High Responsivity Vacuum Nano-Photodiode Using Single-Crystal CsPbBr3 Micro-Sheet

Abstract

:1. Introduction

2. Materials and Methods

2.1. Preparation of Single-Crystal CsPbBr3 Micro-Sheets

2.2. Device Fabrication and Characterizations

2.3. Finite Element Simulations

3. Results and Discussion

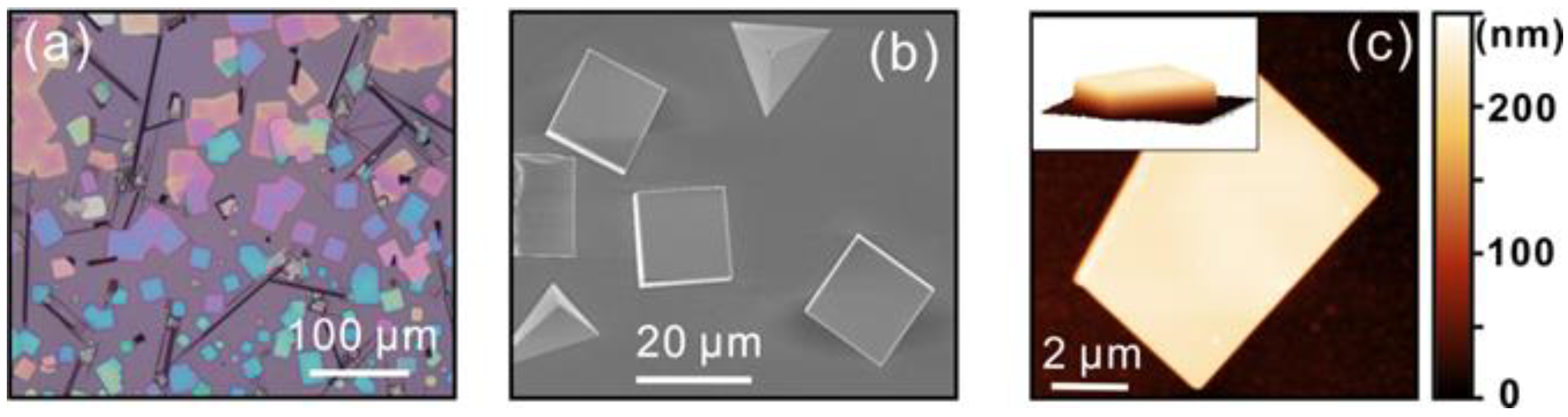

