Measurement of Thermal Stress by X-ray Nano-Diffraction in (111)-Oriented Nanotwinned Cu Bumps for Cu/SiO2 Hybrid Joints

Abstract

:1. Introduction

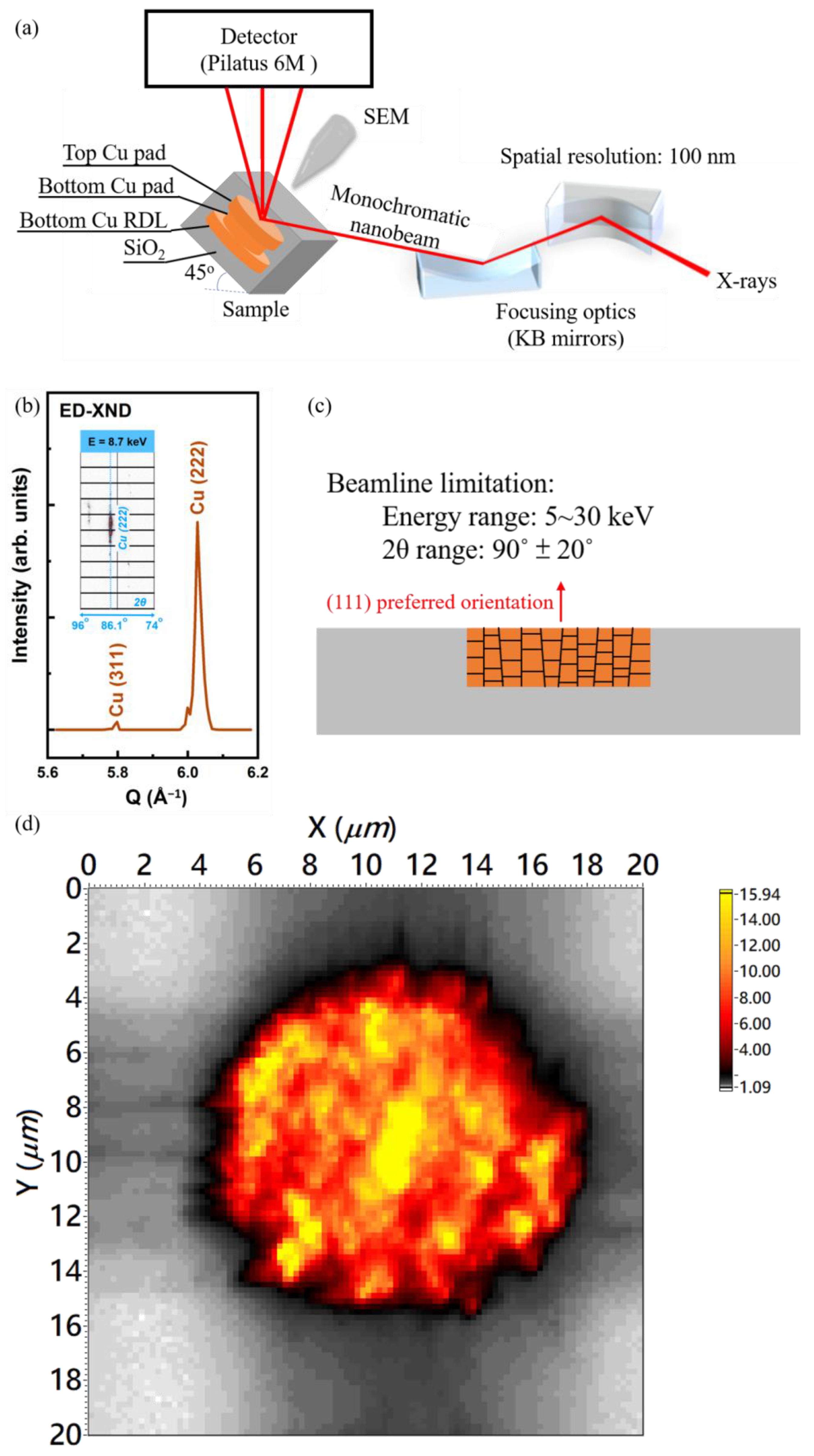

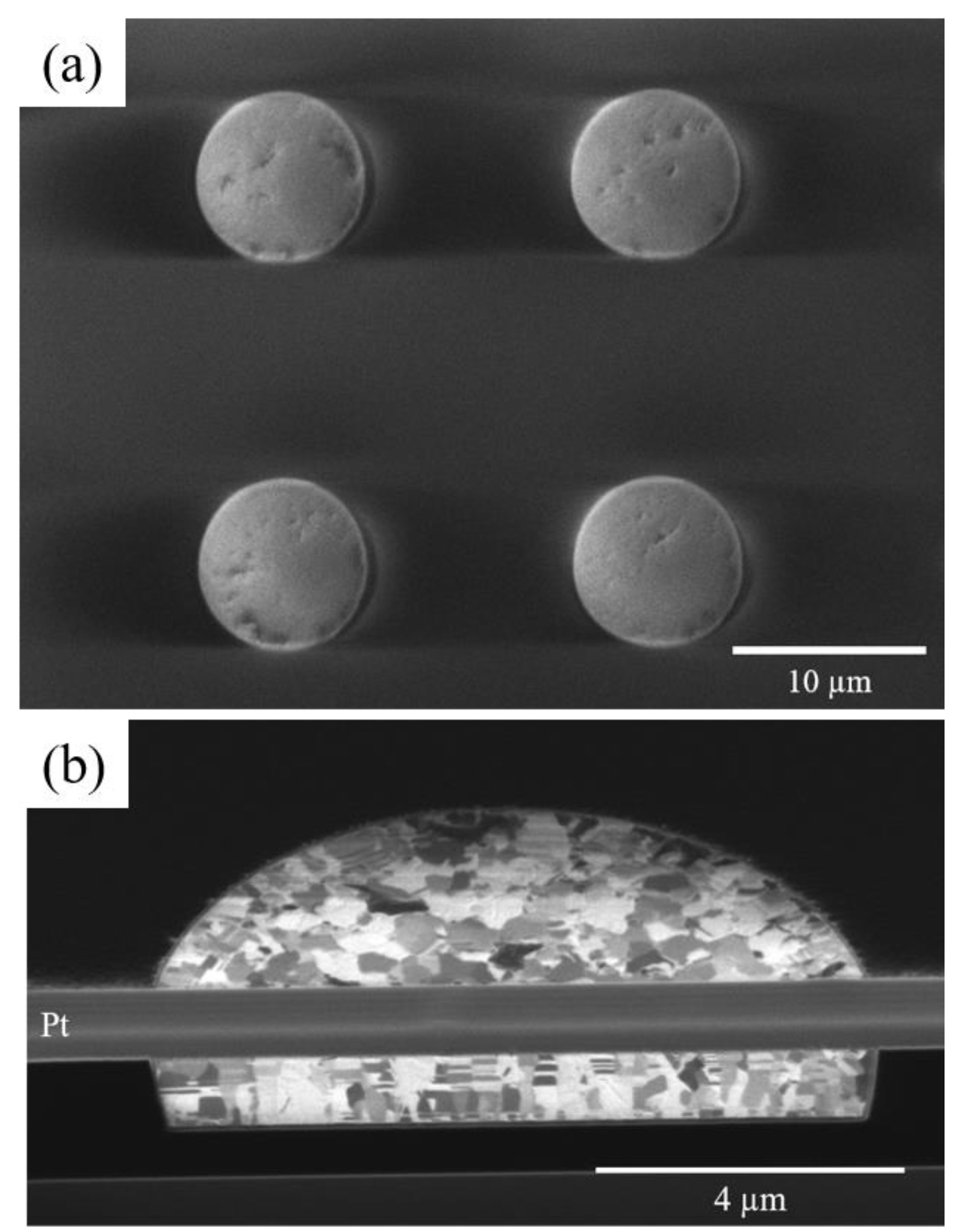

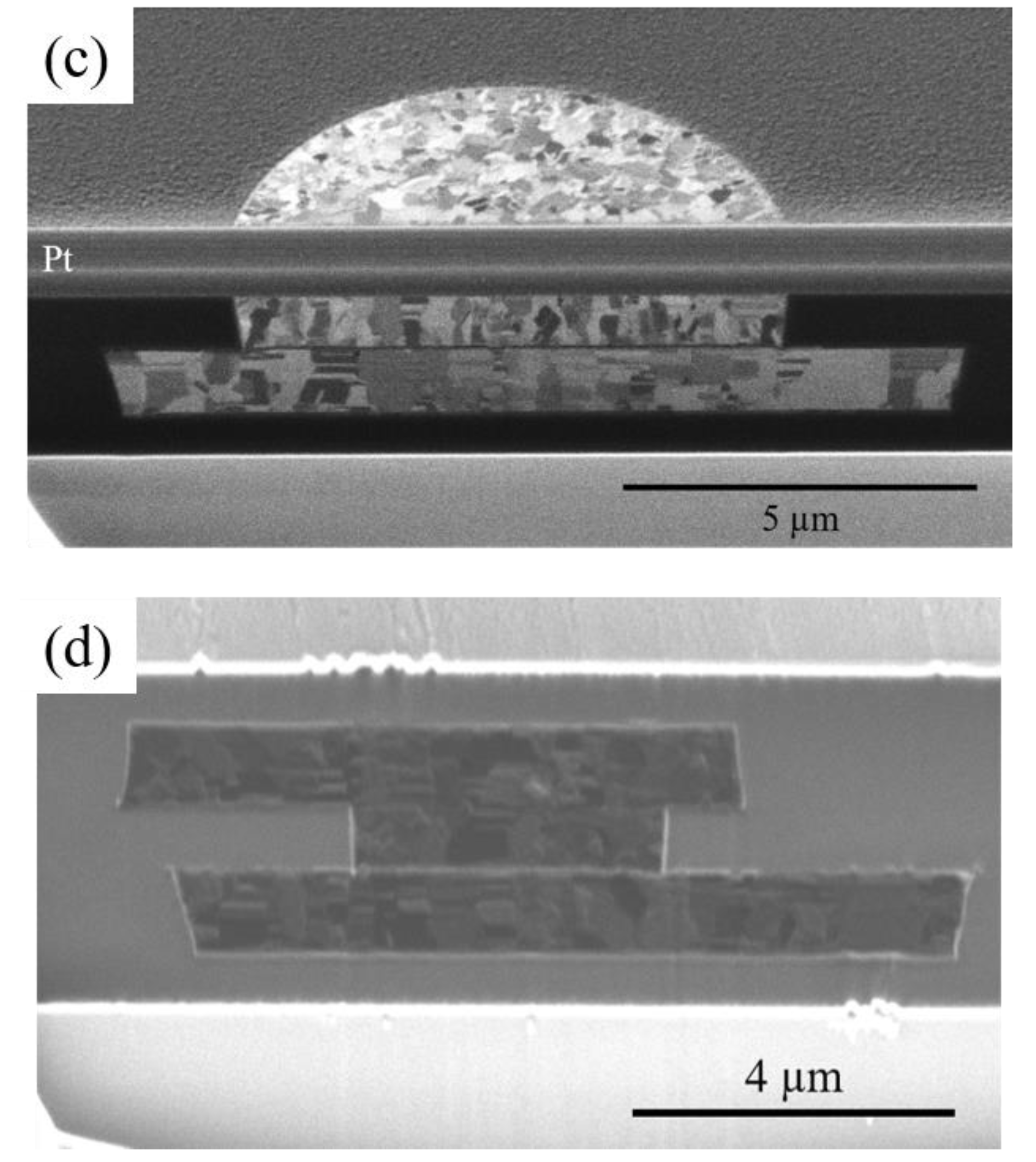

2. Materials and Methods

3. Results and Discussion

3.1. Diffraction Intensity and Microstructure

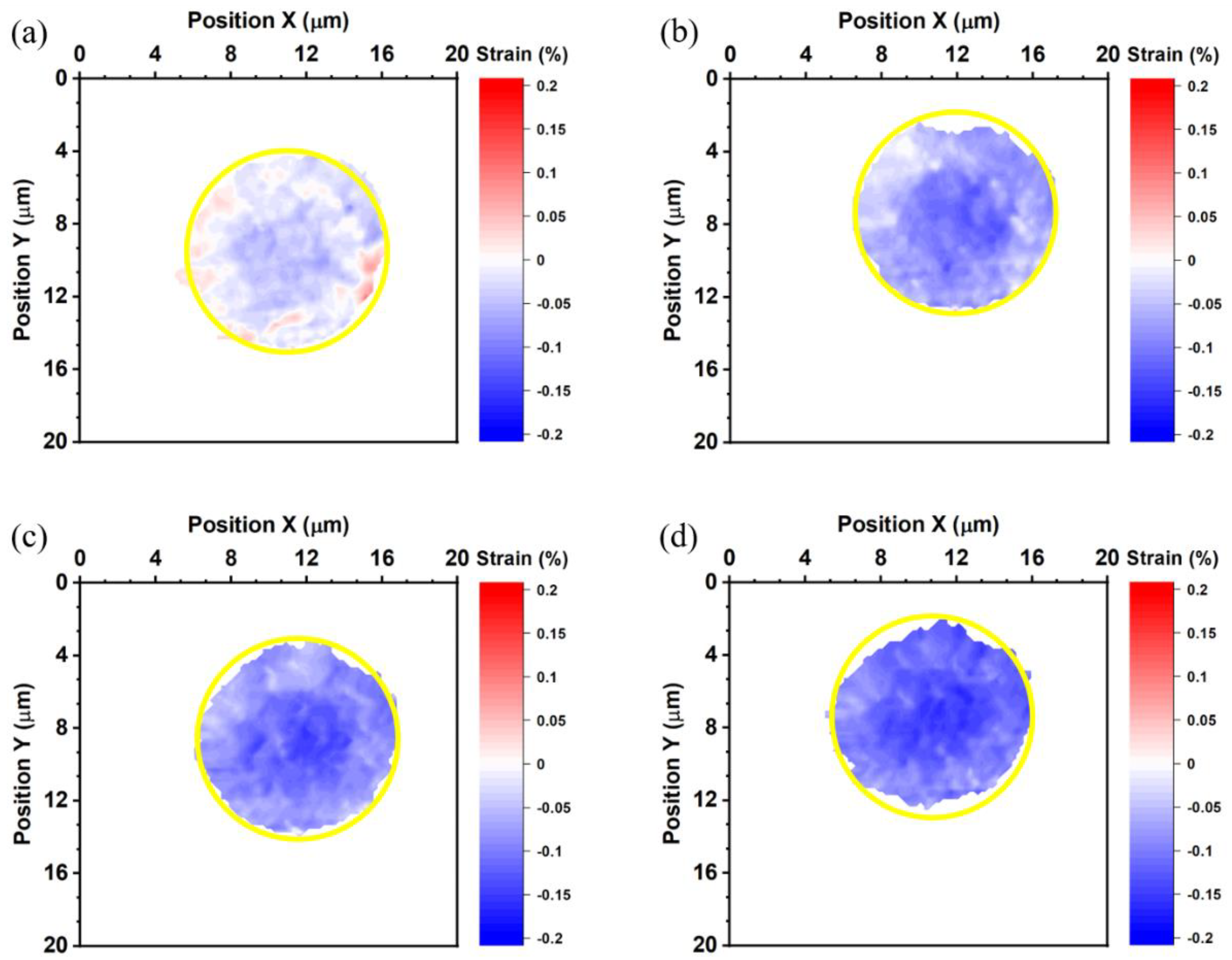

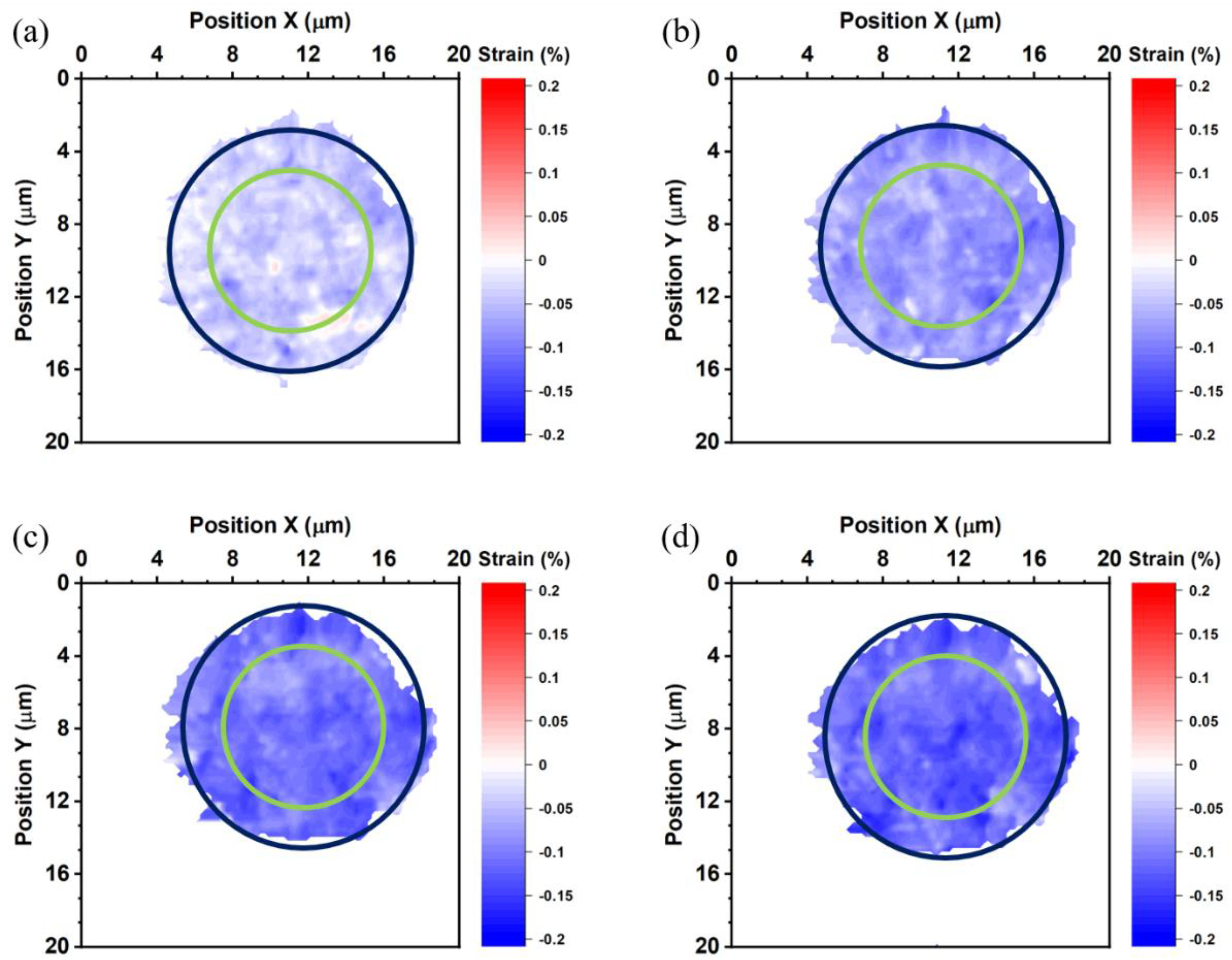

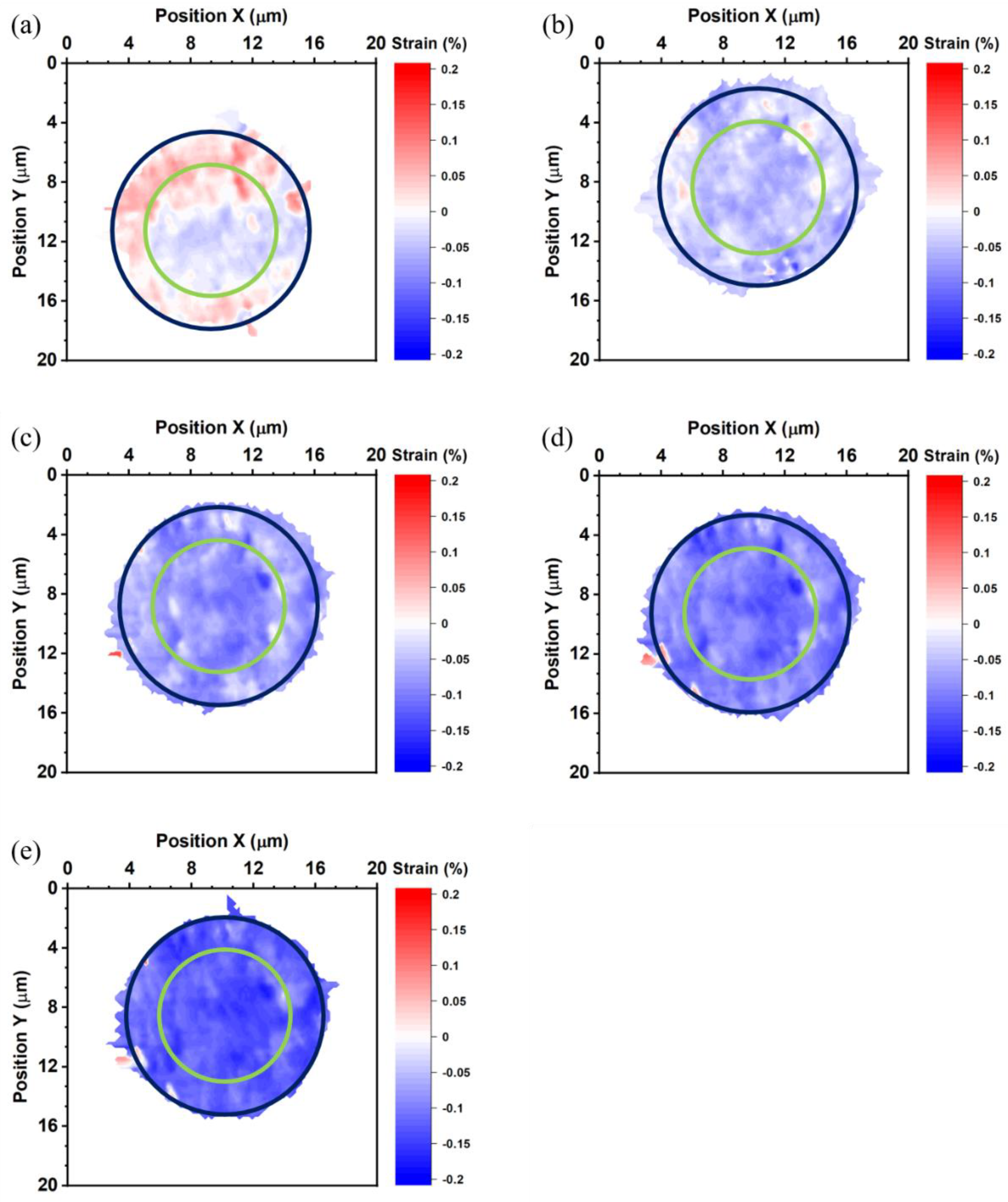

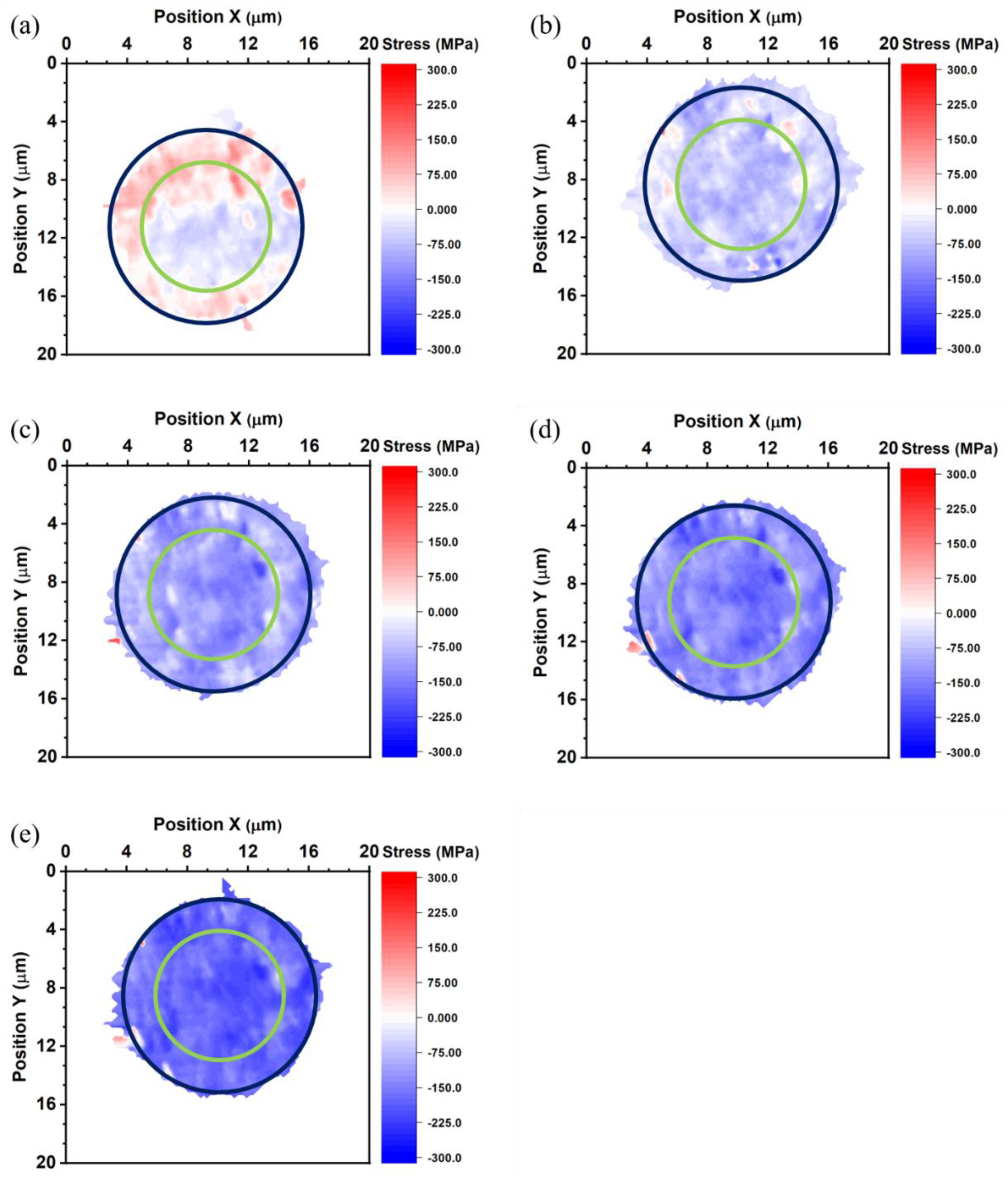

3.2. Thermal Strain/Stress Maps

