Thermal Conductivity of GaAs Nanowire Arrays Measured by the 3ω Method

Abstract

:1. Introduction

2. Materials and Methods

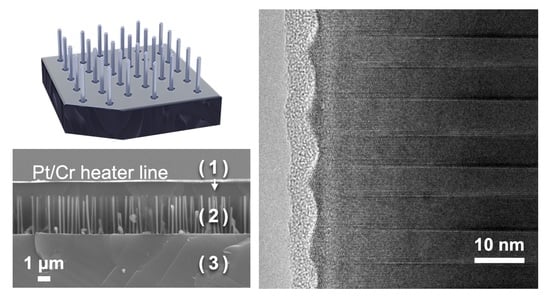

2.1. Nanowire Growth and Characterization

2.2. Device Fabrication

2.3. 3ω Measurements

2.4. 3ω Data Fitting

3. Results and Discussion

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Appendix A

Appendix B

| Parameter | Units | (i) | (ii) | (iii) | Ref. Value |

|---|---|---|---|---|---|

| W/m-K | 0.55 ± 0.03 | 0.19 ± 0.04 | 0.17 ± 0.04 | 0.18–0.29 [66,67,68,69] | |

| J/cm3-K | 1.10 ± 0.03 | 1.88 ± 0.04 | 1.99 ± 0.04 | 2.19–2.29 [66,70] | |

| W/m-K | 0.20 ± 0.05 | 0.65 ± 0.04 | 0.70 ± 0.06 | ||

| J/cm3-K | 3.70 × 10−7 | 0.41 | 4.57 × 10−7 | ||

| W/m-K | 266 | 67 | 46 | 35–55 [71] | |

| J/cm3-K | 0.0920 | 1.22 | 0.97 | - | |

| cm2-K/W | 0 | 0.0114 | 0.028 | - | |

| J/cm3-K | 0 | 0 | 2.82 | 2.82 [52] | |

| nm | 0 | 0 | 157 | - | |

| 10−3 K2 | 19.2 | 2.25 | 1.92 |

| Parameter | Units | (i) | (ii) | (iii) | Ref. Value |

|---|---|---|---|---|---|

| W/m-K | 0.47 ± 0.02 | 0.19 ± 0.04 | 0.17 ± 0.04 | 0.18–0.29 [66,67,68,69] | |

| J/cm3-K | 1.18 ± 0.04 | 1.93 ± 0.04 | 2.02 ± 0.04 | 2.19–2.29 [66,70] | |

| W/m-K | 0.20 ± 0.05 | 0.61 ± 0.04 | 0.68 ± 0.07 | ||

| J/cm3-K | 2.91 | 0.38 | 0.37 | ||

| W/m-K | 8.46 × 105 | 57 | 48 | 35–55 [71] | |

| J/cm3-K | 4.68 | 2.02 | 2.05 | - | |

| cm2-K/W | 0 | 0.010 | 0.027 | - | |

| J/cm3-K | 0 | 0 | 2.82 | 2.82 [52] | |

| nm | 0 | 0 | 157 | - | |

| 10−3 K2 | 39.2 | 2.23 | 3.01 |

| Parameter. | Units | (i) | (ii) | (iii) | Ref. Value |

|---|---|---|---|---|---|

| W/m-K | 0.20 ± 0.03 | 0.19 ± 0.03 | 0.17 ± 0.03 | 0.18–0.29 [66,67,68,69] | |

| J/cm3-K | 2.22 ± 0.05 | 1.85 ± 0.05 | 2.05 ± 0.05 | 2.19–2.29 [66,70] | |

| W/m-K | 256 | 142 | 5.03 × 104 | 145–156 [72,73] | |

| J/cm3-K | 1.87 | 1.82 | 1.91 | 1.66 [74] | |

| cm2-K/W | 0 | 0.012 | 0.025 | - | |

| J/cm3-K | 0 | 0 | 2.82 | 2.82 [52] | |

| nm | 0 | 0 | 157 | - | |

| 10−3 K2 | 143 | 1.30 | 11.7 |

Appendix C

Appendix D

| Abbreviations | Symbols | Symbols Units | ||

|---|---|---|---|---|

| BCB | benzocyclobutene | thermoelectric figure of merit | 1 | |

| MSE | mean squared error | Seebeck coefficient | V/K | |

| NW | nanowire | electrical conductivity | S/m | |

| SA | self-assisted | absolute temperature | K | |

| SAED | selective-area electron diffraction | total thermal conductivity | W/m-K | |

