Patterning of Silicon Substrate with Self-Assembled Monolayers Using Vertically Aligned Carbon Nanotube Electron Sources

Abstract

1. Introduction

2. Materials and Methods

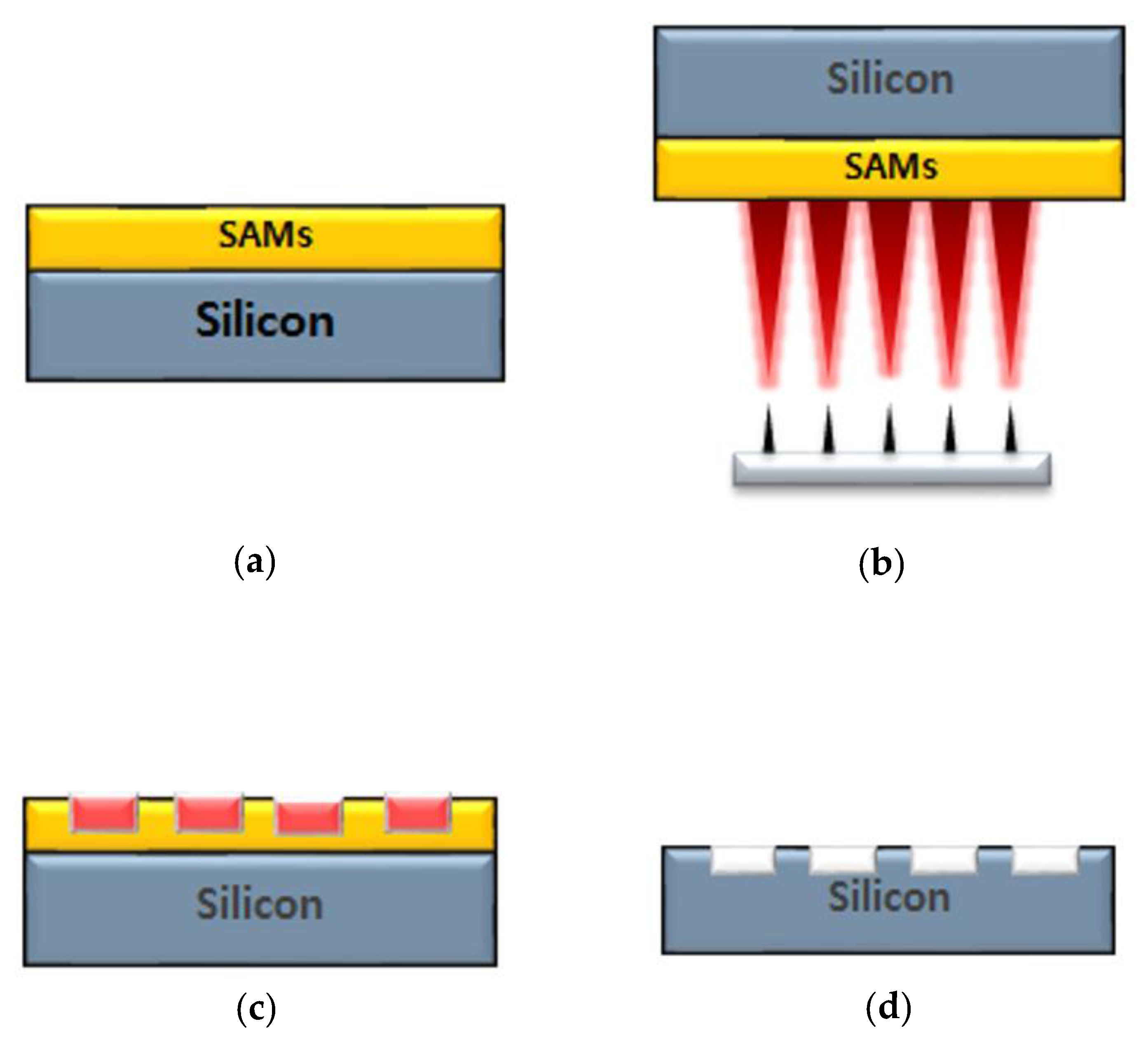

