A Sustainable and Low-Cost Route to Design NiFe2O4 Nanoparticles/Biomass-Based Carbon Fibers with Broadband Microwave Absorption

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of NiFe2O4/Carbonized Cotton Fibers

2.3. Preparation of NiFe2O4/Carbonized Hemp Fibers and NiFe2O4/Carbonized Bamboo Fibers

2.4. Characterization

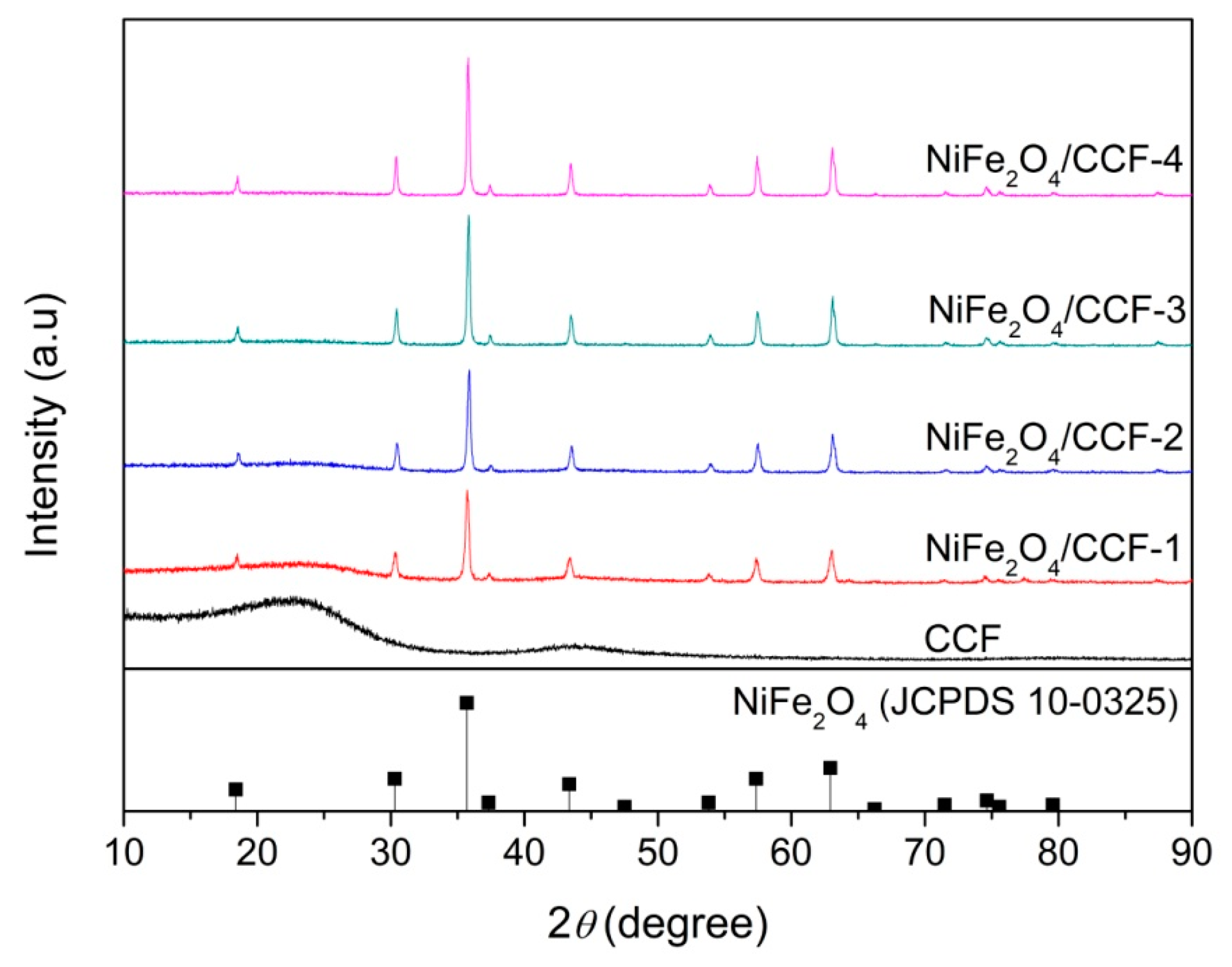

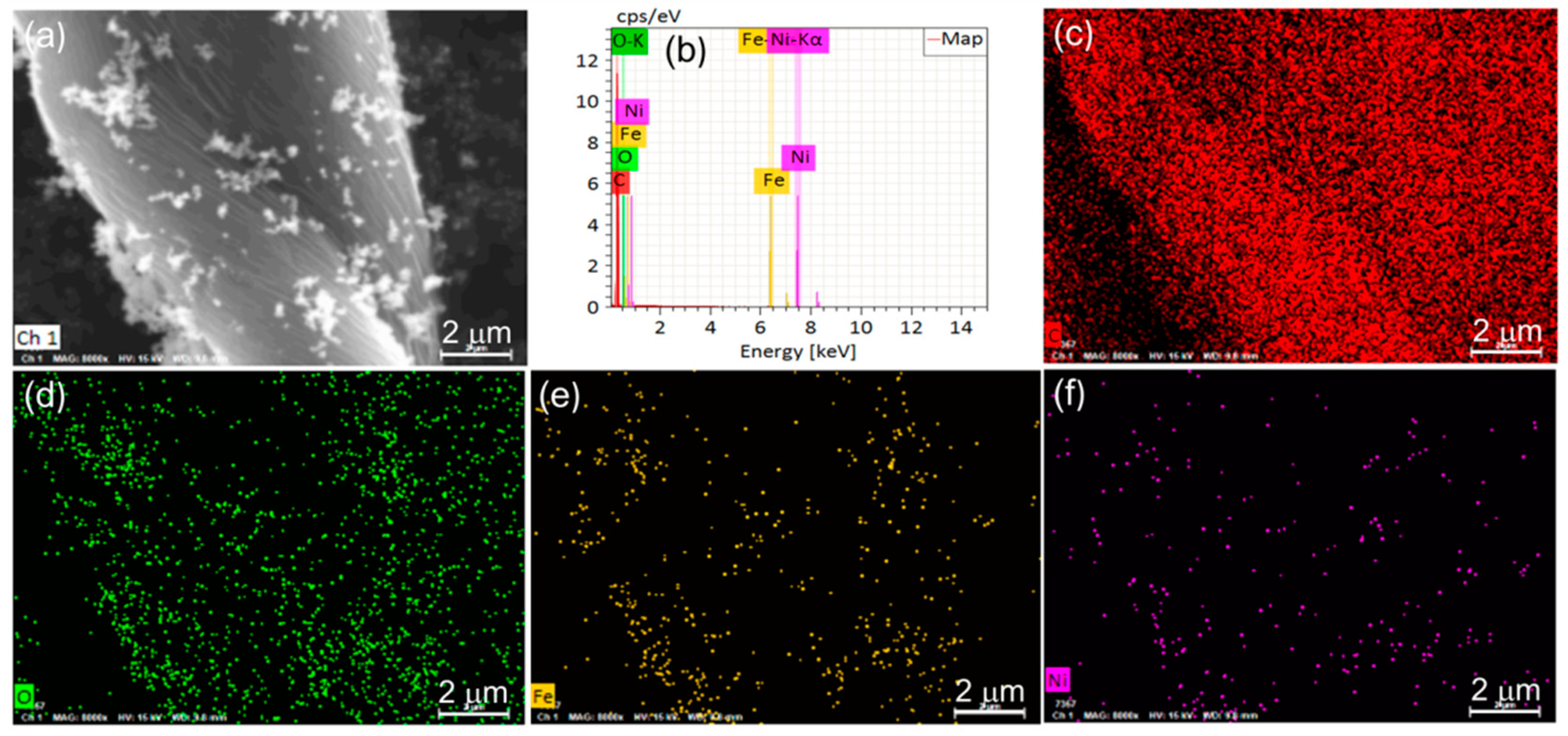

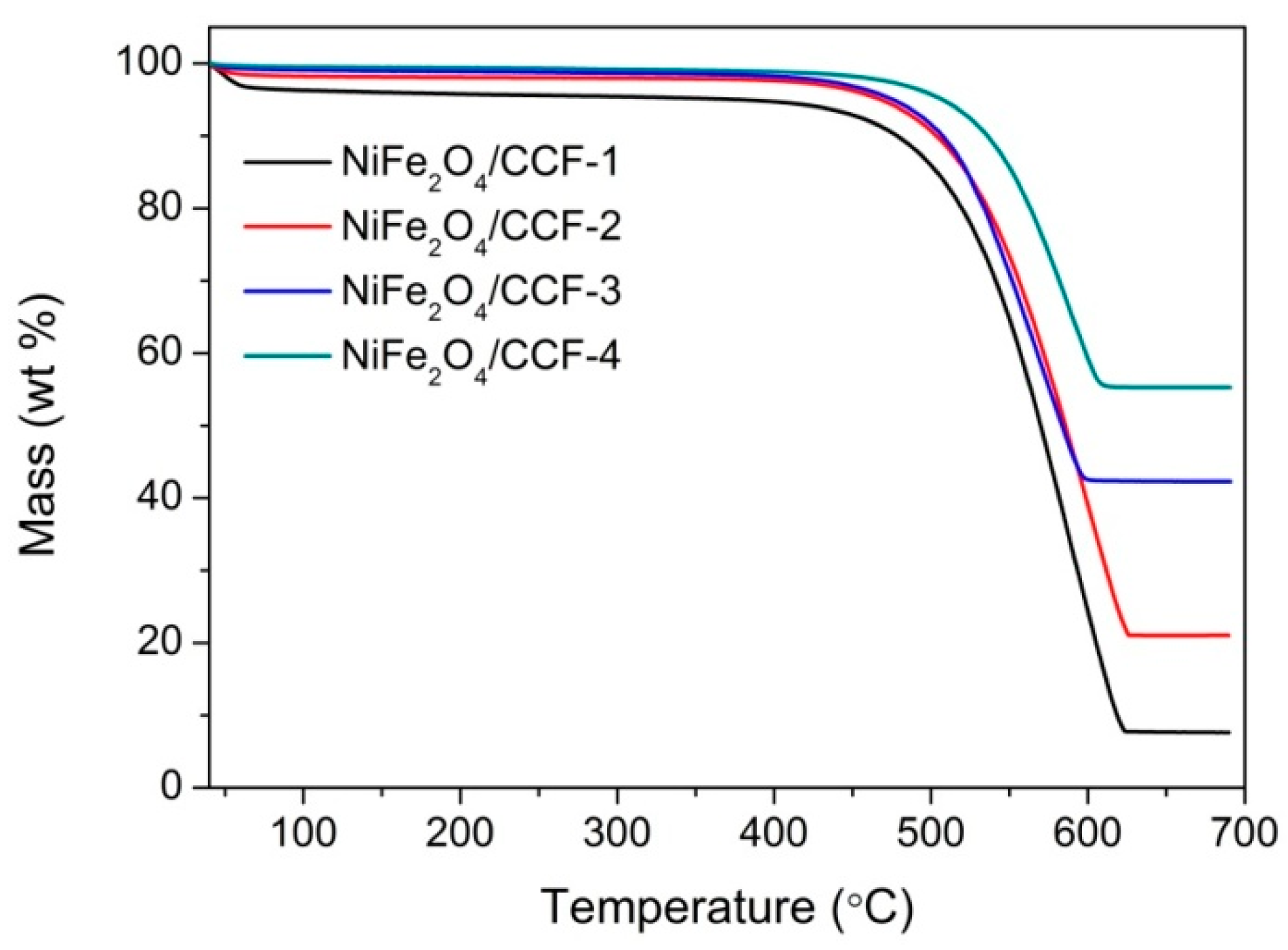

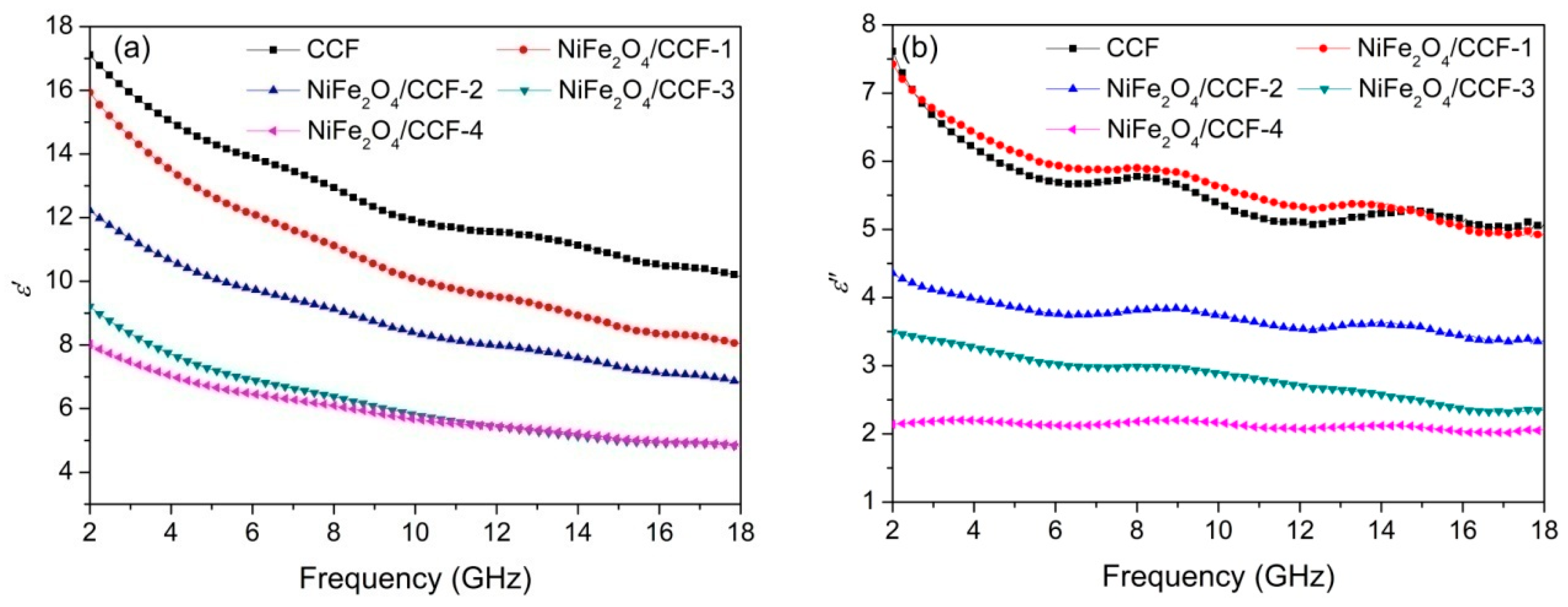

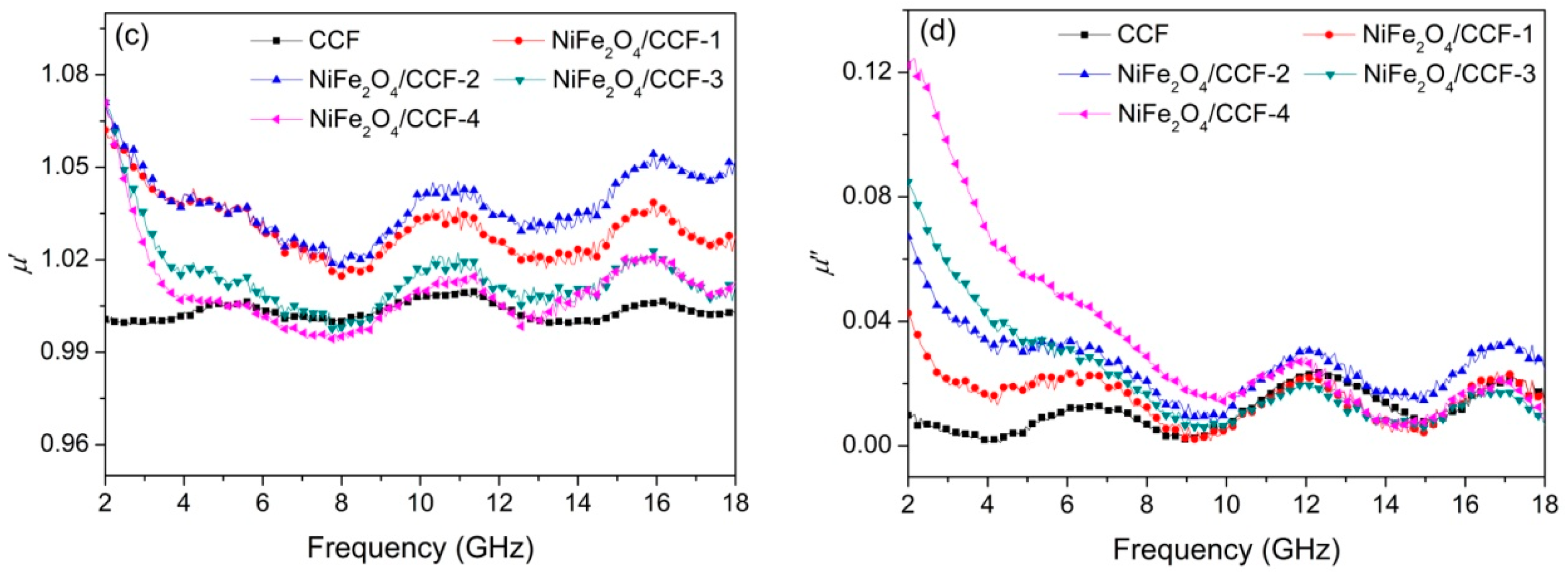

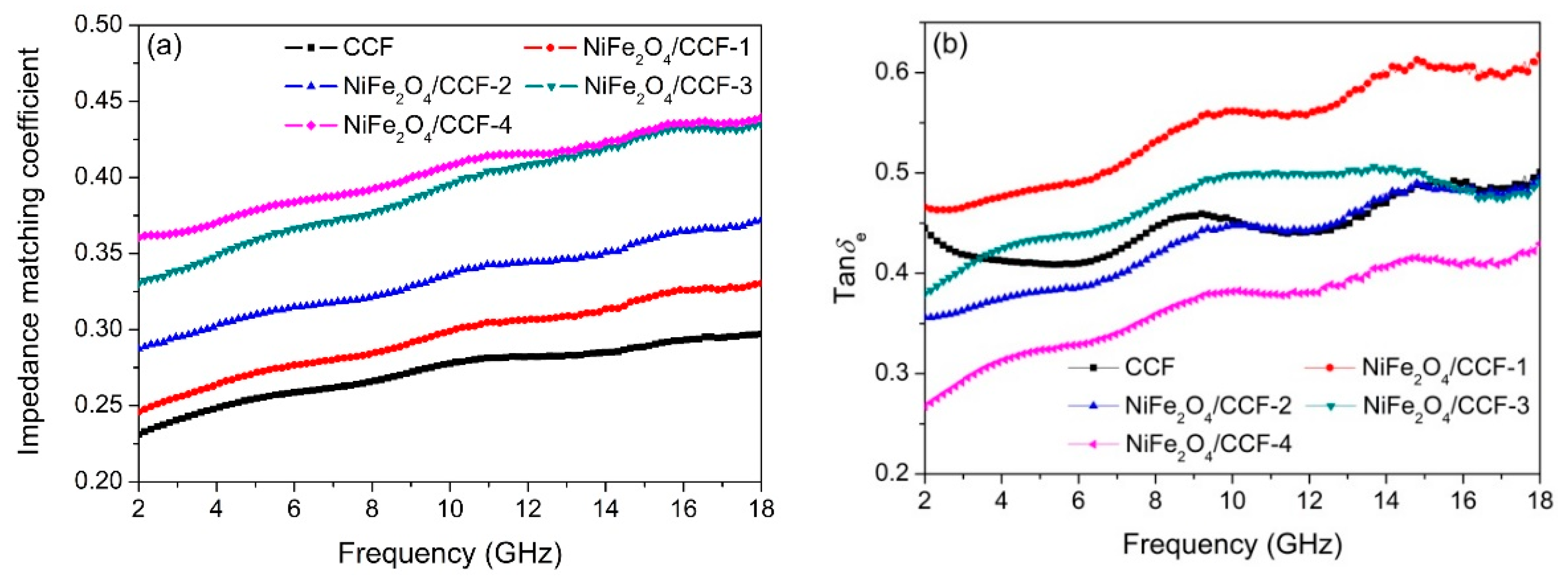

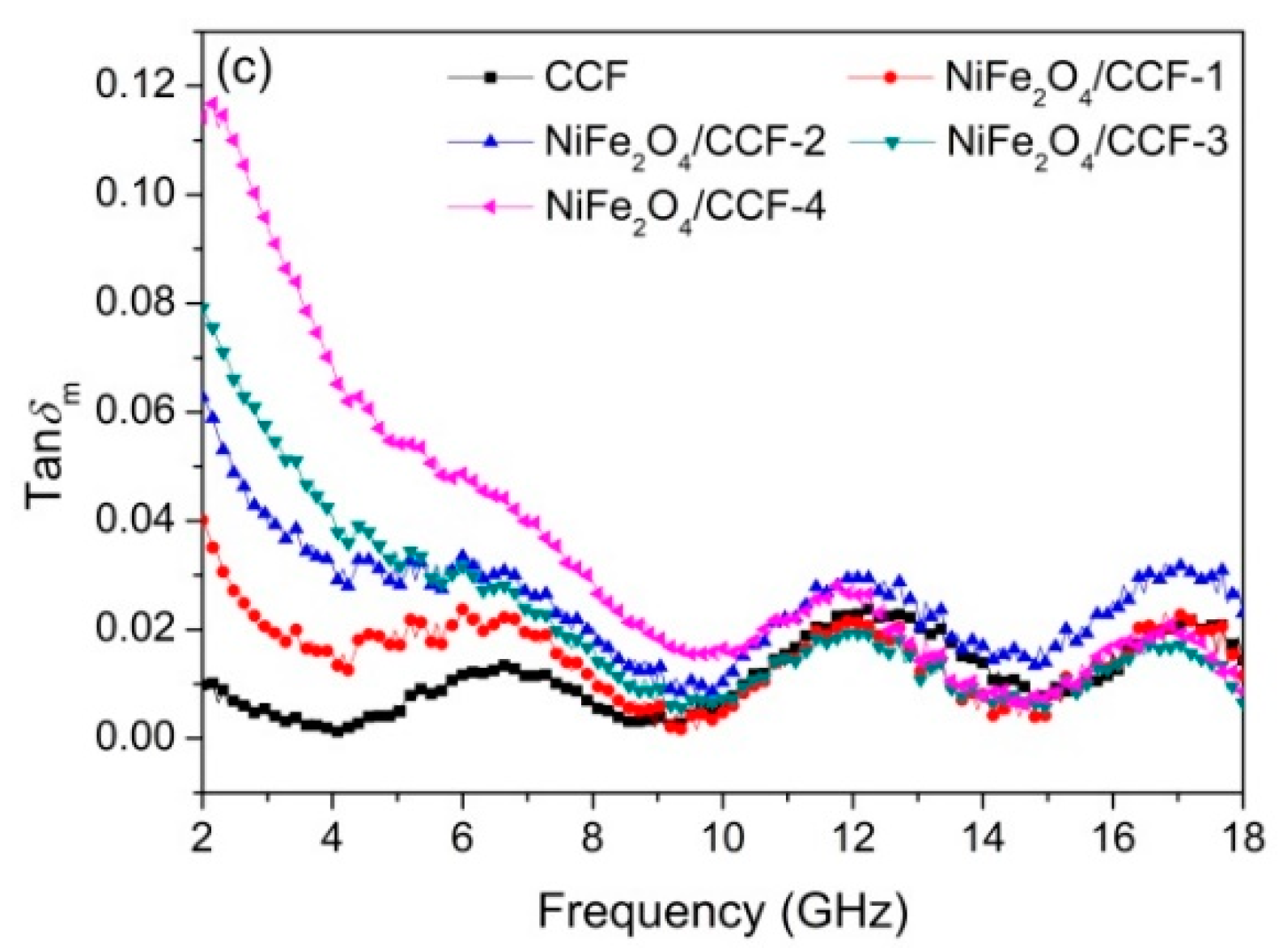

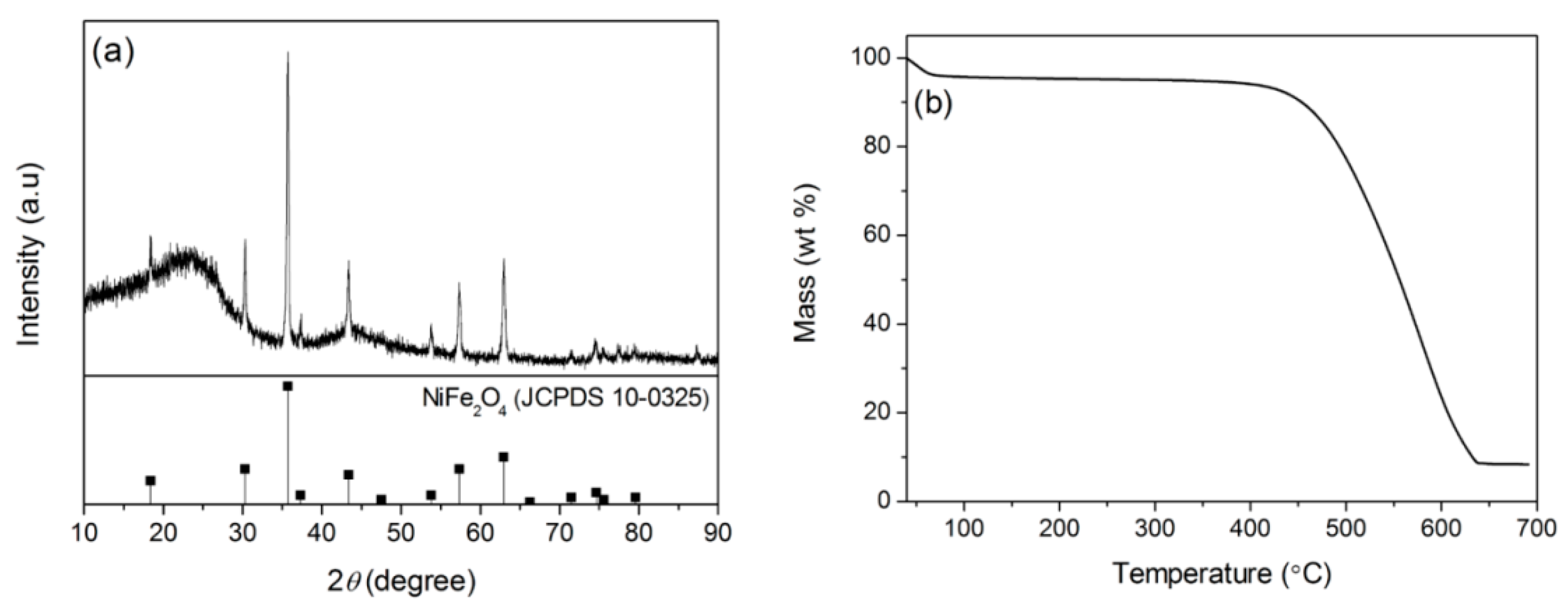

3. Results

4. Discussion

