Structure and Dielectric Properties of Poly(vinylidenefluoride-co-trifluoroethylene) Copolymer Thin Films Using Atmospheric Pressure Plasma Deposition for Piezoelectric Nanogenerator

Abstract

:1. Introduction

2. Materials and Methods

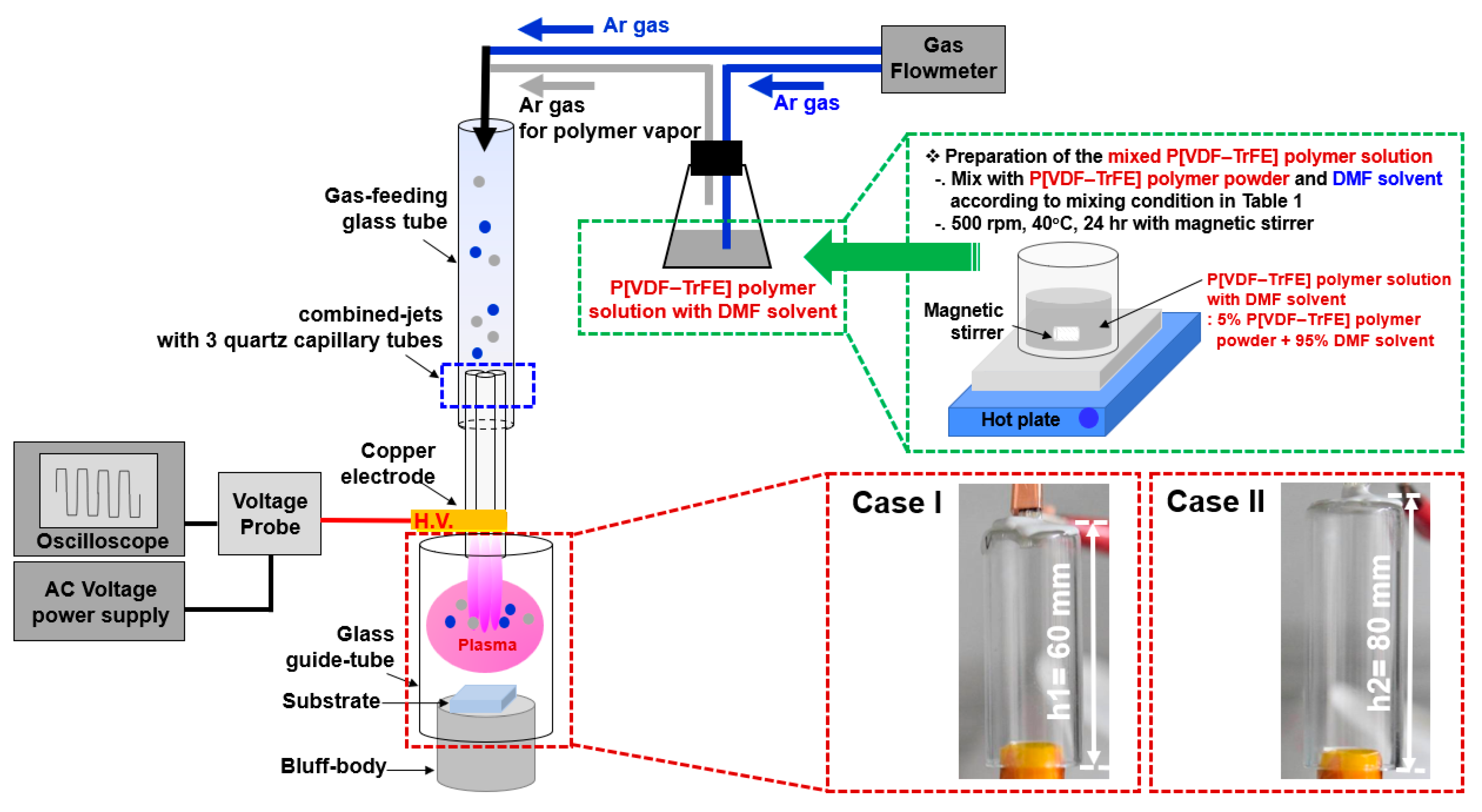

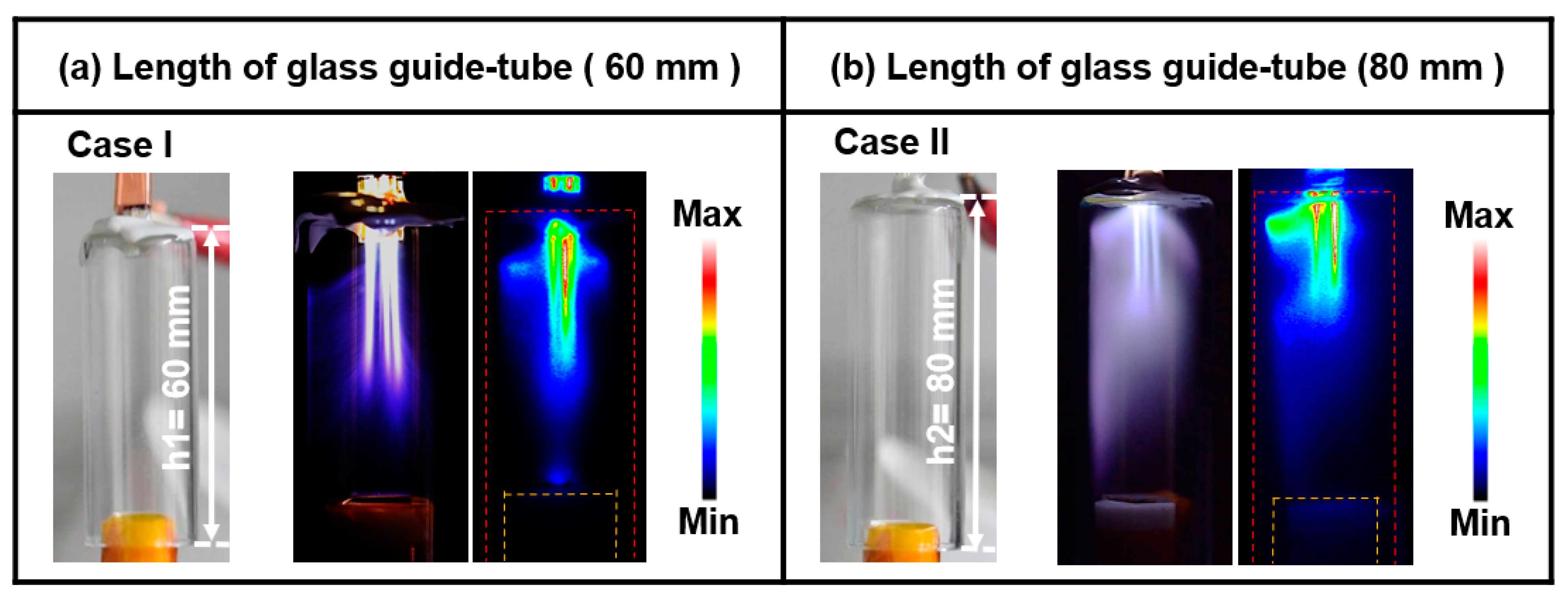

2.1. Experimental Setup

2.2. Intensified Charge-Coupled Device

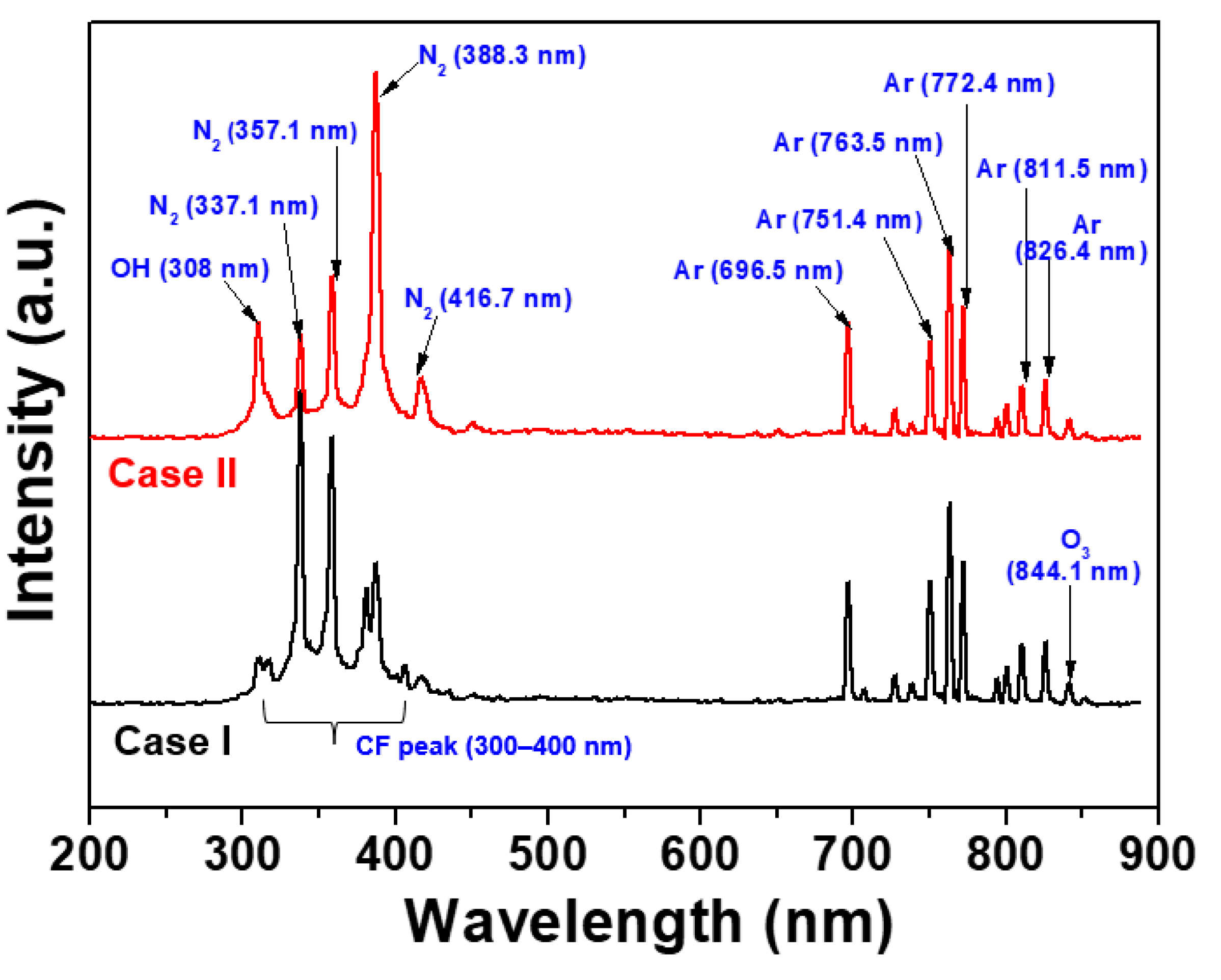

2.3. Optical Emission Spectroscopy

2.4. Field Emission Scanning Electron Microscopy

2.5. X-ray Diffraction

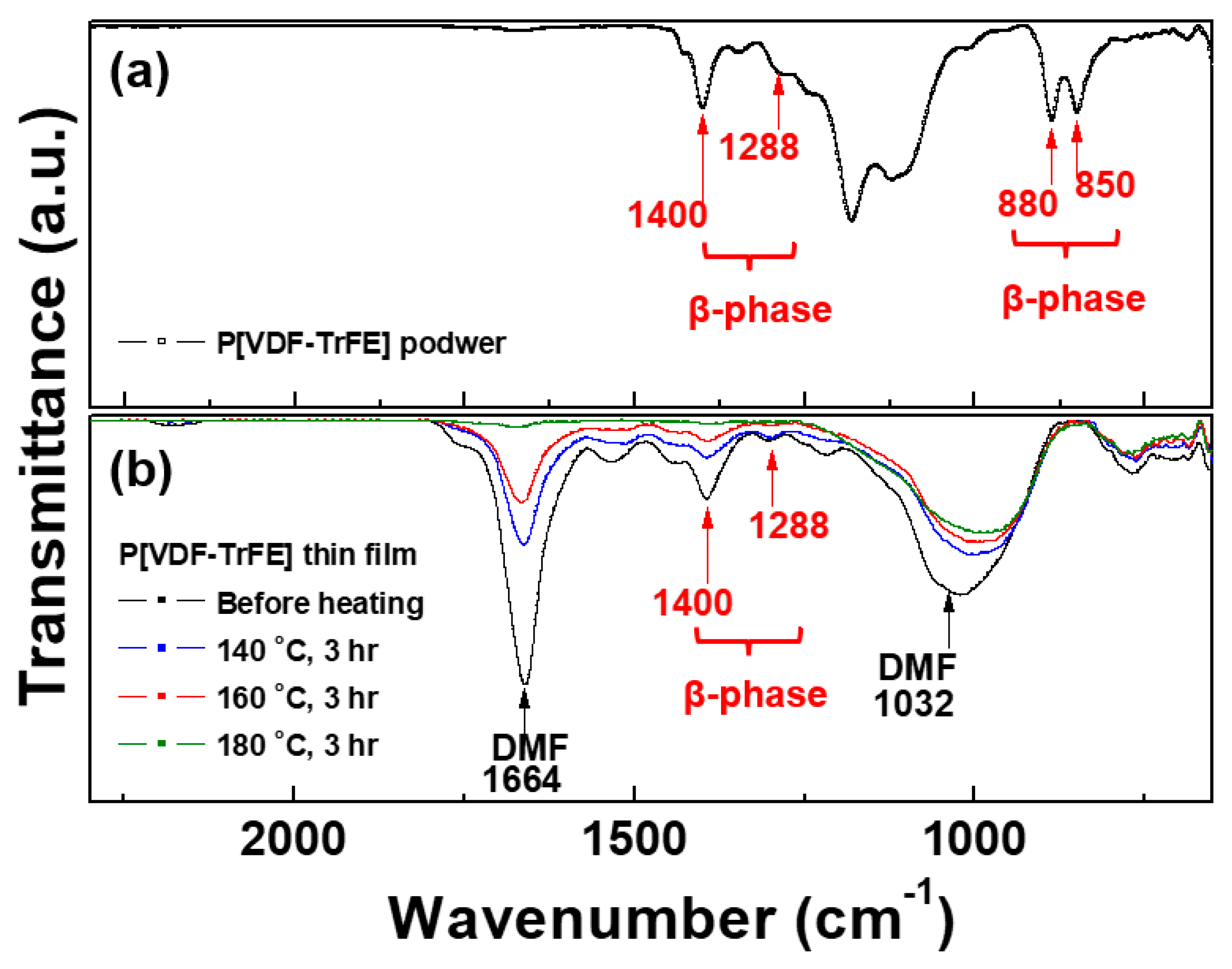

2.6. Fourier Transformation Infrared Spectroscopy

2.7. Stylus Profiler

2.8. Impedance Analyzer

3. Results

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Horchidan, N.; Ciomaga, C.E.; Curecheriu, L.P.; Stoian, G.; Botea, M.; Florea, M.; Maraloiu, V.A.; Pintilie, L.; Tufescu, F.M.; Tiron, V.; et al. Increasing permittivity and mechanical harvesting response of PVDF-based flexible composites by using Ag nanoparticles onto BaTiO3 Nanofillers. Nanomaterials 2022, 12, 934. [Google Scholar] [CrossRef] [PubMed]