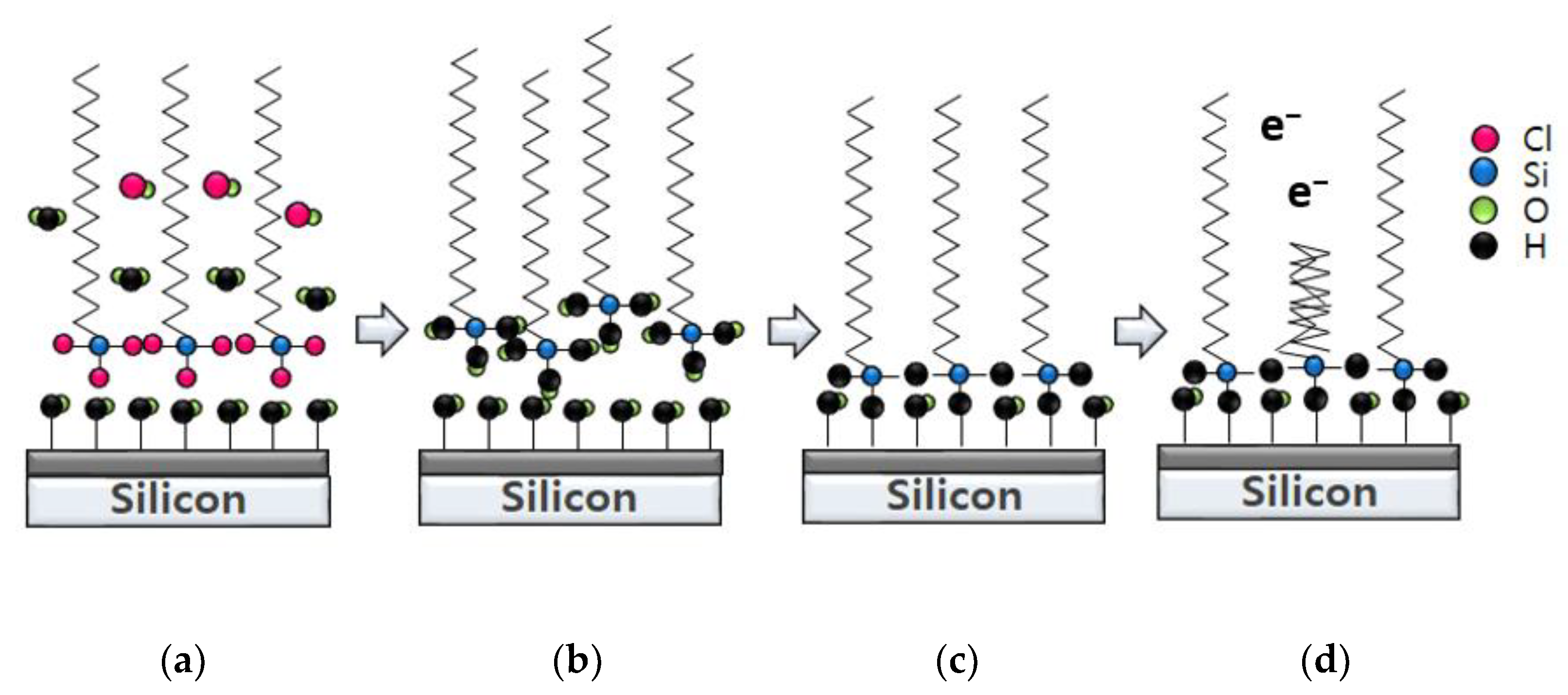

2.1. SAM Sample Preparation

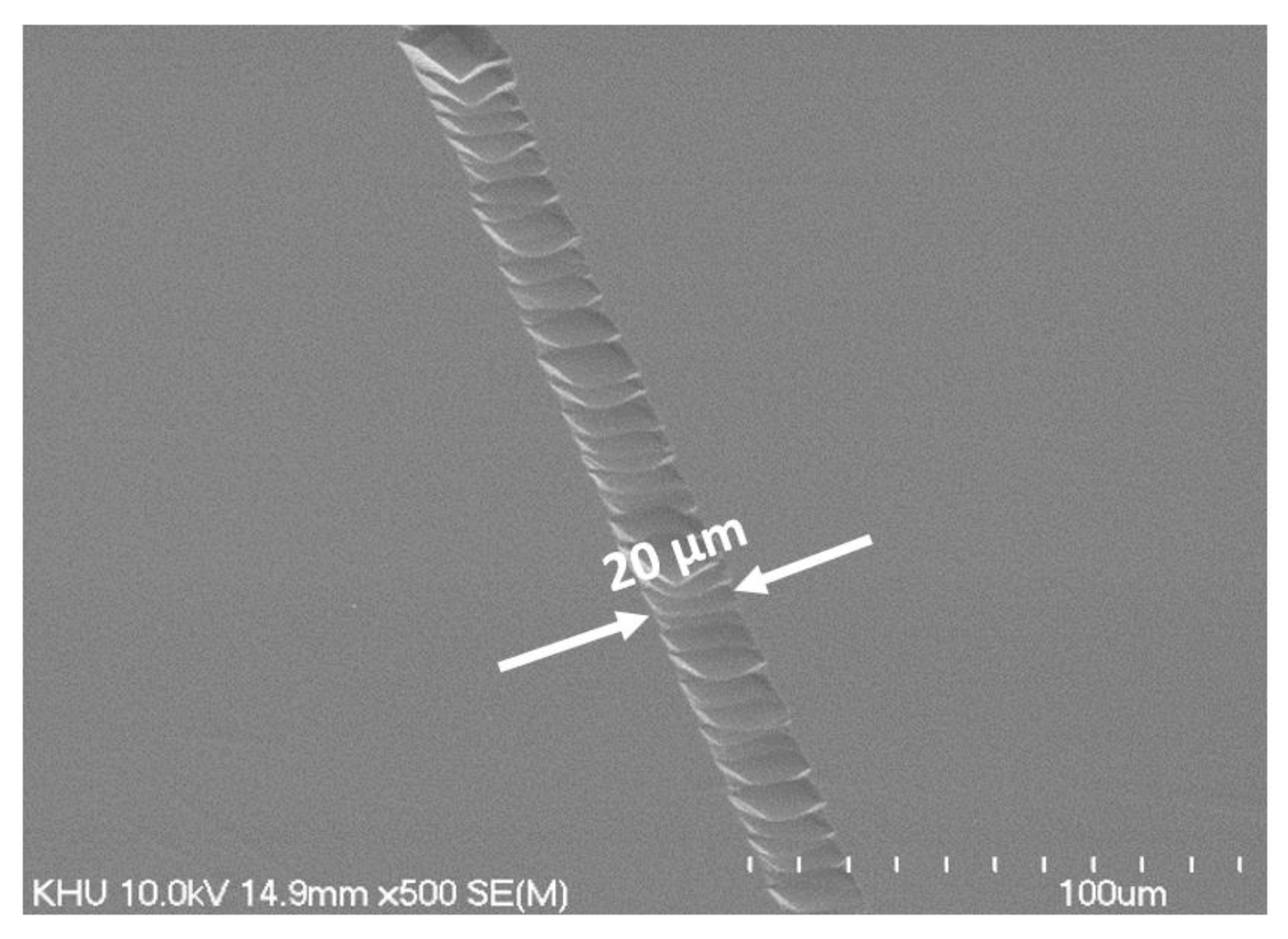

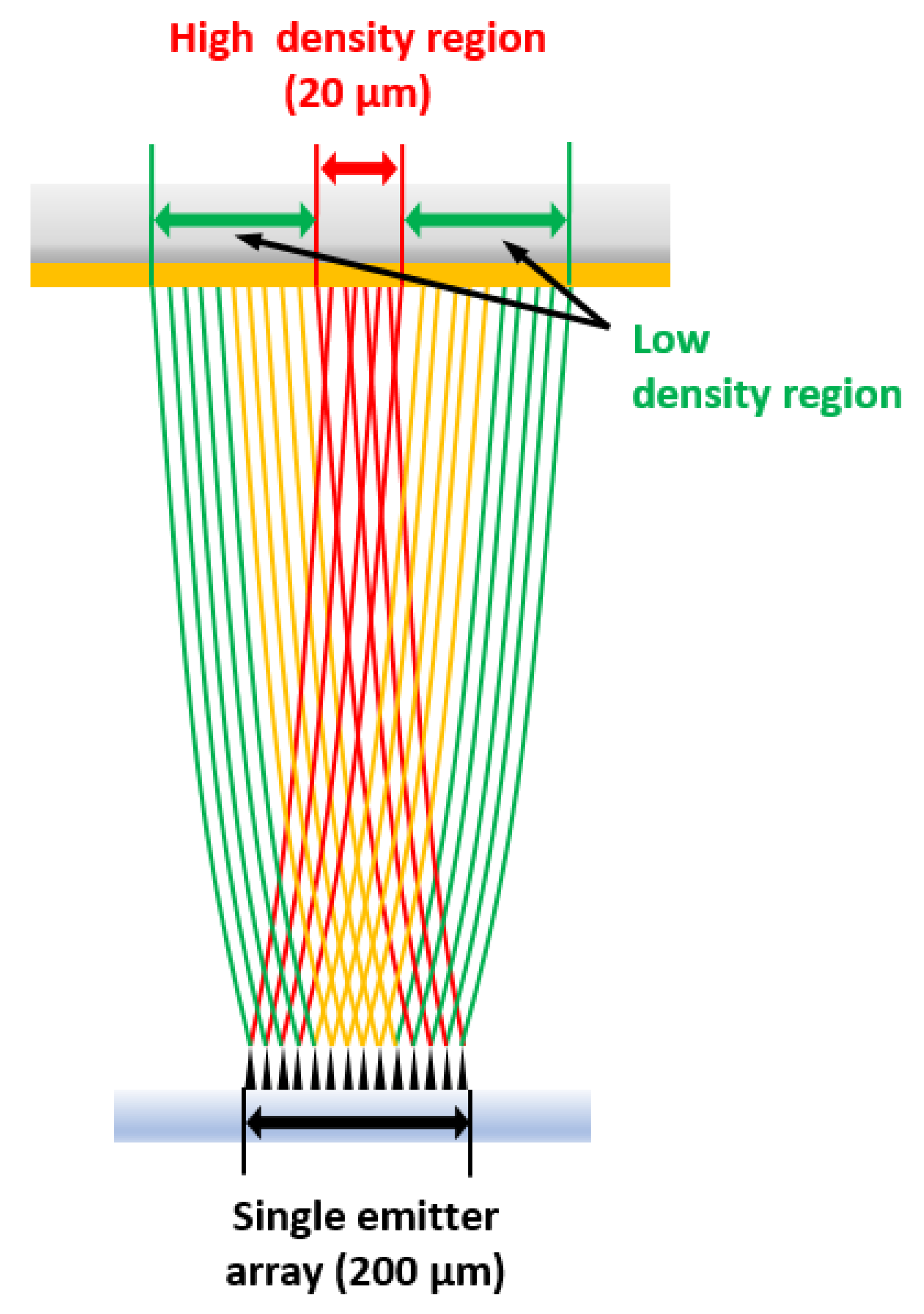

2.2. Fabrication of VACNT Emitter

