Power-Dependent Optical Characterization of the InGaN/GaN-Based Micro-Light-Emitting-Diode (LED) in High Spatial Resolution

Abstract

:1. Introduction

2. Materials and Methods

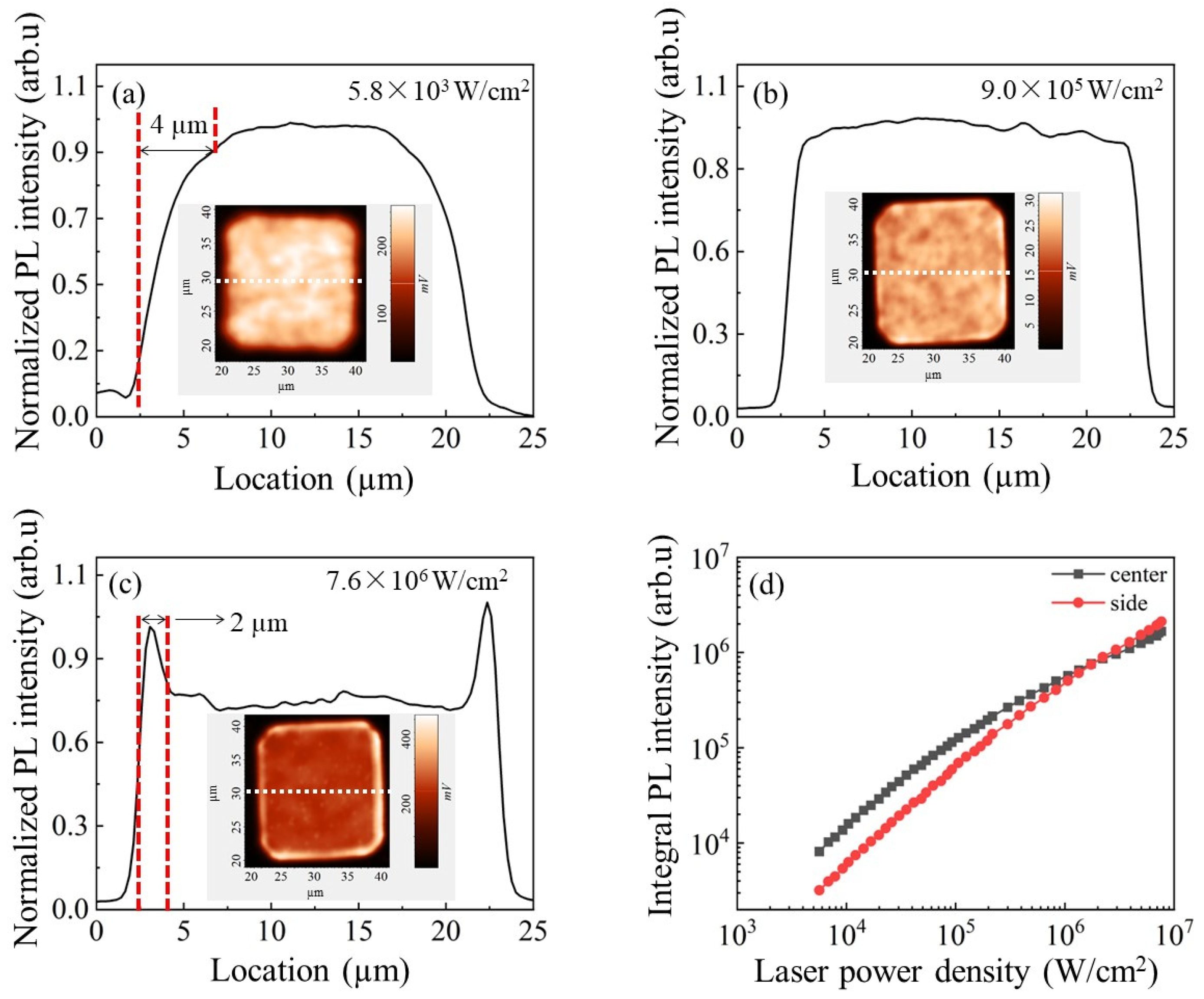

3. Results and Discussion

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Wasisto, H.S.; Prades, J.D.; Gülink, J.; Waag, A. Beyond solid-state lighting: Miniaturization, hybrid integration, and applications of GaN nano-and micro-LEDs. Appl. Phys. Rev. 2019, 6, 041315. [Google Scholar] [CrossRef] [Green Version]