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Oi, K.; Otake, S.; Shimizu, N.; Watanabe, S.; Kunimoto, Y.; Kurihara, T.; Koyama, T.; Tanaka, M.; Aryasomayajula, L.; Kutlu, Z. Development of New 2.5D Package with Novel Integrated Organic Interposer Substrate with Ultra-Fine Wiring and High Density Bumps. In Proceedings of the 2014 IEEE 64th Electronic Components and Technology Conference (ECTC), Orlando, FL, USA, 27–30 May 2014; IEEE: Piscataway Township, NJ, USA, 2014; pp. 348–353. [Google Scholar] [CrossRef]

- Juang, J.; Lu, S.; Zhan, C.; Su-Ching, C.; Fan, C.; Peng, J.; Chen, T. Development of 30 Um Pitch Cu/Ni/SnAg Micro-Bump-Bonded Chip-on-Chip (COC) Interconnects. In Proceedings of the 2010 5th International Microsystems Packaging Assembly and Circuits Technology Conference, Taipei, Taiwan, 20–22 October 2010; IEEE: Piscataway Township, NJ, USA, 2010; pp. 1–4. [Google Scholar]

- Juang, J.Y.; Huang, S.Y.; Zhan, C.J.; Lin, Y.M.; Huang, Y.W.; Fan, C.W.; Chung, S.C.; Chen, S.M.; Peng, J.S.; Lu, Y.L.; et al. Effect of Metal Finishing Fabricated by Electro and Electroless Plating Process on Reliability Performance of 30 μm-Pitch Solder Micro Bump Interconnection. In Proceedings of the 2013 IEEE 63rd Electronic Components and Technology Conference, Las Vegas, NV, USA, 28–31 