| SEM | scanning electron microscopy | electronic thermal conductivity | W/m-K | |

| TEM | transmission electron microscopy | lattice thermal conductivity | W/m-K | |

| TSL | twinning superlattice | electrical resistivity | Ω-m | |

| VLS | vapor–liquid–solid | measured temperature rise | K | |

| WZ | wurtzite | measured source current | A | |

| ZB | zincblende | heater line resistance coefficient | Ω/K | |

| measured in-phase voltage | V | |||

| measured out-of-phase voltage | V | |||

| frequency | Hz | |||

| corrected heater temperature rise | K | |||

| base heater temperature rise | K | |||

| heat flux | W/m2 | |||

| heater line thermal contact resistance | m2-K/W | |||

| heater line heat capacity | J/m3-K | |||

| heater line thickness | m | |||

| peak electrical power | W | |||

| heater line length | m | |||

| cross-plane thermal conductivity of layer n | W/m-K | |||

| heat capacity of layer n | J/m3-K | |||

| thickness of layer n | m | |||

| thermal conductivity anisotropy ratio of layer n | 1 | |||

| recursive coefficient Equation (5) | 1 | |||

| coefficient Equation (5) | m−1 | |||

| heater line half-width | m | |||

| integration variable Equation (5) | m−1 | |||

| mean squared error | K2 | |||

| sample parameters vector | - | |||

| measured NW-BCB thermal conductivity | W/m-K | |||

| measured NW array thermal conductivity | W/m-K | |||

| measured BCB thermal conductivity | W/m-K | |||

| NW volume fraction in sample A(B) | 1 | |||

| NW diameter in sample A(B) | m | |||

| NW array thermal conductivity in sample A(B) | W/m-K | |||

References

- Zebarjadi, M.; Esfarjani, K.; Dresselhaus, M.S.; Ren, Z.F.; Chen, G. Perspectives on Thermoelectrics: From Fundamentals to Device Applications. Energy Environ. Sci. 2012, 5, 5147–5162. [Google Scholar] [CrossRef] [Green Version]

- Vineis, C.J.; Shakouri, A.; Majumdar, A.; Kanatzidis, M.G. Nanostructured Thermoelectrics: Big Efficiency Gains from Small Features. Adv. Mater. 2010, 22, 3970–3980. [Google Scholar] [CrossRef]

- Rowe, D.M. CRC Handbook of Thermoelectrics; CRC Press: Boca Raton, FL, USA, 2018; ISBN 978-0-429-95667-6. [Google Scholar]

- Pichanusakorn, P.; Bandaru, P. Nanostructured Thermoelectrics. Mater. Sci. Eng. R Rep. 2010, 67, 19–63. [Google Scholar] [CrossRef]

- Hicks, L.D.; Dresselhaus, M.S. Thermoelectric Figure of Merit of a One-Dimensional Conductor. Phys. Rev. B 1993, 47, 16631–16634. [Google Scholar] [CrossRef]

- Hicks, L.D.; Dresselhaus, M.S. Effect of Quantum-Well Structures on the Thermoelectric Figure of Merit. Phys. Rev. B 1993, 47, 12727–12731. [Google Scholar] [CrossRef]

- Hochbaum, A.I.; Chen, R.; Delgado, R.D.; Liang, W.; Garnett, E.C.; Najarian, M.; Majumdar, A.; Yang, P. Enhanced Thermoelectric Performance of Rough Silicon Nanowires. Nature 2008, 451, 163–167. [Google Scholar] [CrossRef]

- Seol, J.H.; Moore, A.L.; Saha, S.K.; Zhou, F.; Shi, L.; Ye, Q.L.; Scheffler, R.; Mingo, N.; Yamada, T. Measurement and Analysis of Thermopower and Electrical Conductivity of an Indium Antimonide Nanowire from a Vapor-Liquid-Solid Method. J. Appl. Phys. 2007, 101, 023706. [Google Scholar] [CrossRef]

