The Influence of Capping Layers on Tunneling Magnetoresistance and Microstructure in CoFeB/MgO/CoFeB Magnetic Tunnel Junctions upon Annealing

Abstract

:1. Introduction

2. Experimental Section

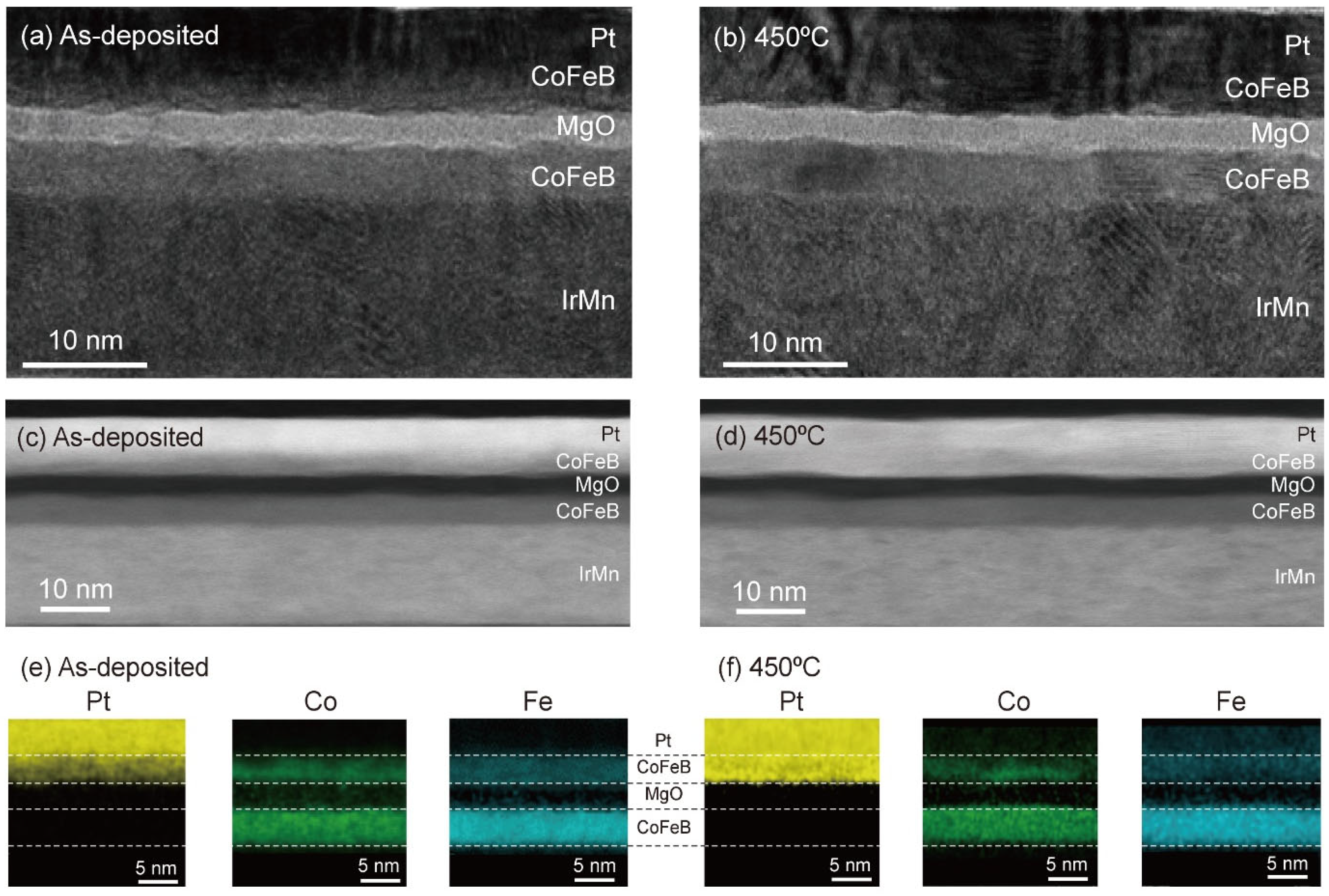

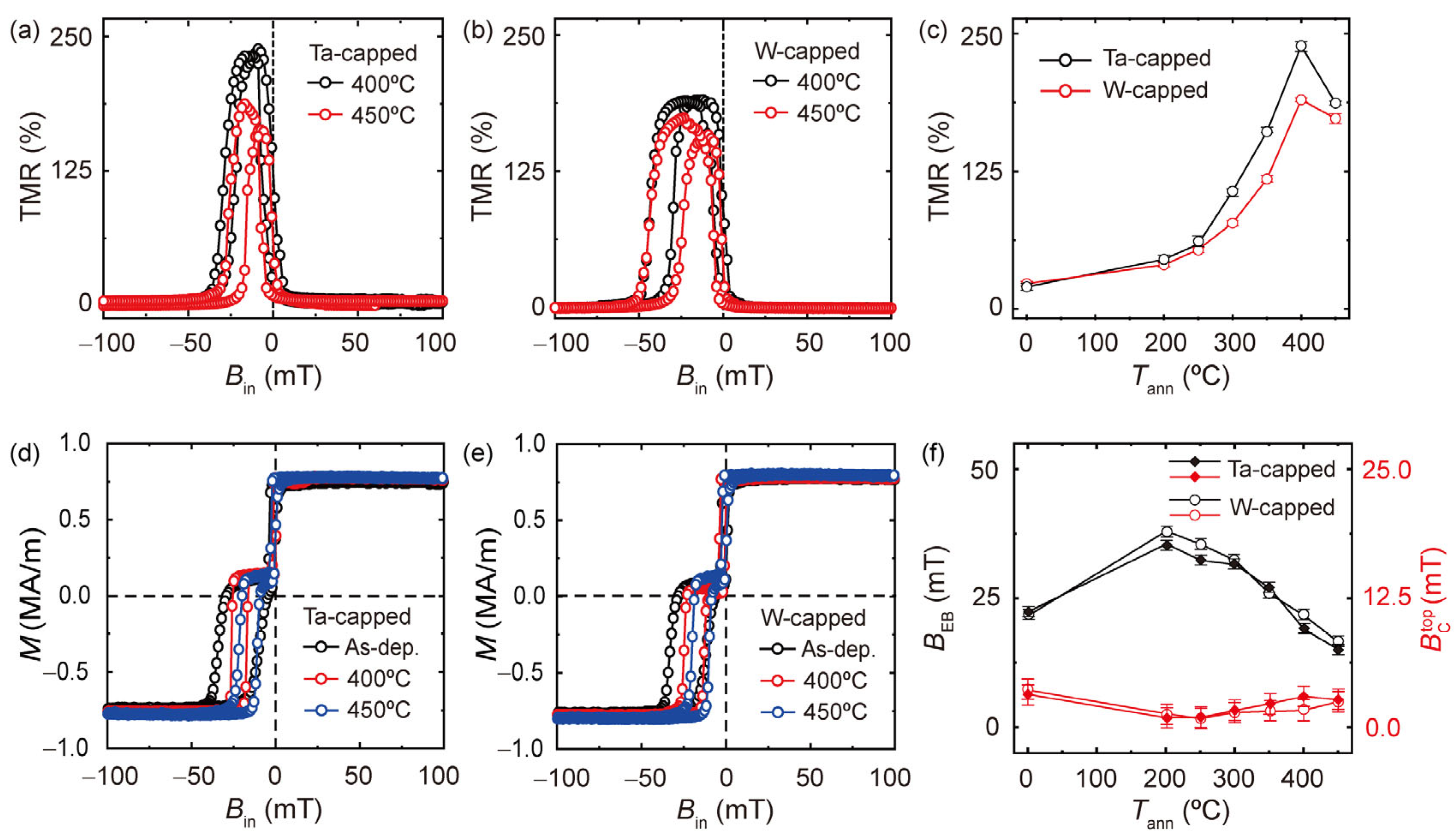

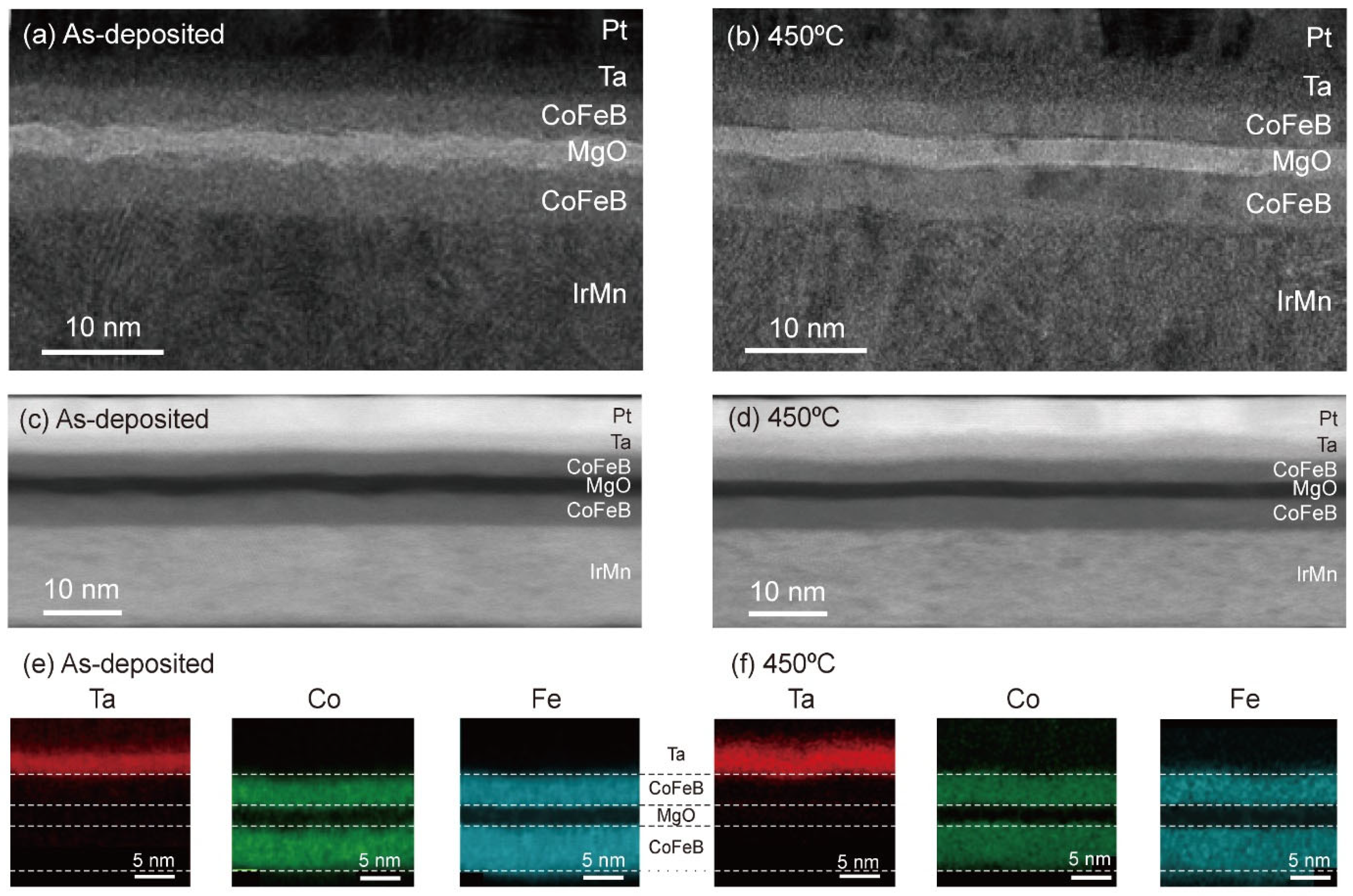

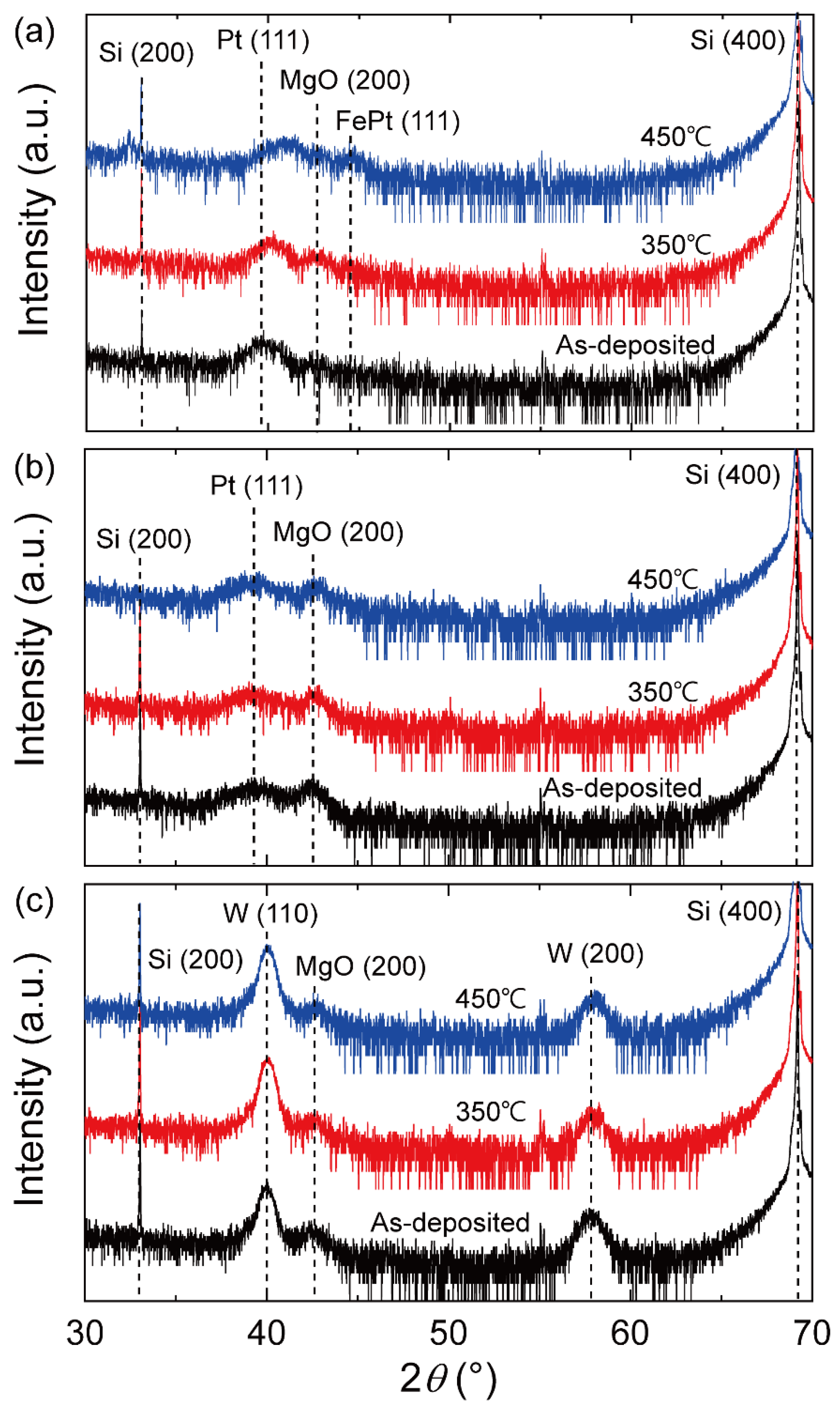

3. Results and Discussion

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Zhu, J.-G.; Park, C. Magnetic tunnel junctions. Mater Today 2006, 9, 36–45. [Google Scholar] [CrossRef]