May 2013; IEEE: Piscataway Township, NJ, USA, 2013; pp. 653–659. [Google Scholar] [CrossRef]

- Kim, S.W.; Fodor, F.; Heylen, N.; Iacovo, S.; DeVos, J.; Miller, A.; Beyer, G.; Beyne, E. Novel Cu/SiCN Surface Topography Control for 1 Μm Pitch Hybrid Wafer-to-Wafer Bonding. In Proceedings of the 2020 IEEE 70th Electronic Components and Technology Conference (ECTC), Orlando, FL, USA, 3–30 June 2020; IEEE: Piscataway Township, NJ, USA, 2020; pp. 216–222. [Google Scholar] [CrossRef]

- Beyne, E.; Kim, S.W.; Peng, L.; Heylen, N.; DeMessemaeker, J.; Okudur, O.O.; Phommahaxay, A.; Kim, T.G.; Stucchi, M.; Velenis, D.; et al. Scalable, Sub 2μm Pitch, Cu/SiCN to Cu/SiCN Hybrid Wafer-to-Wafer Bonding Technology. In Proceedings of the Technical Digest—International Electron Devices Meeting, IEDM, San Francisco, CA, USA, 1–5 December 2018; IEEE: Piscataway Township, NJ, USA, 2018; pp. 32.4.1–32.4.4. [Google Scholar]

- Chen, M.F.; Chen, F.C.; Chiou, W.C.; Yu, D.C.H. System on Integrated Chips (SoIC(TM) for 3D Heterogeneous Integration. In Proceedings of the 2019 IEEE 69th Electronic Components and Technology Conference (ECTC), Las Vegas, NV, USA, 28–31 May 2019; IEEE: Piscataway Township, NJ, USA, 2019; pp. 594–599. [Google Scholar] [CrossRef]

