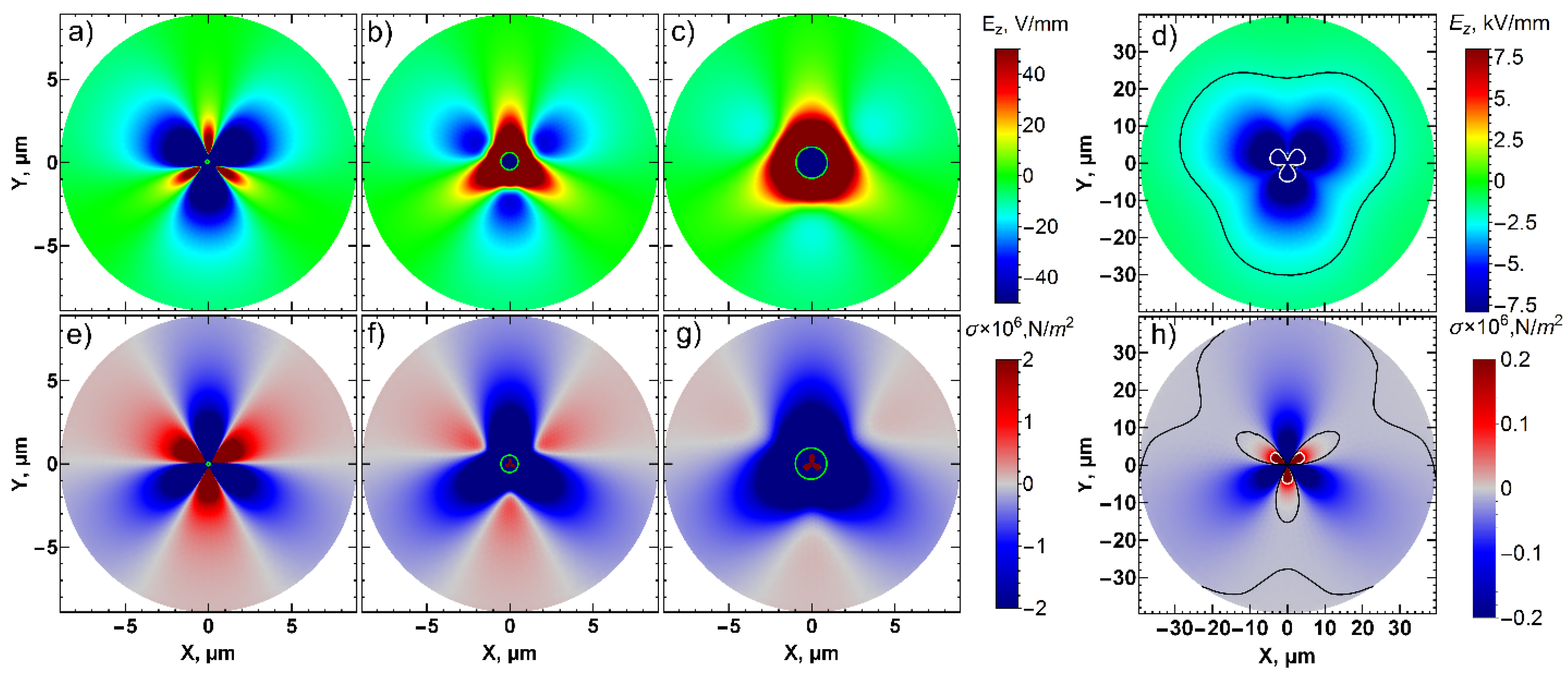

3.1. Local Switching in the Dry Atmosphere

3.2. Local Switching in Humid Conditions

4. Discussion

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Scott, J.F.; Hershkovitz, A.; Ivry, Y.; Lu, H.; Gruverman, A.; Gregg, J.M. Superdomain dynamics in ferroelectric-ferroelastic films: Switching, jamming, and relaxation. Appl. Phys. Rev. 2017, 4, 041104. [Google Scholar] [CrossRef]

- Seidel, J.; Martin, L.W.; He, Q.; Zhan, Q.; Chu, Y.-H.; Rother, A.; Hawkridge, M.E.; Maksymovych, P.; Yu, P.; Gajek, M.; et al. Conduction at domain walls in oxide multiferroics. Nat. Mater. 2009, 8, 229–234. [Google Scholar] [CrossRef] [Green Version]

