State of the Art Progress in Copper Vanadate Materials for Solar Water Splitting

Abstract

:1. Introduction

2. Hydrogen

3. Hydrogen Production Pathways

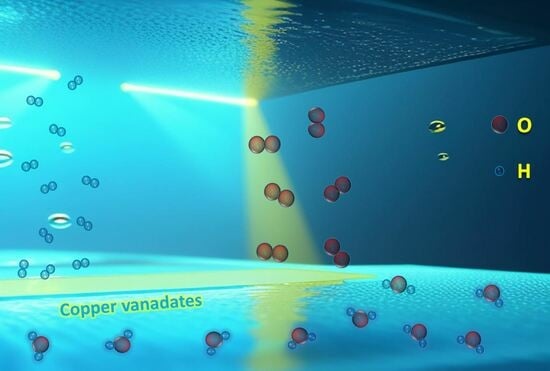

4. Photoelectrochemical Water Spitting

5. Copper Vanadates

6. Synthesis Routes of Copper Vanadates in Solar Water Splitting

7. Crystal Structure of Copper Vanadates

8. Copper Vanadates Photoelectrodes in Water Splitting

8.1. CuV2O6

8.2. Cu2V2O7

8.3. Cu3V2O8

8.4. Cu5V2O10

8.5. Cu11V6O26

9. Conclusions and Outlooks

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Capellán-Pérez, I.; Mediavilla, M.; de Castro, C.; Carpintero, Ó.; Miguel, L.J. Fossil Fuel Depletion and Socio-Economic Scenarios: An Integrated Approach. Energy 2014, 77, 641–666. [Google Scholar] [CrossRef]

- Barreto, R.A. Fossil Fuels, Alternative Energy and Economic Growth. Econ. Model. 2018, 75, 196–220. [Google Scholar] [CrossRef]

- Brockway, P.E.; Owen, A.; Brand-Correa, L.I.; Hardt, L. Estimation of Global Final-Stage Energy-Return-on-Investment for Fossil Fuels with Comparison to Renewable Energy Sources. Nat. Energy 2019, 4, 612–621. [Google Scholar] [CrossRef]

- Wood, N.; Roelich, K. Tensions, Capabilities, and Justice in Climate Change Mitigation of Fossil Fuels. Energy Res. Soc. Sci. 2019, 52, 114–122. [Google Scholar] [CrossRef]

- Baz, K.; Cheng, J.; Xu, D.; Abbas, K.; Ali, I.; Ali, H.; Fang, C. Asymmetric Impact of Fossil Fuel and Renewable Energy Consumption on Economic Growth: A Nonlinear Technique. Energy 2021, 226, 120357. [Google Scholar] [CrossRef]

- Haines, A.; Smith, K.R.; Anderson, D.; Epstein, P.R.; McMichael, A.J.; Roberts, I.; Wilkinson, P.; Woodcock, J.; Woods, J. Policies for Accelerating Access to Clean Energy, Improving Health, Advancing Development, and Mitigating Climate Change. Lancet 2007, 370, 1264–1281. [Google Scholar] [CrossRef]

- Kittner, N.; Lill, F.; Kammen, D.M. Energy Storage Deployment and Innovation for the Clean Energy Transition. Nat. Energy 2017, 2, 17125. [Google Scholar] [CrossRef]

- Lowitzsch, J.; Hoicka, C.E.; van Tulder, F.J. Renewable Energy Communities under the 2019 European Clean Energy Package—Governance Model for the Energy Clusters of the Future? Renew. Sustain. Energy Rev. 2020, 122, 109489. [Google Scholar] [CrossRef]

- Haram, M.H.S.M.; Lee, J.W.; Ramasamy, G.; Ngu, E.E.; Thiagarajah, S.P.; Lee, Y.H. Feasibility of Utilising Second Life EV Batteries: Applications, Lifespan, Economics, Environmental Impact, Assessment, and Challenges. Alex. Eng. J. 2021, 60, 4517–4536. [Google Scholar] [CrossRef]

