Preparation and Bolometric Responses of MoS2 Nanoflowers and Multi-Walled Carbon Nanotube Composite Network

Abstract

1. Introduction

2. Materials and Methods

2.1. Preparation of the CNT–MoS2 Composite Network

2.2. Structural Characterization Methods

2.3. Characterization of the Thermal Diffusivity and TCR

2.4. Test of Bolometric Response

2.5. Measurement of the Response Time

3. Results

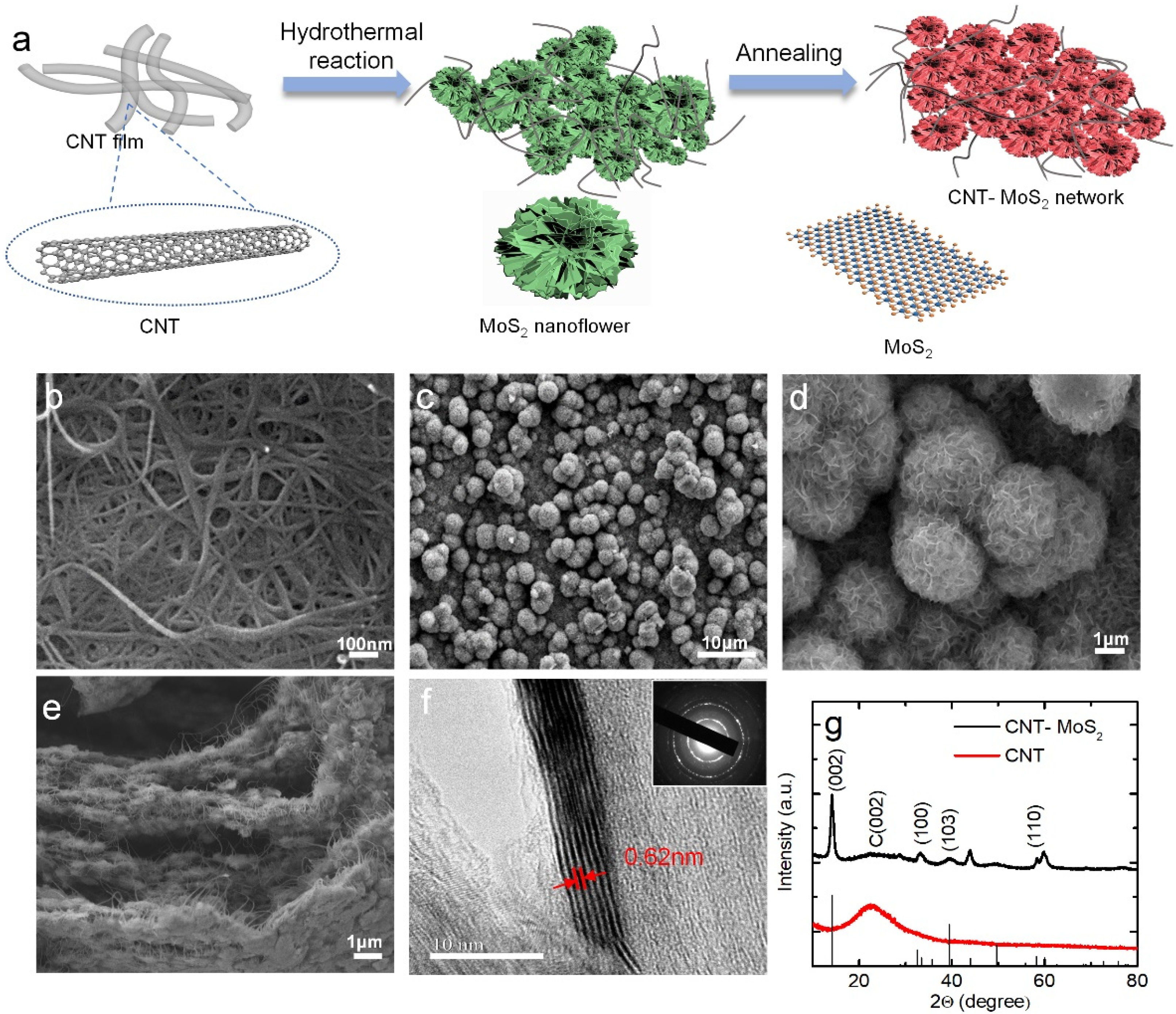

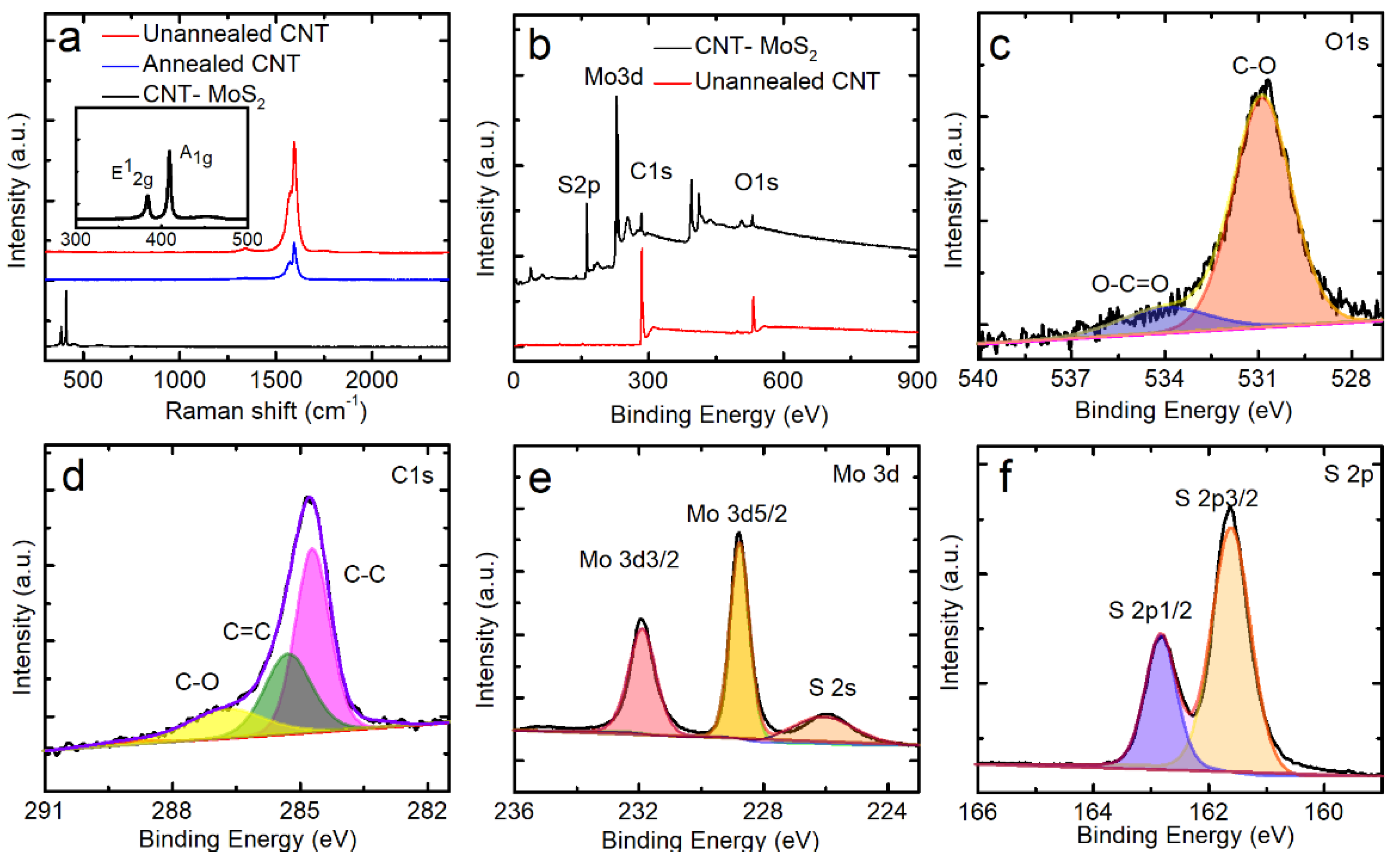

3.1. Material Synthesis and Structural Characterization

3.2. Thermal Properties and Temperature Sensitivity

