The Effects of Stresses and Interfaces on Texture Transformation in Silver Thin Films

Abstract

:1. Introduction

2. Fabrication and Experiment Methods

2.1. Design and Fabrication of the Test Specimens for the Experiment

2.2. Experimental Method

3. Results and Discussion

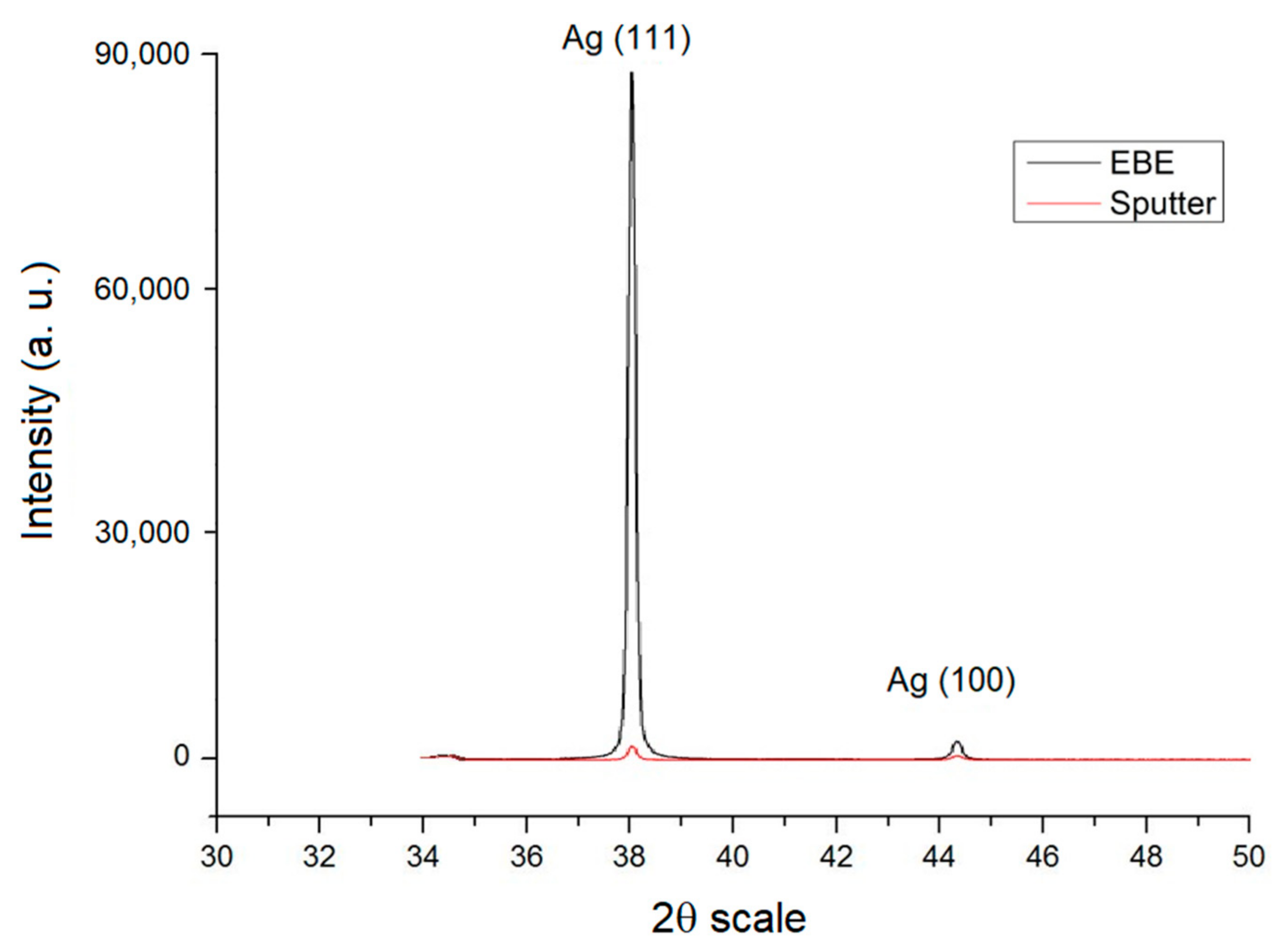

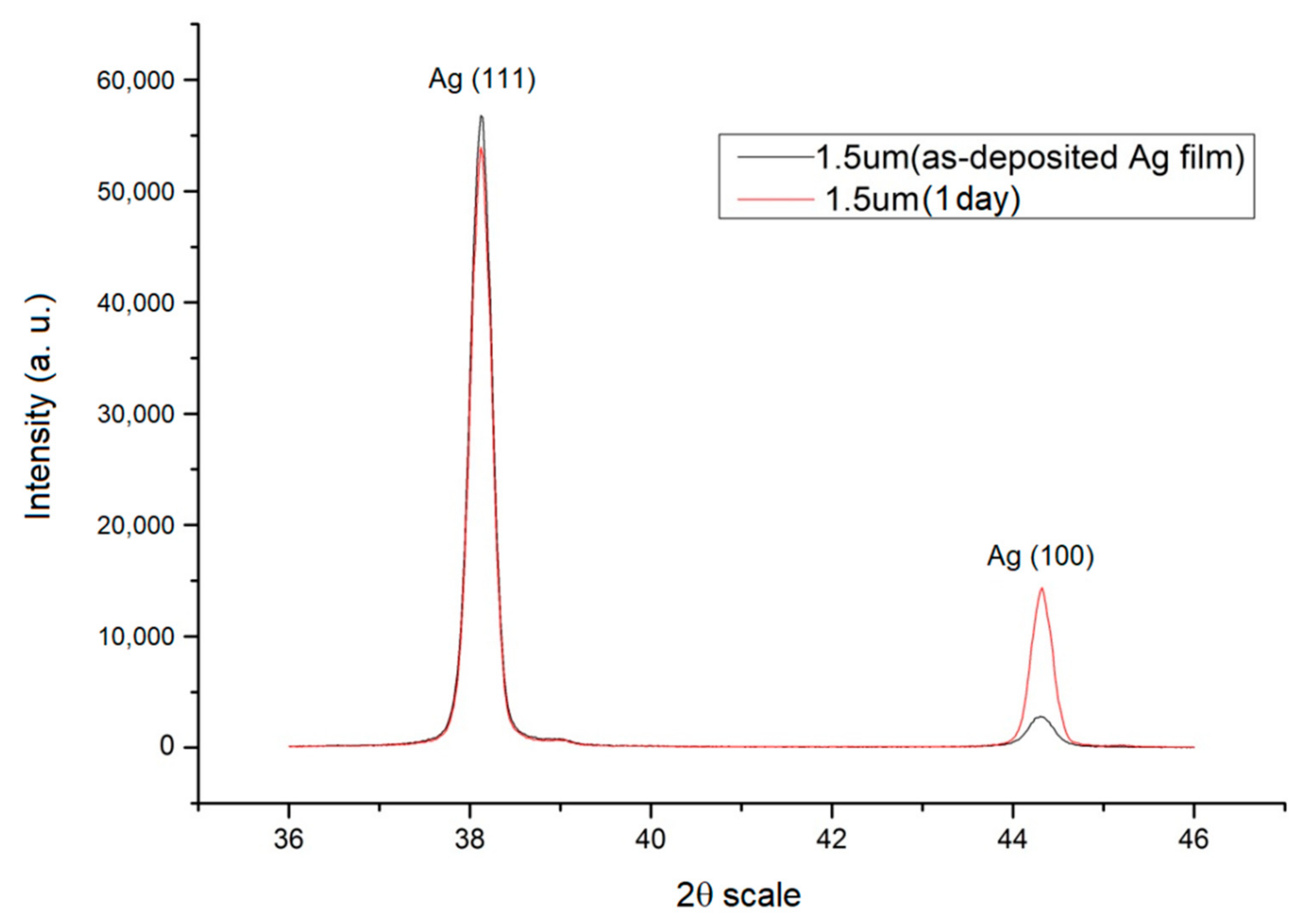

3.1. Texture Changes after Deposition at Room Temperature

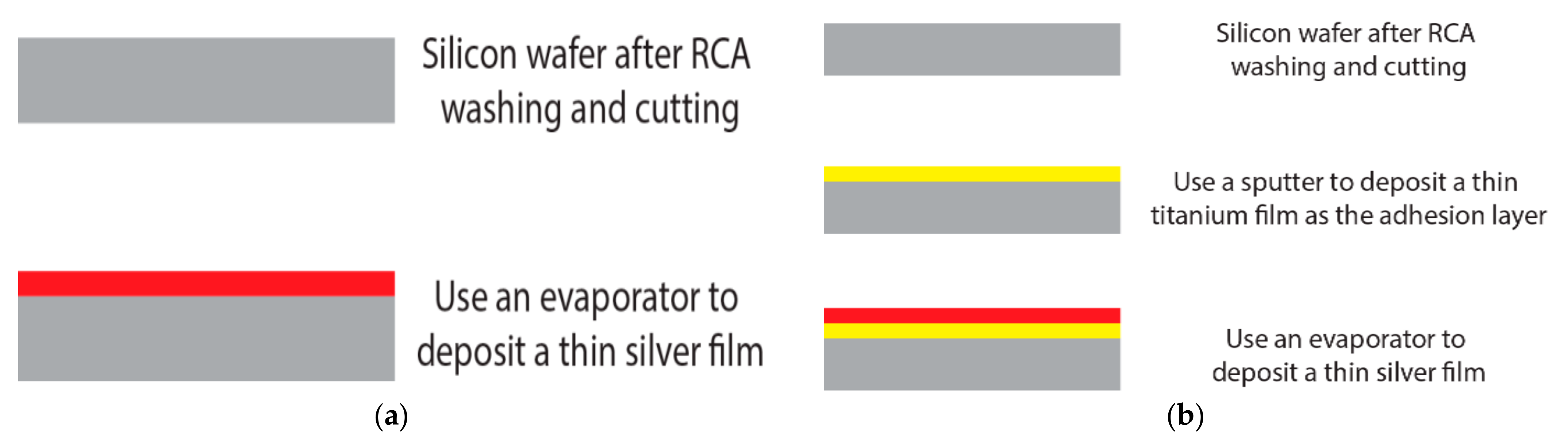