- Gao, Y.; Zhu, C.; Zhang, X.; Guo, B. Implementation and Evaluation of a Practical Electrochemical- Thermal Model of Lithium-Ion Batteries for EV Battery Management System. Energy 2021, 221, 119688. [Google Scholar] [CrossRef]

- Yang, Z.; Huang, H.; Lin, F. Sustainable Electric Vehicle Batteries for a Sustainable World: Perspectives on Battery Cathodes, Environment, Supply Chain, Manufacturing, Life Cycle, and Policy. Adv. Energy Mater. 2022, 12, 2200383. [Google Scholar] [CrossRef]

- Masias, A.; Marcicki, J.; Paxton, W.A. Opportunities and Challenges of Lithium Ion Batteries in Automotive Applications. ACS Energy Lett. 2021, 6, 621–630. [Google Scholar] [CrossRef]

- Oshiro, K.; Fujimori, S. Role of Hydrogen-Based Energy Carriers as an Alternative Option to Reduce Residual Emissions Associated with Mid-Century Decarbonization Goals. Appl. Energy 2022, 313, 118803. [Google Scholar] [CrossRef]

- Safari, F.; Dincer, I. A Review and Comparative Evaluation of Thermochemical Water Splitting Cycles for Hydrogen Production. Energy Convers. Manag. 2020, 205, 112182. [Google Scholar] [CrossRef]

- Dixon, R.K.; Li, J.; Wang, M.Q. 13—Progress in Hydrogen Energy Infrastructure Development—Addressing Technical and Institutional Barriers. In Compendium of Hydrogen Energy; Gupta, R.B., Basile, A., Veziroğlu, T.N., Eds.; Woodhead Publishing Series in Energy; Woodhead Publishing: Sawston, UK, 2016; pp. 323–343. ISBN 978-1-78242-362-1. [Google Scholar]

- Manoharan, Y.; Hosseini, S.E.; Butler, B.; Alzhahrani, H.; Senior, B.T.F.; Ashuri, T.; Krohn, J. Hydrogen Fuel Cell Vehicles; Current Status and Future Prospect. Appl. Sci. 2019, 9, 2296. [Google Scholar] [CrossRef]

- Nicoletti, G.; Arcuri, N.; Nicoletti, G.; Bruno, R. A Technical and Environmental Comparison between Hydrogen and Some Fossil Fuels. Energy Convers. Manag. 2015, 89, 205–213. [Google Scholar] [CrossRef]

- Lv, X.-W.; Tian, W.-W.; Yuan, Z.-Y. Recent Advances in High-Efficiency Electrocatalytic Water Splitting Systems. Electrochem. Energy Rev. 2023, 6, 23. [Google Scholar] [CrossRef]

- Fujishima, A.; Honda, K. Electrochemical Photolysis of Water at a Semiconductor Electrode. Nature 1972, 238, 37–38. [Google Scholar] [CrossRef]

- Lewis, N.S. Research Opportunities to Advance Solar Energy Utilization. Science 2016, 351, aad1920. [Google Scholar] [CrossRef]

- Raza, A.; Zhang, X.; Ali, S.; Cao, C.; Rafi, A.A.; Li, G. Photoelectrochemical Energy Conversion over 2D Materials. Photochem 2022, 2, 272–298. [Google Scholar] [CrossRef]

- Kalanur, S.S.; Duy, L.T.; Seo, H. Recent Progress in Photoelectrochemical Water Splitting Activity of WO3 Photoanodes. Top. Catal. 2018, 61, 1043–1076. [Google Scholar] [CrossRef]

- Nguyen, P.D.; Duong, T.M.; Tran, P.D. Current Progress and Challenges in Engineering Viable Artificial Leaf for Solar Water Splitting. J. Sci. Adv. Mater. Devices 2017, 2, 399–417. [Google Scholar] [CrossRef]

- Kalanur, S.S.; Lee, S.H.; Hwang, Y.J.; Joo, O.-S. Enhanced Photoanode Properties of CdS Nanoparticle Sensitized TiO2 Nanotube Arrays by Solvothermal Synthesis. J. Photochem. Photobiol. A Chem. 2013, 259, 1–9. [Google Scholar] [CrossRef]