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zeng, X.J.; Cheng, X.Y.; Yu, R.H.; Stucky, G.D. Electromagnetic microwave absorption theory and recent achievements in microwave absorbers. Carbon 2020, 168, 606–623. [Google Scholar] [CrossRef]

- Wang, F.; Gu, W.H.; Chen, J.B.; Wu, Y.; Zhou, M.; Tang, S.L.; Cao, X.Z.; Zhang, P.; Ji, G.B. The point defect and electronic structure of K doped LaCo0.9Fe0.1O3 perovskite with enhanced microwave absorbing ability. Nano Res. 2022, 15, 3720–3728. [Google Scholar] [CrossRef]

- Zhang, M.; Cao, M.S.; Shu, J.C.; Cao, W.Q.; Li, L.; Yuan, J. Electromagnetic absorber converting radiation for multifunction. Mater. Sci. Eng. R 2021, 145, 100627. [Google Scholar] [CrossRef]

- Zhang, Z.W.; Cai, Z.H.; Wang, Z.Y.; Peng, Y.L.; Xia, L.; Ma, S.P.; Yin, Z.Z.; Huang, Y. A review on metal–organic framework-derived porous carbon-based novel microwave absorption materials. Nano-Micro Lett. 2021, 13, 56. [Google Scholar] [CrossRef] [PubMed]

