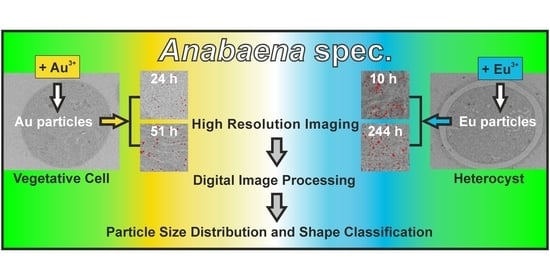

Time-Dependent Size and Shape Evolution of Gold and Europium Nanoparticles from a Bioproducing Microorganism, a Cyanobacterium: A Digitally Supported High-Resolution Image Analysis

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

3.1. Exemplary TEM Images with Nanoparticles

3.2. Particle Size Distributions (PSDs)

3.2.1. PSDs of all NPs in Complete Cells

3.2.2. High-Resolution (HR)-PSD of Cell Sections

3.2.3. Local PSDs within an Exemplary Cell

3.3. Shape Classification

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Ghosh, S.; Ahmad, R.; Banerjee, K.; AlAjmi, M.F.; Rahman, S. Mechanistic Aspects of Microbe-Mediated Nanoparticle Synthesis. Front. Microbiol. 2021, 12, 1–12. [Google Scholar] [CrossRef] [PubMed]

- Xie, J.; Ping, H.; Tan, T.; Lei, L.; Xie, H.; Yang, X.Y.; Fu, Z. Bioprocess-inspired fabrication of materials with new structures and functions. Prog. Mater. Sci. 2019, 105, 100571. [Google Scholar] [CrossRef]

- Kratochvil, D.; Volesky, B. Advances in the biosorption of heavy metals. Trends Biotechnol. 1998, 16, 291–300. [Google Scholar] [CrossRef]

- Vieira, R.H.S.F.; Volesky, B. Biosorption: A solution to pollution? Int. Microbiol. 2000, 3, 17–24. [Google Scholar] [CrossRef] [PubMed]

- Cadogan, E.I.; Lee, C.H.; Popuri, S.R.; Lin, H.Y. Efficiencies of chitosan nanoparticles and crab shell particles in europium uptake from aqueous solutions through biosorption: Synthesis and characterization. Int. Biodeterior. Biodegrad. 2014, 95, 232–240. [Google Scholar] [CrossRef]

- Gwenzi, W.; Makuvara, Z.; Marumure, J. Rare earth elements: Human exposure, risk factors, and health risks (Chapter 15). In Emerging Contaminants in the Terrestrial-Aquatic-Atmosphere Continuum. Occurrence, Health Risks, and Mitigation; Gwenzi, W., Ed.; Elsevier: Amsterdam, The Netherlands, 2022; pp. 273–290. [Google Scholar]

- Jally, B.; Laubie, B.; Tang, Y.-T.; Simonnot, M.-O. Processing of Plants to Products: Gold, REEs and Other Elements. In Agromining: Farming for Metals: Extracting Unconventional Resources Using Plants, 2nd ed.; van der Ent, A., Baker, A.J.M., Echevarria, G., Simonnot, M.-O., Morel, J.L., Eds.; Springer International Publishing: Cham, Switzerland, 2021; pp. 63–74. [Google Scholar] [CrossRef]

- Maleke, M.; Valverde, A.; Gomez-Arias, A.; Cason, E.D.; Vermeulen, J.G.; Coetsee-Hugo, L.; Swart, H.; van Heerden, E.; Castillo, J. Anaerobic reduction of europium by a Clostridium strain as a strategy for rare earth biorecovery. Sci. Rep. 2019, 9, 14339. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Srivastava, R.R.; Ilyas, S.; Kim, H.; Choi, S.; Trinh, H.B.; Ghauri, M.A.; Ilyas, N. Biotechnological recycling of critical metals from waste printed circuit boards. J. Chem. Technol. Biotechnol. 2020, 95, 2796–2810. [Google Scholar] [CrossRef]

- Forti, V.; Baldé, C.P.; Kuehr, R.; Bel, G. Surge in Global E-Waste, up 21 Per Cent in 5 Years. The Global E-waste Monitor 2020. 2020. Available online: https://api.globalewaste.org/publications/file/271/The-Global-E-waste-Monitor-2020-Quantities-flows-and-the-circular-economy-potential.zip (accessed on 1 December 2022).