- Burns, S.R.; Tselev, A.; Ievlev, A.V.; Agar, J.C.; Martin, L.W.; Kalinin, S.V.; Sando, D.; Maksymovych, P. Tunable microwave conductance of nanodomains in ferroelectric PbZr0.2Ti0.8O3 thin film. Adv. Electron. Mater. 2022, 8, 2100952. [Google Scholar] [CrossRef]

- McConville, J.P.V.; Lu, H.; Wang, B.; Tan, Y.; Cochard, C.; Conroy, M.; Moore, K.; Harvey, A.; Bangert, U.; Chen, L.-Q.; et al. Ferroelectric domain wall memristor. Adv. Funct. Mater. 2020, 30, 2000109. [Google Scholar] [CrossRef]

- Lu, H.; Tan, Y.; McConville, J.P.V.; Ahmadi, Z.; Wang, B.; Conroy, M.; Moore, K.; Bangert, U.; Shield, J.E.; Chen, L.-Q.; et al. Electrical tunability of domain wall conductivity in LiNbO3 Thin Films. Adv. Mater. 2019, 31, 1902890. [Google Scholar] [CrossRef]

- Rojac, T.; Ursic, H.; Bencan, A.; Malic, B.; Damjanovic, D. Mobile domain walls as a bridge between nanoscale conductivity and macroscopic electromechanical response. Adv. Funct. Mater. 2015, 25, 2099–2108. [Google Scholar] [CrossRef]

- Hopkins, P.E.; Adamo, C.; Ye, L.; Huey, B.D.; Lee, S.R.; Schlom, D.G.; Ihlefeld, J.F. Effects of coherent ferroelastic domain walls on the thermal conductivity and Kapitza conductance in bismuth ferrite. Appl. Phys. Lett. 2013, 102, 121903. [Google Scholar] [CrossRef] [Green Version]

- Liu, C.; Chen, Y.; Dames, C. Electric-field-controlled thermal switch in ferroelectric materials using first-principles calculations and domain-wall engineering. Phys. Rev. Appl. 2019, 11, 044002. [Google Scholar] [CrossRef]

- Qiu, C.; Wang, B.; Zhang, N.; Zhang, S.; Liu, J.; Walker, D.; Wang, Y.; Tian, H.; Shrout, T.R.; Xu, Z.; et al. Transparent ferroelectric crystals with ultrahigh piezoelectricity. Nature 2020, 577, 350–354. [Google Scholar] [CrossRef]

- Bokov, A.A.; Ye, Z.-G. Recent progress in relaxor ferroelectrics with perovskite structure. J. Mater. Sci. 2006, 41, 31–52. [Google Scholar] [CrossRef]

- Shur, V.Y.; Akhmatkhanov, A.R.; Baturin, I.S. Micro- and nano-domain engineering in lithium niobate. Appl. Phys. Rev. 2015, 2, 040604. [Google Scholar] [CrossRef]

- Hu, Y.; You, L.; Xu, B.; Li, T.; Morris, S.A.; Li, Y.; Zhang, Y.; Wang, X.; Lee, P.S.; Fan, H.J.; et al. Ferroelastic-switching-driven large shear strain and piezoelectricity in a hybrid ferroelectric. Nat. Mater. 2021, 20, 612–617. [Google Scholar] [CrossRef] [PubMed]

- Huang, F.; Hu, C.; Zhou, Z.; Meng, X.; Tan, P.; Wang, Y.; Wang, C.; Tian, H. Improving strain in single crystal by composition-gradients design. Acta Mater. 2020, 200, 24–34. [Google Scholar] [CrossRef]

- Lang, S.B.; Chan, H.L.W. Frontiers of Ferroelectricity; Springer: Boston, MA, USA, 2007; ISBN 978-0-387-38037-7. [Google Scholar]

- Tagantsev, A.K.; Fousek, F.; Cross, L.E. Domains in Ferroic Crystals and Thin Films; Springer: New York, NY, USA, 2010; ISBN 978-1-4419-1416-3. [Google Scholar]

- Jona, F.; Shirane, G. Ferroelectric Crystals; Dover Publications: New York, NY, USA, 1993; ISBN 978-0-486-67386-8. [Google Scholar]

