In-Situ Grown NiMn2O4/GO Nanocomposite Material on Nickel Foam Surface by Microwave-Assisted Hydrothermal Method and Used as Supercapacitor Electrode

Abstract

:1. Introduction

2. Experimental

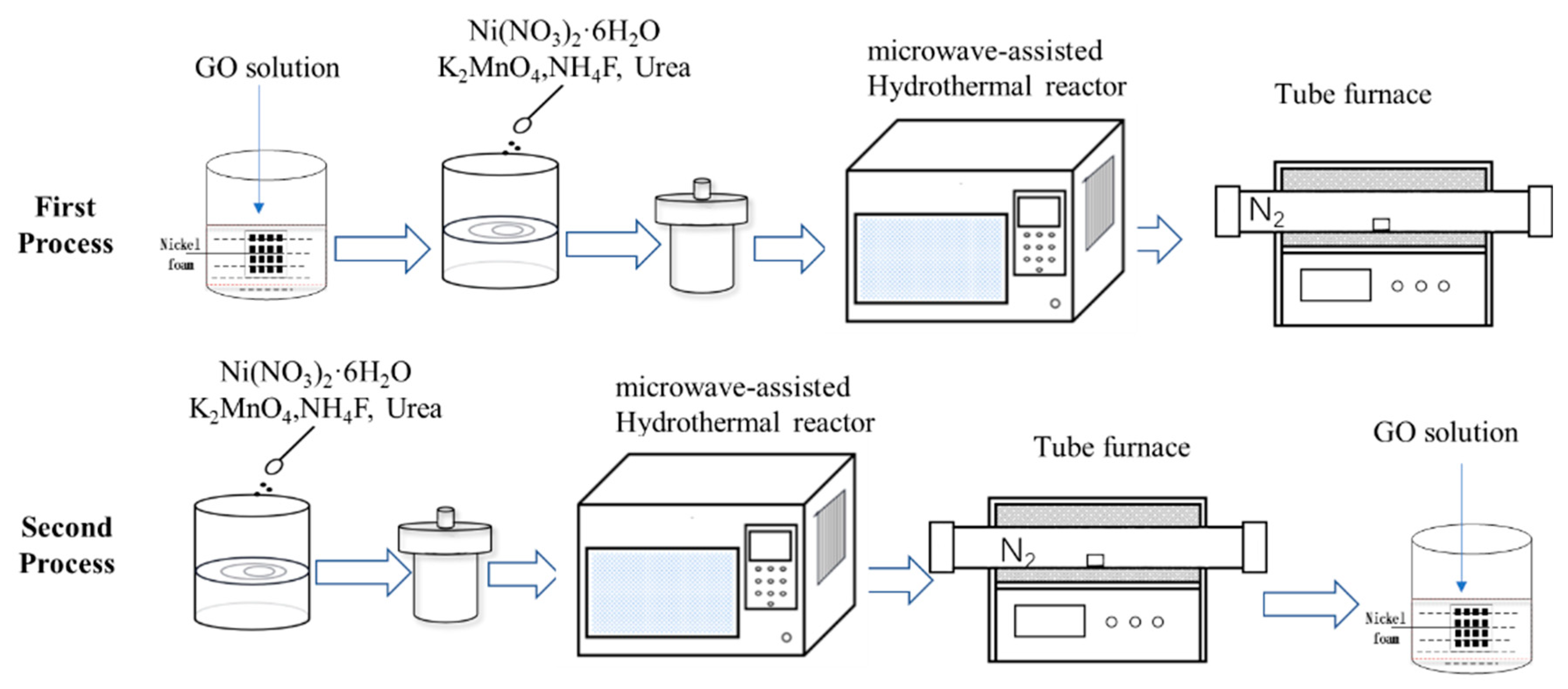

2.1. The Synthesis of Nanocomposite

- (1)

- A total of 30 mL of GO aqueous solutions with different concentrations (0, 2.5, 5, and 7.5 mg/mL) were prepared and poured into Petri dishes, respectively.

- (2)

- The pre-treated nickel foam was soaked in the petri dish for 1.5 h and then washed gently in deionized water several times, and then put into a drying oven at 60 °C for 12 h to get graphene-coated nickel foam.