- Mu, J.; Xian, S.; Yu, J.; Zhao, J.; Song, J.; Li, Z.; Hou, X.; Chou, X.; He, J. Fused synergistic enhancement properties of a flexible integrated PAN/PVDF piezoelectric sensor for human posture recognition. Nanomaterials 2022, 12, 1155. [Google Scholar] [CrossRef] [PubMed]

- Matko, V.; Milanovič, M. Detection principles of temperature compensated oscillators with reactance influence on piezoelectric resonator. Sensors 2020, 20, 802. [Google Scholar] [CrossRef] [PubMed]

- Matko, V.; Milanovič, M. Temperature-compensated capacitance–frequency converter with high resolution. Sens. Actuators A Phys. 2014, 220, 262–269. [Google Scholar] [CrossRef]

- Tao, R.; Shi, J.; Rafiee, M.; Akbarzadeh, A.; Therriault, D. Fused filament fabrication of PVDF films for piezoelectric sensing and energy harvesting applications. Mater. Adv. 2022, 3, 4851–4860. [Google Scholar] [CrossRef]

- Ongun, M.Z.; Oguzlar, S.; Doluel, E.C.; Kartal, U.; Yurddaskal, M. Enhancement of piezoelectric energy-harvesting capacity of electrospun β-PVDF nanogenerators by adding GO and rGO. J. Mater. Sci. Mater. Electron. 2020, 31, 1960–1968. [Google Scholar] [CrossRef]

- Sahu, M.; Hajra, S.; Lee, K.; Deepti, P.; Mistewicz, K.; Kim, H.J. Piezoelectric nanogenerator based on lead-free flexible PVDF-barium titanate composite films for driving Low power electronics. Crystals 2021, 11, 85. [Google Scholar] [CrossRef]

- Whiter, R.A.; Narayan, V.; Kar-Narayan, S. A scalable nanogenerator based on self-poled piezoelectric polymer nanowires with high energy conversion efficiency. Adv. Energy Mater. 2014, 4, 1400519. [Google Scholar] [CrossRef]

- Ico, G.; Showalter, A.; Bosze, W.; Gott, S.C.; Kim, B.S.; Rao, M.P.; Myung, N.V.; Nam, J. Size-dependent piezoelectric and mechanical properties of electrospun P(VDF-TrFE) nanofibers for enhanced energy harvesting. J. Mater. Chem. A 2016, 4, 2293–2304. [Google Scholar] [CrossRef]