- Yuasa, S.; Fukushima, A.; Yakushiji, K.; Nozaki, T.; Konoto, M.; Maehara, H.; Kubota, H.; Taniguchi, T.; Arai, H.; Imamura, H.; et al. Future prospects of MRAM technologies. In Proceedings of the 2013 IEEE International Electron Devices Meeting, Washington, DC, USA, 9–11 December 2013; pp. 3.1.1–3.1.4. [Google Scholar] [CrossRef]

- Hirohata, A.; Yamada, K.; Nakatani, Y.; Prejbeanu, I.-L.; Diény, B.; Pirro, P.; Hillebrands, B. Review on spintronics: Principles and device applications. J. Magn. Magn. Mater. 2020, 509, 166711. [Google Scholar] [CrossRef]

- Dieny, B.; Prejbeanu, I.L.; Garello, K.; Gambardella, P.; Freitas, P.; Lehndorff, R.; Raberg, W.; Ebels, U.; Demokritov, S.O.; Akerman, J.; et al. Opportunities and challenges for spintronics in the microelectronics industry. Nat. Electron. 2020, 3, 446–459. [Google Scholar] [CrossRef]

- Yuasa, S.; Djayaprawira, D.D. Giant tunnel magnetoresistance in magnetic tunnel junctions with a crystalline MgO(001) barrier. J. Phys. D Appl. Phys. 2007, 40, R337–R354. [Google Scholar] [CrossRef]

- Butler, W.H.; Zhang, X.-G.; Schulthess, T.C.; MacLaren, J.M. Spin-dependent tunneling conductance of Fe/MgO/Fe sandwiches. Phys. Rev. B 2001, 63, 054416. [Google Scholar] [CrossRef]

- Mathon, J.; Umerski, A. Theory of tunneling magnetoresistance of an epitaxial Fe/MgO/Fe(001) junction. Phys. Rev. B. 2001, 63, 200403. [Google Scholar] [CrossRef]

- Zhang, X.-G.; Butler, W.H. Large magnetoresistance in bcc Co/MgO/Co and FeCo/MgO/FeCo tunnel junctions. Phys. Rev. B 2004, 70, 172407. [Google Scholar] [CrossRef]

- Parkin, S.S.P.; Kaiser, C.; Panchula, A.; Rice, P.M.; Hughes, B.; Samant, M.; Yang, S.-H. Giant tunnelling magnetoresistance at room temperature with MgO (100) tunnel barriers. Nat. Mater. 2004, 3, 862–867. [Google Scholar] [CrossRef]

