An Optical 1×4 Power Splitter Based on Silicon–Nitride MMI Using Strip Waveguide Structures

Abstract

:1. Introduction

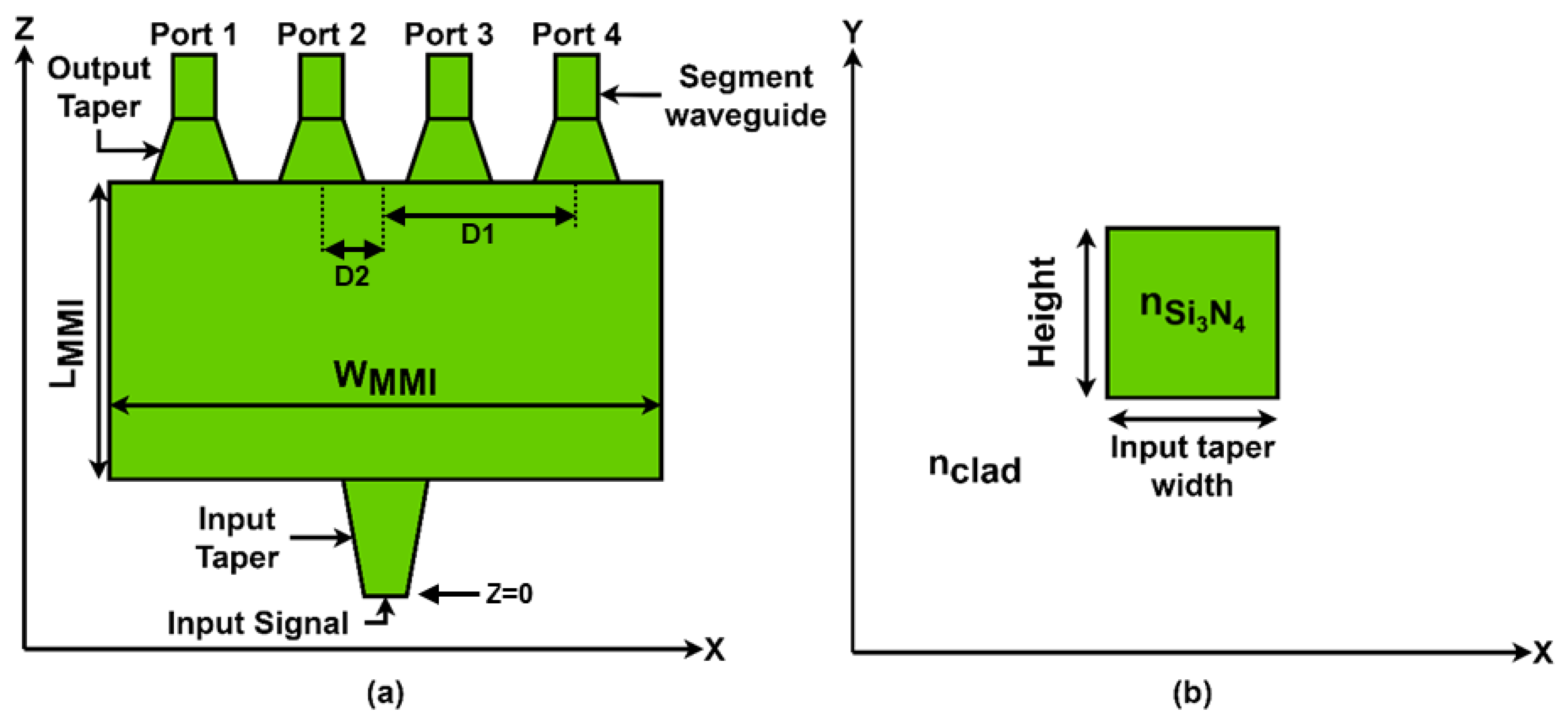

2. The Power Splitter Structure and Theoretical Aspect

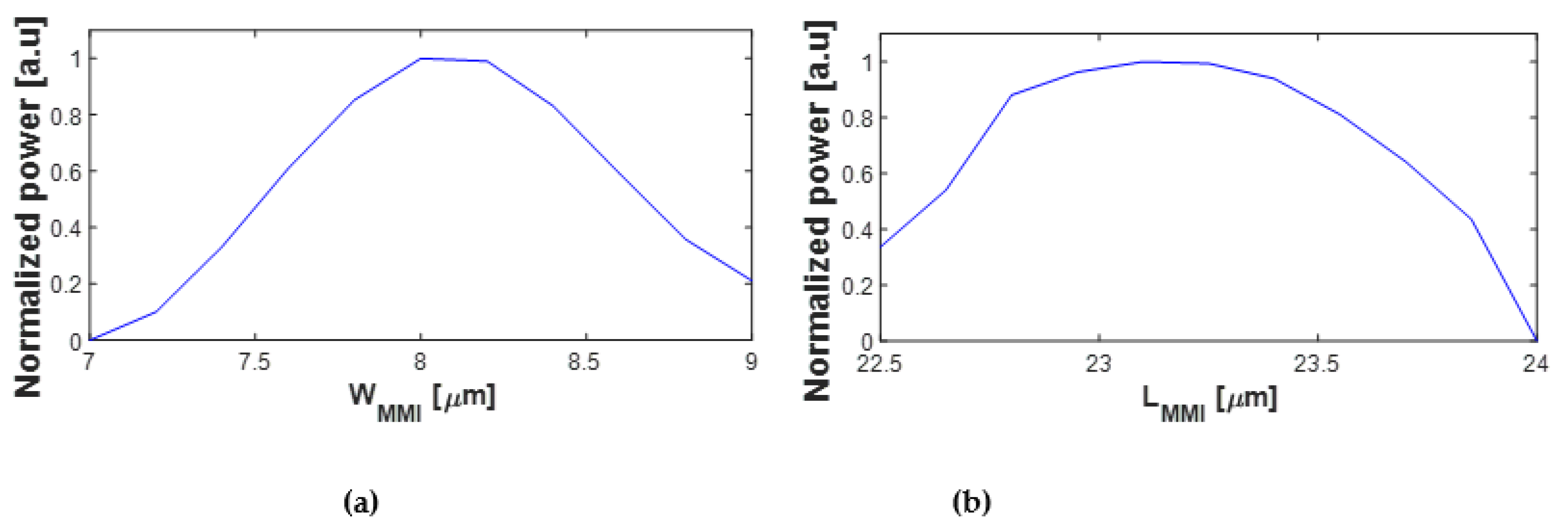

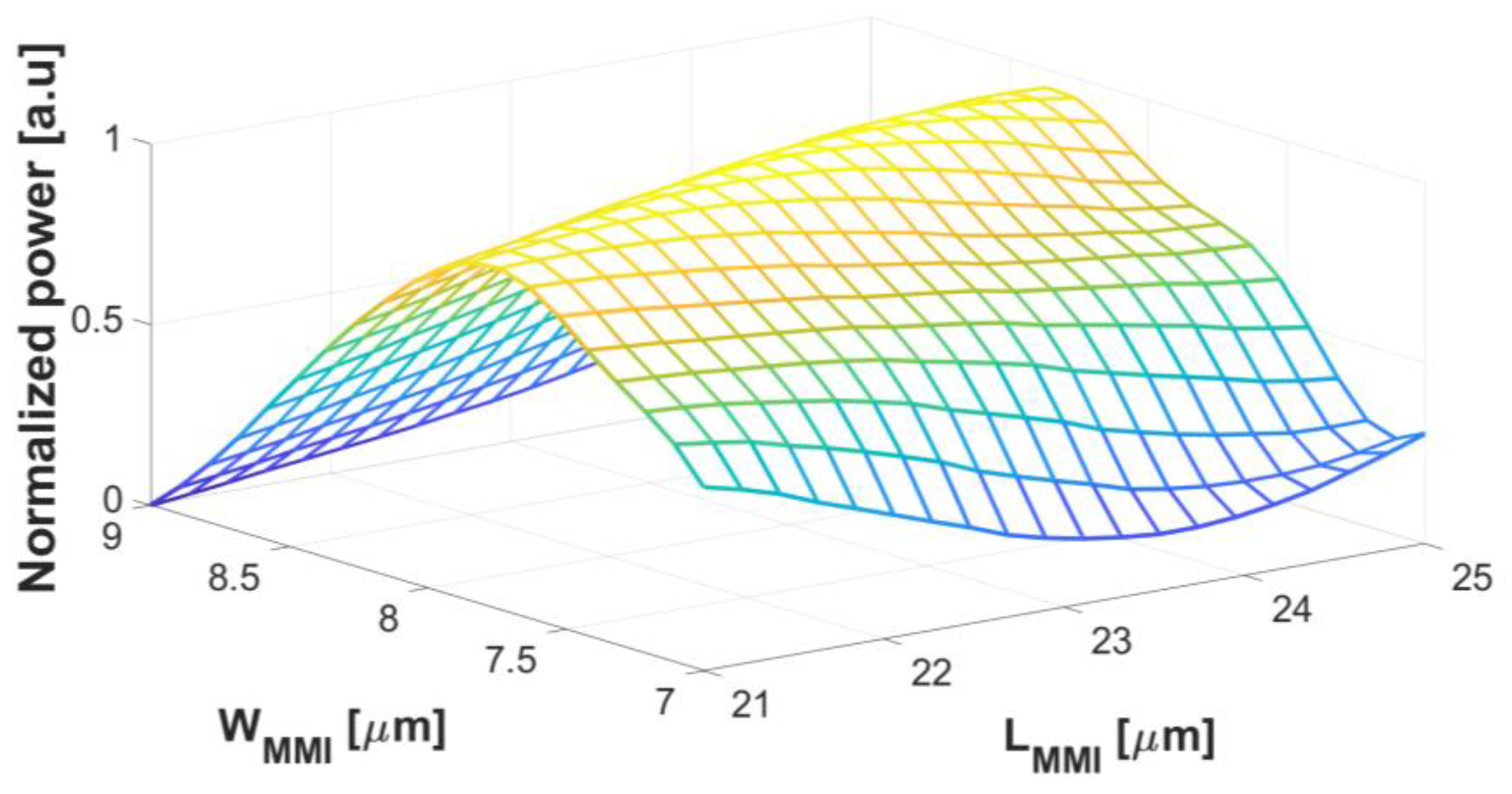