- Kim, Y.T.; Hong, S.V.; Oh, S.H.; Choi, Y.-Y.; Choi, H.W.; No, K.S. The Effects of an alkaline treatment on the ferroelectric properties of poly(vinylidene fluoride trifluoroethylene) films. Electron. Mater. Lett. 2015, 11, 586–591. [Google Scholar] [CrossRef]

- Kim, S.; Towfeeq, I.; Dong, Y.C.; Gorman, S.; Rao, A.M.; Koley, G. P(VDF-TrFE) film on PDMS substrate for energy harvesting applications. Appl. Sci. 2018, 8, 213. [Google Scholar] [CrossRef]

- Yang, L.; Yang, L.; Ma, K.; Wang, Y.; Song, T.; Gong, L.; Sun, J.; Zhao, L.; Yang, Z.; Xu, J.; et al. Free volum dependence of dielectric behaviour in sandwich-structured high dielectric performances of poly(vinylidene fluoride) compoite films. Nanoscale 2021, 13, 300–310. [Google Scholar] [CrossRef] [PubMed]

- Manchi, P.; Graham, S.A.; Patnam, H.; Alluri, N.R.; Kim, S.-J.; Yu, J.S. LiTaO3-based flexible piezoelectric nanogenerators for mechanical energy harvesting. ACS Appl. Mater. Interfaces 2021, 13, 46526–46536. [Google Scholar] [CrossRef] [PubMed]