- Schmidt, V.; Mensch, P.F.J.; Karg, S.F.; Gotsmann, B.; Das Kanungo, P.; Schmid, H.; Riel, H. Using the Seebeck Coefficient to Determine Charge Carrier Concentration, Mobility, and Relaxation Time in InAs Nanowires. Appl. Phys. Lett. 2014, 104, 012113. [Google Scholar] [CrossRef]

- Hasan, N.; Wahid, H.; Nayan, N.; Ali, M.S.M. Inorganic Thermoelectric Materials: A Review. Int. J. Energy Res. 2020, 44, 6170–6222. [Google Scholar] [CrossRef]

- Zhou, F.; Moore, A.L.; Bolinsson, J.; Persson, A.; Fröberg, L.; Pettes, M.T.; Kong, H.; Rabenberg, L.; Caroff, P.; Stewart, D.A.; et al. Thermal Conductivity of Indium Arsenide Nanowires with Wurtzite and Zinc Blende Phases. Phys. Rev. B 2011, 83, 205416. [Google Scholar] [CrossRef] [Green Version]

- Ren, P.; Zhu, X.; Han, J.; Xu, J.; Ma, L.; Li, H.; Zhuang, X.; Zhou, H.; Zhang, Q.; Xia, M.; et al. Synthesis and Diameter-Dependent Thermal Conductivity of InAs Nanowires. Nano-Micro Lett. 2014, 6, 301–306. [Google Scholar] [CrossRef] [Green Version]

- Persson, A.I.; Koh, Y.K.; Cahill, D.G.; Samuelson, L.; Linke, H. Thermal Conductance of InAs Nanowire Composites. Nano Lett. 2009, 9, 4484–4488. [Google Scholar] [CrossRef] [PubMed]

- Swinkels, M.; van Delft, M.; Oliveira, D.; Cavalli, A.; Zardo, I.; van der Heijden, R.; Bakkers, E. Diameter Dependence of the Thermal Conductivity of InAs Nanowires. Nanotechnology 2015, 26, 385401. [Google Scholar] [CrossRef] [PubMed]

- Soini, M.; Zardo, I.; Uccelli, E.; Funk, S.; Koblmüller, G.; Abstreiter, G. Thermal Conductivity of GaAs Nanowires Studied by Micro-Raman Spectroscopy Combined with Laser Heating. Appl. Phys. Lett. 2010, 97, 263107. [Google Scholar] [CrossRef]

- Kim, H.; Park, Y.-H.; Kim, I.; Kim, J.; Choi, H.-J.; Kim, W. Effect of Surface Roughness on Thermal Conductivity of VLS-Grown Rough Si1−xGex Nanowires. Appl. Phys. A 2011, 104, 23–28. [Google Scholar] [CrossRef]

- Juntunen, T.; Koskinen, T.; Khayrudinov, V.; Haggren, T.; Jiang, H.; Lipsanen, H.; Tittonen, I. Thermal Conductivity Suppression in GaAs–AlAs Core–Shell Nanowire Arrays. Nanoscale 2019, 11, 20507–20513. [Google Scholar] [CrossRef] [Green Version]

- Holland, M.G. Analysis of Lattice Thermal Conductivity. Phys. Rev. 1963, 132, 2461–2471. [Google Scholar] [CrossRef]

- Carlson, R.O.; Slack, G.A.; Silverman, S.J. Thermal Conductivity of GaAs and GaAs1− xPx Laser Semiconductors. J. Appl. Phys. 1965, 36, 505–507. [Google Scholar] [CrossRef]

- Li, D.; Wu, Y.; Fan, R.; Yang, P.; Majumdar, A. Thermal Conductivity of Si/SiGe Superlattice Nanowires. Appl. Phys. Lett. 2003, 83, 3186–3188. [Google Scholar] [CrossRef] [Green Version]

- Li, D.; Wu, Y.; Kim, P.; Shi, L.; Yang, P.; Majumdar, A. Thermal Conductivity of Individual Silicon Nanowires. Appl. Phys. Lett. 2003, 83, 2934–2936. [Google Scholar] [CrossRef]