- Kammerlander, K.K.K.; Köhler, L.; Huittinen, N.; Bok, F.; Steudtner, R.; Oschatz, C.; Vogel, M.; Stumpf, T.; Brunner, E. Sorption of europium on diatom biosilica as model of a “green” sorbent for f-elements. Appl. Geochem. 2021, 126, 104823. [Google Scholar] [CrossRef]

- Cadogan, E.I.; Lee, C.H.; Popuri, S.R. Facile synthesis of chitosan derivatives and Arthrobacter sp. biomass for the removal of europium(III) ions from aqueous solution through biosorption. Int. Biodeterior. Biodegrad. 2015, 102, 286–297. [Google Scholar] [CrossRef]

- Serna, D.D.; Ortiz, M.; Rayson, G.D. Spectroscopic Comparison of Eu(III) Binding to Various Biosorbents. Sep. Sci. Technol. 2014, 49, 209–213. [Google Scholar] [CrossRef]

- Kim, E.B.; Seo, J.M.; Kim, G.W.; Lee, S.Y.; Park, T.J. In vivo synthesis of europium selenide nanoparticles and related cytotoxicity evaluation of human cells. Enzyme Microb. Technol. 2016, 95, 201–208. [Google Scholar] [CrossRef] [PubMed]

- Rösken, L.M.; Cappel, F.; Körsten, S.; Fischer, C.B.; Schönleber, A.; van Smaalen, S.; Geimer, S.; Beresko, C.; Ankerhold, G.; Wehner, S. Time-dependent growth of crystalline Au0-nanoparticles in cyanobacteria as self-reproducing bioreactors: 2. Anabaena cylindrical. Beilstein J. Nanotechnol. 2016, 7, 312–327. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Rösken, L.M.; Körsten, S.; Fischer, C.B.; Schönleber, A.; van Smaalen, S.; Geimer, S.; Wehner, S. Time-dependent growth of crystalline Au0-nanoparticles in cyanobacteria as self-reproducing bioreactors: 1. Anabaena sp. J. Nanopart. Res. 2014, 16, 12–27. [Google Scholar] [CrossRef]

- Naveed, S.; Li, C.; Lu, X.; Chen, S.; Yin, B. Technology Microalgal extracellular polymeric substances and their interactions with metalloids: A review. Crit. Rev. Environ. Sci. Technol. 2019, 49, 1769–1802. [Google Scholar] [CrossRef]

- Dahoumane, S.A.; Yéprémian, C.; Djédiat, C.; Couté, A.; Fiévet, F.; Coradin, T.; Brayner, R. A global approach of the mechanism involved in the biosynthesis of gold colloids using micro-algae. J. Nanopart. Res. 2014, 16, 2607. [Google Scholar] [CrossRef]

- Lenartowicz, M.; Marek, P.H.; Madura, I.D.; Lipok, J. Formation of Variously Shaped Gold Nanoparticles by Anabaena laxa. J. Clust. Sci. 2017, 28, 3035–3055. [Google Scholar] [CrossRef] [Green Version]

- Khanna, P.; Kaur, A.; Goyal, D. Algae-based metallic nanoparticles: Synthesis, characterization and applications. J. Microbiol. Methods. 2019, 163, 105656. [Google Scholar] [CrossRef] [PubMed]

- Dahoumane, S.A.; Yéprémian, C.; Djédiat, C.; Couté, A.; Fiévet, F.; Coradin, T.; Brayner, R. Improvement of kinetics, yield, and colloidal stability of biogenic gold nanoparticles using living cells of Euglena gracilis microalga. J. Nanopart. Res. 2016, 18, 79. [Google Scholar] [CrossRef] [Green Version]

- Castro, L.; Blázquez, M.L.; González, F.; Muñoz, J.Á.; Ballester, A. Exploring the possibilities of biological fabrication of gold nanostructures using orange peel extract. Metals 2015, 5, 1609–1619. [Google Scholar] [CrossRef]

- Ramrakhiani, L.; Ghosh, S. Metallic nanoparticle synthesised by biological route: Safer candidate for diverse applications. IET Nanobiotechnol. 2018, 12, 392–404. [Google Scholar] [CrossRef]

- Jana, S. Advances in nanoscale alloys and intermetallics: Low temperature solution chemistry synthesis and application in catalysis. Dalt. Trans. 2015, 44, 18692–18717. [Google Scholar] [CrossRef] [PubMed]

- Vetchinkina, E.; Loshchinina, E.; Kupryashina, M.; Burov, A.; Nikitina, V. Shape and Size Diversity of Gold, Silver, Selenium, and Silica Nanoparticles Prepared by Green Synthesis Using Fungi and Bacteria. Ind. Eng. Chem. Res. 2019, 58, 17207–17218. [Google Scholar] [CrossRef]