- Salje, E.K.H. Ferroelastic Materials. Annu. Rev. Mater. Res. 2012, 42, 265–283. [Google Scholar] [CrossRef]

- Ignatans, R.; Damjanovic, D.; Tileli, V. Individual Barkhausen Pulses of Ferroelastic Nanodomains. Phys. Rev. Lett. 2021, 127, 167601. [Google Scholar] [CrossRef]

- Daniels, J.E.; Cozzan, C.; Ukritnukun, S.; Tutuncu, G.; Andrieux, J.; Glaum, J.; Dosch, C.; Jo, W.; Jones, J.L. Two-step polarization reversal in biased ferroelectrics. J. Appl. Phys. 2014, 115, 224104. [Google Scholar] [CrossRef] [Green Version]

- Schultheiß, J.; Liu, L.; Kungl, H.; Weber, M.; Kodumudi Venkataraman, L.; Checchia, S.; Damjanovic, D.; Daniels, J.E.; Koruza, J. Revealing the sequence of switching mechanisms in polycrystalline ferroelectric/ferroelastic materials. Acta Mater. 2018, 157, 355–363. [Google Scholar] [CrossRef]

- Jiang, B.; Bai, Y.; Chu, W.; Su, Y.; Qiao, L. Direct observation of two 90° steps of 180° domain switching in under an antiparallel electric field Direct observation of two 90° steps of 180° domain switching in BaTiO3 single crystal under an antiparallel electric field. Appl. Phys. Lett. 2008, 93, 152905. [Google Scholar] [CrossRef]

- Khan, A.I.; Marti, X.; Serrao, C.; Ramesh, R.; Salahuddin, S. Voltage-Controlled ferroelastic switching in Pb(Zr0.2Ti0.8)O3 thin films. Nano Lett. 2015, 15, 2229–2234. [Google Scholar] [CrossRef]

- Xu, R.; Liu, S.; Grinberg, I.; Karthik, J.; Damodaran, A.R.; Rappe, A.M.; Martin, L.W. Ferroelectric polarization reversal via successive ferroelastic transitions. Nat. Mater. 2015, 14, 79–86. [Google Scholar] [CrossRef]

- Damodaran, A.R.; Pandya, S.; Agar, J.C.; Cao, Y.; Vasudevan, R.K.; Xu, R.; Saremi, S.; Li, Q.; Kim, J.; McCarter, M.R.; et al. Three-state ferroelastic switching and large electromechanical responses in PbTiO3 thin films. 2017, 29, 1702069. Adv. Mater. 2017, 29, 1702069. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ushakov, A.D.; Esin, A.A.; Akhmatkhanov, A.R.; Hu, Q.; Liu, X.; Zhao, Y.; Andreev, A.A.; Wei, X.; Shur, V.Y. Direct observation of domain kinetics in rhombohedral PMN-28PT single crystals during polarization reversal. Appl. Phys. Lett. 2019, 115, 102903. [Google Scholar] [CrossRef]

- Ushakov, A.D.; Turygin, A.P.; Akhmatkhanov, A.R.; Alikin, D.O.; Hu, Q.; Liu, X.; Zhao, Y.; Xu, Z.; Wei, X.; Shur, V.Y. Dense ferroelectric-ferroelastic domain structures in rhombohedral PMN-28PT single crystals. Appl. Phys. Lett. 2020, 116, 182901. [Google Scholar] [CrossRef]

- Li, M.; Wang, B.; Liu, H.-J.; Huang, Y.-L.; Zhang, J.; Ma, X.; Liu, K.; Yu, D.; Chu, Y.-H.; Chen, L.-Q.; et al. Direct observation of weakened interface clamping effect enabled ferroelastic domain switching. Acta Mater. 2019, 171, 184–189. [Google Scholar] [CrossRef]

- Genenko, Y.A.; Khachaturyan, R.; Vorotiahin, I.S.; Schultheiß, J.; Daniels, J.E.; Grünebohm, A.; Koruza, J. Multistep stochastic mechanism of polarization reversal in rhombohedral ferroelectrics. Phys. Rev. B 2020, 102, 064107. [Google Scholar] [CrossRef]

