Biomaterials and Encapsulation Techniques for Probiotics: Current Status and Future Prospects in Biomedical Applications

Abstract

:1. Introduction

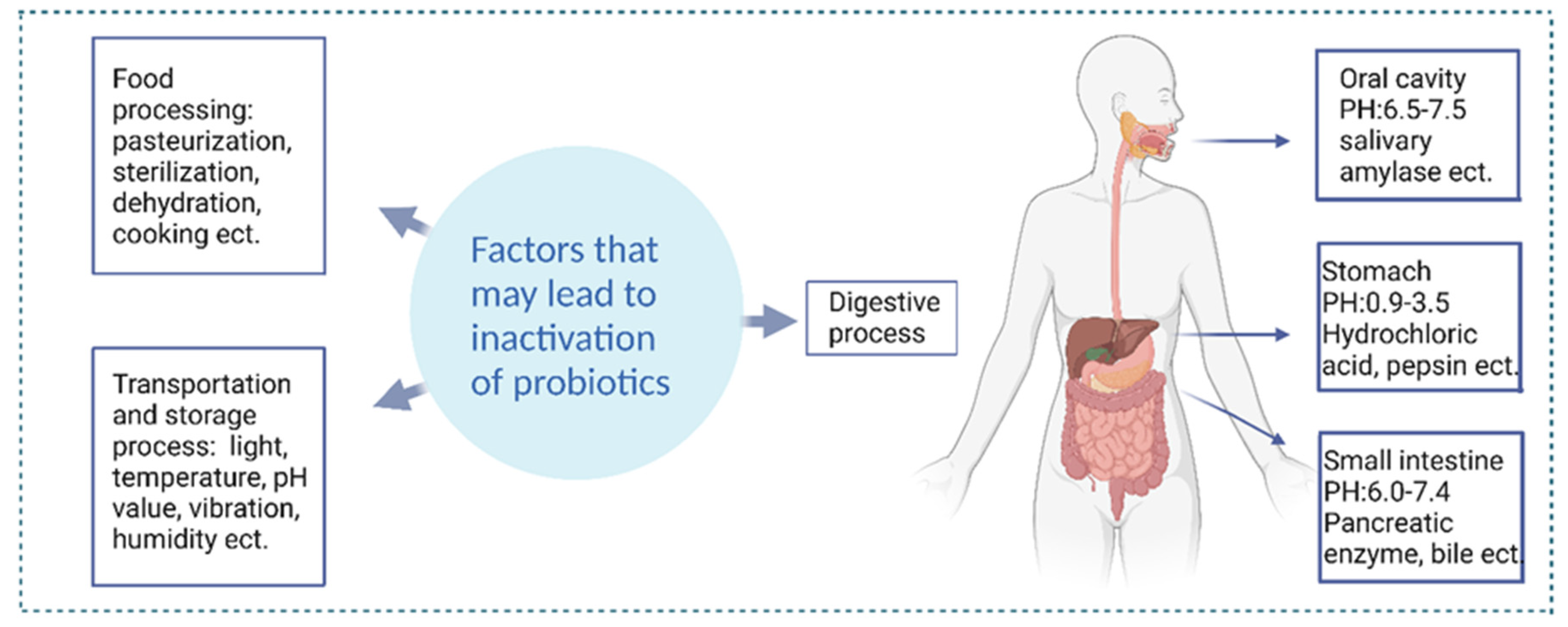

2. The Necessity of Encapsulating Probiotics with Polymers

3. Polymer Choice for Combining Probiotics

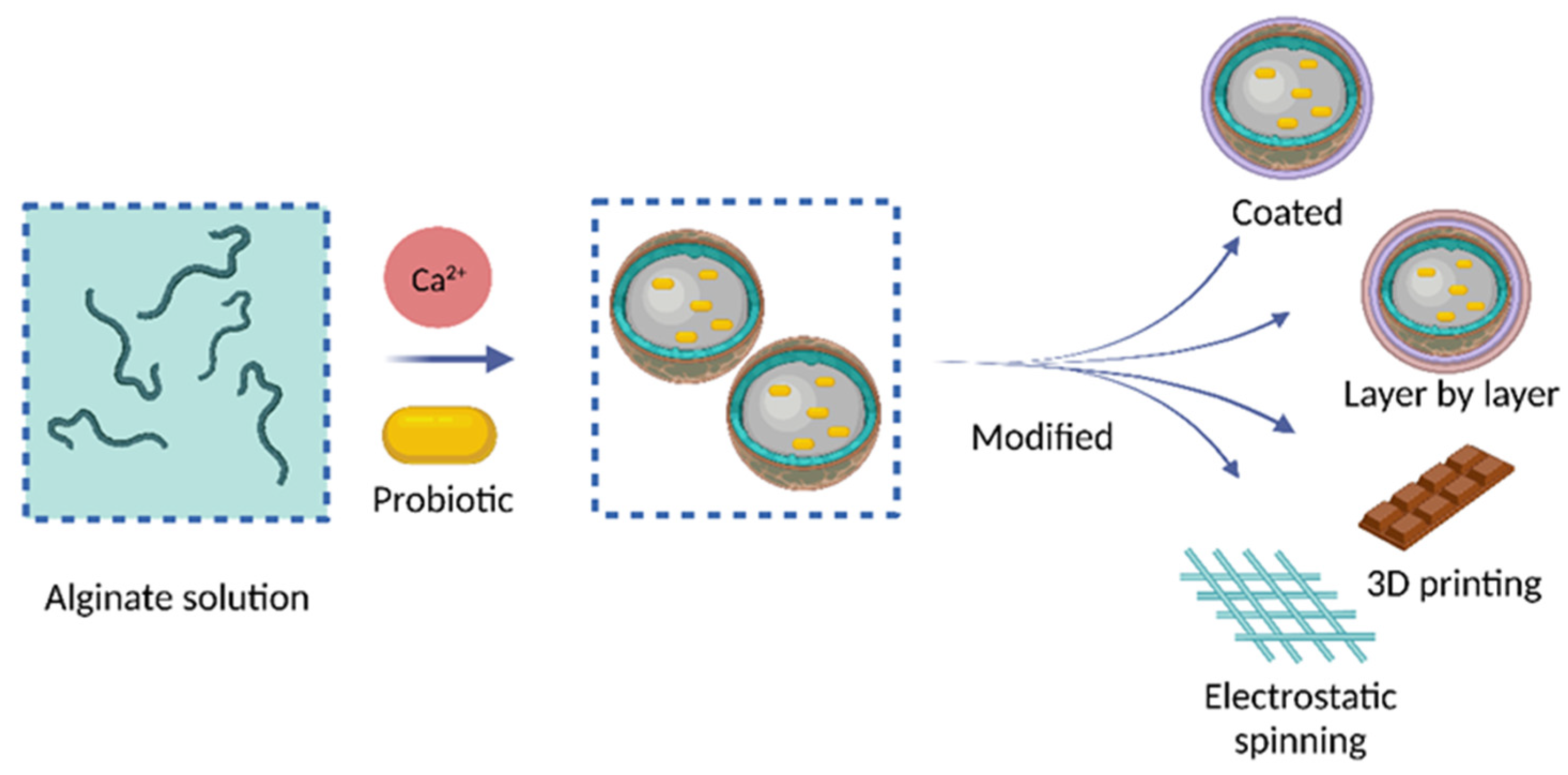

3.1. Encapsulation in Polysaccharides

3.2. Encapsulation in Protein

3.3. Encapsulation in Lipids

3.4. Encapsulation in Synthetic Polymers

| Reference | Bacteria Systems | Polymers | Functionality |

|---|---|---|---|

| Hong, X. et al. [109] | Lactobacillus acidophilus | Polygamma-glutamic acid hydrogel | The microcapsule is NO responsive, rapidly releases probiotics, maintains the intestinal mechanical barrier, and regulates the intestinal flora balance. |

| Deng, J. et al. [110] | Lactococcus lactis | Heparin grafted with Poloxam 407 | Protect the release of probiotic VEGF without loss of activity, and can limit the spread of VEGF to achieve local release. |

| Liu, W. et al. [111] | Lactobacillus reuteri | Methylacrylylated gelatin (GelMA), methylacrylylated hyaluronic acid (HAMA) | Protecting probiotics from the attack of the immune system; also helps prevent the potential threat of probiotics escaping. |

| Liu, J. et al. [112] | E. coli Nissle 1917 | Yeast membrane cell coating (YMs) | The survival rate of gastric acid and bile salts was improved, and the β-glucan contained in yeast membrane was recognized by the Dectin-1 receptor of M cells and promoted the uptake of M cells, thus stimulating a strong mucosal immune response. |

| Neel S. Joshi. et al. [113] | E. coli Nissle 1917 | Fusion protein hydrogel | Genetically programmed E. coli can secrete curly fusion TFFs without pathogenicity. It enhanced the protective effect on mice colitis induced by sodium dextran sulfate and was related to mucosal healing and immune regulation. |

| Zeng, R. et al. [114] | Lactobacillus plantarum | Oxidized Bletilla Polysaccharide (OBSP), Chitosan (CS) | Maintain wound moisture, promote VEGF factor high expression, inhibit inflammation, accelerate collagen deposition, prevent scar formation, and significantly promote wound healing. |

| Zhou, Q. et al. [115] | Lactobacillus rhamnosus | Dihydrazine adipate Modified hyaluronic acid (HA-ADH), PF127-CHO, polysaccharide fucosan sulfate (FD) | Has enhanced antibacterial properties and promotes superbug-induced wound healing. |

| Duan, J. et al. [116] | Lactobacillus rhamnosus | Sulfhydrylated hyaluronic acid (HA-SH) | Protect probiotics from gastrointestinal acid, bile acid, and other stresses. |

| Shrivastava, S. et al. [117] | Lactobacillus acidophilus and Lactobacillus casei | glucose, galactose, rhamnose, galactouronic acid and fucose | Demonstrated protection against simulated gastrointestinal conditions at high and low temperatures, ensuring higher viability of embedded probiotic cells. |

| Jin, W. et al. [118] | Lactobacillus rhamnosus | Bentonite, alginate | The survival rate of LGG under gastric pH value is improved. Complete intestinal release of LGG was observed after hydrogel decomposition. |

| Zhou, L. et al. [119] | Bifidobacterium lactis | Whey protein isolate (WPI), pectin, D-gluconate-delta-lactone (GDL), Calcium | Increased probiotic activity, especially after exposure to the stomach stage. |

| Lou, Y. et al. [120] | Lactobacillus paracei | Starch, metal ions | High gastric acid tolerance, showing excellent controlled release properties against probiotics |

4. Techniques and Evaluations of Probiotic Encapsulation

4.1. Probiotic Encapsulation Technology

4.1.1. Microencapsulation

| Reference | Methods | Feature |

|---|---|---|

| Ana Jaklenec. et al. [142] | layer-by-layer | This technology has high controllability and adjustability. |

| R Paul Ross. et al. [143] | spray drying | The particle size can be controlled, the cost is low, the production yield is high, and it has strong water retention ability, suitable for industrial applications. But the viability loss of the probiotics is very high and product stability is poor. |

| Xiaojun Ma. et al. [144] | emulsification | The production yield is high, easy to scale up, suitable for industrialization and the particle size is smaller, but there may be residual oil and the droplet size distribution is not uniform. |

| Amparo Lopez-Rubio. et al., [145] | electrospraying | Convenient and fast, economical and efficient, mild conditions, strong adaptability and easy to scale up. |

| Wee Sim Choo. et al. [146] | extrusion | The method is characterized by low cost, simple operation, mild conditions, and uniform size, but the production yield is small and the particle size is larger, difficult to use in large scale productions. |

| Siddalingaiya Gurudutt Prapulla. et al. [147] | freeze-drying | The product stability is good, suitable for embedding thermosensitive materials, but it is expensive, has complicated operation, and the surface of the product may wrinkle and shrink. |

| Costas G. Biliaderis. et al. [148] | complex coacervation | The production volume is large, but the process is complex and the cost is high. |

