The Effect of Mono and Hybrid Additives of Ceramic Nanoparticles on the Tribological Behavior and Mechanical Characteristics of an Al-Based Composite Matrix Produced by Friction Stir Processing

Abstract

1. Introduction

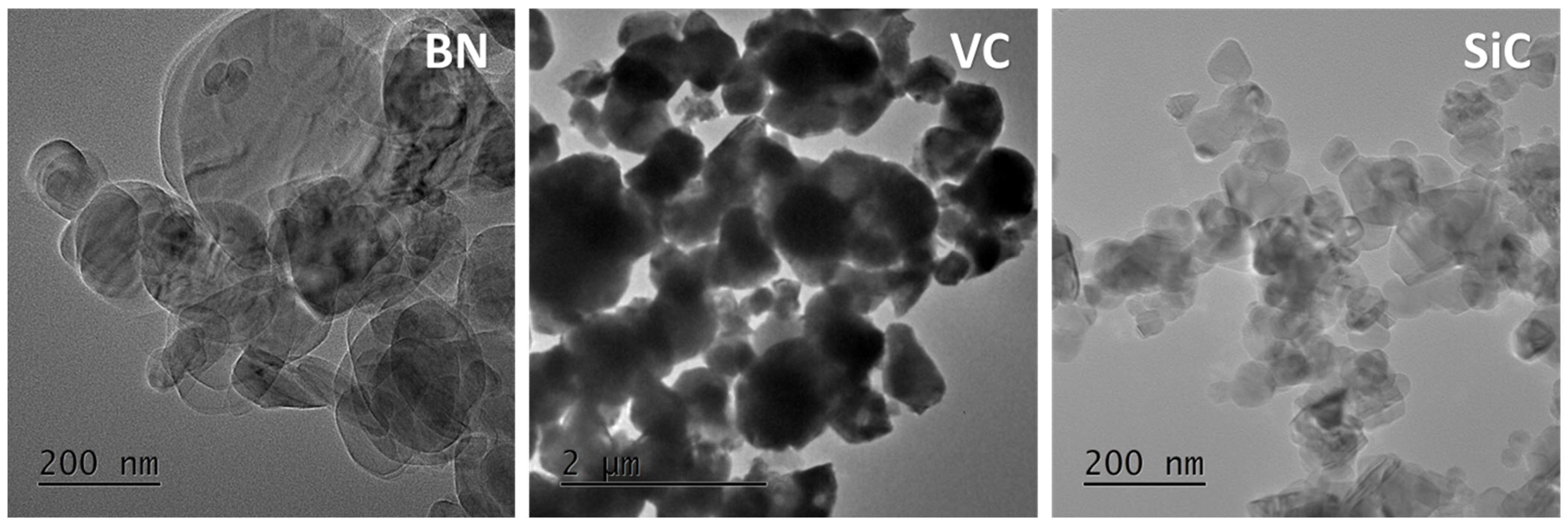

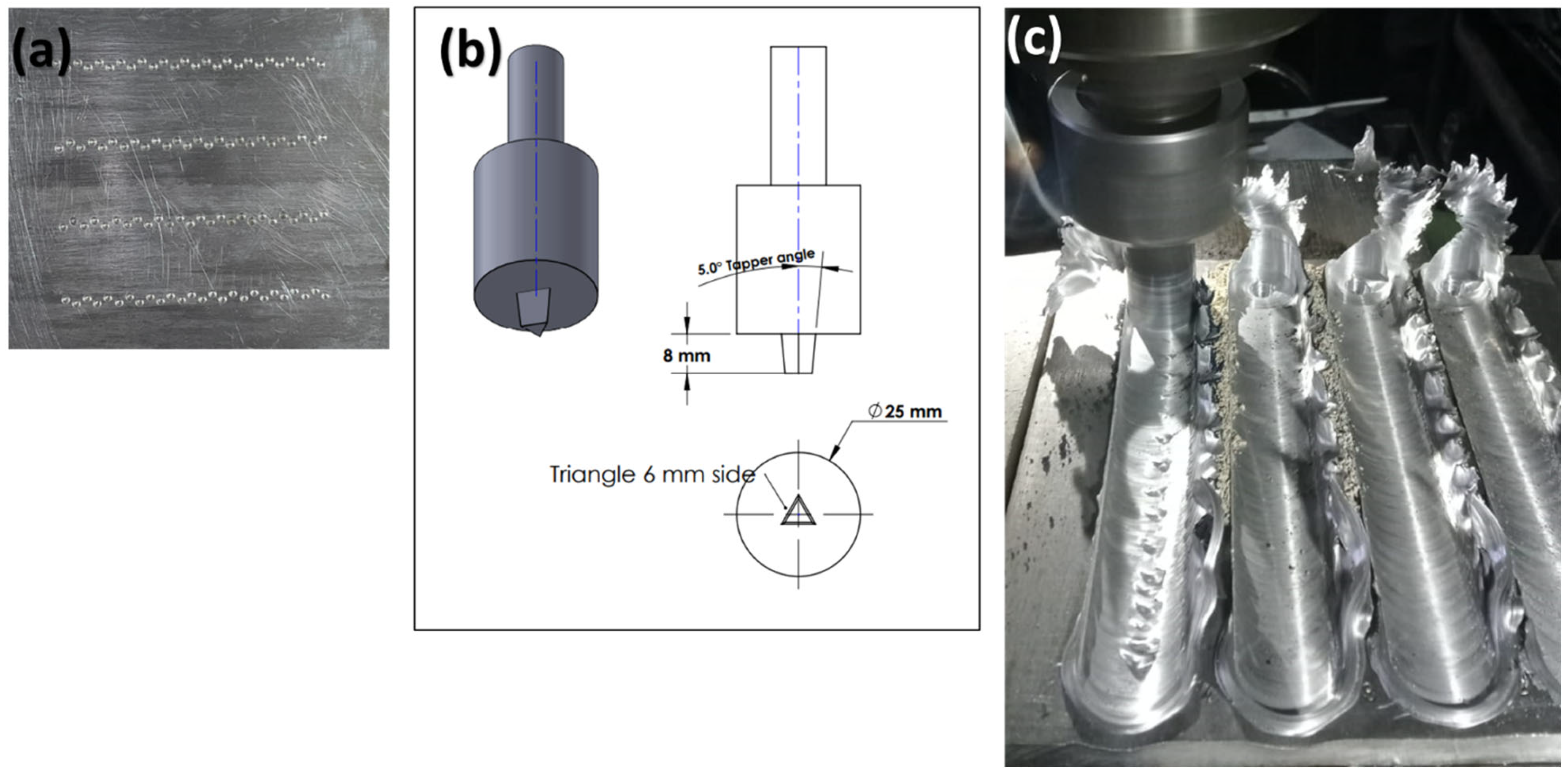

2. Materials and Methods

