Thermal Nanoimprint Lithography—A Review of the Process, Mold Fabrication, and Material

Abstract

1. Introduction

1.1. Demand for Micro/Nanopatterning

1.2. Basis of Nanoimprint Lithography

2. Various T-NIL Processes

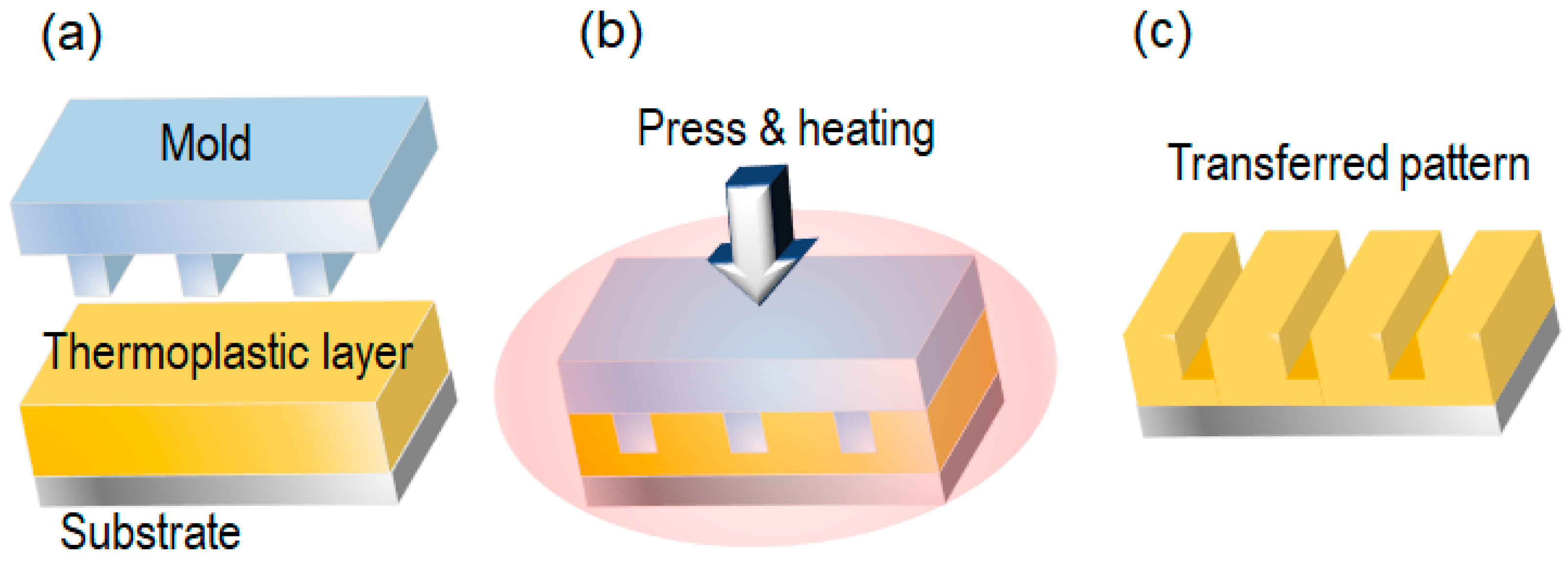

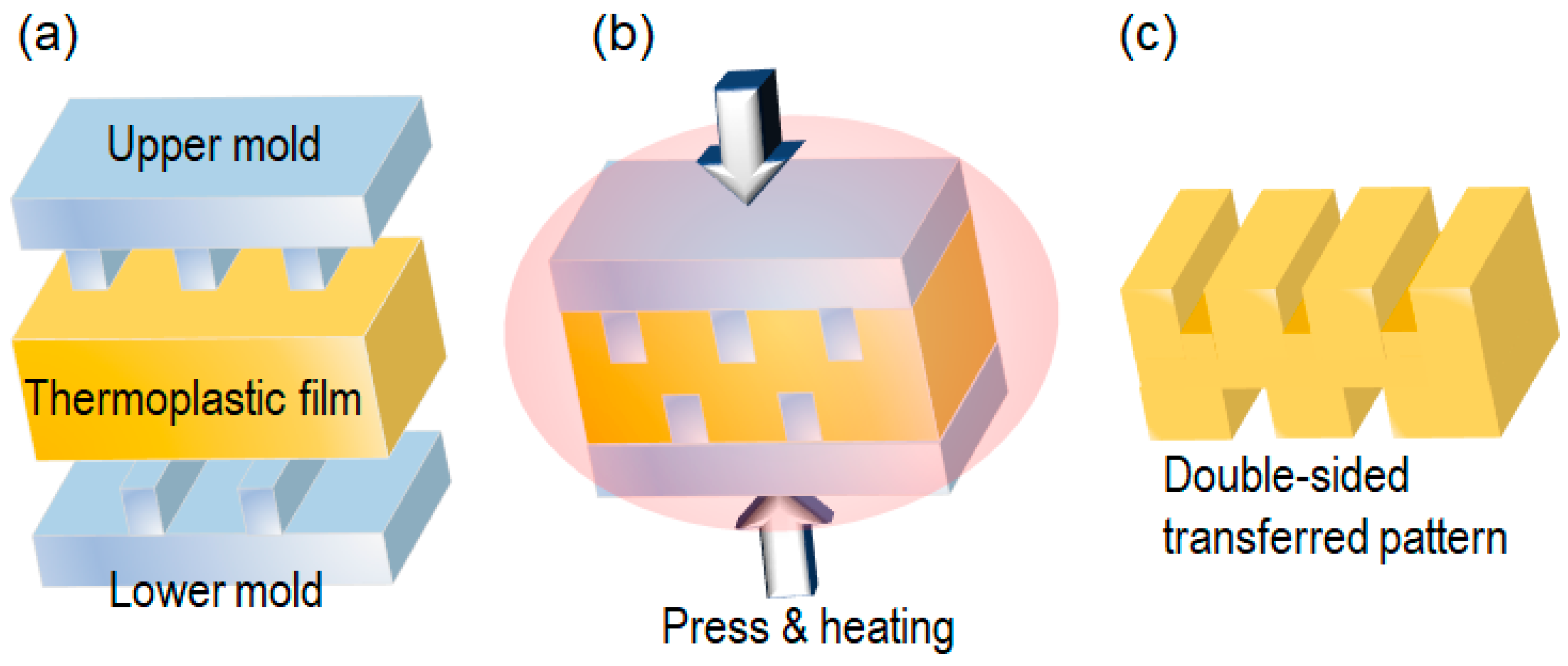

2.1. Planar T-NIL

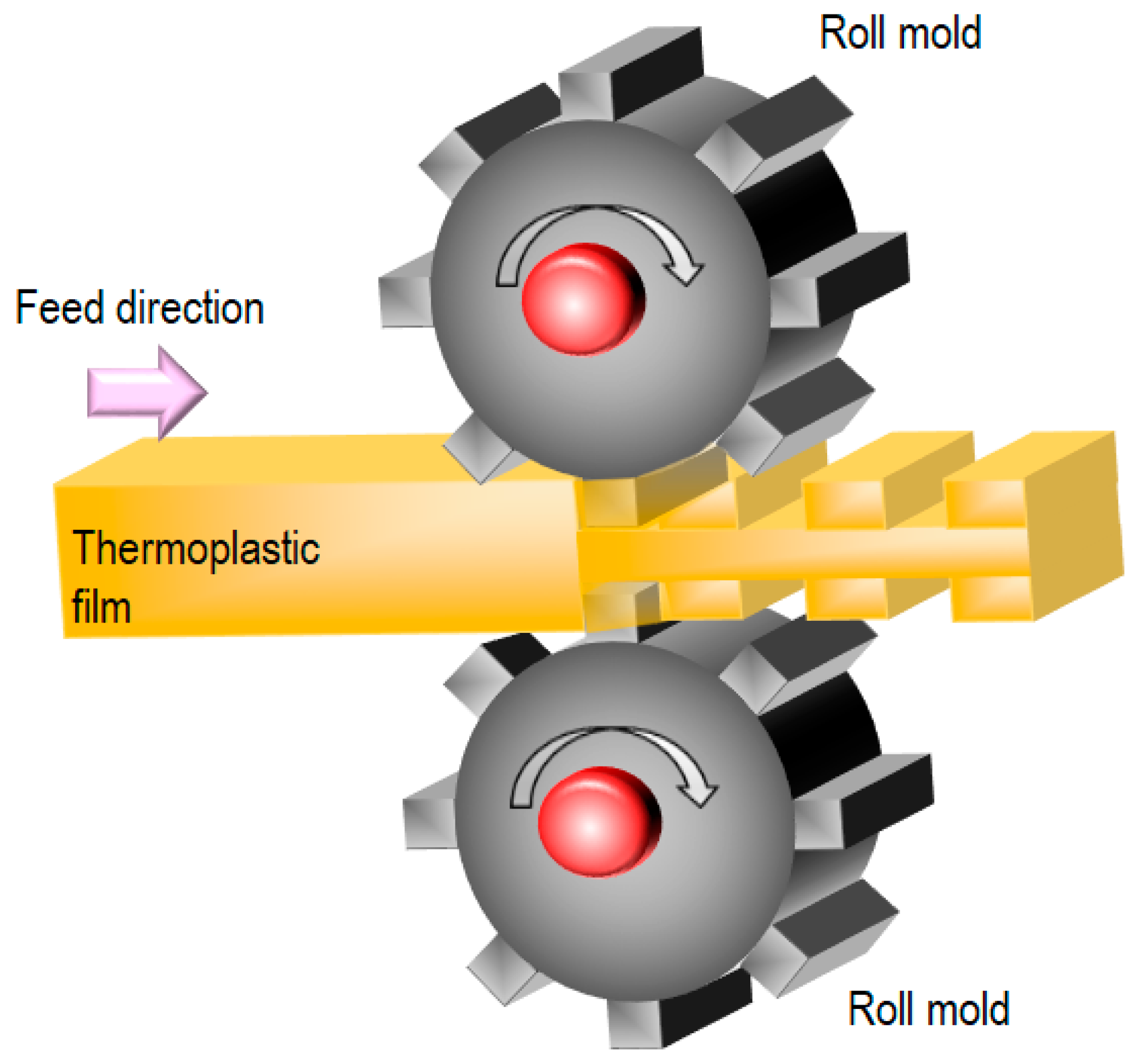