4.1.2. Electrostatic Spinning

| Reference | Bacteria Systems | Polymers | Processing Parameter | Nanofiber Average Diameter |

|---|---|---|---|---|

| Hong Wu. et al. [168] | Lactobacillus plantarum | PVA | 16 Kv, 0.3–0.6 mL/h, 14 cm | 410 ± 150 nm |

| Enes Dertli et al. [156] | Lactobacillus paracasei KS-199 | PVA, sodium alginate (SA) | 22 Kv, 1.2 mL/h, 10 cm | 305 nm |

| Fauzia Yusuf Hafeez. et al. [169] | Enterococcus mundtii QAUEM2808 | PVA, PVP, glycerol | 16 Kv, 0.6 mL/h, 15 cm | 318 nm |

| Juncai Hou. et al. [170] | Lactobacillus encapsulation | gum arabic (GA), pullulan (PUL) | 16 Kv, 0.4 mL/h, 10 cm | 105–283 nm |

| Wael Mamdouh. et al. [163] | Lactobacillus | PVA, inulin | 16 Kv, 0.6 mL/h, 10 cm | 200–400 nm |

| Anja Boisen et al. [171] | LGG | Pullulan, Poly-lactic-co-glycolic acid (PLGA) | 12 Kv, 1 mL/h, 15 cm | 287 ± 102 nm |

| Huda Ateeq. et al. [172] | Lactobacillus acidophilus | Gum Arabic (GA) and PVA | 16.8 Kv, 90 mm/s, 15 cm | 617 nm |

| Adem Gharsallaoui. et al. [173] | lactobacilli | chitosan (CS), PVA | 18 Kv, 0.1 mL/h, 15 cm | 117.5 ± 70.6–217.6 ± 62.7 nm |

| Maryam Azizkhani. et al. [174] | Lactobacillus and Bifidobacterium | corn starch (CS), SA | 24 Kv, 1.5 mL/h, 12 cm | 295 nm |

| Bin Jiang. et al. [175] | Lactobacillus plantarum | polylactic acid (PLA) | 16 Kv, 0.25 mL/h, 15 cm | 676 ± 162 nm |

| Zsombor K. Nagy. et al. [176] | Lactobacillus | PVA, polyethylene oxide (PEO) | 40 Kv, 20 mL/h, 35 cm | 100 nm |

| Min-Tze Liong. et al. [177] | Lactobacillus acidophilus | PVA, soluble dietary fiber (SDF), | 12 Kv, 0.1 mL/h, 15 cm | 229–730 nm |

4.1.3. Other Techniques

4.2. Methodologies for Testing the GI Behavior of Encapsulated Bacteria

4.2.1. Criteria for Assessing the Quality of Probiotic Encapsulation

4.2.2. In Vitro Methodologies

| Reference | System | Type | Advantage | Disadvantage |

|---|---|---|---|---|

| Mans Minekus. et al. [242] | The TNO gastro-intestinal model (TIM) | Multi-compartmental system | Reliable and cost-effective in vitro tool which fully assimilates the gastrointestinal tract, mimics crucial parameters of human digestion. | Lacks feedback on the GI conditions of the energy density of the food and is limited in simulating the anatomy of each digestive phase, as well as measuring bioavailability rather than bioaccessibility of a compound. |

| Molly Koen et al. [243] | The simulator of the human intestinal microbial ecosystem (SHIME) | Multi-compartmental system | Can maintain the stability and interaction of microbiota for a long time, and accurately evaluate the effects of drugs and food treatments. It can also study inter-individual variability of microbial communities. | Lacks a realistic physiological environment and anatomy in the digestive tract. |

| Guerra, Aurélie. et al. [244] | The new engineered stomach and small intestine model (ESIN) | Multi-compartmental system | Broad range of applications but needs further validation for applications outside of liquid drug digestion. In addition, can simulate the sieving effect of the gastric pylorus and allow the real-size food bolus to enter the stomach. | Cannot mimic the anatomy of each digestive organ nor simulate colonic fermentation. The model also struggles to simulate peristalsis and contractions in small intestinal chambers. |

| Daniel Picque. et al. [245] | The dynamic gastrointestinal digester (DIDGI) | Multi-compartmental system | Able to evaluate the digestion of infant formula and cheese-ripening microbiota in the GI tract and flexible working environment and can hold most masticated food. In addition, transparent chambers for direct observation of biochemical and physical processes during digestion. | Lacks the capability to simulate essential biomechanical and anatomical aspects of food digestion as well as the signals that control digestion speed and satiety. |

| Barroso, Elvira. et al. [246] | The simulator of the gastrointestinal tract (SIMGI) | Multi-compartmental system | Can reproduce stable microbial communities and explore the effects of diet and food on microbiota. It has automatic control and flexibility. | Lacks the ability to simulate gut microbiota–host interactions, metabolite absorption, and digestive anatomy. |

| Norwich et al. [247] | Dynamic gastric model (DGM) | mono-compartmental system | Simulate real human gastric biochemical conditions, predict the influence of food on health, and test the solubility of orally administered solid drugs. | Cannot provide visual observation, is exposed to air, and can only simulate a part of the gastric digestion process. |

| Fanbin Kong. et al. [248] | The human gastric simulator (HGS) | mono-compartmental system | Simulate the human digestive process, combine secretion, emptying, and temperature control, and hold several liters of material for digestion studies. Additionally, the solid-state polyester mesh bag in HGS allows for particle screening, simulating the sieving effect of the pylorus. | Only simulates stomach digestion and is costly for testing high-value ingredients due to sample size limitations. In addition, not transparent, and does not provide feedback on pH control, limiting its ability to assess processed foods in real-time. |

| Kozu Hiroyuki et al. [249] | The gastric digestion simulator (GDS) | mono-compartmental system | Allow for quantitative analysis and real-time visualization of the digestion process, as well as simulating peristaltic motion and mixing | Need for validation against in vivo data and does not mimic the characteristic “J” shape of human gastric morphology. Additionally, the number and location of the rollers used in the models are not fully adequate in simulating the real stomach peristalsis, and they only simulate one compartment of the human digestive tract. |

| Awad, T. S. et al. [250] | The in vitro mechanical gastric system (IMGS) | mono-compartmental system | It simulates the shape and peristaltic waves of the human stomach and can adjust the pressure and monitor the pH value. Compared with other models, gastric peristalsis is more realistic. | It does not simulate the filtering function and continuous secretion of gastric juice, which may affect the accuracy of simulation results. More experiments are needed to verify its practicality and reliability, and its ability to handle gastric emptying is relatively simple. |

| Cordonnier, Charlotte. et al. [251] | The artificial colon model (ARCOL) | mono-compartmental system | Semi-continuous fermentation system with various ports and probes, making it suitable for studying the survival rate of yeast probiotics and their effects on intestinal microbial metabolism. The system is capable of maintaining anaerobic conditions through the activity of gut microbiota and has a hollow fiber membrane to simulate passive absorption of metabolites. | Does not distinguish between different colon conditions and lacks mucosal contact surface. |

4.2.3. In Vivo Methodologies

5. Challenge of Commercializing Encapsulated Probiotics

6. Conclusions and Future Scope

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Williams, N.T. Probiotics. Am. J. Health-Syst. Pharm. 2010, 67, 449–458. [Google Scholar] [CrossRef]

- Markowiak, P.; Śliżewska, K. Effects of Probiotics, Prebiotics, and Synbiotics on Human Health. Nutrients 2017, 9, 1021. [Google Scholar] [CrossRef] [PubMed]

- Li, S.-C.; Hsu, W.-F.; Chang, J.-S.; Shih, C.-K. Combination of Lactobacillus acidophilus and Bifidobacterium animalis subsp. Lactis shows a stronger anti-inflammatory effect than individual strains in HT-29 cells. Nutrients 2019, 11, 969. [Google Scholar]

- Sundararaman, A.; Ray, M.; Ravindra, P.; Halami, P.M. Role of probiotics to combat viral infections with emphasis on COVID-19. Appl. Microbiol. Biotechnol. 2020, 104, 8089–8104. [Google Scholar]

- Ayivi, R.D.; Gyawali, R.; Krastanov, A.; Aljaloud, S.O.; Worku, M.; Tahergorabi, R.; Silva, R.C.D.; Ibrahim, S.A. Lactic acid bacteria: Food safety and human health applications. Dairy 2020, 1, 202–232. [Google Scholar]

- Zeng, W.; Shen, J.; Bo, T.; Peng, L.; Xu, H.; Nasser, M.I.; Zhuang, Q.; Zhao, M. Cutting edge: Probiotics and fecal microbiota transplantation in immunomodulation. J. Immunol. Res. 2019, 2019, 1603758. [Google Scholar]

- Kekkonen, R. Immunomodulatory Effects of Probiotic Bacteria in Healthy Adults; University of Helsinki: Helsinki, Finland, 2008. [Google Scholar]

- Siro, I.; Kápolna, E.; Kápolna, B.; Lugasi, A. Functional food. Product development, marketing and consumer acceptance—A review. Appetite 2008, 51, 456–467. [Google Scholar]

- Xu, C.; Ban, Q.; Wang, W.; Hou, J.; Jiang, Z. Novel nano-encapsulated probiotic agents: Encapsulate materials, delivery, and encapsulation systems. J. Control. Release 2022, 349, 184–205. [Google Scholar]

- Kullisaar, T.; Songisepp, E.; Zilmer, M. Probiotics and oxidative stress. In Oxidative Stress-Environmental Induction and Dietary Antioxidants; Lushchak, V., Ed.; Delve Publishing: Burlington, ON, Canada, 2012; pp. 203–222. [Google Scholar]

- Wu, T.; Wang, G.; Xiong, Z.; Xia, Y.; Song, X.; Zhang, H.; Wu, Y.; Ai, L. Probiotics interact with lipids metabolism and affect gut health. Front. Nutr. 2022, 9, 917043. [Google Scholar] [CrossRef]

- Feng, T.; Wang, J. Oxidative stress tolerance and antioxidant capacity of lactic acid bacteria as probiotic: A systematic review. Gut Microbes 2020, 12, 1801944. [Google Scholar]

- Vidhyalakshmi, R.; Bhakyaraj, R.; Subhasree, R. Encapsulation “the future of probiotics”—A review. Adv. Biol. Res. 2009, 3, 96–103. [Google Scholar]

- Serna-Cock, L.; Vallejo-Castillo, V. Probiotic encapsulation. Afr. J. Microbiol. Res. 2013, 7, 4743–4753. [Google Scholar]

- Hu, M.-X.; Li, J.-N.; Guo, Q.; Zhu, Y.-Q.; Niu, H.-M. Probiotics biofilm-integrated electrospun nanofiber membranes: A new starter culture for fermented milk production. J. Agric. Food Chem. 2019, 67, 3198–3208. [Google Scholar]

- Chandrashekhar, P.; Minooei, F.; Arreguin, W.; Masigol, M.; Steinbach-Rankins, J.M. Perspectives on existing and novel alternative intravaginal probiotic delivery methods in the context of bacterial vaginosis infection. AAPS J. 2021, 23, 66. [Google Scholar] [CrossRef] [PubMed]

- Neekhra, S.; Pandith, J.A.; Mir, N.A.; Manzoor, A.; Ahmad, S.; Ahmad, R.; Sheikh, R.A. Innovative approaches for microencapsulating bioactive compounds and probiotics: An updated review. J. Food Process. Preserv. 2022, 46, e16935. [Google Scholar]

- Kuo, C.-C.; Clark, S.; Qin, H.; Shi, X. Development of a shelf-stable, gel-based delivery system for probiotics by encapsulation, 3D printing, and freeze-drying. LWT 2022, 157, 113075. [Google Scholar]

- Zhang, Y.; Xie, Y.; Liu, H.; McClements, D.J.; Cheng, C.; Zou, L.; Liu, W.; Liu, W. Probiotic encapsulation in water-in-oil high internal phase emulsions: Enhancement of viability under food and gastrointestinal conditions. LWT 2022, 163, 113499. [Google Scholar]

- Luan, Q.; Zhang, H.; Chen, C.; Jiang, F.; Yao, Y.; Deng, Q.; Zeng, K.; Tang, H.; Huang, F. Controlled nutrient delivery through a pH-responsive wood vehicle. ACS Nano 2022, 16, 2198–2208. [Google Scholar]

- Centurion, F.; Merhebi, S.; Baharfar, M.; Abbasi, R.; Zhang, C.; Mousavi, M.; Xie, W.; Yang, J.; Cao, Z.; Allioux, F.M. Cell-mediated biointerfacial phenolic assembly for probiotic nano encapsulation. Adv. Funct. Mater. 2022, 32, 2200775. [Google Scholar]