Fabrication Process Using the FSP Method

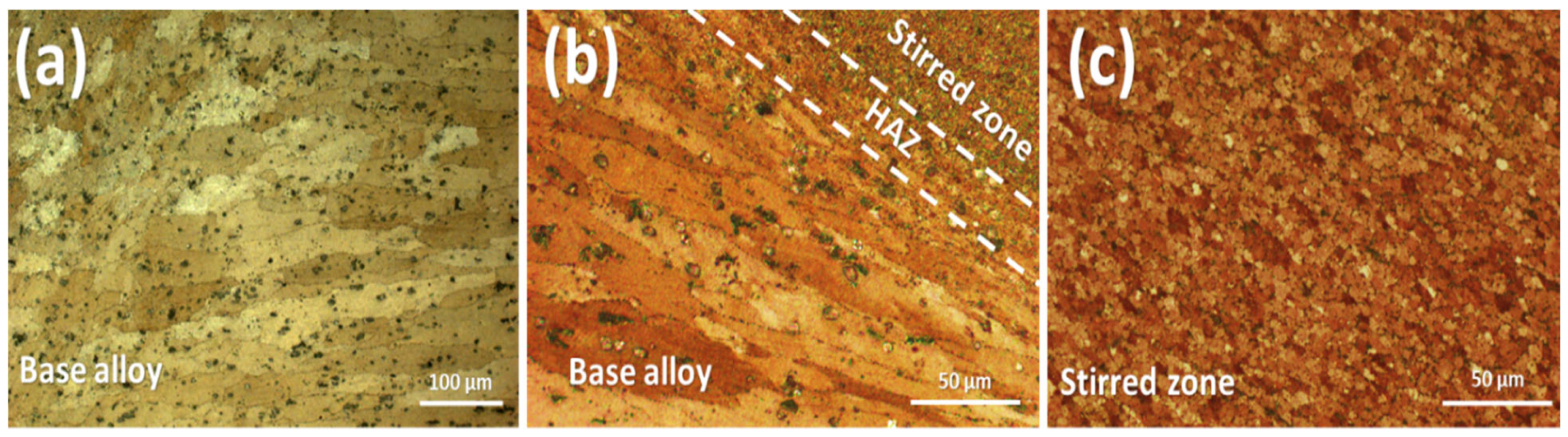

3. Results and Discussions

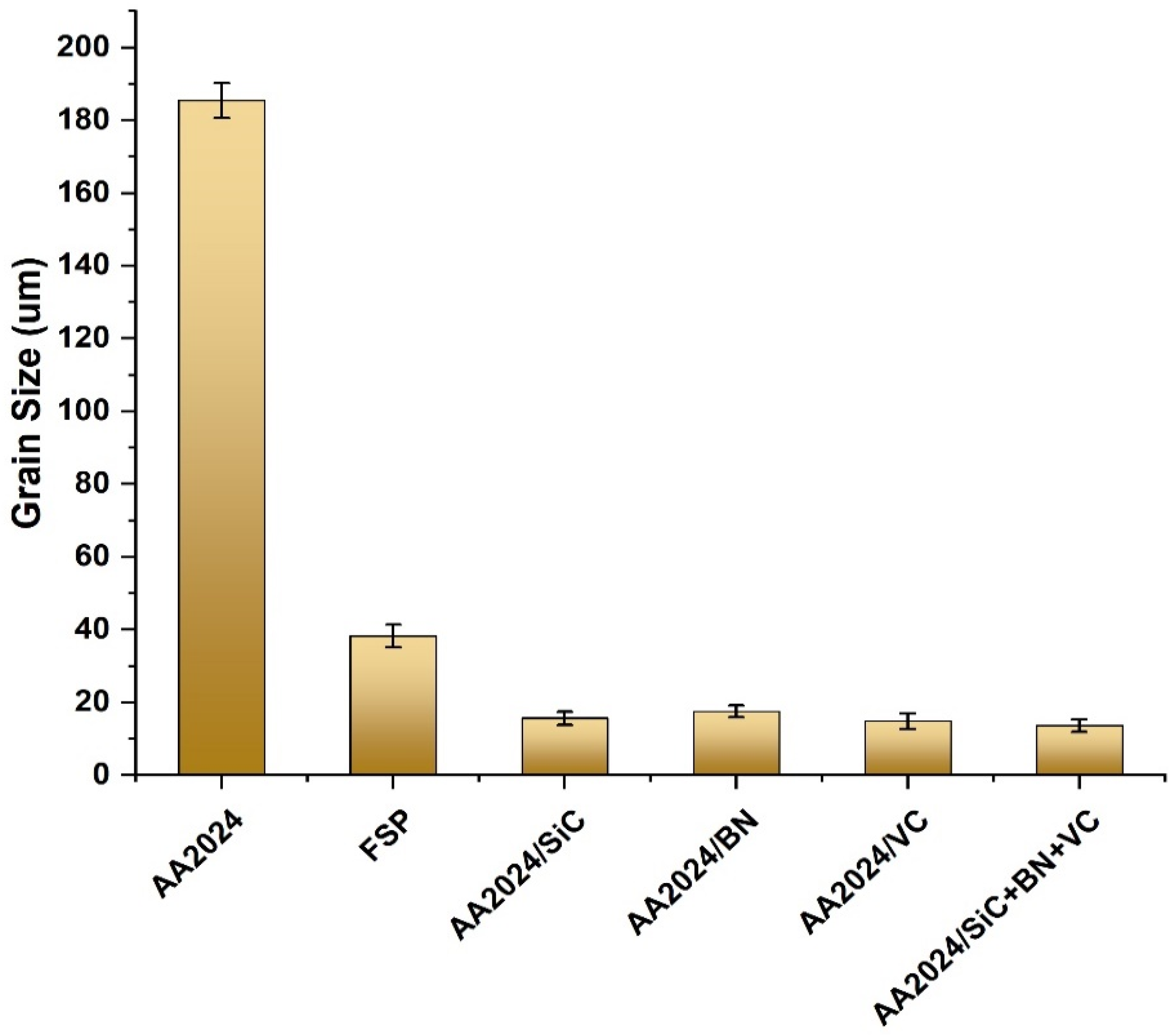

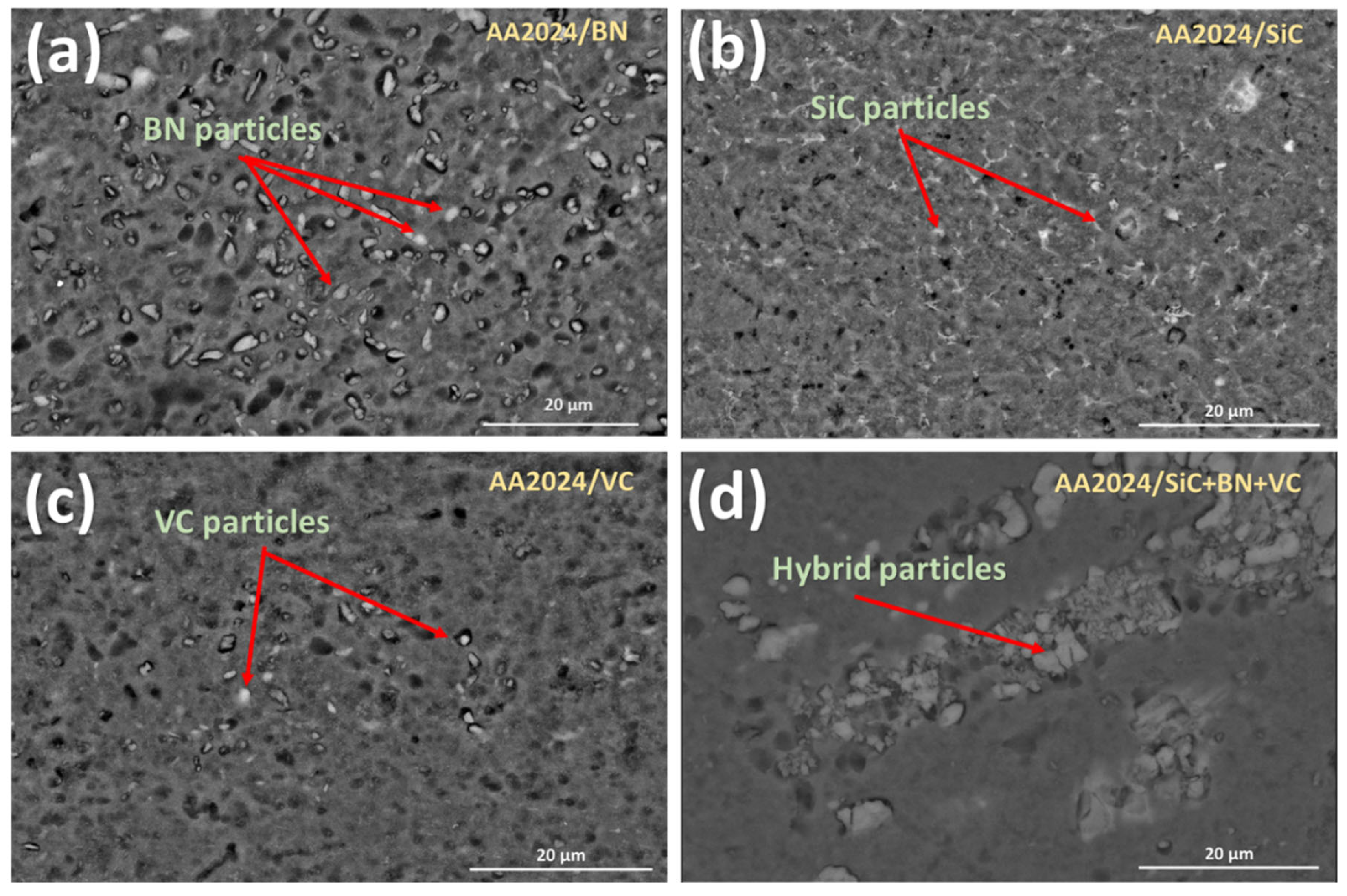

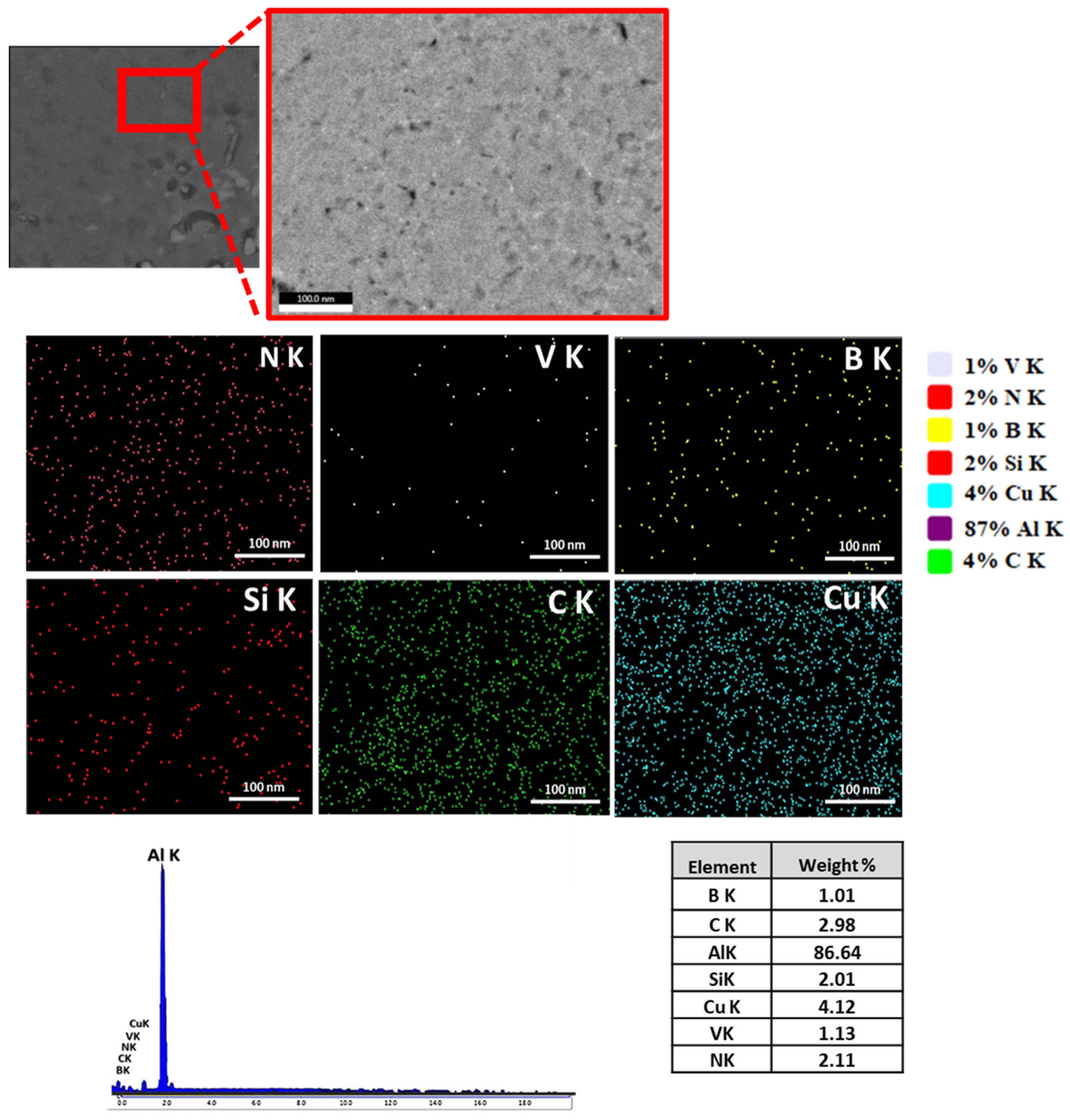

3.1. Microstructure Observation

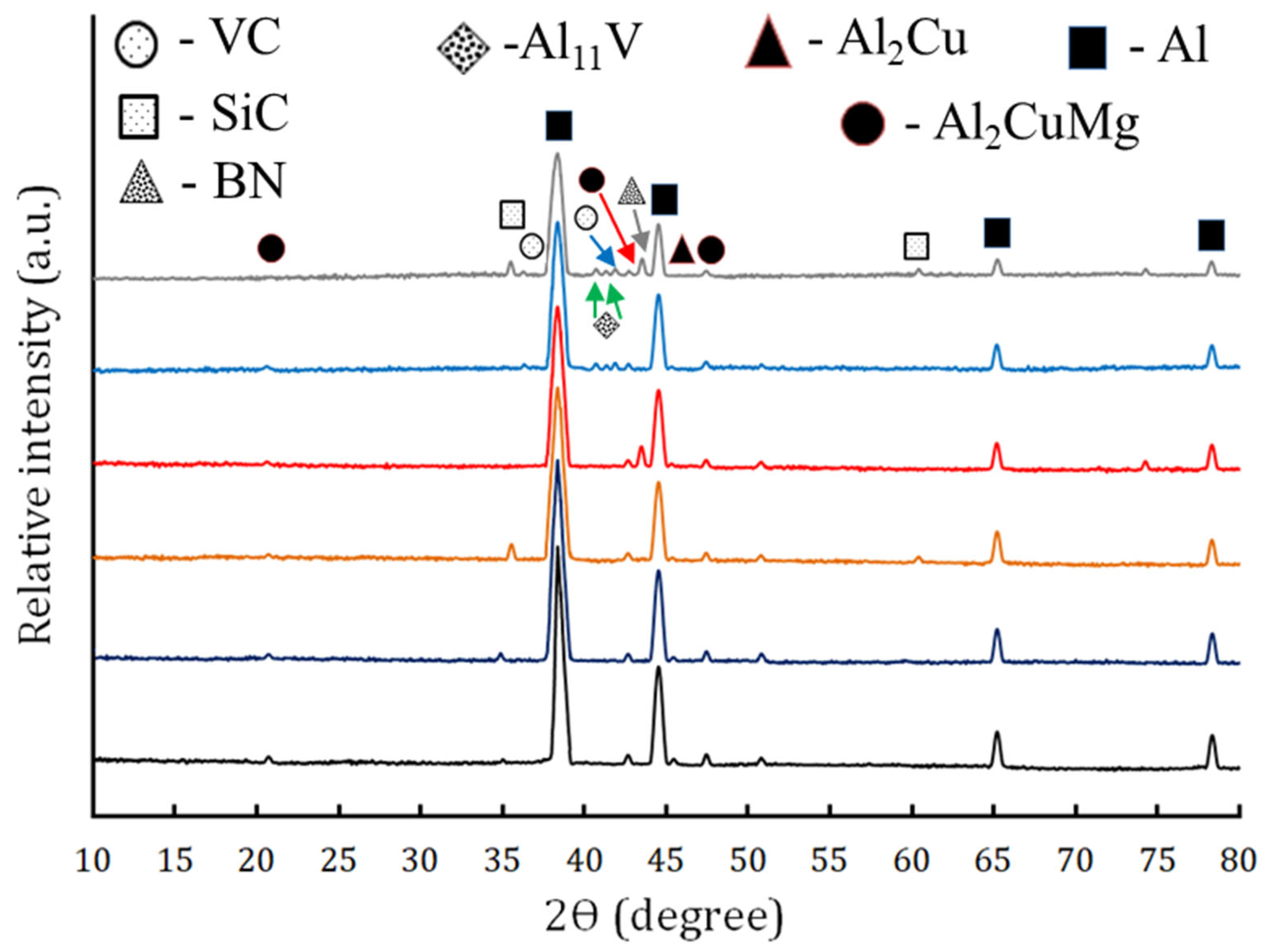

