Effect of Different Solvents on Morphology and Gas-Sensitive Properties of Grinding-Assisted Liquid-Phase-Exfoliated MoS2 Nanosheets

Abstract

1. Introduction

2. Materials and Methods

2.1. Preparation of Materials

2.2. Characterizations

2.3. Device Fabrication and Testing

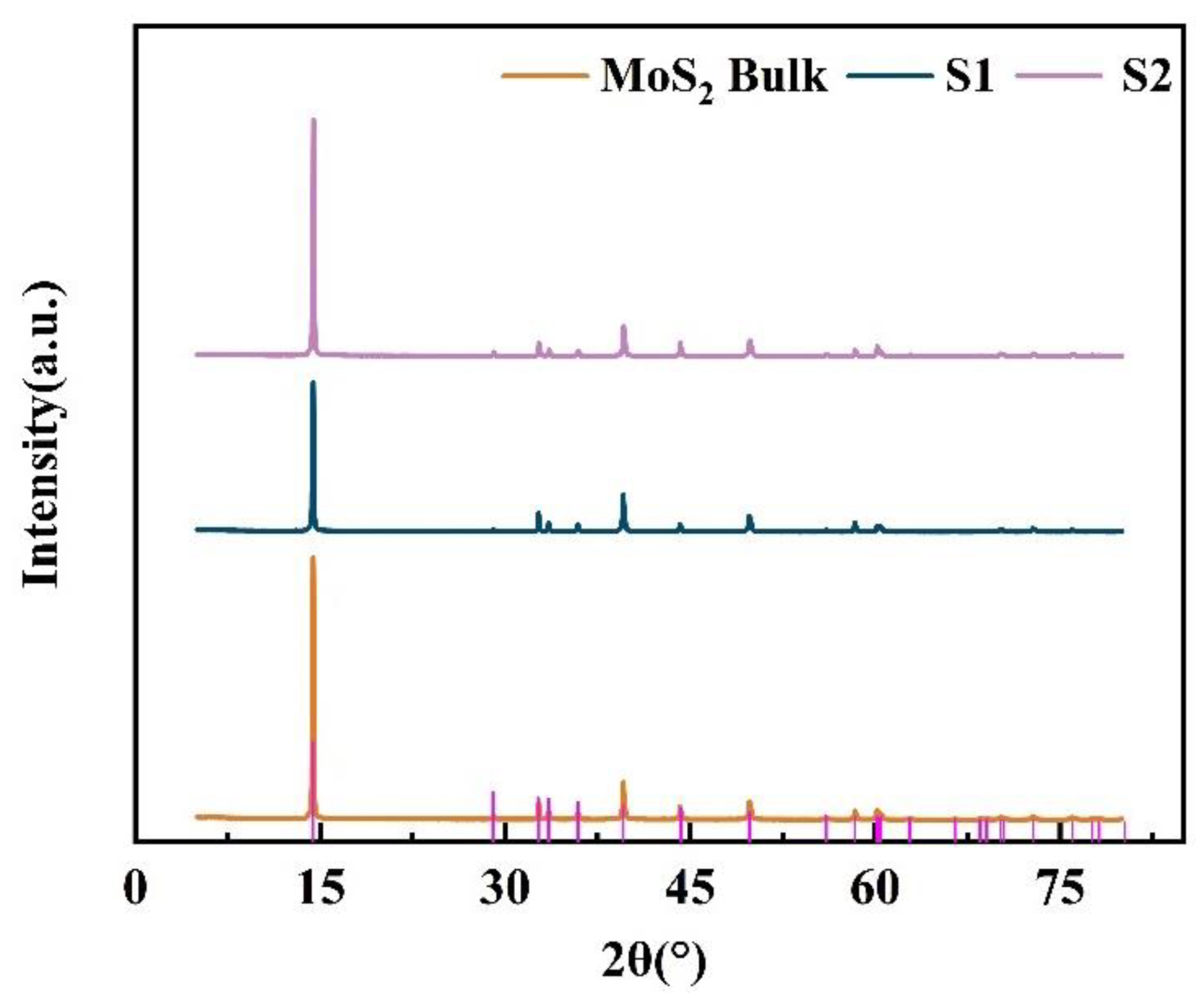

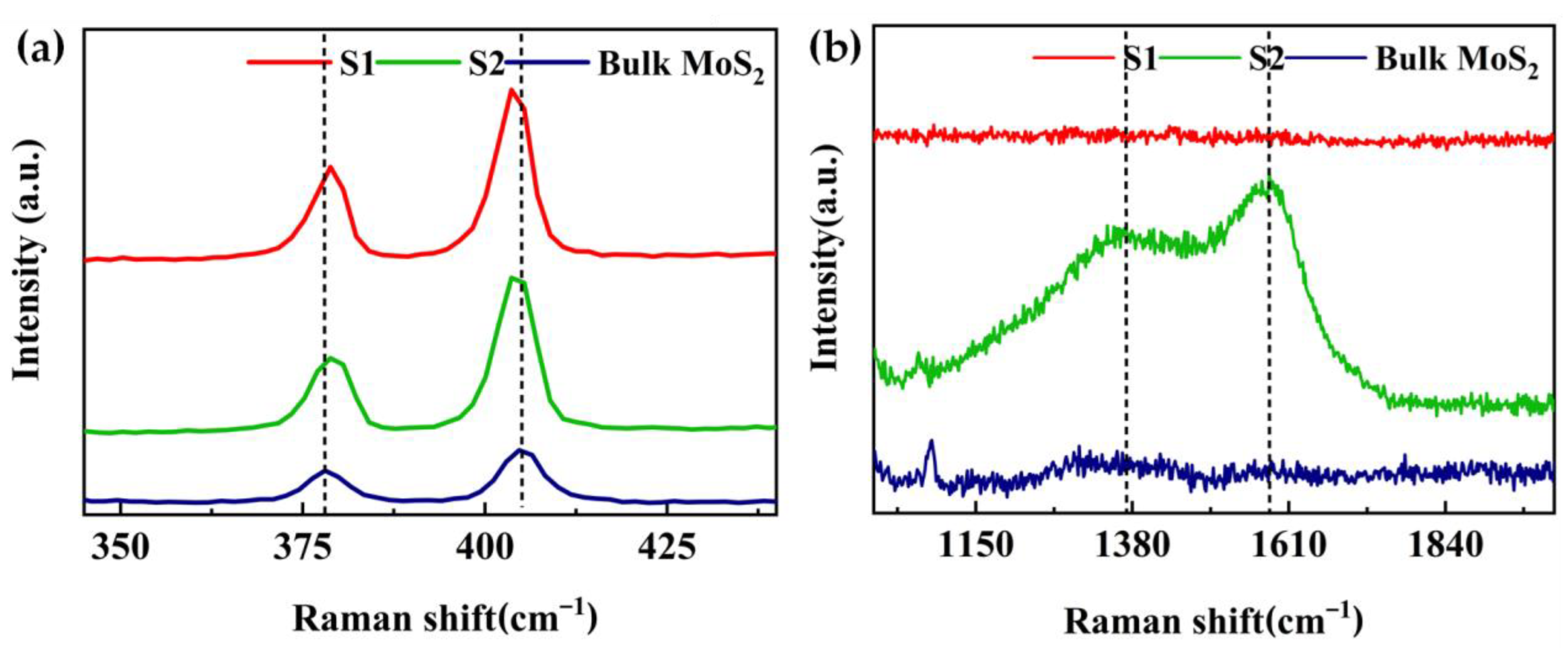

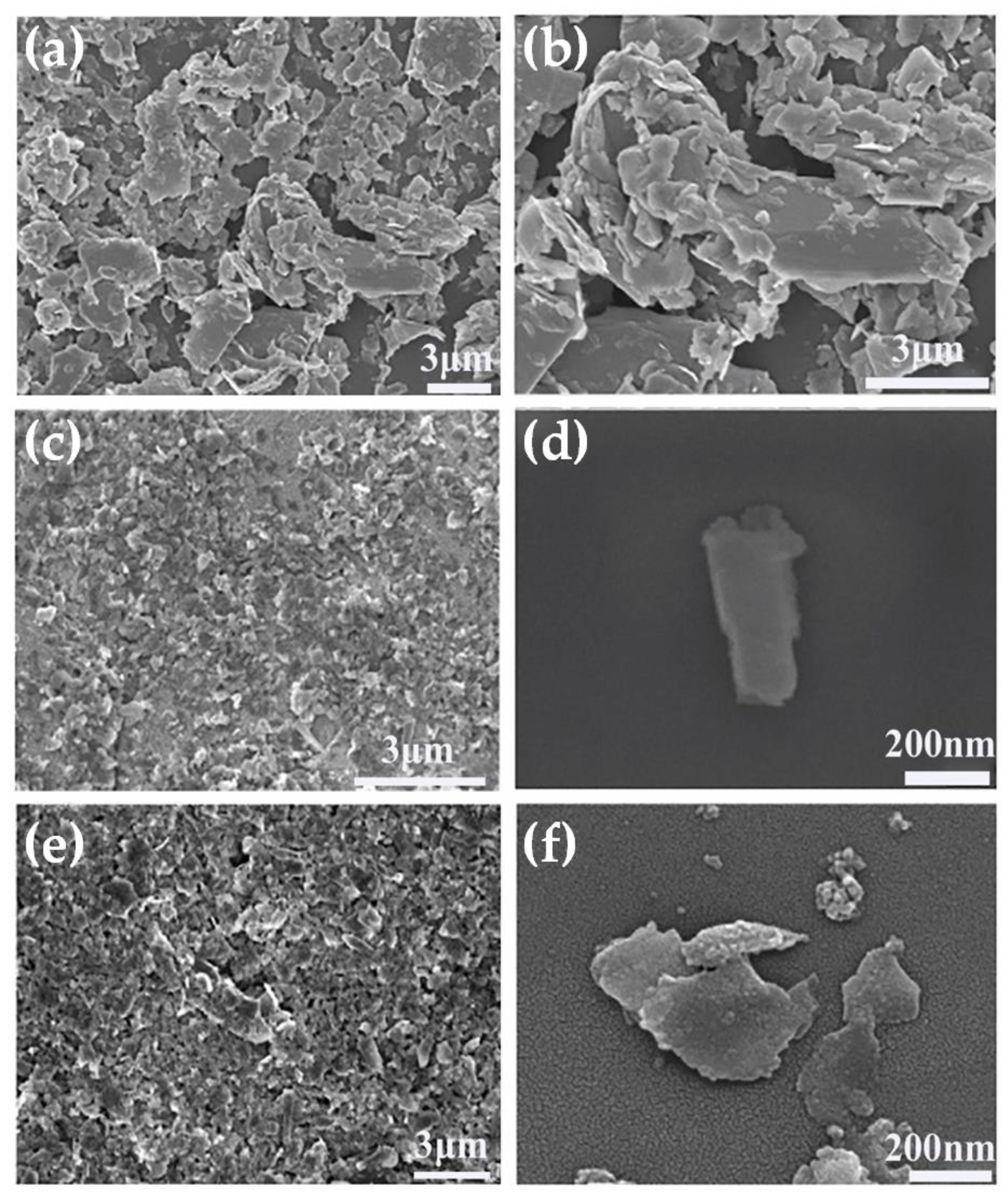

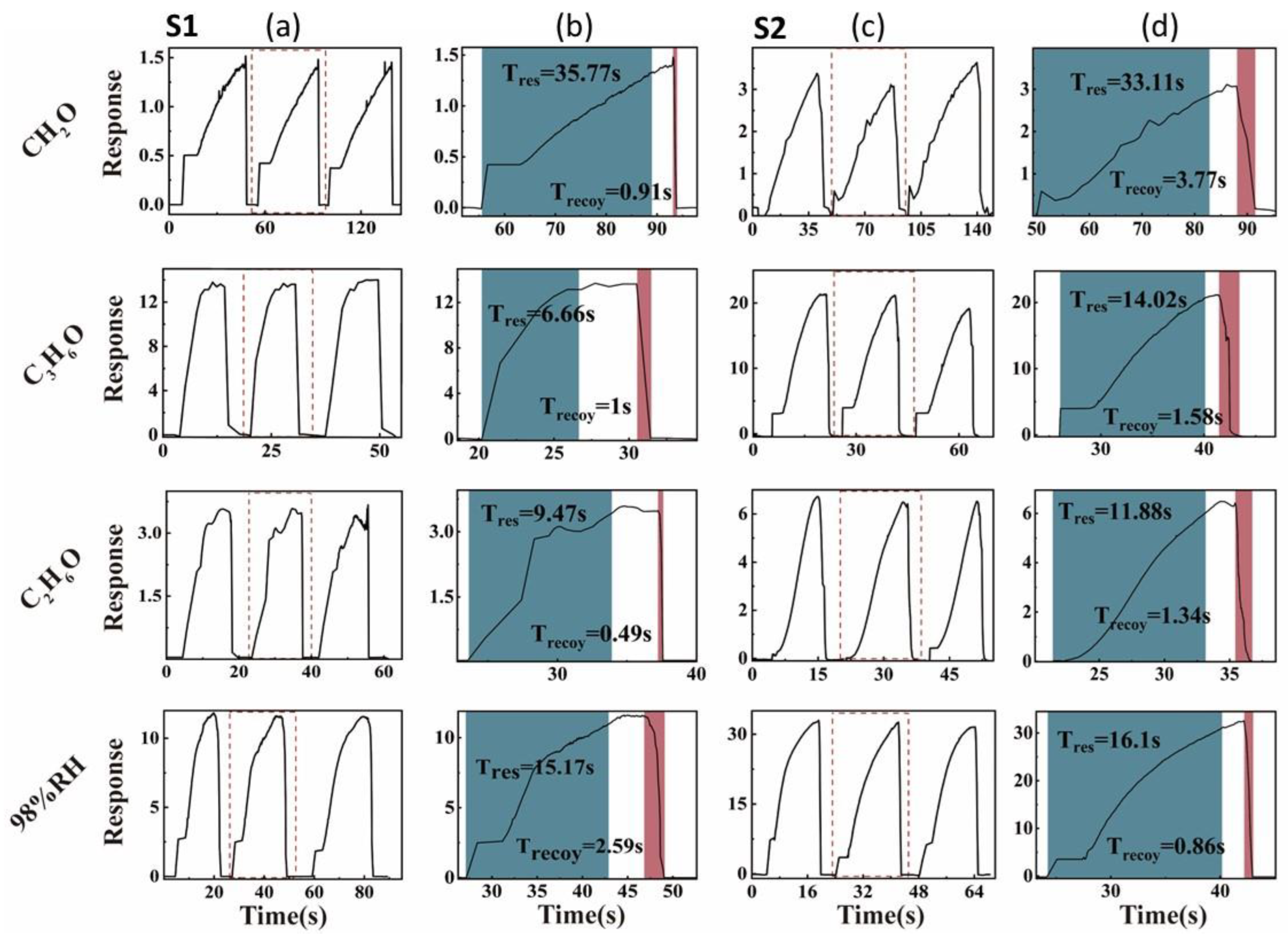

3. Results and Discussion

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Hur, J.H.; Park, J.; Kim, D.; Jeon, S. Model for the Operation of a Monolayer MoS2 Thin-Film Transistor with Charges Trapped near the Channel Interface. Phys. Rev. Appl. 2017, 7, 044030–044036. [Google Scholar] [CrossRef]