- Park, H.J.; Lee, G.H.; Jun, J.-H.; Son, M.; Choi, Y.S.; Choi, M.-K.; Kang, M.J. Formulation and in vivo evaluation of probiotics-encapsulated pellets with hydroxypropyl methylcellulose acetate succinate (HPMCAS). Carbohydr. Polym. 2016, 136, 692–699. [Google Scholar]

- Yoha, K.; Nida, S.; Dutta, S.; Moses, J.; Anandharamakrishnan, C. Targeted delivery of probiotics: Perspectives on research and commercialization. Probiotics Antimicrob. Proteins 2021, 14, 15–48. [Google Scholar] [PubMed]

- Kwiecień, I.; Kwiecień, M. Application of polysaccharide-based hydrogels as probiotic delivery systems. Gels 2018, 4, 47. [Google Scholar] [CrossRef] [Green Version]

- Govender, M.; Choonara, Y.E.; Kumar, P.; du Toit, L.C.; van Vuuren, S.; Pillay, V. A review of the advancements in probiotic delivery: Conventional vs. non-conventional formulations for intestinal flora supplementation. Aaps PharmSciTech 2014, 15, 29–43. [Google Scholar] [PubMed] [Green Version]

- Wang, G.; Chen, Y.; Xia, Y.; Song, X.; Ai, L. Characteristics of probiotic preparations and their applications. Foods 2022, 11, 2472. [Google Scholar] [PubMed]

- Gao, Y.; Wang, X.; Xue, C.; Wei, Z. Latest developments in food-grade delivery systems for probiotics: A systematic review. Crit. Rev. Food Sci. Nutr. 2021, 63, 4371–4388. [Google Scholar] [PubMed]

- Silva, D.R.; Sardi, J.d.C.O.; de Souza Pitangui, N.; Roque, S.M.; da Silva, A.C.B.; Rosalen, P.L. Probiotics as an alternative antimicrobial therapy: Current reality and future directions. J. Funct. Foods 2020, 73, 104080. [Google Scholar] [CrossRef]

- Maleki, G.; Woltering, E.J.; Mozafari, M.R. Applications of chitosan-based carrier as an encapsulating agent in food industry. Trends Food Sci. Technol. 2022, 120, 88–99. [Google Scholar]

- Siuta-Cruce, P.; Goulet, J. Improving probiotic survival rates: Microencapsulation preserves the potency of probiotic microorganisms in food systems. Food Technol. 2001, 55, 36–42. [Google Scholar]

- Donaldson, G.P.; Lee, S.M.; Mazmanian, S.K. Gut biogeography of the bacterial microbiota. Nat. Rev. Microbiol. 2016, 14, 20–32. [Google Scholar] [CrossRef] [Green Version]

- Manojlović, V.; Nedović, V.A.; Kailasapathy, K.; Zuidam, N.J. Encapsulation of probiotics for use in food products. In Encapsulation Technologies for Active Food Ingredients and Food Processing; Springer: New York, NY, USA, 2010; pp. 269–302. [Google Scholar]

- Davachi, S.M.; Pottackal, N.; Torabi, H.; Abbaspourrad, A. Development and characterization of probiotic mucilage based edible films for the preservation of fruits and vegetables. Sci. Rep. 2021, 11, 16608. [Google Scholar] [CrossRef]

- Barbosa, J.; Teixeira, P. Development of probiotic fruit juice powders by spray-drying: A review. Food Rev. Int. 2017, 33, 335–358. [Google Scholar]

- de Almada, C.N.; Almada, C.N.; Martinez, R.C.; Sant’Ana, A.S. Paraprobiotics: Evidences on their ability to modify biological responses, inactivation methods and perspectives on their application in foods. Trends Food Sci. Technol. 2016, 58, 96–114. [Google Scholar]

- Ghosh, M.; Schild, H. Continuous recording of acid gastric secretion in the rat. Br. J. Pharmacol. Chemother. 1958, 13, 54–61. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Dodoo, C.C.; Wang, J.; Basit, A.W.; Stapleton, P.; Gaisford, S. Targeted delivery of probiotics to enhance gastrointestinal stability and intestinal colonisation. Int. J. Pharm. 2017, 530, 224–229. [Google Scholar] [CrossRef] [PubMed]

- Ouwehand, A.; Tölkkö, S.; Salminen, S. The effect of digestive enzymes on the adhesion of probiotic bacteria in vitro. J. Food Sci. 2001, 66, 856–859. [Google Scholar]

- Spiller, R. Probiotics and prebiotics in irritable bowel syndrome. Aliment. Pharmacol. Ther. 2008, 28, 385–396. [Google Scholar]

- Yao, M.; Xie, J.; Du, H.; McClements, D.J.; Xiao, H.; Li, L. Progress in microencapsulation of probiotics: A review. Compr. Rev. Food Sci. Food Saf. 2020, 19, 857–874. [Google Scholar] [CrossRef] [Green Version]

- Kailasapathy, K. Survival of free and encapsulated probiotic bacteria and their effect on the sensory properties of yoghurt. LWT-Food Sci. Technol. 2006, 39, 1221–1227. [Google Scholar]

- Stanford, K.; McAllister, T.; Niu, Y.; Stephens, T.; Mazzocco, A.; Waddell, T.; Johnson, R. Oral delivery systems for encapsulated bacteriophages targeted at Escherichia coli O157: H7 in feedlot cattle. J. Food Prot. 2010, 73, 1304–1312. [Google Scholar]

- Hati, S.; Mandal, S.; Khamrui, K.; Prajapati, J. Microencapsulation of probiotic cultures for preparation of yoghurt. Int. J. Fermented Foods 2013, 2, 47–61. [Google Scholar]

- Kailasapathy, K. Biopolymers for administration and gastrointestinal delivery of functional food ingredients and probiotic bacteria. Funct. Polym. Food Sci. 2015, 2, 231–265. [Google Scholar]

- Sun, Q.; Shen, Z.; Liang, X.; He, Y.; Kong, D.; Midgley, A.C.; Wang, K. Progress and current limitations of materials for artificial bile duct engineering. Materials 2021, 14, 7468. [Google Scholar]

- Ashaolu, T.J. Emerging applications of nanotechnologies to probiotics and prebiotics. Int. J. Food Sci. Technol. 2021, 56, 3719–3725. [Google Scholar]

- Pushpamalar, J.; Veeramachineni, A.K.; Owh, C.; Loh, X.J. Biodegradable polysaccharides for controlled drug delivery. ChemPlusChem 2016, 81, 504–514. [Google Scholar] [CrossRef]

- Reddy, M.M.; Vivekanandhan, S.; Misra, M.; Bhatia, S.K.; Mohanty, A.K. Biobased plastics and bionanocomposites: Current status and future opportunities. Prog. Polym. Sci. 2013, 38, 1653–1689. [Google Scholar]

- Hao, Y.; Zheng, W.; Sun, Z.; Zhang, D.; Sui, K.; Shen, P.; Li, P.; Zhou, Q. Marine polysaccharide-based composite hydrogels containing fucoidan: Preparation, physicochemical characterization, and biocompatible evaluation. Int. J. Biol. Macromol. 2021, 183, 1978–1986. [Google Scholar] [PubMed]

- Ichiura, H.; Konishi, T.; Morikawa, M. Alginate film prepared on polyethylene nonwoven sheet and its function for ellagic acid release in response to sodium ions. J. Mater. Sci. 2009, 44, 992–997. [Google Scholar]

- Tan, L.L.; Sampathkumar, K.; Wong, J.H.; Loo, S.C.J. Divalent cations are antagonistic to survivability of freeze-dried probiotics encapsulated in cross-linked alginate. Food Bioprod. Process. 2020, 124, 369–377. [Google Scholar] [CrossRef]

- Ahmad, A.; Mubarak, N.M.; Jannat, F.T.; Ashfaq, T.; Santulli, C.; Rizwan, M.; Najda, A.; Bin-Jumah, M.; Abdel-Daim, M.M.; Hussain, S.; et al. A Critical Review on the Synthesis of Natural Sodium Alginate Based Composite Materials: An Innovative Biological Polymer for Biomedical Delivery Applications. Processes 2021, 9, 137. [Google Scholar]

- Yuan, L.; Wei, H.; Yang, X.Y.; Geng, W.; Peterson, B.W.; van der Mei, H.C.; Busscher, H.J. Escherichia coli Colonization of Intestinal Epithelial Layers In Vitro in the Presence of Encapsulated Bifidobacterium breve for Its Protection against Gastrointestinal Fluids and Antibiotics. ACS Appl. Mater. Interfaces 2021, 13, 15973–15982. [Google Scholar]

- Vega-Carranza, A.S.; Cervantes-Chávez, J.A.; Luna-Bárcenas, G.; Luna-González, A.; Diarte-Plata, G.; Nava-Mendoza, R.; Rodríguez-Morales, J.A.; Escamilla-Montes, R.; Pool, H. Alginate microcapsules as delivery and protective systems of Bacillus licheniformis in a simulated shrimp’s digestive tract. Aquaculture 2021, 540, 736675. [Google Scholar] [CrossRef]

- Wang, K.; Ni, J.; Li, H.; Tian, X.; Tan, M.; Su, W. Survivability of probiotics encapsulated in kelp nanocellulose/alginate microcapsules on microfluidic device. Food Res. Int. 2022, 160, 111723. [Google Scholar]

- Nezamdoost-Sani, N.; Khaledabad, M.A.; Amiri, S.; Mousavi Khaneghah, A. Alginate and derivatives hydrogels in encapsulation of probiotic bacteria: An updated review. Food Biosci. 2023, 52, 102433. [Google Scholar] [CrossRef]

- Li, Z.; Behrens, A.M.; Ginat, N.; Tzeng, S.Y.; Lu, X.; Sivan, S.; Langer, R.; Jaklenec, A. Biofilm-Inspired Encapsulation of Probiotics for the Treatment of Complex Infections. Adv. Mater. 2018, 30, e1803925. [Google Scholar]

- Yuan, Y.; Yin, M.; Chen, L.; Liu, F.; Chen, M.; Zhong, F. Effect of calcium ions on the freeze-drying survival of probiotic encapsulated in sodium alginate. Food Hydrocoll. 2022, 130, 107668. [Google Scholar] [CrossRef]

- George, M.; Abraham, T.E. Polyionic hydrocolloids for the intestinal delivery of protein drugs: Alginate and chitosan—A review. J. Control. Release 2006, 114, 1–14. [Google Scholar]

- Yeung, T.W.; Üçok, E.F.; Tiani, K.A.; McClements, D.J.; Sela, D.A. Microencapsulation in alginate and chitosan microgels to enhance viability of Bifidobacterium longum for oral delivery. Front. Microbiol. 2016, 7, 494. [Google Scholar] [CrossRef] [Green Version]

- Avadi, M.R.; Sadeghi, A.M.M.; Mohammadpour, N.; Abedin, S.; Atyabi, F.; Dinarvand, R.; Rafiee-Tehrani, M. Preparation and characterization of insulin nanoparticles using chitosan and Arabic gum with ionic gelation method. Nanomed. Nanotechnol. Biol. Med. 2010, 6, 58–63. [Google Scholar] [CrossRef] [PubMed]

- Riaz, Q.U.A.; Masud, T. Recent trends and applications of encapsulating materials for probiotic stability. Crit. Rev. Food Sci. Nutr. 2013, 53, 231–244. [Google Scholar] [CrossRef] [PubMed]

- Morales, M.E.; Ruiz, M.A. Microencapsulation of probiotic cells: Applications in nutraceutic and food industry. Nutraceuticals 2016, 1, 627–668. [Google Scholar]

- Chávarri, M.; Marañón, I.; Ares, R.; Ibáñez, F.C.; Marzo, F.; del Carmen Villarán, M. Microencapsulation of a probiotic and prebiotic in alginate-chitosan capsules improves survival in simulated gastro-intestinal conditions. Int. J. Food Microbiol. 2010, 142, 185–189. [Google Scholar] [CrossRef] [PubMed]

- Krasaekoopt, W.; Bhandari, B.; Deeth, H. The influence of coating materials on some properties of alginate beads and survivability of microencapsulated probiotic bacteria. Int. Dairy J. 2004, 14, 737–743. [Google Scholar] [CrossRef]

