Overcoming the Fermi-Level Pinning Effect in the Nanoscale Metal and Silicon Interface

Abstract

:1. Introduction

2. Materials and Methods

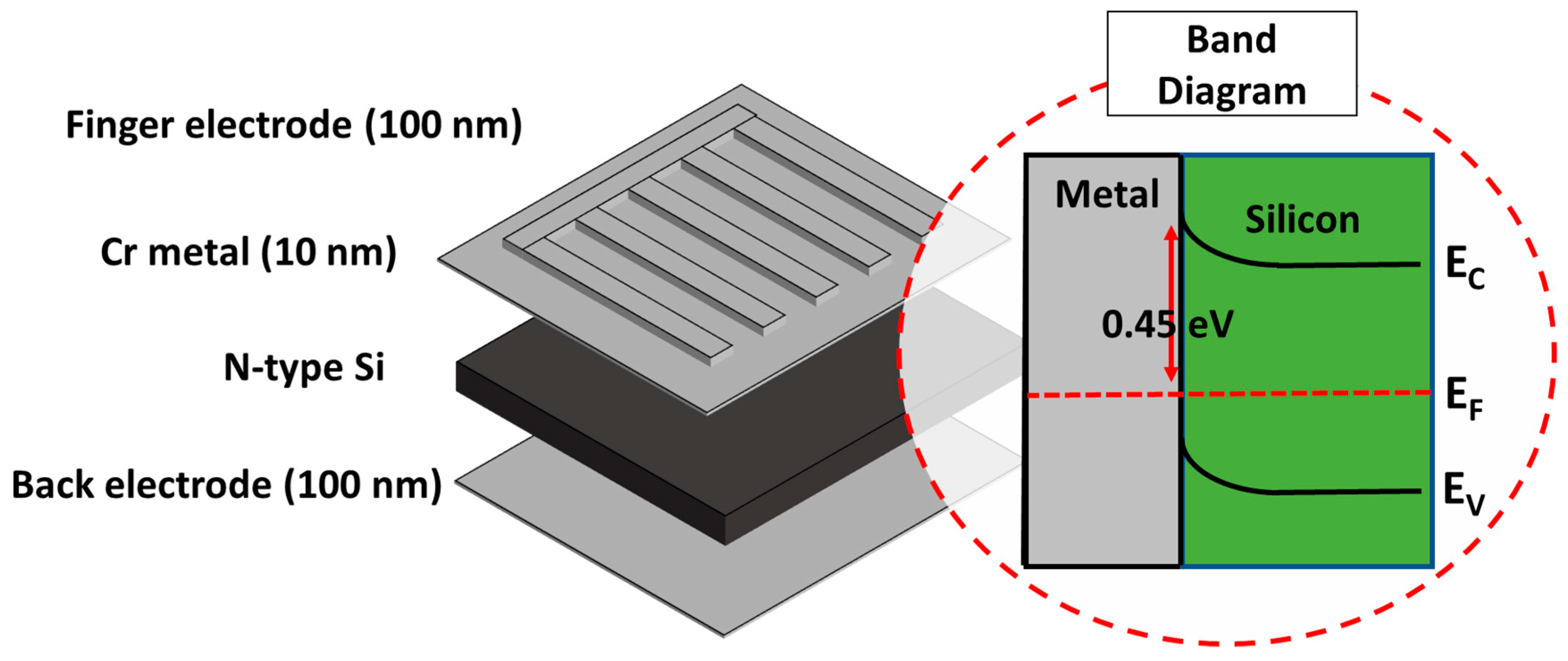

2.1. Device Fabrication

2.2. Device Characterization

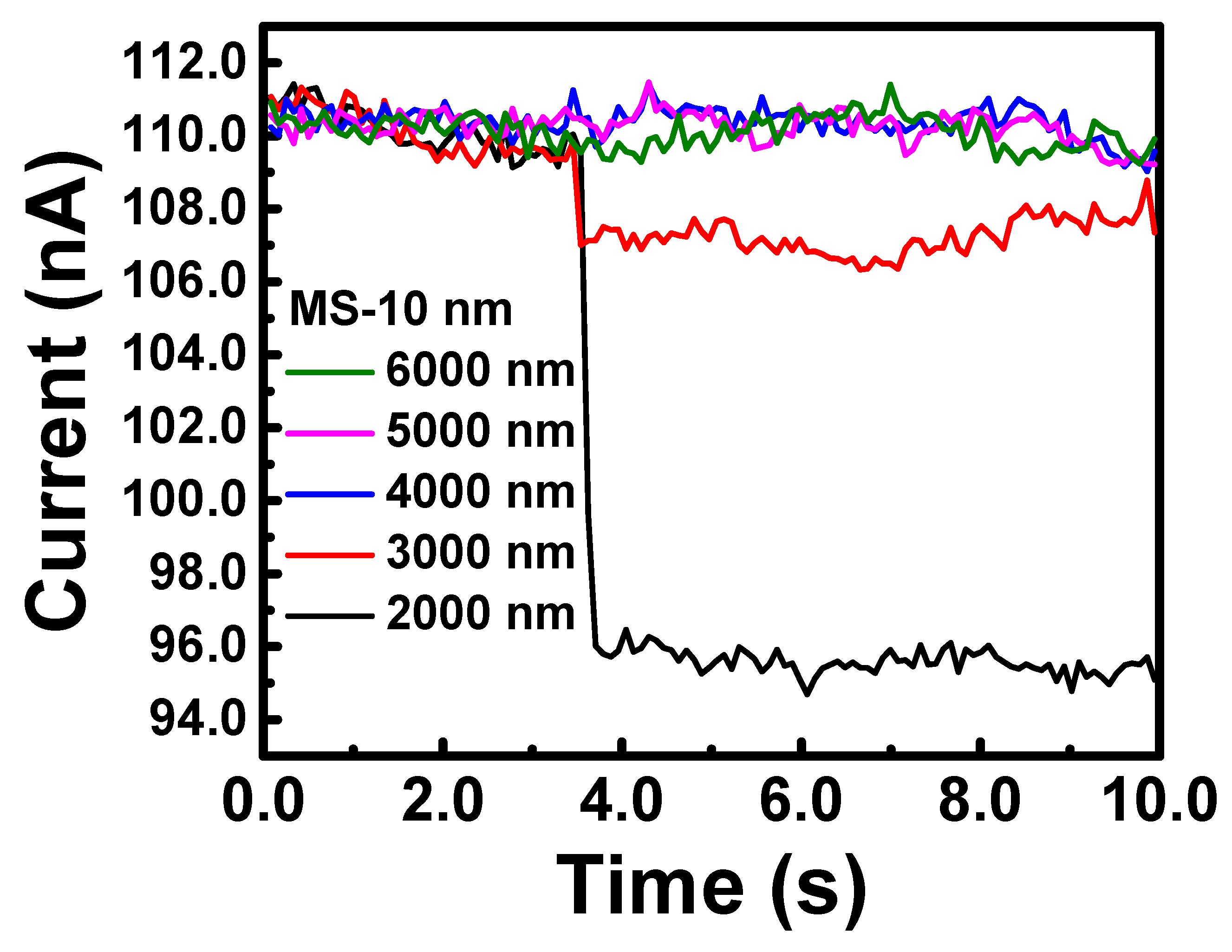

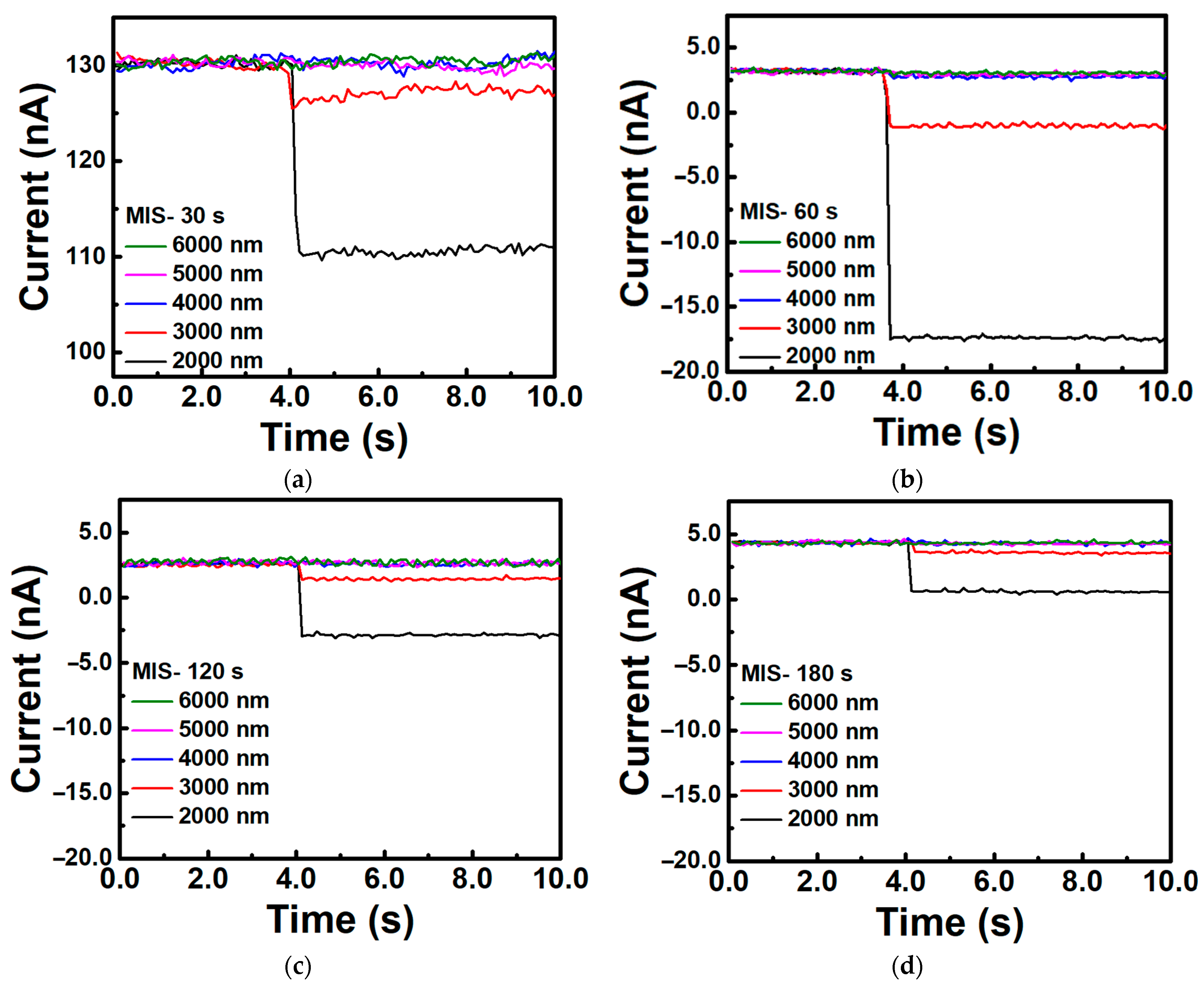

3. Results