- Fabbri, F.; Rotunno, E.; Cinquanta, E.; Campi, D.; Bonnini, E.; Kaplan, D.; Lazzarini, L.; Bernasconi, M.; Ferrari, C.; Longo, M.; et al. Novel Near-infrared Emission from Crystal Defects in MoS2 Multilayer Flakes. Nat. Commun. 2016, 7, 13044–13051. [Google Scholar] [CrossRef] [PubMed]

- Mak, K.F.; Lee, C.; Hone, J.; Heinz, T.F. Atomically Thin MoS2: A New Direct-gap Semiconductor. Phys. Rev. Lett. 2010, 105, 136805. [Google Scholar] [CrossRef] [PubMed]

- Posudievsky, O.Y.; Khazieieva, O.A.; Cherepanov, V.V.; Dovbeshko, G.I.; Shkavro, A.G.; Koshechko, V.G.; Pokhodenko, V.D. Improved Dispersant-free Liquid Exfoliation down to the Graphene-like State of Solvent-free Mechanochemically DelamiNated Bulk MoS2. J. Mater. Chem. C 2013, 1, 6411–6415. [Google Scholar] [CrossRef]

- Chang, H.Y.; Yogeesh, M.N.; Ghosh, R.; Rai, A.; Sanne, A.; Yang, S.; Lu, N.; Banerjee, S.K.; Akinwande, D. Large-Area Monolayer MoS2 for Flexible Low-Power RF Nanoelectronics in the GHz Regime. Adv. Mater. 2016, 28, 1818–1823. [Google Scholar] [CrossRef]

- Wang, Q.H.; Kalantar-Zadeh, K.; Kis, A.; Coleman, J.N.; Strano, M.S. Electronics and Optoelectronics of Two-Dimensional Transition Metal Dichalcogenides. Nat. Nanotechnol. 2012, 7, 699–712. [Google Scholar] [CrossRef]

- Radisavljevic, B.; Radenovic, A.; Brivio, J.; Giacometti, V.; Kis, A. Single-Layer MoS2 Transistors. Nat. Nanotechnol. 2011, 6, 147–150. [Google Scholar] [CrossRef]

- Lee, G.H.; Yu, Y.J.; Cui, X.; Petrone, N.; Lee, C.H.; Choi, M.S.; Lee, D.Y.; Lee, C.; Yoo, W.J.; Watanabe, K.; et al. Flexible and Transparent MoS2 Field-Effect Transistors on Hexagonal Boron Nitride-Graphene Heterostructures. ACS Nano 2013, 7, 7931–7936. [Google Scholar] [CrossRef]

- Zhang, D.; Wu, J.; Li, P.; Cao, Y. Room-temperature SO2 Gas Sensing Properties Based on Metal-doped MoS2 Nanoflower:An Experimental and Density Functional Theory Investigation. J. Mater. Chem. A 2017, 5, 20666–20677. [Google Scholar] [CrossRef]

- Zhang, D.; Sun, Y.; Li, P.; Zhang, Y. Facile Fabrication of MoS2-modified SnO2 Hybrid Nanocomposite for Ultrasensitive Humidity Sensing. ACS App. Mater. Inter. 2016, 8, 14142–14149. [Google Scholar] [CrossRef]

- Zhang, D.; Wu, J.; Cao, Y. Ultrasensitive H2S Gas Sensing Properties of CuO Nanorods/MoS2 Nanosheets Nanoheterostructure with Synergistic Effect. Sens. Actuators B Chem. 2019, 287, 346–355. [Google Scholar] [CrossRef]