- Dudem, B.; Kim, D.H.; Bharat, L.K.; Yu, J.S. Highly-flexible piezoelectric nanogenerators with silver nanowires and barium titanate embedded composite films for mechanical energy harvesting. Appl. Energy 2018, 230, 865–874. [Google Scholar] [CrossRef]

- Zhao, B.; Chen, Z.; Cheng, Z.; Wang, S.; Yu, T.; Yang, W.; Li, Y. Piezoelectric nanogenerators based on electrospun PVDF-coated mats composed of multilayer polymer-coated BaTiO3nanowires. ACS Appl. Nano Mater. 2022, 5, 8417–8428. [Google Scholar] [CrossRef]

- Kim, S.M.; Nguyen, T.M.H.; He, R.; Bark, C.W. Particle size effect of lanthanum-modified bismuth titanate ceramics on ferroelectric effect for energy harvesting. Nanoscale Res. Lett. 2022, 16, 115. [Google Scholar] [CrossRef]

- Du, X.; Zhou, Z.; Zhang, Z.; Yao, L.; Zhang, Q.; Yang, H. Porous, multi-layered piezoelectric composites based on highly oriented PZT/PVDF electrospinning fibers for high-performance piezoelectric nanogenerators. J. Adv. Ceram. 2022, 11, 331–344. [Google Scholar] [CrossRef]

- Chen, X.; Shao, J.; Li, X.; Tian, H. A flexible piezoelectric-pyroelectric hybrid nanogenerator based on P(VDF-TrFE) nanowire array. IEEE Trans. Nanotechnol. 2016, 15, 295–302. [Google Scholar] [CrossRef]

- Apelt, S.; Höhne, S.; Mehner, E.; Böhm, C.; Malanin, M.; Eichhorn, K.-J.; Jehnichen, D.; Uhlmann, P.; Bergmann, U. Poly(vinylidene fluoride-co-trifluoroethylene) thin films after dip- and spin-coating. Macromol. Mater. Eng. 2022, 307, 2200296. [Google Scholar] [CrossRef]

- Soulestin, T.; Ladmiral, V.; Santos, F.D.D.; Améduri, B. Vinylidene fluoride- and trifluoroethylene-containing fluorinated electroactive copolymers. How does chemistry impact properties? Prog. Polym. Sci. 2017, 72, 16–60. [Google Scholar] [CrossRef]

- Park, C.-S.; Kim, D.H.; Shin, B.J.; Kim, D.Y.; Lee, H.-K.; Tae, H.-S. Conductive polymer synthesis with single-crystallinity via a novel plasma polymerization technique for gas sensor applications. Materials 2016, 9, 812. [Google Scholar] [CrossRef] [PubMed]

- Jang, H.J.; Park, C.-S.; Jung, E.Y.; Bae, G.T.; Shin, B.J.; Tae, H.-S. Synthesis and properties of thiophene and aniline copolymer using atmospheric pressure plasma jets copolymerization technique. Polymers 2020, 12, 2225. [Google Scholar] [CrossRef] [PubMed]

- Park, C.-S.; Kim, D.Y.; Kim, D.H.; Lee, H.-K.; Shin, B.J.; Tae, H.-S. Humidity-independent conducting polyaniline films synthesized using advanced atmospheric pressure plasma polymerization with in-situ iodine doping. Appl. Phys. Lett. 2017, 110, 033502. [Google Scholar] [CrossRef]

- Kim, D.H.; Park, C.-S.; Kim, W.H.; Shin, B.J.; Hong, J.G.; Park, T.S.; Seo, J.H.; Tae, H.-S. Influences of guide-tube and bluff-body on advanced atmospheric pressure plasma source for single-crystalline polymer nanoparticle synthesis at low temperature. Phys. Plasma 2017, 24, 023506. [Google Scholar] [CrossRef]

- Polat, S. Dielectric properties of GNPs@MgO/CuO@PVDF composite films. J. Inst. Sci. Technol. 2021, 37, 412–422. [Google Scholar]

- Wang, R.; Zhang, C.; Liu, X.; Xie, Q.; Yan, P.; Shao, T. Microsecond pulse driven Ar/CF4 plasma jet for polymethylmethacrylate surface modification at atmospheric pressure. Appl. Surf. Sci. 2015, 328, 509–515. [Google Scholar] [CrossRef]

- Habibur, R.M.; Yaqoob, U.; Muhammad, S.; Uddin, A.S.M.I.; Kim, H.C. The effect of RGO on dielectric and energy harvesting properties of P(VDF-TrFE) matrix by optimizing electroactive β phase without traditional polling process. Mater. Chem. Phys. 2018, 215, 46–55. [Google Scholar] [CrossRef]

- Singh, P.K.; Gaur, M.S. Enhancement of β-phase of P(VDF-TrFE)60/40 by BaTiO3 nanofiller. Ferroelectrics 2018, 524, 37–43. [Google Scholar] [CrossRef]