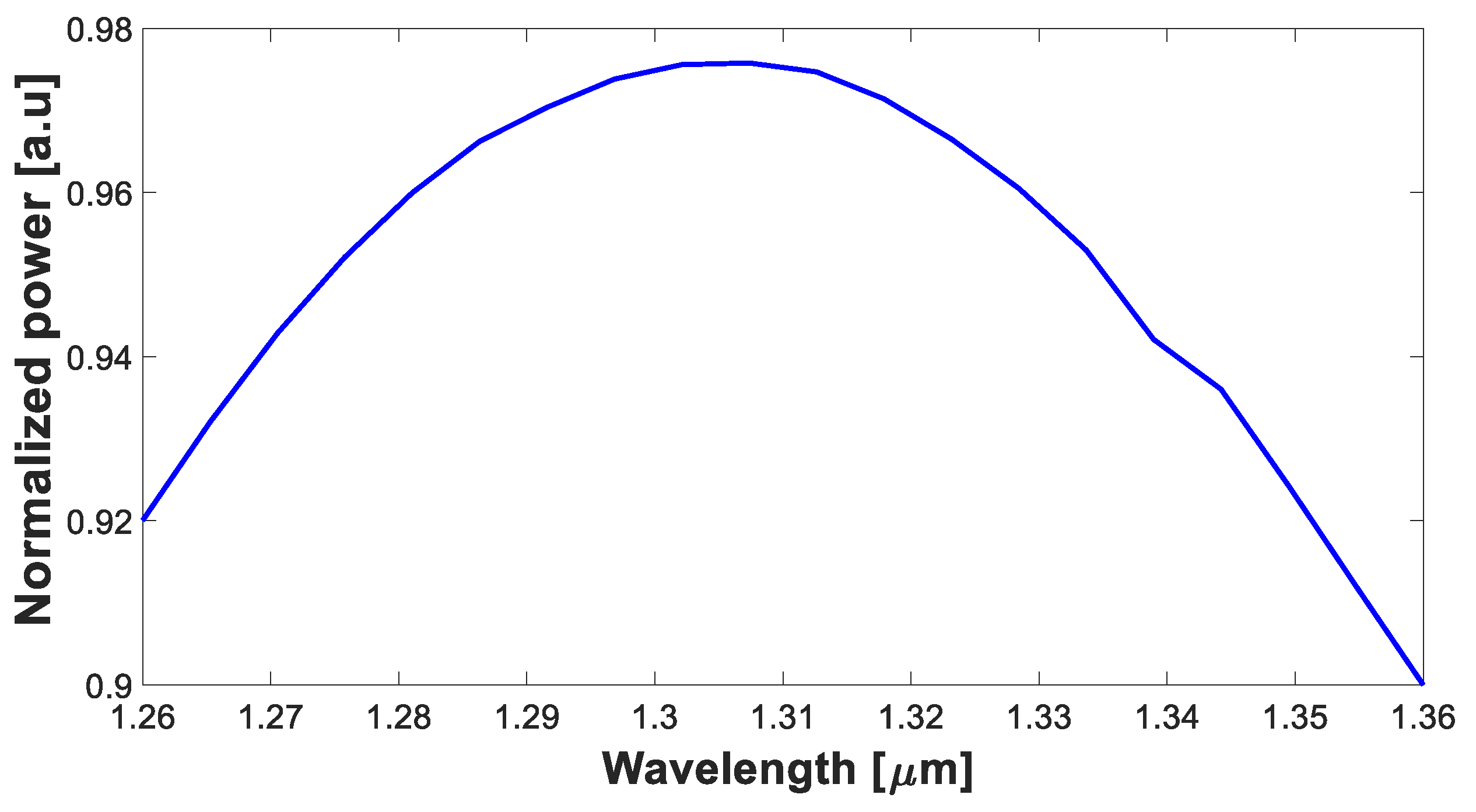

3. Simulation Results

4. Silicon-Nitride Fabrication

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Huang, Z.; Scarmozzino, R.; Osgood, R.M., Jr. A new design approach to large input/output number multimode interference couplers and its application to low-crosstalk WDM routers IEEE Photon. Technol. Lett. 1998, 10, 1292–1294. [Google Scholar] [CrossRef]

- Phillips, A.J.; Senior, J.M.; Mercinelli, R.; Valvo, M.; Vetter, P.J.; Martin, C.M.; van Deventer, M.O.; Vaes, P.; Qiu, X.Z. Redundancy Strategies for a High Splitting Optically Amplified Passive Optical Network. J. Light. Technol. 2011, 19, 137–149. [Google Scholar] [CrossRef]

- Soldano, L.B.; Smit, M.; Vreede, D.; Uffelen, J.; Verbeek, B.; Bennekom, V.; Krom, D.; Etten, V. New all-passive 4 × 4 planar optical phase diversity network. In Proceedings of the European Conference on Optical Communication (ECOC), Paris, France, 26–30 September 1991; pp. 96–99. [Google Scholar]