- Han, S.W.; Kwon, H.; Kim, S.K.; Ryu, S.; Yun, W.S.; Kim, D.H.; Hwang, J.H.; Kang, J.S.; Baik, J.; Shin, H.J.; et al. Band-Gap Transition Induced by Interlayer van Der Waals Interaction in MoS2. Phys. Rev. B 2011, 84, 045409. [Google Scholar] [CrossRef]

- Cheng, R.; Jiang, S.; Chen, Y.; Liu, Y.; Weiss, N.; Cheng, H.C.; Wu, H.; Huang, Y.; Duan, X. Few-Layer Molybdenum Disulfide Transistors and Circuits for High-Speed Flexible Electronics. Nat. Commun. 2014, 5, 5143. [Google Scholar] [CrossRef] [PubMed]

- Splendiani, A.; Sun, L.; Zhang, Y.; Li, T.; Kim, J.; Chim, C.-Y.; Galli, G.; Wang, F. Emerging Photoluminescence in Monolayer MoS2. Nano Lett. 2010, 10, 1271–1275. [Google Scholar] [CrossRef] [PubMed]

- Varghese, S.S.; Varghese, S.H.; Swaminathan, S.; Singh, K.K.; Mittal, V. Two Dimensional Materials for Sensing: Graphene and Beyond. Electronics 2015, 4, 651–687. [Google Scholar] [CrossRef]

- Kumar, M.; Agrawal, A.V.; Moradi, M.; Yousef, R. Chapter 6—Nanosensors for Gas Sensing Applications. In Nanomaterials for Air Remediation; Abdeltif, A., Assadi, A.A., Nguyen-Tri, P., Eds.; Elsevier: Amsterdam, The Netherlands, 2020; pp. 107–130. [Google Scholar]

- Wypych, F.; Schöllhorn, R. 1T-MoS2, A New Metallic Modifcation of Molybdenum Disulfde. J. Chem. Soc. Chem. Commun. 1992, 19, 1386–1388. [Google Scholar] [CrossRef]

- Eda, G.; Yamaguchi, H.; Voiry, D.; Fujita, T.; Chen, M.; Chhowalla, M. Photoluminescence from Chemically Exfoliated MoS2. Nano Lett. 2011, 11, 5111–5116. [Google Scholar] [CrossRef]

- Agrawal, A.V.; Kumar, N.; Kumar, M. Strategy and Future Prospects to Develop Room-Temperature-Recoverable NO2 Gas Sensor Based on Two-Dimensional Molybdenum Disulfide. Nano-Micro Lett. 2021, 13, 38. [Google Scholar] [CrossRef]

- Zhao, W.; Ribeiro, R.M.; Eda, G. Electronic Structure and Optical Signatures of Semiconducting Transition Metal Dichalcogenide Nanosheets. Acc. Chem. Res. 2015, 48, 91–99. [Google Scholar] [CrossRef]

- Barzegar, M.; Iraji-zad, A.; Tiwari, A. On the Performance of Vertical MoS2 Nanoflakes as a Gas Sensor. Vacuum 2019, 167, 90–97. [Google Scholar] [CrossRef]

- Ansari, S.A.; Fouad, H.; Ansari, S.G.; Pallashuddin Sk, M.; Cho, M.H. Mechanically Exfoliated MoS2 Sheet Coupled with Conductive Polyaniline as a Superior Supercapacitor Electrode Material. J. Colloid Interface Sci. 2017, 504, 276–282. [Google Scholar] [CrossRef] [PubMed]

- Joensen, P.; Frindt, R.F.; Morrison, S.R. Single-layer MoS2. Mater. Res. Bull. 1986, 21, 457–461. [Google Scholar] [CrossRef]

- Halim, U.; Chu, R.Z.; Yu, C. A Rational Design of Cosolvent Exfoliation of Layered Materials by Directly Probing Liquid-solid Interaction. Nat. Commun. 2013, 4, 2213. [Google Scholar] [CrossRef] [PubMed]

- Yao, Y.; Tolentino, L.; Yang, Z. High-Concentration Aqueous Dispersions of MoS2. Adv. Funct. Mater. 2013, 23, 3577–3583. [Google Scholar] [CrossRef]

- Kim, H.-S.; Kumar, M.D.; Kim, J.D. Lim Vertical Growth of MoS2 Layers by Sputtering Method for Efficient Photoelectric Application. Sens. Actuators A Phys. 2018, 269, 355–362. [Google Scholar] [CrossRef]

- Goni, F.; Chemelli, A.; Uhlig, F. High-Yield Production of Selected 2D Materials by Understanding Their Sonication-Assisted Liquid-Phase Exfoliation. Nanomaterials 2021, 11, 3253. [Google Scholar] [CrossRef]