3.3. Photothermal Performance

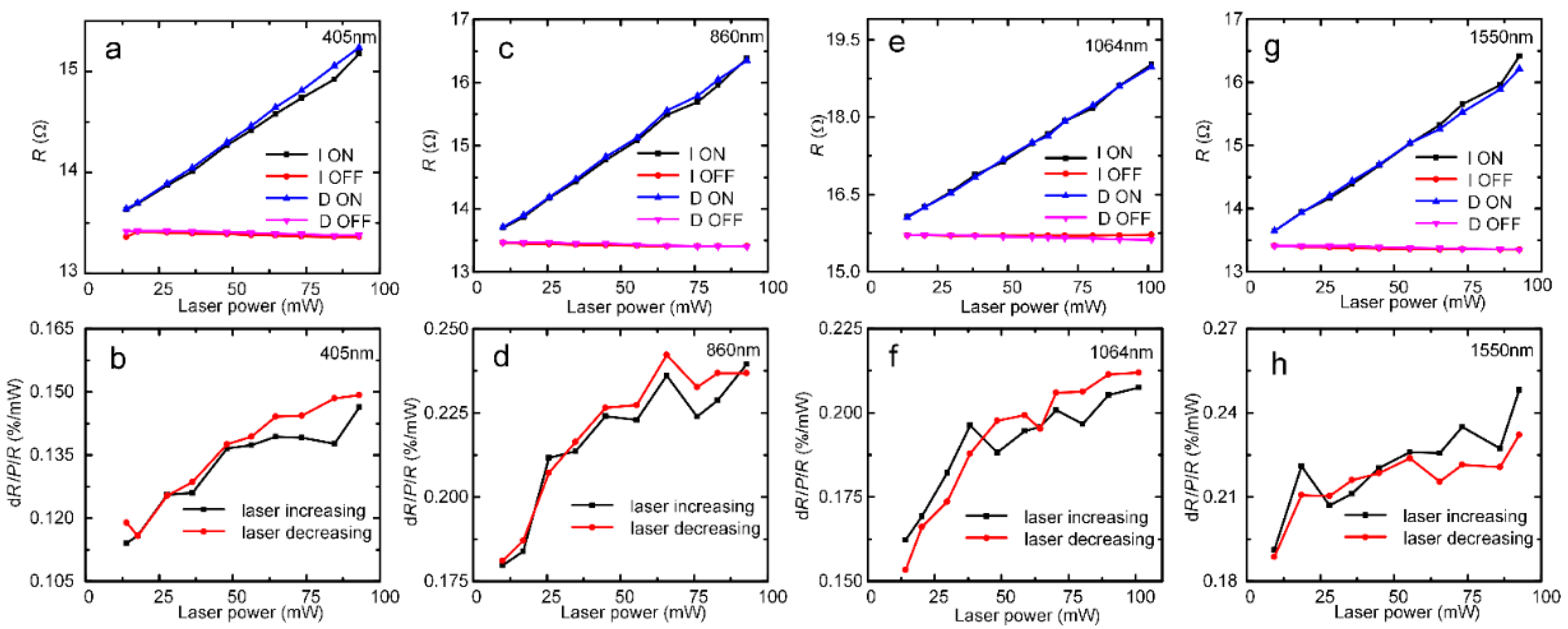

3.4. Bolometer Performance

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Xie, Y.; Han, M.; Wang, R.; Zobeiri, H.; Deng, X.; Zhang, P.; Wang, X. Graphene Aerogel Based Bolometer for Ultrasensitive Sensing from Ultraviolet to Far-Infrared. ACS Nano 2019, 13, 5385–5396. [Google Scholar] [CrossRef] [PubMed]

- Lee, G.-H.; Efetov, D.K.; Jung, W.; Ranzani, L.; Walsh, E.D.; Ohki, T.A.; Taniguchi, T.; Watanabe, K.; Kim, P.; Englund, D.; et al. Graphene-based Josephson junction microwave bolometer. Nature 2020, 586, 42–46. [Google Scholar] [CrossRef] [PubMed]

- Zhang, M.; Yeow, J.T.W. Flexible Polymer–Carbon Nanotube Composite with High-Response Stability for Wearable Thermal Imaging. ACS Appl. Mater. Interfaces 2018, 10, 26604–26609. [Google Scholar] [CrossRef] [PubMed]

- Blaikie, A.; Miller, D.; Alemán, B.J. A fast and sensitive room-temperature graphene nanomechanical bolometer. Nat. Commun. 2019, 10, 4726. [Google Scholar] [CrossRef]

- Tarasov, M.; Svensson, J.; Kuzmin, L.; Campbell, E.E.B. Carbon nanotube bolometers. Appl. Phys. Lett. 2007, 90, 163503. [Google Scholar] [CrossRef]