- Caroff, P.; Dick, K.A.; Johansson, J.; Messing, M.E.; Deppert, K.; Samuelson, L. Controlled Polytypic and Twin-Plane Superlattices in III–V Nanowires. Nat. Nanotechnol. 2009, 4, 50–55. [Google Scholar] [CrossRef] [PubMed]

- McIntyre, P.C.; Fontcuberta i Morral, A. Semiconductor Nanowires: To Grow or Not to Grow? Mater. Today Nano 2020, 9, 100058. [Google Scholar] [CrossRef]

- Burgess, T.; Breuer, S.; Caroff, P.; Wong-Leung, J.; Gao, Q.; Tan, H.H.; Jagadish, C. Twinning Superlattice Formation in GaAs Nanowires. ACS Nano 2013, 7, 8105–8114. [Google Scholar] [CrossRef] [PubMed]

- Panciera, F.; Baraissov, Z.; Patriarche, G.; Dubrovskii, V.G.; Glas, F.; Travers, L.; Mirsaidov, U.; Harmand, J.-C. Phase Selection in Self-Catalyzed GaAs Nanowires. Nano Lett. 2020, 20, 1669–1675. [Google Scholar] [CrossRef] [PubMed]

- Goktas, N.I.; Sokolovskii, A.; Dubrovskii, V.G.; LaPierre, R.R. Formation Mechanism of Twinning Superlattices in Doped GaAs Nanowires. Nano Lett. 2020, 20, 3344–3351. [Google Scholar] [CrossRef] [PubMed]

- Weathers, A.; Moore, A.L.; Pettes, M.T.; Salta, D.; Kim, J.; Dick, K.; Samuelson, L.; Linke, H.; Caroff, P.; Shi, L. Phonon Transport and Thermoelectricity in Defect-Engineered InAs Nanowires. In MRS Proceedings; Cambridge University Press: Cambridge, UK, 2012; Volume 1404. [Google Scholar] [CrossRef]

- Fedorov, V.V.; Dvoretckaia, L.N.; Kirilenko, D.A.; Mukhin, I.S.; Dubrovskii, V.G. Formation of Wurtzite Sections in Self-Catalyzed GaP Nanowires by Droplet Consumption. Nanotechnology 2021, 32, 495601. [Google Scholar] [CrossRef]

- Algra, R.E.; Verheijen, M.A.; Borgström, M.T.; Feiner, L.-F.; Immink, G.; van Enckevort, W.J.P.; Vlieg, E.; Bakkers, E.P.A.M. Twinning Superlattices in Indium Phosphide Nanowires. Nature 2008, 456, 369–372. [Google Scholar] [CrossRef] [Green Version]

- Yuan, X.; Guo, Y.; Caroff, P.; He, J.; Tan, H.H.; Jagadish, C. Dopant-Free Twinning Superlattice Formation in InSb and InP Nanowires. Phys. Status Solidi RRL 2017, 11, 1700310. [Google Scholar] [CrossRef]

- Karg, S.F. Full Thermoelectric Characterization of InAs Nanowires Using MEMS Heater/Sensors. Nanotechnology 2014, 25, 305702. [Google Scholar] [CrossRef]

- De Luca, M.; Fasolato, C.; Verheijen, M.A.; Ren, Y.; Swinkels, M.Y.; Kölling, S.; Bakkers, E.P.A.M.; Rurali, R.; Cartoixà, X.; Zardo, I. Phonon Engineering in Twinning Superlattice Nanowires. Nano Lett. 2019, 19, 4702–4711. [Google Scholar] [CrossRef] [Green Version]

- Hu, M.; Poulikakos, D. Si/Ge Superlattice Nanowires with Ultralow Thermal Conductivity. Nano Lett. 2012, 12, 5487–5494. [Google Scholar] [CrossRef] [PubMed]

- Porter, A.; Tran, C.; Sansoz, F. Intrinsic Nanotwin Effect on Thermal Boundary Conductance in Bulk and Single-Nanowire Twinning Superlattices. Phys. Rev. B 2016, 93, 195431. [Google Scholar] [CrossRef] [Green Version]

