Insulation Performance and Simulation Analysis of SiO2-Aramid Paper under High-Voltage Bushing

Abstract

:1. Introduction

2. Aramid Sample Preparation and Property Testing

2.1. Material Preparation

- The SiO2 nanoparticles with a diameter of about 12 nm are added to deionized water together with a 12% dispersant solution, and the mixed solution is dispersed ultrasonically with the aid of an ultrasonic cleaner;

- Take a fiber dissociator, add an appropriate amount of aramid short-cut fibers with a length of 12 mm to it, add the previously prepared nano-SiO2 particles dispersion solution after being dispersed evenly, and stir it fully for 8 min. Subsequently add an appropriate amount of aramid pulp with a length of 2 mm, and stir it fully for 8 min to obtain a mixed original pulp containing nano-SiO2 particles;

- Use a paper sample copying machine to copy and form the mixed original pulp containing the nano-SiO2 particles to obtain dry paper containing the mixture of nano-SiO2 particles;

- The obtained dry paper containing the mixture of nano-SiO2 particles is superheated and calendered to obtain an improved aramid insulating paper containing nano-SiO2 particles.

2.2. Test Methods

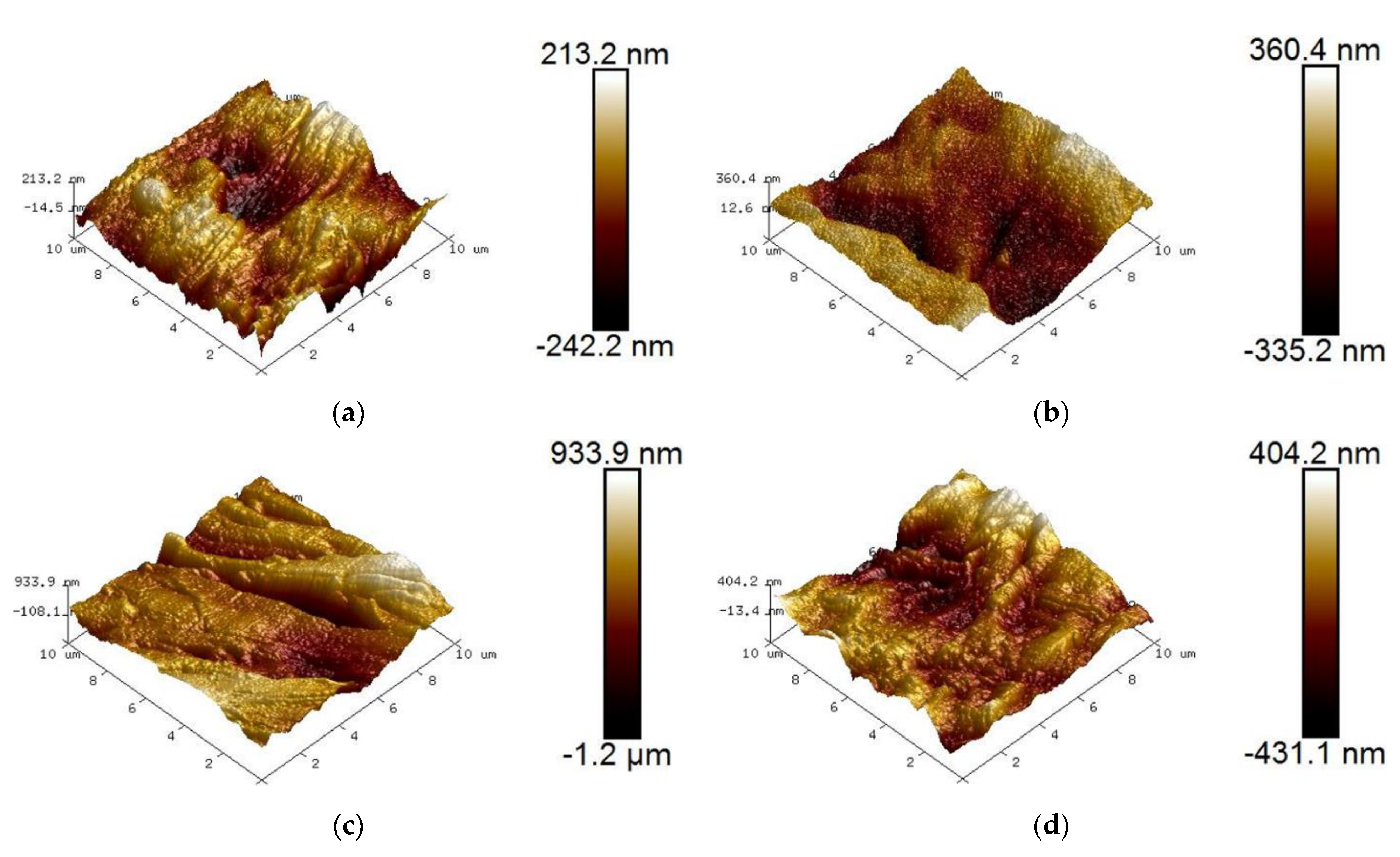

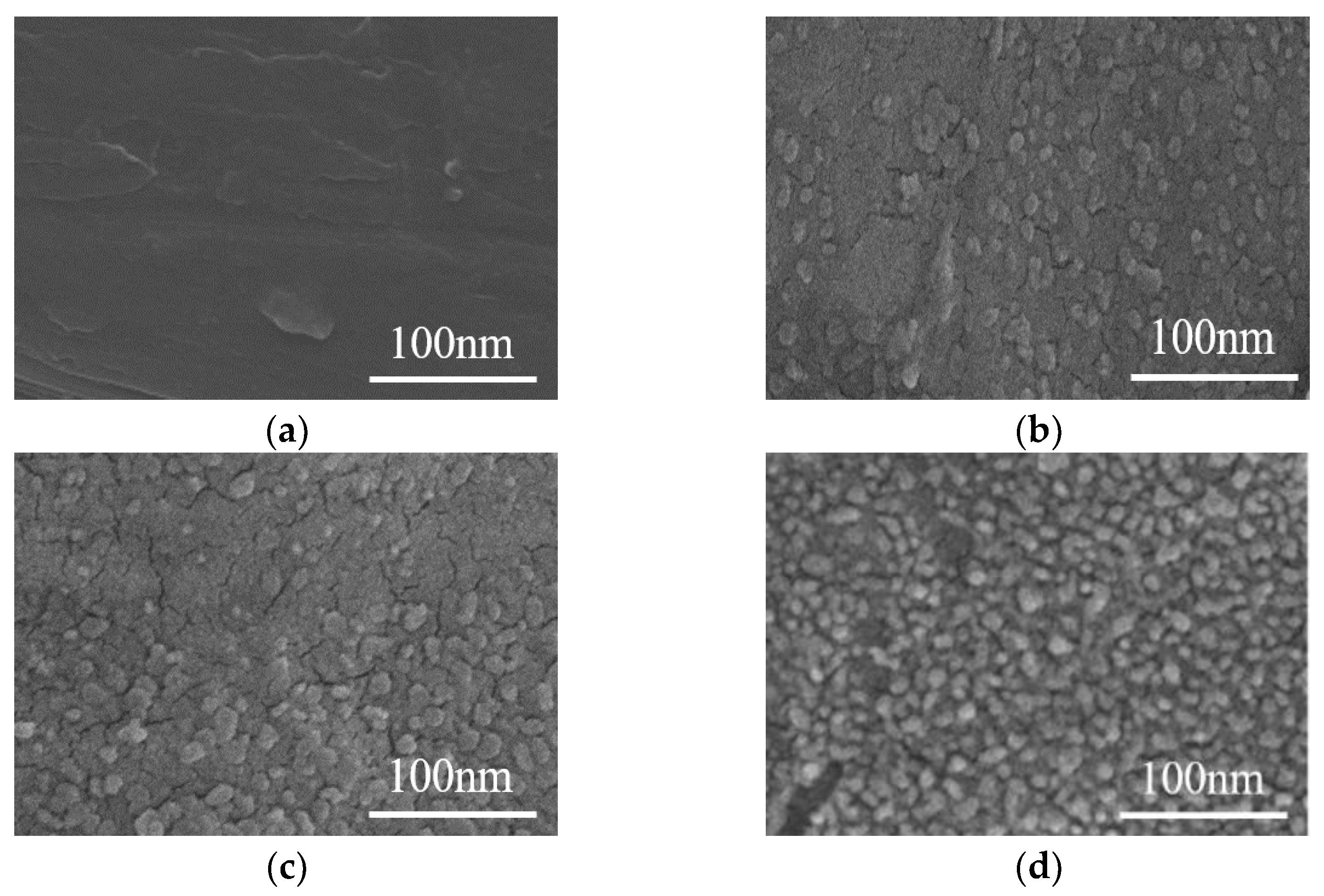

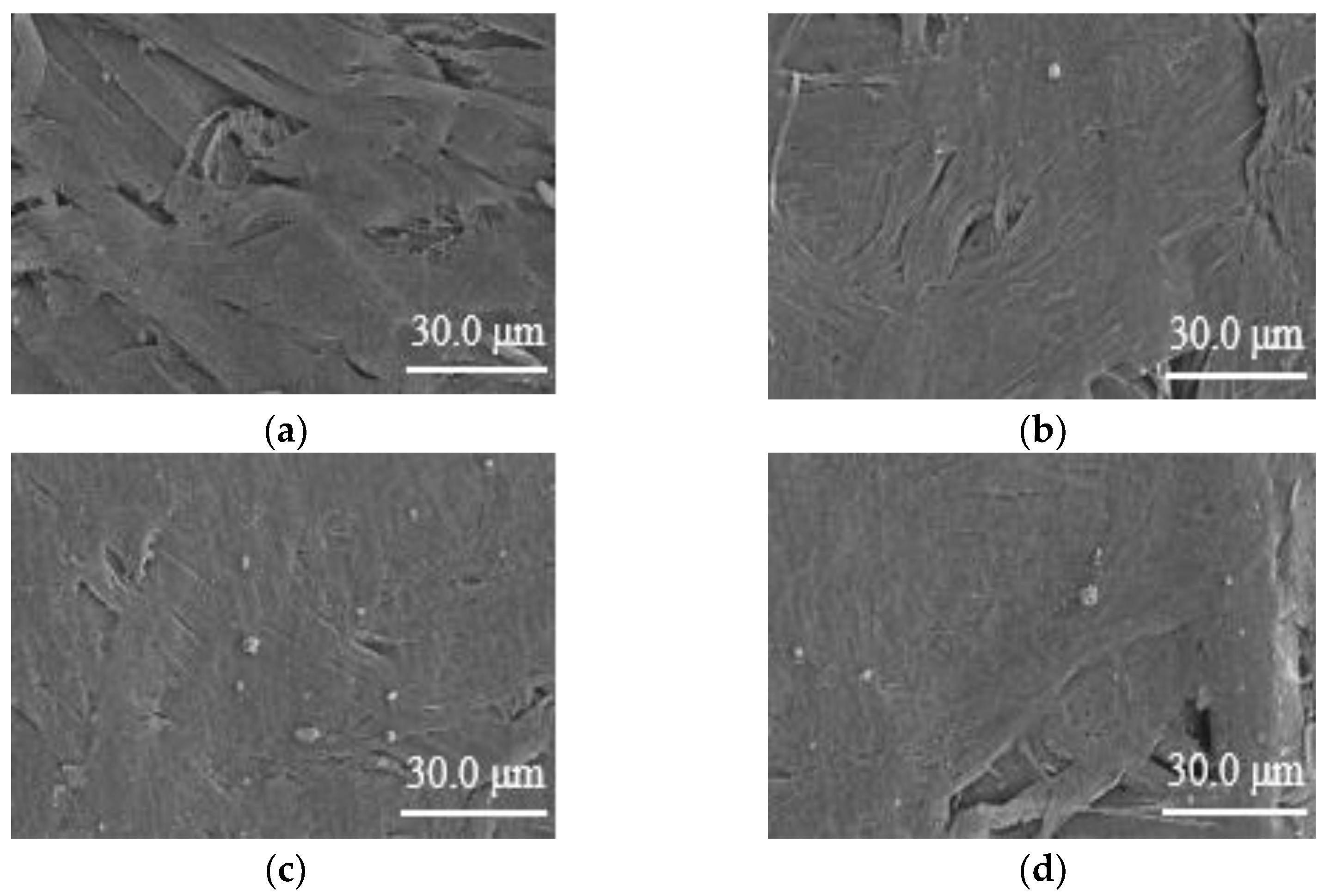

3. Physical Test Results

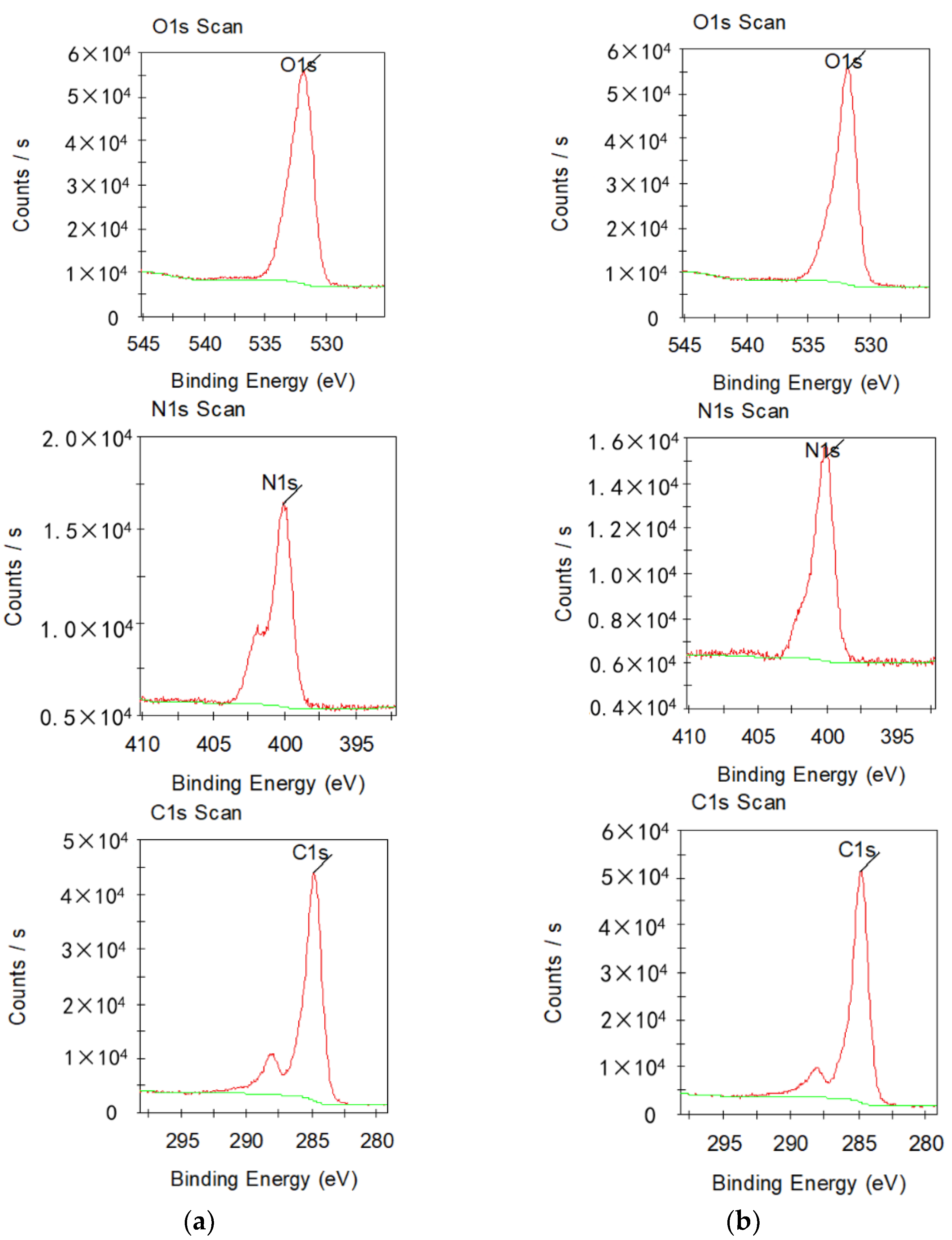

4. Chemical Test Results

5. Dielectric Constant Test Results

6. Finite Element Simulation Model of Transformer Bushings

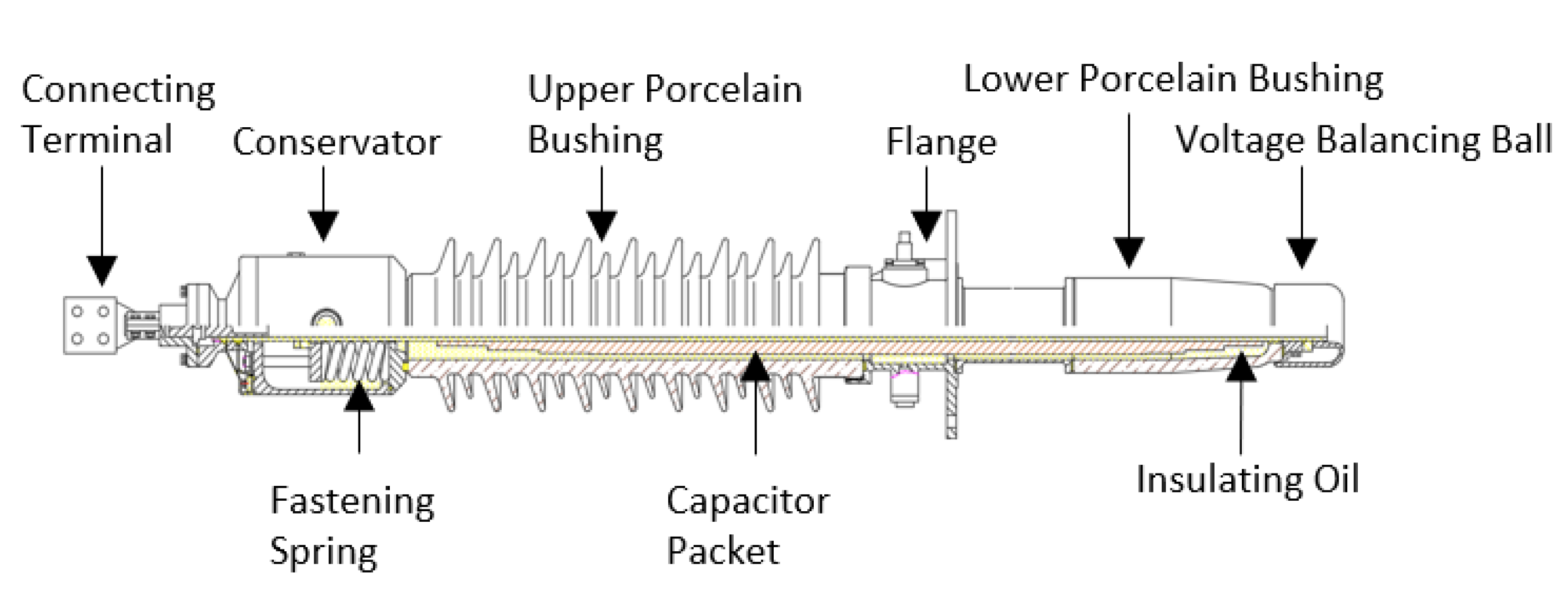

6.1. Structure of the Oil-Filled Paper Condenser Type Bushing

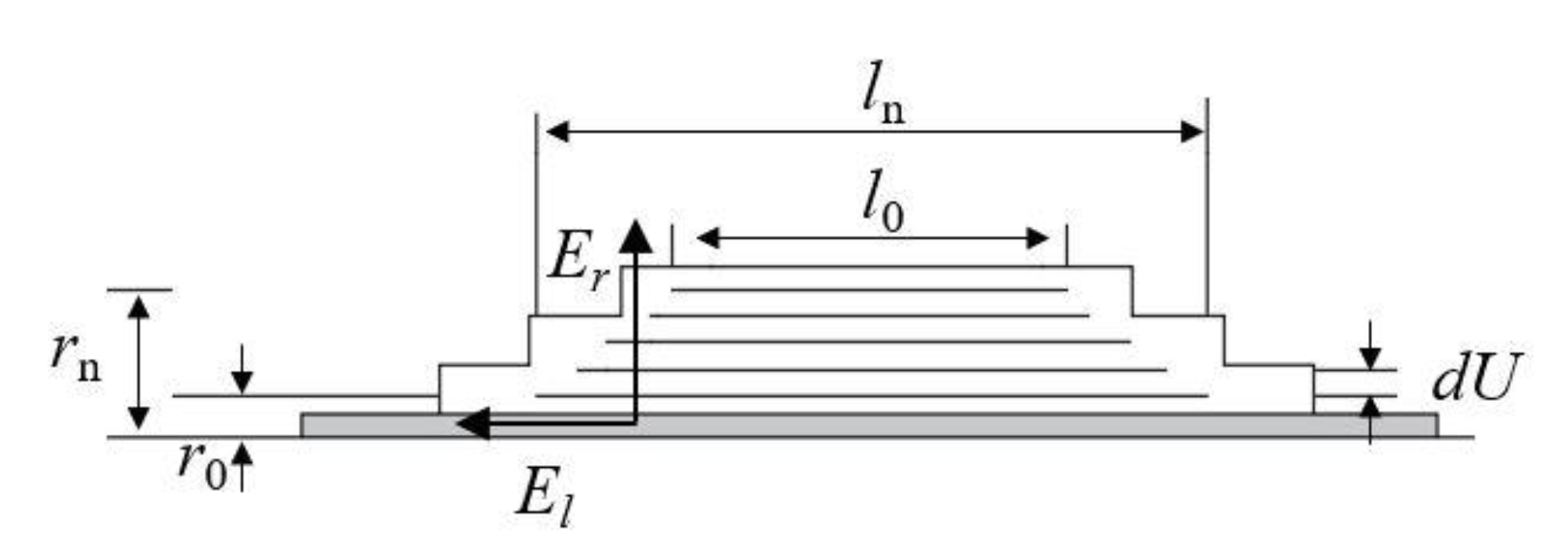

6.2. Insulation Principle of Capacitor Packet