- (3)

- Accurately weighted 0.5 mmol nickel nitrate hexahydrate, 3 mmol ammonium fluoride, and 7.5 mmol urea were all dissolved in 30 mL deionized water and magnetically stirred for 15 min to obtain a clear, light-green solution. Then, 1 mmol potassium permanganate was added into the above solution, which was continuously magnetically stirred for 30 min. Finally, the purplish-red solution was obtained.

- (4)

- The treated foam nickel was put into a 100 mL microwave reactor containing the purplish-red solution and then put into the microwave synthesis instrument. The reactor was heated to 140 °C for 3 h and then cooled to room temperature.

- (5)

- The nickel foam was taken out, ultrasonicated with deionized water for 5 min and anhydrous ethanol several times, and then dried in a drying oven at 60 °C for 12 h.

- (6)

- The dried nickel foam was annealed at 450 °C for 2 h in a tube furnace with a heating rate of 10 °C/min at N2 atmosphere and then cooled to room temperature in the furnace.

- (1)

- Accurately weighted 0.5 mmol nickel nitrate hexahydrate, 3 mmol ammonium fluoride, and 7.5 mmol urea were all dissolved in 30 mL deionized water, and magnetically stirred for 15 min to obtain a clear, light-green solution. Then, 1 mmol potassium permanganate was added into the above solution and magnetically stirred for 30 min. The purplish-red solution was obtained.

- (2)

- The pre-treated nickel foam was immersed into a 100 mL microwave container having the prepared solution for 30 min. The container was put into the microwave synthesis instrument and heated to 140 °C for 3 h with certain procedures and then cooled to room temperature.

- (3)

- The nickel foam was removed, cleaned by ultrasonic for 5 min with deionized water and anhydrous ethanol several times, and then dried in a drying oven at 60 °C for 12 h.

- (4)

- The dried nickel foam was heated to 450 °C with a heating rate of 10 °C/min in a tube furnace at N2 atmosphere held for 2 h and then cooled to room temperature. The nickel foam with NiMn2O4 on the surface was obtained.

- (5)

- The treated nickel foam was put in a Petri dish containing 30 mL of GO aqueous solution with different concentrations and immersed for 1.5 h.

- (6)

- The soaked nickel foam was gently washed with deionized water several times, and then dried in a blast oven at 60 °C for 12 h.