- Yuasa, S.; Nagahama, T.; Fukushima, A.; Suzuki, Y.; Ando, K. Giant room-temperature magnetoresistance in single-crystal Fe/MgO/Fe magnetic tunnel junctions. Nat. Mater. 2004, 3, 868–871. [Google Scholar] [CrossRef]

- Hayakawa, J.; Ikeda, S.; Matsukura, F.; Takahashi, H.; Ohno, H. Dependence of Giant Tunnel Magnetoresistance of Sputtered CoFeB/MgO/CoFeB Magnetic Tunnel Junctions on MgO Barrier Thickness and Annealing Temperature. Jpn. J. Appl. Phys. 2005, 4, L587–L589. [Google Scholar] [CrossRef]

- Djayaprawira, D.D.; Tsunekawa, K.; Nagai, M.; Maehara, H.; Yamagata, S.; Watanabe, N.; Yuasa, S.; Suzuki, Y.; Ando, K. 230% room-temperature magnetoresistance in CoFeB/MgO/CoFeB magnetic tunnel junctions. Appl. Phys. Lett. 2005, 86, 092502. [Google Scholar] [CrossRef]

- Yuasa, S.; Suzuki, Y.; Katayama, T.; Ando, K. Characterization of growth and crystallization processes in CoFeB∕MgO∕CoFeB magnetic tunnel junction structure by reflective high-energy electron diffraction. Appl. Phys. Lett. 2005, 87, 242503. [Google Scholar] [CrossRef]

- Ikeda, S.; Hayakawa, J.; Lee, Y.M.; Tanikawa, T.; Matsukura, F.; Ohno, H. Tunnel magnetoresistance in MgO-barrier tunnel junctions with bcc-CoFe(B) and fcc-CoFe free layers. J. Appl. Phys. 2006, 99, 08A907. [Google Scholar] [CrossRef]

- Bae, J.Y.; Lim, W.C.; Kim, H.J.; Lee, T.D.; Kim, K.W.; Kim, T.W. Compositional change of MgO barrier and interface in CoFeB∕MgO∕CoFeB tunnel junction after annealing. J. Appl. Phys. 2006, 99, 08T316. [Google Scholar] [CrossRef]

- Read, J.C.; Mather, P.G.; Buhrman, R.A. X-ray photoemission study of CoFeB/MgO thin film bilayers. Appl. Phys. Lett. 2007, 90, 132503. [Google Scholar] [CrossRef]

- Mizuguchi, M.; Suzuki, Y.; Nagahama, T.; Yuasa, S. In situ scanning tunneling microscopy observations of polycrystalline MgO(001) tunneling barriers grown on amorphous CoFeB electrode. Appl. Phys. Lett. 2007, 90, 012507. [Google Scholar] [CrossRef]

- Cha, J.J.; Read, J.C.; Buhrman, R.A.; Muller, D.A. Spatially resolved electron energy-loss spectroscopy of electron-beam grown and sputtered CoFeB∕MgO∕CoFeB magnetic tunnel junctions. Appl. Phys. Lett. 2007, 90, 062516. [Google Scholar] [CrossRef]

- Ikeda, S.; Hayakawa, J.; Ashizawa, Y.; Lee, Y.M.; Miura, K.; Hasegawa, H.; Tsunoda, M.; Matsukura, F.; Ohno, H. Tunnel magnetoresistance of 604% at 300K by suppression of Ta diffusion in CoFeB∕MgO∕CoFeB pseudo-spin-valves annealed at high temperature. Appl. Phys. Lett. 2008, 93, 082508. [Google Scholar] [CrossRef]

- Ikeda, S.; Miura, K.; Yamamoto, H.; Mizunuma, K.; Gan, H.D.; Endo, M.; Kanai, S.; Hayakawa, J.; Matsukura, F.; Ohno, H. A perpendicular-anisotropy CoFeB–MgO magnetic tunnel junction. Nat. Mater. 2010, 9, 721–724. [Google Scholar] [CrossRef]

- Cardoso, S.; Freitas, P.P.; de Jesus, C.; Soares, J.C. High thermal stability tunnel junctions. J. Appl. Phys. 2000, 87, 6058–6060. [Google Scholar] [CrossRef]

- Yamane, K.; Higo, Y.; Uchida, H.; Nanba, Y.; Sasaki, S.; Ohmori, H.; Bessho, K.; Hosomi, M. Spin Torque Switching of Perpendicularly Magnetized CoFeB-Based Tunnel Junctions With High Thermal Tolerance. IEEE Trans. Magn. 2013, 49, 4335–4338. [Google Scholar] [CrossRef]