- Lee, C.-S.; Shim, S.J.; Kim, T.H. Scalable Preparation of Low-Defect Graphene by Urea-Assisted Liquid-Phase Shear Exfoliation of Graphite and Its Application in Doxorubicin Analysis. Nanomaterials 2020, 10, 267. [Google Scholar] [CrossRef]

- Coleman, J.N.; Lotya, M.; O’Neill, A.; Bergin, S.D.; King, P.J.; Khan, U.; Young, K.; Gaucher, A.; De, S.; Smith, R.J.; et al. Two-Dimensional Nanosheets Produced by Liquid Exfoliation of Layered Materials. Science 2011, 331, 568–571. [Google Scholar] [CrossRef]

- Zhou, K.G.; Mao, N.N. A Mixed-Solvent Strategy for Efficient Exfoliation of Inorganic Graphene Analogues. Angew. Chem. Int. Ed. 2011, 50, 10839–10842. [Google Scholar] [CrossRef]

- Hernandez, Y.; Nicolosi, V.; Lotya, M.; Blighe, F.M.; Sun, Z.; De, S.; McGovern, I.T.; Holland, B.; Byrne, M.; Gun’ko, Y.K.; et al. High-Yield Production of Graphene by Liquid-Phase Exfoliation of Graphite. Nat. Nanotechnol. 2008, 3, 563–568. [Google Scholar] [CrossRef]

- Tang, Q.; Zhou, Z. Graphene-Analogous Low-Dimensional Materials. Prog. Mater. Sci. 2013, 58, 1244–1315. [Google Scholar] [CrossRef]

- Li, Y.; Yin, X.; Wu, W. Preparation of Few-Layer MoS2 Nanosheets via an Efficient Shearing Exfoliation Method. Ind. Eng. Chem. Res. 2018, 57, 2838–2846. [Google Scholar] [CrossRef]

- Emily, P.N.; Benjamin, J.C.; Torben, D.; Jian, Z.O.; Kay, L.; Serge, Z.; Kourosh, K. Investigation of Two-solvent Grinding-assisted Liquid Phase Exfoliation of Layered MoS2. Chem. Mater. 2015, 27, 53–59. [Google Scholar] [CrossRef]

- Xia, Y.; Wu, Z.; Qin, Z.; Chen, F.; Lv, C.; Zhang, M.; Shaymurat, T.; Duan, H. Wool-Based Carbon Fiber/MoS2 Composite Prepared by Low-Temperature Catalytic Hydrothermal Method and Its Application in the Field of Gas Sensors. Nanomaterials 2022, 12, 1105. [Google Scholar] [CrossRef] [PubMed]

- Lin, Y.; Liu, K.; Chen, Y.; Liu, L. Influence of Graphene Functionalized with Zine Dimethacrylate on the Mechanical and Thermal Properties of Natural Rubber Nanocomposites. Polym. Compos. 2014, 36, 1775–1785. [Google Scholar] [CrossRef]

- Shao, L.; Wu, Z.; Duan, H.; Talgar, S. Discriminative and rapid detection of ozone realized by sensor array of Zn2+ doping tailored MoS2 ultrathin nanosheets. Sens. Actuators B-Chem. 2018, 258, 937–946. [Google Scholar] [CrossRef]

- Cho, S.Y.; Kim, S.J.; Lee, Y.; Kim, J.S.; Jung, W.B.; Yoo, H.W.; Kim, J.; Jung, H.-T. Highly Enhanced Gas Adsorption Properties in Vertically Aligned MoS2 Layers. ACS Nano 2015, 9, 9314–9321. [Google Scholar] [CrossRef]

- Xie, J.; Zhang, J.; Li, S.; Grote, F.; Zhang, X.; Zhang, H.; Wang, R.; Lei, Y.; Pan, B.; Xie, Y. Controllable Disorder Engineering in Oxygen-Incorporated MoS2 Ultrathin Nanosheets for Efficient Hydrogen Evolution. J. Am. Chem. Soc. 2013, 135, 17881–17888. [Google Scholar] [CrossRef]

- Lin, H.; Wang, J.; Luo, Q.; Peng, H.; Luo, C.; Qi, R.; Huang, R.; Travas-Sejdic, J.; Duan, C. Rapid and Highly Efficient Chemical Exfoliation of Layered MoS2 and WS2. J. Alloys Compd. 2017, 699, 222–229. [Google Scholar] [CrossRef]

- Lee, C.; Yan, H.; Lee, C.; Yan, H.; Brus, L.E.; Heinz, T.F.; Hone, J.; Ryu, S. Anomalous Lattice Vibrations of Single-and Few-layer MoS2. ACS Nano 2010, 4, 2695–2700. [Google Scholar] [CrossRef]

- Hussain, S.; Liu, T.; Javed, M.S.; Aslam, N.; Zeng, W. Highly Reactive 0D ZnS Nanospheres and Nanoparticles for Formaldehyde Gas-sensing Properties. Sens. Actuators B Chem. 2017, 239, 1243–1250. [Google Scholar] [CrossRef]

