Low-Temperature Fluoro-Borosilicate Glass for Controllable Nano-Crystallization in Glass Ceramic Fibers

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials Preparation

2.2. Characterizations

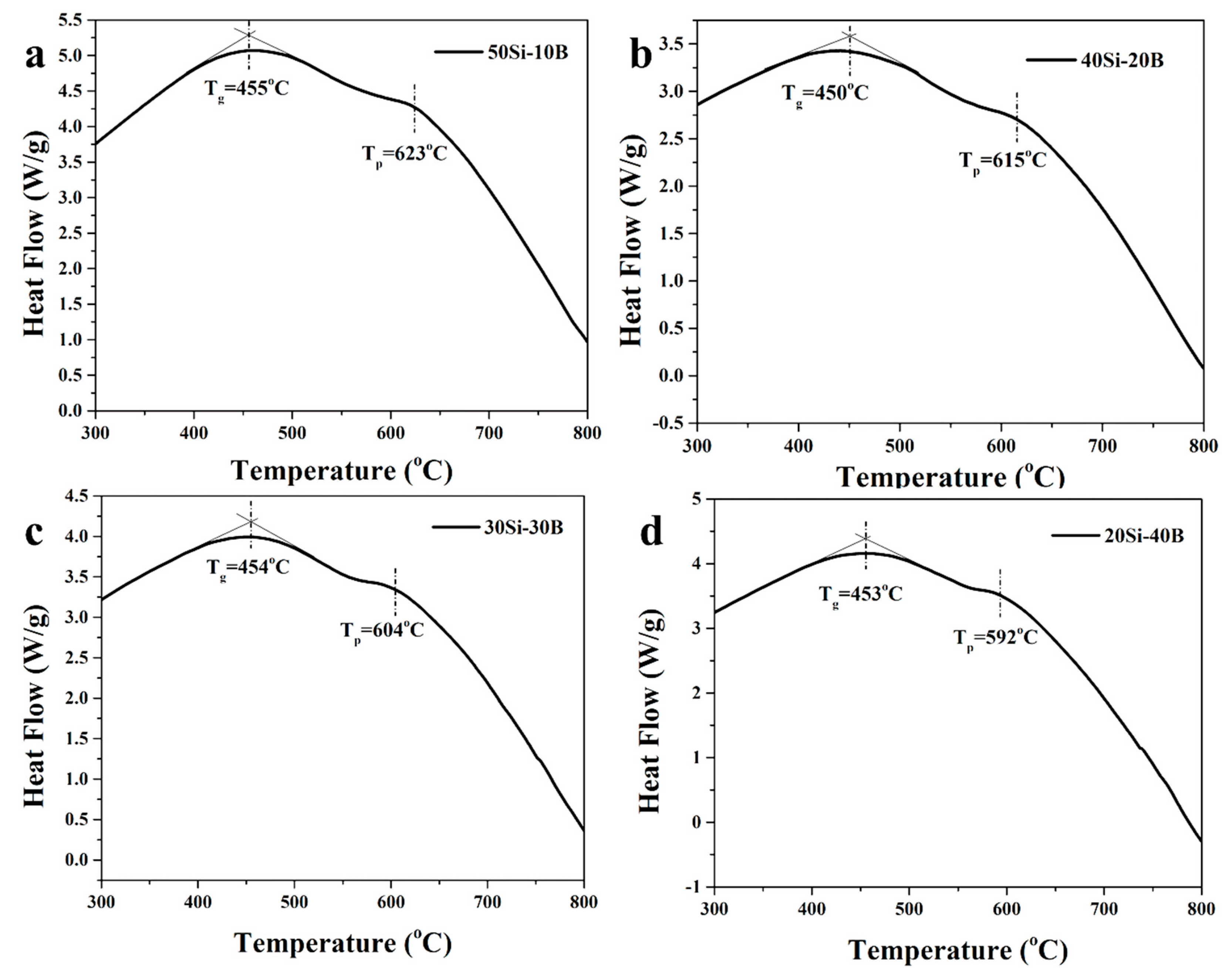

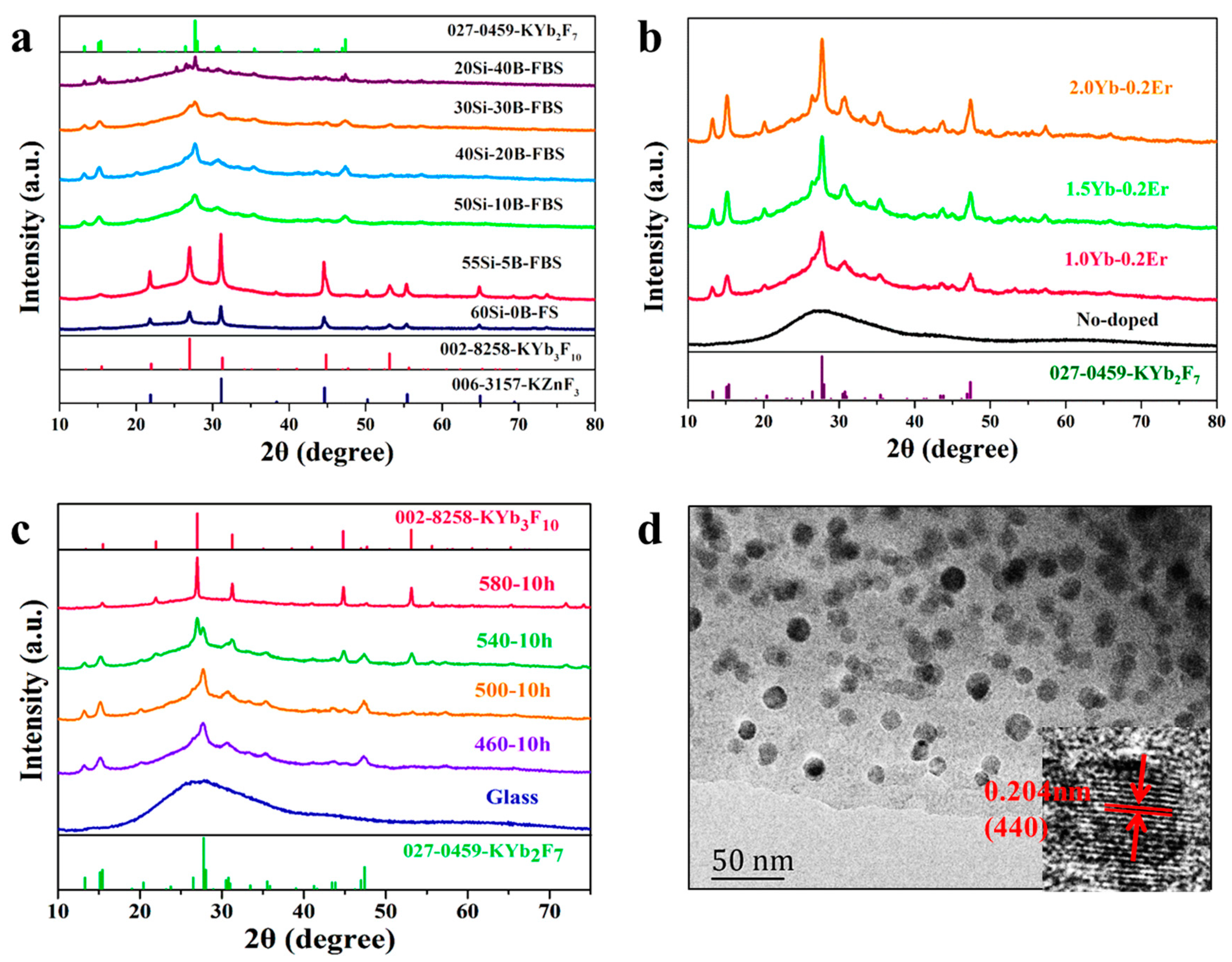

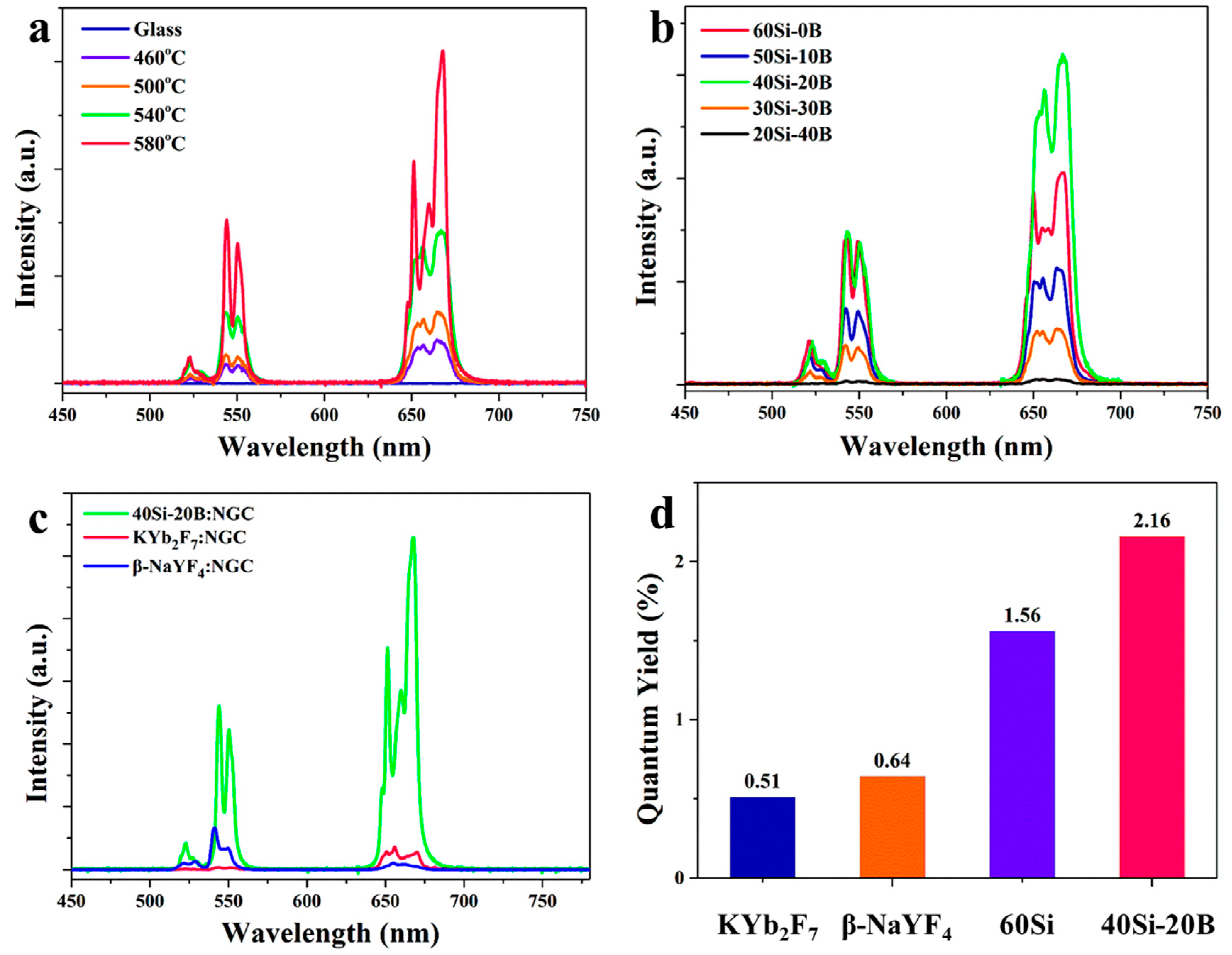