- Lin, J.; Jiang, H. Development of microLED. Appl. Phys. Lett. 2020, 116, 100502. [Google Scholar] [CrossRef]

- Sheen, M.; Ko, Y.; Kim, D.-U.; Kim, J.; Byun, J.-H.; Choi, Y.; Ha, J.; Yeon, K.Y.; Kim, D.; Jung, J. Highly efficient blue InGaN nanoscale light-emitting diodes. Nature 2022, 608, 56–61. [Google Scholar] [CrossRef]

- Jiang, H.; Lin, J. Nitride micro-LEDs and beyond—A decade progress review. Opt. Express 2013, 21, A475–A484. [Google Scholar] [CrossRef] [PubMed]

- Wolter, S.; Spende, H.; Gülink, J.; Hartmann, J.; Wehmann, H.-H.; Waag, A.; Lex, A.; Avramescu, A.; Lugauer, H.-J.; Malm, N.V. Size-dependent electroluminescence and current-voltage measurements of blue ingan/gan µleds down to the submicron scale. Nanomaterials 2021, 11, 836. [Google Scholar] [CrossRef] [PubMed]

- Xu, F.; Tan, Y.; Xie, Z.; Zhang, B. Implantation energy-and size-dependent light output of enhanced-efficiency micro-LED arrays fabricated by ion implantation. Opt. Express 2021, 29, 7757–7766. [Google Scholar] [CrossRef]

- Boroditsky, M.; Gontijo, I.; Jackson, M.; Vrijen, R.; Yablonovitch, E.; Krauss, T.; Cheng, C.-C.; Scherer, A.; Bhat, R.; Krames, M. Surface recombination measurements on III–V candidate materials for nanostructure light-emitting diodes. J. Appl. Phys. 2000, 87, 3497–3504. [Google Scholar] [CrossRef] [Green Version]

- Li, K.; Cheung, Y.; Cheung, W.; Choi, H. Confocal microscopic analysis of optical crosstalk in GaN micro-pixel light-emitting diodes. Appl. Phys. Lett. 2015, 107, 171103. [Google Scholar] [CrossRef] [Green Version]

- Tian, P.; McKendry, J.J.; Gong, Z.; Guilhabert, B.; Watson, I.M.; Gu, E.; Chen, Z.; Zhang, G.; Dawson, M.D. Size-dependent efficiency and efficiency droop of blue InGaN micro-light emitting diodes. Appl. Phys. Lett. 2012, 101, 231110. [Google Scholar] [CrossRef]

- Xie, E.; Chen, Z.; Edwards, P.; Gong, Z.; Liu, N.; Tao, Y.; Zhang, Y.; Chen, Y.; Watson, I.; Gu, E. Strain relaxation in InGaN/GaN micro-pillars evidenced by high resolution cathodoluminescence hyperspectral imaging. J. Appl. Phys. 2012, 112, 013107. [Google Scholar] [CrossRef] [Green Version]

- Yang, F.; Xu, Y.; Li, L.; Cai, X.; Li, J.; Tao, J.; Zheng, S.; Cao, B.; Xu, K. Optical and microstructural characterization of Micro-LED with sidewall treatment. J. Phys. D Appl. Phys. 2022, 55, 435103. [Google Scholar] [CrossRef]

- Olivier, F.; Tirano, S.; Dupré, L.; Aventurier, B.; Largeron, C.; Templier, F. Influence of size-reduction on the performances of GaN-based micro-LEDs for display application. J. Lumin. 2017, 191, 112–116. [Google Scholar] [CrossRef]