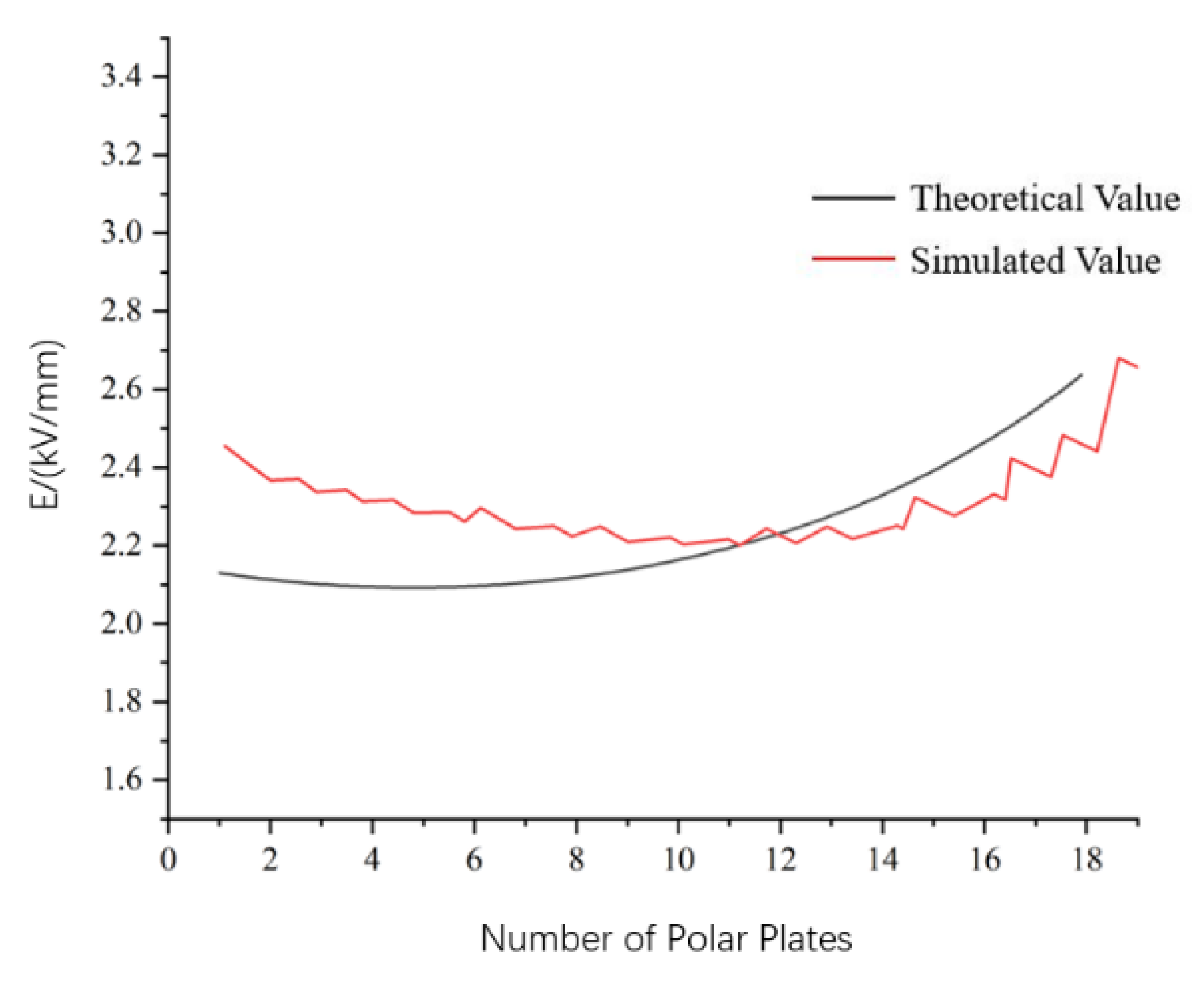

6.3. Finite Element Simulation Theory

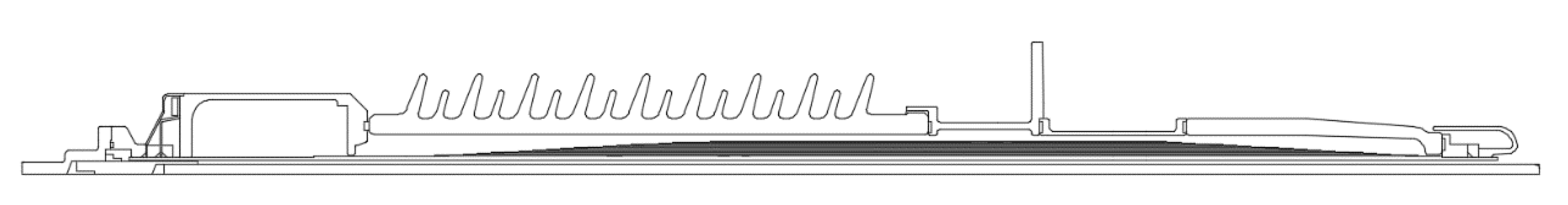

6.4. Parameters and Settings of Finite Element Simulation

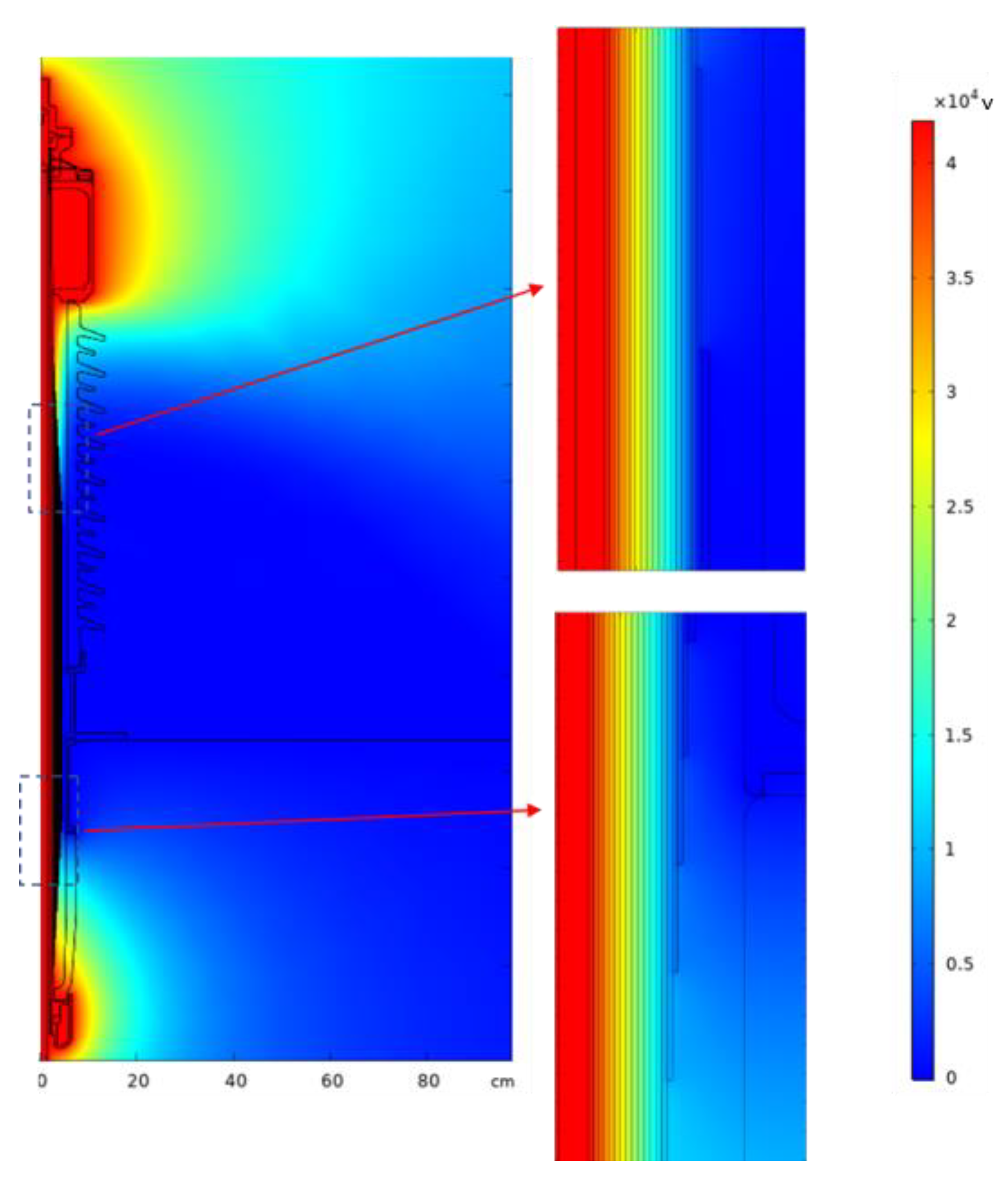

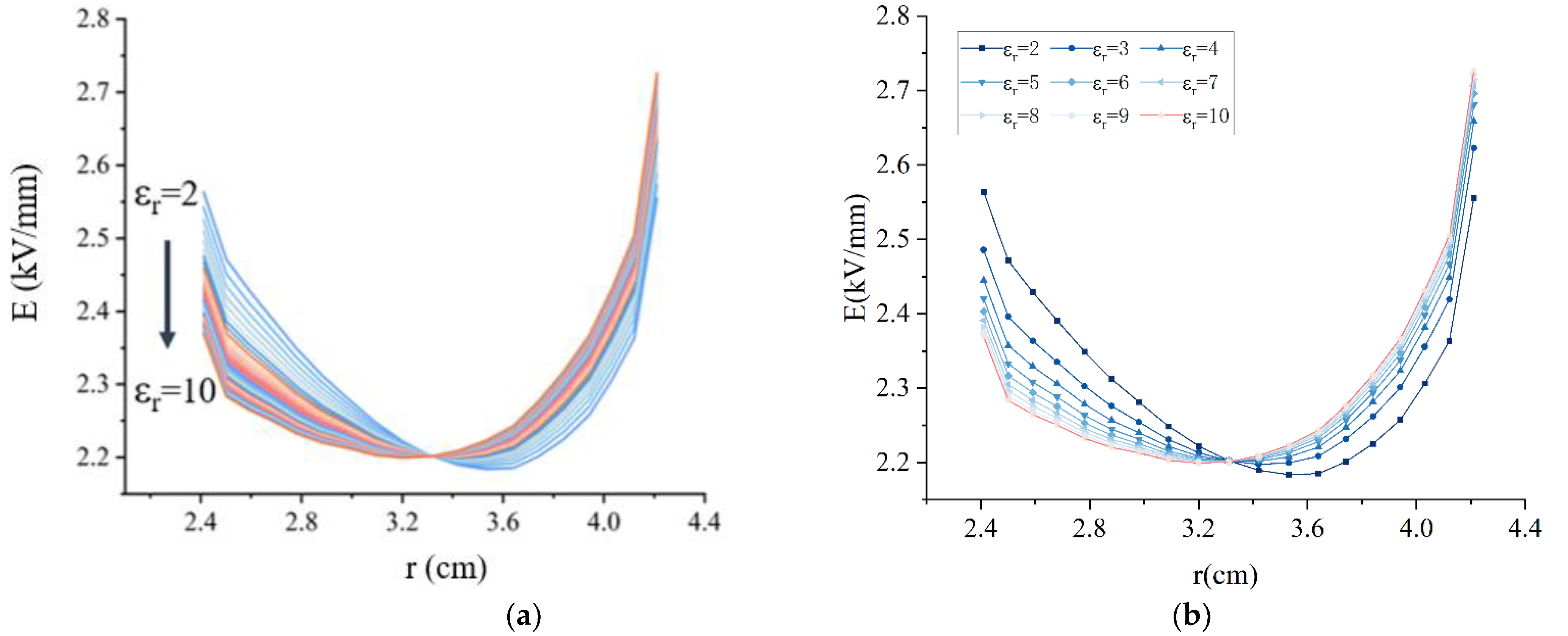

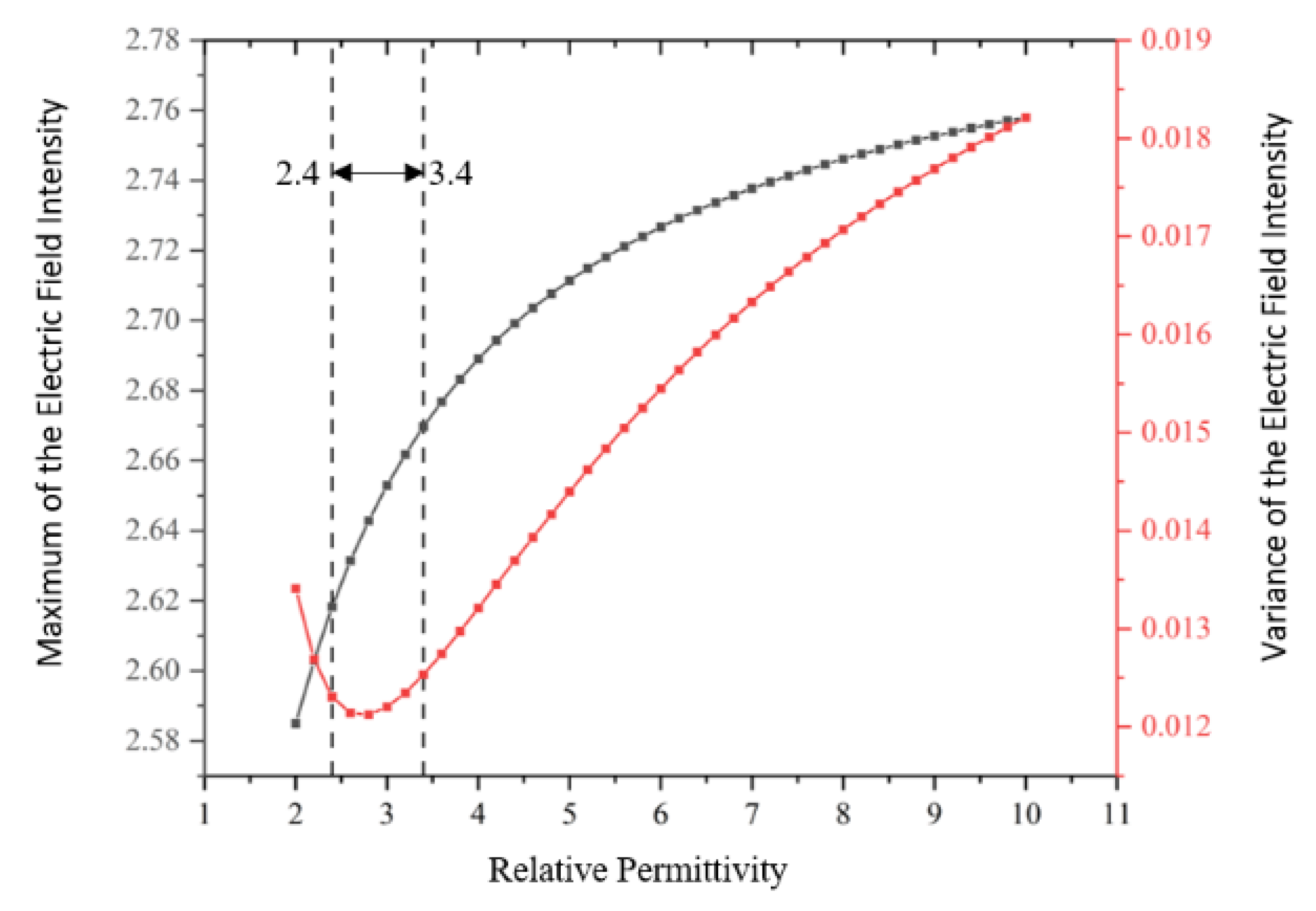

7. Analysis of the Simulation Results

8. Conclusions

- The surface of aramid insulation paper sample can be effectively stripped by nano-modification technology, which increases the degree of etching of a nano-SiO2 particle modifier on its surface gradually and the surface roughness of the sample, making the surface gouge situation increase significantly. However, with the increase of nano-SiO2 particle modifier content, it is influenced by the aggregation of nano-particles into clusters, which leads to the reduction of its surface roughness instead.