- Commandeur, D.; Brown, G.; Hills, E.; Spencer, J.; Chen, Q. Defect-Rich ZnO Nanorod Arrays for Efficient Solar Water Splitting. ACS Appl. Nano Mater. 2019, 2, 1570–1578. [Google Scholar] [CrossRef]

- Mor, G.K.; Varghese, O.K.; Paulose, M.; Shankar, K.; Grimes, C.A. A Review on Highly Ordered, Vertically Oriented TiO2 Nanotube Arrays: Fabrication, Material Properties, and Solar Energy Applications. Sol. Energy Mater. Sol. Cells 2006, 90, 2011–2075. [Google Scholar] [CrossRef]

- Thoa Huynh, T.K.; Lee, Y.; Kalanur, S.S.; Seo, H. Defect Tuned SnO2 Nanolayer Coated TiO2 1-D Core-Shell Structure for Enhanced Overall Solar Water Splitting. Ceram. Int. 2022, 48, 1013–1023. [Google Scholar] [CrossRef]

- Zayed, M.; Nasser, N.; Shaban, M.; Alshaikh, H.; Hamdy, H.; Ahmed, A.M. Effect of Morphology and Plasmonic on Au/ZnO Films for Efficient Photoelectrochemical Water Splitting. Nanomaterials 2021, 11, 2338. [Google Scholar] [CrossRef]

- Kalanur, S.S.; Singh, R.; Seo, H. Enhanced Solar Water Splitting of an Ideally Doped and Work Function Tuned {002} Oriented One-Dimensional WO3 with Nanoscale Surface Charge Mapping Insights. Appl. Catal. B Environ. 2021, 295, 120269. [Google Scholar] [CrossRef]

- Kalanur, S.S.; Jae Lee, Y.; Seo, H.; Pollet, B.G. Enhanced Photoactivity towards Bismuth Vanadate Water Splitting through Tantalum Doping: An Experimental and Density Functional Theory Study. J. Colloid. Interface Sci. 2023, 650, 94–104. [Google Scholar] [CrossRef]

- Kalanoor, B.S.; Seo, H.; Kalanur, S.S. Multiple Ion Doping in BiVO4 as an Effective Strategy of Enhancing Photoelectrochemical Water Splitting: A Review. Mater. Sci. Energy Technol. 2021, 4, 317–328. [Google Scholar] [CrossRef]

- Xiang, X.; Wang, L.; Zhang, J.; Cheng, B.; Yu, J.; Macyk, W. Cadmium Chalcogenide (CdS, CdSe, CdTe) Quantum Dots for Solar-to-Fuel Conversion. Adv. Photonics Res. 2022, 3, 2200065. [Google Scholar] [CrossRef]

- Zhang, J.; Zhang, M.; Dong, Y.; Bai, C.; Feng, Y.; Jiao, L.; Lv, H. CdTe/CdSe-Sensitized Photocathode Coupling with Ni-Substituted Polyoxometalate Catalyst for Photoelectrochemical Generation of Hydrogen. Nano Res. 2022, 15, 1347–1354. [Google Scholar] [CrossRef]

- Yang, Y.; Zheng, X.; Song, Y.; Liu, Y.; Wu, D.; Li, J.; Liu, W.; Fu, L.; Shen, Y.; Tian, X. CuInS2-Based Photocatalysts for Photocatalytic Hydrogen Evolution via Water Splitting. Int. J. Hydrog. Energy 2023, 48, 3791–3806. [Google Scholar] [CrossRef]

- Kobayashi, H.; Sato, N.; Orita, M.; Kuang, Y.; Kaneko, H.; Minegishi, T.; Yamada, T.; Domen, K. Development of Highly Efficient CuIn0.5Ga0.5Se2-Based Photocathode and Application to Overall Solar Driven Water Splitting. Energy Environ. Sci. 2018, 11, 3003–3009. [Google Scholar] [CrossRef]

- Seo, J.; Nishiyama, H.; Yamada, T.; Domen, K. Visible-Light-Responsive Photoanodes for Highly Active, Stable Water Oxidation. Angew. Chem. Int. Ed. 2018, 57, 8396–8415. [Google Scholar] [CrossRef]