- Thomas, L.; Jan, G.; Zhu, J.; Liu, H.; Lee, Y.-J.; Le, S.; Tong, R.-Y.; Pi, K.; Wang, Y.-J.; Shen, D.; et al. Perpendicular spin transfer torque magnetic random access memories with high spin torque efficiency and thermal stability for embedded applications. J. Appl. Phys. 2014, 115, 172615. [Google Scholar] [CrossRef]

- You, C.Y.; Ohkubo, T.; Takahashi, Y.K.; Hono, K. Boron segregation in crystallized MgO/amorphous-Co40Fe40B20 thin films. J. Appl. Phys. 2008, 104, 033517. [Google Scholar] [CrossRef]

- Lee, J.H.; Kim, S.J.; Yoon, C.S.; Kim, C.K.; Park, B.G.; Lee, T.D. Thermal stability of the exchanged biased CoFe/IrMn electrode for the magnetic tunnel junction as a function of CoFe thickness. J. Appl. Phys. 2002, 92, 6241–6244. [Google Scholar] [CrossRef]

- Lee, Y.M.; Hayakawa, J.; Ikeda, S.; Matsukura, F.; Ohno, H. Giant tunnel magnetoresistance and high annealing stability in CoFeB∕MgO∕CoFeB magnetic tunnel junctions with synthetic pinned layer. Appl. Phys. Lett. 2006, 89, 042506. [Google Scholar] [CrossRef]

- Wang, Y.; Zeng, Z.M.; Han, X.F.; Zhang, X.G.; Sun, X.C.; Zhang, Z. Temperature-dependent Mn-diffusion modes in CoFeB- and CoFe-based magnetic tunnel junctions: Electron-microscopy studies. Phys. Rev. B 2007, 75, 214424. [Google Scholar] [CrossRef]

- Miyajima, T.; Ibusuki, T.; Umehara, S.; Sato, M.; Eguchi, S.; Tsukada, M.; Kataoka, Y. Transmission electron microscopy study on the crystallization and boron distribution of CoFeB/MgO/CoFeB magnetic tunnel junctions with various capping layers. Appl. Phys. Lett. 2009, 94, 122501. [Google Scholar] [CrossRef]

- Pong, P.W.T.; Egelhoff, W.F. Enhancement of tunneling magnetoresistance by optimization of capping layer thicknesses in CoFeB/MgO/CoFeB magnetic tunnel junctions. J. Appl. Phys. 2009, 105, 07C915. [Google Scholar] [CrossRef]

- Mizunuma, K.; Ikeda, S.; Sato, H.; Yamanouchi, M.; Gan, H.; Miura, K.; Yamamoto, H.; Hayakawa, J.; Matsukura, F.; Ohno, H. Tunnel magnetoresistance properties and annealing stability in perpendicular anisotropy MgO-based magnetic tunnel junctions with different stack structures. J. Appl. Phys. 2011, 109, 07C711. [Google Scholar] [CrossRef]

- Karthik, S.V.; Takahashi, Y.K.; Ohkubo, T.; Hono, K.; Gan, H.D.; Ikeda, S.; Ohno, H. Transmission electron microscopy study on the effect of various capping layers on CoFeB/MgO/CoFeB pseudo spin valves annealed at different temperatures. J. Appl. Phys. 2012, 111, 083922. [Google Scholar] [CrossRef]

- Bouchikhaoui, H.; Stender, P.; Akemeier, D.; Baither, D.; Hono, K.; Hütten, A.; Schmitz, G. On the role of Ta cap in the recrystallization process of CoFeB layers. Appl. Phys. Lett. 2013, 103, 142412. [Google Scholar] [CrossRef]

- Almasi, H.; Hickey, D.R.; Newhouse-Illige, T.; Xu, M.; Rosales, M.R.; Nahar, S.; Held, J.T.; Mkhoyan, K.A.; Wang, W.G. Enhanced tunneling magnetoresistance and perpendicular magnetic anisotropy in Mo/CoFeB/MgO magnetic tunnel junctions. Appl. Phys. Lett. 2015, 106, 182406. [Google Scholar] [CrossRef]

- Bouchikhaoui, H.; Stender, P.; Balogh, Z.; Baither, D.; Hütten, A.; Hono, K.; Schmitz, G. Nano-analysis of Ta/FeCoB/MgO tunnel magneto resistance structures. Acta Mater. 2016, 116, 298–307. [Google Scholar] [CrossRef]