- Baek, S.H.; Jang, H.W.; Folkman, C.M.; Li, Y.L.; Winchester, B.; Zhang, J.X.; He, Q.; Chu, Y.H.; Nelson, C.T.; Rzchowski, M.S.; et al. Ferroelastic switching for nanoscale non-volatile magnetoelectric devices. Nat. Mater. 2010, 9, 309–314. [Google Scholar] [CrossRef]

- Balke, N.; Choudhury, S.; Jesse, S.; Huijben, M.; Chu, Y.H.; Baddorf, A.P.; Chen, L.Q.; Ramesh, R.; Kalinin, S.V. Deterministic control of ferroelastic switching in multiferroic materials. Nat. Nanotechnol. 2009, 4, 868–875. [Google Scholar] [CrossRef]

- Rodriguez, B.J.; Eng, L.M.; Gruverman, A. Web-like domain structure formation in barium titanate single crystals. Appl. Phys. Lett. 2010, 97, 042902. [Google Scholar] [CrossRef] [Green Version]

- Zhao, K.Y.; Zhao, W.; Zeng, H.R.; Yu, H.Z.; Ruan, W.; Xu, K.Q.; Li, G.R. Tip-bias-induced domain evolution in PMN–PT transparent ceramics via piezoresponse force microscopy. Appl. Surf. Sci. 2015, 337, 125–129. [Google Scholar] [CrossRef]

- Kholkin, A.L.; Bdikin, I.K.; Shvartsman, V.V.; Pertsev, N.A. Anomalous polarization inversion in ferroelectrics via scanning force microscopy. Nanotechnology 2007, 18, 095502. [Google Scholar] [CrossRef]

- Zhao, B.; Chen, Z.; Meng, J.; Lu, H.; Zhang, D.W.; Jiang, A. Ferroelectric polarization and defect-dipole switching in an epitaxial (111) BiFeO3 thin film. J. Appl. Phys. 2015, 117, 204103. [Google Scholar] [CrossRef]

- Su, D.; Meng, Q.; Vaz, C.A.F.; Han, M.-G.; Segal, Y.; Walker, F.J.; Sawicki, M.; Broadbridge, C.; Ahn, C.H. Origin of 90° domain wall pinning in Pb(Zr0.2Ti0.8)O3 heteroepitaxial thin films. Appl. Phys. Lett. 2011, 99, 102902. [Google Scholar] [CrossRef]

- Nagarajan, V.; Roytburd, A.; Stanishevsky, A.; Prasertchoung, S.; Zhao, T.; Chen, L.; Melngailis, J.; Auciello, O.; Ramesh, R. Dynamics of ferroelastic domains in ferroelectric thin films. Nat. Mater. 2003, 2, 43–47. [Google Scholar] [CrossRef] [PubMed]

- Béa, H.; Ziegler, B.; Bibes, M.; Barthélémy, A.; Paruch, P. Nanoscale polarization switching mechanisms in multiferroic BiFeO 3 thin films. J. Phys. Condens. Matter 2011, 23, 142201. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Baek, S.H.; Eom, C.B. Reliable polarization switching of BiFeO3. Philos. Trans. R. Soc. A 2012, 370, 4872–4889. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Britson, J.; Nelson, C.; Pan, X.; Chen, L.-Q. First-order morphological transition of ferroelastic domains in ferroelectric thin films. Acta Mater. 2014, 75, 188–197. [Google Scholar] [CrossRef]

- Li, W.; Alexe, M. Investigation on switching kinetics in epitaxial Pb(Zr0.2Ti0.8)O3 ferroelectric thin films: Role of the 90° domain walls. Appl. Phys. Lett. 2007, 91, 262903. [Google Scholar] [CrossRef]

- Ivry, Y.; Scott, J.F.; Salje, E.K.H.; Durkan, C. Nucleation, growth, and control of ferroelectric-ferroelastic domains in thin polycrystalline films. Phys. Rev. 2012, 86, 205428. [Google Scholar] [CrossRef] [Green Version]

- Lu, X.; Chen, Z.; Cao, Y.; Tang, Y.; Xu, R.; Saremi, S.; Zhang, Z.; You, L.; Dong, Y.; Das, S.; et al. Mechanical-force-induced non-local collective ferroelastic switching in epitaxial lead-titanate thin films. Nat. Commun. 2019, 10, 3951. [Google Scholar] [CrossRef] [Green Version]