- Jourdon, J.; Lhostis, S.; Moreau, S.; Chossat, J.; Arnoux, M.; Sart, C.; Henrion, Y.; Lamontagne, P.; Arnaud, L.; Bresson, N.; et al. Hybrid Bonding for 3D Stacked Image Sensors: Impact of Pitch Shrinkage on Interconnect Robustness. In Proceedings of the 2018 IEEE International Electron Devices Meeting (IEDM), San Francisco, CA, USA, 1–5 December 2018; IEEE: Piscataway Township, NJ, USA, 2019; pp. 7.3.1–7.3.4. [Google Scholar] [CrossRef]

- Roshanghias, A.; Kaczynski, J.; Rodrigues, A.; Karami, R.; Pires, M.; Burggraf, J.; Schmidt, A. 3D Integration via D2D Bump-Less Cu Bonding with Protruded and Recessed Topographies. ECS J. Solid State Sci. Technol. 2023, 12, 084001. [Google Scholar] [CrossRef]

- Oprins, H.; Cherman, V.; Webers, T.; Kim, S.W.; DeVos, J.; Van DerPlas, G.; Beyne, E. 3D Wafer-to-Wafer Bonding Thermal Resistance Comparison: Hybrid Cu/Dielectric Bonding versus Dielectric via-Last Bonding. In Proceedings of the 2020 19th IEEE Intersociety Conference on Thermal and Thermomechanical Phenomena in Electronic Systems (ITherm), Orlando, FL, USA, 21–23 July 2020; IEEE: Piscataway Township, NJ, USA, 2020; pp. 219–228. [Google Scholar] [CrossRef]

- Iacovo, S.; Peng, L.; Nagano, F.; Uhrmann, T.; Burggraf, J.; Fehkührer, A.; Conard, T.; Inoue, F.; Kim, S.W.; deVos, J.; et al. Characterization of Bonding Activation Sequences to Enable Ultra-Low Cu/SiCN Wafer Level Hybrid Bonding. In Proceedings of the 2021 IEEE 71st Electronic Components and Technology Conference (ECTC), Virtual, 1 June–4 July 2021; IEEE: Piscataway Township, NJ, USA, 2021; pp. 2097–2104. [Google Scholar]

- Lau, J.H. Recent Advances and Trends in Advanced Packaging. IEEE Trans. Compon. Packag. Manuf. Technol. 2022, 12, 228–252. [Google Scholar] [CrossRef]

- Kagawa, Y.; Fujii, N.; Aoyagi, K.; Kobayashi, Y.; Nishi, S.; Todaka, N.; Takeshita, S.; Taura, J.; Takahashi, H.; Nishimura, Y.; et al. Novel Stacked CMOS Image Sensor with Advanced Cu2Cu Hybrid Bonding. In Proceedings of the 2016 IEEE International Electron Devices Meeting (IEDM), San Francisco, CA, USA, 3–7 December 2016; IEEE: Piscataway Township, NJ, USA, 2017; pp. 8.4.1–8.4.4. [Google Scholar] [CrossRef]

- Chen, M.F.; Lin, C.S.; Liao, E.B.; Chiou, W.C.; Kuo, C.C.; Hu, C.C.; Tsai, C.H.; Wang, C.T.; Yu, D. SoIC for Low-Temperature, Multi-Layer 3D Memory Integration. In Proceedings of the 2020 IEEE 70th Electronic Components and Technology Conference (ECTC), Orlando, FL, USA, 3–30 June 2020; IEEE: Piscataway Township, NJ, USA, 2020; pp. 855–860. [Google Scholar] [CrossRef]

- Kagawa, Y.; Hida, S.; Kobayashi, Y.; Takahashi, K.; Miyanomae, S.; Kawamura, M.; Kawashima, H.; Yamagishi, H.; Hirano, T.; Tatani, K.; et al. The Scaling of Cu-Cu Hybrid Bonding For High Density 3D Chip Stacking. In Proceedings of the 2019 Electron Devices Technology and Manufacturing Conference (EDTM), Singapore, 12–15 March 2019; IEEE: Piscataway Township, NJ, USA, 2019; pp. 297–299. [Google Scholar] [CrossRef]

- Panigrahi, A.K.; Bonam, S.; Ghosh, T.; Singh, S.G.; Vanjari, S.R.K. Ultra-Thin Ti Passivation Mediated Breakthrough in High Quality Cu-Cu Bonding at Low Temperature and Pressure. Mater. Lett. 2016, 169, 269–272. [Google Scholar] [CrossRef]

- Ong, J.J.; Chiu, W.L.; Lee, O.H.; Chiang, C.W.; Chang, H.H.; Wang, C.H.; Shie, K.C.; Yang, S.C.; Tran, D.P.; Tu, K.N.; et al. Low-Temperature Cu/SiO2 Hybrid Bonding with Low Contact Resistance Using (111)-Oriented Cu Surfaces. Materials 2022, 15, 1888. [Google Scholar] [CrossRef]

- Kim, T.H.; Howlader, M.M.R.; Itoh, T.; Suga, T. Room Temperature Cu–Cu Direct Bonding Using Surface Activated Bonding Method. J. Vac. Sci. Technol. A Vac. Surf. Film. 2003, 21, 449–453. [Google Scholar] [CrossRef]

- Hong, Z.J.; Weng, M.W.; Chen, C.H.; Hsu, M.P.; Hu, H.W.; Lin, T.Y.; Hung, Y.C.; Chen, K.N. Scheme for Multi-Chiplet Integration With Low Thermal Budget by Asymmetric Cu-Cu Bonding With Au Passivation Bonding Structure. IEEE Electron Device Lett. 2023, 44, 492–495. [Google Scholar] [CrossRef]

- Tu, K.; Chen, C.; Chen, H. Electronic Packaging Science and Technology; John Wiley & Sons: Hoboken, NJ, USA, 2021; ISBN 1119418313, 9781119418313. [Google Scholar]