- Xi, X.; Zhao, L.; Li, T.; Li, X.; Yang, C. The Fabrication of GaN Nanostructures Using Cost-Effective Methods for Application in Water Splitting. Crystals 2023, 13, 873. [Google Scholar] [CrossRef]

- Yu, W. Understanding the Stability of Semiconducting Photocathodes for Solar Water Splitting. Curr. Opin. Electrochem. 2023, 39, 101262. [Google Scholar] [CrossRef]

- Kalanur, S.S.; Lee, Y.J.; Seo, H. Enhanced and Stable Photoelectrochemical H2 Production Using a Engineered Nano Multijunction with Cu2O Photocathode. Mater. Today Chem. 2022, 26, 101031. [Google Scholar] [CrossRef]

- Yoo, I.; Kalanur, S.S.; Seo, H. A Nanoscale p–n Junction Photoelectrode Consisting of an NiOx Layer on a TiO2/CdS Nanorod Core-Shell Structure for Highly Efficient Solar Water Splitting. Appl. Catal. B: Environ. 2019, 250, 200–212. [Google Scholar] [CrossRef]

- Du, D.; Wang, L.; Ding, D.; Guo, Y.; Xu, J.; Qiao, F.; Wang, H.; Shen, W. One-Step Synthesis of Aqueous CdTe/CdSe Composite QDs toward Efficiency Enhancement of Solar Cell. Chem. Eng. J. 2023, 461, 142040. [Google Scholar] [CrossRef]

- Yoon, N.; Joo, O.S.; Chae, S.Y.; Park, E.D. Recent Advances in CuInS2-Based Photocathodes for Photoelectrochemical H2 Evolution. Nanomaterials 2023, 13, 1361. [Google Scholar] [CrossRef] [PubMed]

- Chae, S.Y.; Yoon, N.; Park, E.D.; Joo, O.S. Surface Modification of CuInS2 Photocathodes with Ruthenium Co-Catalysts for Efficient Solar Water Splitting. Appl. Surf. Sci. 2023, 612, 155856. [Google Scholar] [CrossRef]

- Wu, B.; Wang, T.; Liu, B.; Li, H.; Wang, Y.; Wang, S.; Zhang, L.; Jiang, S.; Pei, C.; Gong, J. Stable Solar Water Splitting with Wettable Organic-Layer-Protected Silicon Photocathodes. Nat. Commun. 2022, 13, 4460. [Google Scholar] [CrossRef] [PubMed]

- Siavash Moakhar, R.; Hosseini-Hosseinabad, S.M.; Masudy-Panah, S.; Seza, A.; Jalali, M.; Fallah-Arani, H.; Dabir, F.; Gholipour, S.; Abdi, Y.; Bagheri-Hariri, M.; et al. Photoelectrochemical Water-Splitting Using CuO-Based Electrodes for Hydrogen Production: A Review. Adv. Mater. 2021, 33, 2007285. [Google Scholar] [CrossRef]

- Jiang, C.; Wu, J.; Moniz, S.J.A.; Guo, D.; Tang, M.; Jiang, Q.; Chen, S.; Liu, H.; Wang, A.; Zhang, T.; et al. Stabilization of GaAs Photoanodes by in Situ Deposition of Nickel-Borate Surface Catalysts as Hole Trapping Sites. Sustain. Energy Fuels 2019, 3, 814–822. [Google Scholar] [CrossRef]

- Yoo, I.-H.; Lee, Y.-J.; Kalanur, S.S.; Seo, H. Assembly of Nonstoichiometric Molybdenum Oxide on Si as P-n Junction Photocathode for Enhanced Hydrogen Evolution. Appl. Catal. B Environ. 2020, 264, 118542. [Google Scholar] [CrossRef]

- Ali, R.B.; Sial, Q.A.; Lee, Y.J.; Waqas, M.; Kalanur, S.S.; Seo, H. A Synergic Effect of Bi-Metallic Layered Hydro-Oxide Cocatalyst on 1-D TiO2 Driven Photoelectrochemical Water Splitting. J. Asian Ceram. Soc. 2023, 11, 424–435. [Google Scholar] [CrossRef]