- Weiler, D.; Hochschulz, F.; Würfel, D.; Lerch, R.; Geruschke, T.; Wall, S.; Heß, J.; Wang, Q.; Vogt, H. Uncooled digital IRFPA-family with 17μm pixel-pitch based on amorphous silicon with massively parallel Sigma-Delta-ADC readout. In Proceedings of the Infrared Technology and Applications XL, Baltimore, MD, USA, 5–9 May 2014; Volume 9070, p. 90701. [Google Scholar] [CrossRef]

- Sumesh, M.A.; Thomas, B.; Vijesh, T.V.; Rao, G.M.; Viswanathan, M.; Karanth, S.P. Optically Immersed Bolometer IR Detectors Based on V2O5 Thin Films with Polyimide Thermal Impedance Control Layer for Space Applications. J. Infrared Millim. Terahertz Waves 2017, 39, 6–23. [Google Scholar] [CrossRef]

- Sumesh, M.; Karanth, S.; Prakash, S.; Laxmiprasad, A.; Nagendra, C. Ion beam sputtered Ge-Si-O amorphous thin films for microbolometer infrared detectors and their application in earth sensors. Sens. Actuators A Phys. 2013, 192, 81–91. [Google Scholar] [CrossRef]

- Syllaios, A.J.; Ha, M.J.; McCardel, W.L.; Schimert, T.R. Measurement of thermal time constant of microbolometer arrays. In Proceedings of the Infrared Technology and Applications XXXI, Orlando, FL, USA, 28 March–1 April 2005; Volume 5783, pp. 625–631. [Google Scholar] [CrossRef]

- Esteves, B.; Pimenta, S.; Vieira, E.M.F.; Freitas, J.R.; Rodrigues, J.A.; Correia, J.H. SnOX and a-Si thin-films based photodiode in a flexible substrate for visible spectral region. Mater. Lett. 2021, 286, 129251. [Google Scholar] [CrossRef]

- Yang, J.; Teng, Y.; Wu, J.; Chen, H.; Wang, G.; Song, L.; Yue, W.; Zuo, R.; Zhai, Y. Current status and associated human health risk of vanadium in soil in China. Chemosphere 2017, 171, 635–643. [Google Scholar] [CrossRef]

- Wang, S.; Zhang, B.; Li, T.; Li, Z.; Fu, J. Soil vanadium(V)-reducing related bacteria drive community response to vanadium pollution from a smelting plant over multiple gradients. Environ. Int. 2020, 138, 105630. [Google Scholar] [CrossRef]

- Han, Q.; Gao, T.; Zhang, R.; Chen, Y.; Chen, J.; Liu, G.; Zhang, Y.; Liu, Z.; Wu, X.; Yu, D. Highly sensitive hot electron bolometer based on disordered graphene. Sci. Rep. 2013, 3, 3533. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.; Qiu, B.; Nagai, N.; Nomura, M.; Volz, S.; Hirakawa, K. Enhanced thermal sensitivity of MEMS bolometers integrated with nanometer-scale hole array structures. AIP Adv. 2019, 9, 085102. [Google Scholar] [CrossRef]

- Evlashin, S.; Dyakonov, P.; Khmelnitsky, R.; Dagesyan, S.; Klokov, A.; Sharkov, A.; Timashev, P.; Minaeva, S.; Maslakov, K.; Svyakhovskiy, S.; et al. Controllable Laser Reduction of Graphene Oxide Films for Photoelectronic Applications. ACS Appl. Mater. Interfaces 2016, 8, 28880–28887. [Google Scholar] [CrossRef]

- St-Antoine, B.C.; Menard, D.; Martel, R. Single-Walled Carbon Nanotube Thermopile For Broadband Light Detection. Nano Lett. 2011, 11, 609–613. [Google Scholar] [CrossRef]

- Zhang, Y.; Deng, T.; Li, S.; Sun, J.; Yin, W.; Fang, Y.; Liu, Z. Highly sensitive ultraviolet photodetectors based on single wall carbon nanotube-graphene hybrid films. Appl. Surf. Sci. 2020, 512, 145651. [Google Scholar] [CrossRef]