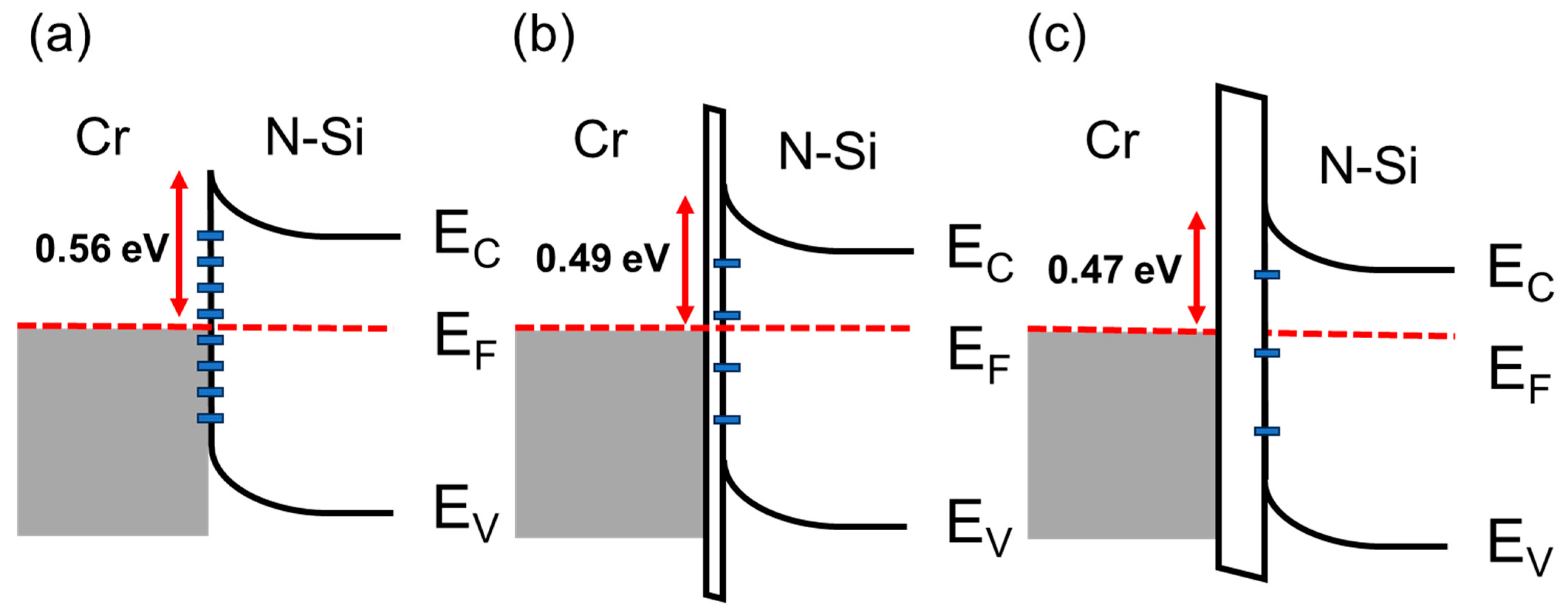

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Huang, T.; Fan, C.; Ma, L.; Zhang, X.; Fan, P.; Yang, Y.; Hu, W.; Zhou, H.; Zhuang, X.; Zhu, X.; et al. Single-crystalline InGaAs nanowires for room-temperature high-performance near-infrared photodetectors. Nano-Micro Lett. 2016, 8, 29–35. [Google Scholar]

- Miao, J.; Hu, W.; Guo, N.; Lu, Z.; Zou, X.; Liao, L.; Shi, S.; Chen, P.; Fan, Z.; Ho, J.C.; et al. Single InAs nanowire room-temperature near-infrared photodetectors. ACS Nano 2014, 8, 3628–3635. [Google Scholar] [CrossRef]

- Kuo, C.-H.; Wu, J.-M.; Lin, S.-J.; Chang, W.-C. High sensitivity of middle-wavelength infrared photodetectors based on an individual InSb nanowire. Nanoscale Res. Lett. 2013, 8, 327. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Shen, Y.; Li, Y.; Chen, W.; Jiang, S.; Li, C.; Cheng, Q. High-Performance Graphene Nanowalls/Si Self-Powered Photodetectors with HfO2 as an Interfacial Layer. Nanomaterials 2023, 13, 1681. [Google Scholar] [CrossRef] [PubMed]