- Kalanur, S.S.; Seo, H. An Experimental and Density Functional Theory Studies of Nb-Doped BiVO4 Photoanodes for Enhanced Solar Water Splitting. J. Catal. 2022, 410, 144–155. [Google Scholar] [CrossRef]

- Shi, Q.; Qin, Z.; Yu, C.; Waheed, A.; Xu, H.; Gao, Y.; Abroshan, H.; Li, G. Experimental and Mechanistic Understanding of Photo-Oxidation of Methanol Catalyzed by CuO/TiO2-Spindle Nanocomposite: Oxygen Vacancy Engineering. Nano Res. 2020, 13, 939–946. [Google Scholar] [CrossRef]

- Kalanur, S.S.; Seo, H. Work Function Tuned, Surface Cs Intercalated BiVO4 for Enhanced Photoelectrochemical Water Splitting Reactions. J. Energy Chem. 2022, 68, 612–623. [Google Scholar] [CrossRef]

- Kalanoor, B.S.; Seo, H.; Kalanur, S.S. Recent Developments in Photoelectrochemical Water-Splitting Using WO3/BiVO4 Heterojunction Photoanode: A Review. Mater. Sci. Energy Technol. 2018, 1, 49–62. [Google Scholar] [CrossRef]

- Shao, W.; Xiao, M.; Yang, C.; Cheng, M.; Cao, S.; He, C.; Zhou, M.; Ma, T.; Cheng, C.; Li, S. Assembling and Regulating of Transition Metal-Based Heterophase Vanadates as Efficient Oxygen Evolution Catalysts. Small 2022, 18, 2105763. [Google Scholar] [CrossRef] [PubMed]

- Zhang, X.; Shi, Q.; Liu, X.; Li, J.; Xu, H.; Ding, H.; Li, G. Facile Assembly of InVO4/TiO2 Heterojunction for Enhanced Photo-Oxidation of Benzyl Alcohol. Nanomaterials 2022, 12, 1544. [Google Scholar] [CrossRef]

- He, D.; Wang, Q.; Zhang, W.; Liu, X.; Cui, X. BiVO4 Heterojunctions as Efficient Photoanodes for Photoelectrochemical Water Oxidation: A Minireview. ChemPhotoChem 2023, e202300080. [Google Scholar] [CrossRef]

- Cheng, F.; Chen, J. Transition Metal Vanadium Oxides and Vanadate Materials for Lithium Batteries. J. Mater. Chem. 2011, 21, 9841–9848. [Google Scholar] [CrossRef]

- Yao, G.; Zhang, N.; Zhang, Y.; Zhou, T. Nanostructured Transition Metal Vanadates as Electrodes for Pseudo-Supercapacitors: A Review. J. Nanopart Res. 2021, 23, 57. [Google Scholar] [CrossRef]

- Khan, I.; Gu, Y.; Wooh, S. Shape-Controlled First-Row Transition Metal Vanadates for Electrochemical and Photoelectrochemical Water Splitting. Chem. Rec. 2023, e202300127. [Google Scholar] [CrossRef] [PubMed]

- Kawada, T.; Tajiri, T.; Yamashita, H.; Machida, M. Molten Copper Hexaoxodivanadate: An Efficient Catalyst for SO3 Decomposition in Solar Thermochemical Water Splitting Cycles. Catal. Sci. Technol. 2014, 4, 780–785. [Google Scholar] [CrossRef]

- Guo, W.; Chemelewski, W.D.; Mabayoje, O.; Xiao, P.; Zhang, Y.; Mullins, C.B. Synthesis and Characterization of CuV2O6 and Cu2V2O7: Two Photoanode Candidates for Photoelectrochemical Water Oxidation. J. Phys. Chem. C 2015, 119, 27220–27227. [Google Scholar] [CrossRef]

- Kim, M.; Joshi, B.; Yoon, H.; Ohm, T.Y.; Kim, K.; Al-Deyab, S.S.; Yoon, S.S. Electrosprayed Copper Hexaoxodivanadate (CuV2O6) and Pyrovanadate (Cu2V2O7) Photoanodes for Efficient Solar Water Splitting. J. Alloys Compd. 2017, 708, 444–450. [Google Scholar] [CrossRef]