- Algharib, S.A.; Dawood, A.; Zhou, K.; Chen, D.; Li, C.; Meng, K.; Zhang, A.; Luo, W.; Ahmed, S.; Huang, L. Preparation of chitosan nanoparticles by ionotropic gelation technique: Effects of formulation parameters and in vitro characterization. J. Mol. Struct. 2022, 1252, 132129. [Google Scholar]

- Silvestro, I.; Sergi, R.; D’Abusco, A.S.; Mariano, A.; Martinelli, A.; Piozzi, A.; Francolini, I. Chitosan scaffolds with enhanced mechanical strength and elastic response by combination of freeze gelation, photo-crosslinking and freeze-drying. Carbohydr. Polym. 2021, 267, 118156. [Google Scholar] [CrossRef]

- Du, H.; Liu, M.; Yang, X.; Zhai, G. The design of pH-sensitive chitosan-based formulations for gastrointestinal delivery. Drug Discov. Today 2015, 20, 1004–1011. [Google Scholar] [CrossRef] [PubMed]

- And, C.I.; Kailasapathy, K. Effect of co-encapsulation of probiotics with prebiotics on increasing the viability of encapsulated bacteria under in vitro acidic and bile salt conditions and in yogurt. J. Food Sci. 2005, 70, M18–M23. [Google Scholar] [CrossRef]

- Singh, P.; Medronho, B.; Alves, L.; Da Silva, G.J.; Miguel, M.G.; Lindman, B. Development of carboxymethyl cellulose-chitosan hybrid micro- and macroparticles for encapsulation of probiotic bacteria. Carbohydr. Polym. 2017, 175, 87–95. [Google Scholar] [CrossRef]

- Li, Q.; Lin, H.; Li, J.; Liu, L.; Huang, J.; Cao, Y.; Zhao, T.; McClements, D.J.; Chen, J.; Liu, C.; et al. Improving probiotic (Lactobacillus casei) viability by encapsulation in alginate-based microgels: Impact of polymeric and colloidal fillers. Food Hydrocoll. 2023, 134, 108028. [Google Scholar] [CrossRef]

- Zaeim, D.; Sarabi-Jamab, M.; Ghorani, B.; Kadkhodaee, R.; Tromp, R.H. Electrospray assisted fabrication of hydrogel microcapsules by single-and double-stage procedures for encapsulation of probiotics. Food Bioprod. Process. 2017, 102, 250–259. [Google Scholar] [CrossRef]

- Moghaddas Kia, E.; Ghasempour, Z.; Ghanbari, S.; Pirmohammadi, R.; Ehsani, A. Development of probiotic yogurt by incorporation of milk protein concentrate (MPC) and microencapsulated Lactobacillus paracasei in gellan-caseinate mixture. Br. Food J. 2018, 120, 1516–1528. [Google Scholar]

- Sharma, A.; Kumar, B.; Singh, S.K.; Gulati, M.; Vaidya, Y.; Rathee, H.; Ghai, D.; Malik, A.H.; Yadav, A.K.; Maharshi, P. In-vitro and in-vivo pharmacokinetic evaluation of guar gum-eudragit® S100 based colon-targeted spheroids of sulfasalazine Co-administered with probiotics. Curr. Drug Deliv. 2018, 15, 367–387. [Google Scholar] [CrossRef] [PubMed]

- Liu, H.; Xie, M.; Nie, S. Recent trends and applications of polysaccharides for microencapsulation of probiotics. Food Front. 2020, 1, 45–59. [Google Scholar]

- Ahmed, W.; Rashid, S. Functional and therapeutic potential of inulin: A comprehensive review. Crit. Rev. Food Sci. Nutr. 2019, 59, 1–13. [Google Scholar]

- Ghorbani, S.; Eyni, H.; Bazaz, S.R.; Nazari, H.; Asl, L.S.; Zaferani, H.; Kiani, V.; Mehrizi, A.A.; Soleimani, M. Hydrogels based on cellulose and its derivatives: Applications, synthesis, and characteristics. Polym. Sci. Ser. A 2018, 60, 707–722. [Google Scholar]

- Halahlah, A.; Piironen, V.; Mikkonen, K.S.; Ho, T.M. Polysaccharides as wall materials in spray-dried microencapsulation of bioactive compounds: Physicochemical properties and characterization. Crit. Rev. Food Sci. Nutr. 2022, 25, 1–33. [Google Scholar] [CrossRef]

- Li, M.-F.; Cui, H.-L.; Lou, W.-Y. Millettia speciosa Champ cellulose-based hydrogel as a novel delivery system for Lactobacillus paracasei: Its relationship to structure, encapsulation and controlled release. Carbohydr. Polym. 2023, 316, 121034. [Google Scholar]

- Cook, M.T.; Tzortzis, G.; Khutoryanskiy, V.V.; Charalampopoulos, D. Layer-by-layer coating of alginate matrices with chitosan–alginate for the improved survival and targeted delivery of probiotic bacteria after oral administration. J. Mater. Chem. B 2013, 1, 52–60. [Google Scholar]

- Yoo, S.; Gwon, T.; Eom, T.; Kim, S.; Hwang, C.S. Multicolor changeable optical coating by adopting multiple layers of ultrathin phase change material film. ACS Photonics 2016, 3, 1265–1270. [Google Scholar] [CrossRef]

- Phillips, G.; Williams, P. Introduction to food proteins. In Handbook of Food Proteins; Elsevier: Amsterdam, The Netherlands, 2011; pp. 1–12. [Google Scholar]

- Kim, W.; Wang, Y.; Selomulya, C. Dairy and plant proteins as natural food emulsifiers. Trends Food Sci. Technol. 2020, 105, 261–272. [Google Scholar]

- Chen, L.; Remondetto, G.E.; Subirade, M. Food protein-based materials as nutraceutical delivery systems. Trends Food Sci. Technol. 2006, 17, 272–283. [Google Scholar]

- Alipal, J.; Mohd Pu’ad, N.A.S.; Lee, T.C.; Nayan, N.H.M.; Sahari, N.; Basri, H.; Idris, M.I.; Abdullah, H.Z. A review of gelatin: Properties, sources, process, applications, and commercialisation. Mater. Today Proc. 2021, 42, 240–250. [Google Scholar] [CrossRef]

- de Almeida Paula, D.; Martins EM, F.; de Almeida Costa, N.; de Oliveira, P.M.; de Oliveira, E.B.; Ramos, A.M. Use of gelatin and gum arabic for microencapsulation of probiotic cells from Lactobacillus plantarum by a dual process combining double emulsification followed by complex coacervation. Int. J. Biol. Macromol. 2019, 133, 722–731. [Google Scholar] [CrossRef] [PubMed]

- Patarroyo, J.L.; Florez-Rojas, J.S.; Pradilla, D.; Valderrama-Rincón, J.D.; Cruz, J.C.; Reyes, L.H. Formulation and characterization of gelatin-based hydrogels for the encapsulation of Kluyveromyces lactis—Applications in packed-bed reactors and probiotics delivery in humans. Polymers 2020, 12, 1287. [Google Scholar] [CrossRef] [PubMed]

- Zhao, M.; Huang, X.; Zhang, H.; Zhang, Y.; Gänzle, M.; Yang, N.; Nishinari, K.; Fang, Y. Probiotic encapsulation in water-in-water emulsion via heteroprotein complex coacervation of type-A gelatin/sodium caseinate. Food Hydrocoll. 2020, 105, 105790. [Google Scholar] [CrossRef]

- Hansen, L.T.; Allan-Wojtas, P.; Jin, Y.-L.; Paulson, A. Survival of Ca-alginate microencapsulated Bifidobacterium spp. in milk and simulated gastrointestinal conditions. Food Microbiol. 2002, 19, 35–45. [Google Scholar] [CrossRef]

- Yao, M.; Li, B.; Ye, H.; Huang, W.; Luo, Q.; Xiao, H.; McClements, D.J.; Li, L. Enhanced viability of probiotics (Pediococcus pentosaceus Li05) by encapsulation in microgels doped with inorganic nanoparticles. Food Hydrocoll. 2018, 83, 246–252. [Google Scholar]

- Xu, D.; Liu, Z.; An, Z.; Hu, L.; Li, H.; Mo, H.; Hati, S. Incorporation of probiotics into 3D printed Pickering emulsion gel stabilized by tea protein/xanthan gum. Food Chem. 2023, 409, 135289. [Google Scholar] [CrossRef]

- Yasmin, I.; Saeed, M.; Pasha, I.; Zia, M.A. Development of whey protein concentrate-pectin-alginate based delivery system to improve survival of B. longum BL-05 in simulated gastrointestinal conditions. Probiotics Antimicrob. Proteins 2019, 11, 413–426. [Google Scholar]

- Krunić, T.Ž.; Obradović, N.S.; Rakin, M.B. Application of whey protein and whey protein hydrolysate as protein based carrier for probiotic starter culture. Food Chem. 2019, 293, 74–82. [Google Scholar] [CrossRef]

- Su, J.; Wang, X.; Li, W.; Chen, L.; Zeng, X.; Huang, Q.; Hu, B. Enhancing the viability of Lactobacillus plantarum as probiotics through encapsulation with high internal phase emulsions stabilized with whey protein isolate microgels. J. Agric. Food Chem. 2018, 66, 12335–12343. [Google Scholar]

- Doherty, S.; Gee, V.; Ross, R.; Stanton, C.; Fitzgerald, G.; Brodkorb, A. Efficacy of whey protein gel networks as potential viability-enhancing scaffolds for cell immobilization of Lactobacillus rhamnosus GG. J. Microbiol. Methods 2010, 80, 231–241. [Google Scholar] [CrossRef]

- Đorđević, V.; Balanč, B.; Belščak-Cvitanović, A.; Lević, S.; Trifković, K.; Kalušević, A.; Kostić, I.; Komes, D.; Bugarski, B.; Nedović, V. Trends in encapsulation technologies for delivery of food bioactive compounds. Food Eng. Rev. 2015, 7, 452–490. [Google Scholar]

- Reque, P.M.; Brandelli, A. Encapsulation of probiotics and nutraceuticals: Applications in functional food industry. Trends Food Sci. Technol. 2021, 114, 1–10. [Google Scholar] [CrossRef]

- Toublan, F.J.-J. Fats and waxes in microencapsulation of food ingredients. In Microencapsulation in the Food Industry; Elsevier: Amsterdam, The Netherlands, 2014; pp. 253–266. [Google Scholar]

- Rodríguez-Rosales, R.J. Phytoglycogen and Its Derivatives to Incorporate Curcumin for Enhanced Solubility and Efficacy. Doctoral Dissertation, Purdue University, West Lafayette, IN, USA, 2018. [Google Scholar]

- Nsairat, H.; Khater, D.; Sayed, U.; Odeh, F.; Al Bawab, A.; Alshaer, W. Liposomes: Structure, composition, types, and clinical applications. Heliyon 2022, 8, e09394. [Google Scholar] [CrossRef] [PubMed]

- McCormack, B.; Gregoriadis, G. Entrapment of cyclodextrin-drug complexes into liposomes: Potential advantages in drug delivery. J. Drug Target. 1994, 2, 449–454. [Google Scholar] [CrossRef] [PubMed]

- Miere, F.; Fritea, L.; Cavalu, S.; Vicas, S. Formulation, characterization, and advantages of using liposomes in multiple therapies. Pharmacophore 2020, 11, 1–12. [Google Scholar]

- Brandl, M. Liposomes as drug carriers: A technological approach. Biotechnol. Annu. Rev. 2001, 7, 59–85. [Google Scholar] [PubMed]

- Mundo, J.L.M.; Zhou, H.; Tan, Y.; Liu, J.; McClements, D.J. Enhancing emulsion functionality using multilayer technology: Coating lipid droplets with saponin-polypeptide-polysaccharide layers by electrostatic deposition. Food Res. Int. 2021, 140, 109864. [Google Scholar]

- Gao, M.; Su, H.; Lin, Y.; Ling, X.; Li, S.; Qin, A.; Tang, B.Z. Photoactivatable aggregation-induced emission probes for lipid droplets-specific live cell imaging. Chem. Sci. 2017, 8, 1763–1768. [Google Scholar] [CrossRef] [Green Version]