- Li, G.; Maekita, K.; Mitsuno, H.; Maruyama, T.; Iiyama, K. Over 10 GHz lateral silicon photodetector fabricated on silicon-on-insulator substrate by CMOS-compatible process. Jpn. J. Appl. Phys. 2015, 54, 04DG06. [Google Scholar] [CrossRef]

- Liu, J.; Zhu, K.-M.; Zaslavsky, A.; Cristoloveanu, S.; Arsalan, M.; Wan, J. Photodiode with low dark current built in silicon-on-insulator using electrostatic doping. Solid-State Electron. 2020, 168, 107733. [Google Scholar] [CrossRef]

- Ghioni, M.; Zappa, F.; Kesan, V.; Warnock, J. A VLSI-compatible high-speed silicon photodetector for optical data link applications. IEEE Trans. Electron Devices 1996, 43, 1054–1060. [Google Scholar] [CrossRef]

- Liu, A.; Liao, L.; Rubin, D.; Nguyen, H.; Ciftcioglu, B.; Chetrit, Y.; Izhaky, N.; Paniccia, M. High-speed optical modulation based on carrier depletion in a silicon waveguide. Opt. Express 2007, 15, 660–668. [Google Scholar] [CrossRef] [Green Version]

- Casalino, M.; Coppola, G.; Iodice, M.; Rendina, I.; Sirleto, L. Near-infrared sub-bandgap all-silicon photodetectors: State of the art and perspectives. Sensors 2010, 10, 10571–10600. [Google Scholar] [CrossRef]

- Jalabert, R.; Das Sarma, S. Inelastic scattering in a doped polar semiconductor. Phys. Rev. B 1990, 41, 3651. [Google Scholar] [CrossRef]

- Petersen, C.L.; Lyon, S.A. Observation of hot-electron energy loss through the emission of phonon–plasmon coupled modes in GaAs. Phys. Rev. Lett. 1990, 65, 760. [Google Scholar] [CrossRef] [PubMed]

- Sicault, D.; Teissier, R.; Pardo, F.; Pelouard, J.-L.; Mollot, F. Experimental study of hot-electron inelastic scattering rate in p-type InGaAs. Phys. Rev. B 2002, 65, 121301. [Google Scholar] [CrossRef]

- Hilsum, C. Infrared absorption of thin metal films. J. Opt. Soc. Am. 1954, 44, 188–191. [Google Scholar] [CrossRef]

- Qi, Z.; Zhai, Y.; Wen, L.; Wang, Q.; Chen, Q.; Iqbal, S.; Chen, G.; Xu, J.; Tu, Y. Au nanoparticle-decorated silicon pyramids for plasmon-enhanced hot electron near-infrared photodetection. Nanotechnology 2017, 28, 275202. [Google Scholar] [CrossRef]

- Zhai, Y.; Li, Y.; Ji, J.; Wu, Z.; Wang, Q. Hot electron generation in silicon micropyramids covered with nanometer-thick gold films for near-infrared photodetectors. ACS Appl. Nano Mater. 2020, 3, 149–155. [Google Scholar] [CrossRef] [Green Version]

- Su, Z.-C.; Li, Y.-H.; Lin, C.-F. Mid-Infrared Response from Cr/n-Si Schottky Junction with an Ultra-Thin Cr Metal. Nanomaterials 2022, 12, 1750. [Google Scholar] [CrossRef]

- Sotthewes, K.; Van Bremen, R.; Dollekamp, E.; Boulogne, T.; Nowakowski, K.; Kas, D.; Zandvliet, H.J.W.; Bampoulis, P. Universal Fermi-level pinning in transition-metal dichalcogenides. J. Phys. Chem. C 2019, 123, 5411–5420. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Yuan, H.; Cheng, G.; You, L.; Li, H.; Zhu, H.; Li, W.; Kopanski, J.J.; Obeng, Y.S.; Walker, A.R.H.; Gundlach, D.J. Influence of Metal-MoS2 Interface on MoS2 Transistor Performance: Comparison of Ag and Ti Contacts. ACS Appl. Mater. Interfaces 2015, 7, 1180–1187. [Google Scholar] [CrossRef]