- Zhao, Y.; Hao, L.L.; Zhang, X.D.; Tan, S.J.; Li, H.H.; Zheng, J.; Ji, G.B. A novel strategy in electromagnetic wave absorbing and shielding materials design: Multi-responsive field effect. Small Sci. 2022, 2, 2100077. [Google Scholar] [CrossRef]

- Zhao, H.Q.; Cheng, Y.; Lv, H.L.; Ji, G.B.; Du, Y.W. A novel hierarchically porous magnetic carbon derived from biomass for strong lightweight microwave absorption. Carbon 2019, 142, 245–253. [Google Scholar] [CrossRef]

- Duan, Y.B.; Liang, Q.X.; Yang, Z.; Li, Z.H.; Yin, H.Y.; Cao, Y.; Li, D.C. A wide-angle broadband electromagnetic absorbing metastructure using 3D printing technology. Mater. Des. 2021, 208, 109900. [Google Scholar] [CrossRef]

- Yan, L.W.; Hong, C.Q.; Sun, B.Q.; Zhao, G.D.; Cheng, Y.H.; Dong, S.; Zhang, D.Y.; Zhang, X.H. In situ growth of core–sheath heterostructural SiC nanowire arrays on carbon fibers and enhanced electromagnetic wave absorption performance. ACS Appl. Mater. Interfaces 2017, 9, 6320–6331. [Google Scholar] [CrossRef]

- He, X.; Peng, H.L.; Xiong, Z.Q.; Nie, X.L.; Wang, D.; Wang, G.S.; Liu, C.B. A sustainable and low-cost route to prepare magnetic particle-embedded ultra-thin carbon nanosheets with broadband microwave absorption from biowastes. Carbon 2022, 198, 195–206. [Google Scholar] [CrossRef]

- Han, C.; Zhang, M.; Cao, W.Q.; Cao, M.S. Electrospinning and in-situ hierarchical thermal treatment to tailor C-NiCo2O4 nanofibers for tunable microwave absorption. Carbon 2021, 171, 953–962. [Google Scholar] [CrossRef]

- Li, X.L.; Yin, X.W.; Song, C.Q.; Han, M.K.; Xu, H.L.; Duan, W.Y.; Cheng, L.F.; Zhang, L.T. Self-assembly core-shell graphene-bridged hollow MXenes spheres 3D foam with ultrahigh specific EM absorption performance. Adv. Funct. Mater. 2018, 28, 1803938. [Google Scholar] [CrossRef]

- Jiang, Z.Y.; Si, H.X.; Chen, X.; Liu, H.M.; Zhang, L.; Zhang, Y.H.; Gong, C.H.; Zhang, J.W. Simultaneous enhancement of impedance matching and the absorption behavior of BN/RGO nanocomposites for efficiency microwave absorption. Compos. Commun. 2020, 22, 100503. [Google Scholar] [CrossRef]

- Chen, X.T.; Zhou, M.; Zhao, Y.; Gu, W.H.; Wu, Y.; Tang, S.L.; Ji, G.B. Morphology control of eco-friendly chitosan-derived carbon aerogels for efficient microwave absorption at thin thickness and thermal stealth. Green Chem. 2022, 24, 5280–5290. [Google Scholar] [CrossRef]