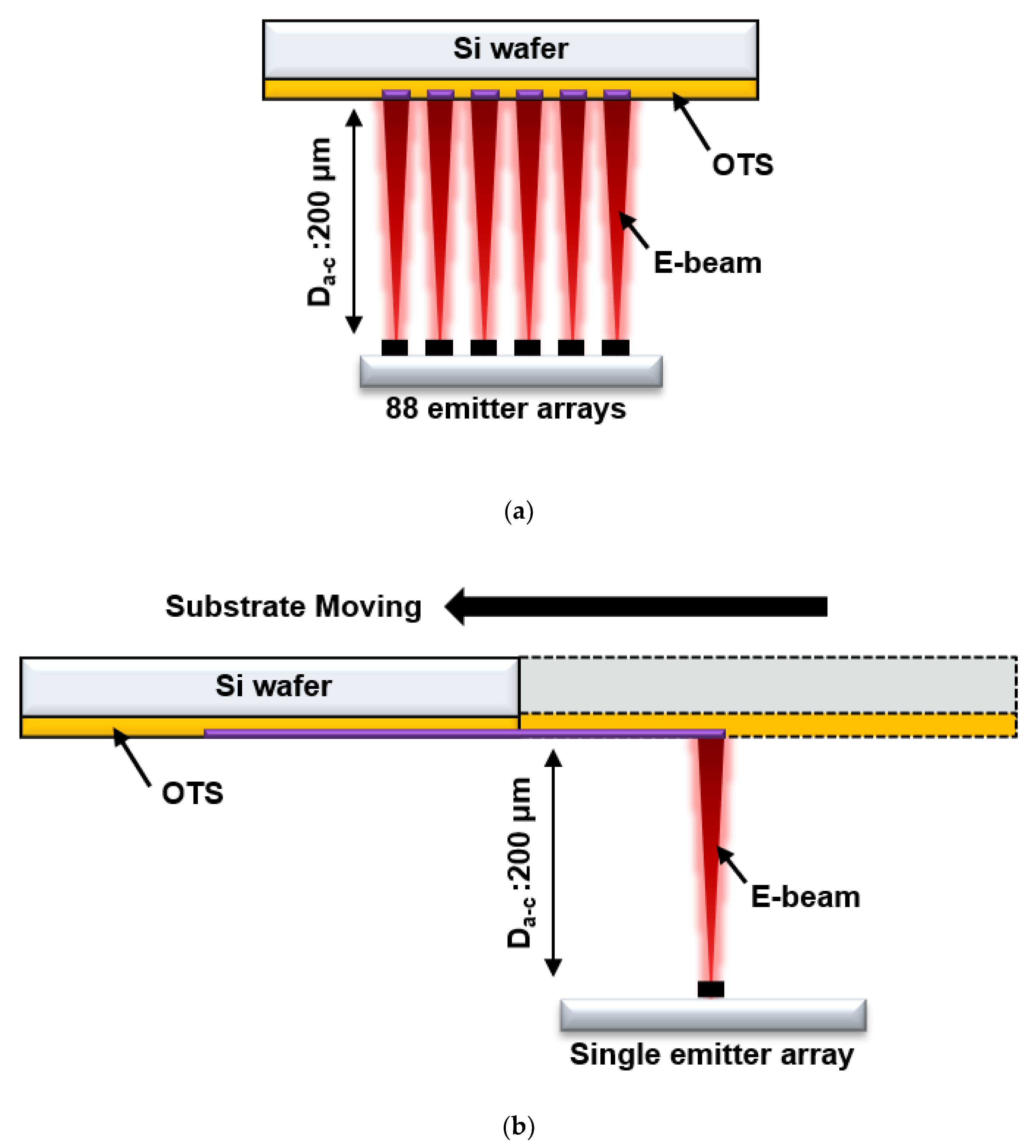

2.3. OTS Patterning and Si Wafer Patterning

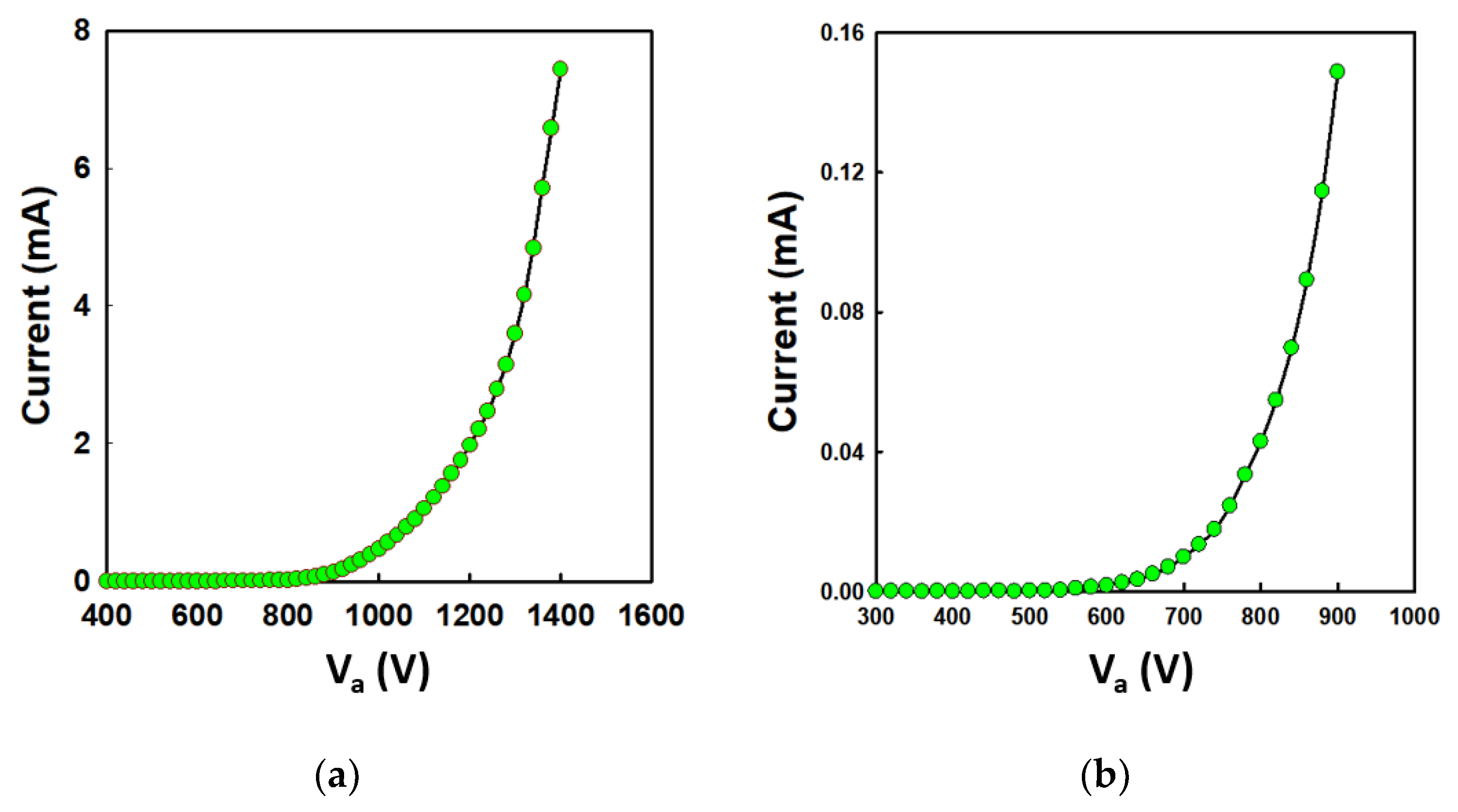

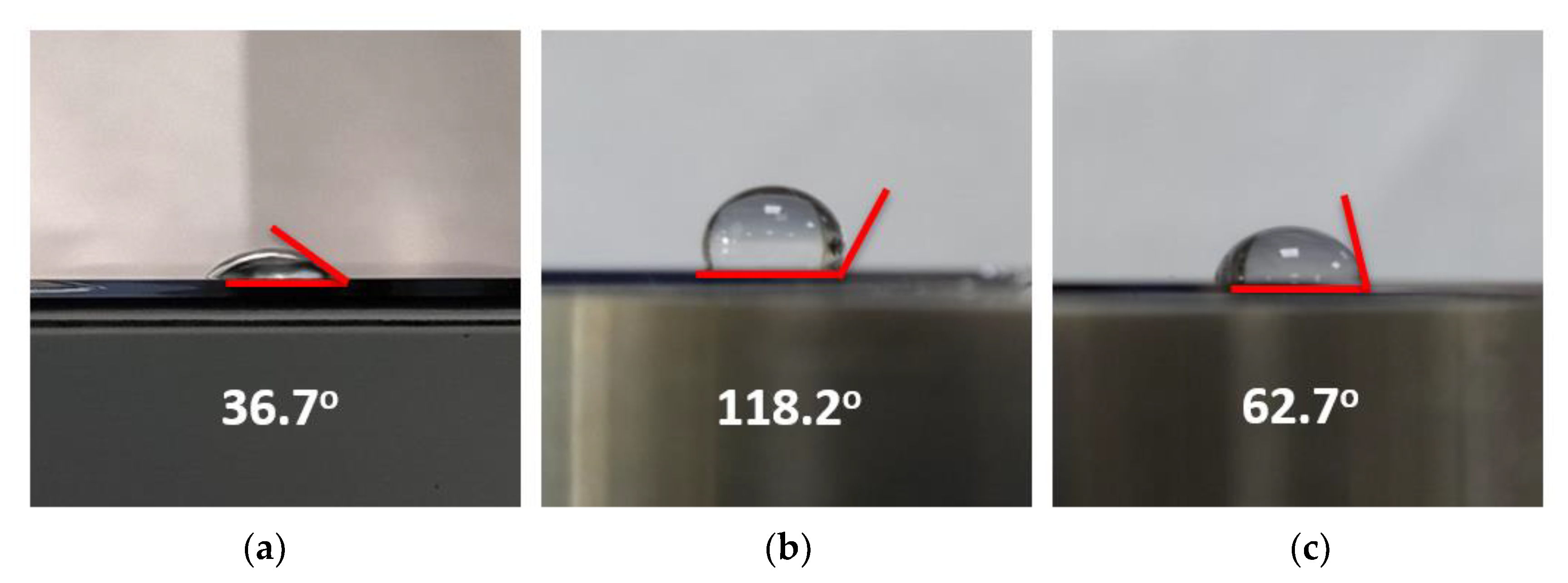