- Braun, T.; Voges, S.; Töpper, M.; Wilke, M.; Wöhrmann, M.; Maaß, U.; Huhn, M.; Becker, K.F.; Raatz, S.; Kim, J.U.; et al. Material and Process Trends for Moving from FOWLP to FOPLP. In Proceedings of the 2015 IEEE 17th Electronics Packaging and Technology Conference (EPTC), Singapore, 2–4 December 2015; IEEE: Piscataway Township, NJ, USA, 2016; pp. 1–6. [Google Scholar] [CrossRef]

- Chou, T.C.; Yang, K.M.; Li, J.C.; Yu, T.Y.; Chung, Y.T.; Ko, C.T.; Chen, Y.H.; Tseng, T.J.; Chen, K.N. Non-Planarization Cu-Cu Direct Bonding and Gang Bonding with Low Temperature and Short Duration in Ambient Atmosphere. In Proceedings of the 2019 IEEE International Electron Devices Meeting (IEDM), San Francisco, CA, USA, 7–11 December 2019; IEEE: Piscataway Township, NJ, USA, 2019; pp. 106–109. [Google Scholar] [CrossRef]

- Kim, S.; Nam, Y.; Kim, S.E. Effects of Forming Gas Plasma Treatment on Low-Temperature Cu-Cu Direct Bonding. JPN J. Appl. Phys. 2016, 55, 2–6. [Google Scholar] [CrossRef]

- Hong, Z.J.; Liu, D.; Hu, H.W.; Cho, C.I.; Weng, M.W.; Liu, J.H.; Chen, K.N. Investigation of Bonding Mechanism for Low-Temperature Cu–Cu Bonding with Passivation Layer. Appl. Surf. Sci. 2022, 592, 153243. [Google Scholar] [CrossRef]

- Hsu, M.-P.; Chen, C.-Y.; Chang, H.-C.; Hong, Z.-J.; Weng, M.-W.; Chen, K.-N. Development of Low-Temperature Bonding Platform Using Ultra-Thin Area Selective Deposition for Heterogeneous Integration. Appl. Surf. Sci. 2023, 635, 157645. [Google Scholar] [CrossRef]

- Lu, L.; Shen, Y.; Chen, X.; Qian, L.; Lu, K. Ultrahigh Strength and High Electrical Conductivity in Copper. Science 2004, 304, 422–426. [Google Scholar] [CrossRef]

- Anderoglu, O.; Misra, A.; Wang, H.; Zhang, X. Thermal Stability of Sputtered Cu Films with Nanoscale Growth Twins. J. Appl. Phys. 2008, 103, 094322. [Google Scholar] [CrossRef]

- Lu, L.; Chen, X.; Huang, X.; Lu, K. Revealing the Maximum Strength in Nanotwinned Copper. Science 2009, 323, 607–610. [Google Scholar] [CrossRef] [PubMed]

- Zhan, X.; Lian, J.; Li, H.; Wang, X.; Zhou, J.; Trieu, K.; Zhang, X. Preparation of Highly (111) Textured Nanotwinned Copper by Medium-Frequency Pulsed Electrodeposition in an Additive-Free Electrolyte. Electrochim. Acta 2021, 365, 137391. [Google Scholar] [CrossRef]

- Cheng, G.; Li, H.; Xu, G.; Gai, W.; Luo, L. In Situ Observation of Nanotwins Formation through Twin Terrace Growth in Pulse Electrodeposited Cu Films. Sci. Rep. 2017, 7, 12393. [Google Scholar] [CrossRef] [PubMed]

- Hasegawa, M.; Mieszala, M.; Zhang, Y.; Erni, R.; Michler, J.; Philippe, L. Orientation-Controlled Nanotwinned Copper Prepared by Electrodeposition. Electrochim. Acta 2015, 178, 458–467. [Google Scholar] [CrossRef]

- Zhang, X.; Wang, H.; Chen, X.H.; Lu, L.; Lu, K.; Hoagland, R.G.; Misra, A. High-Strength Sputter-Deposited Cu Foils with Preferred Orientation of Nanoscale Growth Twins. Appl. Phys. Lett. 2006, 88, 2004–2007. [Google Scholar] [CrossRef]

- Hsiao, H.Y.; Liu, C.M.; Lin, H.W.; Liu, T.C.; Lu, C.L.; Huang, Y.S.; Chen, C.; Tu, K.N. Unidirectional Growth of Microbumps on (111)-Oriented and Nanotwinned Copper. Science 2012, 336, 1007–1010. [Google Scholar] [CrossRef]

- Agrawal, P.M.; Rice, B.M.; Thompson, D.L. Predicting Trends in Rate Parameters for Self-Diffusion on FCC Metal Surfaces. Surf. Sci. 2002, 515, 21–35. [Google Scholar] [CrossRef]

- Tseng, C.H.; Tu, K.N.; Chen, C. Comparison of Oxidation in Uni-Directionally and Randomly Oriented Cu Films for Low Temperature Cu-to-Cu Direct Bonding. Sci. Rep. 2018, 8, 10671. [Google Scholar] [CrossRef]

- Lu, T.-F.; Lai, T.-Y.; Chu, Y.Y.; Wu, Y.S. Effect of Nanotwin Boundary on the Cu–Cu Bonding. ECS J. Solid State Sci. Technol. 2021, 10, 074001. [Google Scholar] [CrossRef]

- Hu, Z.J.; Qu, X.P.; Lin, H.; Huang, R.D.; Ge, X.C.; Li, M.; Chen, S.M.; Zhao, Y.H. Cu CMP Process Development and Characterization of Cu Dishing with 1.8 Μm Cu Pad and 3.6 Μm Pitch in Cu/SiO2 Hybrid Bonding. JPN J. Appl. Phys. 2019, 58, SHHC01. [Google Scholar] [CrossRef]

- Li, Y.J.; Tu, K.N.; Chen, C. Tensile Properties of <111>-Oriented Nanotwinned Cu with Different Columnar Grain Structures. Materials 2020, 13, 1310. [Google Scholar] [CrossRef] [PubMed]

- Hodge, A.M.; Furnish, T.A.; Navid, A.A.; Barbee, T.W. Shear Band Formation and Ductility in Nanotwinned Cu. Scr. Mater. 2011, 65, 1006–1009. [Google Scholar] [CrossRef]