- Yamamoto, T.; Nozaki, T.; Yakushiji, K.; Tamaru, S.; Kubota, H.; Fukushima, A.; Yuasa, S. Perpendicular magnetic anisotropy and its voltage control in MgO/CoFeB/MgO junctions with atomically thin Ta adhesion layers. Acta Mater. 2021, 216, 117097. [Google Scholar] [CrossRef]

- Chatterjee, J.; Sousa, R.C.; Perrissin, N.; Auffret, S.; Ducruet, C.; Dieny, B. Enhanced annealing stability and perpendicular magnetic anisotropy in perpendicular magnetic tunnel junctions using W layer. Appl. Phys. Lett. 2017, 110, 202401. [Google Scholar] [CrossRef]

- Xu, X.; Mukaiyama, K.; Kasai, S.; Ohkubo, T.; Hono, K. Impact of boron diffusion at MgO grain boundaries on magneto-transport properties of MgO/CoFeB/W magnetic tunnel junctions. Acta Mater. 2018, 161, 360. [Google Scholar] [CrossRef]

- Manos, O.; Böhnke, A.; Bougiatioti, P.; Klett, R.; Rott, K.; Niesen, A.; Schmalhorst, J.-M.; Reiss, G. Tunneling magnetoresistance of perpendicular CoFeB-based junctions with exchange bias. J. Appl. Phys. 2017, 122, 103904. [Google Scholar] [CrossRef]

- Zhu, Y.; Zhang, Z.; Ma, B.; Jin, Q.Y. Thermal stability of CoFeB/Pt multilayers with perpendicular magnetic anisotropy. J. Appl. Phys. 2012, 111, 07C106. [Google Scholar] [CrossRef]

- Cestarollo, L.; Srinivasan, K.; El-Ghazaly, A. Investigation of perpendicular magnetic anisotropy in Pt/Co20Fe60B20/Pt multi-layer structures. J. Magn. Magn. Mater. 2022, 562, 169825. [Google Scholar] [CrossRef]

- Lee, D.-Y.; Shim, T.-H.; Park, J.-G. Effects of Pt capping layer on perpendicular magnet anisotropy in pseudo-spin valves of Ta/CoFeB/MgO/CoFeB/Pt magnetic-tunneling junctions. Appl. Phys. Lett. 2013, 102, 212409. [Google Scholar] [CrossRef]

- Miron, I.M.; Garello, K.; Gaudin, G.; Zermatten, P.-J.; Costache, M.V.; Auffret, S.; Bandiera, S.; Rodmacq, B.; Schuhl, A.; Gambardella, P. Perpendicular switching of a single ferromagnetic layer induced by in-plane current injection. Nature 2011, 476, 189–193. [Google Scholar] [CrossRef] [PubMed]

- Liu, L.; Pai, C.-F.; Li, Y.; Tseng, H.W.; Ralph, D.C.; Buhrman, R.A. Spin-Torque Switching with the Giant Spin Hall Effect of Tantalum. Science 2012, 336, 555–558. [Google Scholar] [CrossRef] [PubMed]

- Manchon, A.; Železný, J.; Miron, I.M.; Jungwirth, T.; Sinova, J.; Thiaville, A.; Garello, K.; Gambardella, P. Current-induced spin-orbit torques in ferromagnetic and antiferromagnetic systems. Rev. Mod. Phys. 2019, 91, 035004. [Google Scholar] [CrossRef]

- Ryu, J.; Lee, S.; Lee, K.; Park, B. Current-Induced Spin–Orbit Torques for Spintronic Applications. Adv. Mater. 2020, 32, e1907148. [Google Scholar] [CrossRef] [PubMed]

- Messina, L.; Nastar, M.; Sandberg, N.; Olsson, P. Systematic electronic-structure investigation of substitutional impurity diffusion and flux coupling in bcc iron. Phys. Rev. B 2016, 93, 184302. [Google Scholar] [CrossRef]

- Almasi, H.; Sun, C.L.; Li, X.; Newhouse-Illige, T.; Bi, C.; Price, K.C.; Nahar, S.; Grezes, C.; Hu, Q.; Amiri, P.K.; et al. Perpendicular magnetic tunnel junction with W seed and capping layers. J. Appl. Phys. 2017, 121, 153902. [Google Scholar] [CrossRef]

- Lee, H.-Y.; Kim, S.; Park, J.-Y.; Oh, Y.-W.; Park, S.-Y.; Ham, W.; Kotani, Y.; Nakamura, T.; Suzuki, M.; Ono, T.; et al. Enhanced spin–orbit torque via interface engineering in Pt/CoFeB/MgO heterostructures. APL Mater. 2019, 7, 031110. [Google Scholar] [CrossRef]