3.2. Phase Composition

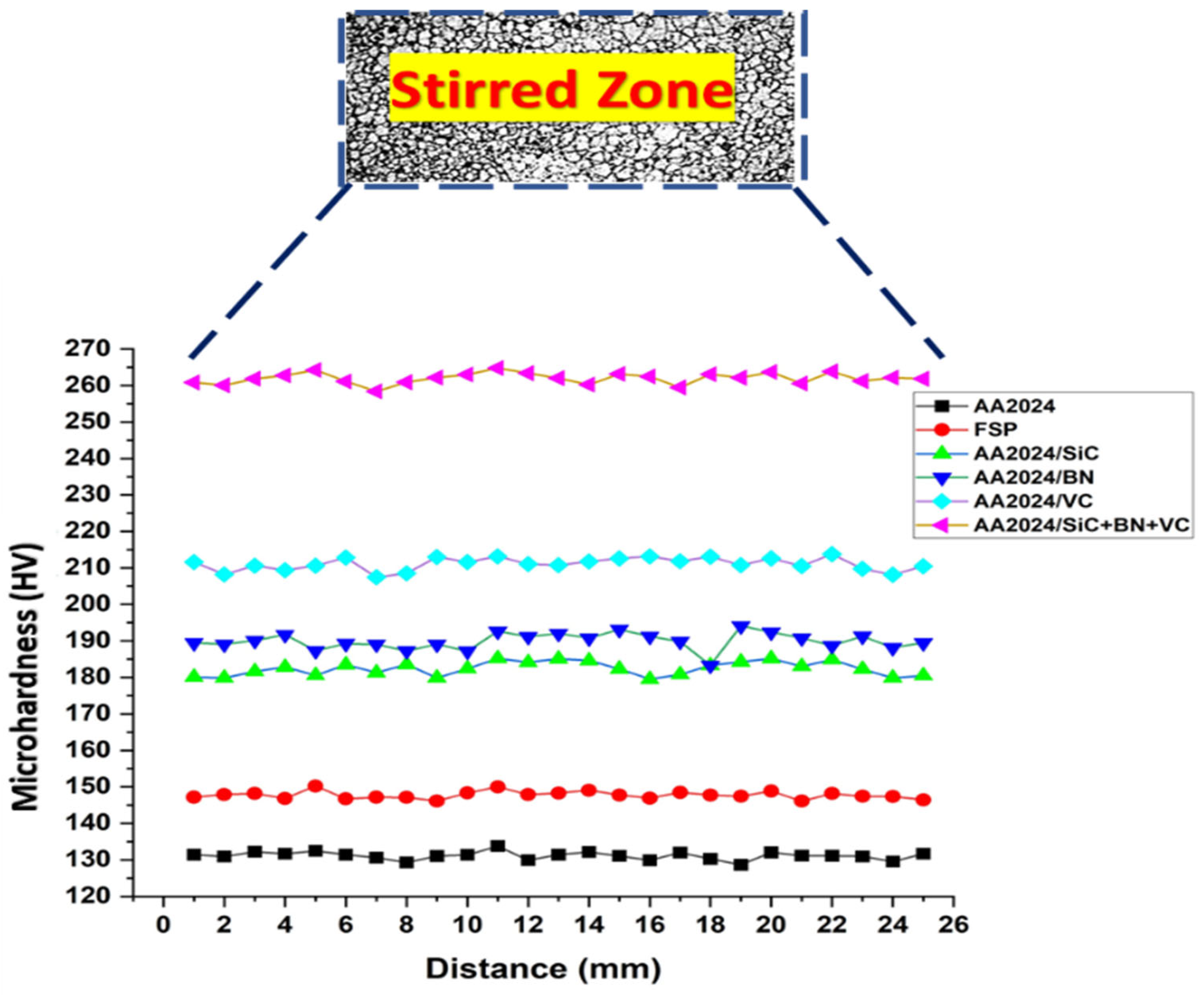

3.3. Microhardness

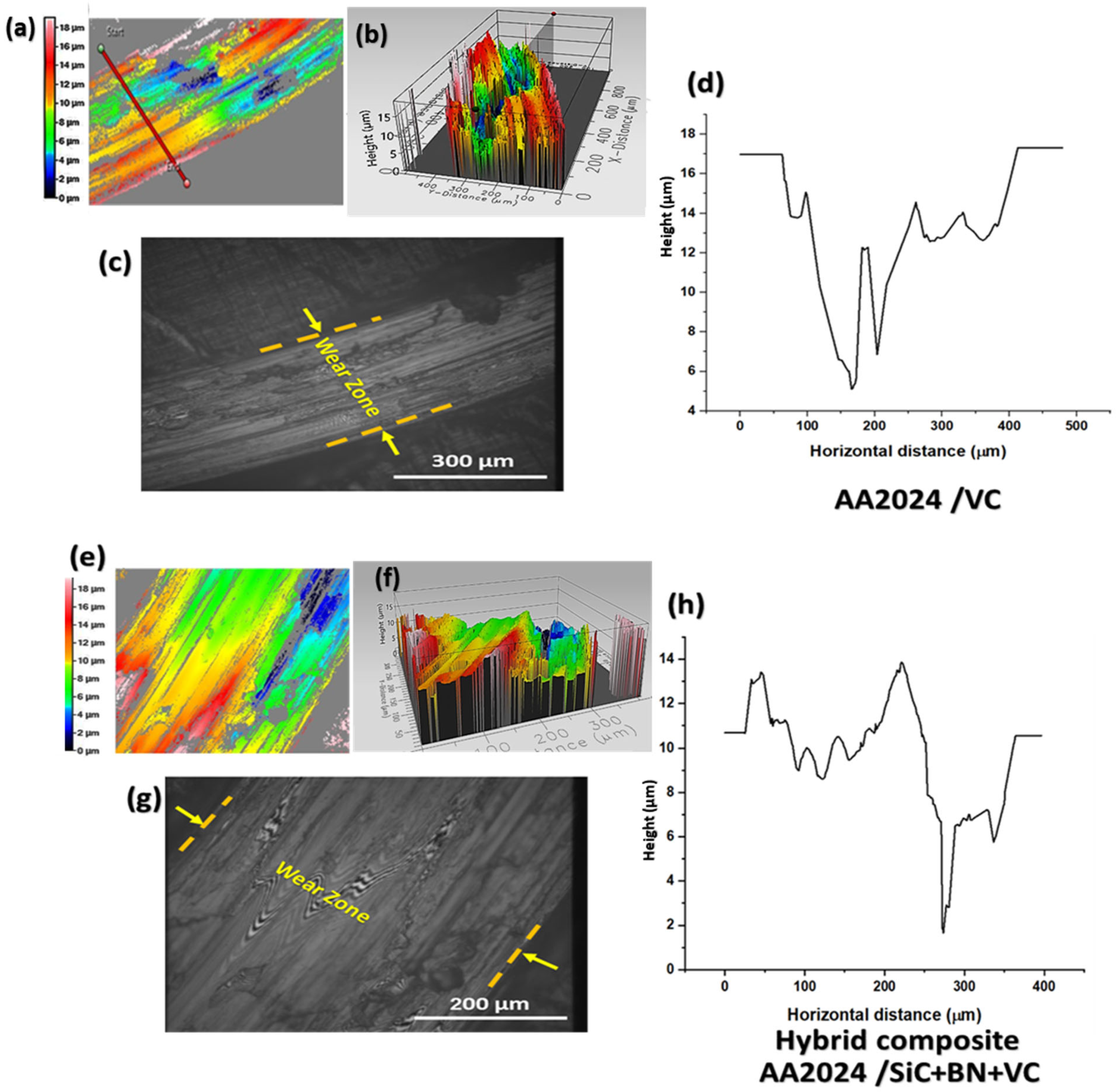

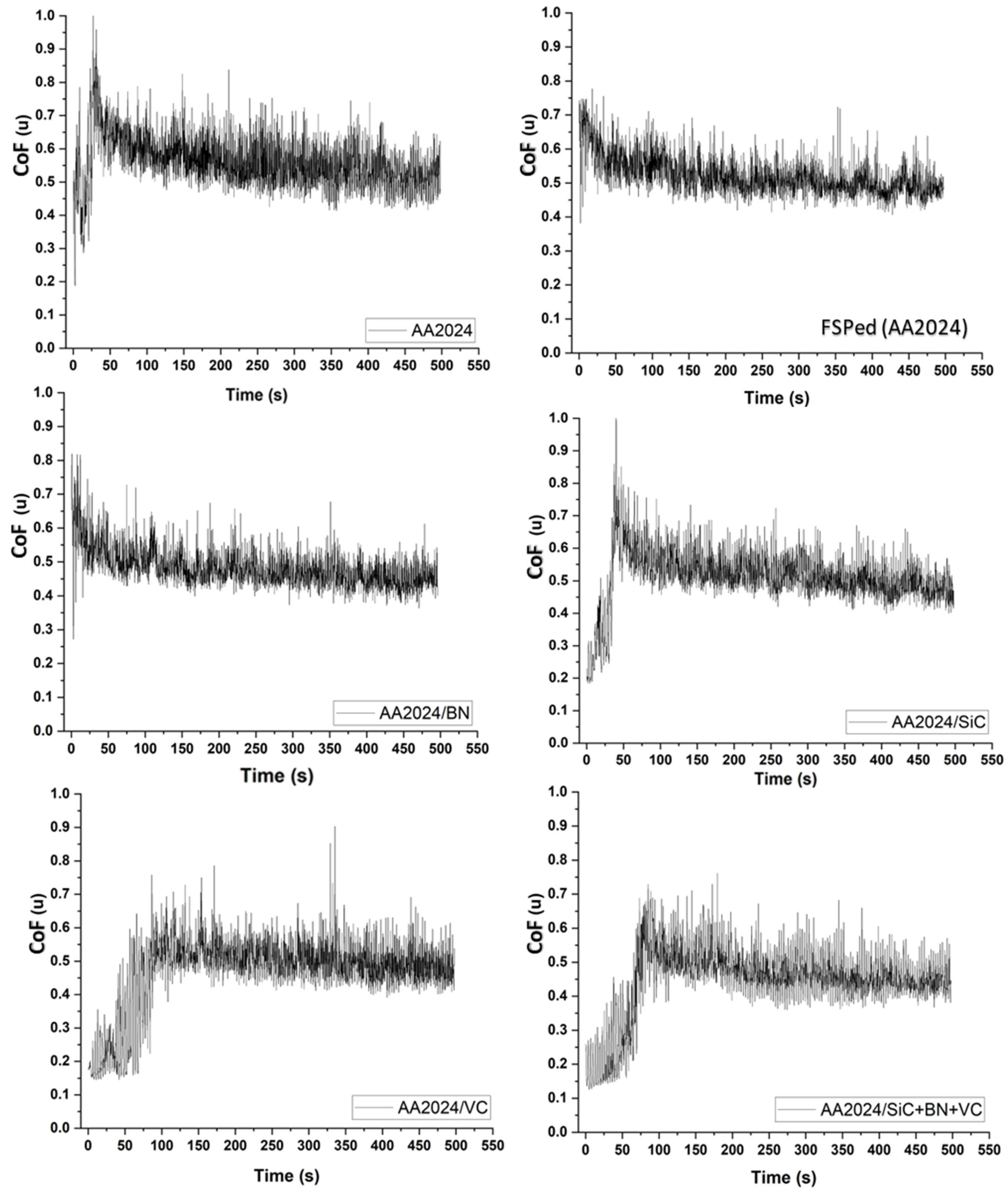

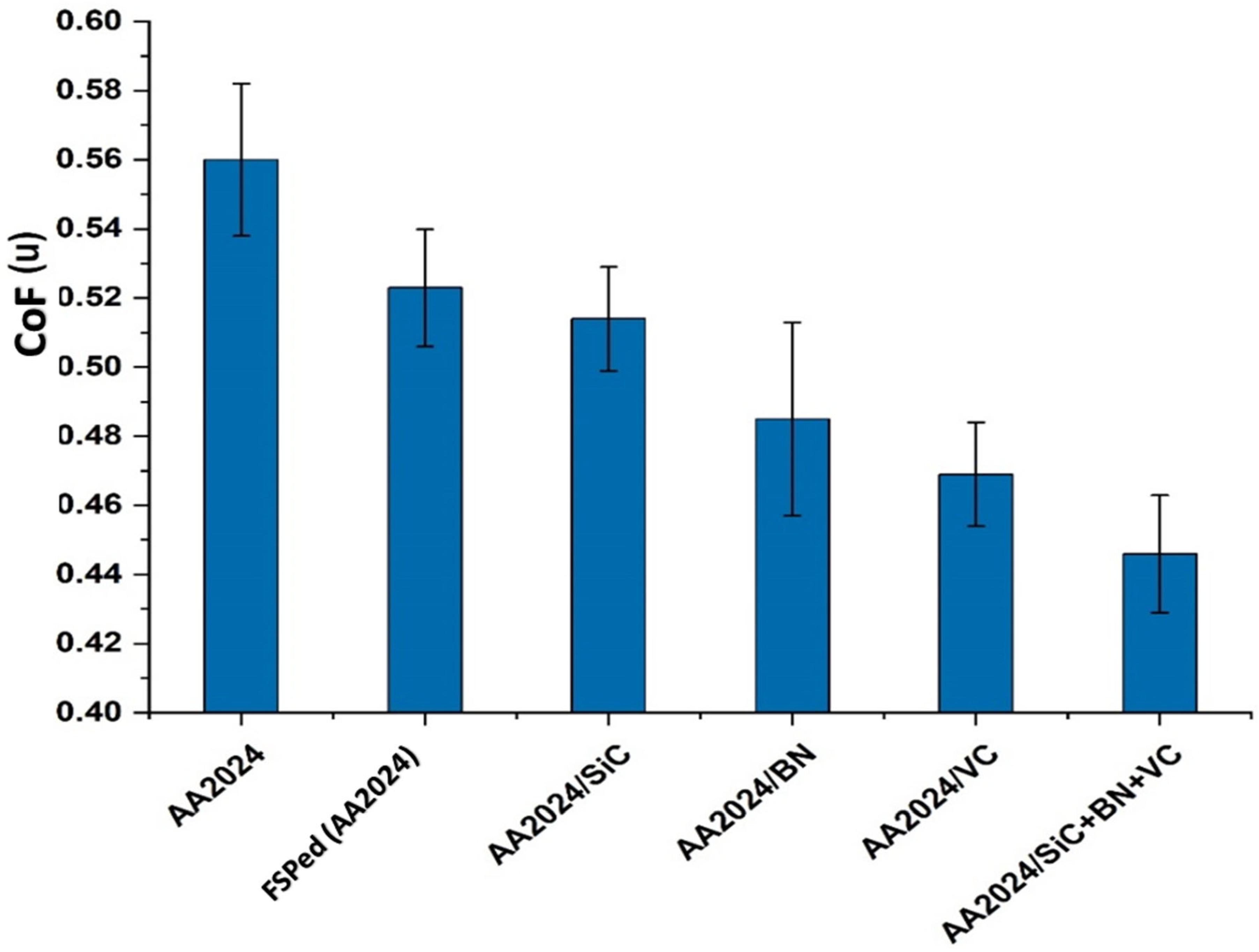

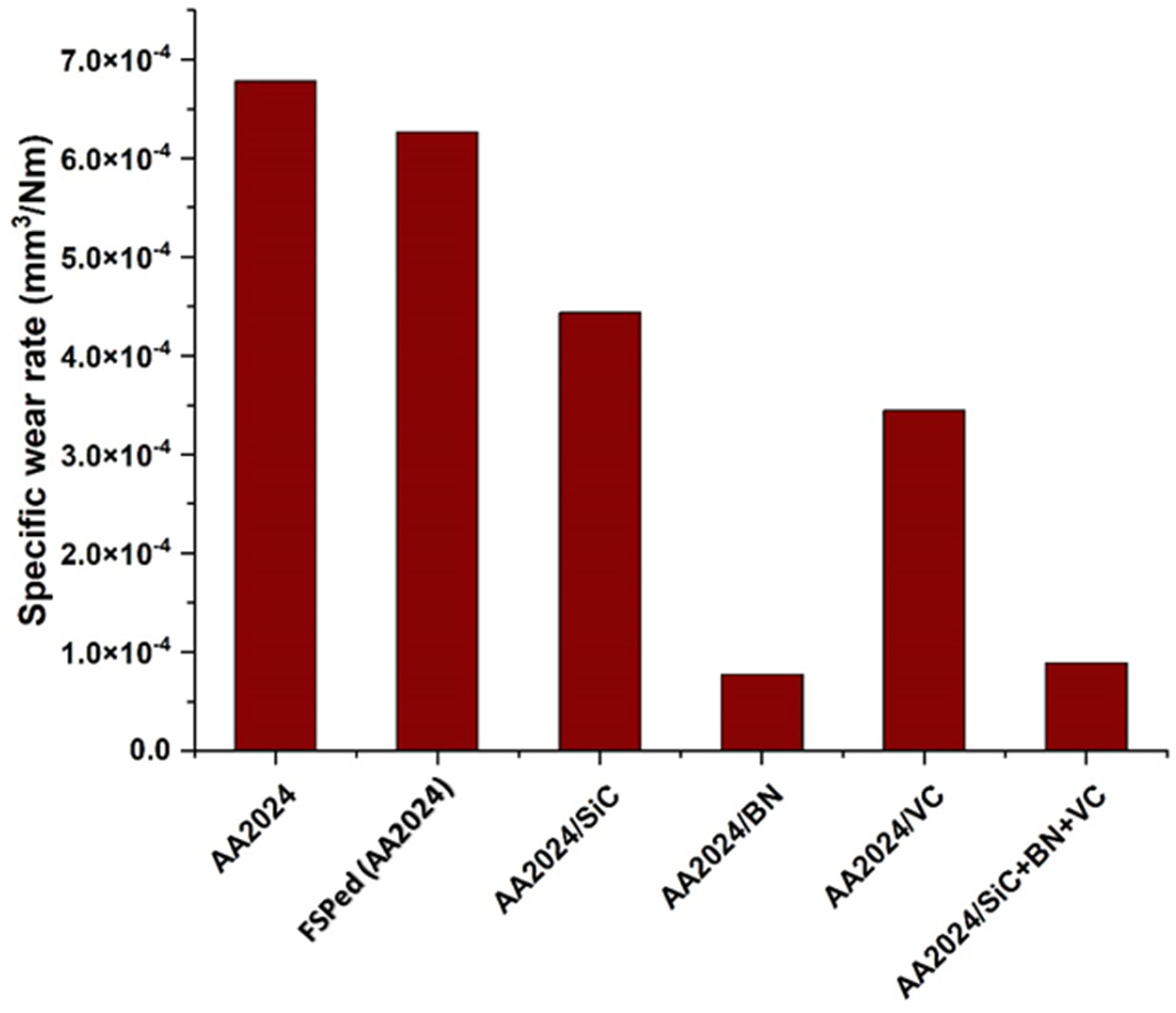

3.4. Wear Behavior of the Processed Surface

4. Conclusions

- The findings of the study showed that the addition of both singular and multiple nanoparticles of BN, VC, and SiC significantly influenced the microstructure grains. The inclusion of ceramic particles played a pivotal role in achieving a reduction in particulate size during friction stir processing. The mobile dislocations were pinned by the particles, which limited grain growth. The high surface-area-to-volume ratio of the particles facilitated their efficient activation within the material during processing, thereby contributing to the enhancement of the microstructure. As a result, the particle refinement level was 13.6 times greater than that of the wrought alloy.

- The uniform dispersion of ceramic nanoparticles is essential for improving metal matrix composites’ mechanical and physical properties (MMCs). In fact, the microhardness of hybrid composite matrices has been shown to increase by more than 95% when ceramic nanoparticles are uniformly dispersed.