- Chen, C.; Xi, J.B.; Zhou, E.Z.; Peng, L.; Chen, Z.C.; Gao, C. Porous graphene microflowers for high-performance microwave absorption. Nano-Micro Lett. 2018, 10, 26. [Google Scholar] [CrossRef]

- Guo, S.N.; Zhang, Y.Q.; Chen, J.B.; Wu, Y.; Cao, J.M.; Tang, S.L.; Ji, G.B. The excellent electromagnetic wave absorbing properties of carbon fiber composites: Effect of metal content. Inorg. Chem. Front. 2022, 9, 3244–3250. [Google Scholar] [CrossRef]

- Zhang, X.C.; Zhang, X.; Yuan, H.R.; Li, K.Y.; Ouyang, Q.Y.; Zhu, C.L.; Zhang, S.; Chen, Y.J. CoNi nanoparticles encapsulated by nitrogen-doped carbon nanotube arrays on reduced graphene oxide sheets for electromagnetic wave absorption. Chem. Eng. J. 2020, 383, 123208. [Google Scholar] [CrossRef]

- Wang, Y.C.; Yao, L.H.; Zheng, Q.; Cao, M.S. Graphene-wrapped multiloculated nickel ferrite: A highly efficient electromagnetic attenuation material for microwave absorbing and green shielding. Nano Res. 2022, 15, 6751–6760. [Google Scholar] [CrossRef]

- Zhang, X.; Qiao, J.; Jiang, Y.Y.; Wang, F.L.; Tian, X.L.; Wang, Z.; Wu, L.L.; Liu, W.; Liu, J.R. Carbon-based MOF derivatives: Emerging efficient electromagnetic wave absorption agents. Nano-Micro Lett. 2021, 13, 135. [Google Scholar] [CrossRef]

- Song, N.J.; Ma, C.L.; Li, P.; Li, W.X.; Guo, F.; Du, Y.E.; Chen, Y.Q. A novel method of enhancing the nitrogen content in biomass hard carbon: Pyrolysis-deposition-self-doping strategy. Int. J. Energy Res. 2022, 46, 9892–9899. [Google Scholar] [CrossRef]

- Gu, W.H.; Sheng, J.Q.; Huang, Q.Q.; Wang, G.H.; Chen, J.B.; Ji, G.B. Environmentally friendly and multifunctional shaddock peel-based carbon aerogel for thermal insulation and microwave absorption. Nano-Micro Lett. 2021, 13, 102. [Google Scholar] [CrossRef]

- Wu, N.N.; Liu, C.; Xu, D.M.; Liu, J.R.; Liu, W.; Shao, Q.; Guo, Z.H. Enhanced electromagnetic wave absorption of three-dimensional porous Fe3O4/C composite flowers. ACS Sustain. Chem. Eng. 2018, 6, 12471–12480. [Google Scholar] [CrossRef]

- Shen, G.Z.; Ren, J.Z.; Zhao, B.; Mei, B.Q.; Wu, H.Y.; Fang, X.M.; Xu, Y.W. Magnetic hollow mesoporous carbon composites with impedance matching for highly effective microwave absorption. J. Mater. Sci. 2019, 54, 4024–4037. [Google Scholar] [CrossRef]

- Wang, H.G.; Meng, F.B.; Li, J.Y.; Li, T.; Chen, Z.J.; Luo, H.B.; Zhou, Z.W. Carbonized design of hierarchical porous carbon/Fe3O4@Fe derived from loofah sponge to achieve tunable high-performance microwave absorption. ACS Sustain. Chem. Eng. 2018, 6, 11801–11810. [Google Scholar] [CrossRef]

- Pinto, S.S.; Machado, J.P.B.; Gomes, N.A.S.; Rezende, M.C. Influence of the aspect ratio of magnetic metallic additives on the microwave absorbing performance. Mater. Res. Express 2017, 4, 096101. [Google Scholar] [CrossRef]

- Gorriti, A.G.; Marin, P.; Cortina, D.; Hernando, A. Microwave attenuation with composite of copper microwires. J. Magn. Magn. Mater. 2010, 322, 1505–1510. [Google Scholar] [CrossRef]

- Gueye, P.G.B.; Sánchez, J.L.; Navarro, E.; Serrano, A.; Marín, P. Control of the length of Fe73.5Si13.5Nb3Cu1B9 microwires to be used for magnetic and microwave absorbing purposes. ACS Appl. Mater. Interfaces 2020, 12, 15644–15656. [Google Scholar] [CrossRef]

- Li, W.X.; Qi, H.X.; Guo, F.; Du, Y.E.; Song, N.J.; Liu, Y.Y.; Chen, Y.Q. Co nanoparticles supported on cotton-based carbon fibers: A novel broadband microwave absorbent. J. Alloys Compd. 2019, 772, 760–769. [Google Scholar] [CrossRef]

- Zhao, H.Q.; Cheng, Y.; Ma, J.N.; Zhang, Y.N.; Ji, G.B.; Du, Y.W. A sustainable route from biomass cotton to construct lightweight and high-performance microwave absorber. Chem. Eng. J. 2018, 339, 432–441. [Google Scholar] [CrossRef]

- Wei, Y.; Liu, H.J.; Liu, S.C.; Zhang, M.M.; Shi, Y.P.; Zhang, J.W.; Zhang, L.; Gong, C.H. Waste cotton-derived magnetic porous carbon for high-efficiency microwave absorption. Compos. Commun. 2018, 9, 70–75. [Google Scholar] [CrossRef]

- Yao, L.H.; Cao, W.Q.; Zhao, J.G.; Zheng, Q.; Wang, Y.C.; Jiang, S.; Pan, Q.L.; Song, J.; Zhu, Y.Q.; Cao, M.S. Regulating bifunctional flower-like NiFe2O4/graphene for green EMI shielding and lithium ion storage. J. Mater. Sci. Eng. 2022, 127, 48–60. [Google Scholar] [CrossRef]

- Zhang, M.; Song, S.N.; Liu, Y.M.; Hou, Z.X.; Tang, W.Y.; Li, S.N. Microstructural design of necklace-like Fe3O4/multiwall carbon nanotube (MWCNT) composites with enhanced microwave absorption performance. Materials 2021, 14, 4783. [Google Scholar] [CrossRef] [PubMed]

- Liu, J.L.; Zhang, L.M.; Wu, H.J. Enhancing the low/middle-frequency electromagnetic wave absorption of metal sulfides through F− regulation engineering. Adv. Funct. Mater. 2022, 32, 2110496. [Google Scholar] [CrossRef]