- Xiong, S.; Kosevich, Y.A.; Sääskilahti, K.; Ni, Y.; Volz, S. Tunable Thermal Conductivity in Silicon Twinning Superlattice Nanowires. Phys. Rev. B 2014, 90, 195439. [Google Scholar] [CrossRef]

- Venkatasubramanian, R. Lattice Thermal Conductivity Reduction and Phonon Localizationlike Behavior in Superlattice Structures. Phys. Rev. B 2000, 61, 3091–3097. [Google Scholar] [CrossRef]

- Elyamny, S.; Dimaggio, E.; Magagna, S.; Narducci, D.; Pennelli, G. High Power Thermoelectric Generator Based on Vertical Silicon Nanowires. Nano Lett. 2020, 20, 4748–4753. [Google Scholar] [CrossRef] [PubMed]

- Xu, B.; Khouri, W.; Fobelets, K. Two-Sided Silicon Nanowire Array/Bulk Thermoelectric Power Generator. IEEE Electron Device Lett. 2014, 35, 596–598. [Google Scholar] [CrossRef]

- Curtin, B.M.; Fang, E.W.; Bowers, J.E. Highly Ordered Vertical Silicon Nanowire Array Composite Thin Films for Thermoelectric Devices. J. Electron. Mater. 2012, 41, 887–894. [Google Scholar] [CrossRef]

- Li, Y.; Buddharaju, K.; Singh, N.; Lo, G.Q.; Lee, S.J. Chip-Level Thermoelectric Power Generators Based on High-Density Silicon Nanowire Array Prepared With Top-Down CMOS Technology. IEEE Electron Device Lett. 2011, 32, 674–676. [Google Scholar] [CrossRef]

- Keyani, J.; Stacy, A.M.; Sharp, J. Assembly and Measurement of a Hybrid Nanowire-Bulk Thermoelectric Device. Appl. Phys. Lett. 2006, 89, 233106. [Google Scholar] [CrossRef]

- Wang, W.; Jia, F.; Huang, Q.; Zhang, J. A New Type of Low Power Thermoelectric Micro-Generator Fabricated by Nanowire Array Thermoelectric Material. Microelectron. Eng. 2005, 77, 223–229. [Google Scholar] [CrossRef]

- Abramson, A.R.; Kim, W.C.; Huxtable, S.T.; Yan, H.; Wu, Y.; Majumdar, A.; Tien, C.-L.; Yang, P. Fabrication and Characterization of a Nanowire/Polymer-Based Nanocomposite for a Prototype Thermoelectric Device. J. Microelectromech. Syst. 2004, 13, 505–513. [Google Scholar] [CrossRef]

- Cahill, D.G. Thermal Conductivity Measurement from 30 to 750 K: The 3ω Method. Rev. Sci. Instrum. 1990, 61, 802–808. [Google Scholar] [CrossRef]

- Borca-Tasciuc, T.; Kumar, A.R.; Chen, G. Data Reduction in 3ω Method for Thin-Film Thermal Conductivity Determination. Rev. Sci. Instrum. 2001, 72, 2139–2147. [Google Scholar] [CrossRef]

- Paterson, J.; Singhal, D.; Tainoff, D.; Richard, J.; Bourgeois, O. Thermal Conductivity and Thermal Boundary Resistance of Amorphous Al2O3 Thin Films on Germanium and Sapphire. J. Appl. Phys. 2020, 127, 245105. [Google Scholar] [CrossRef]

- Singhal, D.; Paterson, J.; Ben-Khedim, M.; Tainoff, D.; Cagnon, L.; Richard, J.; Chavez-Angel, E.; Fernandez, J.J.; Sotomayor-Torres, C.M.; Lacroix, D.; et al. Nanowire Forest of Pnictogen–Chalcogenide Alloys for Thermoelectricity. Nanoscale 2019, 11, 13423–13430. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Singhal, D.; Paterson, J.; Tainoff, D.; Richard, J.; Ben-Khedim, M.; Gentile, P.; Cagnon, L.; Bourgault, D.; Buttard, D.; Bourgeois, O. Measurement of Anisotropic Thermal Conductivity of a Dense Forest of Nanowires Using the 3ω Method. Rev. Sci. Instrum. 2018, 89, 084902. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Goktas, N.I.; Wilson, P.; Ghukasyan, A.; Wagner, D.; McNamee, S.; LaPierre, R.R. Nanowires for Energy: A Review. Appl. Phys. Rev. 2018, 5, 041205. [Google Scholar] [CrossRef]