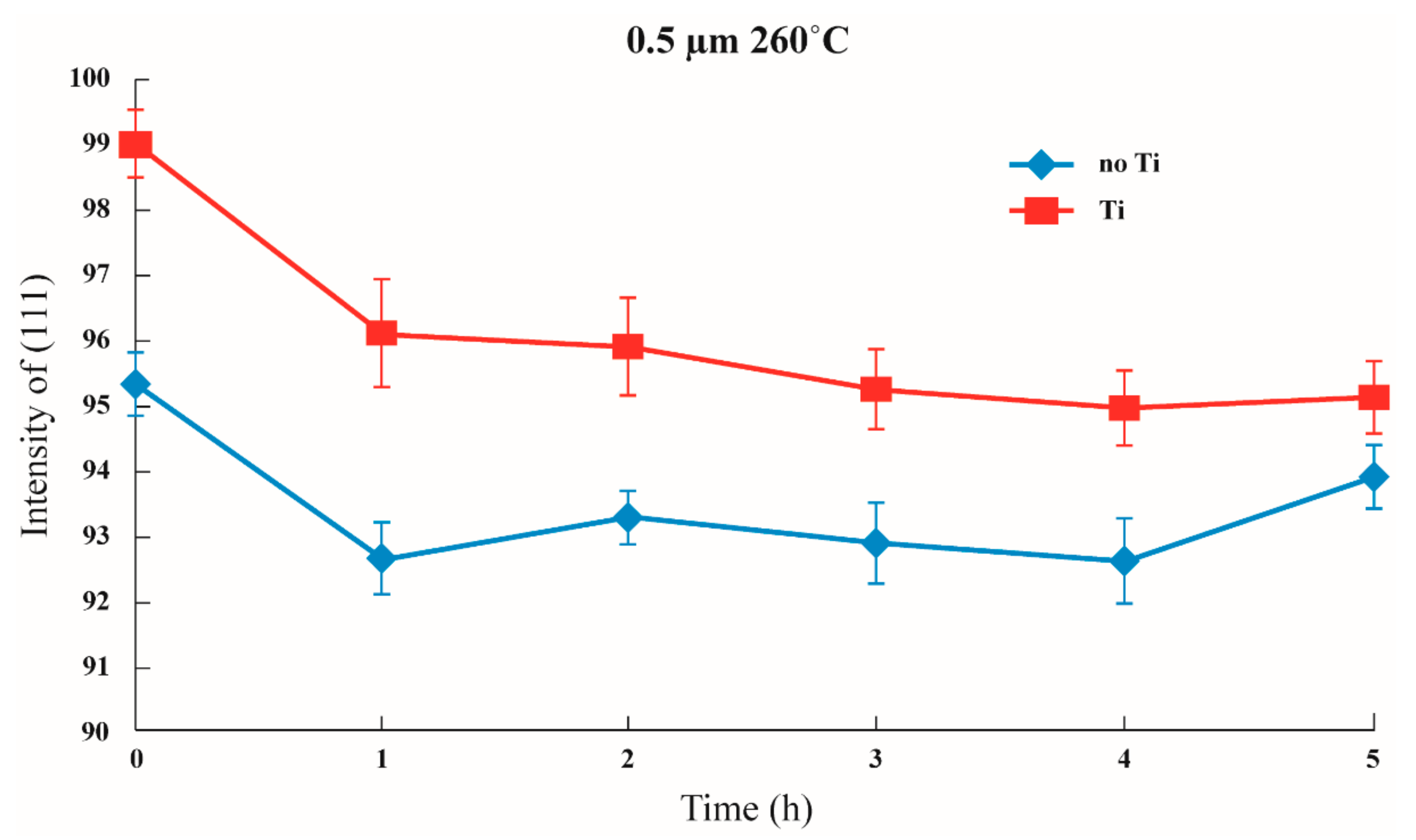

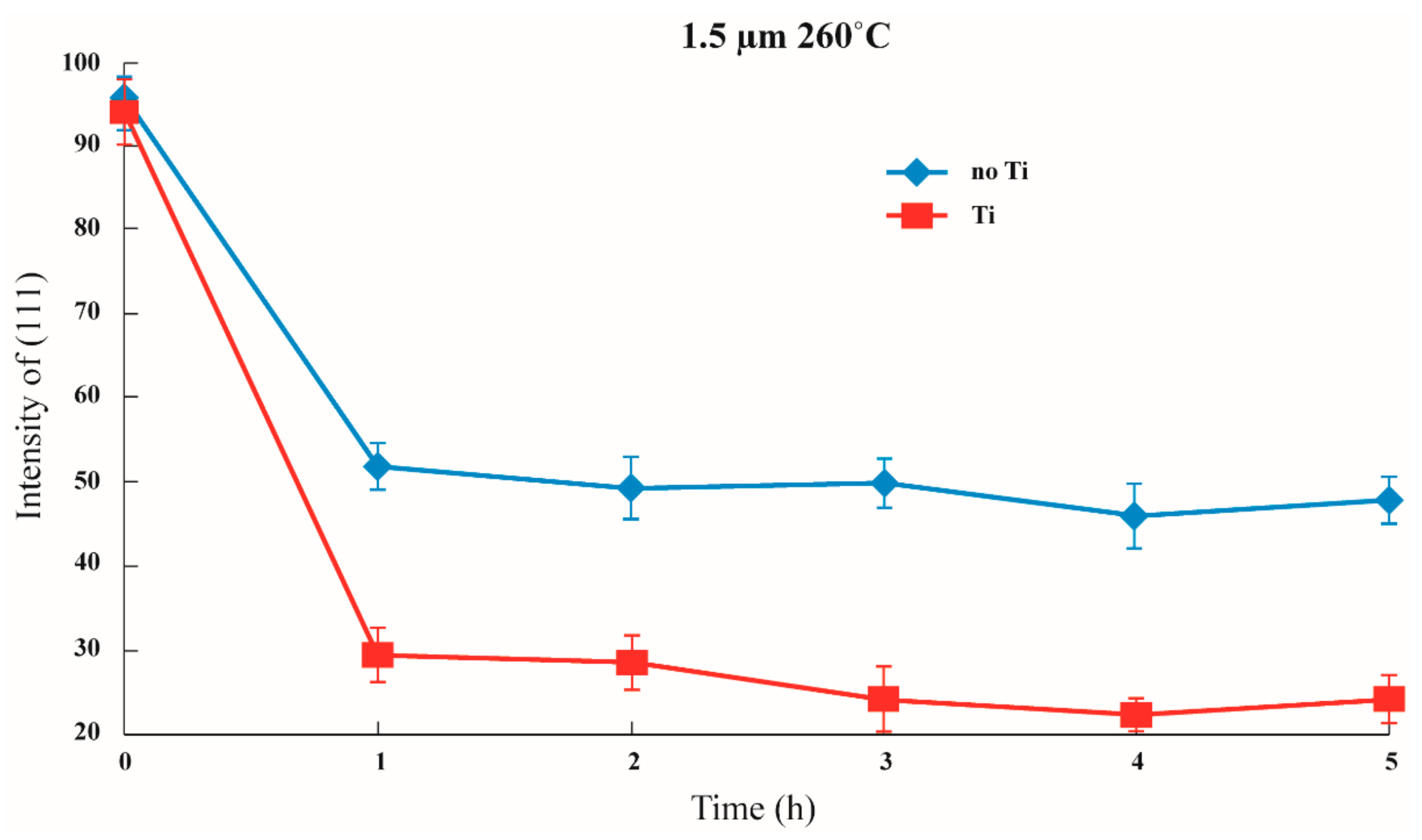

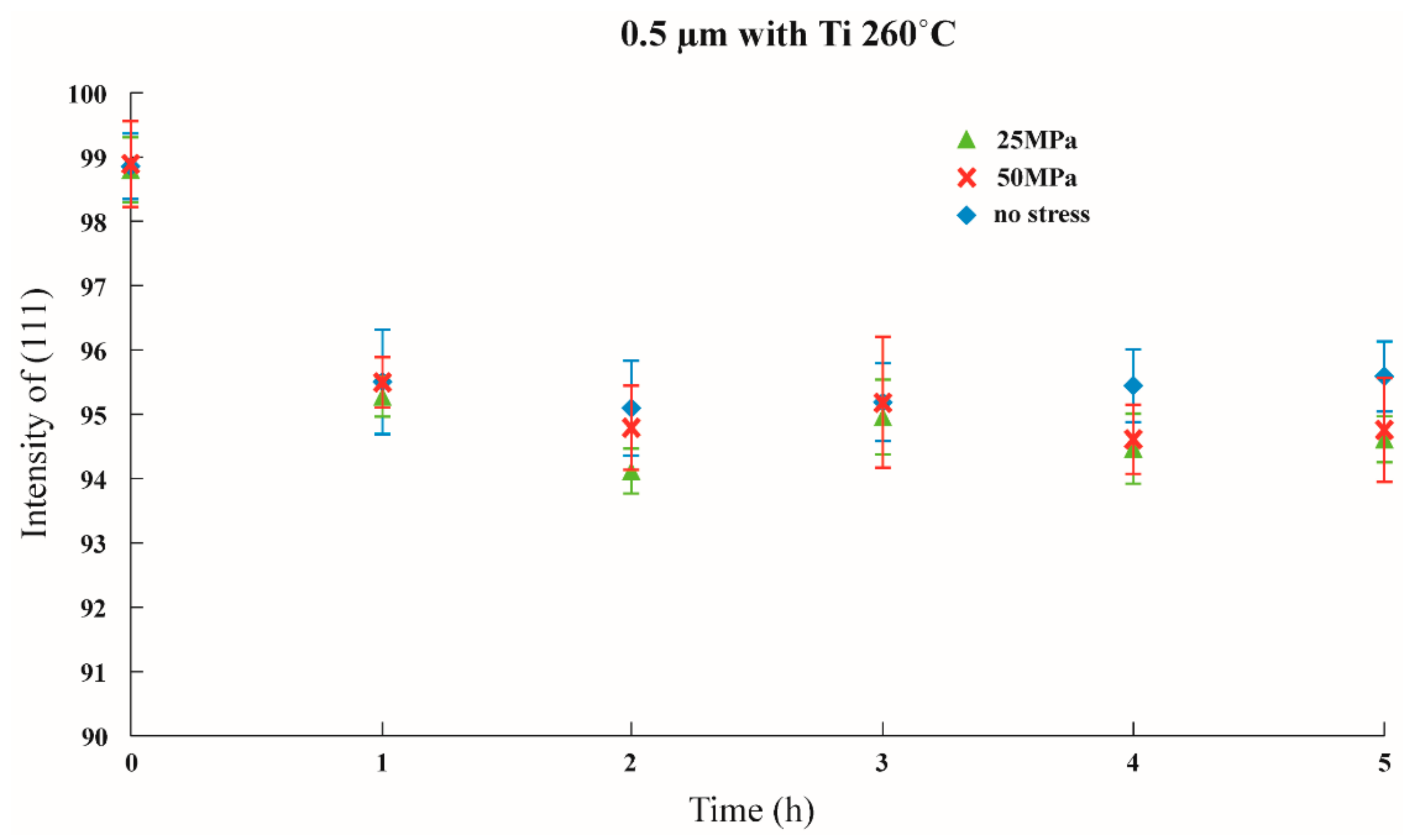

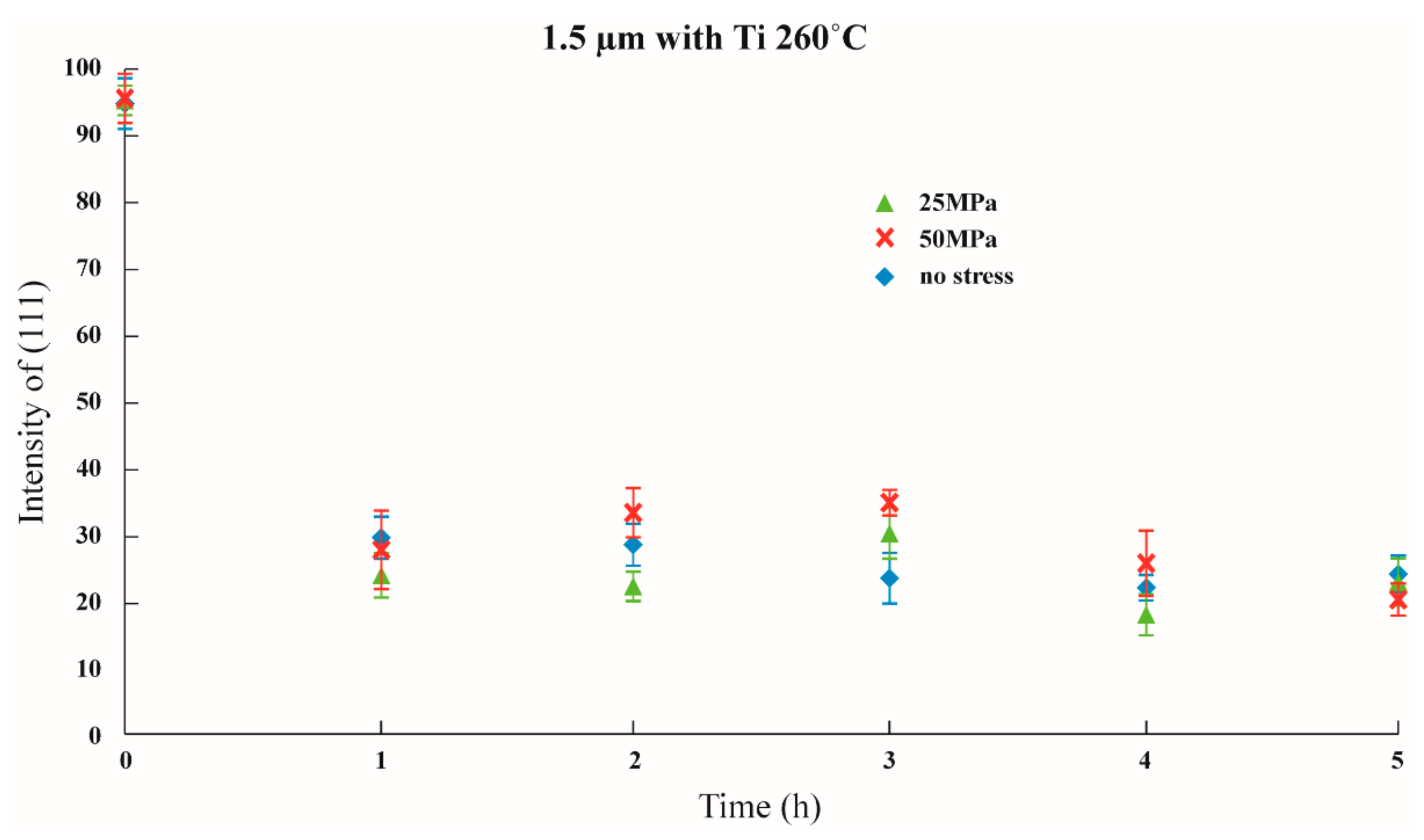

3.2. Influences of an Adhesion Layer

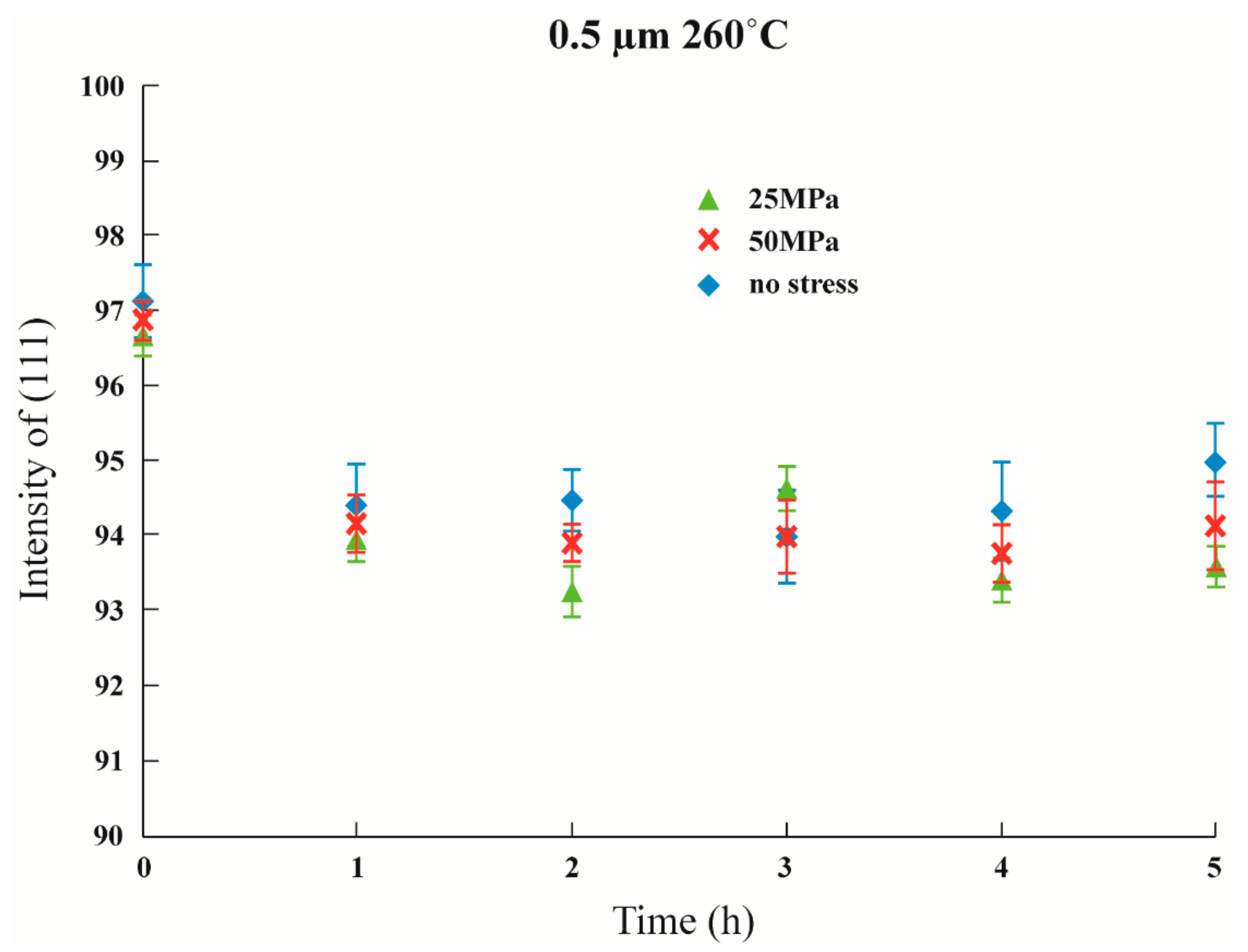

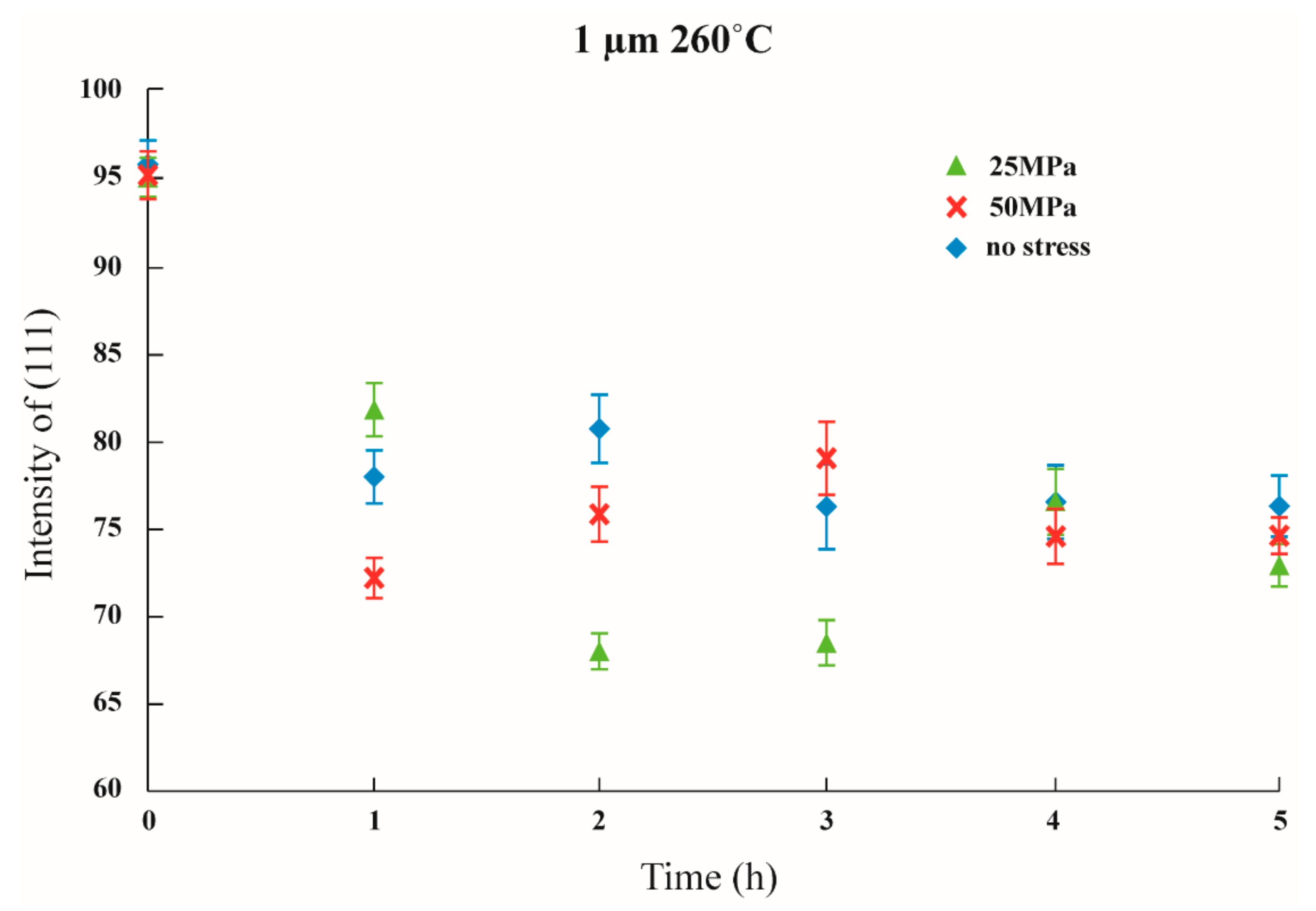

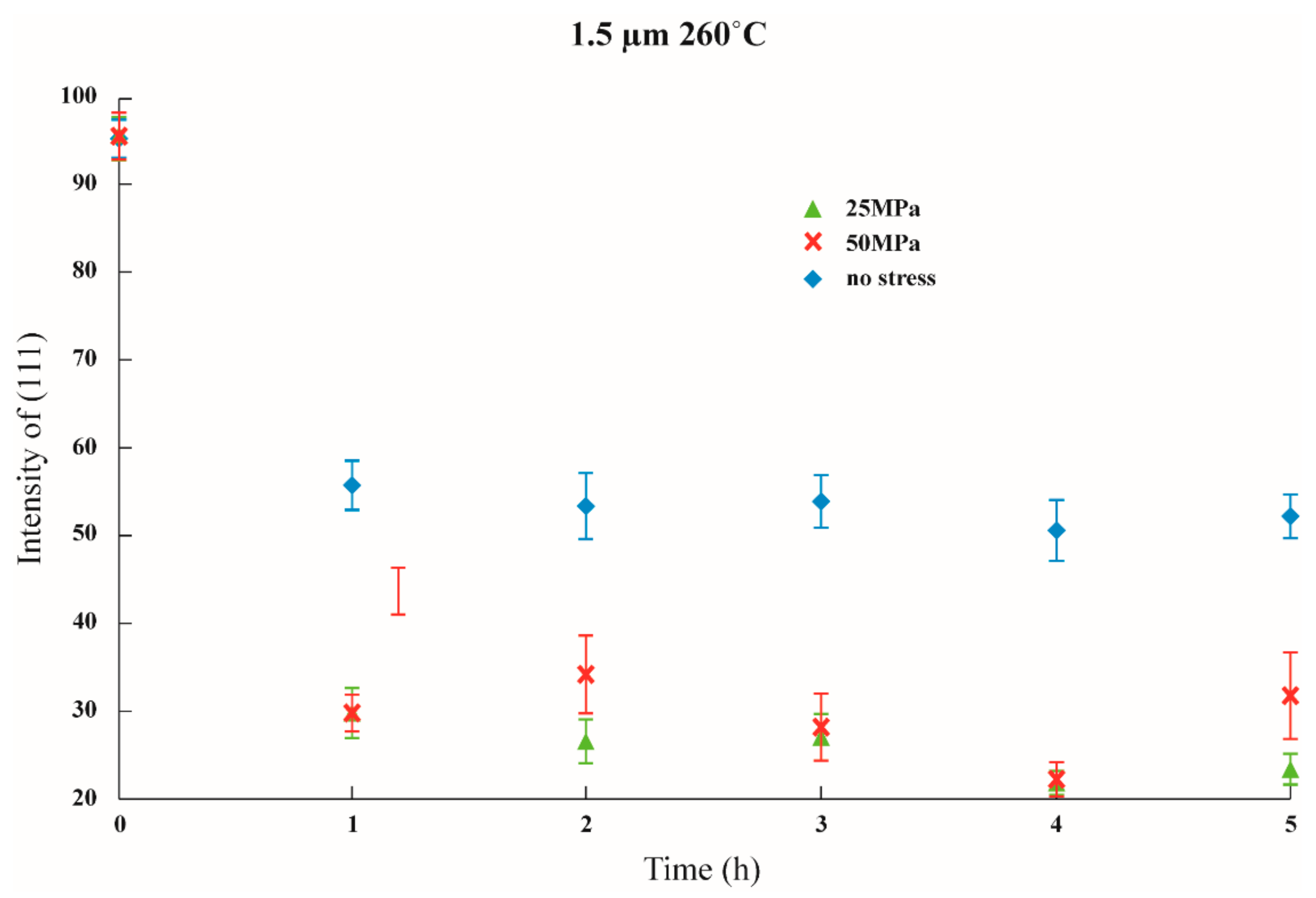

3.3. Influences of an Imposed Initial Stress

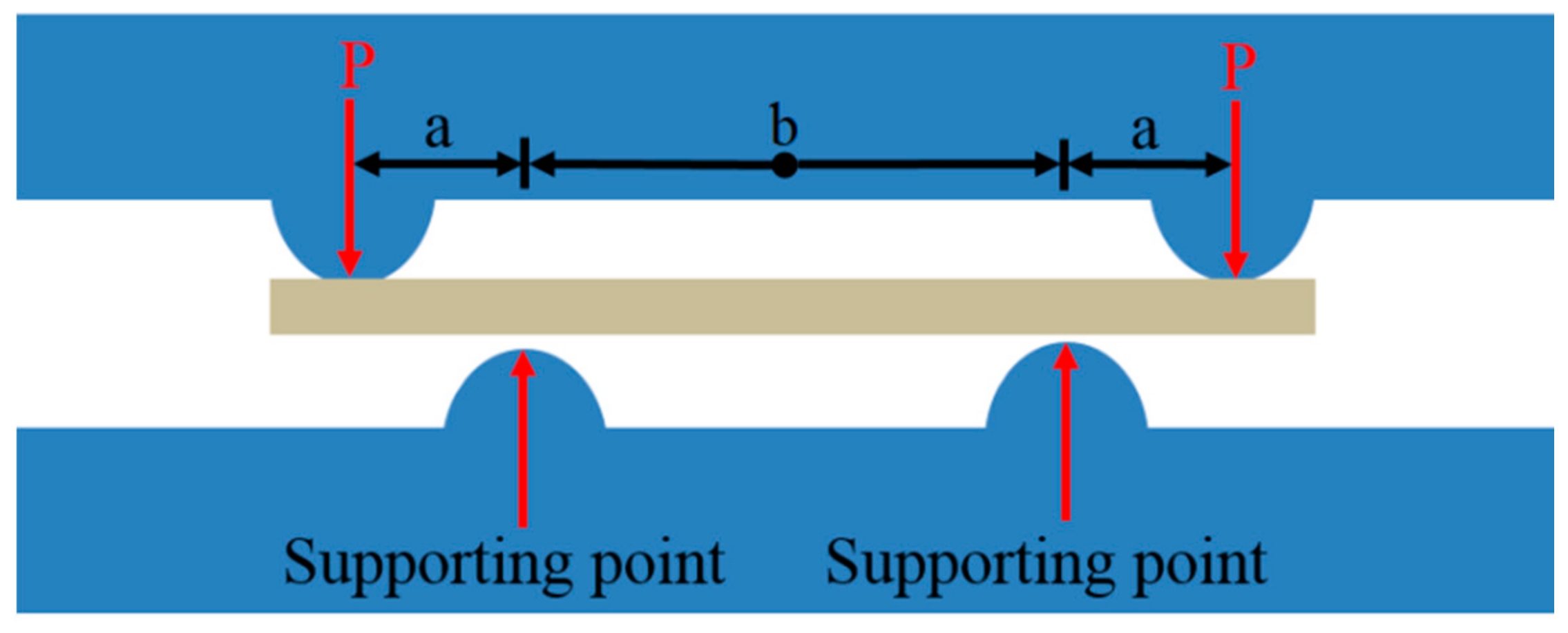

3.4. Internal Stress in Metal Thin Film during Annealing