- Sharma, P.; McQuaid, R.G.P.; McGilly, L.J.; Gregg, J.M.; Gruverman, A. Nanoscale dynamics of superdomain boundaries in single-crystal BaTiO3 lamellae. Adv. Mater. 2013, 25, 1323–1330. [Google Scholar] [CrossRef]

- Liu, G.; Jiang, W.; Zhu, J.; Cao, W. Electromechanical properties and anisotropy of single- and multi-domain 0.72Pb(Mg1/3Nb2/3)O3-0.28PbTiO3 single crystals. Appl. Phys. Lett. 2011, 99, 162901. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ievlev, A.V.; Morozovska, A.N.; Shur, V.Y.; Kalinin, S.V. Humidity effects on tip-induced polarization switching in lithium niobate. Appl. Phys. Lett. 2014, 104, 092908. [Google Scholar] [CrossRef] [Green Version]

- Shishkina, E.V.; Pelegova, E.V.; Kosobokov, M.S.; Akhmatkhanov, A.R.; Yudin, P.V.; Dejneka, A.; Shur, V.Y. Influence of humidity on local polarization reversal in a Rb:KTP single crystal. ACS Appl. Electron. Mater. 2021, 3, 260–266. [Google Scholar] [CrossRef]

- Rodriguez, B.J.; Nemanich, R.J.; Kingon, A.; Gruverman, A.; Kalinin, S.V.; Terabe, K.; Liu, X.Y.; Kitamura, K. Domain growth kinetics in lithium niobate single crystals studied by piezoresponse force microscopy. Appl. Phys. Lett. 2005, 86, 012906. [Google Scholar] [CrossRef]

- Ievlev, A.V.; Jesse, S.; Morozovska, A.N.; Strelcov, E.; Eliseev, E.A.; Pershin, Y.V.; Kumar, A.; Shur, V.Y.; Kalinin, S.V. Intermittency, quasiperiodicity and chaos in probe-induced ferroelectric domain switching. Nat. Phys. 2013, 10, 59–66. [Google Scholar] [CrossRef]

- Brugère, A.; Gidon, S.; Gautier, B. Abnormal switching of ferroelectric domains created by the tip of an atomic force microscope in a congruent LiTaO3 single-crystal thin film. J. Appl. Phys. 2011, 110, 024102. [Google Scholar] [CrossRef]

- Liu, G.; Kong, L.; Hu, Q.; Zhang, S. Diffused morphotropic phase boundary in relaxor-PbTiO3 crystals: High piezoelectricity with improved thermal stability. Appl. Phys. Rev. 2020, 7, 021405. [Google Scholar] [CrossRef]

| Vector of Spontaneous Polarization | Notation | Vector of Spontaneous Polarization | Notation |

|---|---|---|---|

| c↑ | c↓ | ||

| a1↑ | a1↓ | ||

| a2↑ | a2↓ | ||

| a3↑ | a3↓ |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alikin, D.; Turygin, A.; Ushakov, A.; Kosobokov, M.; Alikin, Y.; Hu, Q.; Liu, X.; Xu, Z.; Wei, X.; Shur, V. Competition between Ferroelectric and Ferroelastic Domain Wall Dynamics during Local Switching in Rhombohedral PMN-PT Single Crystals. Nanomaterials 2022, 12, 3912. https://doi.org/10.3390/nano12213912

Alikin D, Turygin A, Ushakov A, Kosobokov M, Alikin Y, Hu Q, Liu X, Xu Z, Wei X, Shur V. Competition between Ferroelectric and Ferroelastic Domain Wall Dynamics during Local Switching in Rhombohedral PMN-PT Single Crystals. Nanomaterials. 2022; 12(21):3912. https://doi.org/10.3390/nano12213912

Chicago/Turabian StyleAlikin, Denis, Anton Turygin, Andrei Ushakov, Mikhail Kosobokov, Yurij Alikin, Qingyuan Hu, Xin Liu, Zhuo Xu, Xiaoyong Wei, and Vladimir Shur. 2022. "Competition between Ferroelectric and Ferroelastic Domain Wall Dynamics during Local Switching in Rhombohedral PMN-PT Single Crystals" Nanomaterials 12, no. 21: 3912. https://doi.org/10.3390/nano12213912