- Klekotko, M.; Brach, K.; Olesiak-Banska, J.; Samoc, M.; Matczyszyn, K. Popcorn-shaped gold nanoparticles: Plant extract-mediated synthesis, characterization and multiphoton-excited luminescence properties. Mater. Chem. Phys. 2019, 229, 56–60. [Google Scholar] [CrossRef]

- Anastopoulos, I.; Bhatnagar, A.; Lima, E.C. Adsorption of rare earth metals: A review of recent literature. J. Mol. Liq. 2016, 221, 954–962. [Google Scholar] [CrossRef]

- Dahoumane, S.A.; Wujcik, E.K.; Jeffryes, C. Noble metal, oxide and chalcogenide-based nanomaterials from scalable phototrophic culture systems. Enzyme Microb. Technol. 2016, 95, 13–27. [Google Scholar] [CrossRef]

- Rochert, A.S.; Rösken, L.M.; Fischer, C.B.; Schönleber, A.; Ecker, D.; van Smaalen, S.; Geimer, S.; Wehner, S. Bioselective synthesis of gold nanoparticles from diluted mixed Au, Ir, and Rh ion solution by Anabaena cylindrica. J. Nanopart. Res. 2017, 19, 355. [Google Scholar] [CrossRef]

- Fischer, C.B.; Körsten, S.; Rösken, L.M.; Cappel, F.; Beresko, C.; Ankerhold, G.; Schönleber, A.; Geimer, S.; Ecker, D.; Wehner, S. Cyanobacterial promoted enrichment of rare earth elements europium, samarium and neodymium and intracellular europium particle formation. RSC Adv. 2019, 9, 32581–32593. [Google Scholar] [CrossRef] [Green Version]

- Brayner, R.; Claude, Y.; Djediat, C.; Coradin, T.; Livage, J.; Fi, F.; Cout, A. Photosynthetic Microorganism-Mediated Synthesis of Akaganeite (β -FeOOH) Nanorods. Langmuir 2009, 25, 10062–10067. [Google Scholar] [CrossRef]

- Nicolaisen, K.; Hahn, A.; Valdebenito, M.; Moslavac, S.; Samborski, A.; Maldener, I.; Wilken, C.; Valladares, A.; Flores, E.; Hantke, K.; et al. The interplay between siderophore secretion and coupled iron and copper transport in the heterocyst-forming cyanobacterium Anabaena sp. PCC 7120. Biochim. Biophys. Acta-Biomembr. 2010, 1798, 2131–2140. [Google Scholar] [CrossRef]

- Dahoumane, S.A.; Mechouet, M.; Wijesekera, K.; Filipe, C.D.M.; Sicard, C.; Bazylinski, D.A.; Jeffryes, C. Algae-mediated biosynthesis of inorganic nanomaterials as a promising route in nanobiotechnology-a review. Green Chem. 2017, 19, 552–587. [Google Scholar] [CrossRef]

- Henriques, B.; Morais, T.; Cardoso, C.E.D.; Freitas, R.; Viana, T.; Ferreira, N.; Fabre, E.; Pinheiro-Torres, J.; Pereira, E. Can the recycling of europium from contaminated waters be achieved through living macroalgae? Study on accumulation and toxicological impacts under realistic concentrations. Sci. Total Environ. 2021, 786, 147176. [Google Scholar] [CrossRef] [PubMed]

- Reynolds, E.S. The use of lead citrate at high pH as an electron-opaque stain in electron microscopy. J. Cell Biol. 1963, 17, 208–212. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Igathinathane, C.; Pordesimo, L.O.; Columbus, E.P.; Batchelor, W.D.; Methuku, S.R. Shape identification and particles size distribution from basic shape parameters using ImageJ. Comput. Electron. Agric. 2008, 63, 168–182. [Google Scholar] [CrossRef]

- Fritz, M.; Körsten, S.; Chen, X.; Yang, G.; Lv, Y.; Liu, M.; Wehner, S.; Fischer, C.B. High-resolution particle size and shape analysis of the first Samarium nanoparticles biosynthesized from aqueous solutions via cyanobacteria Anabaena cylindrical. NanoImpact 2022, 26, 100398. [Google Scholar] [CrossRef]