- Cho, S.; Baek, S.-H.C.; Lee, K.-D.; Jo, Y.; Park, B.-G. Large spin Hall magnetoresistance and its correlation to the spin-orbit torque in W/CoFeB/MgO structures. Sci. Rep. 2015, 5, 14668. [Google Scholar] [CrossRef]

- Cha, I.H.; Lee, M.H.; Kim, G.W.; Kim, T.; Kim, Y.K. Spin-orbit torque efficiency in Ta or W/Ta-W/CoFeB junctions. Mater. Res. Express 2021, 8, 106102. [Google Scholar] [CrossRef]

- Okamoto, H. Co-W (Cobalt-Tungsten). J. Phase Equilibria Diffus. 2008, 29, 119. [Google Scholar] [CrossRef]

- Okamoto, H. Fe-Ta (Iron-Tantalum). J. Phase Equilibria Diffus. 2013, 34, 165–166. [Google Scholar] [CrossRef]

- Shinagawa, K.; Chinen, H.; Omori, T.; Oikawa, K.; Ohnuma, I.; Ishida, K.; Kainuma, R. Phase equilibria and thermodynamic calculation of the Co–Ta binary system. Intermetallics 2014, 49, 87–97. [Google Scholar] [CrossRef]

- Okamoto, H. Supplemental Literature Review of Binary Phase Diagrams: B-Fe, Cr-Zr, Fe-Np, Fe-W, Fe-Zn, Ge-Ni, La-Sn, La-Ti, La-Zr, Li-Sn, Mn-S, and Nb-Re. J. Phase Equilibria Diffus. 2016, 37, 621–634. [Google Scholar] [CrossRef]

- Okamoto, H. Supplemental Literature Review of Binary Phase Diagrams: Au-La, Ce-Pt, Co-Pt, Cr-S, Cu-Sb, Fe-Ni, Lu-Pd, Ni-S, Pd-Ti, Si-Te, Ta-V, and V-Zn. J. Phase Equilibria Diffus. 2019, 40, 743–756. [Google Scholar] [CrossRef]

- Wen, Z.; Wang, Y.; Wang, C.; Jiang, M.; Li, H.; Ren, Y.; Qin, G. Redetermination of the Fe–Pt phase diagram by using diffusion couple technique combined with key alloys. Int. J. Mater. Res. 2022, 113, 428–439. [Google Scholar] [CrossRef]

- Wang, B.; Berry, D.C.; Chiari, Y.; Barmak, K. Experimental measurements of the heats of formation of Fe3Pt, FePt, and FePt3 using differential scanning calorimetry. J. Appl. Phys. 2011, 110, 013903. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, G.; Lee, S.; Lee, S.; Song, B.; Lee, B.-K.; Lee, D.; Lee, J.S.; Lee, M.H.; Kim, Y.K.; Park, B.-G. The Influence of Capping Layers on Tunneling Magnetoresistance and Microstructure in CoFeB/MgO/CoFeB Magnetic Tunnel Junctions upon Annealing. Nanomaterials 2023, 13, 2591. https://doi.org/10.3390/nano13182591

Kim G, Lee S, Lee S, Song B, Lee B-K, Lee D, Lee JS, Lee MH, Kim YK, Park B-G. The Influence of Capping Layers on Tunneling Magnetoresistance and Microstructure in CoFeB/MgO/CoFeB Magnetic Tunnel Junctions upon Annealing. Nanomaterials. 2023; 13(18):2591. https://doi.org/10.3390/nano13182591

Chicago/Turabian StyleKim, Geunwoo, Soogil Lee, Sanghwa Lee, Byonggwon Song, Byung-Kyu Lee, Duhyun Lee, Jin Seo Lee, Min Hyeok Lee, Young Keun Kim, and Byong-Guk Park. 2023. "The Influence of Capping Layers on Tunneling Magnetoresistance and Microstructure in CoFeB/MgO/CoFeB Magnetic Tunnel Junctions upon Annealing" Nanomaterials 13, no. 18: 2591. https://doi.org/10.3390/nano13182591

APA StyleKim, G., Lee, S., Lee, S., Song, B., Lee, B.-K., Lee, D., Lee, J. S., Lee, M. H., Kim, Y. K., & Park, B.-G. (2023). The Influence of Capping Layers on Tunneling Magnetoresistance and Microstructure in CoFeB/MgO/CoFeB Magnetic Tunnel Junctions upon Annealing. Nanomaterials, 13(18), 2591. https://doi.org/10.3390/nano13182591