- Bachmann, M.; Smit, M.K.; Besse, P.A.; Gini, E.; Melchior, H.; Soldano, L.B. Polarization-insensitive low-voltage optical waveguide switch using InGaAsP/InP four-port Mach–Zehnder interferometer. In Proceedings of the Optical Fiber Communication Conference (OFC), San JoSe, CA, USA, 21 February 1993; pp. 32–33. [Google Scholar]

- Besse, P.A.; Bachmann, M.; Melchior, H.; Soldano, L.B.; Smit, M.K. Optical bandwidth and fabrication tolerances of multimode interference couplers. J. Light. Technol. 1994, 12, 1001–1009. [Google Scholar] [CrossRef] [Green Version]

- Soldano, L.B.; Pennings, E.C.M. Optical multimode interference devices based on self-imaging: Principles and applications. J. Light. Technol. 1995, 13, 615–627. [Google Scholar] [CrossRef] [Green Version]

- Siew, S.Y.; Li, B.; Gao, F.; Zheng, H.Y.; Zhang, W.; Guo, P.; Xie, S.W.; Song, A.; Dong, B.; Luo, L.W.; et al. Review of Silicon Photonics Technology and Platform Development. J. Light. Technol. 2021, 39, 4374–4389. [Google Scholar] [CrossRef]

- Xu, C.; Hong, X.; Huang, W.P. Design optimization of integrated BiDi triplexer optical filter based on planar lightwave circuit. Opt. Express 2006, 14, 4675–4686. [Google Scholar] [CrossRef] [PubMed]

- Irace, A.; Breglio, G. All-silicon optical temperature sensor based on Multi-Mode Interference. Opt. Express 2003, 11, 2807–2812. [Google Scholar] [CrossRef]

- Ioudashkin, E.; Malka, D. A Three Demultiplexer C-Band Using Angled Multimode Interference in GaN–SiO2 Slot Waveguide Structures. Nanomaterials 2020, 10, 238. [Google Scholar] [CrossRef]

- Gindi, M.; Melamed, A.; Malka, D. A four green-light demultiplexer using a multi-gallium nitride slot-waveguide structure. Photonics Nanostruct.-Fundam. Appl. 2020, 42, 100855. [Google Scholar] [CrossRef]

- Zhang, Y.; Liu, L.; Wu, X.; Xu, L. Splitting-on-demand optical power splitters using multimode interference (MMI) waveguide with programmed modulations. Opt. Commun. 2008, 281, 426–432. [Google Scholar] [CrossRef]

- Hosseini, A.; Kwong, D.N.; Zhang, Y.; Subbaraman, H.; Xu, X.; Chen, R.T. 1 × N Multimode Interference Beam Splitter Design Techniques for on-Chip Optical Interconnections. J. Light. Technol. 2011, 17, 510–514. [Google Scholar] [CrossRef]

- Tajaldini, M.; Jafri, M.Z.M. Ultracompact Multimode Interference Coupler Designed by Parallel Particle Swarm Optimization with Parallel Finite-Difference Time-Domain. J. Light. Technol. 2014, 32, 1282–1289. [Google Scholar] [CrossRef]

- Brand, O.; Wolftson, B.; Malka, D. A Compact Polarization MMI Combiner Using Silicon Slot-Waveguide Structures. Micromachines 2023, 14, 1203. [Google Scholar] [CrossRef]

- Menahem, J.; Malka, D. A Two-Channel Silicon Nitride Multimode Interference Coupler with Low Back Reflection. Appl. Sci. 2022, 12, 11812. [Google Scholar] [CrossRef]

- Vlasov, Y.; Mcnab, S. Losses in single-mode silicon-on-insulator strip waveguides and bends. Opt. Express 2004, 12, 1622–1631. [Google Scholar] [CrossRef] [PubMed]

- Yulianti, I.; Supa’at, A.S.M.; Idrus, S.M.; Mohammad, A.B. Mohammad Optimization of buried type waveguide for single-mode operation. In Proceedings of the Fifth IASTED International Conference on Communication Systems and Networks (AsiaCSN 2008), Langkawi, Malaysia, 2–4 April 2008. [Google Scholar]