- You, S.; Shi, H.; Wu, J.; Shan, L.; Guo, S.; Dong, S. A flexible, wave-shaped P(VDF-TrFE)/metglas piezoelectric composite for wearable applications. J. Appl. Phys. 2016, 120, 234103. [Google Scholar] [CrossRef]

- Mahdi, R.I.; Gan, W.C.; Majid, W.H.A. Hot plate annealing at a low temperature of a thin ferroelectric P(VDF-TrFE) film with an improved crystalline structure for sensors and actuators. Sensors 2014, 14, 19115–19127. [Google Scholar] [CrossRef]

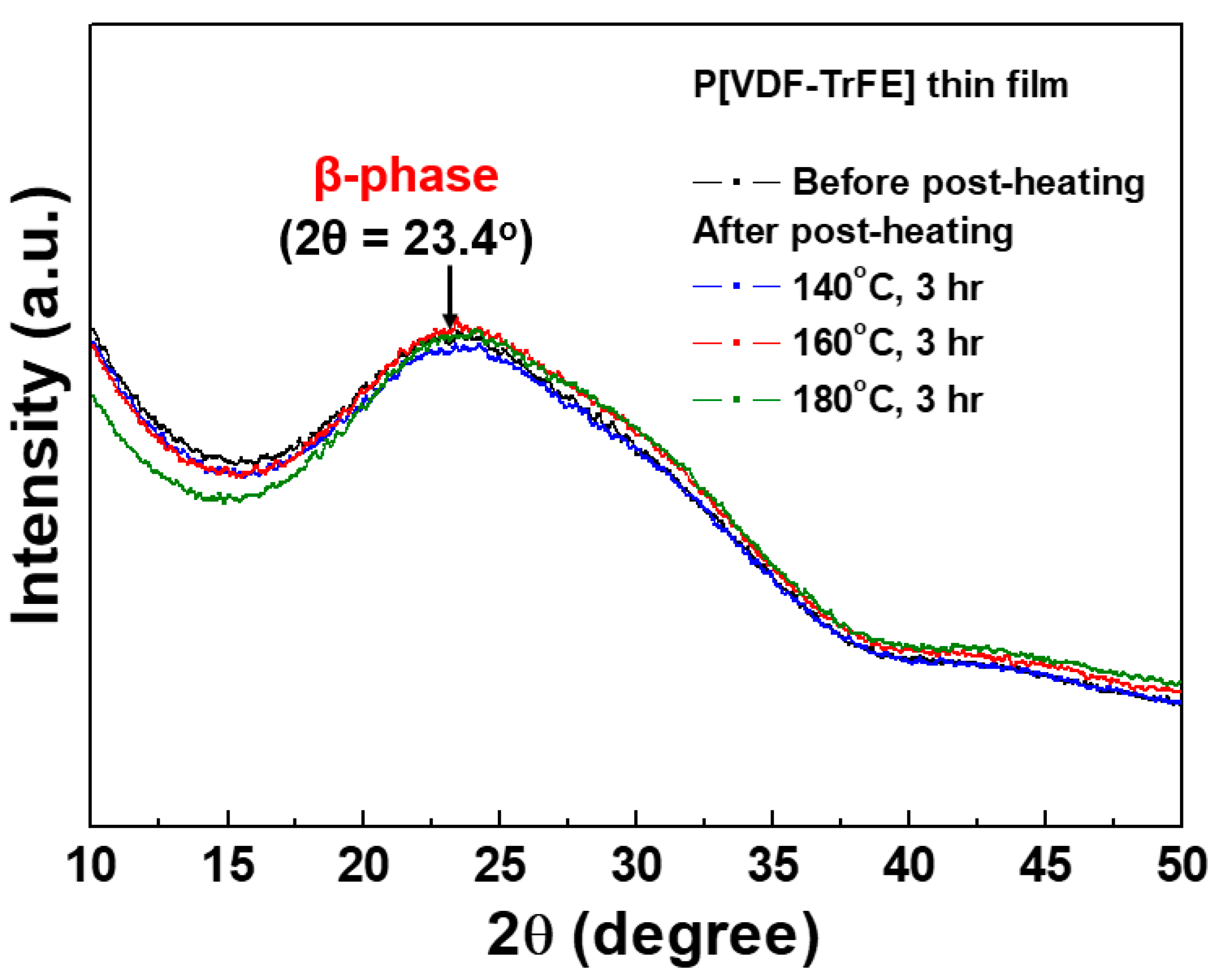

- Jung, E.Y.; Park, C.-S.; Kim, D.; Kim, S.; Bae, G.T.; Shin, B.J.; Lee, D.H.; Chien, S.-I.; Tae, H.-S. Influences of post-heating treatment on crystalline phases of PVDF thin films prepared by atmospheric pressure plasma deposition. Mol. Cryst. Liq. Cryst. 2021, 678, 9–19. [Google Scholar] [CrossRef]