- Khan, I.; Qurashi, A. Shape Controlled Synthesis of Copper Vanadate Platelet Nanostructures, Their Optical Band Edges, and Solar-Driven Water Splitting Properties. Sci. Rep. 2017, 7, 14370. [Google Scholar] [CrossRef]

- Hossain, M.K.; Sotelo, P.; Sarker, H.P.; Galante, M.T.; Kormányos, A.; Longo, C.; Macaluso, R.T.; Huda, M.N.; Janáky, C.; Rajeshwar, K. Rapid One-Pot Synthesis and Photoelectrochemical Properties of Copper Vanadates. ACS Appl. Energy Mater. 2019, 2, 2837–2847. [Google Scholar] [CrossRef]

- Girardi, L.; Rizzi, G.A.; Bigiani, L.; Barreca, D.; Maccato, C.; Marega, C.; Granozzi, G. Copper Vanadate Nanobelts as Anodes for Photoelectrochemical Water Splitting: Influence of CoOx Overlayers on Functional Performances. ACS Appl. Mater. Interfaces 2020, 12, 31448–31458. [Google Scholar] [CrossRef] [PubMed]

- Hossain, M.K.; Sarker, H.P.; Sotelo, P.; Dang, U.; Rodríguez-Gutiérrez, I.; Blawat, J.; Vali, A.; Xie, W.; Oskam, G.; Huda, M.N.; et al. Phase-Pure Copper Vanadate (α-CuV2O6): Solution Combustion Synthesis and Characterization. Chem. Mater. 2020, 32, 6247–6255. [Google Scholar] [CrossRef]

- Jansi Rani, B.; Ravi, G.; Yuvakkumar, R.; Praveen Kumar, M.; Ravichandran, S.; Velauthapillai, D.; Thambidurai, M.; Dang, C. Photoelectrochemical Activity of Copper Vanadate Nanostructures. Mater. Lett. 2020, 274, 127996. [Google Scholar] [CrossRef]

- Jiang, C.-M.; Segev, G.; Hess, L.H.; Liu, G.; Zaborski, G.; Toma, F.M.; Cooper, J.K.; Sharp, I.D. Composition-Dependent Functionality of Copper Vanadate Photoanodes. ACS Appl. Mater. Interfaces 2018, 10, 10627–10633. [Google Scholar] [CrossRef] [PubMed]

- Kalanur, S.S.; Seo, H. Facile Growth of Compositionally Tuned Copper Vanadate Nanostructured Thin Films for Efficient Photoelectrochemical Water Splitting. Appl. Catal. B Environ. 2019, 249, 235–245. [Google Scholar] [CrossRef]

- Song, A.; Chemseddine, A.; Ahmet, I.Y.; Bogdanoff, P.; Friedrich, D.; Abdi, F.F.; Berglund, S.P.; Krol, R. van de Evaluation of Copper Vanadate (β-Cu2V2O7) as a Photoanode Material for Photoelectrochemical Water Oxidation. Chem. Mater. 2020, 32, 2408–2419. [Google Scholar] [CrossRef]

- Seabold, J.A.; Neale, N.R. All First Row Transition Metal Oxide Photoanode for Water Splitting Based on Cu3V2O8. Chem. Mater. 2015, 27, 1005–1013. [Google Scholar] [CrossRef]

- Cardenas-Morcoso, D.; Peiro-Franch, A.; Herraiz-Cardona, I.; Gimenez, S. Chromium Doped Copper Vanadate Photoanodes for Water Splitting. Catal. Today 2017, 290, 65–72. [Google Scholar] [CrossRef]

- Pulipaka, S.; Boni, N.; Meduri, P. Copper Vanadate (Cu3V2O8): (Mo, W) Doping Insights to Enhance Performance as an Anode for Photoelectrochemical Water Splitting. ACS Appl. Energy Mater. 2020, 3, 6060–6064. [Google Scholar] [CrossRef]