- Liu, P.J.; Yao, Z.J.; Ng, V.M.H.; Zhou, J.T.; Kong, L.B.; Yue, K. Facile synthesis of ultrasmall Fe3O4 nanoparticles on MXenes for high microwave absorption performance. Compos. Part A 2018, 115, 371–382. [Google Scholar] [CrossRef]

- Liang, X.H.; Quan, B.; Chen, J.B.; Gu, W.H.; Zhang, B.S.; Ji, G.B. Nano bimetallic@carbon layer on porous carbon nanofibers with multiple interfaces for microwave absorption applications. ACS Appl. Nano Mater. 2018, 1, 5712–5721. [Google Scholar] [CrossRef]

- Zhang, R.N.; Qiao, J.; Zhang, X.; Yang, Y.F.; Zheng, S.N.; Li, B.; Liu, W.; Liu, J.R.; Zeng, Z.H. Biomass-derived porous carbon for microwave absorption. Mater. Chem. Phys. 2022, 289, 126437. [Google Scholar] [CrossRef]

- Cheng, Y.; Ji, G.B.; Li, Z.Y.; Lv, H.L.; Liu, W.; Zhao, Y.; Cao, J.M.; Du, Y.W. Facile synthesis of FeCo alloys with excellent microwave absorption in the whole Ku-band: Effect of Fe/Co atomic ratio. J. Alloys Compd. 2017, 704, 289–295. [Google Scholar] [CrossRef]

- Du, Y.C.; Liu, W.W.; Qing, R.; Wang, Y.; Han, X.J.; Ma, J.; Xu, P. Shell thickness-dependent microwave absorption of core–shell Fe3O4@C composites. ACS Appl. Mater. Interfaces 2014, 6, 12997–13006. [Google Scholar] [CrossRef] [PubMed]

- Zhao, H.B.; Cheng, J.B.; Zhu, J.Y.; Wang, Y.Z. Ultralight CoNi/rGO aerogels toward excellent microwave absorption at ultrathin thickness. J. Mater. Chem. C 2019, 7, 441–448. [Google Scholar] [CrossRef]

- Mu, Z.G.; Wei, G.K.; Zhang, H.; Gao, L.; Zhao, Y.; Tang, S.L.; Ji, G.B. The dielectric behavior and efficient microwave absorption of doped nanoscale LaMnO3 at elevated temperature. Nano Res. 2022, 15, 7731–7741. [Google Scholar] [CrossRef]

- Guan, X.M.; Yang, Z.H.; Zhu, Y.T.; Yang, L.J.; Zhou, M.; Wu, Y.; Yang, L.; Deng, T.W.; Ji, G.B. The controllable porous structure and s-doping of hollow carbon sphere synergistically act on the microwave attenuation. Carbon 2022, 188, 1–11. [Google Scholar] [CrossRef]

- Liu, J.L.; Zhang, L.M.; Wu, H.J.; Zang, D.Y. Boosted electromagnetic wave absorption performance from vacancies, defects and interfaces engineering in Co(OH)F/Zn0.76Co0.24S/Co3S4 composite. Chem. Eng. J. 2021, 411, 128601. [Google Scholar] [CrossRef]

- Masoudpanah, S.M. PVP-assisted hydrothermal synthesis of rod-like NiCo2O4 powders as high-performance microwave absorbers. J. Mater. Res. Technol. 2022, 20, 3264–3274. [Google Scholar] [CrossRef]

- Cai, L.; Pan, F.; Zhu, X.J.; Dong, Y.Y.; Shi, Y.Y.; Xiang, Z.; Cheng, J.; Jiang, H.J.; Shi, Z.; Lu, W. Etching engineering and electrostatic self-assembly of N-doped MXene/hollow Co-ZIF hybrids for high-performance microwave absorbers. Chem. Eur. J. 2022, 434, 133865. [Google Scholar] [CrossRef]

- Deng, L.J.; Han, M.G. Microwave absorbing performances of multiwalled carbon nanotube composites with negative permeability. Appl. Phys. Lett. 2007, 91, 023119. [Google Scholar] [CrossRef]

- Liu, P.J.; Ng, V.M.H.; Yao, Z.J.; Zhou, J.T.; Lei, Y.M.; Yang, Z.H.; Lv, H.L.; Kong, L.B. Facile synthesis and hierarchical assembly of flowerlike NiO structures with enhanced dielectric and microwave absorption properties. ACS Appl. Mater. Interfaces 2017, 9, 16404–16416. [Google Scholar] [CrossRef]

- Lü, Y.Y.; Wang, Y.T.; Li, H.L.; Lin, Y.; Jiang, Z.Y.; Xie, Z.X.; Kuang, Q.; Zheng, L.S. MOF-derived porous Co/C nanocomposites with excellent electromagnetic wave absorption properties. ACS Appl. Mater. Interfaces 2015, 7, 13604–13611. [Google Scholar] [CrossRef]

- Yan, F.; Guo, D.; Zhang, S.; Li, C.Y.; Zhu, C.L.; Zhang, X.T.; Chen, Y.J. An ultra-small NiFe2O4 hollow particle/graphene hybrid: Fabrication and electromagnetic wave absorption property. Nanoscale 2018, 10, 2697–2703. [Google Scholar] [CrossRef]

- Wang, L.X.; Guan, Y.K.; Qiu, X.; Zhu, H.L.; Pan, S.B.; Yu, M.X.; Zhang, Q.T. Efficient ferrite/Co/porous carbon microwave absorbing material based on ferrite@metal–organic framework. Chem. Eng. J. 2017, 326, 945–955. [Google Scholar] [CrossRef]

- Li, X.; Cui, E.B.; Xiang, Z.; Yu, L.Z.; Xiong, J.; Pan, F.; Lu, W. Fe@NPC@CF nanocomposites derived from Fe-MOFs/biomass cotton for lightweight and high-performance electromagnetic wave absorption applications. J. Alloys Compd. 2020, 819, 152952. [Google Scholar] [CrossRef]

- Yan, J.; Huang, Y.; Chen, X.F.; Wei, C. Conducting polymers-NiFe2O4 coated on reduced graphene oxide sheets as electromagnetic (EM) wave absorption materials. Synth. Metals 2016, 221, 291–298. [Google Scholar] [CrossRef]

- Xie, P.T.; Li, H.Y.; He, B.; Dang, F.; Lin, J.; Fan, R.H.; Hou, C.X.; Liu, H.; Zhang, J.X.; Ma, Y.; et al. Bio-gel derived nickel/carbon nanocomposites with enhanced microwave absorption. J. Mater. Chem. C 2018, 6, 8812–8822. [Google Scholar] [CrossRef]