- Mandal, D.; Henkel, K.; Müller, K.; Schmeißer, D. Bandgap determination of P(VDF–TrFE) copolymer film by electron energy loss spectroscopy. Bull. Mater. Sci. 2010, 33, 457–461. [Google Scholar] [CrossRef]

- Li, C.; Shi, L.; Yang, W.; Zhou, Y.; Li, X.; Zhang, C.; Yang, Y. All polymer dielectric films for achieving high energy density film capacitors by blending poly(vinylidene fluoride-trifluoroethylene-chlorofluoroethylene) with aromatic polythiourea. Nanoscale Res. Lett. 2020, 15, 36. [Google Scholar] [CrossRef]

- Gusarova, E.; Viala, B.; Plihon, A.; Gusarov, B.; Gimeno, L.; Cugat, O. Flexible screen-printed piezoelectric P(VDF-TrFE) copolymer microgenerators for energy harvesting. In Proceedings of the 2015 Transducers—2015 18th International Conference on Solid-State Sensors, Actuators and Microsystems (TRANSDUCERS), Anchorage, AK, USA, 21–25 June 2015. [Google Scholar]

- Kalel, S.; Wang, W.-C. Optical properties of PVDF-TrFE and PVDF-TrFE-CTFE films in terahertz band. Mater. Res. Express 2023, 10, 045304. [Google Scholar] [CrossRef]

- Rozana, M.D.; Arshad, A.N.; Wahid, M.H.; Sarip, M.N.; Rusop, M. Electrical and structural properties of PVDF/MgO (7%) nanocomosites thin films at various annealing temperatures. Int. J. Res. Sci. 2017, 3, 8. [Google Scholar]

- Wang, W.; Yang, J.; Liu, Z. Dielectric and energy storage properties of PVDF films with large area prepared by solution tape casting process. IEEE Trans. Dielectr. Electr. Insul. 2017, 24, 697–703. [Google Scholar] [CrossRef]

- Kong, D.S.; Lee, T.K.; Ko, Y.J.; Jung, J.H. Dielectric and ferroelectric properties of P(VDF-TrFE) films with different polar solvents. J. Korean Phys. Soc. 2019, 74, 78–81. [Google Scholar] [CrossRef]

- Zak, A.K.; Chen, G.W.; Majid, W.H.A. Dielectric properties of PVDF/PZT. AIP Conf. Proc. 2011, 1328, 237–240. [Google Scholar]

- Meng, N.; Zhu, X.; Mao, R.; Reece, M.J.; Bilotti, E. Nanoscale interfacial electroactivity in PVDF/PVDF-TrFE blended films with Enhanced dielectric and ferroelectric properties. J. Mater. Chem. C 2017, 5, 3296–3305. [Google Scholar] [CrossRef]

- Wang, D.H.; Kurish, B.A.; Treufeld, I.; Zhu, L.; Tan, L.-S. Synthesis and characterization of high nitrile content polyimides as dielectric films for electrical energy storage. J. Polym. Sci. Part A Polym. Chem. 2015, 53, 422–436. [Google Scholar] [CrossRef]

| Precursor Polymer Solution | 5% P[VDF–TrFE] Polymer Nano Powder + 95% DMF Solvent |

|---|---|

| Voltage (Vp) | 12.5 kV (fixed) |

| Frequency | 26 kHz (fixed) |

| Ar gas flow for polymer vapor | 450 sccm (fixed) |

| Ar gas flow | 2500 sccm (fixed) |

| Bluff-body height | 15 mm (fixed) |

| Length of the glass guide tube | Case I: 60 mm |

| Case II: 80 mm | |

| Deposition time | 1 h (fixed) |

| Deposition temperature | Room temperature (fixed) |

| Post-heating temperature | 140 °C, 160 °C, 180 °C (controllable) |

| Post-heating time | 3 h (fixed) |

| Wavenumber (cm–1) | Peak Assignment | |

|---|---|---|

| P[VDF–TrFE] Powder | P[VDF–TrFE] Thin Film | |

| 850 cm−1 | CF2 symmetric stretching (β-phase) | |

| 880 cm−1 | CF2 in-plane rocking deformations (β-phase) | |

| 1288 cm−1 | 1288 cm−1 | CF2 symmetric stretching (β-phase) |

| 1400 cm−1 | 1400 cm−1 | CH2 bond and C-C asymmetric stretching CH2 wagging vibration (β-phase) |