- Tong, C.-D.; Guo, W.-J.; Zhong, C.-M.; Wang, Z.-Y.; Gao, Y.-L.; Chen, Y.-Y.; Zhu, W.-P.; Zhu, L.-H.; Lu, Y.-J.; Wu, Z.-Z. Effect of current on the inhomogeneous light emission from AlGaInP-based flip-chip red mini-LEDs. IEEE Electron Device Lett. 2022, 43, 402–405. [Google Scholar] [CrossRef]

- Zheng, L.; Guo, Z.; Lu, Y.; Zeng, P.; Lai, S.; Chen, G.; Gao, Y.; Zhu, L.; Guo, W.; Lin, Y. Explore Luminance Attenuation and Optical Crosstalk of RGB Mini Light-Emitting Diode via Microscopic Hyperspectral Imaging. IEEE J. Electron Devices Soc. 2022, 10, 827–832. [Google Scholar] [CrossRef]

- Lai, S.; Lin, W.; Chen, J.; Lu, T.; Liu, S.; Lin, Y.; Lu, Y.; Lin, Y.; Chen, Z.; Kuo, H.-C. The impacts of sidewall passivation via atomic layer deposition on GaN-based flip-chip blue mini-LEDs. J. Phys. D Appl. Phys. 2022, 55, 374001. [Google Scholar] [CrossRef]

- Zhan, J.; Chen, Z.; Jiao, Q.; Feng, Y.; Li, C.; Chen, Y.; Chen, Y.; Jiao, F.; Kang, X.; Li, S. Investigation on strain relaxation distribution in GaN-based μLEDs by Kelvin probe force microscopy and micro-photoluminescence. Opt. Express 2018, 26, 5265–5274. [Google Scholar] [CrossRef]

- Zheng, X.; Guo, W.; Tong, C.; Zeng, P.; Chen, G.; Gao, Y.; Zhu, L.; Chen, Y.; Wang, S.; Lin, Z. Origin of the Inhomogeneous Electroluminescence of GaN-Based Green Mini-LEDs Unveiled by Microscopic Hyperspectral Imaging. ACS Photonics 2022, 9, 3685–3695. [Google Scholar] [CrossRef]

- Guo, W.; Su, C.; Lu, H.; Peng, Z.; Ke, Z.; Lu, Y.; Wu, T.; Lin, Y.; Chen, Z. Origins of inhomogeneous light emission from GaN-based flip-chip green micro-LEDs. IEEE Electron Device Lett. 2019, 40, 1132–1135. [Google Scholar] [CrossRef]

- Hang, S.; Chuang, C.-M.; Zhang, Y.; Chu, C.; Tian, K.; Zheng, Q.; Wu, T.; Liu, Z.; Zhang, Z.-H.; Li, Q. A review on the low external quantum efficiency and the remedies for GaN-based micro-LEDs. J. Phys. D Appl. Phys. 2021, 54, 153002. [Google Scholar] [CrossRef]

- Hwang, D.; Mughal, A.; Pynn, C.D.; Nakamura, S.; DenBaars, S.P. Sustained high external quantum efficiency in ultrasmall blue III–nitride micro-LEDs. Appl. Phys. Express 2017, 10, 032101. [Google Scholar] [CrossRef]

- Kim, M.-H.; Schubert, M.F.; Dai, Q.; Kim, J.K.; Schubert, E.F.; Piprek, J.; Park, Y. Origin of efficiency droop in GaN-based light-emitting diodes. Appl. Phys. Lett. 2007, 91, 183507. [Google Scholar] [CrossRef] [Green Version]

- Li, Z.; Ryan, T. Photoluminescence Mapping as a Tool to Improve LED Production. In Light-Emitting Diodes: Materials, Devices, and Applications for Solid State Lighting XIII; SPIE: Bellingham, WA, USA, 2009; pp. 77–85. [Google Scholar]