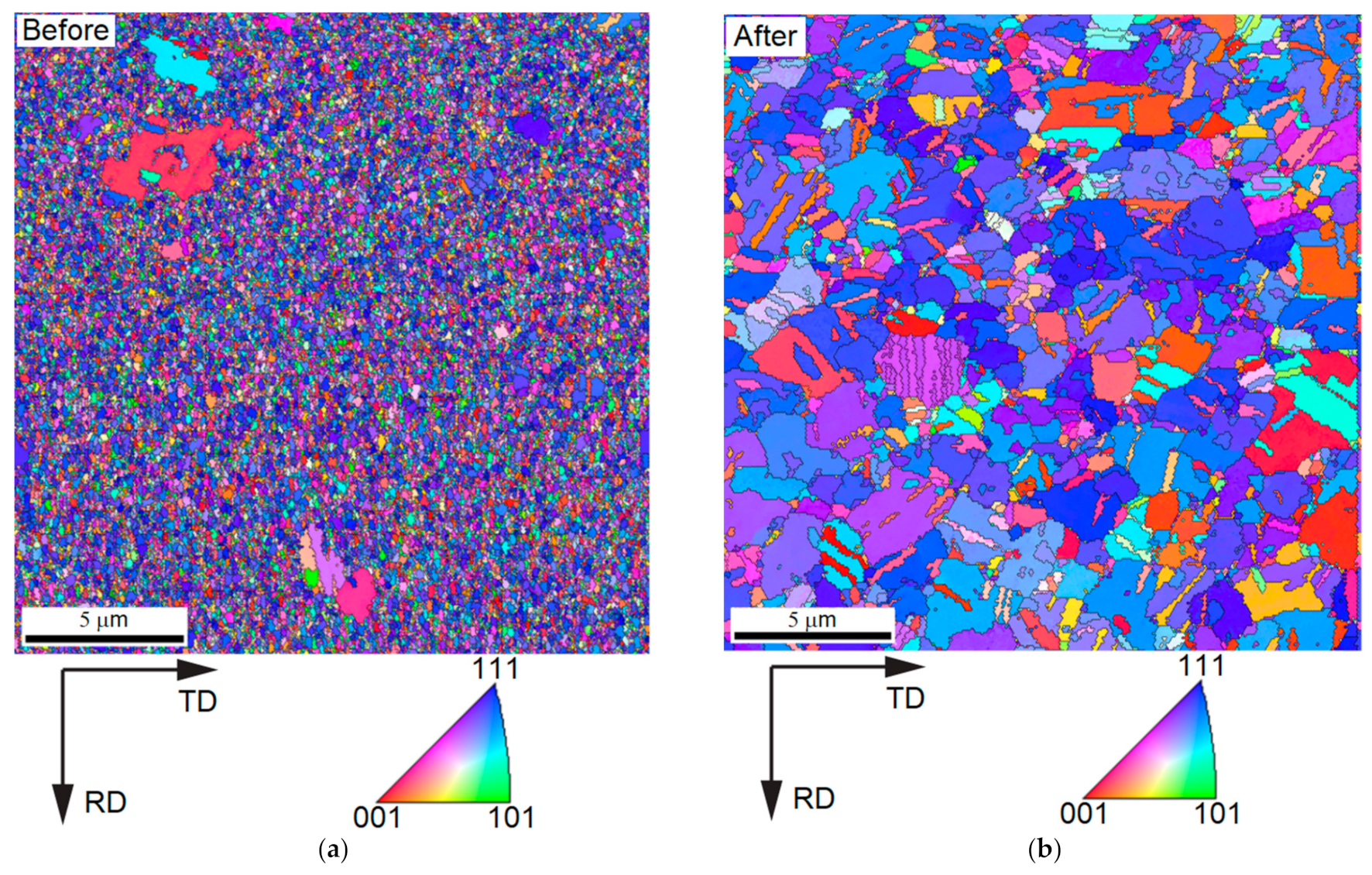

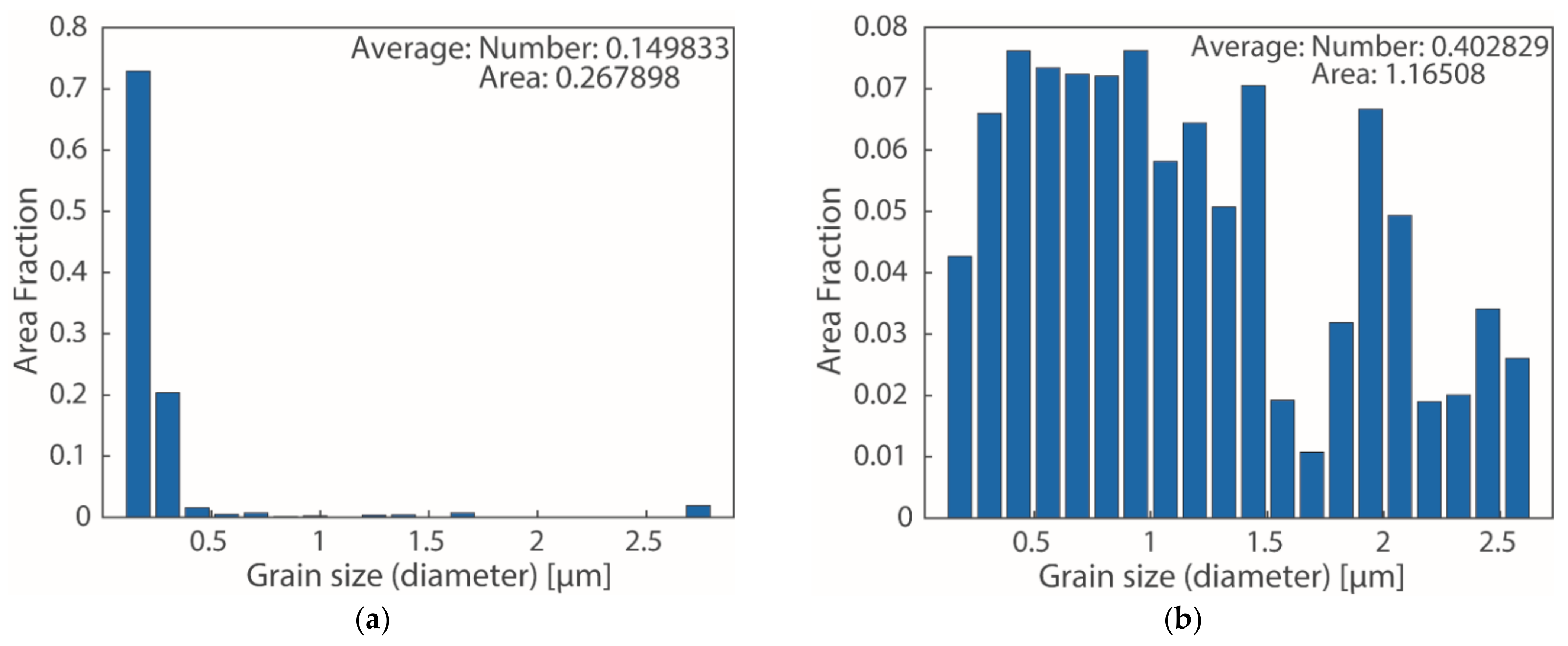

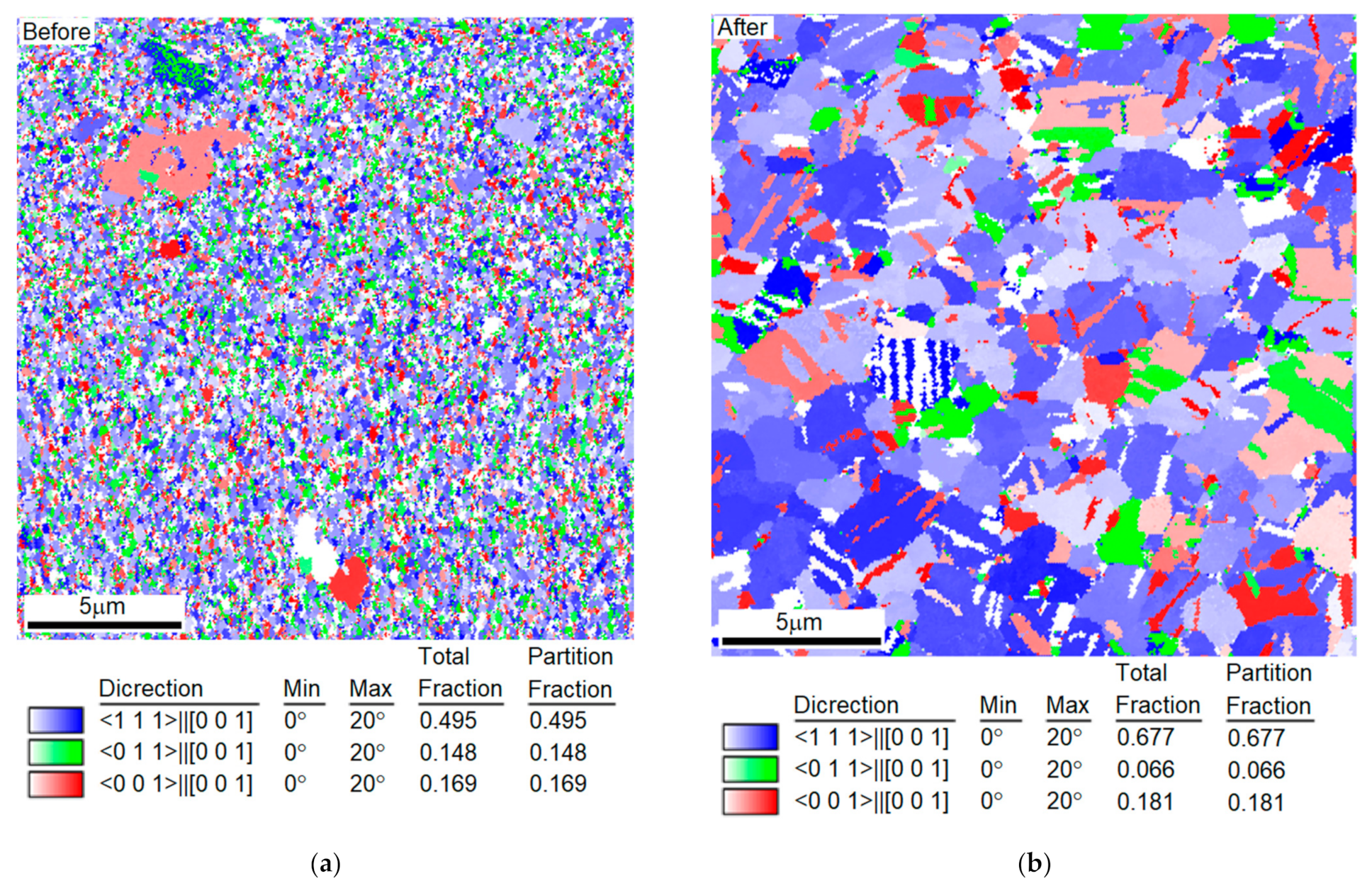

3.5. Measurement Results from EBSD

3.6. Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Nix, W.D. Mechanical properties of thin films. Metall. Trans. A 1989, 20, 2217–2245. [Google Scholar] [CrossRef]

- Spearing, S.M. Materials issues in microelectromechanical systems (MEMS). Acta Mater. 2000, 48, 179–196. [Google Scholar] [CrossRef]