2.2. Roller T-NIL

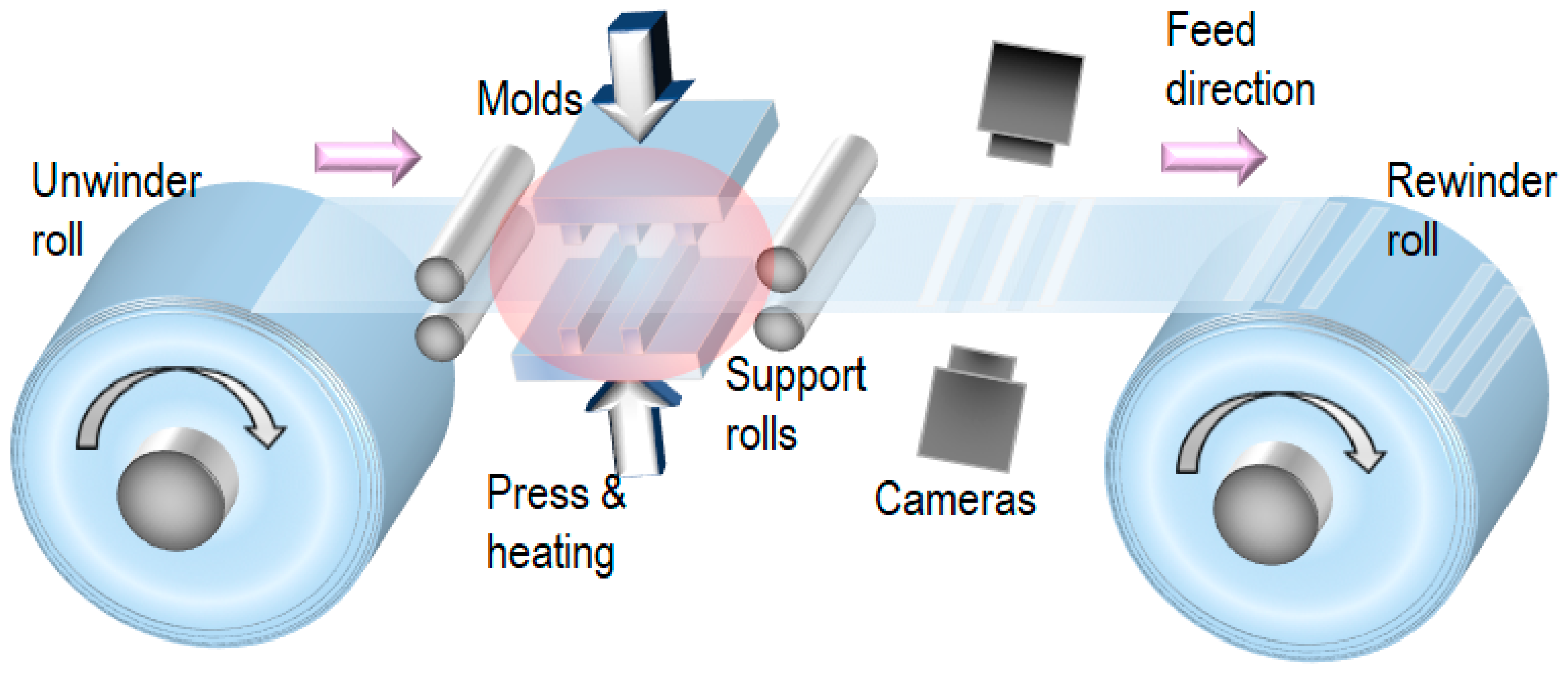

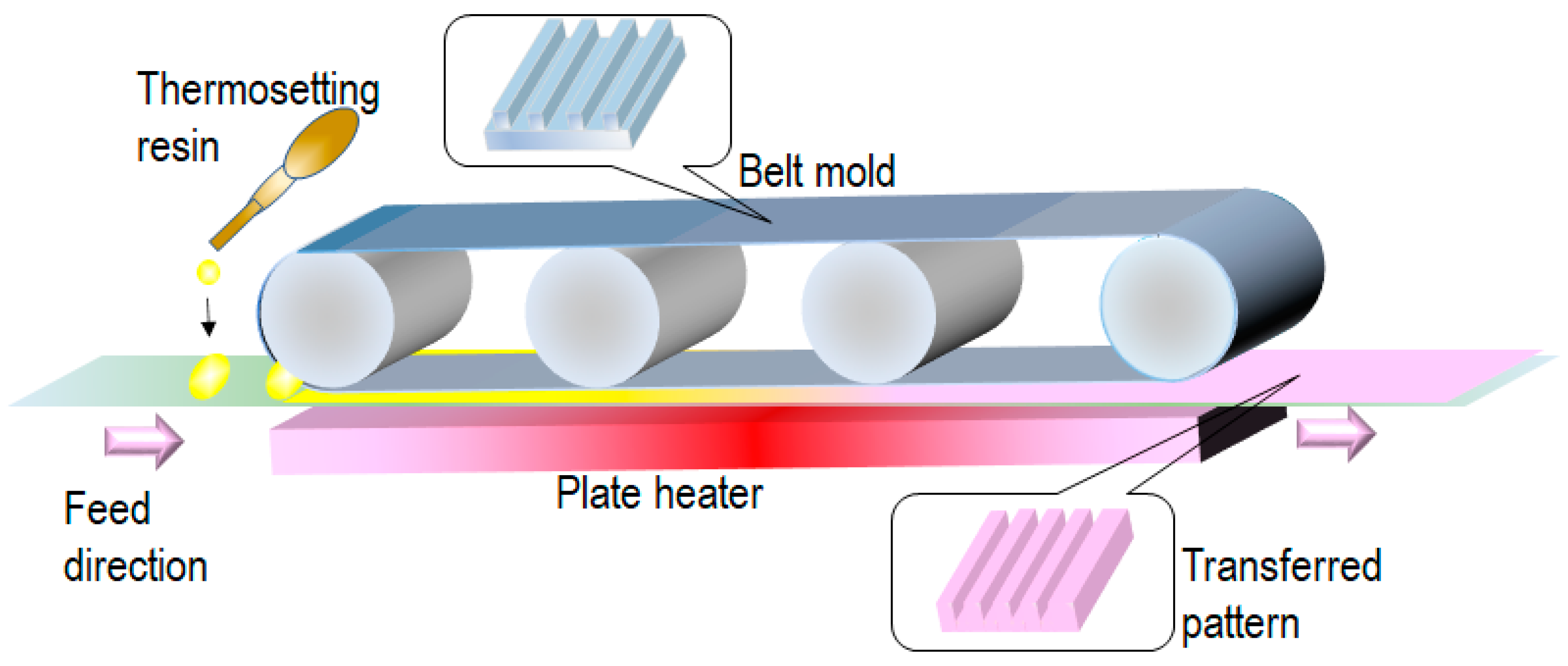

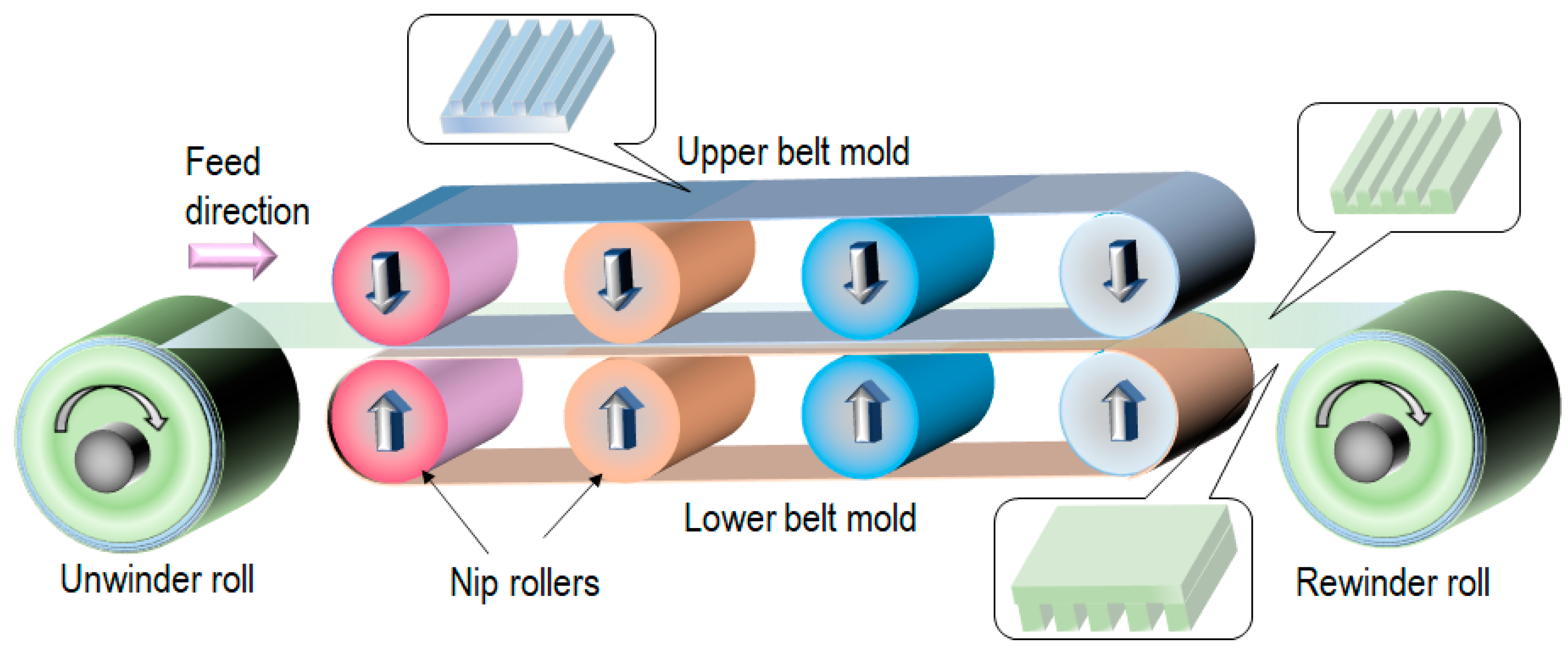

2.3. Roll-to-Roll T-NIL

2.4. Nanotransfer Printing (nTP)

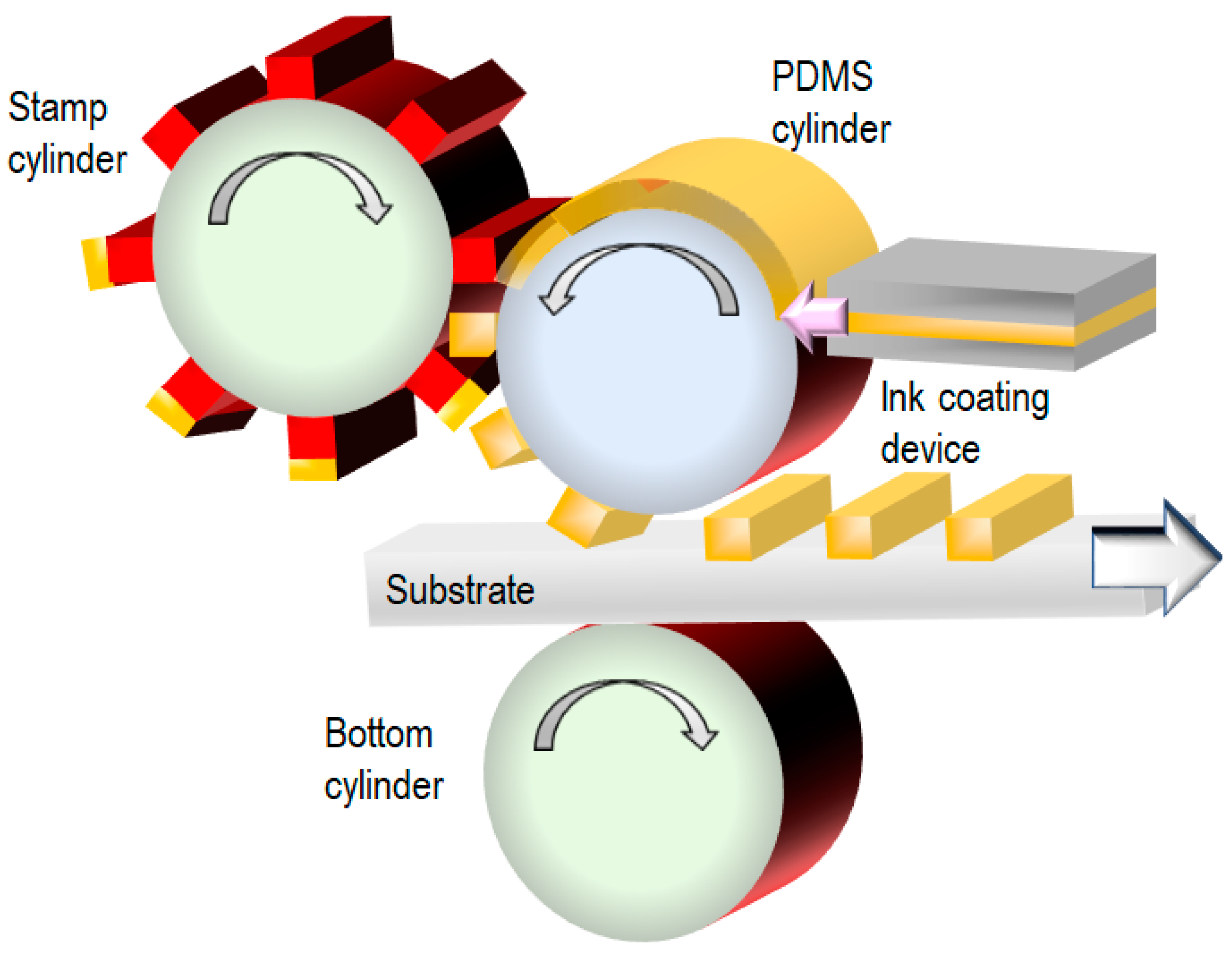

2.5. Reverse Offset Technology

3. Seamless Roll Mold Fabrication Technique

3.1. Advanced Machining Technology

3.2. Direct Laser Beam Writing