- Lu, R.; Christianson, C.; Weintrub, B.; Wu, J.Z. High Photoresponse in Hybrid Graphene–Carbon Nanotube Infrared Detectors. ACS Appl. Mater. Interfaces 2013, 5, 11703–11707. [Google Scholar] [CrossRef]

- Lu, R.; Shi, J.J.; Baca, F.J.; Wu, J.Z. High performance multiwall carbon nanotube bolometers. J. Appl. Phys. 2010, 108, 084305. [Google Scholar] [CrossRef]

- Pathak, P.; Park, S.; Cho, H.J. A Carbon Nanotube–Metal Oxide Hybrid Material for Visible-Blind Flexible UV-Sensor. Micromachines 2020, 11, 368. [Google Scholar] [CrossRef]

- Itkis, M.E.; Borondics, F.; Yu, A.; Haddon, R.C. Bolometric Infrared Photoresponse of Suspended Single-Walled Carbon Nanotube Films. Science 2006, 312, 413–416. [Google Scholar] [CrossRef]

- Nandi, S.; Misra, A. Spray Coating of Two-Dimensional Suspended Film of Vanadium Oxide-Coated Carbon Nanotubes for Fabrication of a Large Volume Infrared Bolometer. ACS Appl. Mater. Interfaces 2020, 12, 1315–1321. [Google Scholar] [CrossRef]

- Hou, J.; Wang, Z.; Ding, Z.; Zhang, Z.; Zhang, J. Facile synthesize VO2 (M1) nanorods for a low-cost infrared photodetector application. Sol. Energy Mater. Sol. Cells 2018, 176, 142–149. [Google Scholar] [CrossRef]

- Bertoni, G.; Cepek, C.; Romanato, F.; Casari, C.; Bassi, A.L.; Bottani, C.; Sancrotti, M. Growth of multi-wall and single-wall carbon nanotubes with in situ high vacuum catalyst deposition. Carbon 2004, 42, 440–443. [Google Scholar] [CrossRef]

- Lin, D.; Zhang, S.; Liu, W.; Yu, Y.; Zhang, J. Carburization of Fe/Ni Catalyst for Efficient Growth of Single-Walled Carbon Nanotubes. Small 2019, 15, e1902240. [Google Scholar] [CrossRef] [PubMed]

- Kumar, R.; Khan, M.A.; Anupama, A.; Krupanidhi, S.B.; Sahoo, B. Infrared photodetectors based on multiwalled carbon nanotubes: Insights into the effect of nitrogen doping. Appl. Surf. Sci. 2020, 538, 148187. [Google Scholar] [CrossRef]

- Zhang, J.; Wei, Y.; Yao, F.; Li, D.; Ma, H.; Lei, P.; Fang, H.; Xiao, X.; Lu, Z.; Yang, J.; et al. SWCNT-MoS2-SWCNT Vertical Point Heterostructures. Adv. Mater. 2017, 29, 1604469. [Google Scholar] [CrossRef]

- Wang, J.X.; Yang, J.F.; Yang, J.; Qiao, G.J.; Hang, W.; Rui, H. Superior MoS2-decorated CNT composite materials for photoelectric detectors. Opt. Mater. 2018, 86, 113–118. [Google Scholar]

- Fu, W.B.; Ma, H.; Wei, Y.; Jiang, K.; Fei, G.T.; De Zhang, L. Preparation and infrared response properties of vanadium dioxide nanowire/carbon nanotube composite film. J. Mater. Sci. 2017, 52, 7224–7231. [Google Scholar] [CrossRef]

- Yang, X.; Yang, Y.; Fu, L.; Zou, M.; Li, Z.; Cao, A.; Yuan, Q. An Ultrathin Flexible 2D Membrane Based on Single-Walled Nanotube-MoS2 Hybrid Film for High-Performance Solar Steam Generation. Adv. Funct. Mater. 2017, 28, 1704505. [Google Scholar] [CrossRef]

- Tahersima, M.H.; Sorger, V.J. Strong Photon Absorption in 2D Material-Based Spiral Photovoltaic Cells. MRS Adv. 2016, 1, 3915–3921. [Google Scholar] [CrossRef][Green Version]

- Feng, X.; Zhao, J.; Sun, D.; Shanmugam, L.; Kim, J.-K.; Yang, J. Novel onion-like graphene aerogel beads for efficient solar vapor generation under non-concentrated illumination. J. Mater. Chem. A 2019, 7, 4400–4407. [Google Scholar] [CrossRef]