3.1. Single-Crystal CsPbBr3 Micro-Sheets

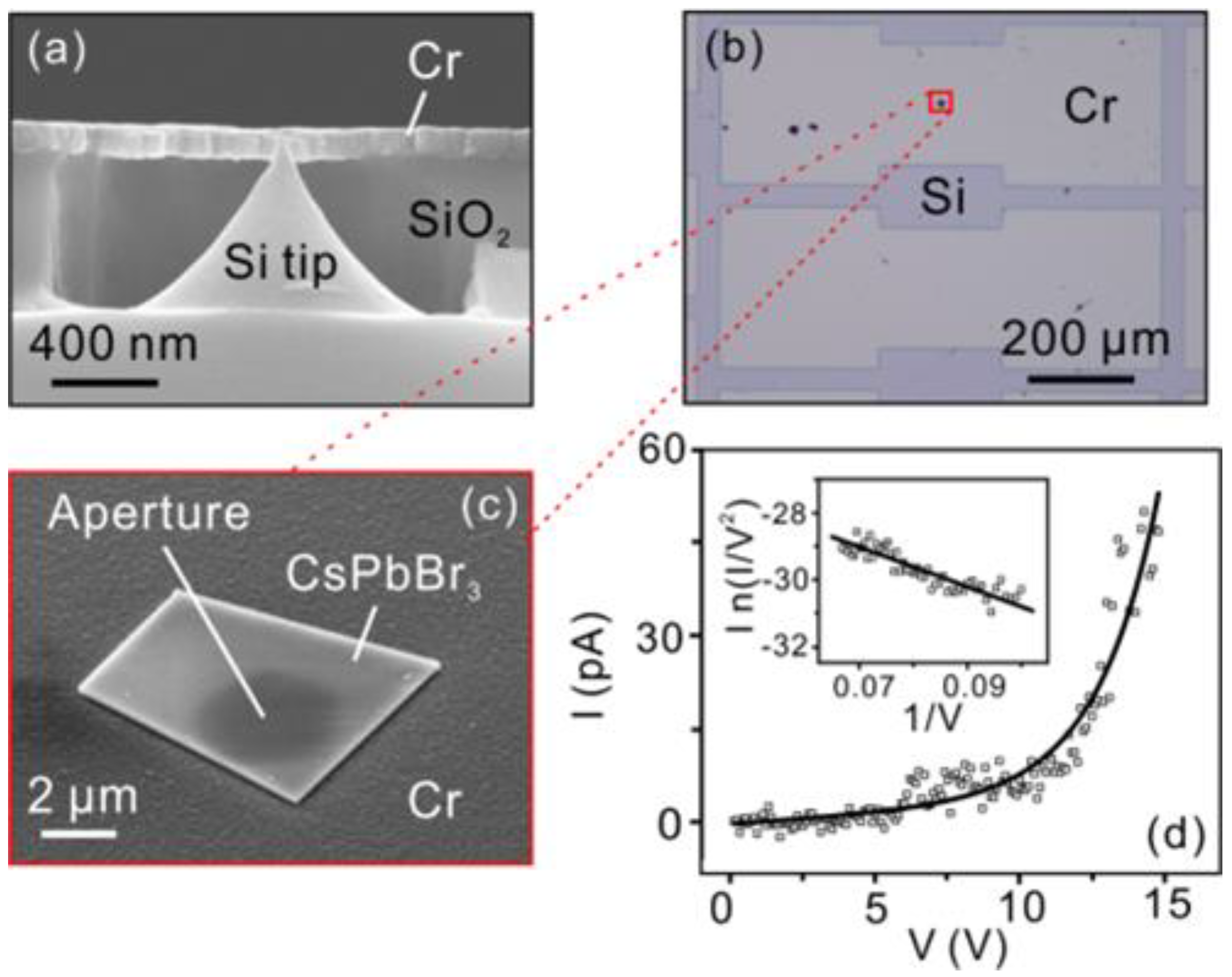

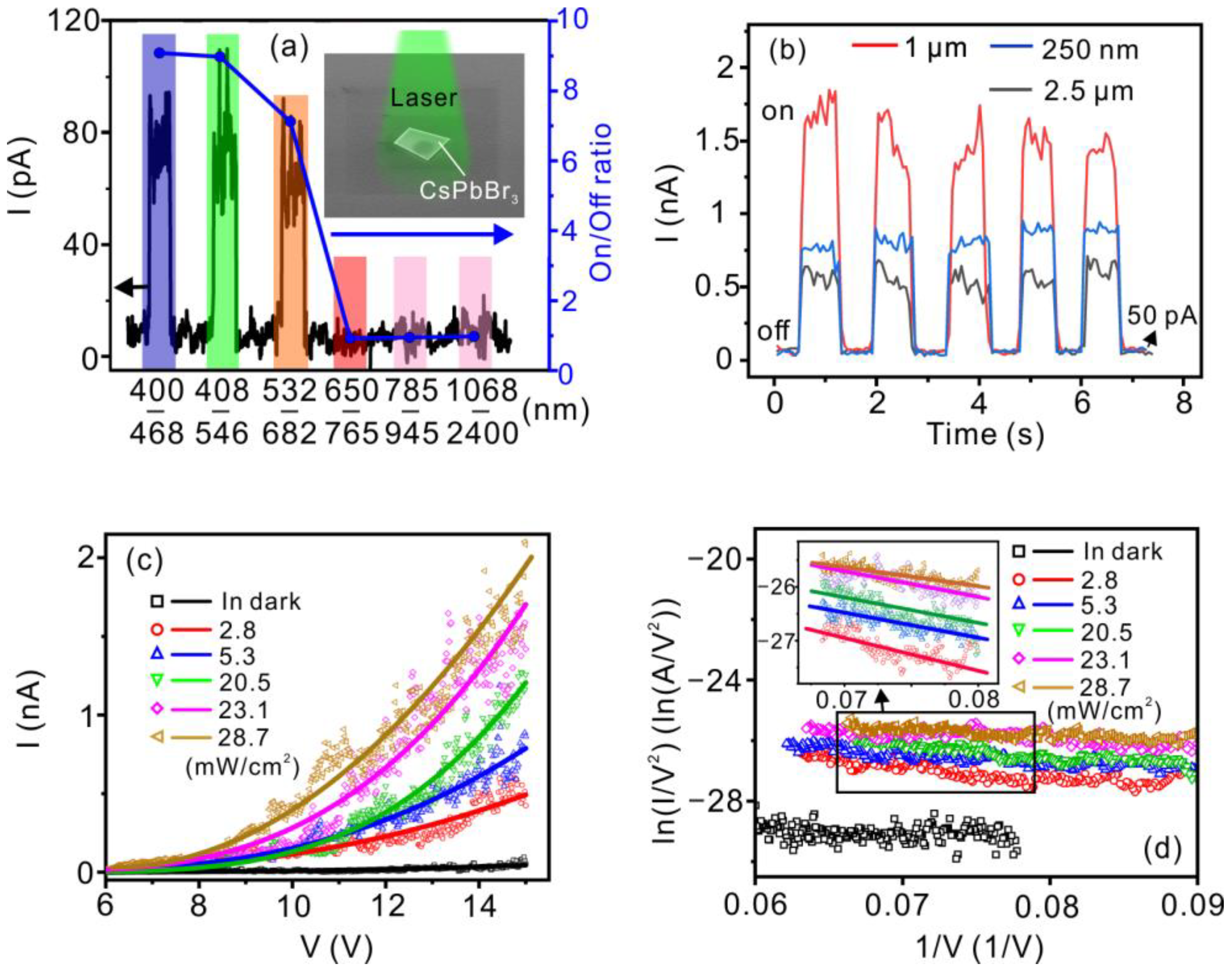

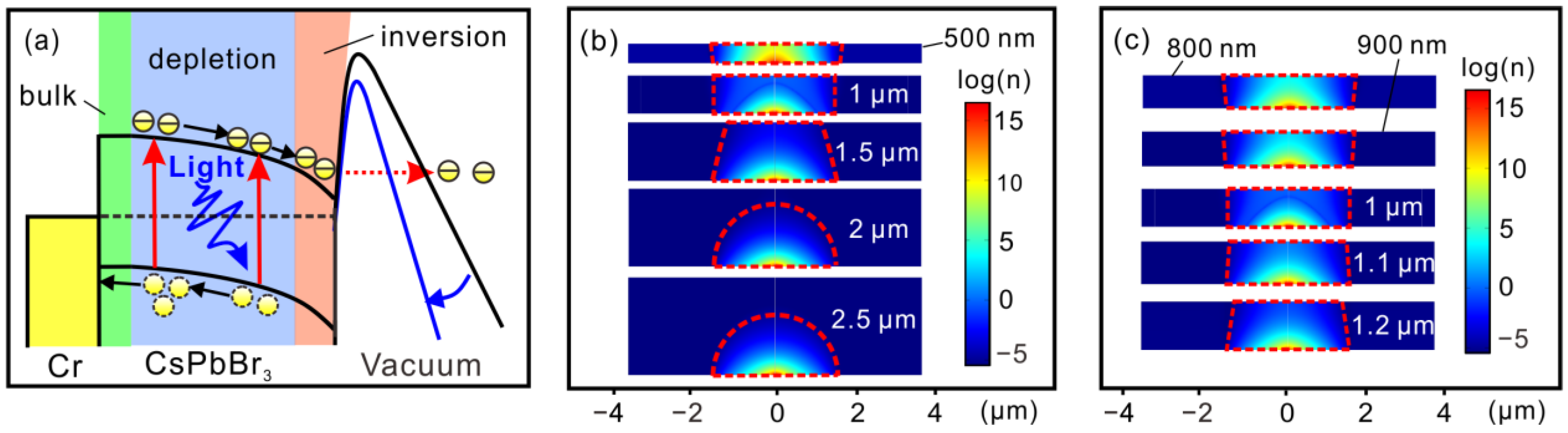

3.2. CsPbBr3 Vacuum Nano-Photodiode and the Photo-Responsivity

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Busta, H.H. Vacuum Microelectronics-1992. J. Micromech. Microeng. 1992, 2, 43–74. [Google Scholar] [CrossRef]

- Stoner, B.R.; Glass, J.T. Nothing Is Like a Vacuum. Nat. Nanotechnol. 2012, 7, 485–487. [Google Scholar] [CrossRef] [PubMed]

- Han, J.-W.; Sub Oh, J.; Meyyappan, M. Vacuum Nanoelectronics: Back to the Future?—Gate Insulated Nanoscale Vacuum Channel Transistor. Appl. Phys. Lett. 2012, 100, 213505. [Google Scholar] [CrossRef] [Green Version]