3.3. Direct Electron Beam Writing

3.4. Self-Assembled Patterns

4. Key Technology for T-NIL

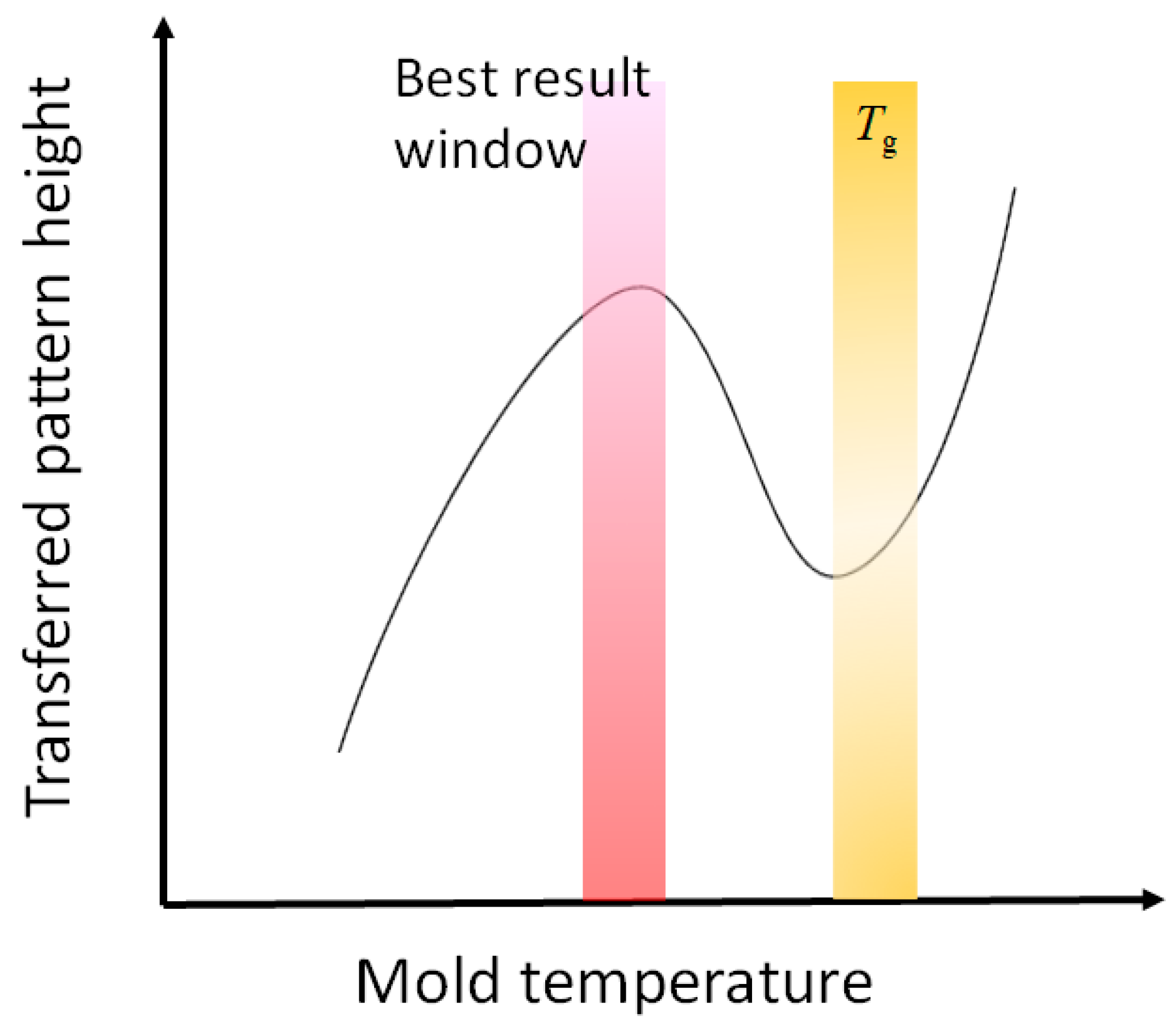

4.1. Viscoelastic Behavior (N-Curve)

4.2. High-Speed Heating and Cooling Method

4.3. Replica Mold for High-Temperature Durability

4.4. Film Preparation and Web System in Roll-to-Roll T-NIL

5. Materials for the T-NIL Process

6. Conclusions and Overview of the Next-Generation T-NIL Process

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Shulaker, M.M.; Hills, G.; Park, R.S.; Howe, R.T.; Saraswat, K.; Wong, H.S.P.; Mitra, S. Three-dimensional integration of nanotechnologies for computing and data storage on a single chip. Nature 2017, 547, 74–78. [Google Scholar] [CrossRef] [PubMed]