- After comparing the samples of aramid insulation paper modified with nano-SiO2 particles with those of aramid insulating paper without nano-SiO2 particles, it can be seen that with the gradual increase of nano-SiO2 particles filler, the chemical state of its surface changed accordingly, the content of groups on the surface of aramid fiber changed significantly, the content of group-C-OH increased, and the content of group-C=O showed a trend of first increasing and then decreasing.

- Electric intensity has the smallest variance and the electric field distribution is the most uniform. However, the manufacturing process of the material does not guarantee that the dielectric constant is accurately controlled at 2.8. Controlling the relative dielectric constant between 2.4 and 3.4 can achieve a more uniform electric field and a smaller maximum intensity. In this paper, the modified aramid paper insulation dielectric constant is basically close to the range of 2.4–3.4, which can achieve a more uniform electric field and a smaller maximum electric intensity.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ruijin, L.; Yongyong, D.; Jun, G.; Dingchun, L.; Jin, G. Effect of moisture on the frequency domain dielectric response of oil-paper capacitive bushings. Power Autom. Equip. 2019, 39, 8–12. [Google Scholar]

- Liao, Z.L. Market demand for aramid and the application of aramid pulp. High Technol. Fibers Appl. 2008, 33, 36–39. [Google Scholar]

- Lu, Z.E.; Zhang, M.Y.; Wang, C.J. Aramid 1313 fiber paper-based composites and their research progress. Mater. Guide 2006, 20, 32–34. (In Chinese) [Google Scholar]