- Liu, M.-X.; Ding, N.; Chen, S.; Yu, Y.-L.; Wang, J.-H. One-step synthesis of carbon nanoparticles capable of long-term tracking lipid droplet for real-time monitoring of lipid catabolism and pharmacodynamic evaluation of lipid-lowering drugs. Anal. Chem. 2021, 93, 5284–5290. [Google Scholar] [CrossRef]

- Bollom, M.A.; Clark, S.; Acevedo, N.C. Edible lecithin, stearic acid, and whey protein bigels enhance survival of probiotics during in vitro digestion. Food Biosci. 2021, 39, 100813. [Google Scholar] [CrossRef]

- Liu, X.; Qin, Y.; Dong, L.; Han, Z.; Liu, T.; Tang, Y.; Yu, Y.; Ye, J.; Tao, J.; Zeng, X.; et al. Living symbiotic bacteria-involved skin dressing to combat indigenous pathogens for microbiome-based biotherapy toward atopic dermatitis. Bioact. Mater. 2023, 21, 253–266. [Google Scholar] [CrossRef]

- Wang, R.; Guo, K.; Zhang, W.; He, Y.; Yang, K.; Chen, Q.; Yang, L.; Di, Z.; Qiu, J.; Lei, P. Poly-γ-glutamic acid microgel-encapsulated probiotics with gastric acid resistance and smart inflammatory factor targeted delivery performance to ameliorate colitis. Adv. Funct. Mater. 2022, 32, 2113034. [Google Scholar] [CrossRef]

- Lu, Y.; Li, H.; Wang, J.; Yao, M.; Peng, Y.; Liu, T.; Li, Z.; Luo, G.; Deng, J. Engineering Bacteria-Activated Multifunctionalized Hydrogel for Promoting Diabetic Wound Healing. Adv. Funct. Mater. 2021, 31, 2105749. [Google Scholar]

- Ming, Z.; Han, L.; Bao, M.; Zhu, H.; Qiang, S.; Xue, S.; Liu, W. Living Bacterial Hydrogels for Accelerated Infected Wound Healing. Adv. Sci. 2021, 8, e2102545. [Google Scholar] [CrossRef]

- Lin, S.; Mukherjee, S.; Li, J.; Hou, W.; Pan, C.; Liu, J. Mucosal immunity–mediated modulation of the gut microbiome by oral delivery of probiotics into Peyer’s patches. Sci. Adv. 2021, 7, eabf0677. [Google Scholar] [CrossRef]

- Praveschotinunt, P.; Duraj-Thatte, A.M.; Gelfat, I.; Bahl, F.; Chou, D.B.; Joshi, N.S. Engineered E. coli Nissle 1917 for the delivery of matrix-tethered therapeutic domains to the gut. Nat. Commun. 2019, 10, 5580. [Google Scholar] [CrossRef] [Green Version]

- Yang, L.; Han, Z.; Chen, C.; Li, Z.; Yu, S.; Qu, Y.; Zeng, R. Novel probiotic-bound oxidized Bletilla striata polysaccharide-chitosan composite hydrogel. Mater. Sci. Eng. C 2020, 117, 111265. [Google Scholar] [CrossRef]

- Mei, L.; Zhang, D.; Shao, H.; Hao, Y.; Zhang, T.; Zheng, W.; Ji, Y.; Ling, P.; Lu, Y.; Zhou, Q. Injectable and Self-Healing Probiotics-Loaded Hydrogel for Promoting Superbacteria-Infected Wound Healing. ACS Appl. Mater. Interfaces 2022, 14, 20538–20550. [Google Scholar] [CrossRef]

- Xiao, Y.; Lu, C.; Liu, Y.; Kong, L.; Bai, H.; Mu, H.; Li, Z.; Geng, H.; Duan, J. Encapsulation of Lactobacillus rhamnosus in Hyaluronic Acid-Based Hydrogel for Pathogen-Targeted Delivery to Ameliorate Enteritis. ACS Appl. Mater. Interfaces 2020, 12, 36967–36977. [Google Scholar] [CrossRef]

- Roy, A.; Patra, M.; Sarkhel, S.; Sengupta, S.; Saha, S.; Jha, S.; Sarkhel, G.; Shrivastava, S.L. Fucose-containing Abroma augusta mucilage hydrogel as a potential probiotic carrier with prebiotic function. Food Chem. 2022, 387, 132941. [Google Scholar]

- Kim, J.; Hlaing, S.P.; Lee, J.; Saparbayeva, A.; Yoo, J.W. Exfoliated bentonite/alginate nanocomposite hydrogel enhances intestinal delivery of probiotics by resistance to gastric pH and on-demand disintegration. Carbohydr. Polym. 2021, 272, 118462. [Google Scholar] [PubMed]

- Gao, H.; Ma, L.; Sun, W.; Mcclements, D.J.; Cheng, C.; Zeng, H.; Zou, L.; Liu, W. Impact of encapsulation of probiotics in oil-in-water high internal phase emulsions on their thermostability and gastrointestinal survival. Food Hydrocoll. 2022, 126, 107478. [Google Scholar] [CrossRef]

- Zhang, Z.H.; Li, M.F.; Peng, F.; Zhong, S.R.; Lou, W.Y. Oxidized High-amylose Starch Macrogel as a Novel Delivery Vehicle for Probiotic and Bioactive Substances. Food Hydrocoll. 2020, 114, 106578. [Google Scholar]

- Abbas, M.S.; Saeed, F.; Afzaal, M.; Jianfeng, L.; Hussain, M.; Ikram, A.; Jabeen, A. Recent trends in encapsulation of probiotics in dairy and beverage: A review. J. Food Process. Preserv. 2022, 46, e16689. [Google Scholar] [CrossRef]

- Okuro, P.K.; de Matos Junior, F.E.; Favaro-Trindade, C.S. Technological challenges for spray chilling encapsulation of functional food ingredients. Food Technol. Biotechnol. 2013, 51, 171. [Google Scholar]

- Baral, K.C.; Bajracharya, R.; Lee, S.H.; Han, H.-K. Advancements in the pharmaceutical applications of probiotics: Dosage forms and formulation technology. Int. J. Nanomed. 2021, 16, 7535. [Google Scholar]

- Zabot, G.L.; Schaefer Rodrigues, F.; Polano Ody, L.; Vinícius Tres, M.; Herrera, E.; Palacin, H.; Córdova-Ramos, J.S.; Best, I.; Olivera-Montenegro, L. Encapsulation of Bioactive Compounds for Food and Agricultural Applications. Polymers 2022, 14, 4194. [Google Scholar] [CrossRef]

- Rokka, S.; Rantamäki, P. Protecting probiotic bacteria by microencapsulation: Challenges for industrial applications. Eur. Food Res. Technol. 2010, 231, 1–12. [Google Scholar] [CrossRef]

- Kvakova, M.; Bertkova, I.; Stofilova, J.; Savidge, T.C. Co-encapsulated synbiotics and immobilized probiotics in human health and gut Microbiota modulation. Foods 2021, 10, 1297. [Google Scholar]

- Mattila-Sandholm, T.; Myllärinen, P.; Crittenden, R.; Mogensen, G.; Fondén, R.; Saarela, M. Technological challenges for future probiotic foods. Int. Dairy J. 2002, 12, 173–182. [Google Scholar]

- Nafea, E.H.; Marson, A.; Poole-Warren, L.A.; Martens, P.J. Immunoisolating semi-permeable membranes for cell encapsulation: Focus on hydrogels. J. Control. Release 2011, 154, 110–122. [Google Scholar] [CrossRef] [PubMed]

- Kaushik, P.; Dowling, K.; Barrow, C.J.; Adhikari, B. Microencapsulation of omega-3 fatty acids: A review of microencapsulation and characterization methods. J. Funct. Foods 2015, 19, 868–881. [Google Scholar]

- Livney, Y.D. Milk proteins as vehicles for bioactives. Curr. Opin. Colloid Interface Sci. 2010, 15, 73–83. [Google Scholar]

- Suvarna, V.; Boby, V. Probiotics in human health: A current assessment. Curr. Sci. 2005, 88, 1744–1748. [Google Scholar]

- Lara-Flores, M. The use of probiotic in aquaculture: An overview. Int. Res. J. Microbiol. 2011, 2, 471–478. [Google Scholar]

- Balassa, L.L.; Fanger, G.O.; Wurzburg, O.B. Microencapsulation in the food industry. Crit. Rev. Food Sci. Nutr. 1971, 2, 245–265. [Google Scholar]

- Aguiar, J.; Estevinho, B.N.; Santos, L. Microencapsulation of natural antioxidants for food application–The specific case of coffee antioxidants–A review. Trends Food Sci. Technol. 2016, 58, 21–39. [Google Scholar]

- de Freitas Santos, P.D.; Rubio, F.T.V.; da Silva, M.P.; Pinho, L.S.; Favaro-Trindade, C.S. Microencapsulation of carotenoid-rich materials: A review. Food Res. Int. 2021, 147, 110571. [Google Scholar]

- Dhewa, T.; Pant, S.; Mishra, V. Development of freeze dried synbiotic formulation using a probiotic strain of Lactobacillus plantarum. J. Food Sci. Technol. 2014, 51, 83–89. [Google Scholar]

- Her, J.-Y.; Kim, M.S.; Lee, K.-G. Preparation of probiotic powder by the spray freeze-drying method. J. Food Eng. 2015, 150, 70–74. [Google Scholar] [CrossRef]

- Liu, T.; Wang, Y.; Zhong, W.; Li, B.; Mequanint, K.; Luo, G.; Xing, M. Biomedical applications of layer-by-layer self-assembly for cell encapsulation: Current status and future perspectives. Adv. Healthc. Mater. 2019, 8, 1800939. [Google Scholar]

- Priya, A.J.; Vijayalakshmi, S.; Raichur, A.M. Enhanced survival of probiotic Lactobacillus acidophilus by encapsulation with nanostructured polyelectrolyte layers through layer-by-layer approach. J. Agric. Food Chem. 2011, 59, 11838–11845. [Google Scholar] [PubMed]

- Dong, L.M.; Luan, N.T.; Thuy, D.T.K. Enhancing the viability rate of probiotic by co-encapsulating with prebiotic in alginate microcapsules supplemented to cupcake production. Microbiol. Biotechnol. Lett. 2020, 48, 113–120. [Google Scholar]

- do Amaral, P.H.R.; Andrade, P.L.; de Conto, L.C. Microencapsulation and Its Uses in Food Science and Technology: A review. In Microencapsulation: Processes, Technologies and Industrial Applications; BoD–Books on Demand: Norderstedt, Germany, 2019; p. 93. [Google Scholar]

- Anselmo, A.C.; McHugh, K.J.; Webster, J.; Langer, R.; Jaklenec, A. Layer-by-layer encapsulation of probiotics for delivery to the microbiome. Adv. Mater. 2016, 28, 9486–9490. [Google Scholar] [PubMed] [Green Version]

- Desmond, C.; Stanton, C.; Fitzgerald, G.F.; Collins, K.; Ross, R.P. Environmental adaptation of probiotic lactobacilli towards improvement of performance during spray drying. Int. Dairy J. 2001, 11, 801–808. [Google Scholar]

- Song, H.; Yu, W.; Gao, M.; Liu, X.; Ma, X. Microencapsulated probiotics using emulsification technique coupled with internal or external gelation process. Carbohydr. Polym. 2013, 96, 181–189. [Google Scholar]

- Gomez-Mascaraque, L.G.; Morfin, R.C.; Pérez-Masiá, R.; Sanchez, G.; Lopez-Rubio, A. Optimization of electrospraying conditions for the microencapsulation of probiotics and evaluation of their resistance during storage and in-vitro digestion. LWT-Food Sci. Technol. 2016, 69, 438–446. [Google Scholar]

- Sultana, M.; Chan, E.-S.; Pushpamalar, J.; Choo, W.S. Advances in extrusion-dripping encapsulation of probiotics and omega-3 rich oils. Trends Food Sci. Technol. 2022, 123, 69–86. [Google Scholar]

- Reddy, K.B.P.K.; Awasthi, S.P.; Madhu, A.N.; Prapulla, S.G. Role of cryoprotectants on the viability and functional properties of probiotic lactic acid bacteria during freeze drying. Food Biotechnol. 2009, 23, 243–265. [Google Scholar]

- Bosnea, L.A.; Moschakis, T.; Biliaderis, C.G. Complex coacervation as a novel microencapsulation technique to improve viability of probiotics under different stresses. Food Bioprocess Technol. 2014, 7, 2767–2781. [Google Scholar]