- Dames, C. Measuring the Thermal Conductivity of Thin Films: 3 Omega and Related Electrothermal Methods. Annu. Rev. Heat Transf. 2013, 16, 43. [Google Scholar] [CrossRef]

- Dames, C.; Chen, G. 1ω, 2ω, and 3ω Methods for Measurements of Thermal Properties. Rev. Sci. Instrum. 2005, 76, 124902. [Google Scholar] [CrossRef]

- Cardarelli, F. Materials Handbook: A Concise Desktop Reference; Springer International Publishing: Cham, Switzerland, 2018; ISBN 978-3-319-38923-3. [Google Scholar]

- Lide, D.R.; Baysinger, G.; Chemistry, S.; Berger, L.I.; Goldberg, R.N.; Kehiaian, H.V. CRC Handbook of Chemistry and Physics; CRC Press: Boca Raton, FL, USA, 2004; p. 2661. ISBN 0-8493-0485-7. [Google Scholar]

- Blakemore, J.S. Semiconducting and Other Major Properties of Gallium Arsenide. J. Appl. Phys. 1982, 53, R123–R181. [Google Scholar] [CrossRef]

- Mingo, N.; Broido, D.A. Lattice Thermal Conductivity Crossovers in Semiconductor Nanowires. Phys. Rev. Lett. 2004, 93, 246106. [Google Scholar] [CrossRef] [PubMed]

- Martin, P.N.; Aksamija, Z.; Pop, E.; Ravaioli, U. Reduced Thermal Conductivity in Nanoengineered Rough Ge and GaAs Nanowires. Nano Lett. 2010, 10, 1120–1124. [Google Scholar] [CrossRef] [PubMed]

- Olson, B.W.; Graham, S.; Chen, K. A Practical Extension of the 3ω Method to Multilayer Structures. Rev. Sci. Instrum. 2005, 76, 053901. [Google Scholar] [CrossRef]

- Venkatasubramanian, R.; Siivola, E.; Colpitts, T.; O’Quinn, B. Thin-Film Thermoelectric Devices with High Room-Temperature Figures of Merit. Nature 2001, 413, 597–602. [Google Scholar] [CrossRef]

- Sheng, P. Introduction to Wave Scattering, Localization, and Mesoscopic Phenomena, 2nd ed.; Springer Series in Materials Science; Springer: Berlin/Heidelberg, Germany; New York, NY, USA, 2006; ISBN 978-3-540-29155-8. [Google Scholar]

- Tian, Z.; Esfarjani, K.; Chen, G. Green’s Function Studies of Phonon Transport across Si/Ge Superlattices. Phys. Rev. B 2014, 89, 235307. [Google Scholar] [CrossRef] [Green Version]

- Mu, X. Ultra-Low Thermal Conductivity in Si/Ge Hierarchical Superlattice Nanowire. Sci. Rep. 2015, 5, 16697. [Google Scholar] [CrossRef] [Green Version]

- Choi, S.B.; Song, M.S.; Kim, Y. Zn3P2 Twinning Superlattice Nanowires Grown on Fluorine-Doped Tin Oxide Glass Substrates. J. Phys. Chem. C 2019, 123, 4597–4604. [Google Scholar] [CrossRef]

- Wilson, D.P.; Dubrovskii, V.G.; LaPierre, R.R. Improving the Yield of GaAs Nanowires on Silicon by Ga Pre-Deposition. Nanotechnology 2021, 32, 265301. [Google Scholar] [CrossRef] [PubMed]

- Goktas, N.I.; Fiordaliso, E.M.; LaPierre, R.R. Doping Assessment in GaAs Nanowires. Nanotechnology 2018, 29, 234001. [Google Scholar] [CrossRef]