- Kim, C.; Moon, I.; Lee, D.; Choi, M.S.; Ahmed, F.; Nam, S.; Cho, Y.; Shin, H.-J.; Park, S.; Yoo, W.J. Fermi Level Pinning at Electrical Metal Contacts of Monolayer Molybdenum Dichalcogenides. ACS Nano 2017, 11, 1588–1596. [Google Scholar] [CrossRef]

- Zhang, Y.; Chen, X.; Zhang, H.; Wei, X.; Guan, X.; Wu, Y.; Wang, J. Fermi-level pinning mechanism in MoS2 field-effect transistors developed by thermionic emission theory. Appl. Sci. 2020, 10, 2754. [Google Scholar] [CrossRef]

- Sankey, F.; Allen, R.E.; Dow, J.D. Si/transition-metal Schottky barriers: Fermi-level pinning by Si dangling bonds at interfacial vacancies. Solid State Commun. 1984, 49, 1–5. [Google Scholar] [CrossRef]

- Khakbaz, P.; Driussi, F.; Giannozzi; Gambi, A.; Lizzit, D.; Esseni, D. Engineering of metal-MoS2 contacts to overcome Fermi level pinning. Solid-State Electron. 2022, 194, 108378. [Google Scholar] [CrossRef]

- Connelly, D.; Faulkner, C.; Clifton, A.; Grup, D.E. Fermi-level depinning for low-barrier Schottky source/drain transistors. Appl. Phys. Lett. 2006, 88, 012105. [Google Scholar] [CrossRef]

- Islam, R.; Shine, G.; Saraswat, K.C. Schottky barrier height reduction for holes by Fermi level depinning using metal/nickel oxide/silicon contacts. Appl. Phys. Lett. 2014, 105, 182103. [Google Scholar] [CrossRef] [Green Version]

- Kang, J.; Liu, W.; Sarkar, D.; Jena, D.; Banerjee, K. Computational study of metal contacts to monolayer transition-metal dichalcogenide semiconductors. Phys. Rev. X 2014, 4, 031005. [Google Scholar] [CrossRef] [Green Version]

- Park, I.; Lee, D.; Jin, B.; Kim, J.; Lee, J.-S. Improvement of Fermi-level pinning and contact resistivity in Ti/Ge contact using carbon implantation. Micromachines 2022, 13, 108. [Google Scholar] [CrossRef] [PubMed]

- Nazif, K.N.; Daus, A.; Hong, J.; Lee, N.; Vaziri, S.; Kumar, A.; Saraswat, K.C. High-specific-power flexible transition metal dichalcogenide solar cells. Nat. Commun. 2021, 12, 7034. [Google Scholar] [CrossRef]

- Elsmani, M.I.; Fatima, N.; Jallorina, M.P.A.; Sepeai, S.; Su’ait, M.S.; Ludin, N.A.; Teridi, M.A.M.; Sopian, K.; Ibrahim, M.A. Recent issues and configuration factors in perovskite-silicon tandem solar cells towards large scaling production. Nanomaterials 2021, 11, 3186. [Google Scholar] [CrossRef]

- Miao, J.; Zhang, X.; Tian, Y.; Zhao, Y. Recent Progress in Contact Engineering of Field-Effect Transistor Based on Two-Dimensional Materials. Nanomaterials 2022, 12, 3845. [Google Scholar] [CrossRef]

- Richstein, B.; Hellmich, L.; Knoch, J. Silicon nitride interface engineering for Fermi level depinning and realization of dopant-free MOSFETs. Micro 2021, 1, 228–241. [Google Scholar] [CrossRef]