- Boussadi, Y.; Rochat, N.; Barnes, J.-P.; Bakir, B.B.; Ferrandis, P.; Masenelli, B.; Licitra, C. Investigation of sidewall damage induced by reactive ion etching on AlGaInP MESA for micro-LED application. J. Lumin. 2021, 234, 117937. [Google Scholar] [CrossRef]

- Lee, T.-X.; Lin, C.-Y.; Ma, S.-H.; Sun, C.-C. Analysis of position-dependent light extraction of GaN-based LEDs. Opt. Express 2005, 13, 4175–4179. [Google Scholar] [CrossRef] [PubMed]

- Takeuchi, T.; Sota, S.; Katsuragawa, M.; Komori, M.; Takeuchi, H.; Amano, H.A.H.; Akasaki, I.A.I. Quantum-confined Stark effect due to piezoelectric fields in GaInN strained quantum wells. Jpn. J. Appl. Phys. 1997, 36, L382. [Google Scholar] [CrossRef]

- Watanabe, S.; Yamada, N.; Nagashima, M.; Ueki, Y.; Sasaki, C.; Yamada, Y.; Taguchi, T.; Tadatomo, K.; Okagawa, H.; Kudo, H. Internal quantum efficiency of highly-efficient In x Ga 1− x N-based near-ultraviolet light-emitting diodes. Appl. Phys. Lett. 2003, 83, 4906–4908. [Google Scholar] [CrossRef]

- Konoplev, S.S.; Bulashevich, K.A.; Karpov, S.Y. From large-size to micro-LEDs: Scaling trends revealed by modeling. Phys. Status Solidi A 2018, 215, 1700508. [Google Scholar] [CrossRef]

- Wong, M.S.; Hwang, D.; Alhassan, A.I.; Lee, C.; Ley, R.; Nakamura, S.; DenBaars, S.P. High efficiency of III-nitride micro-light-emitting diodes by sidewall passivation using atomic layer deposition. Opt. Express 2018, 26, 21324–21331. [Google Scholar] [CrossRef]

- Kou, J.; Shen, C.-C.; Shao, H.; Che, J.; Hou, X.; Chu, C.; Tian, K.; Zhang, Y.; Zhang, Z.-H.; Kuo, H.-C. Impact of the surface recombination on InGaN/GaN-based blue micro-light emitting diodes. Opt. Express 2019, 27, A643–A653. [Google Scholar] [CrossRef]

- Wong, M.S.; Lee, C.; Myers, D.J.; Hwang, D.; Kearns, J.A.; Li, T.; Speck, J.S.; Nakamura, S.; DenBaars, S.P. Size-independent peak efficiency of III-nitride micro-light-emitting-diodes using chemical treatment and sidewall passivation. Appl. Phys. Express 2019, 12, 097004. [Google Scholar] [CrossRef]

- Zhu, J.; Takahashi, T.; Ohori, D.; Endo, K.; Samukawa, S.; Shimizu, M.; Wang, X.-L. Near-complete elimination of size-dependent efficiency decrease in GaN micro-light-emitting diodes. Phys. Status Solidi A 2019, 216, 1900380. [Google Scholar] [CrossRef]

- Tian, W.; Li, J. Size-dependent optical-electrical characteristics of blue GaN/InGaN micro-light-emitting diodes. Appl. Opt. 2020, 59, 9225–9232. [Google Scholar] [CrossRef] [PubMed]

- van der Gon, D.D.; Timmerman, D.; Matsude, Y.; Ichikawa, S.; Ashida, M.; Schall, P.; Fujiwara, Y. Size dependence of quantum efficiency of red emission from GaN: Eu structures for application in micro-LEDs. Opt. Lett. 2020, 45, 3973–3976. [Google Scholar] [CrossRef] [PubMed]

- Horng, R.-H.; Ye, C.-X.; Chen, P.-W.; Iida, D.; Ohkawa, K.; Wu, Y.-R.; Wuu, D.-S. Study on the effect of size on InGaN red micro-LEDs. Sci. Rep. 2022, 12, 1324. [Google Scholar] [CrossRef] [PubMed]