- Shi, X.; Zhou, W.; Ma, D.; Ma, Q.; Bridges, D.; Ma, Y.; Hu, A. Electrospinning of nanofibers and their applications for energy devices. J. Nanomater. 2015, 16, 122. [Google Scholar]

- Valizadeh, A.; Mussa Farkhani, S. Electrospinning and electrospun nanofibres. IET Nanobiotechnol. 2014, 8, 83–92. [Google Scholar] [CrossRef]

- Noruzi, M. Electrospun nanofibres in agriculture and the food industry: A review. J. Sci. Food Agric. 2016, 96, 4663–4678. [Google Scholar] [PubMed]

- Rodrigo-Navarro, A.; Sankaran, S.; Dalby, M.J.; del Campo, A.; Salmeron-Sanchez, M. Engineered living biomaterials. Nat. Rev. Mater. 2021, 6, 1175–1190. [Google Scholar]

- Bhushani, J.A.; Anandharamakrishnan, C. Electrospinning and electrospraying techniques: Potential food based applications. Trends Food Sci. Technol. 2014, 38, 21–33. [Google Scholar]

- Wei, L.; Zhou, D.; Kang, X. Electrospinning as a novel strategy for the encapsulation of living probiotics in polyvinyl alcohol/silk fibroin. Innov. Food Sci. Emerg. Technol. 2021, 71, 102726. [Google Scholar]

- Xu, C.; Ma, J.; Liu, Z.; Wang, W.; Liu, X.; Qian, S.; Chen, L.; Gu, L.; Sun, C.; Hou, J. Preparation of shell-core fiber-encapsulated Lactobacillus rhamnosus 1.0320 using coaxial electrospinning. Food Chem. 2023, 402, 134253. [Google Scholar]

- Yilmaz, M.T.; Taylan, O.; Karakas, C.Y.; Dertli, E. An alternative way to encapsulate probiotics within electrospun alginate nanofibers as monitored under simulated gastrointestinal conditions and in kefir. Carbohydr. Polym. 2020, 244, 116447. [Google Scholar] [CrossRef]

- Yilmaz, A.; Bozkurt, F.; Cicek, P.K.; Dertli, E.; Durak, M.Z.; Yilmaz, M.T. A novel antifungal surface-coating application to limit postharvest decay on coated apples: Molecular, thermal and morphological properties of electrospun zein–nanofiber mats loaded with curcumin. Innov. Food Sci. Emerg. Technol. 2016, 37, 74–83. [Google Scholar]

- Zhang, L.D.H. Recent advances in probiotics encapsulation by electrospinning. ES Food Agrofor. 2020, 2, 3–12. [Google Scholar]

- Li, Z.; Wang, C.; Li, Z.; Wang, C. Effects of working parameters on electrospinning. In One-Dimensional Nanostructures: Electrospinning Technique and Unique Nanofibers; Springer: Berlin/Heidelberg, Germany, 2013; pp. 15–28. [Google Scholar]

- Robb, B.; Lennox, B. The electrospinning process, conditions and control. In Electrospinning for Tissue Regeneration; Elsevier: Amsterdam, The Netherlands, 2011; pp. 51–66. [Google Scholar]

- Brenner, E.K.; Schiffman, J.D.; Thompson, E.A.; Toth, L.J.; Schauer, C.L. Electrospinning of hyaluronic acid nanofibers from aqueous ammonium solutions. Carbohydr. Polym. 2012, 87, 926–929. [Google Scholar] [CrossRef] [PubMed]

- Jeun, J.-P.; Kim, Y.-H.; Lim, Y.-M.; Choi, J.-H.; Jung, C.-H.; Kang, P.-H.; Nho, Y.-C. Electrospinning of Poly (L-lactide-co-D, L-lactide). J. Ind. Eng. Chem. 2007, 13, 592–596. [Google Scholar]

- Wahbi, W.; Siam, R.; Kegere, J.; El-Mehalmey, W.A.; Mamdouh, W. Novel Inulin Electrospun Composite Nanofibers: Prebiotic and Antibacterial Activities. ACS Omega 2020, 5, 3006–3015. [Google Scholar] [CrossRef]

- Athira, S.; Sanpui, P.; Chatterjee, K. Fabrication of poly (Caprolactone) nanofibers by electrospinning. J. Polym. Biopolym. Phys. Chem. 2014, 2, 62–66. [Google Scholar]

- De Vrieze, S.; Westbroek, P.; Van Camp, T.; Van Langenhove, L. Electrospinning of chitosan nanofibrous structures: Feasibility study. J. Mater. Sci. 2007, 42, 8029–8034. [Google Scholar] [CrossRef]

- Cramariuc, B.; Cramariuc, R.; Scarlet, R.; Manea, L.R.; Lupu, I.G.; Cramariuc, O. Fiber diameter in electrospinning process. J. Electrost. 2013, 71, 189–198. [Google Scholar] [CrossRef]

- Zhu, Y.; Wang, Z.; Bai, L.; Deng, J.; Zhou, Q. Biomaterial-based encapsulated probiotics for biomedical applications: Current status and future perspectives. Mater. Des. 2021, 210, 110018. [Google Scholar] [CrossRef]

- Feng, K.; Zhai, M.-Y.; Zhang, Y.; Linhardt, R.J.; Zong, M.-H.; Li, L.; Wu, H. Improved viability and thermal stability of the probiotics encapsulated in a novel electrospun fiber mat. J. Agric. Food Chem. 2018, 66, 10890–10897. [Google Scholar] [CrossRef]

- Khan, M.A.; Hussain, Z.; Ali, S.; Qamar, Z.; Imran, M.; Hafeez, F.Y. Fabrication of electrospun probiotic functionalized nanocomposite scaffolds for infection control and dermal burn healing in a mice model. ACS Biomater. Sci. Eng. 2019, 5, 6109–6116. [Google Scholar] [CrossRef]

- Ma, J.; Xu, C.; Yu, H.; Feng, Z.; Yu, W.; Gu, L.; Liu, Z.; Chen, L.; Jiang, Z.; Hou, J. Electro-encapsulation of probiotics in gum Arabic-pullulan blend nanofibres using electrospinning technology. Food Hydrocoll. 2021, 111, 106381. [Google Scholar] [CrossRef]

- Ajalloueian, F.; Guerra, P.R.; Bahl, M.I.; Torp, A.M.; Te Hwu, E.; Licht, T.R.; Boisen, A. Multi-layer PLGA-pullulan-PLGA electrospun nanofibers for probiotic delivery. Food Hydrocoll. 2022, 123, 107112. [Google Scholar] [CrossRef]

- Fareed, F.; Saeed, F.; Afzaal, M.; Imran, A.; Ahmad, A.; Mahmood, K.; Shah, Y.A.; Hussain, M.; Ateeq, H. Fabrication of electrospun gum Arabic–polyvinyl alcohol blend nanofibers for improved viability of the probiotic. J. Food Sci. Technol. 2022, 59, 4812–4821. [Google Scholar] [CrossRef]

- Mojaveri, S.J.; Hosseini, S.F.; Gharsallaoui, A. Viability improvement of Bifidobacterium animalis Bb12 by encapsulation in chitosan/poly (vinyl alcohol) hybrid electrospun fiber mats. Carbohydr. Polym. 2020, 241, 116278. [Google Scholar] [CrossRef]

- Atraki, R.; Azizkhani, M. Survival of probiotic bacteria nanoencapsulated within biopolymers in a simulated gastrointestinal model. Innov. Food Sci. Emerg. Technol. 2021, 72, 102750. [Google Scholar] [CrossRef]

- Yu, H.; Liu, W.; Li, D.; Liu, C.; Feng, Z.; Jiang, B. Targeting delivery system for Lactobacillus plantarum based on functionalized electrospun nanofibers. Polymers 2020, 12, 1565. [Google Scholar] [CrossRef] [PubMed]

- Hirsch, E.; Pantea, E.; Vass, P.; Domján, J.; Molnár, M.; Suhajda, Á.; Andersen, S.K.; Vigh, T.; Verreck, G.; Marosi, G.J.; et al. Probiotic bacteria stabilized in orally dissolving nanofibers prepared by high-speed electrospinning. Food Bioprod. Process. 2021, 128, 84–94. [Google Scholar] [CrossRef]

- Fung, W.-Y.; Yuen, K.-H.; Liong, M.-T. Agrowaste-based nanofibers as a probiotic encapsulant: Fabrication and characterization. J. Agric. Food Chem. 2011, 59, 8140–8147. [Google Scholar] [CrossRef] [PubMed]

- Xu, J.; Huang, Y.; Zhu, S.; Abbes, N.; Jing, X.; Zhang, L. A review of the green synthesis of ZnO nanoparticles using plant extracts and their prospects for application in antibacterial textiles. J. Eng. Fibers Fabr. 2021, 16, 15589250211046242. [Google Scholar] [CrossRef]

- Katiyar, V. Sustainable Polymers for Food Packaging. In Sustainable Polymers for Food Packaging; Walter de Gruyter GmbH & Co KG: Berlin, Germany, 2020. [Google Scholar]

- Álvarez-Paino, M.; Muñoz-Bonilla, A.; Fernández-García, M. Antimicrobial polymers in the nano-world. Nanomaterials 2017, 7, 48. [Google Scholar] [CrossRef] [Green Version]

- Yang, E.; Qin, X.; Wang, S. Electrospun crosslinked polyvinyl alcohol membrane. Mater. Lett. 2008, 62, 3555–3557. [Google Scholar] [CrossRef]

- Pech-Canul, A.d.l.C.; Ortega, D.; García-Triana, A.; González-Silva, N.; Solis-Oviedo, R.L. A brief review of edible coating materials for the microencapsulation of probiotics. Coatings 2020, 10, 197. [Google Scholar] [CrossRef] [Green Version]

- Yang, J.; Zhang, G.; Yang, X.; Peng, M.; Ge, S.; Tan, S.; Wen, Z.; Wang, Y.; Wu, S.; Liang, Y.; et al. An oral “Super probiotics” with versatile self-assembly adventitia for enhanced intestinal colonization by autonomous regulating the pathological microenvironment. Chem. Eng. J. 2022, 446, 137204. [Google Scholar] [CrossRef]

- Zhang, C.; Gao, X.; Ren, X.; Xu, T.; Peng, Q.; Zhang, Y.; Chao, Z.; Jiang, W.; Jia, L.; Han, L. Bacteria-Induced Colloidal Encapsulation for Probiotic Oral Delivery. ACS Nano 2023, 17, 6886–6898. [Google Scholar] [CrossRef]

- Muita, K.; Westerlund, M.; Rajala, R. The evolution of rapid production: How to adopt novel manufacturing technology. IFAC-Pap. 2015, 48, 32–37. [Google Scholar]

- Kanyilmaz, A.; Demir, A.G.; Chierici, M.; Berto, F.; Gardner, L.; Kandukuri, S.Y.; Kassabian, P.; Kinoshita, T.; Laurenti, A.; Paoletti, I. Role of metal 3D printing to increase quality and resource-efficiency in the construction sector. Addit. Manuf. 2022, 50, 102541. [Google Scholar] [CrossRef]

- Saadi, M.; Maguire, A.; Pottackal, N.T.; Thakur, M.S.H.; Ikram, M.M.; Hart, A.J.; Ajayan, P.M.; Rahman, M.M. Direct ink writing: A 3D printing technology for diverse materials. Adv. Mater. 2022, 34, 2108855. [Google Scholar] [CrossRef]

- Zhang, L.; Lou, Y.; Schutyser, M.A.I. 3D printing of cereal-based food structures containing probiotics. Food Struct. 2018, 18, 14–22. [Google Scholar] [CrossRef]

- Liu, Z.; Bhandari, B.; Zhang, M. Incorporation of probiotics (Bifidobacterium animalis subsp. Lactis) into 3D printed mashed potatoes: Effects of variables on the viability. Food Res. Int. 2020, 128, 108795. [Google Scholar] [CrossRef]

- Polli, J.E. In vitro studies are sometimes better than conventional human pharmacokinetic in vivo studies in assessing bioequivalence of immediate-release solid oral dosage forms. AAPS J. 2008, 10, 289–299. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Brodkorb, A.; Egger, L.; Alminger, M.; Alvito, P.; Assunção, R.; Ballance, S.; Bohn, T.; Bourlieu-Lacanal, C.; Boutrou, R.; Carrière, F. INFOGEST static in vitro simulation of gastrointestinal food digestion. Nat. Protoc. 2019, 14, 991–1014. [Google Scholar]