- Yang, J.C.; Huang, H.F.; Li, J.H.; Lee, Y.J.; Wang, Y.H. Nitrogen plasma treatment of a TiO2 layer for MIS ohmic contact on n-type Ge substrate. Vacuum 2020, 171, 108996. [Google Scholar] [CrossRef]

- Shine, G.; Saraswat, K.C. Analysis of atomistic dopant variation and Fermi level depinning in nanoscale contacts. IEEE Trans. Electron Devices 2017, 64, 3768–3774. [Google Scholar] [CrossRef]

- Agrawal, A.; Lin, J.; Zheng, B.; Sharma, S.; Chopra, S.; Wang, K.; Datta, S. Barrier height reduction to 0.15 eV and contact resistivity reduction to 9.1 × 10−9 Ω-cm2 using ultrathin TiO2−x interlayer between metal and silicon. In Proceedings of the 2013 Symposium on VLSI Technology, Kyoto, Japan, 11–13 June 2013. [Google Scholar]

- Dev, S.; Meena, M.; Vardhan, H.; Lodha, S. Statistical simulation study of metal grain-orientation-induced MS and MIS contact resistivity variability for 7-nm FinFETs. IEEE Trans. Electron Devices 2018, 65, 3104–3111. [Google Scholar] [CrossRef]

- Zhang, T.; Raynaud, C.; Planson, D. Measure and analysis of 4H-SiC Schottky barrier height with Mo contacts. Eur. Phys. J. Appl. Phys. 2019, 85, 10102. [Google Scholar] [CrossRef]

- Orak, İ.; Kocyiğit, A.; Karataş, Ş. The analysis of the electrical and photovoltaic properties of Cr/p-Si structures using current-voltage measurements. Silicon 2018, 10, 2109–2116. [Google Scholar] [CrossRef]

- Bozhkov, V.G.; Torkhov, N.A.; Shmargunov, A.V. About the determination of the Schottky barrier height with the CV method. J. Appl. Phys. 2011, 109, 7. [Google Scholar] [CrossRef]

- Raynaud, C.; Isoird, K.; Lazar, M.; Johnson, C.M.; Wright, N. Barrier height determination of SiC Schottky diodes by capacitance and current-voltage measurements. J. Appl. Phys. 2002, 91, 9841–9847. [Google Scholar] [CrossRef]

- Khurelbaatar, Z.; Kil, Y.-H.; Yun, H.-J.; Shim, K.-H.; Nam, J.T.; Kim, K.-S.; Lee, S.-K.; Choi, C.-J. Modification of Schottky barrier properties of Au/n-type Ge Schottky barrier diode using monolayer graphene interlayer. J. Alloys Compd. 2014, 614, 323–329. [Google Scholar] [CrossRef]

- Bampoulis, P.; van Bremen, R.; Yao, Q.; Poelsema, B.; Zandvliet, H.J.W.; Sotthewes, K. Defect dominated charge transport and fermi level pinning in MoS2/metal contacts. ACS Appl. Mater. Interfaces 2017, 9, 19278–19286. [Google Scholar] [CrossRef] [Green Version]

- Schroder, D.K. Electrical characterization of defects in gate dielectrics. In Defects in Microelectronic Materials and Devices; Taylor & Francis Group: Abingdon, UK, 2009; pp. 119–163. [Google Scholar]

- Hung, K.K.; Cheng, Y.C. Process Dependence of the Si-SiO2 Interface Trap Density for Thin Oxides. J. Electrochem. Soc. 1987, 134, 2814. [Google Scholar] [CrossRef]

- Ji, C.H.; Kim, K.T.; Oh, S.Y. High-detectivity perovskite-based photodetector using a Zr-doped TiOx cathode interlayer. RSC Adv. 2018, 8, 8302–8309. [Google Scholar] [CrossRef] [PubMed]