- Menahem, J.; Malka, D. 1 × 4 Wavelength Demultiplexer C-Band Using Cascaded Multimode Interference on SiN Buried Waveguide Structure. Materials 2022, 15, 5067. [Google Scholar] [CrossRef] [PubMed]

- Dadabayev, R.; Shabairou, N.; Zalevsky, Z.; Malka, D. A visible light RGB wavelength demultiplexer based on silicon-nitride multicore PCF. Opt. Laser Technol. 2019, 111, 411–416. [Google Scholar] [CrossRef]

- Blumenthal, D.J.; Heideman, R.; Geuzebroek, D.; Leinse, A.; Roeloffzen, C. Silicon nitride in silicon photonics. Proc. IEEE 2018, 106, 2209–2231. [Google Scholar] [CrossRef] [Green Version]

- Katash, N.; Khateeb, S.; Malka, D. Combining Four Gaussian Lasers Using Silicon Nitride MMI Slot Waveguide Structure. Micromachines 2022, 13, 1680. [Google Scholar] [CrossRef]

- Gao, G.; Chen, D.; Tao, S.; Zhang, Y.; Zhu, S.; Xiao, X.; Xia, J. Silicon nitride O-Band (de)multiplexers with low thermal sensitivity. Opt. Express 2017, 25, 12260–12267. [Google Scholar] [CrossRef]

- Xiang, C.; Guo, J.; Jin, W.; Wu, L.; Peters, J.; Xie, W.; Chang, L.; Shen, B.; Wang, H.; Yang, Q.; et al. High-performance lasers for fully integrated silicon nitride photonics. Nat. Commun. 2021, 12, 6650. [Google Scholar] [CrossRef]

- Karempudi, V.; Thakkar, I.; Hastings, J. A Silicon Nitride Microring Based High-Speed, Tuning-Efficient, Electro-Refractive Modulator. In Proceedings of the 2022 IEEE International Symposium on Smart Electronic Systems (iSES), Warangal, India, 19–22 December 2022; pp. 307–311. [Google Scholar]

- Bauters, J.F.; Heck, M.J.R.; John, D.; Dai, D.; Tien, M.-C.; Barton, J.S.; Leinse, A.; Heideman, R.G.; Blumenthal, D.J.; Bowers, J.E. Ultra-low-loss high-aspect-ratio Si3N4 waveguides. Opt. Express 2011, 19, 3163–3174. [Google Scholar] [CrossRef] [PubMed]

- Melloni, A.; Costa, R.; Cusmai, G.; Morichetti, F.; Martinelli, M. Waveguide index contrast: Implications for passive integrated optical components. In Proceedings of the 2005 IEEE/LEOS Workshop on Fibres and Optical Passive Components, Mondello, Italy, 22–24 June 2005; pp. 246–253. [Google Scholar]

- Pennings, E.; Van Roijen, R.; Van Stralen, M.; De Waard, P.; Koumans, R.; Verbeck, B. Reflection properties of multimode interference devices. IEEE Photon. Technol. Lett. 1994, 6, 715–718. [Google Scholar] [CrossRef] [Green Version]

- Hanfoug, R.; Augustin, L.M.; Barbarin, Y.; van der Tol, J.J.G.M.; Bente, E.; Karouta, F.; Rogers, D.; Oei, Y.S.; Leijtens, X.J.M.; Smit, M.K. A Multimode Interference coupler with low reflections. In Proceedings of the Symposium IEEE/LEOS Benelux Chapter 2005, Mons, Belgium, 1–2 December 2008; pp. 97–100. [Google Scholar]

- Khateeb, S.; Katash, N.; Malka, D. O-Band Multimode Interference Coupler Power Combiner Using Slot-Waveguide Structures. Appl. Sci. 2022, 12, 6444. [Google Scholar] [CrossRef]