- Hybrid composites exhibit a greater surface microhardness when compared to composites consisting of a single type of particle. This observed phenomenon can be ascribed to reinforcing particles, which seem to strengthen the interfaces between grains and impede the movement of dislocations within the composite material. The enhancement of internal grain boundaries and the initiation of a dispersion–strengthening mechanism are ascribed to the formation of uniformly distributed particles within the matrix. The hybrid composite surface demonstrated a significant improvement of 30% in tribological performance compared to the base metal.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Heidarzadeh, A.; Mironov, S.; Kaibyshev, R.; Çam, G.; Simar, A.; Gerlich, A.; Khodabakhshi, F.; Mostafaei, A.; Field, D.; Robson, J.; et al. Friction stir welding/processing of metals and alloys: A comprehensive review on microstructural evolution. Prog. Mater. Sci. 2021, 117, 100752. [Google Scholar] [CrossRef]

- Parveez, B.; Kittur, M.I.; Badruddin, I.A.; Kamangar, S.; Hussien, M.; Umarfarooq, M.A. Scientific Advancements in Composite Materials for Aircraft Applications: A Review. Polymers 2022, 14, 5007. [Google Scholar] [CrossRef]

- Moustafa, E. Effect of Multi-Pass Friction Stir Processing on Mechanical Properties for AA2024/Al2O3 Nanocomposites. Materials 2017, 10, 1053. [Google Scholar] [CrossRef]

- Moustafa, E.B.; Taha, M.A. Preparation of high strength graphene reinforced Cu-based nanocomposites via mechanical alloying method: Microstructural, mechanical and electrical properties. Appl. Phys. A 2020, 126, 220. [Google Scholar] [CrossRef]

- Ardila-Rodríguez, L.; Menezes, B.; Pereira, L.; Takahashi, R.; Oliveira, A.; Travessa, D. Surface modification of aluminum alloys with carbon nanotubes by laser surface melting. Surf. Coatings Technol. 2019, 377, 124930. [Google Scholar] [CrossRef]

- Su, J.-Q.; Nelson, T.W.; Sterling, C.J. Friction stir processing of large-area bulk UFG aluminum alloys. Scr. Mater. 2005, 52, 135–140. [Google Scholar] [CrossRef]

- Ashwath, P.; Xavior, M.A. Surface modification on aluminum metal matrix composite for high strength application -Current state of art. Mater. Today Proc. 2020, 46, 7130–7134. [Google Scholar]

- Singh, H.; Brar, G.S.; Kumar, H.; Aggarwal, V. A review on metal matrix composite for automobile applications. Mater. Today Proc. 2021, 43, 320–325. [Google Scholar] [CrossRef]

- He, X.; Gu, F.; Ball, A. A review of numerical analysis of friction stir welding. Prog. Mater. Sci. 2014, 65, 1–66. [Google Scholar] [CrossRef]

- Padhy, G.; Wu, C.; Gao, S. Friction stir based welding and processing technologies-processes, parameters, microstructures and applications: A review. J. Mater. Sci. Technol. 2018, 34, 1–38. [Google Scholar] [CrossRef]

- Prabhakar, D.; Shettigar, A.K.; Herbert, M.A.; Patel, M.G.C.; Pimenov, D.Y.; Giasin, K.; Prakash, C. A comprehensive review of friction stir techniques in structural materials and alloys: Challenges and trends. J. Mater. Res. Technol. 2022, 20, 3025–3060. [Google Scholar]

- Gupta, M.K. Friction stir process: A green fabrication technique for surface composites—A review paper. SN Appl. Sci. 2020, 2, 532. [Google Scholar] [CrossRef]

- Shvydyuk, K.O.; Nunes-Pereira, J.; Rodrigues, F.F.; Silva, A.P. Review of Ceramic Composites in Aeronautics and Aerospace: A Multifunctional Approach for TPS, TBC and DBD Applications. Ceramics 2023, 6, 195–230. [Google Scholar] [CrossRef]

- Coetzee, D.; Venkataraman, M.; Militky, J.; Petru, M. Influence of Nanoparticles on Thermal and Electrical Conductivity of Composites. Polymers 2020, 12, 742. [Google Scholar] [CrossRef]

- AbuShanab, W.S.; Moustafa, E.B. Effects of friction stir processing parameters on the wear resistance and mechanical properties of fabricated metal matrix nanocomposites (MMNCs) surface. J. Mater. Res. Technol. 2020, 9, 7460–7471. [Google Scholar] [CrossRef]

- Kheirkhah, S.; Imani, M.; Aliramezani, R.; Zamani, M.H.; Kheilnejad, A. Microstructure, mechanical properties and corrosion resistance of Al6061/BN surface composite prepared by friction stir processing. Surf. Topogr. Metrol. Prop. 2019, 7, 035002. [Google Scholar] [CrossRef]

- Moradi, M.; Khalaj, G.; Ghaffari, G.; Abdolmaleki, B. Studying the impact of multi-pass friction stir processing on microstructure and mechanical properties of low-carbon steel. Met. Mater. 2023, 61, 161–173. [Google Scholar] [CrossRef]

- Dieguez, T.; Burgueño, A.; Svoboda, H. Superplasticity of a Friction Stir Processed 7075-T651 Aluminum Alloy. Procedia Mater. Sci. 2012, 1, 110–117. [Google Scholar] [CrossRef]

- Kurt, A.; Uygur, I.; Cete, E. Surface modification of aluminium by friction stir processing. J. Mater. Process. Technol. 2011, 211, 313–317. [Google Scholar]

- Yadav, D.; Bauri, R. Processing, microstructure and mechanical properties of nickel particles embedded aluminium matrix composite. Mater. Sci. Eng. A 2011, 528, 1326–1333. [Google Scholar] [CrossRef]

- Eskandari, H.; Taheri, R. A Novel Technique for Development of Aluminum Alloy Matrix/TiB2/Al2O3 Hybrid Surface Nanocomposite by Friction Stir Processing. Procedia Mater. Sci. 2015, 11, 503–508. [Google Scholar] [CrossRef]

- Karpasand, F.; Abbasi, A.; Ardestani, M. Effect of amount of TiB2 and B4C particles on tribological behavior of Al7075/B4C/TiB2 mono and hybrid surface composites produced by friction stir processing. Surf. Coat. Technol. 2020, 390, 125680. [Google Scholar] [CrossRef]

- Mazahery, A.; Ostadshabani, M. Investigation on mechanical properties of nano-Al2O3-reinforced aluminum matrix composites. J. Compos. Mater. 2011, 45, 2579–2586. [Google Scholar] [CrossRef]

- Moustafa, E.B.; Melaibari, A.; Basha, M. Wear and microhardness behaviors of AA7075/SiC-BN hybrid nanocomposite surfaces fabricated by friction stir processing. Ceram. Int. 2020, 46, 16938–16943. [Google Scholar] [CrossRef]

- Umanath, K.; Selvamani, S.; Palanikumar, K.; Sabarikreeshwaran, R. Dry Sliding Wear Behaviour of AA6061-T6 Reinforced SiC and Al2O3 Particulate Hybrid Composites. Procedia Eng. 2014, 97, 694–702. [Google Scholar] [CrossRef]

- Wei, Z.; Han, Y.; Li, S.; Zong, N.; Le, J.; Zhang, S.; Chen, J.; Zhong, S.; Huang, G.; Lu, W. Interfacial modification strategy to break through the strength and ductility trade-off in multi-walled carbon nanotubes reinforced titanium matrix composites. Mater. Sci. Eng. A 2023, 880, 145284. [Google Scholar] [CrossRef]

- Kishore, K.; Pandey, A.; Wagri, N.K.; Saxena, A.; Patel, J.; Al-Fakih, A. Technological challenges in nanoparticle-modified geopolymer concrete: A comprehensive review on nanomaterial dispersion, characterization techniques and its mechanical properties. Case Stud. Constr. Mater. 2023, 19, e02265. [Google Scholar] [CrossRef]