2.2. Characterization

2.3. Electrochemical Tests

3. Results and Discussion

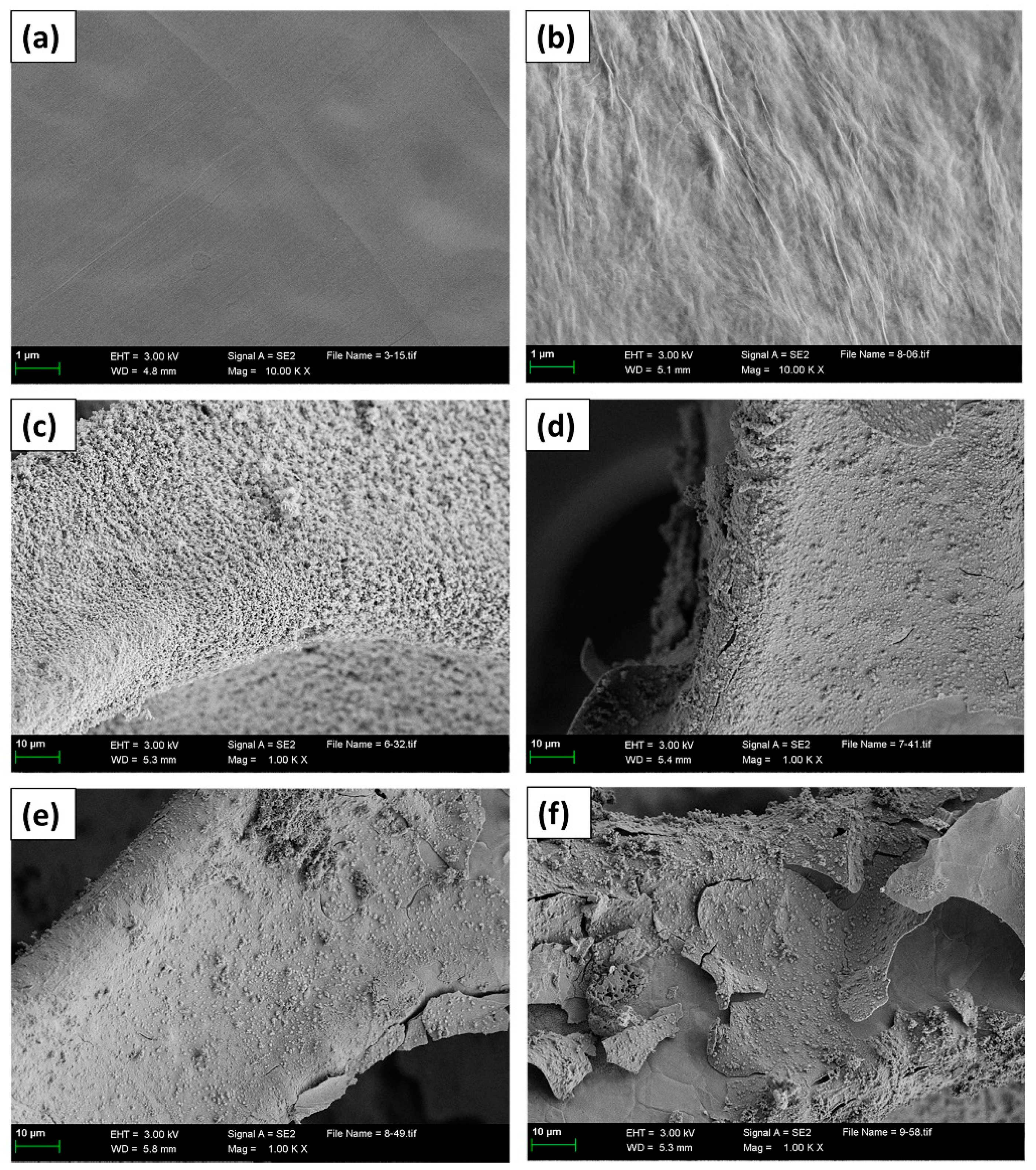

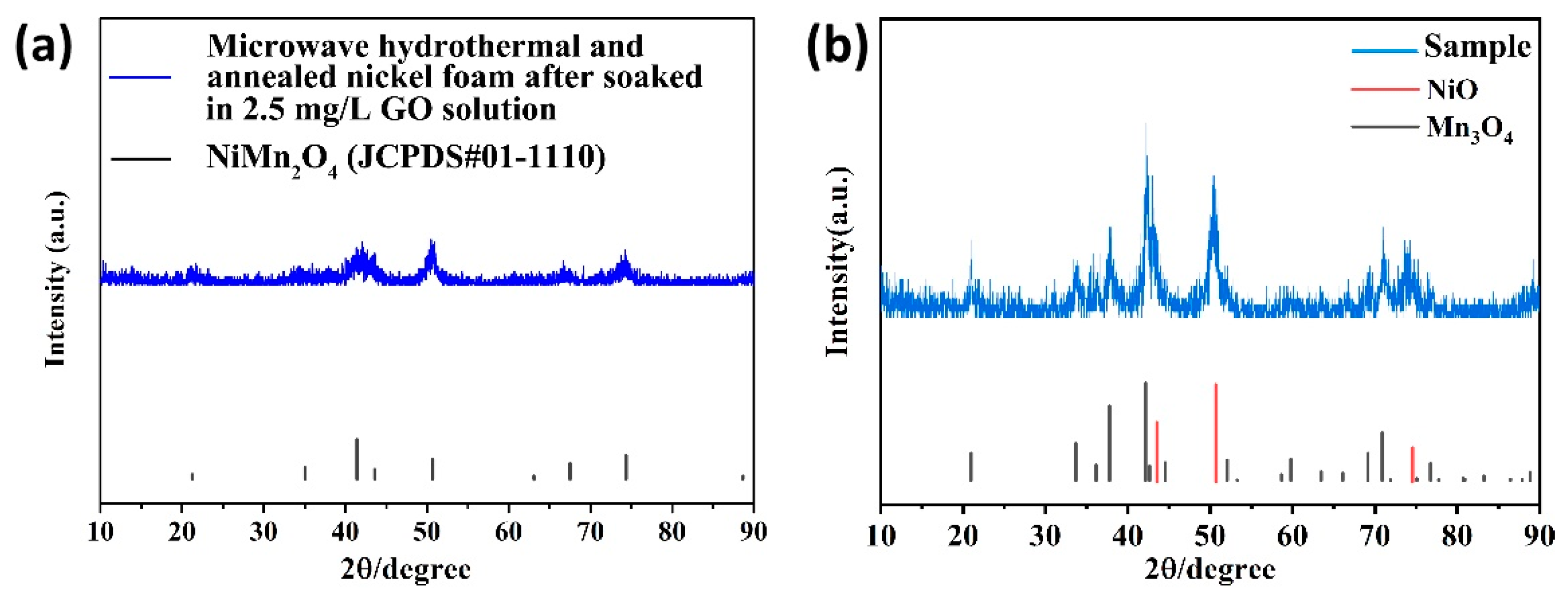

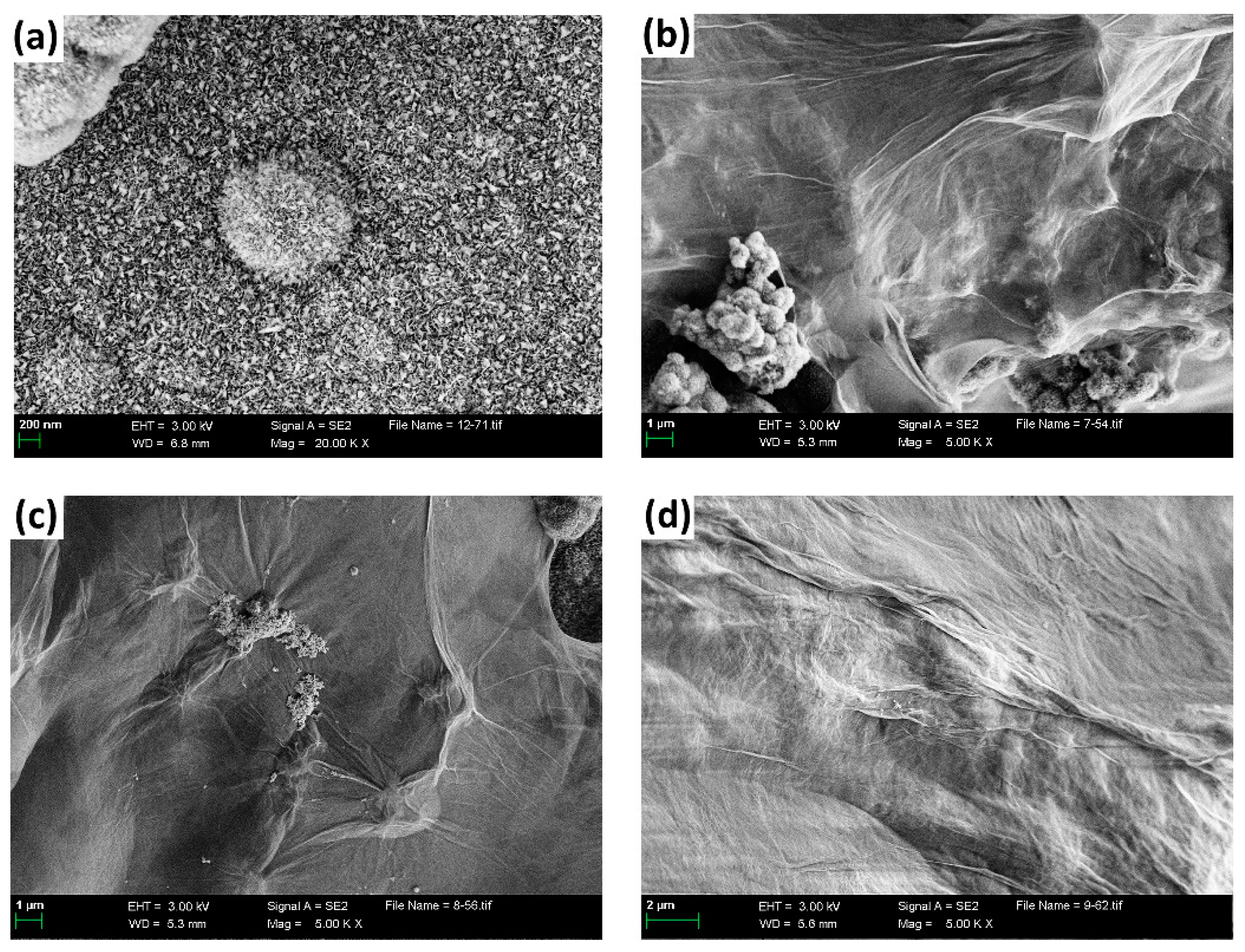