- Tang, Z.; Li, X.; Tan, Y.; Fan, H.; Zhang, X. The material and biological characteristics of osteoinductive calcium phosphate ceramics. Regen. Biomater. 2017, 5, 43–59. [Google Scholar] [CrossRef] [Green Version]

- Nooshkam, M.; Varidi, M. Maillard conjugate-based delivery systems for the encapsulation, protection, and controlled release of nutraceuticals and food bioactive ingredients: A review. Food Hydrocoll. 2020, 100, 105389. [Google Scholar]

- Rajam, R.; Anandharamakrishnan, C. Microencapsulation of Lactobacillus plantarum (MTCC 5422) with fructooligosaccharide as wall material by spray drying. LWT-Food Sci. Technol. 2015, 60, 773–780. [Google Scholar]

- Sompach, G.; Rodklongtan, A.; Nitisinprasert, S.; Chitprasert, P. Microencapsulating role of whey protein isolate and sucrose in protecting the cell membrane and enhancing survival of probiotic lactobacilli strains during spray drying, storage, and simulated gastrointestinal passage. Food Res. Int. 2022, 159, 111651. [Google Scholar] [CrossRef] [PubMed]

- Jantzen, M.; Göpel, A.; Beermann, C. Direct spray drying and microencapsulation of probiotic Lactobacillus reuteri from slurry fermentation with whey. J. Appl. Microbiol. 2013, 115, 1029–1036. [Google Scholar] [CrossRef]

- Jayaprakash, P.; Maudhuit, A.; Gaiani, C.; Desobry, S. Encapsulation of bioactive compounds using competitive emerging techniques: Electrospraying, nano spray drying, and electrostatic spray drying. J. Food Eng. 2022, 339, 111260. [Google Scholar]

- Arslan-Tontul, S. The combined usage of β-cyclodextrin and milk proteins in microencapsulation of Bifidobacterium bifidum BB-12. Probiotics Antimicrob. Proteins 2020, 12, 747–755. [Google Scholar] [CrossRef]

- Viernstein, H.; Raffalt, J.; Polheim, D. Stabilisation of Probiotic Microorganisms: An overview of the techniques and some commercially available products. Appl. Cell Immobil. Biotechnol. 2005, 8B, 439–453. [Google Scholar]

- Gayán, E.; Govers, S.K.; Aertsen, A. Impact of high hydrostatic pressure on bacterial proteostasis. Biophys. Chem. 2017, 231, 3–9. [Google Scholar] [CrossRef]

- Ananta, E.; Knorr, D. Evidence on the role of protein biosynthesis in the induction of heat tolerance of Lactobacillus rhamnosus GG by pressure pre-treatment. Int. J. Food Microbiol. 2004, 96, 307–313. [Google Scholar] [CrossRef] [PubMed]

- Analie, L.-H.; Bennie, C. Yogurt as probiotic carrier food. Int. Dairy J. 2001, 11, 1–17. [Google Scholar]

- Soto, R.I.; Jiménez-Munguía, M.T.; Mani-López, E.; Palou, E.; López-Malo, A. Growth and viability of Lactobacillus acidophilus NRRL B-4495, Lactobacillus casei NRRL B-1922 and Lactobacillus plantarum NRRL B-4496 in milk supplemented with cysteine, ascorbic acid and tocopherols. Int. Dairy J. 2019, 97, 15–24. [Google Scholar] [CrossRef]

- Zhou, Z.; Jing, Y.; Wei, S.; Zhang, Q.; Peng, S.; An, X.; Li, H. Enhancement of butanol production in Clostridium acetobutylicum SE25 through oxidation-reduction potential regulation and analysis of its metabolic mechanisms. Fuel 2023, 331, 125708. [Google Scholar] [CrossRef]

- Fruchart, M.; Scheibner, C.; Vitelli, V. Odd viscosity and odd elasticity. Annu. Rev. Condens. Matter Phys. 2023, 14, 471–510. [Google Scholar] [CrossRef]

- Ye, D.; Chang, C.; Zhang, L. High-strength and tough cellulose hydrogels chemically dual cross-linked by using low-and high-molecular-weight cross-linkers. Biomacromolecules 2019, 20, 1989–1995. [Google Scholar] [CrossRef] [PubMed]

- Rodríguez, R.; Alvarez-Lorenzo, C.; Concheiro, A. Cationic cellulose hydrogels: Kinetics of the cross-linking process and characterization as pH-/ion-sensitive drug delivery systems. J. Control. Release 2003, 86, 253–265. [Google Scholar]

- Razavi, S.; Janfaza, S.; Tasnim, N.; Gibson, D.L.; Hoorfar, M. Microencapsulating polymers for probiotics delivery systems: Preparation, characterization, and applications. Food Hydrocoll. 2021, 120, 106882. [Google Scholar] [CrossRef]

- Seifert, A.; Kashi, Y.; Livney, Y.D. Delivery to the gut microbiota: A rapidly proliferating research field. Adv. Colloid Interface Sci. 2019, 274, 102038. [Google Scholar] [CrossRef]

- Medrzycka, K. The effect of particle concentration on zeta potential in extremely dilute solutions. Colloid Polym. Sci. 1991, 269, 85–90. [Google Scholar] [CrossRef]

- Amiri, S.; Nezamdoost-Sani, N.; Mostashari, P.; McClements, D.J.; Marszałek, K.; Mousavi Khaneghah, A. Effect of the molecular structure and mechanical properties of plant-based hydrogels in food systems to deliver probiotics: An updated review. Crit. Rev. Food Sci. Nutr. 2022, 1–27. [Google Scholar] [CrossRef]

- Ramos, O.L.; Pereira, R.N.; Martins, A.; Rodrigues, R.; Fucinos, C.; Teixeira, J.A.; Pastrana, L.; Malcata, F.X.; Vicente, A.A. Design of whey protein nanostructures for incorporation and release of nutraceutical compounds in food. Crit. Rev. Food Sci. Nutr. 2017, 57, 1377–1393. [Google Scholar] [CrossRef] [Green Version]

- Feng, Y.; Kilker, S.R.; Lee, Y. Surface charge (zeta-potential) of nanoencapsulated food ingredients. In Characterization of Nanoencapsulated Food Ingredients; Elsevier: Amsterdam, The Netherlands, 2020; pp. 213–241. [Google Scholar]

- Sun, D.; Kang, S.; Liu, C.; Lu, Q.; Cui, L.; Hu, B. Effect of zeta potential and particle size on the stability of SiO2 nanospheres as carrier for ultrasound imaging contrast agents. Int. J. Electrochem. Sci. 2016, 11, 8520–8529. [Google Scholar] [CrossRef]

- Narsaiah, K.; Jha, S.N.; Wilson, R.A.; Mandge, H.M.; Manikantan, M.R. Optimizing microencapsulation of nisin with sodium alginate and guar gum. J. Food Sci. Technol. 2014, 51, 4054–4059. [Google Scholar] [CrossRef]

- Mohan, A.; Rajendran, S.R.; He, Q.S.; Bazinet, L.; Udenigwe, C.C. Encapsulation of food protein hydrolysates and peptides: A review. RSC Adv. 2015, 5, 79270–79278. [Google Scholar] [CrossRef] [Green Version]

- Liu, D.; Jiang, S.; Shen, H.; Qin, S.; Liu, J.; Zhang, Q.; Li, R.; Xu, Q. Diclofenac sodium-loaded solid lipid nanoparticles prepared by emulsion/solvent evaporation method. J. Nanopart. Res. 2011, 13, 2375–2386. [Google Scholar] [CrossRef]

- Cui, F.; Shi, K.; Zhang, L.; Tao, A.; Kawashima, Y. Biodegradable nanoparticles loaded with insulin–phospholipid complex for oral delivery: Preparation, in vitro characterization and in vivo evaluation. J. Control. Release 2006, 114, 242–250. [Google Scholar] [PubMed]

- Xiao, Z.; Liu, W.; Zhu, G.; Zhou, R.; Niu, Y. Production and characterization of multinuclear microcapsules encapsulating lavender oil by complex coacervation. Flavour Fragr. J. 2014, 29, 166–172. [Google Scholar] [CrossRef]

- Meng, F.B.; Lei, Y.T.; Zhang, Q.; Li, Y.C.; Chen, W.J.; Liu, D.Y. Encapsulation of Zanthoxylum bungeanum essential oil to enhance flavor stability and inhibit lipid oxidation of C hinese-style sausage. J. Sci. Food Agric. 2022, 102, 4035–4045. [Google Scholar] [CrossRef]

- Geranpour, M.; Assadpour, E.; Jafari, S.M. Recent advances in the spray drying encapsulation of essential fatty acids and functional oils. Trends Food Sci. Technol. 2020, 102, 71–90. [Google Scholar] [CrossRef]

- De Castro, M.; Orive, G.; Hernandez, R.; Gascon, A.; Pedraz, J. Comparative study of microcapsules elaborated with three polycations (PLL, PDL, PLO) for cell immobilization. J. Microencapsul. 2005, 22, 303–315. [Google Scholar] [CrossRef]

- Khutoryanskiy, V.V.; Smyslov, R.Y.; Yakimansky, A.V. Modern methods for studying polymer complexes in aqueous and organic solutions. Polym. Sci. Ser. A 2018, 60, 553–576. [Google Scholar] [CrossRef]

- Vilela, J.A.P.; de Assis Perrechil, F.; Picone, C.S.F.; Sato, A.C.K.; da Cunha, R.L. Preparation, characterization and in vitro digestibility of gellan and chitosan–gellan microgels. Carbohydr. Polym. 2015, 117, 54–62. [Google Scholar] [CrossRef]

- Jung, S.-H.; Bulut, S.; Guerzoni, L.B.; Günther, D.; Braun, S.; De Laporte, L.; Pich, A. Fabrication of pH-degradable supramacromolecular microgels with tunable size and shape via droplet-based microfluidics. J. Colloid Interface Sci. 2022, 617, 409–421. [Google Scholar] [CrossRef]

- He, S.; Hong, X.; Huang, T.; Zhang, W.; Zhou, Y.; Wu, L.; Yan, X. Rapid quantification of live/dead lactic acid bacteria in probiotic products using high-sensitivity flow cytometry. Methods Appl. Fluoresc. 2017, 5, 024002. [Google Scholar]

- Kramer, M.; Obermajer, N.; Bogovič Matijašić, B.; Rogelj, I.; Kmetec, V. Quantification of live and dead probiotic bacteria in lyophilised product by real-time PCR and by flow cytometry. Appl. Microbiol. Biotechnol. 2009, 84, 1137–1147. [Google Scholar] [CrossRef] [PubMed]

- Darabi, P.; Goudarzvand, M.; Natanzi, M.M.; Khodaii, Z. Antibacterial activity of probiotic bacteria isolated from broiler feces and commercial strains. Int. J. Enteric Pathog. 2016, 2, 6–18877. [Google Scholar]

- Hartsough, L. Dynamic Characterization of Bacterial Optogenetic Sensors and Their Use in Manipulating the Gut Microbiome to Extend Host Longevity. Doctoral Dissertation, Rice University, Houston, TX, USA, 2018. [Google Scholar]

- Hernandez-Mendoza, A.; González-Córdova, A.F.; Vallejo-Cordoba, B.; Garcia, H.S. Effect of oral supplementation of Lactobacillus reuteri in reduction of intestinal absorption of aflatoxin B1 in rats. J. Basic Microbiol. 2011, 51, 263–268. [Google Scholar] [CrossRef] [PubMed]

- Sensoy, I. A review on the food digestion in the digestive tract and the used in vitro models. Curr. Res. Food Sci. 2021, 4, 308–319. [Google Scholar] [CrossRef]

- Minekus, M.; Alminger, M.; Alvito, P.; Ballance, S.; Bohn, T.; Bourlieu, C.; Carrière, F.; Boutrou, R.; Corredig, M.; Dupont, D. A standardised static in vitro digestion method suitable for food–an international consensus. Food Funct. 2014, 5, 1113–1124. [Google Scholar] [CrossRef] [Green Version]