- Tu, K.N. Recent advances in electromigration in very-large-scale-integration of interconnects. J. Appl. Phys. 2003, 94, 5451–5473. [Google Scholar] [CrossRef]

- Mehmood, Z.; Haneef, I.; Udrea, F. Material selection for Micro-Electro-Mechanical-Systems (MEMS) using Ashby’s approach. Mater. Des. 2018, 157, 412–430. [Google Scholar] [CrossRef]

- Dang, N.M.; Wang, Z.Y.; Chou, Y.C.; Nguyen, T.A.K.; Dang, T.N.; Lin, M.T. Size Effects in Internal Friction of Nanocrystalline Aluminum Films. Materials 2021, 14, 3401. [Google Scholar] [CrossRef] [PubMed]

- Chopra, K.L.; Paulson, P.D.; Dutta, V. Thin-film solar cells: An overview. Prog. Photovolt. 2004, 12, 69–92. [Google Scholar] [CrossRef]

- Bahadirab, Z.; Torrentb, L.; Hidalgob, M.; Marguí, E. Simultaneous determination of silver and gold nanoparticles by cloud point extraction and total reflection X-ray fluorescence analysis. Spectrochim. Acta Part B At. Spectrosc. 2018, 149, 22–29. [Google Scholar] [CrossRef]

- Ellis, E.A.; Chmielus, M.; Lin, M.T.; Joress, H.; Visser, K.; Woll, A.; Vinci, R.P.; Brown, W.L.; Baker, S.P. Driving forces for texture transformation in thin Ag films. Acta Mater. 2016, 105, 495–504. [Google Scholar] [CrossRef] [Green Version]

- Yan, X.; Brown, W.L.; Li, Y.; Papapolymerou, J.; Palego, C.; Hwang, J.C.M.; Vinci, R.P. Anelastic Stress Relaxation in Gold Films and Its Impact on Restoring Forces in MEMS Devices. J. Microelectromech. Syst. 2009, 18, 570–576. [Google Scholar] [CrossRef]

- Love, J.C.; Estroff, L.A.; Kriebel, J.K.; Nuzzo, R.G.; Whitesides, G.M. Self-assembled monolayers of thiolates on metals as a form of nanotechnology. Chem. Rev. 2005, 105, 1103–1169. [Google Scholar] [CrossRef]

- Fuh, Y.K.; Wang, C.H. In situ roughness monitoring of sputtered Pt thin filmunder dynamic turbulence using adaptive optics. Optik 2014, 125, 2086–2089. [Google Scholar] [CrossRef]