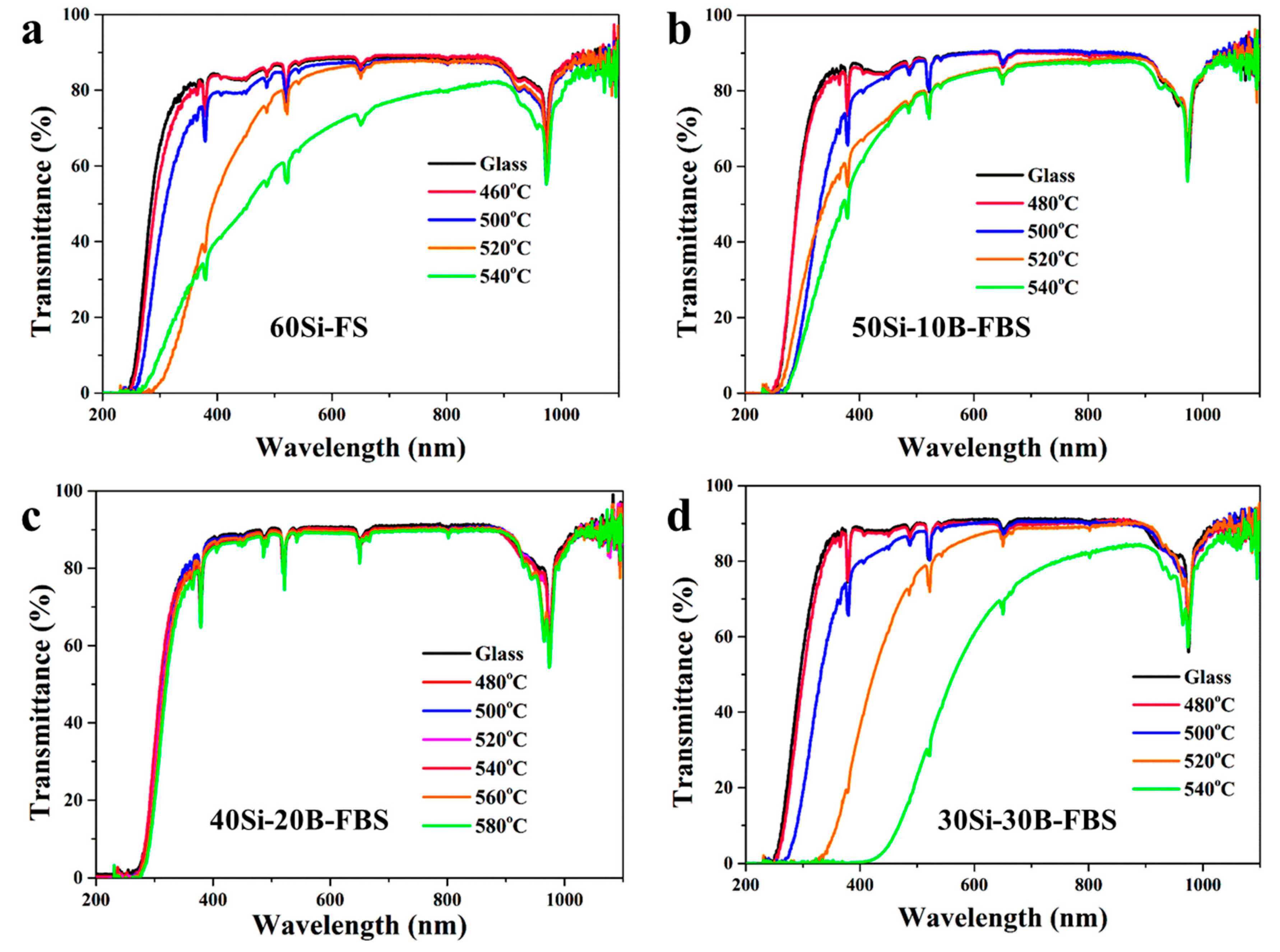

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Jackson, S.D. Towards high-power mid-infrared emission from a fibre laser. Nat. Photonics. 2012, 6, 423–431. [Google Scholar] [CrossRef]

- Jauregui, C.; Limpert, J.; Tünnermann, A. High-power fibre lasers. Nat. Photon. 2013, 7, 861–867. [Google Scholar] [CrossRef]

- Yu, Y.; Fang, Z.; Ma, C.; Inoue, H.; Yang, G.; Zheng, S.; Chen, D.; Yang, Z.; Masuno, A.; Orava, J.; et al. Mesoscale engineering of photonic glass for tunable luminescence. NPG Asia Mater. 2016, 8, e318. [Google Scholar] [CrossRef]

- Fang, Z.; Peng, W.; Zheng, S.; Qiu, J.; Guan, B.-O. Controllable modulation of coordination environments of Mn2+ in glasses and glass-ceramics for tunable luminescence. J. Eur. Ceram. Soc. 2020, 40, 1658–1664. [Google Scholar] [CrossRef]

- Liu, X.; Zhou, J.; Zhou, S.; Yue, Y.; Qiu, J. Transparent glass-ceramics functionalized by dispersed crystals. Prog. Mater. Sci. 2018, 97, 38–96. [Google Scholar] [CrossRef]