- Dubrovskii, V.G.; Hijazi, H.; Goktas, N.I.; LaPierre, R.R. Be, Te, and Si Doping of GaAs Nanowires: Theory and Experiment. J. Phys. Chem. C 2020, 124, 17299–17307. [Google Scholar] [CrossRef]

- Pinel, S.; Marty, A.; Tasselli, J.; Bailbe, J.-P.; Beyne, E.; Van Hoof, R.; Marco, S.; Morante, J.R.; Vendier, O.; Huan, M. Thermal Modeling and Management in Ultrathin Chip Stack Technology. IEEE Trans. Comp. Packag. Technol. 2002, 25, 244–253. [Google Scholar] [CrossRef]

- Gracias, A.; Tokranova, N.; Thelen, B.C.M.; Castracane, J. Influence of Diamond Nanoparticles on the Thermal Properties of Benzocyclobutene (BCB). Phys. Status Solidi A 2011, 208, 684–690. [Google Scholar] [CrossRef]

- Moghaddam, S.; Kiger, K.T.; Modafe, A.; Ghodssi, R. A Novel Benzocyclobutene-Based Device for Studying the Dynamics of Heat Transfer during the Nucleation Process. J. Microelectromech. Syst. 2007, 16, 1355–1366. [Google Scholar] [CrossRef]

- Yang, J. Processing Procedures for CYCLOTENE 3000 Series Dry Etch Resins; DOW Chemical Co.: Midland, MI, USA, 2005. [Google Scholar]

- Modafe, A.; Ghalichechian, N.; Powers, M.; Khbeis, M.; Ghodssi, R. Embedded Benzocyclobutene in Silicon: An Integrated Fabrication Process for Electrical and Thermal Isolation in MEMS. Microelectron. Eng. 2005, 82, 154–167. [Google Scholar] [CrossRef]

- Slack, G.A. Thermal Conductivity of Pure and Impure Silicon, Silicon Carbide, and Diamond. J. Appl. Phys. 1964, 35, 3460–3466. [Google Scholar] [CrossRef]

- Maycock, P.D. Thermal Conductivity of Silicon, Germanium, III-V Compounds and III-V Alloys. Solid-State Electron. 1967, 10, 161–168. [Google Scholar] [CrossRef]

- Glassbrenner, C.J.; Slack, G.A. Thermal Conductivity of Silicon and Germanium from 3°K to the Melting Point. Phys. Rev. 1964, 134, A1058–A1069. [Google Scholar] [CrossRef]

- Flubacher, P.; Leadbetter, A.J.; Morrison, J.A. The Heat Capacity of Pure Silicon and Germanium and Properties of Their Vibrational Frequency Spectra. Philos. Mag. 1959, 4, 273–294. [Google Scholar] [CrossRef]

- Childs, G.E.; Ericks, L.J.; Powell, R.L. Thermal Conductivity of Solids at Room Temperature and Below: A Review and Compilation of the Literature; National Bureau of Standards: Boulder, CO, USA, 1973.

- Piesbergen, U. Die Durchschnittlichen Atomwärmen der AIIIBv-Halbleiter AlSb, GaAs, GaSb, InP, InAs, LnSb und die Atomwärme des Elements Germanium Zwischen 12 und 273°K. Z. Naturforsch. A 1963, 18, 141–147. [Google Scholar] [CrossRef] [Green Version]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ghukasyan, A.; Oliveira, P.; Goktas, N.I.; LaPierre, R. Thermal Conductivity of GaAs Nanowire Arrays Measured by the 3ω Method. Nanomaterials 2022, 12, 1288. https://doi.org/10.3390/nano12081288

Ghukasyan A, Oliveira P, Goktas NI, LaPierre R. Thermal Conductivity of GaAs Nanowire Arrays Measured by the 3ω Method. Nanomaterials. 2022; 12(8):1288. https://doi.org/10.3390/nano12081288

Chicago/Turabian StyleGhukasyan, Ara, Pedro Oliveira, Nebile Isik Goktas, and Ray LaPierre. 2022. "Thermal Conductivity of GaAs Nanowire Arrays Measured by the 3ω Method" Nanomaterials 12, no. 8: 1288. https://doi.org/10.3390/nano12081288