- Hudanski, L.; Minoux, E.; Gangloff, L.; Teo, K.B.; Schnell, J.P.; Xavier, S.; Robertson, J.; Milne, W.I.; Pribat, D.; Legagneux, P. Carbon Nanotube Based Photocathodes. Nanotechnology 2008, 19, 105201. [Google Scholar] [CrossRef] [PubMed]

- Mingels, S.; Porshyn, V.; Prommesberger, C.; Langer, C.; Schreiner, R.; Lützenkirchen-Hecht, D.; Müller, G. Photosensitivity of P-Type Black Si Field Emitter Arrays. J. Appl. Phys. 2016, 119, 165104. [Google Scholar] [CrossRef]

- Vahdani Moghaddam, M.; Yaghoobi, P.; Sawatzky, G.A.; Nojeh, A. Photon-Impenetrable, Electron-Permeable: The Carbon Nanotube Forest as a Medium for Multiphoton Thermal-Photoemission. ACS Nano 2015, 9, 4064–4069. [Google Scholar] [CrossRef]

- Borz, M.; Mammez, M.H.; Blum, I.; Houard, J.; Da Costa, G.; Delaroche, F.; Idlahcen, S.; Haboucha, A.; Hideur, A.; Kleshch, V.I.; et al. Photoassisted and Multiphoton Emission from Single-Crystal Diamond Needles. Nanoscale 2019, 11, 6852–6858. [Google Scholar] [CrossRef] [PubMed]

- Hommelhoff, P.; Sortais, Y.; Aghajani-Talesh, A.; Kasevich, M.A. Field Emission Tip as a Nanometer Source of Free Electron Femtosecond Pulses. Phys. Rev. Lett. 2006, 96, 077401. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zhou, S.; Chen, K.; Cole, M.T.; Li, Z.; Chen, J.; Li, C.; Dai, Q. Ultrafast Field-Emission Electron Sources Based on Nanomaterials. Adv. Mater. 2019, 31, e1805845. [Google Scholar] [CrossRef]

- Zhou, S.; Chen, K.; Cole, M.T.; Li, Z.; Li, M.; Chen, J.; Lienau, C.; Li, C.; Dai, Q. Ultrafast Electron Tunneling Devices-from Electric-Field Driven to Optical-Field Driven. Adv. Mater. 2021, 33, e2101449. [Google Scholar] [CrossRef]

- Shen, Y.; Chen, H.; Xu, N.; Xing, Y.; Wang, H.; Zhan, R.; Gong, L.; Wen, J.; Zhuang, C.; Chen, X.; et al. A Plasmon-Mediated Electron Emission Process. ACS Nano 2019, 13, 1977–1989. [Google Scholar] [CrossRef] [PubMed]

- Zhou, S.; Chen, K.; Guo, X.; Cole, M.T.; Wu, Y.; Li, Z.; Zhang, S.; Li, C.; Dai, Q. Antenna-Coupled Vacuum Channel Nano-Diode with High Quantum Efficiency. Nanoscale 2020, 12, 1495–1499. [Google Scholar] [CrossRef] [PubMed]

- Sapkota, K.R.; Leonard, F.; Talin, A.A.; Gunning, B.P.; Kazanowska, B.A.; Jones, K.S.; Wang, G.T. Ultralow Voltage Gan Vacuum Nanodiodes in Air. Nano Lett. 2021, 21, 1928–1934. [Google Scholar] [CrossRef] [PubMed]

- Nirantar, S.; Ahmed, T.; Ren, G.; Gutruf, P.; Xu, C.; Bhaskaran, M.; Walia, S.; Sriram, S. Metal-Air Transistors: Semiconductor-Free Field-Emission Air-Channel Nanoelectronics. Nano Lett. 2018, 18, 7478–7484. [Google Scholar] [CrossRef] [PubMed]

- Xu, J.; Gu, Z.; Yang, W.; Wang, Q.; Zhang, X. Graphene-Based Nanoscale Vacuum Channel Transistor. Nanoscale Res. Lett. 2018, 13, 311. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Li, W.; Valentine, J. Metamaterial Perfect Absorber Based Hot Electron Photodetection. Nano Lett. 2014, 14, 3510–3514. [Google Scholar] [CrossRef] [PubMed]

- Putnam, W.P.; Hobbs, R.G.; Keathley, P.D.; Berggren, K.K.; Kärtner, F.X. Optical-Field-Controlled Photoemission from Plasmonic Nanoparticles. Nat. Phys. 2016, 13, 335–339. [Google Scholar] [CrossRef]