- Xu, X.; Zhang, W.; Yang, D.; Lu, W.; Qiu, J.; Yu, S.F. Phonon-assisted population inversion in lanthanide-doped upconversion Ba2LaF7 nanocrystals in glass-ceramics. Adv. Mater. 2016, 28, 8045–8050. [Google Scholar] [CrossRef]

- Wang, S.; Lin, J.; He, Y.; Chen, J.; Yang, C.; Huang, F.; Chen, D. Remarkable laser-driven upconverting photothermal effect of Cs3LnF6@ glass nanocomposites for anti-counterfeiting. Chem. Eng. J. 2020, 394, 124889. [Google Scholar] [CrossRef]

- Wu, G.; Fan, S.; Zhang, Y.; Chai, G.; Ma, Z.; Peng, M.; Qiu, J.; Dong, G. 2.7 μm emission in Er3+:CaF2 nanocrystals embedded oxyfluoride glass ceramics. Opt. Lett. 2013, 38, 3071–3074. [Google Scholar] [CrossRef]

- Kang, S.; Huang, Z.; Lin, W.; Yang, D.; Zhao, J.; Qiao, X.; Xiao, X.; Xu, S.; Qiu, J.; Du, J.; et al. Enhanced single-mode fiber laser emission by nano-crystallization of oxyfluoride glass-ceramic cores. J. Mater. Chem. C 2019, 7, 5155–5162. [Google Scholar] [CrossRef]

- Fang, Z.; Li, J.; Sun, L.-P.; Zhi, Y.; Long, Y.; Zheng, S.; Chen, Z.; Qiu, J.; Guan, B.-O. In situ dopant-induced nano-crystallization of rare-earth-fluoride crystals in phase-separated networks for highly-efficient photoemission and photonic devices. J. Mater. Chem. C 2021, 9, 9001–9010. [Google Scholar] [CrossRef]

- Chen, D.; Peng, Y.; Li, X.; Zhong, J.; Huang, H.; Chen, J. Simultaneous tailoring of dual-phase fluoride precipitation and dopant distribution in glass to control upconverting luminescence. ACS Appl. Mater. Interfaces 2019, 11, 30053–30064. [Google Scholar] [CrossRef] [PubMed]

- Wang, S.; Chen, J.; Lin, J.; Yang, C.; Huang, F.; Chen, D. Nanocrystallization of lanthanide-doped KLu2F7-KYb2F7 solid-solutions in aluminosilicate glass for upconverted solid-state-lighting and photothermal anti-counterfeiting. J. Mater. Chem. C 2019, 7, 14571. [Google Scholar] [CrossRef]

- Ali, M.A.; Ren, J.; Liu, X.; Qiao, X.; Qiu, J. Understanding enhanced upconversion luminescence in oxyfluoride glass-ceramics based on local structure characterizations and molecular dynamics simulations. J. Phys. Chem. C 2017, 121, 15384–15391. [Google Scholar] [CrossRef]

- Chen, Z.; Wang, W.; Kang, S.; Cui, W.; Zhang, H.; Yu, G.; Wang, T.; Dong, G.; Jiang, C.; Zhou, S.; et al. Tailorable upconversion white light emission from Pr3+ single-doped glass ceramics via simultaneous dual-lasers excitation. Adv. Opt. Mater. 2018, 6, 1700787. [Google Scholar] [CrossRef]

- Gao, Z.; Guo, S.; Lu, X.; Orava, J.; Wagner, T.; Zheng, L.; Liu, Y.; Sun, S.; He, F.; Yang, P.; et al. Controlling selective doping and energy transfer between transition metal and rare earth ions in nanostructured glassy solids. Adv. Opt. Mater. 2018, 6, 1701407. [Google Scholar] [CrossRef]

- Chen, Z.; Cui, W.; Kang, S.; Zhang, H.; Dong, G.; Jiang, C.; Zhou, S.; Qiu, J. Fast-slow red upconversion fluorescence modulation from Ho3+-doped glass ceramics upon two-wavelength excitation. Adv. Opt. Mater. 2017, 5, 1600554. [Google Scholar] [CrossRef]