- Zhang, S.H.L.; Peng, Z.R. Application of finite element numerical calculation technology to the simulation of three-dimensional electric field of extra-high voltage through-wall casing. High Volt. Technol. 2020, 46, 782–789. [Google Scholar]

- Maity, J.; Jacob, C.; Das, C.K.; Kharitonov, A.P.; Singh, R.P.; Alam, S. Fluorinated aramid fiber reinforced polypropylene composites and their characte-rization. Polym. Compos. 2007, 28, 462–469. [Google Scholar] [CrossRef]

- Mukherjee, M.; Das, C.K.; Kharitonov, A.P.; Banik, K.; Mennig, G.; Chung, T.N. Properties of syndiotactic polystyrene compositeswith surface modified short Kevlar fiber. Mater. Sci. Eng. A 2006, 441, 206–214. [Google Scholar] [CrossRef]

- Wenxiu, G. Study on the Characteristics and Identification of Partial Discharge of Typical Defects in Oil-Paper Capacitive Casing; Shandong University: Jinan, China, 2021. [Google Scholar]

- Xidong, C.; Jie, Y.; Xiaodong, Z.; Xiqiu, F. The development status and application of finite element method. China Manuf. Informatiz. 2010, 39, 6–8. (In Chinese) [Google Scholar]

- Zhang, H.Z.; Li, J.; Liang, Y.; Yang, L.J.; Liao, R.J.; Zhao, Y.S. Electrical dendrite growth properties of low-density polyethylene-montmorillonite nanocomposites. Chin. J. Electr. Eng. 2010, 30, 137–142. [Google Scholar]

- Fuzhou, Z.; Ruijin, L.; Yuan, Y.; Yusen, L.; Qingjun, P.; Tuan, L. Preparation of low dielectric constant insulating paper and its breakdown performance. High Volt. Technol. 2012, 38, 691–696. (In Chinese) [Google Scholar]

- Heqian, L.; Minghe, J.; Qingguo, C.; Ziwei, G.; Xuecheng, Z.; Xinlao, W. Analysis of dielectric properties of nano-alumina modified insulating paperboard. Chin. J. Electr. Eng. 2017, 37, 4246–4253, 4304. (In Chinese) [Google Scholar]