- Cao, J.; Zhang, N.; Yang, S.; Xu, W.; Zhang, X.; Zhang, H.; Wang, S. Study on the Selectivity Difference of Formaldehyde and Ethanol Induced by Variation of Energy Gap in In2O3 Hierarchical Materials. Colloids Surf. A. 2022, 648, 129306. [Google Scholar] [CrossRef]

- Zhang, D.; Jiang, C.; Wu, J. Layer-by-layer Assembled In2O3 Nanocubes/flower-like MoS2 Nanofilm for Room Temperature Formaldehyde Sensing. Sens. Actuators B Chem. 2018, 273, 176–184. [Google Scholar] [CrossRef]

- Zhang, D.; Cao, Y.; Yang, Z.; Wu, J. Nanoheterostructure Construction and DFT Study of Ni-doped In2O3 Nanocubes/WS2 Hexagon Nanosheets for Formaldehyde Sensing at Room Temperature. ACS Appl. Mater. Interfaces 2020, 12, 11979–11989. [Google Scholar] [CrossRef]

- Zhang, S.; Zhao, L.; Huang, B.; Li, X. Enhanced Sensing Performance of Au-decorated TiO2 Nanospheres with Hollow Structure for Formaldehyde Detectionn at Room Temperature. Sens. Actuators B 2022, 358, 131465. [Google Scholar] [CrossRef]

- Li, X.; Wang, J.; Xie, D.; Xu, J.; Xia, Y.; Li, W.; Xiang, L.; Li, Z.; Xu, S.; Komarneni, S. Flexible Room-temperature Formaldehyde Sensors Based on rGO Film and rGo/MoS2 Hybrid film. Nanotechnology 2017, 28, 325501. [Google Scholar] [CrossRef] [PubMed]

- Shanmugasundaram, A.; Manorama, S.V.; Kim, D.S.; Jeong, Y.J.; Lee, D.W. Toward Point-of-care Chronic Disease Management: Biomarker Detection in Exhaled Breath Using an E-Nose Sensor Based on rGO/SnO2 Superstructures. Chem. Eng. J. 2022, 448, 137736. [Google Scholar] [CrossRef]

- Wang, D.; Zhang, D.; Chen, X.; Zhang, H.; Tang, M.; Wang, J. Multifunctional Respiration-driven Triboelectric Nanogenerator for Self-powered Detection of Formaldehyde in Exhaled Gas and Respiratory Behavior. Nano Energy 2022, 102, 107711. [Google Scholar] [CrossRef]

- Zhang, D.; Mi, Q.; Wang, D.; Li, T. MXene/Co3O4 Composite Based Formaldehyde Sensor Driven by ZnO/MXene Nanowire Arrays Piezoelectric Nanogenerator. Sens. Actuators B 2021, 339, 129923. [Google Scholar] [CrossRef]

- Xiao, C.; Liu, C.; Li, L.; Yu, L.; Wang, Z.; Bo, X. Tungsten Trioxide Nanotubes with High Sensitive and Selective Properties to Acetone. Sens. Actuators B Chem. 2014, 194, 33–37. [Google Scholar] [CrossRef]

- Cho, B.; Hahm, M.G.; Choi, M.; Yoon, J.; Kim, A.; Lee, Y.J.; Park, S.; Kwon, J.; Kim, C.; Song, M.; et al. Charge-transfer-based Gas Sensing Using Atomic-layer MoS2. Sci. Rep. 2015, 5, 8052–8058. [Google Scholar] [CrossRef] [PubMed]

- Liu, X.; Ma, T.; Pinna, N.; Zhang, J. Two-Dimensional Nanostructured Materials for Gas Sensing. Adv. Funct. Mater. 2017, 37, 1702168. [Google Scholar] [CrossRef]

- Zhou, Q.; Wu, H.; Wang, C.; Zhang, S.; Zhang, L.; Zhang, H.; Chen, J.; Pan, G. Ultrasonic-triggered Surface Morphological Reconstruction of MoS2 for Enhanced Ultrasensitive Humidity Sensing. ChemNanoMat 2020, 7, 122–127. [Google Scholar] [CrossRef]

- Tan, Y.; Yu, K.; Yang, T.; Zhang, Q.; Cong, W.; Yin, H.; Zhang, Z.; Chen, Y.; Zhu, Z. The Combinations of Hollow MoS2 Micro@nano-spheres: One-step Synthesis, Excellent Photocatalytic and Humidity Sensing Properties. J. Mater. Chem. C 2014, 2, 27, 5422–5430. [Google Scholar] [CrossRef]