- Fang, Z.; Li, J.; Long, Y.; Guan, B.-O. High-efficiency luminescence in optical glass via the controllable crystallization of KYb3F10 nanocrystals depending on the dopants. Opt. Lett. 2020, 45, 3030–3033. [Google Scholar] [CrossRef]

- Long, Y.; Li, J.; Fang, Z.; Guan, B.-O. Modulation of activator distribution by phase-separation of glass for efficient and tunable upconversion luminescence. RSC Adv. 2020, 10, 12217–12223. [Google Scholar] [CrossRef]

- Li, J.; Long, Y.; Zhao, Q.; Zheng, S.; Fang, Z.; Guan, B.-O. Nano-crystallization of Ln-fluoride crystals in glass-ceramics via inducing of Yb3+ for efficient near-infrared upconversion luminescence of Tm3+. Nanomaterials 2021, 11, 1033. [Google Scholar] [CrossRef]

- Li, J.; Long, Y.; Zhao, Q.; Zheng, S.; Fang, Z.; Guan, B. Efficient white upconversion luminescence in Yb3+/Eu3+ doubly-doped transparent glass ceramic. Opt. Express 2021, 29, 21763–21772. [Google Scholar] [CrossRef]

- Kang, S.; Qiao, T.; Huang, X.; Yang, C.; Liu, X.; Qiu, J.; Yang, Z.; Dong, G. Enhanced CW lasing and Q-switched pulse generation enabled by Tm3+-doped glass ceramic fibers. Adv. Optical. Mater. 2020, 9, 2001774. [Google Scholar] [CrossRef]