- Singh, M.; Bhandari, D.; Goyal, K. A review of the mechanical performance of nanoparticles reinforced aluminium matrix nanocomposites. Mater. Today Proc. 2020, 46, 3198–3204. [Google Scholar] [CrossRef]

- James, J.; Annamalai, A.R.; Muthuchamy, A.; Jen, C.-P. Effect of Wettability and Uniform Distribution of Reinforcement Particle on Mechanical Property (Tensile) in Aluminum Metal Matrix Composite—A Review. Nanomaterials 2021, 11, 2230. [Google Scholar] [CrossRef]

- Lakshmikanthan, A.; Angadi, S.; Malik, V.; Saxena, K.K.; Prakash, C.; Dixit, S.; Mohammed, K.A. Mechanical and Tribological Properties of Aluminum-Based Metal-Matrix Composites. Materials 2022, 15, 6111. [Google Scholar] [CrossRef]

- Cui, G.; Liu, Y.; Gao, G.; Liu, H.; Li, S.; Kou, Z. Preparation, Mechanical Properties, and High-Temperature Wear Resistance of Ti–Al–B alloy. Materials 2019, 12, 3751. [Google Scholar] [CrossRef]

- Abushanab, W.S.; Moustafa, E.B.; Melaibari, A.A.; Kotov, A.D.; Mosleh, A.O. A Novel Comparative Study Based on the Economic Feasibility of the Ceramic Nanoparticles Role’s in Improving the Properties of the AA5250 Nanocomposites. Coatings 2021, 11, 977. [Google Scholar] [CrossRef]

- Zulfia, A.; Zhakiah, T.; Dhaneswara, D. Sutopo Characteristics of Al-Si-Mg Reinforced SiC Composites Produced by Stir Casting Route. IOP Conf. Ser. Mater. Sci. Eng. 2017, 202, 012089. [Google Scholar] [CrossRef]

- Sharath, B.; Madhu, K.; Pradeep, D.; Madhu, P.; Premkumar, B.; Karthik, S. Effects of tertiary ceramic additives on the micro hardness and wear characteristics of Al2618 + Si3N4-B4C-Gr hybrid composites for automotive applications. J. Alloys Met. Syst. 2023, 3, 100014. [Google Scholar] [CrossRef]

- Roduit, N.J. Image Analysis Toolbox for Measuring and Quantifying Components of High-Definition Images. 2019. 1.3.1. Available online: https://jmicrovision.github.io (accessed on 4 February 2023).

- Ferguson, J.B.; Lopez, H.F.; Rohatgi, P.K.; Cho, K.; Kim, C.-S. Impact of Volume Fraction and Size of Reinforcement Particles on the Grain Size in Metal–Matrix Micro and Nanocomposites. Met. Mater. Trans. A 2014, 45, 4055–4061. [Google Scholar] [CrossRef]

- Nie, J.; Liu, Y.; Wang, F.; Zhou, H.; Cao, Y.; Liu, X.; An, X.; Liao, X.; Zhu, Y.; Zhao, Y. Key roles of particles in grain refinement and material strengthening for an aluminum matrix composite. Mater. Sci. Eng. A 2021, 801, 140414. [Google Scholar] [CrossRef]

- Kumar, S.; Sarma, V.S.; Murty, B. Influence of in situ formed TiB2 particles on the abrasive wear behaviour of Al–4Cu alloy. Mater. Sci. Eng. A 2007, 465, 160–164. [Google Scholar] [CrossRef]

- Monikandan, V.V.; Jacob, J.C.; Joseph, M.A.; Rajendrakumar, P.K. Statistical Analysis of Tribological Properties of Aluminum Matrix Composites Using Full Factorial Design. Trans. Indian Inst. Met. 2015, 68, 53–57. [Google Scholar] [CrossRef]

- Jalilvand, M.M.; Mazaheri, Y. Effect of mono and hybrid ceramic reinforcement particles on the tribological behavior of the AZ31 matrix surface composites developed by friction stir processing. Ceram. Int. 2020, 46, 20345–20356. [Google Scholar] [CrossRef]

- Romanova, V.; Balokhonov, R.; Schmauder, S. The influence of the reinforcing particle shape and interface strength on the fracture behavior of a metal matrix composite. Acta Mater. 2009, 57, 97–107. [Google Scholar]

- Günen, A.; Kalkandelen, M.; Gök, M.S.; Kanca, E.; Kurt, B.; Karakaş, M.S.; Karahan, I.H.; Çetin, M. Characteristics and high temperature wear behavior of chrome vanadium carbide composite coatings produced by thermo-reactive diffusion. Surf. Coat. Technol. 2020, 402, 126402. [Google Scholar] [CrossRef]

- Ravindran, P.; Manisekar, K.; Rathika, P.; Narayanasamy, P. Tribological properties of powder metallurgy—Processed aluminium self lubricating hybrid composites with SiC additions. Mater. Des. 2013, 45, 561–570. [Google Scholar] [CrossRef]

| h-BN | VC | SiC | |

|---|---|---|---|

| Chemical Purity | 99.9% | 99.9% | 99.9% |

| Cu | Fe | Si | Mn | Mg | Zn | Cr | Al | |

|---|---|---|---|---|---|---|---|---|

| AA2024 | 4.55 | 0.12 | 0.11 | 0.45 | 1.5 | 0.15 | 0.01 | Remain |

| C | Si | Mn | Cr | Mo | V | |

|---|---|---|---|---|---|---|

| K110 | 1.55 | 0.30 | 0.30 | 11.30 | 0.75 | 0.75 |

| Composite | , g/cm3 | , cm3 | g/cm3 | cm3 | cm3 | g/cm3 |

|---|---|---|---|---|---|---|

| AA2024/SiC | 3.21 | 2.49 | 2.78 | 3.1 | 4.5 | 2.96 |

| AA2024/BN | 2.1 | 2.49 | 2.78 | 3.1 | 4.5 | 2.49 |

| AA2024/VC | 5.77 | 2.49 | 2.78 | 3.1 | 4.5 | 4.05 |

| AA2024/SiC+BN+VC | 5.5 | 2.49 | 2.78 | 3.1 | 4.5 | 6.31 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Moustafa, E.B.; Taha, M.A. The Effect of Mono and Hybrid Additives of Ceramic Nanoparticles on the Tribological Behavior and Mechanical Characteristics of an Al-Based Composite Matrix Produced by Friction Stir Processing. Nanomaterials 2023, 13, 2148. https://doi.org/10.3390/nano13142148

Moustafa EB, Taha MA. The Effect of Mono and Hybrid Additives of Ceramic Nanoparticles on the Tribological Behavior and Mechanical Characteristics of an Al-Based Composite Matrix Produced by Friction Stir Processing. Nanomaterials. 2023; 13(14):2148. https://doi.org/10.3390/nano13142148

Chicago/Turabian StyleMoustafa, Essam B., and Mohammed A. Taha. 2023. "The Effect of Mono and Hybrid Additives of Ceramic Nanoparticles on the Tribological Behavior and Mechanical Characteristics of an Al-Based Composite Matrix Produced by Friction Stir Processing" Nanomaterials 13, no. 14: 2148. https://doi.org/10.3390/nano13142148

APA StyleMoustafa, E. B., & Taha, M. A. (2023). The Effect of Mono and Hybrid Additives of Ceramic Nanoparticles on the Tribological Behavior and Mechanical Characteristics of an Al-Based Composite Matrix Produced by Friction Stir Processing. Nanomaterials, 13(14), 2148. https://doi.org/10.3390/nano13142148