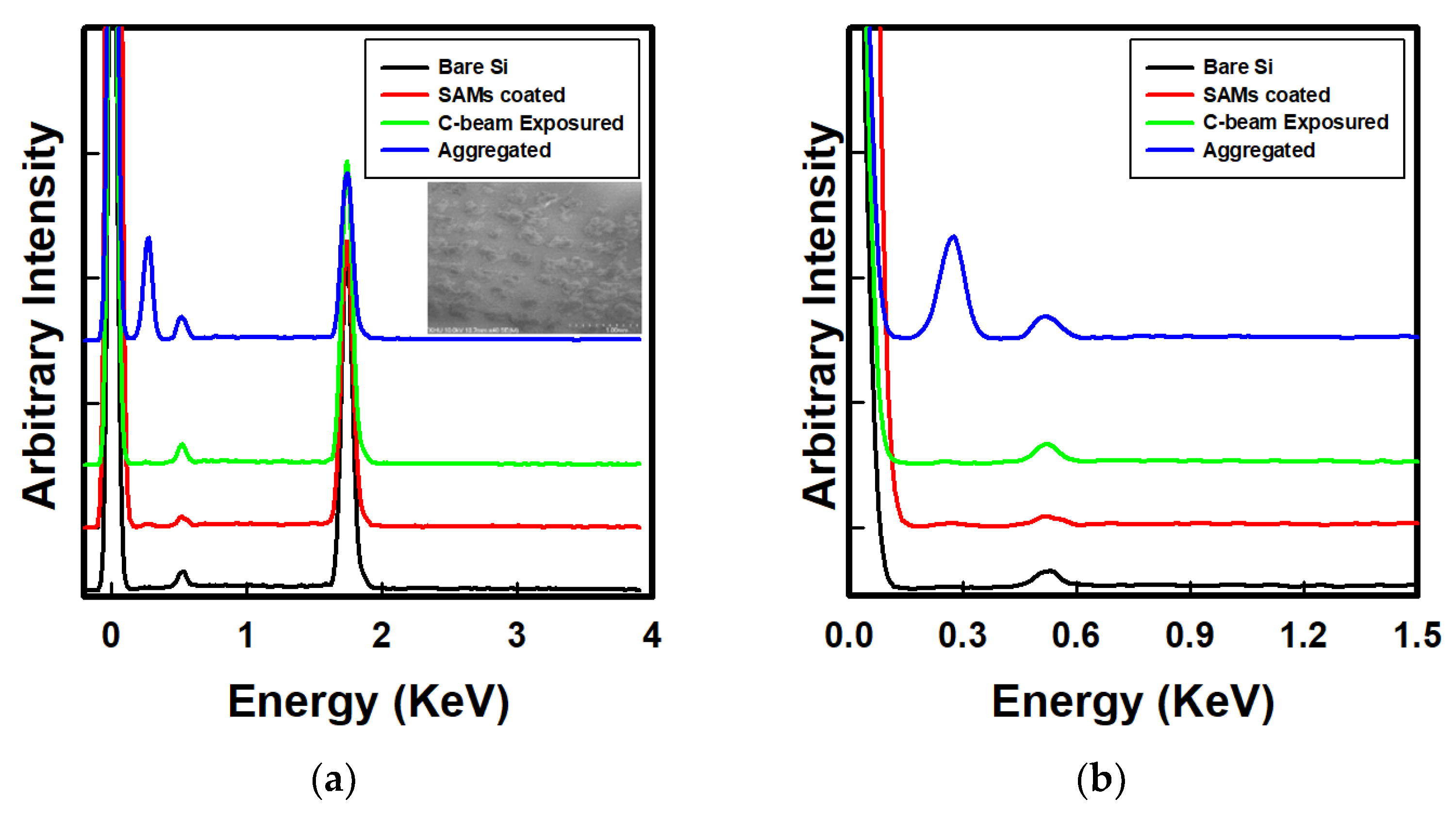

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Sharma, E.; Rathi, R.; Misharwal, J.; Sinhmar, B.; Kumari, S.; Dalal, J.; Kumar, A. Evolution in Lithography Techniques: Microlithography to Nanolithography. Nanomaterials 2022, 12, 2754. [Google Scholar] [CrossRef]

- Pease, R.F.; Chou, S.Y. Lithography and Other Patterning Techniques for Future Electronics. Proc. IEEE 2008, 96, 248–270. [Google Scholar] [CrossRef]

- Naulleau, P. Optical Lithography. In Nanofabrication Handbook; CRC Press: Boca Raton, FL, USA, 2012; pp. 127–139. [Google Scholar] [CrossRef]