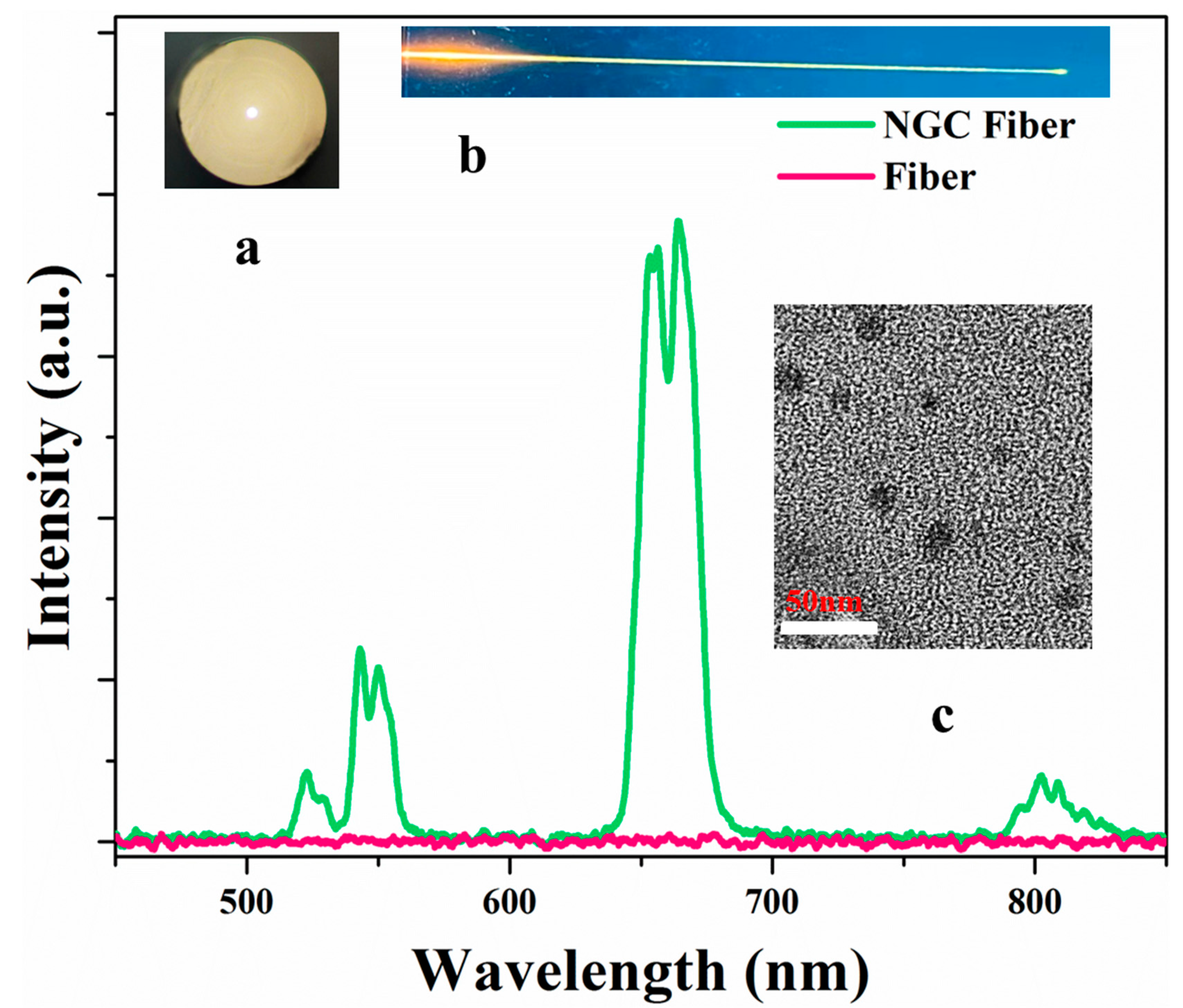

- Chen, Q.; Pan, Q.; Kang, S.; Cai, Z.; Ye, S.; Xiong, P.; Yang, Z.; Qiu, J.; Dong, G. Transparent nanocrystal-in-glass composite (NGC) fibers for multifunctional temperature and pressure sensing. Fundam. Res. 2022. [Google Scholar] [CrossRef]

- Chen, D.; Xu, B.; Fang, Z.; Zhang, D.; Man, T.; Mo, J.; Liu, X.; Xu, Z.; Liu, Y.; Cao, S.; et al. Broadband optical amplification of pbs quantum-dot-doped glass fibers. Adv. Photonics Res. 2022, 3, 2200097. [Google Scholar] [CrossRef]

- Ballato, J.; Peacock, A.C. Perspective: Molten core optical fiber fabrication—A route to new materials and applications. APL Photon. 2018, 3, 120903. [Google Scholar] [CrossRef]

- Wang, W.; Zhou, B.; Xu, S.; Yang, Z.; Zhang, Q. Recent advances in soft optical glass fiber and fiber lasers. Prog. Mater. Sci. 2019, 101, 90–171. [Google Scholar] [CrossRef]

- Tick, P.A. Are low-loss glass–ceramic optical waveguides possible? Opt. Lett. 1998, 23, 1904–1905. [Google Scholar] [CrossRef]

- Blanc, W.; Lu, Z.; Robine, T.; Pigeonneau, F.; Molardi, C.; Tosi, D. Nanoparticles in optical fiber, issue and opportunity of light scattering [Invited]. Opt. Mater. Express 2022, 12, 2635. [Google Scholar] [CrossRef]

- Fang, Z.; Zheng, S.; Peng, W.; Zhang, H.; Ma, Z.; Zhou, S.; Chen, D.; Qiu, J. Fabrication and characterization of glass-ceramic fiber containing Cr3+-Doped ZnAl2O4 Nanocrystals. J. Am. Ceram. Soc. 2015, 98, 2272–2275. [Google Scholar] [CrossRef]

- Fang, Z.; Xiao, X.; Wang, X.; Ma, Z.; Lewis, E.; Farrell, G.; Wang, P.; Ren, J.; Guo, H.; Qiu, J. Glass-ceramic optical fiber containing Ba2TiSi2O8 nanocrystals for frequency conversion of lasers. Sci. Rep. 2017, 7, 44456. [Google Scholar] [CrossRef]

- Fang, Z.; Zheng, S.; Peng, W.; Zhang, H.; Ma, Z.; Dong, G.; Zhou, S.; Chen, D.; Qiu, J. Ni2+ doped glass ceramic fiber fabricated by melt-in-tube method and successive heat treatment. Opt. Express 2015, 23, 28258–28263. [Google Scholar] [CrossRef]

- Huang, X.; Fang, Z.; Kang, S.; Peng, W.; Dong, G.; Zhou, B.; Ma, Z.; Zhou, S.; Qiu, J. Controllable fabrication of novel all solid-state PbS quantum dot-doped glass fibers with tunable broadband near-infrared emission. J. Mater. Chem. C 2017, 5, 7927–7934. [Google Scholar] [CrossRef]