- Patabadige, D.E.; Jia, S.; Sibbitts, J.; Sadeghi, J.; Sellens, K.; Culbertson, C.T. Micro total analysis systems: Fundamental advances and applications. Anal. Chem. 2016, 88, 320–338. [Google Scholar] [CrossRef] [PubMed]

- Tullii, G.; Giona, F.; Lodola, F.; Bonfadini, S.; Bossio, C.; Varo, S.; Desii, A.; Criante, L.; Sala, C.; Pasini, M.; et al. High-aspect-ratio semiconducting polymer pillars for 3D cell cultures. ACS Appl. Mater. Interfaces 2019, 11, 28125–28137. [Google Scholar] [CrossRef] [PubMed]

- Bae, S.I.; Kim, K.; Jang, K.W.; Kim, H.K.; Jeong, K.H. High contrast ultrathin light-field camera using inverted microlens arrays with metal–insulator–metal optical absorber. Adv. Opt. Mater. 2021, 9, 2001657. [Google Scholar] [CrossRef]

- Huang, Y.F.; Chattopadhyay, S.; Jen, Y.J.; Peng, C.Y.; Liu, T.A.; Hsu, Y.K.; Pan, C.L.; Lo, H.C.; Hsu, C.H.; Chang, Y.-H.; et al. Improved broadband and quasi-omnidirectional anti-reflection properties with biomimetic silicon nanostructures. Nat. Nanotechnol. 2007, 2, 770–774. [Google Scholar] [CrossRef]

- Sarkın, A.S.; Ekren, N.; Sağlam, Ş. A review of anti-reflection and self-cleaning coatings on photovoltaic panels. Sol. Energy 2020, 199, 63–73. [Google Scholar] [CrossRef]

- Fakharan, Z.; Dabirian, A. Metal grid technologies for flexible transparent conductors in large-area optoelectronics. Curr. Appl. Phys. 2021, 31, 105–121. [Google Scholar] [CrossRef]

- Li, W.D.; Ding, F.; Hu, J.; Chou, S.Y. Three-dimensional cavity nanoantenna coupled plasmonic nanodots for ultrahigh and uniform surface-enhanced Raman scattering over large area. Opt. Express 2011, 19, 3925–3936. [Google Scholar] [CrossRef]

- Kang, M.G.; Kim, M.S.; Kim, J.; Guo, L.J. Organic solar cells using nanoimprinted transparent metal electrodes. Adv. Mater. 2008, 20, 4408–4413. [Google Scholar] [CrossRef]

- Hossain, M.S.; Li, T.; Yu, Y.; Yong, J.; Bahk, J.H.; Skafidas, E. Recent advances in printable thermoelectric devices: Materials, printing techniques, and applications. RSC Adv. 2020, 10, 8421–8434. [Google Scholar] [CrossRef]

- Tan, M.; Liu, W.D.; Shi, X.L.; Sun, Q.; Chen, Z.G. Minimization of the electrical contact resistance in thin-film thermoelectric device. Appl. Phys. Rev. 2023, 10, 021404. [Google Scholar] [CrossRef]

- Yang, K.; Shi, J.; Wang, L.; Chen, Y.; Liang, C.; Yang, L.; Wang, L.N. Bacterial anti-adhesion surface design: Surface patterning, roughness and wettability: A review. J. Mater. Sci. Technol. 2022, 99, 82–100. [Google Scholar] [CrossRef]

- Hasan, J.; Raj, S.; Yadav, L.; Chatterjee, K. Engineering a nanostructured “super surface” with superhydrophobic and superkilling properties. RSC Adv. 2015, 5, 44953–44959. [Google Scholar] [CrossRef] [PubMed]

- Jing, T.; Kim, Y.; Lee, S.; Kim, D.; Kim, J.; Hwang, W. Frosting and defrosting on rigid superhydrohobic surface. Appl. Surf. Sci. 2013, 276, 37–42. [Google Scholar] [CrossRef]

- Gao, S.; Huang, H. Recent advances in micro-and nano-machining technologies. Front. Mech. Eng. 2017, 12, 18–32. [Google Scholar] [CrossRef]

- Dubey, A.K.; Yadava, V. Laser beam machining—A review. Int. J. Mach. Tools Manuf. 2008, 48, 609–628. [Google Scholar] [CrossRef]

- Unno, N.; Taniguchi, J.; Ishii, Y. Sub-100-nm three-dimensional nanoimprint lithography. J. Vac. Sci. Technol. B Microelectron. Nanometer Struct. Process. Meas. Phenom. 2007, 25, 2361–2364. [Google Scholar] [CrossRef]

- Taniguchi, J.; Satake, S.I.; Oosumi, T.; Fukushige, A.; Kogo, Y. Dwell time adjustment for focused ion beam machining. Nucl. Instrum. Methods Phys. Res. Sect. B Beam Interact. Mater. At. 2013, 307, 248–252. [Google Scholar] [CrossRef]

- Levinson, H.J. High-NA EUV lithography: Current status and outlook for the future. Jpn. J. Appl. Phys. 2022, 61, SD0803. [Google Scholar] [CrossRef]

- Austin, S.; Stone, F.T. Fabrication of thin periodic structures in photoresist: A model. Appl. Opt. 1976, 15, 1071–1074. [Google Scholar] [CrossRef]

- Chou, S.Y.; Krauss, P.R.; Renstrom, P.J. Imprint of sub-25 nm vias and trenches in polymers. Appl. Phys. Lett. 1995, 67, 3114–3116. [Google Scholar] [CrossRef]

- Haisma, J.; Verheijen, M.; Van Den Heuvel, K.; Van Den Berg, J. Mold-assisted nanolithography: A process for reliable pattern replication. J. Vac. Sci. Technol. B Microelectron. Nanometer Struct. Process. Meas. Phenom. 1996, 14, 4124–4128. [Google Scholar] [CrossRef]

- Li, W.D.; Wu, W.; Stanley Williams, R. Combined helium ion beam and nanoimprint lithography attains 4 nm half-pitch dense patterns. J. Vac. Sci. Technol. B Nanotechnol. Microelectron. Mater. Process. Meas. Phenom. 2012, 30, 06F304. [Google Scholar] [CrossRef]

- Iwata, J.; Ando, T. Molecular Dynamics Study on Behavior of Resist Molecules in UV-Nanoimprint Lithography Filling Process. Nanomaterials 2022, 12, 2554. [Google Scholar] [CrossRef] [PubMed]

- Chou, S.Y.; Krauss, P.R.; Renstrom, P.J. Nanoimprint lithography. J. Vac. Sci. Technol. B Microelectron. Nanometer Struct. Process. Meas. Phenom. 1996, 14, 4129–4133. [Google Scholar] [CrossRef]