- Gao, C.; Han, Y.; Zhang, K.; Wei, T.; Jiang, Z.; Wei, Y.; Yin, L.; Piccinelli, F.; Yao, C.; Xie, X.; et al. Templated-Construction of Hollow MoS 2 Architectures with Improved Photoresponses. Adv. Sci. 2020, 7, 2002444. [Google Scholar] [CrossRef] [PubMed]

- Ranganathan, K.; Fiegenbaum-Raz, M.; Ismach, A. Large-Scale and Robust Multifunctional Vertically Aligned MoS2 Photo-Memristors. Adv. Funct. Mater. 2020, 30, 2005718. [Google Scholar] [CrossRef]

- Chacko, L.; Swetha, A.K.; Anjana, R.; Aneesh, P.M. Structural and Optical Studies of Hydrothermally Synthesized MoS2 Nanostructures. Int. Conf. Condens. Matter Appl. Phys. 2016, 1728, 20620. [Google Scholar]

- Guo, J.; Wang, X.; Wang, T. Thermal characterization of microscale conductive and nonconductive wires using transient electrothermal technique. J. Appl. Phys. 2007, 101, 063537. [Google Scholar] [CrossRef]

- Xie, Y.; Wang, T.; Zhu, B.; Yan, C.; Zhang, P.; Wang, X.; Eres, G. 19-Fold thermal conductivity increase of carbon nanotube bundles toward high-end thermal design applications. Carbon 2018, 139, 445–458. [Google Scholar] [CrossRef]

- Liu, T.; Davijani, A.A.B.; Sun, J.; Chen, S.; Kumar, S.; Lee, S.W. Hydrothermally Oxidized Single-Walled Carbon Nanotube Networks for High Volumetric Electrochemical Energy Storage. Small 2016, 12, 3423–3431. [Google Scholar] [CrossRef]

- Wang, S.; Zhu, J.; Shao, Y.; Li, W.; Wu, Y.; Zhang, L.; Hao, X. Three-Dimensional MoS2@CNT/RGO Network Composites for High-Performance Flexible Supercapacitors. Chem. -A Eur. J. 2017, 23, 3438–3446. [Google Scholar] [CrossRef]

- Jiang, Y.; Li, X.; Yu, S.; Jia, L.; Zhao, X.; Wang, C. Reduced Graphene Oxide-Modified Carbon Nanotube/Polyimide Film Supported MoS2Nanoparticles for Electrocatalytic Hydrogen Evolution. Adv. Funct. Mater. 2015, 25, 2693–2700. [Google Scholar] [CrossRef]

- Lei, Z.D.; Yu, X.; Zhang, Y.; Zhan, J. Thermally stable fishnet-like 1T-MoS2/CNT heterostructures with improved electrode performance. J. Mater. Chem. A 2021, 9, 4707–4715. [Google Scholar] [CrossRef]

- Jiab, C.; Yana, C.; Wang, Y.; Xiong, S.; Zhou, F.; Li, Y.; Suna, R.; Wong, C.-P. Thermal conductivity enhancement of CNT/MoS2/graphene-epoxy nanocomposites based on structural synergistic effects and interpenetrating network. Compos. Part B -Eng. 2019, 163, 363–370. [Google Scholar]

- Jiang, L.L.; Wang, Z.K.; Li, M.; Li, C.H.; Fang, P.-F.; Liao, L.-S. Flower-like MoS2 nanocrystals: A powerful sorbent of Li+ in the Spiro-OMeTAD layer for highly efficient and stable perovskite solar cells. J. Mater. Chem. A 2019, 7, 3655–3663. [Google Scholar] [CrossRef]

- Deng, X.; Nie, Q.; Wu, Y.; Fang, H.; Zhang, P.; Xie, Y. Nitrogen-Doped Unusually Superwetting, Thermally Insulating, and Elastic Graphene Aerogel for Efficient Solar Steam Generation. ACS Appl. Mater. Interfaces 2020, 12, 26200–26212. [Google Scholar] [CrossRef] [PubMed]

- Ferrari, A.C. Raman spectroscopy of graphene and graphite: Disorder, electron–phonon coupling, doping and nonadiabatic effects. Solid State Commun. 2007, 143, 47–57. [Google Scholar] [CrossRef]