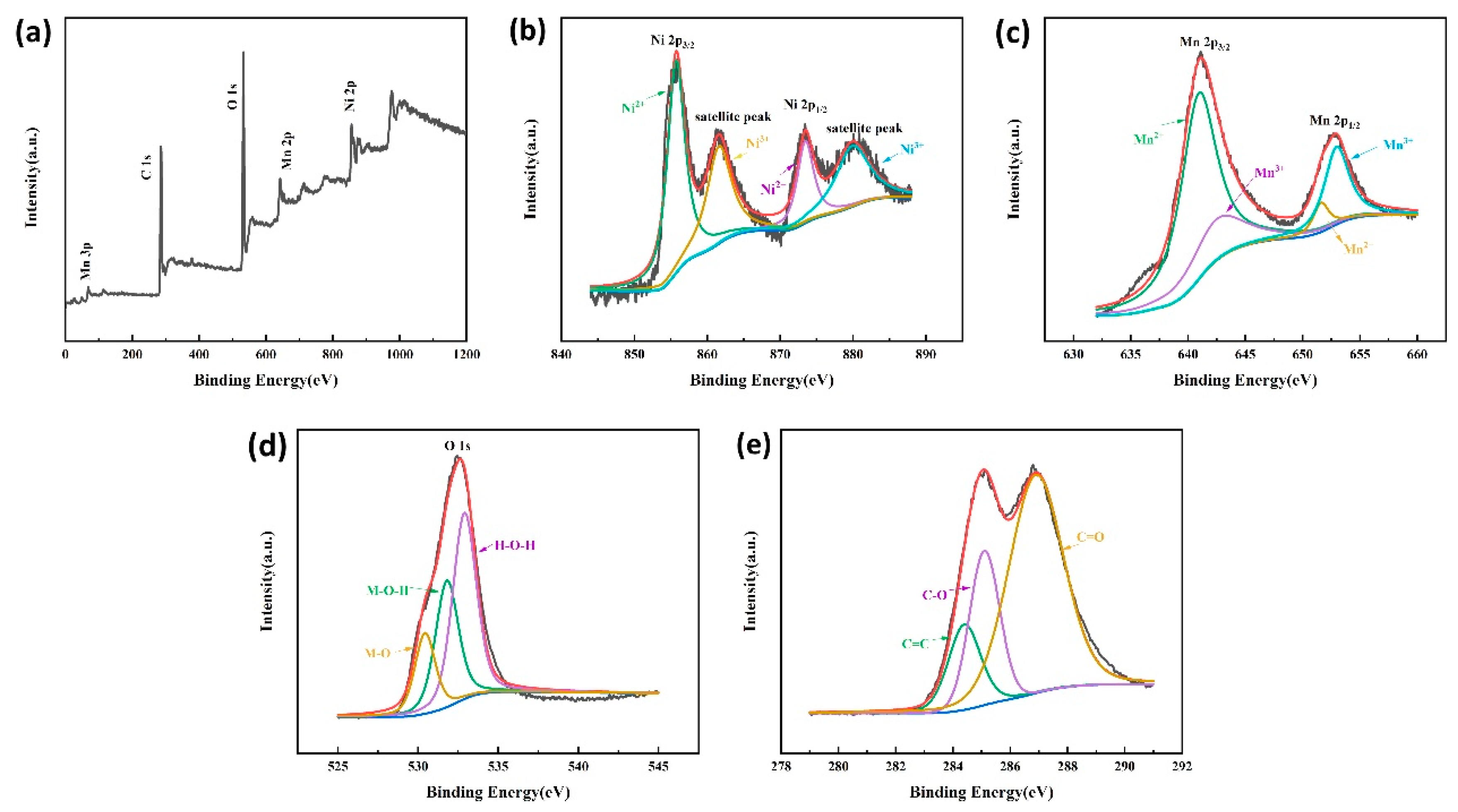

3.1. The Characteristic of Composite Material Fabricated According to the First Process

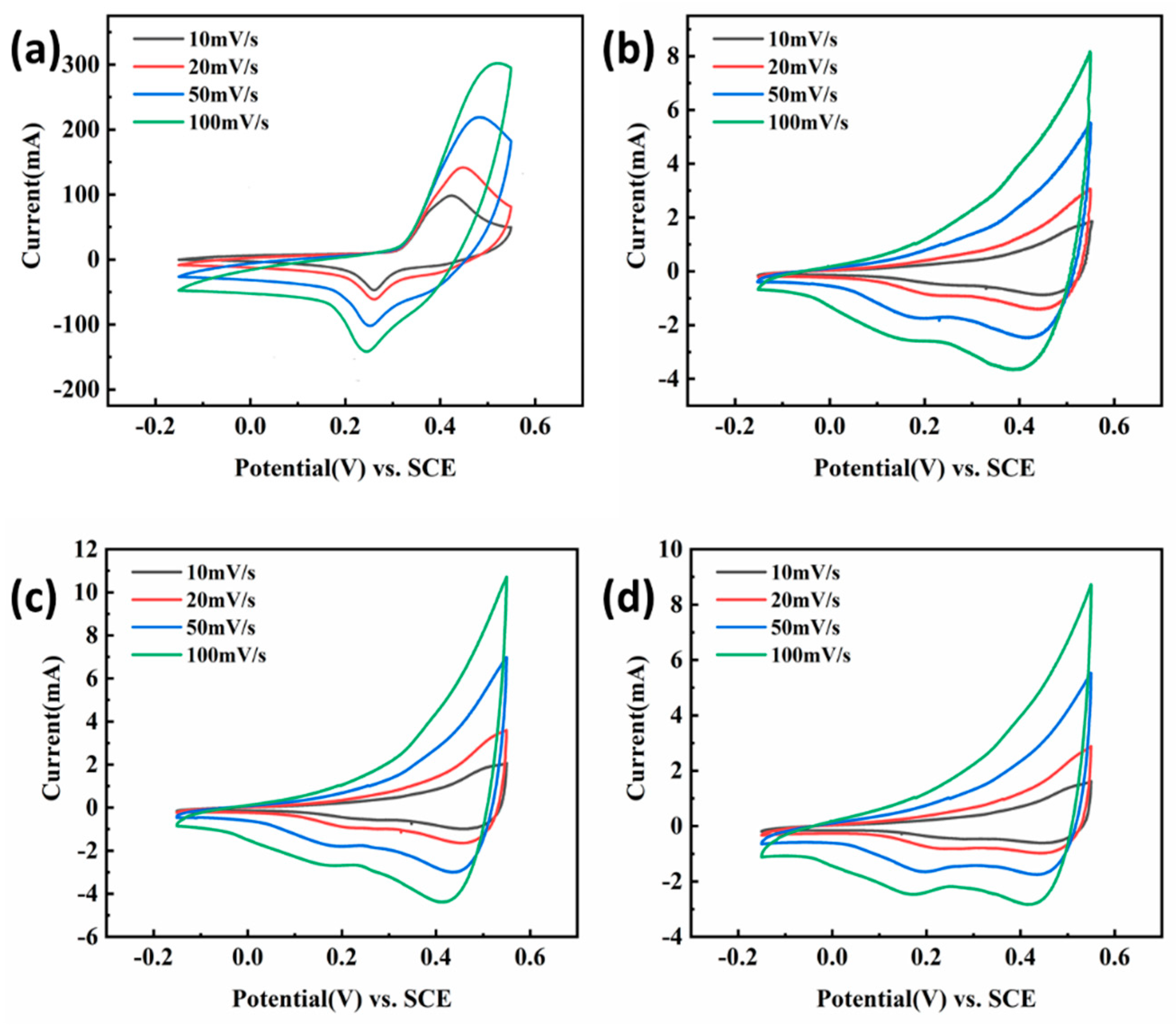

3.2. The Performance of NiMn2O4/GO Nanocomposite Material

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Wang, G.P.; Zhang, L.; Zhang, J.J. A review of electrode materials for electrochemical supercapacitors. Chem. Soc. Rev. 2012, 41, 797–828. [Google Scholar] [CrossRef] [PubMed]

- Zhong, C.; Deng, Y.D.; Hu, W.B.; Qiao, J.; Zhang, L.; Zhang, J. A review of electrolyte materials and compositions for electrochemical supercapacitors. Chem. Soc. Rev. 2015, 44, 7484–7539. [Google Scholar] [CrossRef] [PubMed]