- Talip, N.B.A.; Taniguchi, J. Fabrication of double-sided self-supporting antireflection-structured film by ultraviolet nanoimprint lithography. Jpn. J. Appl. Phys. 2014, 53, 06JK03. [Google Scholar]

- Marumo, T.; Hiwasa, S.; Taniguchi, J. Transfer Durability of Line-Patterned Replica Mold Made of High-Hardness UV-Curable Resin. Nanomaterials 2020, 10, 1956. [Google Scholar] [CrossRef]

- Tan, H.; Gilbertson, A.; Chou, S.Y. Roller nanoimprint lithography. J. Vac. Sci. Technol. B Microelectron. Nanometer Struct. Process. Meas. Phenom. 1998, 16, 3926–3928. [Google Scholar] [CrossRef]

- Lee, S.H.; Kim, S.W.; Kang, B.S.; Chang, P.S.; Kwak, M.K. Scalable and continuous fabrication of bio-inspired dry adhesives with a thermosetting polymer. Soft Matter 2018, 14, 2586–2593. [Google Scholar] [CrossRef]

- Ogino, M.; Hasegawa, M.; Sakaue, K.; Nagai, S.; Miyauchi, A. Fabrication of 200-nm dot pattern on 15-m-long polymer sheet using sheet nanoimprint method. Jpn. J. Appl. Phys. 2013, 52, 035201. [Google Scholar] [CrossRef]

- Mäkelä, T.; Haatainen, T.; Majander, P.; Ahopelto, J.; Lambertini, V. Continuous double-sided roll-to-roll imprinting of polymer film. Jpn. J. Appl. Phys. 2008, 47, 5142. [Google Scholar] [CrossRef]

- Loo, Y.L.; Willett, R.L.; Baldwin, K.W.; Rogers, J.A. Additive, nanoscale patterning of metal films with a stamp and a surface chemistry mediated transfer process: Applications in plastic electronics. Appl. Phys. Lett. 2002, 81, 562–564. [Google Scholar] [CrossRef]

- Unno, N.; Taniguchi, J. Two-tone metal pattern transfer technique using a single mold surface. Microelectron. Eng. 2010, 87, 1019–1023. [Google Scholar] [CrossRef]

- Sneck, A.; Mäkelä, T.; Alastalo, A. Reverse-offset for roll-to-roll high-resolution printing. Flex. Print. Electron. 2018, 3, 014001. [Google Scholar] [CrossRef]

- Sun, J.; Luo, X.; Chang, W.; Ritchie, J.M.; Chien, J.; Lee, A. Fabrication of periodic nanostructures by single-point diamond turning with focused ion beam built tool tips. J. Micromech. Microeng. 2012, 22, 115014. [Google Scholar] [CrossRef]

- Cates, N.; Einck, V.J.; Micklow, L.; Morère, J.; Okoroanyanwu, U.; Watkins, J.J.; Furst, S. Roll-to-roll nanoimprint lithography using a seamless cylindrical mold nanopatterned with a high-speed mastering process. Nanotechnology 2021, 32, 155301. [Google Scholar] [CrossRef]

- So, J.Y.; Bae, W.G. Fabrication of superhydrophobic metallic surface by wire electrical discharge machining for seamless roll-to-roll printing. Metals 2018, 8, 228. [Google Scholar] [CrossRef]

- Ahmmed, K.T.; Grambow, C.; Kietzig, A.M. Fabrication of micro/nano structures on metals by femtosecond laser micromachining. Micromachines 2014, 5, 1219–1253. [Google Scholar] [CrossRef]

- Deubel, M.; Von Freymann, G.; Wegener, M.; Pereira, S.; Busch, K.; Soukoulis, C.M. Direct laser writing of three-dimensional photonic-crystal templates for telecommunications. Nat. Mater. 2004, 3, 444–447. [Google Scholar] [CrossRef]

- Coelho, S.; Baek, J.; Walsh, J.; Justin Gooding, J.; Gaus, K. Direct-laser writing for subnanometer focusing and single-molecule imaging. Nat. Commun. 2022, 13, 647. [Google Scholar] [CrossRef]

- Fischer, J.; von Freymann, G.; Wegener, M. The materials challenge in diffraction-unlimited direct-laser-writing optical lithography. Adv. Mater. 2010, 22, 3578–3582. [Google Scholar] [CrossRef] [PubMed]

- Lu, C.; Lipson, R.H. Interference lithography: A powerful tool for fabricating periodic structures. Laser Photonics Rev. 2010, 4, 568–580. [Google Scholar] [CrossRef]

- Taniguchi, J.; Aratani, M. Fabrication of a seamless roll mold by direct writing with an electron beam on a rotating cylindrical substrate. J. Vac. Sci. Technol. B Microelectron. Nanometer Struct. Process. Meas. Phenom. 2009, 27, 2841–2845. [Google Scholar] [CrossRef]

- Maruyama, H.; Unno, N.; Taniguchi, J. Fabrication of roll mold using electron-beam direct writing and metal lift-off process. Microelectron. Eng. 2012, 97, 113–116. [Google Scholar] [CrossRef]

- Taniguchi, J.; Unno, N.; Maruyama, H. Large-diameter roll mold fabrication method using a small-diameter quartz roll mold and UV nanoimprint lithography. J. Vac. Sci. Technol. B Nanotechnol. Microelectron. Mater. Process. Meas. Phenom. 2011, 29, 06FC08. [Google Scholar] [CrossRef]

- Keller, F.; Hunter, M.S.; Robinson, D.L. Structural features of oxide coatings on aluminum. J. Electrochem. Soc. 1953, 100, 411. [Google Scholar] [CrossRef]

- Hamley, I.W. Nanostructure fabrication using block copolymers. Nanotechnology 2003, 14, R39. [Google Scholar] [CrossRef]

- Yanagishita, T.; Kondo, T.; Nishio, K.; Masuda, H. Optimization of antireflection structures of polymer based on nanoimprinting using anodic porous alumina. J. Vac. Sci. Technol. B Microelectron. Nanometer Struct. Process. Meas. Phenom. 2008, 26, 1856–1859. [Google Scholar] [CrossRef]

- Lu, Y.T.; Barron, A.R. Nanopore-type black silicon anti-reflection layers fabricated by a one-step silver-assisted chemical etching. Phys. Chem. Chem. Phys. 2013, 15, 9862–9870. [Google Scholar] [CrossRef]

- Taniguchi, J.; Nemoto, Y.; Sugiyama, Y. Fabrication of non reflective structure on glassy carbon surface using oxygen ion beam irradiation. J. Nanosci. Nanotechnol. 2009, 9, 445–449. [Google Scholar] [CrossRef]

- Kato, K.; Sugawara, H.; Taniguchi, J. Large-Scale Moth-Eye-Structured Roll Mold Fabrication Using Sputtered Glassy Carbon Layer and Transferred Moth-Eye Film Characterization. Nanomaterials 2023, 13, 1591. [Google Scholar] [CrossRef] [PubMed]

- Unno, N.; Mäkelä, T.; Taniguchi, J. Self-relaxation characteristics of roll-to-roll imprinted nanogratings on plastic film. Microelectron. Eng. 2016, 153, 83–87. [Google Scholar] [CrossRef]