- Daami, A.; Olivier, F.; Dupré, L.; Henry, F.; Templier, F. 59-4: Invited Paper: Electro-Optical Size-Dependence Investigation in GaN Micro-LED Devices; SID Symposium Digest of Technical Papers; Wiley Online Library: Hoboken, NJ, USA, 2018; pp. 790–793. [Google Scholar]

- Yu, L.; Lu, B.; Yu, P.; Wang, Y.; Ding, G.; Feng, Q.; Jiang, Y.; Chen, H.; Huang, K.; Hao, Z. Ultra-small size (1–20 μm) blue and green micro-LEDs fabricated by laser direct writing lithography. Appl. Phys. Lett. 2022, 121, 042106. [Google Scholar] [CrossRef]

- Kim, K.-S.; Han, D.-P.; Kim, H.-S.; Shim, J.-I. Analysis of dominant carrier recombination mechanisms depending on injection current in InGaN green light emitting diodes. Appl. Phys. Lett. 2014, 104, 091110. [Google Scholar] [CrossRef]

- Wang, J.; Meisch, T.; Heinz, D.; Zeller, R.; Scholz, F. Internal quantum efficiency and carrier injection efficiency of c-plane, and InGaN/GaN-based light-emitting diodes. Phys. Status Solidi B 2016, 253, 174–179. [Google Scholar] [CrossRef]

- Li, Y.; Wang, S.; Su, X.; Tang, W.; Li, Q.; Guo, M.; Zhang, Y.; Zhang, M.; Yun, F.; Hou, X. Efficiency droop suppression of distance-engineered surface plasmon-coupled photoluminescence in GaN-based quantum well LEDs. AIP Adv. 2017, 7, 115118. [Google Scholar] [CrossRef] [Green Version]

- Nag, D.; Aggarwal, T.; Sinha, S.; Sarkar, R.; Bhunia, S.; Chen, Y.-F.; Ganguly, S.; Saha, D.; Horng, R.-H.; Laha, A. Carrier-induced defect saturation in green InGaN LEDs: A potential phenomenon to enhance efficiency at higher wavelength regime. ACS Photonics 2021, 8, 926–932. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, H.; Li, Y.; Wang, J.; Li, A.; Li, K.; Xu, C.; Zhang, M.; Tian, Z.; Li, Q.; Yun, F. Power-Dependent Optical Characterization of the InGaN/GaN-Based Micro-Light-Emitting-Diode (LED) in High Spatial Resolution. Nanomaterials 2023, 13, 2014. https://doi.org/10.3390/nano13132014

Yang H, Li Y, Wang J, Li A, Li K, Xu C, Zhang M, Tian Z, Li Q, Yun F. Power-Dependent Optical Characterization of the InGaN/GaN-Based Micro-Light-Emitting-Diode (LED) in High Spatial Resolution. Nanomaterials. 2023; 13(13):2014. https://doi.org/10.3390/nano13132014

Chicago/Turabian StyleYang, Haifeng, Yufeng Li, Jiawei Wang, Aixing Li, Kun Li, Chuangcheng Xu, Minyan Zhang, Zhenhuan Tian, Qiang Li, and Feng Yun. 2023. "Power-Dependent Optical Characterization of the InGaN/GaN-Based Micro-Light-Emitting-Diode (LED) in High Spatial Resolution" Nanomaterials 13, no. 13: 2014. https://doi.org/10.3390/nano13132014

APA StyleYang, H., Li, Y., Wang, J., Li, A., Li, K., Xu, C., Zhang, M., Tian, Z., Li, Q., & Yun, F. (2023). Power-Dependent Optical Characterization of the InGaN/GaN-Based Micro-Light-Emitting-Diode (LED) in High Spatial Resolution. Nanomaterials, 13(13), 2014. https://doi.org/10.3390/nano13132014