- Iqbal, T.; Hassan, A.; Ijaz, M.; Salim, M.; Farooq, M.; Zafar, M.; Tahir, M.B. Chromium Incorporated Copper Vanadate Nano-Materials for Hydrogen Evolution by Water Splitting. Appl. Nanosci. 2021, 11, 1661–1671. [Google Scholar] [CrossRef]

- Song, A.; Berglund, S.P.; Chemseddine, A.; Friedrich, D.; Abdi, F.F.; Krol, R. van de Elucidating the Optical, Electronic, and Photoelectrochemical Properties of p-Type Copper Vanadate (p-Cu5V2O10) Photocathodes. J. Mater. Chem. A 2020, 8, 12538–12547. [Google Scholar] [CrossRef]

- Lumley, M.A.; Choi, K.-S. Investigation of Pristine and (Mo, W)-Doped Cu11V6O26 for Use as Photoanodes for Solar Water Splitting. Chem. Mater. 2017, 29, 9472–9479. [Google Scholar] [CrossRef]

- Diaz-Anichtchenko, D.; Bandiello, E.; Gonzáles-Platas, J.; Liang, A.; He, Z.; Muñoz, A.; Rodríguez-Hernández, P.; Errandonea, D.; Popescu, C. Physical Properties and Structural Stability of Cobalt Pyrovanadate Co2V2O7 under High-Pressure Conditions. J. Phys. Chem. C 2022, 126, 13416–13426. [Google Scholar] [CrossRef]

- Jiang, C.-M.; Farmand, M.; Wu, C.H.; Liu, Y.-S.; Guo, J.; Drisdell, W.S.; Cooper, J.K.; Sharp, I.D. Electronic Structure, Optoelectronic Properties, and Photoelectrochemical Characteristics of γ-Cu3V2O8 Thin Films. Chem. Mater. 2017, 29, 3334–3345. [Google Scholar] [CrossRef]

- Song, A.; Liu, S.; Wang, Q.; Gao, D.; Hu, J. Assessing the Suitability of Copper Vanadate (Cu11V6O26) for Use as a Photoanode Material for Photoelectrochemical Water Oxidation. ACS Appl. Energy Mater. 2022, 5, 9512–9519. [Google Scholar] [CrossRef]

- Zhou, L.; Yan, Q.; Yu, J.; Jones, R.J.R.; Becerra-Stasiewicz, N.; Suram, S.K.; Shinde, A.; Guevarra, D.; Neaton, J.B.; Persson, K.A.; et al. Stability and Self-Passivation of Copper Vanadate Photoanodes under Chemical, Electrochemical, and Photoelectrochemical Operation. Phys. Chem. Chem. Phys. 2016, 18, 9349–9352. [Google Scholar] [CrossRef]

| Material | Synthesis Method | Morphology | n-or p-Type | Photocurrent cm−2 (1.23 V vs. RHE) | O2 Production | Ref |

|---|---|---|---|---|---|---|

| CuV2O6 | Drop-casting | Nanoparticles | n-type | ~25 µA | 4.5 µmol L−1 | [60] |

| CuV2O6 | Hydrothermal | Peculiar platelets | n-type | ~0.64 mA (1.2 V vs. SCE) | NA | [62] |

| α-CuV2O6 | Solution combustion | Nanoparticles | n-type | ~55 µA | N/A | [63] |

| CuV2O7-CoOx | hydrothermal | Nanobelts | n-type | ∼18 μA | N/A | [64] |

| α-CuV2O6 | Solution combustion | N/A | n-type | ∼750 μA (1.74 V vs. RHE) | N/A | [65] |

| Cu2V2O7 | Drop-casting | Nanoparticles | n-type | ~35 μA | ~5 µmol L−1 | [60] |

| Cu2V2O7 | Electrospray | Nanoparticles | n-type | ~0.1 mA | N/A | [61] |

| Cu2V2O7 | Hydrothermal | Micro-flakes | n-type | ~0.70 mA (1.2 V vs. SCE) | N/A | [62] |

| α-Cu2V2O7 | Solution combustion | Nanoparticles | n-type | ~30 μA | N/A | [63] |