- Jung, Y.S. Study on texture evolution and properties of silver thin films prepared by sputtering deposition. Appl. Surf. Sci. 2004, 221, 281–287. [Google Scholar] [CrossRef]

- Vook, R.W.; Witt, F. Structure and Annealing Behavior of Metal Films Deposited on Substrates near 80 °K: I. Copper Films on Glass. J. Vac. Sci. Technol. 1965, 2, 49. [Google Scholar] [CrossRef]

- Patten, J.W.; McClanahan, E.D.; Johnston, J.W. Room- Temperature Recrystallization in Thick Bias-Sputtered Copper Deposits. J. Appl. Phys. 1971, 42, 4371. [Google Scholar] [CrossRef]

- Dahlgren, S.D. Columnar grains and twins in high-purity sputter-deposited copper. J. Vac. Sci. Technol. 1974, 11, 832. [Google Scholar] [CrossRef]

- Ohmi, T.; Saito, T.; Otsuki, M.; Shibata, T. Formation of Copper Thin Films by a Low Kinetic Energy Particle Process. J. Electrochem. Soc. 1991, 138, 1089–1097. [Google Scholar] [CrossRef]

- Floroa, J.A.; Thompsona, C.V.; Carela, R.; Bristowea, P.D. Competition between strain and interface energy during epitaxial grain growth in Ag films on Ni(001). J. Mater. Res. 1994, 9, 2411–2424. [Google Scholar] [CrossRef]

- Zielinski, E.M.; Vinci, R.P.; Bravman, J.C. Effects of barrier layer and annealing on abnormal grain growth in copper thin films. J. Appl. Phys. 1994, 76, 4516. [Google Scholar] [CrossRef]

- Zielinski, E.M.; Vinci, R.P.; Bravman, J.C. The influence of strain energy on abnormal grain growth in copper thin films. Appl. Phys. Lett. 1995, 67, 1078. [Google Scholar] [CrossRef]

- Greisera, J.; Müllera, D.; Müllnera, P.; Thompson, C.V.; Arzt, E. Growth of giant grains in silver thin films. Scr. Mater. 1999, 41, 709–714. [Google Scholar] [CrossRef]

- Koike, J.; Wada, M.; Sanada, M.; Maruyama, K. Effects of crystallographic texture on stress-migration resistance in copper thin films. Appl. Phys. Lett. 2002, 81, 1017. [Google Scholar] [CrossRef]

- Sonnweber-Ribic, P.; Gruber, P.; Dehm, G.; Arzt, E. Texture transition in Cu thin films: Electron backscatter diffraction vs. X-ray diffraction. Acta Mater. 2006, 54, 3863–3870. [Google Scholar] [CrossRef]

- Sonnweber-Ribic, P.; Gruber, P.; Dehm, G.; Strunk, H.P.; Arzt, E. Kinetics and driving forces of abnormal grain growth in thin Cu films. Acta Mater. 2012, 60, 2397–2406. [Google Scholar] [CrossRef]

- Baker, S.P.; Hoffman, B.; Timian, L.; Silvernail, A.; Ellis, E.A. Texture transformations in Ag thin films. Acta Mater. 2013, 61, 7121–7132. [Google Scholar] [CrossRef]

- Polop, C.; Rosiepen, C.; Bleikamp, S.; Drese, R.; Mayer, J.; Dimyati, A.; Michely, T. The STM view of the initial stages of polycrystalline Ag film formation. New J. Phys. 2007, 9, 74. [Google Scholar] [CrossRef]

- Barrios, A.; Zhang, Y.; Maeder, X.; Castelluccio, G.; Pierron, O.; Zhu, T. Abnormal grain growth in ultrafine grained Ni under high-cycle loading. Scr. Mater. 2022, 209, 114372. [Google Scholar] [CrossRef]

- Thompson, C.V.; Carel, R. Stress and grain growth in thin films. J. Mech. Phys. Solids 1996, 44, 657–673. [Google Scholar] [CrossRef]

- Thompson, C.V.; Carel, R. Grain growth and texture evolution in thin films. Mater. Sci. Forum 1996, 204–206, 83–98. [Google Scholar] [CrossRef] [Green Version]

- Greiser, J.; Müllner, P.; Arzt, E. Abnormal growth of "giant" grains in silver thin films. Acta Mater. 2001, 49, 1041–1050. [Google Scholar] [CrossRef]

- Baker, S.P.; Kretschmann, A.; Arzt, E. Thermomechanical Behavior of Different Texture Components in Cu Thin Films. Acta Mater. 2001, 49, 2145–2160. [Google Scholar] [CrossRef]

- Sanchez, J.E., Jr.; Arzt, E. Effects of grain orientation on hillock formation and grain growth in aluminum films on silicon substrates. Scr. Metall. Mater. 1992, 27, 285–290. [Google Scholar] [CrossRef]

- Köstlmeier, S.; Elsässer, C. Density functional study of the Titanium effect’ at metal-ceramic interfaces. J. Phys. Condens. Matter 2000, 12, 1209–1222. [Google Scholar] [CrossRef]

- Ohring, M. Materials Science of Thin Films, 2nd ed.; Academic Press: San Diego, CA, USA, 2001; pp. 95–144. [Google Scholar]

- Chang, Y.A.; Himmel, L. Temperature Dependence of the Elastic Constants of Cu, Ag, and Au above Room Temperature. J. Appl. Phys. 1966, 37, 3567. [Google Scholar] [CrossRef] [Green Version]

- Navid, A.A.; Hodge, A.M. Nanostructured alpha and beta tantalum formation—Relationship between plasma parameters and microstructure. Mater. Sci. Eng. A 2012, 536, 49–56. [Google Scholar] [CrossRef]

- Vodnick, A.M.; Nowak, D.E.; Labat, S.; Thomas, O.; Baker, S.P. Out-of-plane stresses arising from grain interactions in textured thin films. Acta Mater. 2010, 58, 2452–2463. [Google Scholar] [CrossRef]

| Background Pressure | Deposition Rate | Temperature of the Deposit Substrate | Target Material |

|---|---|---|---|

| 3~5 × 10−7 Torr | 25 Å/s | 35~60 °C | 99.99% Ag |

| Background Pressure | Working Pressure | Ar Gas Flow | Power | Deposition Rate | Target Material |

|---|---|---|---|---|---|

| 3~5 × 10−7 Torr | 10−3 × 10−4 Torr | 15 sccm | 250 W | 5.5 Å/sec | 99.99% Ti |

| Material | Young’s Modulus | Initial Stress Imposed | Test Specimen Size |

|---|---|---|---|

| Silicon Wafer (400 μm) | 130 Gpa | 44 Gpa | b = 5.0 mm |

| Thin Silver Film | 76 Gpa | 25 Gpa | a = 6.5 mm |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dang, N.M.; Wang, Z.-Y.; Lin, C.-H.; Lin, M.-T. The Effects of Stresses and Interfaces on Texture Transformation in Silver Thin Films. Nanomaterials 2022, 12, 329. https://doi.org/10.3390/nano12030329

Dang NM, Wang Z-Y, Lin C-H, Lin M-T. The Effects of Stresses and Interfaces on Texture Transformation in Silver Thin Films. Nanomaterials. 2022; 12(3):329. https://doi.org/10.3390/nano12030329

Chicago/Turabian StyleDang, Nhat Minh, Zhao-Ying Wang, Chi-Hang Lin, and Ming-Tzer Lin. 2022. "The Effects of Stresses and Interfaces on Texture Transformation in Silver Thin Films" Nanomaterials 12, no. 3: 329. https://doi.org/10.3390/nano12030329

APA StyleDang, N. M., Wang, Z.-Y., Lin, C.-H., & Lin, M.-T. (2022). The Effects of Stresses and Interfaces on Texture Transformation in Silver Thin Films. Nanomaterials, 12(3), 329. https://doi.org/10.3390/nano12030329