- Shen, Z.J.; Yang, H.L.; Xiong, Z.Q.; Xie, Y.; Liu, C.B. Hollow core-shell CoNi@C and CoNi@NC composites as high-performance microwave absorbers. J. Alloys Compd. 2021, 871, 159574. [Google Scholar] [CrossRef]

- Wang, S.S.; Zhao, Y.; Xue, H.L.; Xie, J.R.; Feng, C.H.; Li, H.S.; Shi, D.X.; Muhammad, S.; Jiao, Q.Z. Preparation of flower-like CoFe2O4@graphene composites and their microwave absorbing properties. Mater. Lett. 2018, 223, 186–189. [Google Scholar] [CrossRef]

- Ojha, G.P.; Pant, B.; Acharya, J.; Park, M. An electrochemically reduced ultra-high mass loading three-dimensional carbon nanofiber network: A high energy density symmetric supercapacitor with a reproducible and stable cell voltage of 2.0 V. Nanoscale 2021, 13, 19537–19548. [Google Scholar] [CrossRef] [PubMed]

- Liu, W.; Tan, S.J.; Yang, Z.H.; Ji, G.B. Enhanced low frequency electromagnetic properties of MOF-derived cobalt through interface design. ACS Appl. Mater. Interfaces 2018, 10, 31610–31622. [Google Scholar] [CrossRef]

- Ding, D.; Wang, Y.; Li, X.D.; Qiang, R.; Xu, P.; Chu, W.L.; Han, X.J.; Du, Y.C. Rational design of core shell Co@C microspheres for high performance microwave absorption. Carbon 2017, 111, 722–732. [Google Scholar] [CrossRef]

- Pan, H.X.; Yin, X.W.; Xue, J.M.; Cheng, L.F.; Zhang, L.T. In-situ synthesis of hierarchically porous and polycrystalline carbon nanowires with excellent microwave absorption performance. Carbon 2016, 107, 36–45. [Google Scholar] [CrossRef]

- Wang, S.S.; Jiao, Q.Z.; Liu, X.F.; Xu, Y.C.; Shi, Q.; Yue, S.; Zhao, Y.; Liu, H.B.; Feng, C.H.; Shi, D.X. Controllable synthesis of γ-Fe2O3 nanotube/porous rGO composites and their enhanced microwave absorption properties. ACS Sustain. Chem. Eng. 2019, 7, 7004–7013. [Google Scholar] [CrossRef]

- Huang, W.H.; Wang, S.; Yang, X.F.; Zhang, X.X.; Zhang, Y.N.; Pei, K.; Che, R.C. Temperature induced transformation of Co@C nanoparticle in 3D hierarchical core-shell nanofiber network for enhanced electromagnetic wave adsorption. Carbon 2022, 195, 44–56. [Google Scholar] [CrossRef]

- Kang, Y.; Jiang, Z.H.; Ma, T.; Chu, Z.Y.; Li, G.Y. Hybrids of reduced graphene oxide and hexagonal boron nitride: Lightweight absorbers with tunable and highly efficient microwave attenuation properties. ACS Appl. Mater. Interfaces 2016, 8, 32468–32476. [Google Scholar] [CrossRef]

- Fang, G.; Liu, C.Y.; Yang, Y.; Peng, K.S.; Cao, Y.F.; Jiang, T.; Zhang, Y.T.; Zhang, Y.J. Regulating percolation threshold via dual conductive phases for high-efficiency microwave absorption performance in C and X bands. ACS Appl. Mater. Interfaces 2021, 13, 37517–37526. [Google Scholar] [CrossRef] [PubMed]

- Wang, K.F.; Chen, Y.J.; Tian, R.; Li, H.; Zhou, Y.; Duan, H.N.; Liu, H.Z. Porous Co-C core-shell nanocomposites derived from Co-MOF-74 with enhanced electromagnetic wave absorption performance. ACS Appl. Mater. Interfaces 2018, 10, 11333–11342. [Google Scholar] [CrossRef] [PubMed]

| Sample | Filling Rate (wt%) | Effective Absorption Bandwidth (GHz) | Minimum RL (dB) | References |

|---|---|---|---|---|

| MOF-Derived Porous Co/C Nanocomposites | 60 | 5.8 | −35.3 | [46] |

| NiFe2O4 hollow particle/graphene | 15 | 4.5 | −40.9 | [47] |

| Ferrite/Co/porous carbon | 70 | 4.8 | −31.0 | [48] |

| Fe@porouscarbon@carbonfiber | 25 | 5.2 | −46.2 | [49] |

| RGO-PANI-NiFe2O4 | 30 | 5.3 | −49.7 | [50] |

| Ni/Carbon nanocomposites | 25 | 4.4 | −21.2 | [51] |

| CoNi@Ccomposites | 50 | 5.0 | −35.8 | [52] |

| CoFe2O4@graphene composites | 45 | 4.6 | −42 | [53] |

| NiFe2O4/carbonized cotton fibers | 25 | 6.5 | −45.3 | This work |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, W.; Guo, F.; Zhao, Y.; Liu, Y. A Sustainable and Low-Cost Route to Design NiFe2O4 Nanoparticles/Biomass-Based Carbon Fibers with Broadband Microwave Absorption. Nanomaterials 2022, 12, 4063. https://doi.org/10.3390/nano12224063

Li W, Guo F, Zhao Y, Liu Y. A Sustainable and Low-Cost Route to Design NiFe2O4 Nanoparticles/Biomass-Based Carbon Fibers with Broadband Microwave Absorption. Nanomaterials. 2022; 12(22):4063. https://doi.org/10.3390/nano12224063

Chicago/Turabian StyleLi, Wanxi, Fang Guo, Yali Zhao, and Yanyun Liu. 2022. "A Sustainable and Low-Cost Route to Design NiFe2O4 Nanoparticles/Biomass-Based Carbon Fibers with Broadband Microwave Absorption" Nanomaterials 12, no. 22: 4063. https://doi.org/10.3390/nano12224063

APA StyleLi, W., Guo, F., Zhao, Y., & Liu, Y. (2022). A Sustainable and Low-Cost Route to Design NiFe2O4 Nanoparticles/Biomass-Based Carbon Fibers with Broadband Microwave Absorption. Nanomaterials, 12(22), 4063. https://doi.org/10.3390/nano12224063