- Malka, D.; Katz, G. An Eight-Channel C-Band Demux Based on Multicore Photonic Crystal Fiber. Nanomaterials 2018, 8, 845. [Google Scholar] [CrossRef] [Green Version]

- Malka, D.; Sintov, Y.; Zalevsky, Z. Design of a 1 × 4 silicon-alumina wavelength demultiplexer based on multimode interference in slot waveguide structures. J. Opt. 2015, 17, 125702. [Google Scholar] [CrossRef]

- Bucio, T.D.; Khokhar, A.Z.; Mashanovich, G.Z.; Gardes, F.Y. N-rich silicon nitride angled MMI for coarse wavelength division (de)multiplexing in the O-band. Opt. Lett. 2018, 43, 1251–1254. [Google Scholar] [CrossRef]

- Mu, J.; Vázquez-Córdova, S.A.; Sefunc, M.A.; Yong, Y.; García-Blanco, S.M. A Low-Loss and Broadband MMI-Based Multi/Demultiplexer in Si3N4/SiO2 Technology. J. Light. Technol. 2016, 34, 3603–3609. [Google Scholar] [CrossRef]

- Ay, F.; Aydinli, A. Comparative investigation of hydrogen bonding in silicon-based PECVD grown dielectrics for optical waveguides. Opt. Mater. 2004, 26, 33–46. [Google Scholar] [CrossRef] [Green Version]

- Bulla, D.A.P.; Borges, B.-H.V.; Romero, M.A.; Morimoto, N.I.; Neto, L.G. Design and fabrication of SiO/sub 2//Si/sub 3/N/sub 4/ integrated-optics waveguides on silicon substrates. IEEE Trans. Microw. Theory Tech. 2022, 50, 9–12. [Google Scholar] [CrossRef]

- Baets, R.; Subramanian, A.Z.; Clemmen, S.; Kuyken, B.; Bienstman, P.; Le Thomas, N.; Roelkens, G.; Van Thourhout, D.; Helin, P.; Severi, S. Silicon Photonics: Silicon nitride versus silicon-on-insulator. In Proceedings of the 2016 Optical Fiber Communications Conference and Exhibition (OFC), Anaheim, CA, USA, 20–24 March 2016. [Google Scholar]

- Witzens, J.; Hochberg, M. Optical detection of target molecule induced aggregation of nanoparticles by means of high-Q resonators. Opt. Express 2011, 19, 7034–7061. [Google Scholar] [CrossRef]

- Yakuhina, A.; Kadochkin, A.; Svetukhin, V.; Gorelov, D.; Generalov, S.; Amelichev, V. Investigation of Side Wall Roughness Effect on Optical Losses in a Multimode Si3N4 Waveguide Formed on a Quartz Substrate. Photonics 2020, 7, 104. [Google Scholar] [CrossRef]

- Lau, V., Jr.; Lan, C.-W. In situ observation and temperature profile study of silicon Thin-sheet growth on quartz and silicon nitride substrates. J. Cryst. Growth 2020, 552, 125938. [Google Scholar] [CrossRef]

- Malka, D.; Danan, Y.; Ramon, Y.; Zalevsky, Z. A Photonic 1 × 4 Power Splitter Based on Multimode Interference in Silicon–Gallium-Nitride Slot Waveguide Structures. Materials 2016, 9, 516. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Li, B.; Li, D.; Tang, B.; Zhang, P.; Yang, Y.; Liu, R.; Xie, L.; Li, Z. Towards monolithic low-loss silicon nitride waveguides on a mature 200 mm CMOS platform. Optik 2022, 250, 168309. [Google Scholar] [CrossRef]

- Nikolaevsky, L.; Shchori, T.; Malka, D. Modeling a 1 × 8 MMI Green Light Power Splitter Based on Gallium-Nitride Slot Waveguide Structure. IEEE Photonics Technol. Lett. 2018, 30, 720–723. [Google Scholar] [CrossRef]