- Ferrari, A.C.; Robertson, J. Interpretation of Raman spectra of disordered and amorphous carbon. Phys. Rev. B 2000, 61, 14095–14107. [Google Scholar] [CrossRef]

- Lee, C.; Yan, H.; Brus, L.E.; Heinz, T.F.; Hone, J.; Ryu, S. Anomalous Lattice Vibrations of Single- and Few-Layer MoS2. ACS Nano 2010, 4, 2695–2700. [Google Scholar] [CrossRef]

- Chowdhury, T.; Kim, J.; Sadler, E.C.; Li, C.; Lee, S.W.; Jo, K.; Xu, W.; Gracias, D.H.; Drichko, N.V.; Jariwala, D.; et al. Substrate-directed synthesis of MoS2 nanocrystals with tunable dimensionality and optical properties. Nat. Nanotechnol. 2019, 15, 29–34. [Google Scholar] [CrossRef]

- Wu, T.; Jing, M.; Liu, Y.; Ji, X. Binding low crystalline MoS2 nanoflakes on nitrogen-doped carbon nanotube: Towards high-rate lithium and sodium storage. J. Mater. Chem. A 2019, 7, 6439–6449. [Google Scholar] [CrossRef]

- Pan, F.; Wang, J.; Yang, Z.; Gu, L.; Yu, Y. MoS2–graphene nanosheet–CNT hybrids with excellent electrochemical performances for lithium-ion batteries. RSC Adv. 2015, 5, 77518–77526. [Google Scholar] [CrossRef]

- Xie, Y.; Xu, S.; Xu, Z.; Wu, H.; Deng, C.; Wang, X. Interface-mediated extremely low thermal conductivity of graphene aerogel. Carbon 2016, 98, 381–390. [Google Scholar] [CrossRef]

- Liu, J.; Xu, Z.; Cheng, Z.; Xu, S.; Wang, X. Thermal Conductivity of Ultrahigh Molecular Weight Polyethylene Crystal: Defect Effect Uncovered by 0 K Limit Phonon Diffusion. ACS Appl. Mater. Interfaces 2015, 7, 27279–27288. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.; Yin, J.; Wang, P.; Hu, Q.; Wang, Y.; Xie, Y.; Zhao, Z.; Dong, Z.; Zhu, J.-L.; Chu, W.; et al. High-Performance, Ultra-Broadband, Ultraviolet to Terahertz Photodetectors Based on Suspended Carbon Nanotube Films. ACS Appl. Mater. Interfaces 2018, 10, 36304–36311. [Google Scholar] [CrossRef] [PubMed]

- Nair, R.R.; Blake, P.; Grigorenko, A.N.; Novoselov, K.S.; Booth, T.J.; Stauber, T.; Peres, N.M.R.; Geim, A.K. Fine Structure Constant Defines Visual Transparency of Graphene. Science 2008, 320, 1308. [Google Scholar] [CrossRef] [PubMed]

- Dużyńska, A.; Taube, A.; Korona, K.; Judek, J.; Zdrojek, M. Temperature-dependent thermal properties of single-walled carbon nanotube thin films. Appl. Phys. Lett. 2015, 106, 183108. [Google Scholar] [CrossRef]

- Kumanek, B.; Janas, D. Thermal conductivity of carbon nanotube networks: A review. J. Mater. Sci. 2019, 54, 7397–7427. [Google Scholar] [CrossRef]

- Yu, C.; Shi, L.; Yao, Z.; Li, D.; Majumdar, A. Thermal Conductance and Thermopower of an Individual Single-Wall Carbon Nanotube. Nano Lett. 2005, 5, 1842–1846. [Google Scholar] [CrossRef] [PubMed]

- Li, Q.W.; Li, Y.; Zhang, X.F.; Chikkannanavar, S.B.; Zhao, Y.H.; Dangelewicz, A.M.; Zheng, L.; Doorn, S.K.; Jia, Q.; Peterson, D.E.; et al. Structure-Dependent Electrical Properties of Carbon Nanotube Fibers. Adv. Mater. 2007, 19, 3358–3363. [Google Scholar] [CrossRef]

- Li, Q.-Y.; Katakami, K.; Ikuta, T.; Kohno, M.; Zhang, X.; Takahashi, K. Measurement of thermal contact resistance between individual carbon fibers using a laser-flash Raman mapping method. Carbon 2018, 141, 92–98. [Google Scholar] [CrossRef]