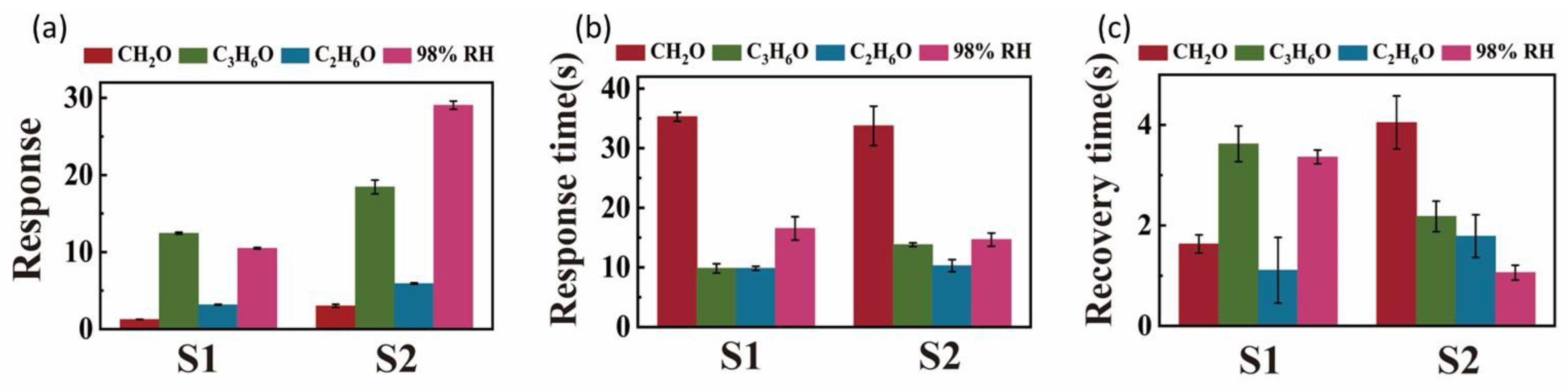

| Materials | Structure | Sensor Types | Con. (ppm) | Response (%) | LoD (ppb) | Temperature (°C) | Response Time (s) | Recovery Time (s) | Ref. |

|---|---|---|---|---|---|---|---|---|---|

| ZnS | 0D nanosphere | Resistance | 50 | 9440 | - | 295 | 11 | 8 | [42] |

| In2O3/MoS2 | Nanocubes/nonfilm | Resistance | 50 | 75 | 200 | RT | 14 | 22 | [43] |

| In2O3 | Nanospheres | Resistance | 1 | 3.5 | 1000 | 180 | 180 | 1000 | [44] |

| In2O3/WS2 | Nanocomposites | Resistance | 5 | 7.5 | - | RT | 98 | 137 | [45] |

| Au/TiO2 | Hybrid films | Resistance | 5 | 8.5 | 100 | RT | 36 | 110 | [46] |

| rGo/MoS2 | Hybrid films | Resistance | 10 | 2.8 | - | RT | - | - | [47] |

| Ni-doped In2O3/WS2 | Nanocomposites | Resistance | 20 | 32 | 150 | RT | 76 | 123 | [45] |

| rGO/SnO2 | Nanocomposites | Resistance | 0.5 | 3200 | 10 | 125 | 31 | 62 | [48] |

| MXene/NH2-MWCNTs | Hybrid films | Self-powered voltage | 5 | 35 | 10 | RT | 51 | 57 | [49] |

| MXene/ Co3O4 | Hybrid films | Self-powered voltage | 10 | 9.2 | 10 | RT | 83 | 5 | [50] |

| MoS2 | Nanosheets | Resistance | 50 | 66.4 | - | RT | 18 | 0.5 | This work |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, H.; Xu, X.; Shaymurat, T. Effect of Different Solvents on Morphology and Gas-Sensitive Properties of Grinding-Assisted Liquid-Phase-Exfoliated MoS2 Nanosheets. Nanomaterials 2022, 12, 4485. https://doi.org/10.3390/nano12244485

Wang H, Xu X, Shaymurat T. Effect of Different Solvents on Morphology and Gas-Sensitive Properties of Grinding-Assisted Liquid-Phase-Exfoliated MoS2 Nanosheets. Nanomaterials. 2022; 12(24):4485. https://doi.org/10.3390/nano12244485

Chicago/Turabian StyleWang, Hao, Xiaojie Xu, and Talgar Shaymurat. 2022. "Effect of Different Solvents on Morphology and Gas-Sensitive Properties of Grinding-Assisted Liquid-Phase-Exfoliated MoS2 Nanosheets" Nanomaterials 12, no. 24: 4485. https://doi.org/10.3390/nano12244485

APA StyleWang, H., Xu, X., & Shaymurat, T. (2022). Effect of Different Solvents on Morphology and Gas-Sensitive Properties of Grinding-Assisted Liquid-Phase-Exfoliated MoS2 Nanosheets. Nanomaterials, 12(24), 4485. https://doi.org/10.3390/nano12244485