- Mack, C.A. Trends in Optical Lithography. Opt. Photonics News 1996, 7, 29. [Google Scholar] [CrossRef]

- Bruning, J.H. Optical Lithography: 40 Years and Holding. Opt. Microlithogr. XX 2007, 6520, 652004. [Google Scholar] [CrossRef]

- Okazaki, S. Resolution Limits of Optical Lithography. J. Vac. Sci. Technol. B Microelectron. Nanom. Struct. 1991, 9, 2829. [Google Scholar] [CrossRef]

- Wu, B.; Kumar, A. Extreme Ultraviolet Lithography: A Review. J. Vac. Sci. Technol. B Microelectron. Nanom. Struct. 2007, 25, 1743. [Google Scholar] [CrossRef]

- Kinoshita, H. Extreme Ultraviolet Lithography. Nanofabr. Fundam. Appl. 2008, 35, 235–284. [Google Scholar] [CrossRef]

- Wu, B.; Kumar, A. Extreme Ultraviolet Lithography and Three Dimensional Integrated Circuit—A Review. Appl. Phys. Rev. 2014, 1, 011104. [Google Scholar] [CrossRef]

- Itani, T.; Kozawa, T. Resist Materials and Processes for Extreme Ultraviolet Lithography. Jpn. J. Appl. Phys. 2013, 52, 10002. [Google Scholar] [CrossRef]

- Chen, Y. Nanofabrication by Electron Beam Lithography and Its Applications: A Review. Microelectron. Eng. 2015, 135, 57–72. [Google Scholar] [CrossRef]

- Altissimo, M. E-Beam Lithography for Micro-/Nanofabrication. Biomicrofluidics 2010, 4, 026503. [Google Scholar] [CrossRef] [PubMed]

- Vieu, C.; Carcenac, F.; Pépin, A.; Chen, Y.; Mejias, M.; Lebib, A.; Manin-Ferlazzo, L.; Couraud, L.; Launois, H. Electron Beam Lithography: Resolution Limits and Applications. Appl. Surf. Sci. 2000, 164, 111–117. [Google Scholar] [CrossRef]

- Fujita, T.; Nishihara, H.; Koyama, J. Fabrication of Micro Lenses Using Electron-Beam Lithography. Opt. Lett. 1981, 6, 613. [Google Scholar] [CrossRef] [PubMed]

- Spiller, E.; Feder, R. X-ray Lithography. In X-ray Optics; Springer: Berlin/Heidelberg, Germany, 1977; pp. 35–92. [Google Scholar]

- Maldonado, J.R.; Peckerar, M. X-ray Lithography: Some History, Current Status and Future Prospects. Microelectron. Eng. 2016, 161, 87–93. [Google Scholar] [CrossRef]

- Park, J.M.; Kim, J.H.; Han, J.S.; Shin, D.S.; Park, S.C.; Son, S.H.; Park, S.J. Fabrication of Tapered Micropillars with High Aspect-Ratio Based on Deep X-Ray Lithography. Materials 2019, 12, 2056. [Google Scholar] [CrossRef]

- Zhang, T.; Yi, F.; Wang, B.; Liu, J.; Liang, X.; Yan, M.; Wang, Y.; Zhao, Z.; Zhang, S.N. Fabrication of Micro-Slot Optics on Curved Substrate by X-Ray Lithography and Electroplating. Microsyst. Technol. 2021, 27, 1895–1900. [Google Scholar] [CrossRef]

- Mack, C.A. Reducing Roughness in Extreme Ultraviolet Lithography. J. Micro/Nanolithogr. MEMS MOEMS 2018, 17, 041006. [Google Scholar] [CrossRef]

- Socol, Y.; Kulipanov, G.N.; Matveenko, A.N.; Shevchenko, O.A.; Vinokurov, N.A. Compact 13.5-Nm Free-Electron Laser for Extreme Ultraviolet Lithography. Phys. Rev. Spec. Top.-Accel. Beams 2011, 14, 3–9. [Google Scholar] [CrossRef]

- Silverman, P.J. Extreme Ultraviolet Lithography: Overview and Development Status. J. Microlithogr. Microfabr. Microsyst. 2005, 4, 011006. [Google Scholar] [CrossRef]

- Ashby, P.D.; Olynick, D.L.; Ogletree, D.F.; Naulleau, P.P. Resist Materials for Extreme Ultraviolet Lithography: Toward Low-Cost Single-Digit-Nanometer Patterning. Adv. Mater. 2015, 27, 5813–5819. [Google Scholar] [CrossRef]

- Yakshin, A.E.; Kozhevnikov, I.V.; Zoethout, E.; Louis, E.; Bijkerk, F. Properties of Broadband Depth-Graded Multilayer Mirrors for EUV Optical Systems. Opt. Express 2010, 18, 6957. [Google Scholar] [CrossRef] [PubMed]

- Lee, B.; Hong, J.; Amos, N.; Dumer, I.; Litvinov, D.; Khizroev, S. Sub-10-Nm-Resolution Electron-Beam Lithography toward Very-High-Density Multilevel 3D Nano-Magnetic Information Devices. J. Nanopart. Res. 2013, 15, 1665. [Google Scholar] [CrossRef]