- Cheng, Z.; Lu, L. The Effect of Gradient Order on Mechanical Behaviors of Gradient Nanotwinned Cu. Scr. Mater. 2019, 164, 130–134. [Google Scholar] [CrossRef]

- Juang, J.Y.; Lu, C.L.; Li, Y.J.; Hsu, P.N.; Tsou, N.T.; Tu, K.N.; Chen, C. A Solid State Process to Obtain High Mechanical Strength in Cu-to-Cu Joints by Surface Creep on (111)-Oriented Nanotwins Cu. J. Mater. Res. Technol. 2021, 14, 719–730. [Google Scholar] [CrossRef]

- Jhan, J.J.; Wataya, K.; Nishikawa, H.; Chen, C.M. Electrodeposition of Nanocrystalline Cu for Cu-Cu Direct Bonding. J. Taiwan Inst. Chem. Eng. 2022, 132, 104127. [Google Scholar] [CrossRef]

- Tang, Y.S.; Chang, Y.J.; Chen, K.N. Wafer-Level Cu-Cu Bonding Technology. Microelectron. Reliab. 2012, 52, 312–320. [Google Scholar] [CrossRef]

- Beilliard, Y.; Estevez, R.; Parry, G.; McGarry, P.; DiCioccio, L.; Coudrain, P. Thermomechanical Finite Element Modeling of Cu–SiO2 Direct Hybrid Bonding with a Dishing Effect on Cu Surfaces. Int. J. Solids Struct. 2017, 117, 208–220. [Google Scholar] [CrossRef]

- Sart, C.; Estevez, R.; Fiori, V.; Lhostis, S.; Deloffre, E.; Parry, G.; Gonella, R. Cu/SiO2 Hybrid Bonding: Finite Element Modeling and Experimental Characterization. In Proceedings of the 2016 6th Electronic System-Integration Technology Conference (ESTC), Grenoble, France, 13–15 September 2016; IEEE: Piscataway Township, NJ, USA, 2016; pp. 1–7. [Google Scholar] [CrossRef]

- Tsau, Y.W.; DeMessemaeker, J.; Salahouelhadj, A.; Gonzalez, M.; Witters, L.; Zhang, B.; Seefeldt, M.; Beyne, E.; DeWolf, I. Simulation of Cu Pad Expansion in Wafer-to-Wafer Cu/SiCN Hybrid Bonding. Microelectron. Reliab. 2022, 138, 114716. [Google Scholar] [CrossRef]

- Hsu, W.Y.; Tseng, I.H.; Chiang, C.Y.; Tu, K.N.; Chen, C. Distribution of Elastic Stress as a Function of Temperature in a 2-µm Redistribution Line of Cu Measured with X-Ray Nanodiffraction Analysis. J. Mater. Res. Technol. 2022, 20, 2799–2808. [Google Scholar] [CrossRef]

- Kagawa, Y.; Kamibayashi, T.; Yamano, Y.; Nishio, K.; Sakamoto, A.; Yamada, T.; Shimizu, K.; Hirano, T.; Iwamoto, H. Development of Face-to-Face and Face-to-Back Ultra-Fine Pitch Cu-Cu Hybrid Bonding. In Proceedings of the 2022 IEEE 72nd Electronic Components and Technology Conference (ECTC), San Diego, CA, USA, 31 May–3 June 2022; IEEE: Piscataway Township, NJ, USA, 2022; pp. 306–311. [Google Scholar] [CrossRef]

| Unit: % | T/°C −55 | 27 | 100 | 150 | 200 |

|---|---|---|---|---|---|

| Top die | N/A | −0.018 | −0.07 | −0.089 | −0.111 |

| Bottom die | N/A | −0.037 | −0.074 | −0.105 | −0.113 |

| Bonded joint | 0.007 | −0.039 | −0.072 | −0.094 | −0.121 |

| Unit: MPa | T/°C −55 | 27 | 100 | 150 | 200 |

|---|---|---|---|---|---|

| Top die | N/A | −25.2 | −98.0 | −124.6 | −155.4 |

| Bottom die | N/A | −51.8 | −103.6 | −147.0 | −158.2 |

| Bonded joint | 9.8 | −54.6 | −100.8 | −131.6 | −169.1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hsu, W.-Y.; Yang, S.-C.; Lin, Y.-Y.; Hsieh, W.-Z.; Tu, K.-N.; Chiu, W.-L.; Chang, H.-H.; Chiang, C.-Y.; Chen, C. Measurement of Thermal Stress by X-ray Nano-Diffraction in (111)-Oriented Nanotwinned Cu Bumps for Cu/SiO2 Hybrid Joints. Nanomaterials 2023, 13, 2448. https://doi.org/10.3390/nano13172448

Hsu W-Y, Yang S-C, Lin Y-Y, Hsieh W-Z, Tu K-N, Chiu W-L, Chang H-H, Chiang C-Y, Chen C. Measurement of Thermal Stress by X-ray Nano-Diffraction in (111)-Oriented Nanotwinned Cu Bumps for Cu/SiO2 Hybrid Joints. Nanomaterials. 2023; 13(17):2448. https://doi.org/10.3390/nano13172448

Chicago/Turabian StyleHsu, Wei-You, Shih-Chi Yang, You-Yi Lin, Wan-Zhen Hsieh, King-Ning Tu, Wei-Lan Chiu, Hsiang-Hung Chang, Ching-Yu Chiang, and Chih Chen. 2023. "Measurement of Thermal Stress by X-ray Nano-Diffraction in (111)-Oriented Nanotwinned Cu Bumps for Cu/SiO2 Hybrid Joints" Nanomaterials 13, no. 17: 2448. https://doi.org/10.3390/nano13172448

APA StyleHsu, W.-Y., Yang, S.-C., Lin, Y.-Y., Hsieh, W.-Z., Tu, K.-N., Chiu, W.-L., Chang, H.-H., Chiang, C.-Y., & Chen, C. (2023). Measurement of Thermal Stress by X-ray Nano-Diffraction in (111)-Oriented Nanotwinned Cu Bumps for Cu/SiO2 Hybrid Joints. Nanomaterials, 13(17), 2448. https://doi.org/10.3390/nano13172448