- Verhoeckx, K.; Cotter, P.; López-Expósito, I.; Kleiveland, C.; Lea, T.; Mackie, A.; Requena, T.; Swiatecka, D.; Wichers, H. The Impact of Food Bioactives on Health: In Vitro and Ex Vivo Models; Springer: Berlin/Heidelberg, Germany, 2015. [Google Scholar]

- Lockyer, S.; Aguirre, M.; Durrant, L.; Pot, B.; Suzuki, K. The role of probiotics on the roadmap to a healthy microbiota: A symposium report. Gut Microbiome 2020, 1, e2. [Google Scholar]

- Darjani, P.; Nezhad, M.H.; Kadkhodaee, R.; Milani, E. Influence of prebiotic and coating materials on morphology and survival of a probiotic strain of Lactobacillus casei exposed to simulated gastrointestinal conditions. LWT 2016, 73, 162–167. [Google Scholar] [CrossRef]

- Qi, X. Improved Viability of Lactobacillus rhamnosus GG during Storage and Simulated Gastrointestinal Digestion by Encapsulation. Doctoral Dissertation, North Dakota State University, Fargo, ND, USA, 2021. [Google Scholar]

- Jamunavathy, R. Fabrication and Characterization of Taste Masked Porous Tablets of Losartan Potassium by Sublimation Technique. Doctoral Dissertation, Adhiparasakthi College of Pharmacy, Melmaruvathur, India, 2012. [Google Scholar]

- Mainville, I.; Arcand, Y.; Farnworth, E. A dynamic model that simulates the human upper gastrointestinal tract for the study of probiotics. Int. J. Food Microbiol. 2005, 99, 287–296. [Google Scholar] [CrossRef]

- Marteau, P.; Minekus, M.; Havenaar, R.; Huis, J. Survival of lactic acid bacteria in a dynamic model of the stomach and small intestine: Validation and the effects of bile. J. Dairy Sci. 1997, 80, 1031–1037. [Google Scholar]

- Molly, K.; Woestyne, M.V.; Smet, I.D.; Verstraete, W. Validation of the simulator of the human intestinal microbial ecosystem (SHIME) reactor using microorganism-associated activities. Microb. Ecol. Health Dis. 1994, 7, 191–200. [Google Scholar]

- De Boever, P.; Deplancke, B.; Verstraete, W. Fermentation by gut microbiota cultured in a simulator of the human intestinal microbial ecosystem is improved by supplementing a soygerm powder. J. Nutr. 2000, 130, 2599–2606. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Minekus, M.; Marteau, P.; Havenaar, R.; Veld, J.H.H.i.t. A multicompartmental dynamic computer-controlled model simulating the stomach and small intestine. Altern. Lab. Anim. 1995, 23, 197–209. [Google Scholar] [CrossRef]

- Molly, K.; Vande Woestyne, M.; Verstraete, W. Development of a 5-step multi-chamber reactor as a simulation of the human intestinal microbial ecosystem. Appl. Microbiol. Biotechnol. 1993, 39, 254–258. [Google Scholar] [CrossRef]

- Guerra, A.; Denis, S.; le Goff, O.; Sicardi, V.; François, O.; Yao, A.F.; Garrait, G.; Manzi, A.P.; Beyssac, E.; Alric, M. Development and validation of a new dynamic computer-controlled model of the human stomach and small intestine. Biotechnol. Bioeng. 2016, 113, 1325–1335. [Google Scholar] [CrossRef] [PubMed]

- Ménard, O.; Cattenoz, T.; Guillemin, H.; Souchon, I.; Deglaire, A.; Dupont, D.; Picque, D. Validation of a new in vitro dynamic system to simulate infant digestion. Food Chem. 2014, 145, 1039–1045. [Google Scholar] [CrossRef]

- Barroso, E.; Cueva, C.; Peláez, C.; Martínez-Cuesta, M.C.; Requena, T. The computer-controlled multicompartmental dynamic model of the gastrointestinal system SIMGI. In The Impact of Food Bioactives on Health: In Vitro and Ex Vivo Models; Springer: Cham, Switzerland, 2015; p. 319. [Google Scholar]

- Thuenemann, E.C.; Mandalari, G.; Rich, G.T.; Faulks, R.M. Dynamic gastric model (DGM). In The Impact of Food Bioactives on Health: In Vitro and Ex Vivo Models; Springer: Cham, Switzerland, 2015; pp. 47–59. [Google Scholar]

- Kong, F.; Singh, R.P. A human gastric simulator (HGS) to study food digestion in human stomach. J. Food Sci. 2010, 75, E627–E635. [Google Scholar] [CrossRef]

- Kozu, H.; Nakata, Y.; Nakajima, M.; Neves, M.A.; Uemura, K.; Sato, S.; Kobayashi, I.; Ichikawa, S. Development of a human gastric digestion simulator equipped with peristalsis function for the direct observation and analysis of the food digestion process. Food Sci. Technol. Res. 2014, 20, 225–233. [Google Scholar] [CrossRef] [Green Version]

- Awad, T.; Moharram, H.; Shaltout, O.; Asker, D.; Youssef, M. Applications of ultrasound in analysis, processing and quality control of food: A review. Food Res. Int. 2012, 48, 410–427. [Google Scholar]

- Cordonnier, C.; Thévenot, J.; Etienne-Mesmin, L.; Denis, S.; Alric, M.; Livrelli, V.; Blanquet-Diot, S. Dynamic in vitro models of the human gastrointestinal tract as relevant tools to assess the survival of probiotic strains and their interactions with gut microbiota. Microorganisms 2015, 3, 725–745. [Google Scholar] [CrossRef] [PubMed]

- Vesterinen, H.; Sena, E.; Egan, K.; Hirst, T.; Churolov, L.; Currie, G.; Antonic, A.; Howells, D.; Macleod, M. Meta-analysis of data from animal studies: A practical guide. J. Neurosci. Methods 2014, 221, 92–102. [Google Scholar] [PubMed] [Green Version]

- Kararli, T.T. Comparison of the gastrointestinal anatomy, physiology, and biochemistry of humans and commonly used laboratory animals. Biopharm. Drug Dispos. 1995, 16, 351–380. [Google Scholar] [PubMed]

- Yadav, R.; Shukla, P. An overview of advanced technologies for selection of probiotics and their expediency: A review. Crit. Rev. Food Sci. Nutr. 2017, 57, 3233–3242. [Google Scholar]

- Ma, Y.; Xing, Y.; Xu, Q.; Wang, T.; Cai, Y.; Cao, D.; Che, Z. Preparation and application characteristics of microencapsulated Lactobacillus acidophilus as probiotics for dogs. Pak. J. Pharm. Sci. 2015, 28, 341–347. [Google Scholar] [PubMed]

- Tzortzis, G.; Goulas, A.K.; Gee, J.M.; Gibson, G.R. A novel galactooligosaccharide mixture increases the bifidobacterial population numbers in a continuous in vitro fermentation system and in the proximal colonic contents of pigs in vivo. J. Nutr. 2005, 135, 1726–1731. [Google Scholar] [CrossRef] [Green Version]

- Zhou, J.; Li, M.; Chen, Q.; Li, X.; Chen, L.; Dong, Z.; Zhu, W.; Yang, Y.; Liu, Z.; Chen, Q. Programmable probiotics modulate inflammation and gut microbiota for inflammatory bowel disease treatment after effective oral delivery. Nat. Commun. 2022, 13, 3432. [Google Scholar] [CrossRef] [PubMed]

- Huang, L.; Wang, J.; Kong, L.; Wang, X.; Li, Q.; Zhang, L.; Shi, J.; Duan, J.; Mu, H. ROS-responsive hyaluronic acid hydrogel for targeted delivery of probiotics to relieve colitis. Int. J. Biol. Macromol. 2022, 222, 1476–1486. [Google Scholar] [CrossRef] [PubMed]

- Ciron, C.; Gee, V.; Kelly, A.; Auty, M. Comparison of the effects of high-pressure microfluidization and conventional homogenization of milk on particle size, water retention and texture of non-fat and low-fat yoghurts. Int. Dairy J. 2010, 20, 314–320. [Google Scholar] [CrossRef]

- Călinoiu, L.-F.; Vodnar, D.-C.; Precup, G. The probiotic bacteria viability under different conditions. Bull. UASVM Food Sci. Technol. 2016, 73, 55–60. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Farnworth, E.R.; Champagne, C. Production of probiotic cultures and their incorporation into foods. In Bioactive Foods in Promoting Health; Elsevier: Amsterdam, The Netherlands, 2010; pp. 3–17. [Google Scholar]

- Mortazavian, A.; Razavi, S.H.; Ehsani, M.R.; Sohrabvandi, S. Principles and methods of microencapsulation of probiotic microorganisms. Iran. J. Biotechnol. 2017, 5, 1–18. [Google Scholar]

- Mortazavian, A.; Ehsani, M.; Mousavi, S.; Rezaei, K.; Sohrabvandi, S.; Reinheimer, J. Effect of refrigerated storage temperature on the viability of probiotic micro-organisms in yogurt. Int. J. Dairy Technol. 2007, 60, 123–127. [Google Scholar] [CrossRef]

- Bruno, F.; Shah, N. Viability of two freeze-dried strains of Bifidobacterium and of commercial preparations at various temperatures during prolonged storage. J. Food Sci. 2003, 68, 2336–2339. [Google Scholar] [CrossRef]

- Su, L.-W.; Cheng, Y.-H.; Hsiao, F.S.-H.; Han, J.-C.; Yu, Y.-H. Optimization of Mixed Solid-state Fermentation of Soybean Meal by Species and. Pol. J. Microbiol. 2018, 67, 297–305. [Google Scholar] [CrossRef] [Green Version]

- Helland, M.H.; Wicklund, T.; Narvhus, J.A. Growth and metabolism of selected strains of probiotic bacteria in milk-and water-based cereal puddings. Int. Dairy J. 2004, 14, 957–965. [Google Scholar] [CrossRef]

- Shahbazi, R.; Yasavoli-Sharahi, H.; Alsadi, N.; Ismail, N.; Matar, C. Probiotics in treatment of viral respiratory infections and neuroinflammatory disorders. Molecules 2020, 25, 4891. [Google Scholar] [CrossRef]

- Baindara, P.; Chakraborty, R.; Holliday, Z.M.; Mandal, S.M.; Schrum, A.G. Oral Probiotics in Coronavirus Disease 2019: Connecting the Gut–Lung Axis to Viral Pathogenesis, Inflammation, Secondary Infection and Clinical Trials; Elsevier: Amsterdam, The Netherlands, 2021; Volume 40, p. 100837. [Google Scholar]

- de Oliveira, G.L.V.; Oliveira, C.N.S.; Pinzan, C.F.; de Salis, L.V.V.; Cardoso, C.R.d.B. Microbiota modulation of the gut-lung axis in COVID-19. Front. Immunol. 2021, 12, 635471. [Google Scholar]

- Yao, M.; Wu, J.; Li, B.; Xiao, H.; McClements, D.J.; Li, L. Microencapsulation of Lactobacillus salivarious Li01 for enhanced storage viability and targeted delivery to gut microbiota. Food Hydrocoll. 2017, 72, 228–236. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sun, Q.; Yin, S.; He, Y.; Cao, Y.; Jiang, C. Biomaterials and Encapsulation Techniques for Probiotics: Current Status and Future Prospects in Biomedical Applications. Nanomaterials 2023, 13, 2185. https://doi.org/10.3390/nano13152185

Sun Q, Yin S, He Y, Cao Y, Jiang C. Biomaterials and Encapsulation Techniques for Probiotics: Current Status and Future Prospects in Biomedical Applications. Nanomaterials. 2023; 13(15):2185. https://doi.org/10.3390/nano13152185

Chicago/Turabian StyleSun, Qiqi, Sheng Yin, Yingxu He, Yi Cao, and Chunping Jiang. 2023. "Biomaterials and Encapsulation Techniques for Probiotics: Current Status and Future Prospects in Biomedical Applications" Nanomaterials 13, no. 15: 2185. https://doi.org/10.3390/nano13152185

APA StyleSun, Q., Yin, S., He, Y., Cao, Y., & Jiang, C. (2023). Biomaterials and Encapsulation Techniques for Probiotics: Current Status and Future Prospects in Biomedical Applications. Nanomaterials, 13(15), 2185. https://doi.org/10.3390/nano13152185