- Unno, N.; Mäkelä, T.; Taniguchi, J. Thermal roll-to-roll imprinted nanogratings on plastic film. J. Vac. Sci. Technol. B Nanotechnol. Microelectron. Mater. Process. Meas. Phenom. 2014, 32, 06FG03. [Google Scholar] [CrossRef]

- Tormen, M.; Malureanu, R.; Pedersen, R.H.; Lorenzen, L.; Rasmussen, K.H.; Lüscher, C.J.; Kristensen, A.; Hansen, O. Fast thermal nanoimprint lithography by a stamp with integrated heater. Microelectron. Eng. 2008, 85, 1229–1232. [Google Scholar] [CrossRef]

- Nagato, K.; Yajima, Y.; Nakao, M. Laser-Assisted thermal imprinting of microlens arrays—Effects of pressing pressure and pattern size. Materials 2019, 12, 675. [Google Scholar] [CrossRef]

- Fu, X.; Chen, Q.; Chen, X.; Zhang, L.; Yang, A.; Cui, Y.; Yuan, C.; Ge, H. A rapid thermal nanoimprint apparatus through induction heating of nickel mold. Micromachines 2019, 10, 334. [Google Scholar] [CrossRef]

- Mekaru, H.; Takahashi, M. Ultrasonic nanoimprint on poly (ethylene terephthalate) at room temperature. Jpn. J. Appl. Phys. 2008, 47, 5178. [Google Scholar] [CrossRef]

- Lee, B.K.; Hong, L.Y.; Lee, H.Y.; Kim, D.P.; Kawai, T. Replica mold for nanoimprint lithography from a novel hybrid resin. Langmuir 2009, 25, 11768–11776. [Google Scholar] [CrossRef]

- Choi, D.G.; Jeong, J.H.; Sim, Y.S.; Lee, E.S.; Kim, W.S.; Bae, B.S. Fluorinated organic− inorganic hybrid mold as a new stamp for nanoimprint and soft lithography. Langmuir 2005, 21, 9390–9392. [Google Scholar] [CrossRef]

- Otsuka, Y.; Hiwasa, S.; Taniguchi, J. Development of release agent-free replica mould material for ultraviolet nanoimprinting. Microelectron. Eng. 2014, 123, 192–196. [Google Scholar] [CrossRef]

- Unno, N.; Kakimoto, S.; Mäkelä, T.; Hiwasa, S.; Taniguchi, J. Thermal roll-to-roll nanoimprinting using a replica mold without release agent. J. Adv. Mech. Des. Syst. Manuf. 2018, 12, JAMDSM0101. [Google Scholar] [CrossRef]

- Mäkelä, T.; Kainlauri, M.; Willberg-Keyriläinen, P.; Tammelin, T.; Forsström, U. Fabrication of micropillars on nanocellulose films using a roll-to-roll nanoimprinting method. Microelectron. Eng. 2016, 163, 1–6. [Google Scholar] [CrossRef]

- Mäkelä, T.; Hokkanen, A.; Sneck, A.; Ruotsalainen, T.; Khakalo, A.; Tammelin, T. Vapour-assisted roll-to-roll nanoimprinting of micropillars on nanocellulose films. Microelectron. Eng. 2020, 225, 111258. [Google Scholar] [CrossRef]

- Scheer, H.C.; Bogdanski, N.; Wissen, M.; Möllenbeck, S. Impact of glass temperature for thermal nanoimprint. J. Vac. Sci. Technol. B Microelectron. Nanometer Struct. Process. Meas. Phenom. 2007, 25, 2392–2395. [Google Scholar] [CrossRef]

- Gourgon, C.; Philippot, G.; Labau, S.; Tortai, J.H.; Benwadih, M.; Bablet, J. Influence of PEN thermal properties on flexible film patterned by nanoimprint lithography. Microelectron. Eng. 2011, 88, 1959–1963. [Google Scholar] [CrossRef]

- Tang, F.; Shao, Z.; Ni, M.; Cui, Y.; Yuan, C.; Ge, H. Fabrication of perforated polyethylene microfiltration membranes for circulating tumor cells separation by thermal nanoimprint method. Appl. Phys. A 2019, 125, 55. [Google Scholar] [CrossRef]

- Muanchan, P.; Suzuki, S.; Kyotani, T.; Ito, H. One-dimensional polymer nanofiber arrays with high aspect ratio obtained by thermal nanoimprint method. Polym. Eng. Sci. 2017, 57, 214–223. [Google Scholar] [CrossRef]

- Cecchini, M.; Signori, F.; Pingue, P.; Bronco, S.; Ciardelli, F.; Beltram, F. High-resolution poly (ethylene terephthalate) (PET) hot embossing at low temperature: Thermal, mechanical, and optical analysis of nanopatterned films. Langmuir 2008, 24, 12581–12586. [Google Scholar] [CrossRef]

- Metwally, K.; Robert, L.; Queste, S.; Gauthier-Manuel, B.; Khan-Malek, C. Roll manufacturing of flexible microfluidic devices in thin PMMA and COC foils by embossing and lamination. Microsyst. Technol. 2012, 18, 199–207. [Google Scholar] [CrossRef]

- Asif, M.; Tait, R.N.; Berini, P. Hot embossing of microfluidics in cyclic-olefin co-polymer using a wafer aligner-bonder. Microsyst. Technol. 2021, 27, 3899–3906. [Google Scholar] [CrossRef]

- Masciullo, C.; Sonato, A.; Romanato, F.; Cecchini, M. Perfluoropolyether (PFPE) intermediate molds for high-resolution thermal nanoimprint lithography. Nanomaterials 2018, 8, 609. [Google Scholar] [CrossRef] [PubMed]

- Osmani, B.; Schift, H.; Vogelsang, K.; Guzman, R.; Kristiansen, P.M.; Crockett, R.; Chacko, A.; Bucher, S.; Töpper, T.; Müller, B. Hierarchically structured polydimethylsiloxane films for ultra-soft neural interfaces. Micro Nano Eng. 2020, 7, 100051. [Google Scholar] [CrossRef]

- Martín-Rubio, C.; Rivelles, A.; Schneider, M.; Del Hoyo, J.C.; Privitera, V.; Worgull, M.; Maicas, M.; Sanz, R. Magnetic characterization of Permalloy nanodome surfaces on flexible PEEK/TiO2 vertical nanotubes composites. In IEEE Transactions on Magnetics; IEEE: Piscataway, NJ, USA, 2022. [Google Scholar]

- Suresh, V.; Ding, L.; Chew, A.B.; Yap, F.L. Fabrication of large-area flexible SERS substrates by nanoimprint lithography. ACS Appl. Nano Mater. 2018, 1, 886–893. [Google Scholar] [CrossRef]

- Zanut, A.; Cian, A.; Cefarin, N.; Pozzato, A.; Tormen, M. Nanoelectrode arrays fabricated by thermal nanoimprint lithography for biosensing application. Biosensors 2020, 10, 90. [Google Scholar] [CrossRef] [PubMed]