- Saravanan, A.; Kumar, P.S.; Karishma, S.; Vo, D.-V.N.; Jeevanantham, S.; Yaashikaa, P.R.; George, C.S. A review on biosynthesis of metal nanoparticles and its environmental applications. Chemosphere 2021, 264, 128580. [Google Scholar] [CrossRef]

- Chaudhary, R.; Nawaz, K.; Khan, A.K.; Hano, C.; Abbasi, B.H.; Anjum, S. An overview of the algae-mediated biosynthesis of nanoparticles and their biomedical applications. Biomolecules 2020, 10, 1498. [Google Scholar] [CrossRef]

- Koul, B.; Poonia, A.K.; Yadav, D.; Jin, J.O. Microbe-mediated biosynthesis of nanoparticles: Applications and future prospects. Biomolecules 2021, 11, 886. [Google Scholar] [CrossRef]

- Roychoudhury, P.; Bhattacharya, A.; Dasgupta, A.; Pal, R. Biogenic synthesis of gold nanoparticle using fractioned cellular components from eukaryotic algae and cyanobacteria. Phycol. Res. 2016, 64, 133–140. [Google Scholar] [CrossRef]

- Chakraborty, N.; Banerjee, A.; Lahiri, S.; Panda, A.; Gosh, A.N.; Pal, R. Biorecovery of gold using cyanobacteria and an eukaryotic alga with special reference to nanogold formation—A novel phenomenon. J. Appl. Phycol. 2009, 21, 145–152. [Google Scholar] [CrossRef]

- Atalah, J.; Espina, G.; Blamey, L.; Muñoz-Ibacache, S.A.; Blamey, J.M. Advantages of using extremophilic bacteria for the biosynthesis of metallic nanoparticles and its potential for rare earth element recovery. Front. Microbiol. 2022, 13, 1–6. [Google Scholar] [CrossRef]

| Ion Contact Time | Cell No. | Zoom | Range [px] | Scale Ratio [px/µm] | Threshold [%] | Counts |

|---|---|---|---|---|---|---|

| Au—24 h | 1 | ×8.0 k | 5–500 | 736 | 0.2 | 178 |

| 2 | ×8.0 k | 10–inf | 732 | 0.2 | 30 | |

| 3 | ×15.0 k | 10–inf | 1374 | 0.2 | 194 | |

| 4 | ×10.0 k | 10–300 | 917 | 0.2 | 371 | |

| Au—51 h | 5 | ×8.0 k | 5–inf | 734 | 0.4 | 552 |

| 6 | ×7.0 k | 10–1000 | 639 | 0.5 | 507 | |

| Eu—10 h | 7 | ×7.0 k | 15–500 | 643 | 1.4 | 416 |

| Eu—244 h | 8 | ×5.0 k | 5–100 | 458 | 0.5 | 742 |

| 9 | ×7.0 k | 20–400 | 639 | 1.3 | 258 | |

| 10 | ×6.0 k | 40–300 | 496 | 1.4 | 220 |

| Class | Very Angular | Angular | Sub- Angular | Sub-Rounded | Rounded | Very Rounded |

|---|---|---|---|---|---|---|

| RAR value | 0.12–0.17 | 0.17–0.25 | 0.25–0.35 | 0.35–0.49 | 0.49–0.70 | 0.70–1.00 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fritz, M.; Körsten, S.; Chen, X.; Yang, G.; Lv, Y.; Liu, M.; Wehner, S.; Fischer, C.B. Time-Dependent Size and Shape Evolution of Gold and Europium Nanoparticles from a Bioproducing Microorganism, a Cyanobacterium: A Digitally Supported High-Resolution Image Analysis. Nanomaterials 2023, 13, 130. https://doi.org/10.3390/nano13010130

Fritz M, Körsten S, Chen X, Yang G, Lv Y, Liu M, Wehner S, Fischer CB. Time-Dependent Size and Shape Evolution of Gold and Europium Nanoparticles from a Bioproducing Microorganism, a Cyanobacterium: A Digitally Supported High-Resolution Image Analysis. Nanomaterials. 2023; 13(1):130. https://doi.org/10.3390/nano13010130

Chicago/Turabian StyleFritz, Melanie, Susanne Körsten, Xiaochen Chen, Guifang Yang, Yuancai Lv, Minghua Liu, Stefan Wehner, and Christian B. Fischer. 2023. "Time-Dependent Size and Shape Evolution of Gold and Europium Nanoparticles from a Bioproducing Microorganism, a Cyanobacterium: A Digitally Supported High-Resolution Image Analysis" Nanomaterials 13, no. 1: 130. https://doi.org/10.3390/nano13010130