- Piltan, S.; Sievenpiper, D. Plasmonic Nano-Arrays for Enhanced Photoemission and Photodetection. J. Opt. Soc. Am. B 2018, 35, 208–213. [Google Scholar] [CrossRef]

- Chen, P.Y.; Alu, A. A Terahertz Photomixer Based on Plasmonic Nanoantennas Coupled to a Graphene Emitter. Nanotechnology 2013, 24, 455202. [Google Scholar] [CrossRef]

- Srisonphan, S.; Kanokbannakorn, W.; Teerakawanich, N. Field Emission Graphene–Oxide–Silicon Field Effect Based Photodetector. Phys. Status Solidi Rapid Res. Lett. 2015, 9, 656–662. [Google Scholar] [CrossRef]

- Srisonphan, S. Hybrid Graphene–Si-Based Nanoscale Vacuum Field Effect Phototransistors. ACS Photonics 2016, 3, 1799–1808. [Google Scholar] [CrossRef]

- Li, Z.J.; Sun, F.S.; Zheng, Z.B.; Chen, J.; Davydov, A.V.; Deng, S.Z.; Zhang, H.R.; Chen, H.J.; Liu, F. High-Quality All-Inorganic Perovskite CsPbBr3 Microsheet Crystals as Low-Loss Subwavelength Exciton-Polariton Waveguides. Nano Lett. 2021, 21, 1822–1830. [Google Scholar] [CrossRef] [PubMed]

- Protesescu, L.; Yakunin, S.; Bodnarchuk, M.I.; Krieg, F.; Caputo, R.; Hendon, C.H.; Yang, R.X.; Walsh, A.; Kovalenko, M.V. Nanocrystals of Cesium Lead Halide Perovskites (CsPbX3, X = Cl, Br, and I): Novel Optoelectronic Materials Showing Bright Emission with Wide Color Gamut. Nano Lett. 2015, 15, 3692–3696. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Liu, H.W.; Lu, J.P.; Fan, H.M.; Sow, C.H.; Tang, S.H.; Zhang, X.H. Temperature and Composition Dependence of Photoluminescence Dynamics in CdSxSe1−X (0 ≤ X ≤ 1) Nanobelts. J. Appl. Phys. 2012, 111, 073112. [Google Scholar] [CrossRef]

- Yan, Z.Z.; Jiang, Z.H.; Lu, J.P.; Ni, Z.H. Interfacial Charge Transfer in WS2 Monolayer/CsPbBr3 Microplate Heterostructure. Front. Phys. 2018, 13, 138115. [Google Scholar] [CrossRef]

- Byrnes, T.; Kim, N.Y.; Yamamoto, Y. Exciton–Polariton Condensates. Nat. Phys. 2014, 10, 803–813. [Google Scholar] [CrossRef] [Green Version]

- D’Innocenzo, V.; Grancini, G.; Alcocer, M.J.; Kandada, A.R.; Stranks, S.D.; Lee, M.M.; Lanzani, G.; Snaith, H.J.; Petrozza, A. Excitons versus Free Charges in Organo-Lead Tri-Halide Perovskites. Nat. Commun. 2014, 5, 3586. [Google Scholar] [CrossRef] [Green Version]

- Grosso, G.; Graves, J.; Hammack, A.T.; High, A.A.; Butov, L.V.; Hanson, M.; Gossard, A.C. Excitonic Switches Operating at around 100 k. Nat. Photonics 2009, 3, 577–580. [Google Scholar] [CrossRef]

- Huang, Y.; Deng, Z.; Wang, W.; Liang, C.; She, J.; Deng, S.; Xu, N. Field-Induced Crystalline-to-Amorphous Phase Transformation on the Si Nano-Apex and the Achieving of Highly Reliable Si Nano-Cathodes. Sci. Rep. 2015, 5, 10631. [Google Scholar] [CrossRef] [Green Version]

- Huang, Z.J.; Huang, Y.F.; Pan, Z.X.; She, J.C.; Deng, S.Z.; Chen, J.; Xu, N.S. Self-Modulated Field Electron Emitter: Gated Device of Integrated Si Tip-on-Nano-Channel. Appl. Phys. Lett. 2016, 109, 233501. [Google Scholar] [CrossRef]

- Xu, N.S.; Huq, S.E. Novel Cold Cathode Materials and Applications. Mater. Sci. Eng. R Rep. 2005, 48, 47–189. [Google Scholar] [CrossRef]