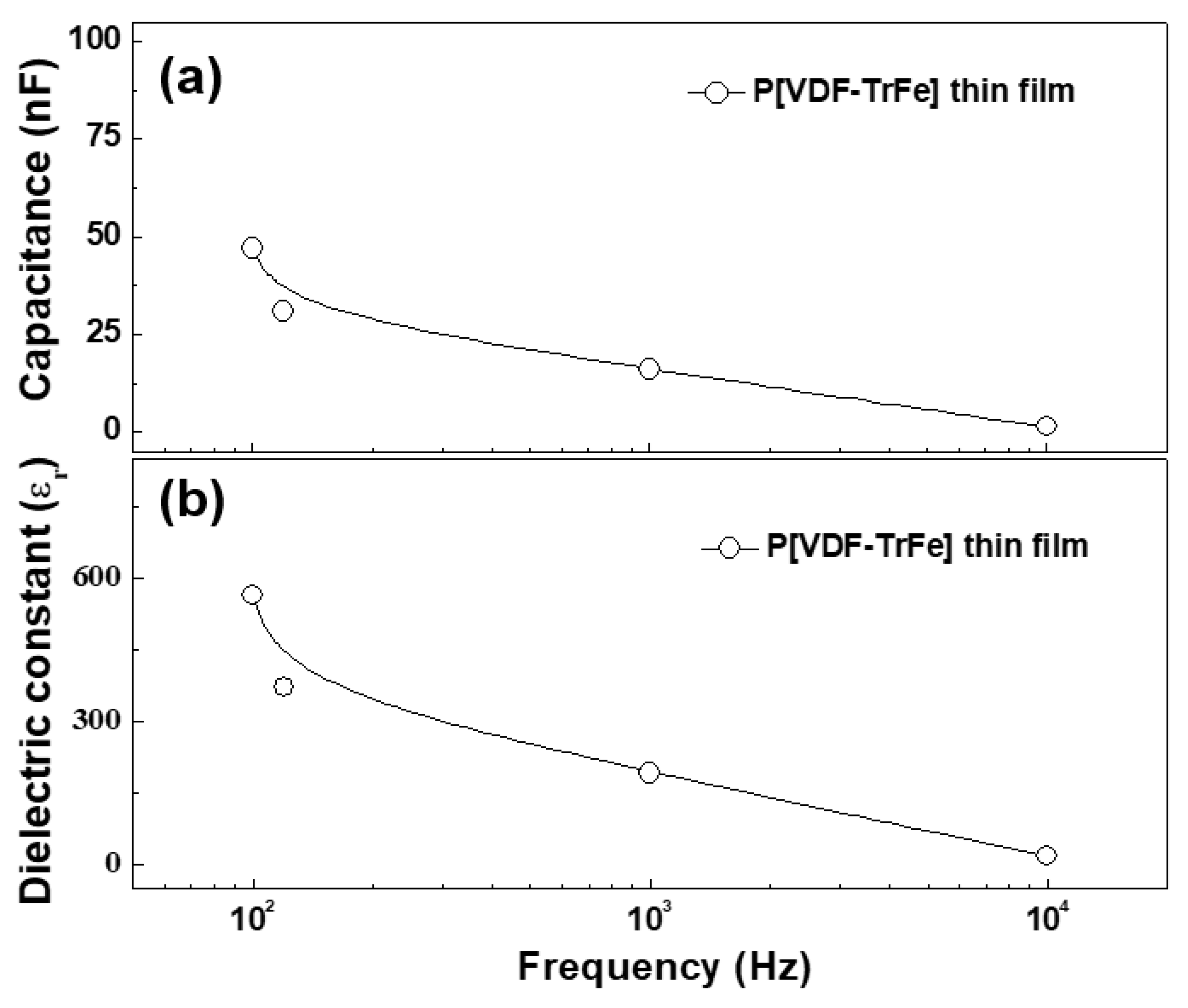

| Frequency | Capacitance (nF) | Dielectric Constant | Dielectric Loss |

|---|---|---|---|

| 100 Hz | 47 | 564 | 0.09 |

| 120 Hz | 31 | 372 | 0.07 |

| 1 kHz | 16 | 192 | 0.05 |

| 10 kHz | 2.5 | 30 | 0.04 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jung, E.; Park, C.-S.; Hong, T.; Tae, H.-S. Structure and Dielectric Properties of Poly(vinylidenefluoride-co-trifluoroethylene) Copolymer Thin Films Using Atmospheric Pressure Plasma Deposition for Piezoelectric Nanogenerator. Nanomaterials 2023, 13, 1698. https://doi.org/10.3390/nano13101698

Jung E, Park C-S, Hong T, Tae H-S. Structure and Dielectric Properties of Poly(vinylidenefluoride-co-trifluoroethylene) Copolymer Thin Films Using Atmospheric Pressure Plasma Deposition for Piezoelectric Nanogenerator. Nanomaterials. 2023; 13(10):1698. https://doi.org/10.3390/nano13101698

Chicago/Turabian StyleJung, Eunyoung, Choon-Sang Park, Taeeun Hong, and Heung-Sik Tae. 2023. "Structure and Dielectric Properties of Poly(vinylidenefluoride-co-trifluoroethylene) Copolymer Thin Films Using Atmospheric Pressure Plasma Deposition for Piezoelectric Nanogenerator" Nanomaterials 13, no. 10: 1698. https://doi.org/10.3390/nano13101698