- Kumar, N.; Sharma, J.D.; Kumar, A.; Ahluwalia, P.K. Band gap engineering in nano structured graphane by applying elastic strain. Solid State Phys. 2013, 57, 192–193. [Google Scholar] [CrossRef]

- Liu, J.; Wang, T.; Xu, S.; Yuan, P.; Xu, X.; Wang, X. Thermal conductivity of giant mono- to few-layered CVD graphene supported on an organic substrate. Nanoscale 2016, 8, 10298–10309. [Google Scholar] [CrossRef]

- Ito, T.; Nishidate, K.; Baba, M.; Hasegawa, M. First principles calculations for electronic band structure of single-walled carbon nanotube under uniaxial strain. Surf. Sci. 2002, 514, 222–226. [Google Scholar] [CrossRef]

- Gautreau, P.; Ragab, T.; Chu, Y.; Basaran, C. Phonon dispersion and quantization tuning of strained carbon nanotubes for flexible electronics. J. Appl. Phys. 2014, 115, 243702. [Google Scholar] [CrossRef]

- Zhang, H.; Zhao, K.; Cui, S.; Yang, J.; Zhou, D.; Tang, L.; Shen, J.; Feng, S.; Zhang, W.; Fu, Y. Anomalous temperature coefficient of resistance in graphene nanowalls/polymer films and applications in infrared photodetectors. Nanophotonics 2018, 7, 883–892. [Google Scholar] [CrossRef]

- Lu, R.; Xu, G.; Wu, J.Z. Effects of thermal annealing on noise property and temperature coefficient of resistance of single-walled carbon nanotube films. Appl. Phys. Lett. 2008, 93, 213101. [Google Scholar] [CrossRef]

- Khosrofian, J.M.; Garetz, B.A. Measurement of a Gaussian Laser-Beam Diameter through the Direct Inversion of Knife-Edge Data. Appl. Opt. 1983, 22, 3406–3410. [Google Scholar] [CrossRef] [PubMed]

| Solution | Na2MoO4 2H2O (g) | CH4N2S (g) | DI Water (mL) |

|---|---|---|---|

| 1 | 0.1210 | 0.1142 | 30 |

| 2 | 0.2420 | 0.2284 | 30 |

| Sample | Length (mm) | Width (mm) | Thickness (μm) | Density (kg∙m−3) |

|---|---|---|---|---|

| S1 (Low MoS2 composite density) | 5.74 ± 0.01 | 0.68 ± 0.01 | 33 ± 2 | 1470 ± 50 |

| S2 (High MoS2 composite density) | 6.90 ± 0.01 | 0.76 ± 0.01 | 36 ± 2 | 1889 ± 50 |

| Unannealed CNT Network | 6.49 ± 0.01 | 0.73 ± 0.01 | 21 ± 2 | 702 ± 50 |

| Annealed CNT Network | 6.49 ± 0.01 | 0.45 ± 0.01 | 21 ± 2 | 365 ± 50 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Q.; Wu, Y.; Deng, X.; Xiang, L.; Xu, K.; Li, Y.; Xie, Y. Preparation and Bolometric Responses of MoS2 Nanoflowers and Multi-Walled Carbon Nanotube Composite Network. Nanomaterials 2022, 12, 495. https://doi.org/10.3390/nano12030495

Wang Q, Wu Y, Deng X, Xiang L, Xu K, Li Y, Xie Y. Preparation and Bolometric Responses of MoS2 Nanoflowers and Multi-Walled Carbon Nanotube Composite Network. Nanomaterials. 2022; 12(3):495. https://doi.org/10.3390/nano12030495

Chicago/Turabian StyleWang, Qin, Yu Wu, Xin Deng, Liping Xiang, Ke Xu, Yongliang Li, and Yangsu Xie. 2022. "Preparation and Bolometric Responses of MoS2 Nanoflowers and Multi-Walled Carbon Nanotube Composite Network" Nanomaterials 12, no. 3: 495. https://doi.org/10.3390/nano12030495

APA StyleWang, Q., Wu, Y., Deng, X., Xiang, L., Xu, K., Li, Y., & Xie, Y. (2022). Preparation and Bolometric Responses of MoS2 Nanoflowers and Multi-Walled Carbon Nanotube Composite Network. Nanomaterials, 12(3), 495. https://doi.org/10.3390/nano12030495