- Tae, G.Y.; Hwang, B.I.; Kim, D.; Hyun, S.; Han, S.M. Polypyrrole−MnO2-coated textile-based flexible-stretchable supercapacitor with high electrochemical and mechanical reliability. ACS Appl. Mater. Interfaces 2015, 7, 9228–9234. [Google Scholar]

- Asad, U.R.; Amir, M.A.; Muhammad, W.I.; Ali, M.; Wabaidur, S.M.; Al-Ammar, E.A.; Mumtaz, S.; Choi, E.H. Highly efficient and stable layered AgZnS@WS2 nanocomposite electrode as superior charge transfer and active redox sites for energy harvesting device. J. Energy Storage 2023, 71, 108022. [Google Scholar]

- Sahoo, S.; Zhang, S.J.; Shim, J.J. Porous ternary high performance supercapacitor electrode based on reduced graphene oxide, NiMn2O4, and polyaniline. Electrochim. Acta 2016, 216, 386–396. [Google Scholar] [CrossRef]

- Yan, H.; Li, T.; Qiu, K.; Lu, Y.; Cheng, J.; Liu, Y.; Xu, J.; Luo, Y. Growth and electrochemical performance of porous NiMn2O4 nanosheets with high specific surface areas. J. Solid State Electrochem. 2015, 19, 3169–3175. [Google Scholar] [CrossRef]

- Chu, D.W.; Li, F.B.; Song, X.M.; Ma, H.; Tan, L.; Pang, H.; Wang, X.; Guo, D.; Xiao, B. A novel dual-tasking hollow cube NiFe2O4-NiCo-LDH@rGO hierarchical material for high preformance supercapacitor and glucose sensor. J. Colloid Interface Sci. 2020, 568, 130–138. [Google Scholar] [CrossRef]

- Li, J.W.; Xiong, D.B.; Wang, L.Z.; Hirbod, M.K.S.; Li, X. High-performance self-assembly MnCo2O4 nanosheets for asymmetric supercapacitors. J. Energy Chem. 2019, 37, 66–72. [Google Scholar] [CrossRef]

- Chen, X.; Xie, R.; Li, H.; Jaber, F.; Musharavati, F.; Zalnezhad, E.; Bae, S.; Hui, K.N. Supercapacitor performance of porous nickel cobaltite nanosheets. Sci. Rep. 2020, 10, 13. [Google Scholar] [CrossRef]

- Muralidharan, M.N.; Rohini, P.R.; Sunny, E.K.; Dayas, K.R.; Seema, A. Effect of Cu and Fe addition on electrical properties of Ni-Mn-Co-O NTC thermistor compositions. Ceram. Int. 2012, 38, 6481–6486. [Google Scholar] [CrossRef]

- Lei, Y.; Li, J.; Wang, Y.Y.; Gu, L.; Chang, Y.; Yuan, H.; Xiao, D. Rapid Microwave-assisted green synthesis of 3D hierarchical flower-shaped NiCo2O4 microsphere for high-performance aupercapacitor. ACS Appl. Mater. Interfaces 2014, 6, 1773–1780. [Google Scholar] [CrossRef] [PubMed]

- Zhang, M.M.; Song, Z.X.; Liu, H.; Ma, T. Biomass-derived highly porous nitrogen-doped graphene orderly supported NiMn2O4 nanocrystals as efficient electrode materials for asymmetric supercapacitors. Appl. Surf. Sci. 2020, 507, 10. [Google Scholar] [CrossRef]

- Nan, H.H.; Ma, W.Q.; Gu, Z.X.; Geng, B.; Zhang, X. Hierarchical NiMn2O4@CNT nanocomposites for high- performance asymmetric supercapacitors. RSC Adv. 2015, 5, 24607–24614. [Google Scholar] [CrossRef]

- Chen, S.M.; Yang, G.; Jia, Y.; Zheng, H. Three-dimensional NiCo2O4@NiWO4 core-shell nanowire arrays for high performance supercapacitors. J. Mater. Chem. A 2017, 5, 1028–1034. [Google Scholar] [CrossRef]

- Chen, Y.; Zhang, Y.; Geng, D.S.; Li, R.; Hong, H.; Chen, J.; Sun, X. One-pot synthesis of MnO2/graphene/carbon nanotube hybrid by chemical method. Carbon 2011, 49, 4434–4442. [Google Scholar] [CrossRef]