- Shahriar, F.; Mehdi, M.; Abbas, A. Design and simulation of a compact and ultra-wideband polarization beam splitter based on a sub-wavelength grating multimode interference coupler. Appl. Phys. B 2020, 126, 118. [Google Scholar]

- Kwong, D.; Zhang, Y.; Hosseini, A.; Liu, Y.; Chen, R. Demonstration of Rib Waveguide Based 1x12 Multimode Interference Optical Beam Splitter on Silicon-on-Insulator. In Proceedings of the 2010 IEEE Photonics Society Summer Topical Meeting Series, PHOSST, Playa del Carmen, Mexico, 19–21 July 2010; pp. 221–222. [Google Scholar]

- Guo, Z.; Xiao, J. Ultracompact mode-order converting power splitter for mid-infrared wavelengths using an MMI coupler embedded with oblique subwavelength grating wires. Opt. Commun. 2021, 488, 126850. [Google Scholar] [CrossRef]

- Li, Z.; Fan, Z.; Zhou, J.; Cong, Q.; Zeng, X.; Zhang, Y.; Jia, L. Process Development of Low-Loss LPCVD Silicon Nitride Waveguides on 8-Inch Wafer. Appl. Sci. 2023, 13, 3660. [Google Scholar] [CrossRef]

- De Paoli, G.; Jantzen, S.L.; Bucio, T.D.; Skandalos, I.; Holmes, C.; Smith, P.G.R.; Milosevic, M.M.; Gardes, F.Y. Laser trimming of the operating wavelength of silicon nitride racetrack resonators. Photon. Res. 2020, 8, 677–683. [Google Scholar] [CrossRef] [Green Version]

- Su, Y.; Zhang, Y.; Qiu, C.; Guo, X.; Sun, L. Silicon Photonic Platform for Passive Waveguide Devices: Materials, Fabrication, and Applications. Adv. Mater. Technol. 2020, 5, 1901153. [Google Scholar] [CrossRef]

| Power Splitter Type | Width × Length [µm] | Number of Outputs [N] | Operation Spectrum [nm] | Insertion Loss [dB] | Back Reflection [dB] | Year of Publication |

|---|---|---|---|---|---|---|

| MMI using GaN–Si slot waveguide [41] | 5 × 24.3 | 4 | 1530–1565 | 0.07 | - | 2016 |

| MMI using GaN–SiO2 slot waveguide [43] | 4 × 16.5 | 8 | 460–670 | 0.11 | - | 2018 |

| MMI subwavelength grating SOI strip waveguide [44] | 4.8 × 21 | 2 | 1380–1630 | 1.2 | - | 2020 |

| MMI SOI rib waveguide [45] | 60 × 900 | 12 | 1550 | 0.8 [experimental result] | - | 2010 |

| MMI SWG SOI-SiO2 strip waveguide [46] | 3.6 × 7 | 2 | 1880–2100 | 0.41 | - | 2021 |

| MMI based on Si3N4 strip waveguide | 8.1 × 39.6 | 4 | 1260–1360 | 0.13 | 42.44 | this work |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Frishman, A.; Malka, D. An Optical 1×4 Power Splitter Based on Silicon–Nitride MMI Using Strip Waveguide Structures. Nanomaterials 2023, 13, 2077. https://doi.org/10.3390/nano13142077

Frishman A, Malka D. An Optical 1×4 Power Splitter Based on Silicon–Nitride MMI Using Strip Waveguide Structures. Nanomaterials. 2023; 13(14):2077. https://doi.org/10.3390/nano13142077

Chicago/Turabian StyleFrishman, Aviv, and Dror Malka. 2023. "An Optical 1×4 Power Splitter Based on Silicon–Nitride MMI Using Strip Waveguide Structures" Nanomaterials 13, no. 14: 2077. https://doi.org/10.3390/nano13142077