- Huang, X.; Fang, Z.; Peng, Z.; Ma, Z.; Guo, H.; Qiu, J.; Dong, G. Formation, element-migration and broadband luminescence in quantum dot-doped glass fibers. Opt. Express 2017, 25, 19691–19700. [Google Scholar] [CrossRef] [PubMed]

- Jose, A.; Krishnapriya, T.; Jose, J.R.; Joseph, C.; Biju, P.R. NIR photoluminescent characteristics of Nd3+ activated fluoroborosilicate glasses for laser material applications. Phys. B Condens. Matter 2022, 634, 413772. [Google Scholar] [CrossRef]

- Peng, W.; Fang, Z.; Ma, Z.; Qiu, J. Enhanced upconversion emission in crystallization-controllable glass-ceramic fiber containing Yb3+-Er3+ codoped CaF2 nanocrystals. Nanotechnology 2016, 27, 405203. [Google Scholar] [CrossRef] [PubMed]

- Huang, X.; Guo, Q.; Yang, D.; Xiao, X.; Liu, X.; Xia, Z.; Fan, F.; Qiu, J.; Dong, G. Reversible 3D laser printing of perovskite quantum dots inside a transparent medium. Nat. Photon. 2020, 14, 82–88. [Google Scholar] [CrossRef]

- Zhang, X.; Hu, L.; Ren, J. Structural studies of rare earth-doped fluoroborosilicate glasses by advanced solid-state NMR. J. Phys. Chem. C 2020, 124, 8919–8929. [Google Scholar] [CrossRef]

- Fang, Z.; Chen, Z.; Peng, W.; Shao, C.; Zheng, S.; Hu, L.; Qiu, J.; Guan, B.-O. Phase-separation engineering of glass for drastic enhancement of upconversion luminescence. Adv. Opt. Mater. 2019, 7, 1801572. [Google Scholar] [CrossRef]

- Li, X.; Chen, D.; Huang, F.; Chang, G.; Zhao, J.; Qiao, X.; Xu, X.; Du, J.; Yin, M. Phase-selective nanocrystallization of NaLnF4 in aluminosilicate glass for random laser and 940 nm LED-excitable upconverted luminescence. Laser Photon-Rev. 2018, 12, 1800030. [Google Scholar] [CrossRef]

- Cao, J.; Hu, F.; Chen, L.; Guo, H.; Duan, C.; Yin, M. Optical thermometry based on up-conversion luminescence behavior of Er3+-doped KYb2F7 nano-crystals in bulk glass ceramics. J. Alloy Compd. 2017, 693, 326–331. [Google Scholar] [CrossRef]

| Nominated (Mass %) | Measured (Mass %) | Fluorine Loss (%) | |

|---|---|---|---|

| 60Si FS glass | 18.29 | 10.91 | 40.35 |

| 40Si-20B FBS glass | 16.23 | 11.75 | 27.60 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, Q.; Li, J.; Zha, T.; Zhang, P.; Long, Y.; Fang, Z. Low-Temperature Fluoro-Borosilicate Glass for Controllable Nano-Crystallization in Glass Ceramic Fibers. Nanomaterials 2023, 13, 1586. https://doi.org/10.3390/nano13101586

Zhao Q, Li J, Zha T, Zhang P, Long Y, Fang Z. Low-Temperature Fluoro-Borosilicate Glass for Controllable Nano-Crystallization in Glass Ceramic Fibers. Nanomaterials. 2023; 13(10):1586. https://doi.org/10.3390/nano13101586

Chicago/Turabian StyleZhao, Qichao, Jianfeng Li, Tingyu Zha, Penghui Zhang, Yi Long, and Zaijin Fang. 2023. "Low-Temperature Fluoro-Borosilicate Glass for Controllable Nano-Crystallization in Glass Ceramic Fibers" Nanomaterials 13, no. 10: 1586. https://doi.org/10.3390/nano13101586

APA StyleZhao, Q., Li, J., Zha, T., Zhang, P., Long, Y., & Fang, Z. (2023). Low-Temperature Fluoro-Borosilicate Glass for Controllable Nano-Crystallization in Glass Ceramic Fibers. Nanomaterials, 13(10), 1586. https://doi.org/10.3390/nano13101586