- Wu, D.; Guo, J.; Wang, C.; Ren, X.; Chen, Y.; Lin, P.; Zeng, L.; Shi, Z.; Li, X.J.; Shan, C.-X.; et al. Ultrabroadband and high-detectivity photodetector based on WS2/Ge heterojunction through defect engineering and interface passivation. ACS Nano 2021, 15, 10119–10129. [Google Scholar] [CrossRef] [PubMed]

- Dou, L.; You, J.; Hong, Z.; Chang, W.-H.; Li, G.; Yang, Y. Solution-processed hybrid perovskite photodetectors with high detectivity. Nat. Commun. 2014, 5, 5404. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Yu, Y.Y.; Peng, Y.C.; Chiu, Y.C.; Liu, S.J.; Chen, C.P. Realizing Broadband NIR Photodetection and Ultrahigh Responsivity with Ternary Blend Organic Photodetector. Nanomaterials 2022, 12, 1378. [Google Scholar] [CrossRef]

| Rex (Ω) | 0 | 1 | 10 | 100 | 150 |

|---|---|---|---|---|---|

| Rs (Ω) | 29.92 | 31.00 | 40.152 | 131.120 | 181.033 |

| n | 1.492 | 1.496 | 1.495 | 1.498 | 1.496 |

| Barrier (eV) | 0.561 | 0.566 | 0.561 | 0.560 | 0.561 |

| T (K) | 300 | 298 | 298 | 298 | 298 |

| ΔRs (Ω) | 0.981 | 10.128 | 101.096 | 151.009 | |

| Relative Error (%) | 1.809 | 1.286 | 1.096 | 0.673 |

| Wavelength (nm) | 2000 | 3000 | 4000 | 5000 | 6000 |

|---|---|---|---|---|---|

| Response (nA) | |||||

| MS-0 s | 14.647 | 2.932 | |||

| MIS-30 s | 19.668 | 2.984 | |||

| MIS-60 s | 20.557 | 4.242 | 0.489 | 0.186 | 0.154 |

| MIS-120 s | 5.496 | 1.088 | |||

| MIS-180 s | 3.772 | 0.742 | |||

| MS | MIS-30 s | MIS-60 s | MIS-120 s | MIS-180 s | |

|---|---|---|---|---|---|

| Rs (Ω) | 29.924 | 38.210 | 20.294 | 25.194 | 27.243 |

| n | 1.492 | 1.773 | 1.97 | 3.127 | 3.267 |

| Barrier (eV) | 0.561 | 0.552 | 0.496 | 0.495 | 0.472 |

| Wavelength (nm) | Responsivity (nA/W) | D* (cmHz1/2W−1) |

|---|---|---|

| 2000 | 2.34 × 105 | 1.17 × 108 |

| 3000 | 4.82 × 104 | 2.41 × 107 |

| 4000 | 5.56 × 103 | 2.78 × 106 |

| 5000 | 2.11 × 103 | 1.06 × 106 |

| 6000 | 1.75 × 103 | 8.75 × 105 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Su, Z.-C.; Lin, C.-F. Overcoming the Fermi-Level Pinning Effect in the Nanoscale Metal and Silicon Interface. Nanomaterials 2023, 13, 2193. https://doi.org/10.3390/nano13152193

Su Z-C, Lin C-F. Overcoming the Fermi-Level Pinning Effect in the Nanoscale Metal and Silicon Interface. Nanomaterials. 2023; 13(15):2193. https://doi.org/10.3390/nano13152193

Chicago/Turabian StyleSu, Zih-Chun, and Ching-Fuh Lin. 2023. "Overcoming the Fermi-Level Pinning Effect in the Nanoscale Metal and Silicon Interface" Nanomaterials 13, no. 15: 2193. https://doi.org/10.3390/nano13152193

APA StyleSu, Z.-C., & Lin, C.-F. (2023). Overcoming the Fermi-Level Pinning Effect in the Nanoscale Metal and Silicon Interface. Nanomaterials, 13(15), 2193. https://doi.org/10.3390/nano13152193