- Fischer, P.; Sanz-Hernández, D.; Streubel, R.; Fernández-Pacheco, A. Launching a New Dimension with 3D Magnetic Nanostructures. APL Mater. 2020, 8, 010701. [Google Scholar] [CrossRef]

- Winkler, R.; Fowlkes, J.D.; Rack, P.D.; Plank, H. 3D Nanoprinting via Focused Electron Beams. J. Appl. Phys. 2019, 125, 210901. [Google Scholar] [CrossRef]

- Randall, J.N.; Owen, J.H.G.; Lake, J.; Fuchs, E. Next Generation of Extreme-Resolution Electron Beam Lithography. J. Vac. Sci. Technol. B 2019, 37, 061605. [Google Scholar] [CrossRef]

- Beam, I.; Ciba, A. Ion Beam Lithography and Nanofabrication: A Review. Int. J. Nanosci. 2005, 4, 269–286. [Google Scholar]

- Joshi-imre, A.; Bauerdick, S. Direct-Write Ion Beam Lithography. J. Nanotechnol. 2014, 2014, 170415. [Google Scholar] [CrossRef]

- Arshak, K.; Mihov, M.; Arshak, A.; McDonagh, D.; Sutton, D. Focused Ion Beam Lithography-Overview and New Approaches. In Proceedings of the 2004 24th International Conference on Microelectronics, Nis, Serbia, 16–19 May 2004; Volume 2, pp. 459–462. [Google Scholar] [CrossRef]

- Choi, Y.; Hong, S.; Lee, L.P. Shadow Overlap Ion-Beam Lithography for Nanoarchitectures. Nano Lett. 2009, 9, 3726–3731. [Google Scholar] [CrossRef]

- Terfort, A.; Zharnikov, M. Electron-Irradiation Promoted Exchange Reaction as a Tool for Surface Engineering and Chemical Lithography. Adv. Mater. Interfaces 2021, 8, 2100148. [Google Scholar] [CrossRef]

- Hong, J.H.; Kang, J.S.; Park, K.C. Fabrication of Glass Sealed X-Ray Tube with High Performance Carbon Nanotube Electron Beam (C-Beam). J. Nanosci. Nanotechnol. 2016, 16, 12059–12062. [Google Scholar] [CrossRef]

- Kanan, S.M.; Tze, W.T.Y.; Tripp, C.P. Method to Double the Surface Concentration and Control the Orientation of Adsorbed (3-Aminopropyl)Dimethylethoxysilane on Silica Powders and Glass Slides. Langmuir 2002, 18, 6623–6627. [Google Scholar] [CrossRef]

| VACNT Emitter Growth Condition | |||||||

|---|---|---|---|---|---|---|---|

| Group | Description | Temp. (°C) | Pressure (Torr) | Time (min.) | C2H2:NH3 (sccm) | Gate Voltage (V) | Cathode Voltage (V) |

| A | 88-island array | 850 | 1.8 | 90 | 16:140 | 300 | −600 |

| B | Single-island array | 850 | 2.2 | 90 | 16:140 | 300 | −600 |

| Element | Area | |||

|---|---|---|---|---|

| Si Substrate | OTS As Deposited | After C-Beam Exposure | Aggregated Area | |

| Carbon (C) | 0 | 13.24 | 7.11 | 58.32 |

| Oxygen (O) | 9.32 | 10.18 | 11.41 | 11.7 |

| Silicon (Si) | 90.68 | 76.58 | 81.48 | 29.91 |

| Exposure Time (s) | Contact Angle (°) | |

|---|---|---|

| Before | After | |

| 5 | 93.6 | 75.9 |

| 10 | 102.6 | 65.3 |

| 20 | 103.9 | 59.3 |

| 30 | 104.9 | 62.9 |

| 40 | 104.9 | 62.9 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yu, Y.Y.; Rodiansyah, A.; Sawant, J.; Park, K.C. Patterning of Silicon Substrate with Self-Assembled Monolayers Using Vertically Aligned Carbon Nanotube Electron Sources. Nanomaterials 2022, 12, 4420. https://doi.org/10.3390/nano12244420

Yu YY, Rodiansyah A, Sawant J, Park KC. Patterning of Silicon Substrate with Self-Assembled Monolayers Using Vertically Aligned Carbon Nanotube Electron Sources. Nanomaterials. 2022; 12(24):4420. https://doi.org/10.3390/nano12244420

Chicago/Turabian StyleYu, Yi Yin, Alfi Rodiansyah, Jaydip Sawant, and Kyu Chang Park. 2022. "Patterning of Silicon Substrate with Self-Assembled Monolayers Using Vertically Aligned Carbon Nanotube Electron Sources" Nanomaterials 12, no. 24: 4420. https://doi.org/10.3390/nano12244420

APA StyleYu, Y. Y., Rodiansyah, A., Sawant, J., & Park, K. C. (2022). Patterning of Silicon Substrate with Self-Assembled Monolayers Using Vertically Aligned Carbon Nanotube Electron Sources. Nanomaterials, 12(24), 4420. https://doi.org/10.3390/nano12244420