| β-Cu2V2O7 | Solution combustion | Nanoparticles | n-type | ~65 μA | N/A | [63] |

| Cu2V2O7 | RF magnetron sputtering | Nanograins | n-type | ~36 µA | N/A | [67] |

| Cu2V2O7 | Hydrothermal | Nanoplate | n-type | ~0.41 mA | ~5.8 µmol L−1 h−1 | [68] |

| β-Cu2V2O7 /Co-Pi | Spray pyrolysis/Electrodeposition | Spherical particles | n-type | 100 µA | 45 pA | [69] |

| γ-Cu3V2O8 | Solution combustion/spray coating | Nanoparticles | n-type | 25 µA | N/A | [63] |

| γ-Cu3V2O8 | RF co-sputtering | Thin film | n-type | 71 µA (0.94 V vs. RHE) | N/A | [67] |

| Cu3V2O8 Mo-doped | Solution-based drop-casting | Nanoparticles | n-type | ~20 µA and ~25 µA | ~0.5 µmol cm−2 per 5 min | [70] |

| Cr/Cu3V2O8 | Precipitation method | Nanoflakes | n-type | ~66 µA | ~1.5 µmol cm−2 | [71] |

| Cu3V2O8 Mo doped W doped | Precipitation method | Nanoparticles | n-type | ~0.18 mA ∼0.55 mA ∼0.60 mA (1.85 V vs. RHE) | N/A | [72] |

| Cr doped Cu3V2O8 | Hydrothermal | Nanoparticle | N/A | N/A | H2:288 µm mol hg−1 | [73] |

| γ-Cu3V2O8 | Reactive Co-sputtering | Nanoparticle/thin film | n-type | ~62 μA | N/A | [77] |

| γ-Cu3V2O8 | RF co-sputtering | Thin film | n-type | ~1 µA (1.34 V vs. RHE) | N/A | [67] |

| Cu5V2O10 | Hydrothermal | Nanorod | n-type | ~270 µA | 2 µmol L−1 | [68] |

| Cu5V2O10 | Spray pyrolysis | Nanoparticles | p-type | ~0.52 mA (0.8 V vs. RHE) | N/A | [74] |

| Cu11V6O26 | RF magnetron co-sputtering | Thin film | n-type | ~53 µA (0.94 V vs. RHE) | N/A | [67] |

| Cu11V6O26 | Hydrothermal | Micropillar | n-type | ~0.076 mA | 1 µmol L−1 | [68] |

| Cu11V6O26 W doped Mo doped | Electrodeposition/drop casting | Globular network of microparticles | n-type | ~0.010 mA ~0.035 mA ~0.075 mA | ~0.25 µmol cm−2 h−1 | [75] |

| Cu11V6O26 γ-Cu3V2O8 | Spray pyrolysis RF co-sputtering | Nanoparticles Thin film | n-type | ~0.16 mA | N/A | [78] |

| n-type | ~1 µA (1.34 V vs. RHE) | N/A | [67] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kalanur, S.S.; Seetharamappa, J.; Sial, Q.A.; Pollet, B.G. State of the Art Progress in Copper Vanadate Materials for Solar Water Splitting. Nanomaterials 2023, 13, 2599. https://doi.org/10.3390/nano13182599

Kalanur SS, Seetharamappa J, Sial QA, Pollet BG. State of the Art Progress in Copper Vanadate Materials for Solar Water Splitting. Nanomaterials. 2023; 13(18):2599. https://doi.org/10.3390/nano13182599

Chicago/Turabian StyleKalanur, Shankara S., Jaldappagari Seetharamappa, Qadeer Akbar Sial, and Bruno G. Pollet. 2023. "State of the Art Progress in Copper Vanadate Materials for Solar Water Splitting" Nanomaterials 13, no. 18: 2599. https://doi.org/10.3390/nano13182599

APA StyleKalanur, S. S., Seetharamappa, J., Sial, Q. A., & Pollet, B. G. (2023). State of the Art Progress in Copper Vanadate Materials for Solar Water Splitting. Nanomaterials, 13(18), 2599. https://doi.org/10.3390/nano13182599