- Ruijin, L.; Binhai, L.; Ge, B.; Jian, H.; Xiao, L.; Yuandi, L. Space charge properties and dielectric properties of nano-SiO2/aramid insulating paper composites. J. Electr. Eng. Technol. 2016, 31, 40–48. (In Chinese) [Google Scholar]

- Liao, R.J.; Lv, C.; Wu, W.Q.; Liang, N.C.; Yang, L.J. Study on the performance of nano-Al2O3 modified transformer insulation paper. J. Electr. Power Sci. Technol. 2014, 29, 3–7. (In Chinese) [Google Scholar]

- Li, H.; Liu, G.; Liu, B.; Chen, W.; Chen, S. Dielectric properties of polyimide/Al2O3 hybrids synthesized by in-situ polymerization. Mater. Lett. 2007, 61, 1507–1511. [Google Scholar] [CrossRef]

- Lv, C.; Liao, R.J.; Wu, W.Q.; Liu, T. Effect of nano-TiO2 on the DC space charge characteristics of oil-paper insulation media. High Volt. Technol. 2015, 41, 417–423. (In Chinese) [Google Scholar]

- Chen, Q.G.; Zhuge, X.L.; Liu, H.Q.; Chi, M.H.; Wei, X.L. Electric field distribution of converter transformer outlet device using nano-modified cardboard. J. Electr. Mach. Control. 2016, 20, 29–34. (In Chinese) [Google Scholar]

- Liao, R.J.; Lv, C.; Wu, W.Q.; Liu, T.; Liu, H.B. Insulation performance of nano-TiO2 modified insulating paper. High Volt. Technol. 2014, 40, 1932–1939. (In Chinese) [Google Scholar]

- Yan, S.; Liao, R.J.; Lv, Y.; Zhao, X.; He, L. Effect of nano-Al2O3 doping on the electrical properties of insulating paper with thermal aging. J. Electr. Eng. Technol. 2017, 32, 225–232. (In Chinese) [Google Scholar]

- Liao, R.J.; Yuan, L.; Zhang, F.; Yang, L.; Wang, K.; Duan, L. Preparation of montmorillonite modified insulating paper and its electrical characteristics. High Volt. Technol. 2014, 40, 33–39. (In Chinese) [Google Scholar]

- Jinyu, X. Study on the Enhancement of Mechanical Properties and Thermal Stability of PMIA Insulating Paper by Nano-SiO2; Southwest University: Chongqing, China, 2017. [Google Scholar]

- Song, Z. Study on the Microscopic Mechanism of Nano-SiO2 Doping Modified Oil-Impregnated Cellulose Insulating Paper; Southwest University: Chongqing, China, 2018. [Google Scholar]

- Guanguan, D. Study on the Performance of Nanoparticle-Enhanced Aramid Paper; Shaanxi University of Science and Technology: Xi’an, China, 2015. [Google Scholar]

- Tanaka, T. Dielectric nanocomposites with insulating properties. IEEE Trans. Dielectr. Electr. Insul. 2005, 12, 914–928. [Google Scholar] [CrossRef]

- Cao, Y.; Irwin, P.C.; Younsi, K. The future of nanodielectrics in the electrical power industry. IEEE Trans. Dielectr. Electr. Insul. 2004, 11, 797–807. [Google Scholar]

- Xu, L.; Li, F.; Fu, W.Y. Disassembly analysis of a 110 kV transformer high-voltage bushing fault. Transformer 2015, 52, 72–73. [Google Scholar]

- Meng, Q.D.; Yang, M.X.; Mao, T. Analysis and treatment of a 500 kV high-voltage bushing with low oil level defect. Electr. Porcelain Lightning Arrester 2013, 251, 12–15. [Google Scholar]

- Yang, N.; Yang, H.X.; He, T. Analysis of the causes of oil seepage in the end screen of 220 kV main transformer casing and measures to deal with it. Power Equip. Manag. 2021, 54, 154–155. [Google Scholar]

- Daosheng, L.; Xingrong, C.; Ziming, Z. Optimization of longitudinal insulation of 60 kV oil-paper bushings based on equal margins. Insul. Mater. 2020, 53, 62–68. [Google Scholar]

- Dai, N.; Qi, B.; Zhuo, R.; Li, C.; Tian, Y.; Fu, M. Simulation and optimization of electric field distribution at the edge of the capacitor core of oil-impregnated paper casing. Power Grid Technol. 2017, 41, 1683–1688. (In Chinese) [Google Scholar]

| Sample Number | Rq/nm |

|---|---|

| F0 | 88 |

| F1 | 134 |

| F2 | 480 |

| F3 | 229 |

| Sample Number | Dielectric Constant |

|---|---|

| F0 | 2.06 |

| F1 | 2.13 |

| F2 | 2.65 |

| F3 | 2.16 |

| Material | Insulating Oil | Oil-Impregnated Paper | Oil-Impregnated Aramid Paper | Porcelain Bushing | Air |

|---|---|---|---|---|---|

| εr | 2.2 | 3.8 | 4.9 | 7 | 1 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, B.; Lv, F.; Fan, X.; Xiao, H.; Bi, H. Insulation Performance and Simulation Analysis of SiO2-Aramid Paper under High-Voltage Bushing. Nanomaterials 2022, 12, 748. https://doi.org/10.3390/nano12050748

Liu B, Lv F, Fan X, Xiao H, Bi H. Insulation Performance and Simulation Analysis of SiO2-Aramid Paper under High-Voltage Bushing. Nanomaterials. 2022; 12(5):748. https://doi.org/10.3390/nano12050748

Chicago/Turabian StyleLiu, Bowen, Fangcheng Lv, Xiaozhou Fan, Hai Xiao, and Hanwen Bi. 2022. "Insulation Performance and Simulation Analysis of SiO2-Aramid Paper under High-Voltage Bushing" Nanomaterials 12, no. 5: 748. https://doi.org/10.3390/nano12050748

APA StyleLiu, B., Lv, F., Fan, X., Xiao, H., & Bi, H. (2022). Insulation Performance and Simulation Analysis of SiO2-Aramid Paper under High-Voltage Bushing. Nanomaterials, 12(5), 748. https://doi.org/10.3390/nano12050748