- Zou, Y.T.; Li, F.; Zhao, C.; Xing, J.; Yu, Z.; Yu, W.L.; Guo, C.L. Anomalous Ambipolar Phototransistors Based on All-Inorganic CsPbBr3 Perovskite at Room Temperature. Adv. Opt. Mater. 2019, 7, 1900676. [Google Scholar] [CrossRef]

- Kim, M.; Kim, H.K. Ultraviolet-Enhanced Photodetection in a Graphene/SiO2/Si Capacitor Structure with a Vacuum Channel. J. Appl. Phys. 2015, 118, 104504. [Google Scholar] [CrossRef]

- Michaelson, H.B. The Work Function of the Elements and Its Periodicity. J. Appl. Phys. 1977, 48, 4729–4733. [Google Scholar] [CrossRef] [Green Version]

- Zhang, B.B.; Wang, F.B.; Zhang, H.J.; Xiao, B.; Sun, Q.H.; Guo, J.; Ben Hafsia, A.; Shao, A.H.; Xu, Y.D.; Zhou, J. Defect Proliferation in CsPbBr3 Crystal Induced by Ion Migration. Appl. Phys. Lett. 2020, 116, 063505. [Google Scholar] [CrossRef]

- Neamen, D.A. Semiconductor Physics and Devices Basic Principles; McGraw-Hill: New York, NY, USA, 2012. [Google Scholar]

- Maes, J.; Balcaen, L.; Drijvers, E.; Zhao, Q.; De Roo, J.; Vantomme, A.; Vanhaecke, F.; Geiregat, P.; Hens, Z. Light Absorption Coefficient of CsPbBr3 Perovskite Nanocrystals. J. Phys. Chem. Lett. 2018, 9, 3093–3097. [Google Scholar] [CrossRef] [PubMed]

- Chiang, C.-J.; Liu, K.X.; Heritage, J.P. Optically Stimulated Picosecond Field Emission Pulses from Gated P-Silicon Field Emitter Arrays. Appl. Phys. Lett. 2007, 90, 083506. [Google Scholar] [CrossRef]

- Zhang, Z.; Wang, K.; Zheng, K.; Deng, S.; Xu, N.; Chen, J. Electron Bombardment Induced Photoconductivity and High Gain in a Flat Panel Photodetector Based on a ZnS Photoconductor and ZnO Nanowire Field Emitters. ACS Photonics 2018, 5, 4147–4155. [Google Scholar] [CrossRef]

| Structure | Cathode Material | Photoresponsivity | EQE | Dark Current | Operating Voltage |

|---|---|---|---|---|---|

| Antenna-coupled nano diode [12] | Au | 0.6 mA∙W−1 | 4% | 300 pA | 1–2 V |

| Si-Graphene [21] | P-doped Silicon | 1.2 A∙W−1 | 235% | ~100 nA | 5 V |

| Black silicon cathode [5] | P-doped Silicon | 1.85 mA∙W−1 | 0.01% | 250 nA | >1000 V |

| Diamond film-Cu [33] | Diamond | ~10 mA∙W−1 | \ | \ | 90–150 V |

| CsPbBr3-Si tip (This work) | Single-crystal CsPbBr3 | 1.75 A∙W−1 | 400% | 50 pA | 15 V |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zeng, X.; Li, S.; Liu, Z.; Chen, Y.; Chen, J.; Deng, S.; Liu, F.; She, J. High Responsivity Vacuum Nano-Photodiode Using Single-Crystal CsPbBr3 Micro-Sheet. Nanomaterials 2022, 12, 4205. https://doi.org/10.3390/nano12234205

Zeng X, Li S, Liu Z, Chen Y, Chen J, Deng S, Liu F, She J. High Responsivity Vacuum Nano-Photodiode Using Single-Crystal CsPbBr3 Micro-Sheet. Nanomaterials. 2022; 12(23):4205. https://doi.org/10.3390/nano12234205

Chicago/Turabian StyleZeng, Xiangjun, Shasha Li, Zairan Liu, Yang Chen, Jun Chen, Shaozhi Deng, Fei Liu, and Juncong She. 2022. "High Responsivity Vacuum Nano-Photodiode Using Single-Crystal CsPbBr3 Micro-Sheet" Nanomaterials 12, no. 23: 4205. https://doi.org/10.3390/nano12234205

APA StyleZeng, X., Li, S., Liu, Z., Chen, Y., Chen, J., Deng, S., Liu, F., & She, J. (2022). High Responsivity Vacuum Nano-Photodiode Using Single-Crystal CsPbBr3 Micro-Sheet. Nanomaterials, 12(23), 4205. https://doi.org/10.3390/nano12234205