- Chen, Y.; Zhang, X.; Xu, C.; Xu, H. The fabrication of asymmetry supercapacitor based on MWCNTs/MnO2/PPy composites. Electrochim. Acta 2019, 309, 424–431. [Google Scholar] [CrossRef]

- Wang, H.L.; Gao, Q.M.; Jiang, L. Facile approach to prepare nickel cobaltite nanowire materials for supercapacitors. Small 2011, 7, 2454–2459. [Google Scholar] [CrossRef]

- Wang, Z.B.; Zhu, Z.H.; Zhang, C.L.; Xu, C.; Chen, C. Facile synthesis of reduced graphene oxide/NiMn2O4 nanorods hybrid materials for high-performance supercapacitors. Electrochim. Acta 2017, 230, 438–444. [Google Scholar] [CrossRef]

- Kang, W.P.; Tang, Y.B.; Li, W.Y.; Yang, X.; Xue, H.; Yang, Q.; Lee, C.S. High interfacial storage capability of porous NiMn2O4/C hierarchical tremella-like nanostructures as the lithium ion battery anode. Nanoscale 2015, 7, 225–231. [Google Scholar] [CrossRef]

- Huang, J.; Wang, W.; Lin, X.; Gu, C.; Liu, J. Three-dimensional sandwich-structured NiMn2O4@reduced graphene oxide nanocomposites for highly reversible Li-ion battery anodes. J. Power Sources 2018, 378, 677–684. [Google Scholar] [CrossRef]

- Wang, Y.Y.; Ye, J.W.; Jiang, C.J.; Cheng, B.; Yu, J. Hierarchical NiMn2O4/rGO composite nanosheets decorated with Pt for low-temperature formaldehyde oxidation. Environ. Sci. Nano 2020, 7, 198–209. [Google Scholar] [CrossRef]

| Name | Grade | Manufacturers |

|---|---|---|

| Nickel dinitrate hexahydrate | analytical | Tianjin Damao Chemical Reagent Factory (Tianjin, China) |

| Potassium permanganate | analytical |

|

| urea | analytical |

|

| ammonium fluoride | analytical | Tianjin Kemio Chemical Reagent Co., Ltd. (Tianjin, China) |

| hydrochloric acid | analytical | Shenyang Liansheng Chemical Co., Ltd. (Shenyang, China) |

| N2 | 99.99% | Dalian bright Special Gas Co., Ltd. (Dalian, China) |

| anhydrous ethanol | analytical |

|

| Nickel foam | ---------- | Ai Lantian HIGH-TECH Materials (Dalian) Co., Ltd. (Dalian, China) |

| graphene oxide solution | 10 mg/mL 5 mg/mL | Suzhou Hengqiu Technology Co., Ltd. (Suzhou, China) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, S.; Du, X.; Liu, S.; Fu, Y.; Huang, N. In-Situ Grown NiMn2O4/GO Nanocomposite Material on Nickel Foam Surface by Microwave-Assisted Hydrothermal Method and Used as Supercapacitor Electrode. Nanomaterials 2023, 13, 2487. https://doi.org/10.3390/nano13172487

Wang S, Du X, Liu S, Fu Y, Huang N. In-Situ Grown NiMn2O4/GO Nanocomposite Material on Nickel Foam Surface by Microwave-Assisted Hydrothermal Method and Used as Supercapacitor Electrode. Nanomaterials. 2023; 13(17):2487. https://doi.org/10.3390/nano13172487

Chicago/Turabian StyleWang, Shusen, Xiaomei Du, Sen Liu, Yingqing Fu, and Naibao Huang. 2023. "In-Situ Grown NiMn2O4/GO Nanocomposite Material on Nickel Foam Surface by Microwave-Assisted Hydrothermal Method and Used as Supercapacitor Electrode" Nanomaterials 13, no. 17: 2487. https://doi.org/10.3390/nano13172487

APA StyleWang, S., Du, X., Liu, S., Fu, Y., & Huang, N. (2023). In-Situ Grown NiMn2O4/GO Nanocomposite Material on Nickel Foam Surface by Microwave-Assisted Hydrothermal Method and Used as Supercapacitor Electrode. Nanomaterials, 13(17), 2487. https://doi.org/10.3390/nano13172487