- Wu, C.C.; Hsu, S.L.C. High density patterns fabricated in low-viscosity thermal-curable epoxy system for thermal-nanoimprint lithography. In 2007 Digest of Papers Microprocesses and Nanotechnology; IEEE: Piscataway, NJ, USA, 2007; pp. 312–313. [Google Scholar]

- Cui, B.; Cortot, Y.; Veres, T. Polyimide nanostructures fabricated by nanoimprint lithography and its applications. Microelectron. Eng. 2006, 83, 906–909. [Google Scholar] [CrossRef]

- Greer, A.I.; Vasiev, I.; Della-Rosa, B.; Gadegaard, N. Fluorinated ethylene–propylene: A complementary alternative to PDMS for nanoimprint stamps. Nanotechnology 2016, 27, 155301. [Google Scholar] [CrossRef]

- Weiss, D.N.; Meyers, S.T.; Keszler, D.A. All-inorganic thermal nanoimprint process. J. Vac. Sci. Technol. B Nanotechnol. Microelectron. Mater. Process. Meas. Phenom. 2010, 28, 823–828. [Google Scholar] [CrossRef]

- Kurose, T.; Shishido, H.; Ishigami, A.; Nemoto, A.; Ito, H. Fabrication of high-resolution conductive patterns on a thermally imprinted polyetherimide film by the capillary flow of conductive ink. Microsyst. Technol. 2020, 26, 1981–1986. [Google Scholar] [CrossRef]

- Vig, A.L.; Mäkelä, T.; Majander, P.; Lambertini, V.; Ahopelto, J.; Kristensen, A. Roll-to-roll fabricated lab-on-a-chip devices. J. Micromech. Microeng. 2011, 21, 035006. [Google Scholar] [CrossRef]

- Striegel, A.; Schneider, M.; Schneider, N.; Benkel, C.; Worgull, M. Seamless tool fabrication for Roll-to-Roll microreplication. Microelectron. Eng. 2018, 194, 8–14. [Google Scholar] [CrossRef]

- Hong, S.H.; Hwang, J.Y.; Lee, H.; Lee, H.C.; Choi, K.W. UV nanoimprint using flexible polymer template and substrate. Microelectron. Eng. 2009, 86, 295–298. [Google Scholar] [CrossRef]

- Jaiswal, A.K.; Hokkanen, A.; Kumar, V.; Makela, T.; Harlin, A.; Orelma, H. Thermoresponsive nanocellulose films as an optical modulation device: Proof-of-concept. ACS Appl. Mater. Interfaces 2021, 13, 25346–25356. [Google Scholar] [CrossRef] [PubMed]

| Method | Pattern Size | Pattern Flexibility | Equipment Cost | Area Size | Aligning Possibility /Accuracy | Multilayering Possibility | Throughput |

|---|---|---|---|---|---|---|---|

| Mechanical Cutting | Sub-µm | Very high | Medium | Medium | Sub-micron | Difficult | Low |

| Direct writing (Laser) | Sub-µm | Very high | High | Small | Sub-micron | High | Low |

| Direct writing (EB and IB) | >nm | Very high | High | Small | Nanoscale | Possible (IB deposition) | Low |

| Photo lithography | >10 nm | High | Extremely High | Large | Nanoscale | Difficult | High |

| Self-assembled patterning | >10 nm | Low | Very low | Very large | Difficult | No | High |

| Future desired technique | >nm | Very high | Very low | Very large | Nanoscale | High | Very high |

| Hot Emboss | Injection Molding | T-NIL | UV-NIL | |

|---|---|---|---|---|

| Pattern size | >Sub-µm | >Sub-µm | >nm | >nm |

| Applicability | Thermosetting/ Thermoplastic resin | Thermosetting/ Thermoplastic resin | Thermosetting/ Thermoplastic resin | UV-curable resin |

| Material cost | Low | Low | Low | High |

| Area | Depends on the heated mold size | Depends on the heated mold size | Depends on the heated mold size | Restricted by the size of the UV exposure field |

| Mold | Typically hard | Typically hard | Hard/tractile/flexible | Hard/soft/flexible |

| Throughput | Low | High | Low (Planar process) | Very High |

| Theory Technological base | Based on continuum mechanics | Based on molecular dynamics [24], like an intermolecular force, surface tension. | ||

| Material Name | T-NIL Type | Process Temperature (°C) | Pressure (MPa) | Force (N) | Process Time | Ref. |

|---|---|---|---|---|---|---|

| PMMA | Planar | 200 | 10 | 3 min | [64] | |

| PS | Planar | 160 | 10 | 3 min | [64] | |

| PS | Belt-type RTR | 120–150 | 1.2 | 0.57 m/min Press time 1 s | [30] | |

| PEN | Planar | 290 | 2.5 | 10 min | [65] | |

| PE | Planar | 140 | 2.7 | N/A | [66] | |

| PP | Planar | 165–225 | 5.0 | 5 min for melting, 30 min for press | [67] | |

| PET | Planar | 75, 150 | 2.0 | 300 s | [68] | |

| COC | Roller | 70–110 | 0.55 | 0.5 m/min | [69] | |

| COC | Planar | 160 | 0.62 | 5 min for thermal equilibrium 30 s for press | [70] | |

| COC | Planar | 150 | 5 | 300 s | [71] | |

| PEEK | Planar | 180–280 | 20 k | 10 min | [72] | |

| PEEK | Planar | 365 | 25 k | 1 min | [73] | |

| PC | Planar | 160 | 5 | 300 s | [74] | |

| PC | Planar | 180 | 10 | 10 min | [75] | |

| Epoxy | Planar | 95 | 1.2 | 10 min | [76] | |

| PI | Planar | 200 | 3 | 2 min | [77] | |

| CNF | RTR | 155 | 8.3 | 0.3 m/min (imprint time 1 s) | [62] | |

| FEP | Planar | 270 | 0.18 | 5 min | [78] | |

| ETFE | Planar | 250 | 1.38 3.10 | 10 s 1 min | [79] | |

| PEI | Planar | 285 | 1.0 | 3 min | [80] | |

| CA | RTR | 115 | 13.6 | 0.2 m/min | [81] | |

| PSU | RTR | 155 | 300 N/mm | 2.1 m/min | [82] | |

| PES | RTR | 166 | 300 N/mm | 2.1 m/min | [82] | |

| PVC | Planar | <120 | <1 | N/A | [83] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Unno, N.; Mäkelä, T. Thermal Nanoimprint Lithography—A Review of the Process, Mold Fabrication, and Material. Nanomaterials 2023, 13, 2031. https://doi.org/10.3390/nano13142031

Unno N, Mäkelä T. Thermal Nanoimprint Lithography—A Review of the Process, Mold Fabrication, and Material. Nanomaterials. 2023; 13(14):2031. https://doi.org/10.3390/nano13142031

Chicago/Turabian StyleUnno, Noriyuki, and Tapio Mäkelä. 2023. "Thermal Nanoimprint Lithography—A Review of the Process, Mold Fabrication, and Material" Nanomaterials 13, no. 14: 2031. https://doi.org/10.3390/nano13142031

APA StyleUnno, N., & Mäkelä, T. (2023). Thermal Nanoimprint Lithography—A Review of the Process, Mold Fabrication, and Material. Nanomaterials, 13(14), 2031. https://doi.org/10.3390/nano13142031