High-Performance Infrared Detectors Based on Black Phosphorus/Carbon Nanotube Heterojunctions

Abstract

:1. Introduction

2. Materials and Methods

2.1. Preparation of the Bulk BP

2.2. Fabrication of the 2D BP

2.3. Preparation of the SWCNT Films

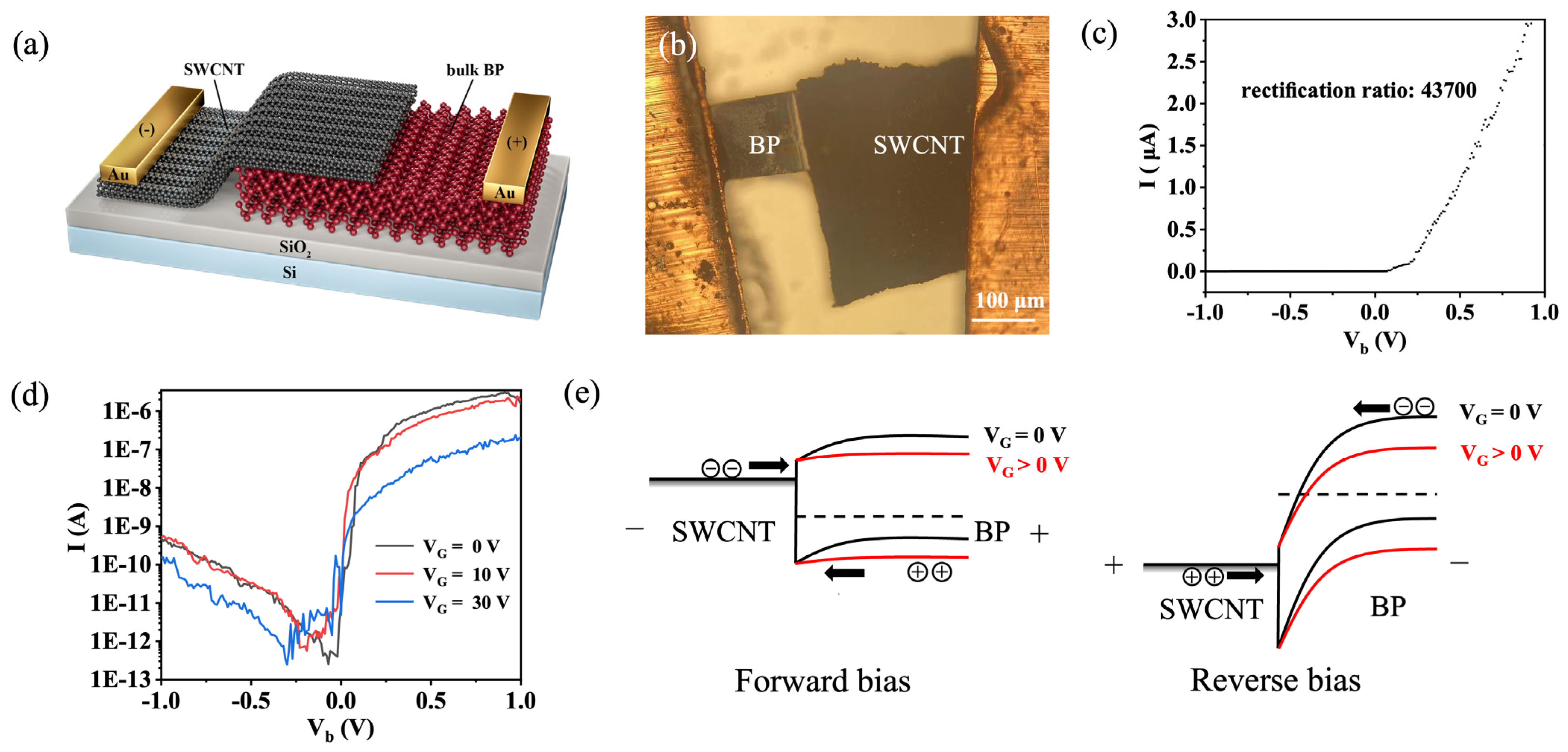

2.4. Fabrication of the Bulk BP/SWCNT Film Schottky Diodes

2.5. Fabrication of the 2D BP/SWCNT Film Photodetectors

2.6. Measurements on the Electrical and Photovoltaic Characteristics of the Devices

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Konstantatos, G.; Howard, I.; Fischer, A.; Hoogland, S.; Clifford, J.; Klem, E.; Levina, L.; Sargent, E.H. Ultrasensitive solu-tion-cast quantum dot photodetectors. Nature 2006, 442, 180–183. [Google Scholar] [CrossRef]

- Michel, J.; Liu, J.; Kimerling, L.C. High-performance Ge-on-Si photodetectors. Nat. Photon. 2010, 4, 527–534. [Google Scholar] [CrossRef]

- Li, L.; Yu, Y.; Ye, G.J.; Ge, Q.; Ou, X.; Wu, H.; Feng, D.; Chen, X.H.; Zhang, Y. Black phosphorus field-effect transistors. Nat. Nanotechnol. 2014, 9, 372–377. [Google Scholar] [CrossRef] [PubMed]

- Qiao, J.; Kong, X.; Hu, Z.-X.; Yang, F.; Ji, W. High-mobility transport anisotropy and linear dichroism in few-layer black phosphorus. Nat. Commun. 2014, 5, 4475. [Google Scholar] [CrossRef]

- Tan, W.C.; Cai, Y.; Ng, R.J.; Huang, L.; Feng, X.; Zhang, G.; Zhang, Y.-W.; Nijhuis, C.A.; Liu, X.; Ang, K.-W. Few-layer black phosphorus carbide field-effect transistor via carbon doping. Adv. Mater. 2017, 29, 1700503. [Google Scholar] [CrossRef]

- Huang, M.; Wang, M.; Chen, C.; Ma, Z.; Li, X.; Han, J.; Wu, Y. Broadband black-phosphorus photodetectors with high responsivity. Adv. Mater. 2016, 28, 3481–3485. [Google Scholar] [CrossRef]

- Zhang, G.; Huang, S.; Wang, F.; Xing, Q.; Song, C.; Wang, C.; Lei, Y.; Huang, M.; Yan, H. The optical conductivity of few-layer black phosphorus by infrared spectroscopy. Nat. Commun. 2020, 11, 1847. [Google Scholar] [CrossRef]

- Kumar, A.; Viscardi, L.; Faella, E.; Giubileo, F.; Intonti, K.; Pelella, A.; Sleziona, S.; Kharsah, O.; Schleberger, M.; Di Bartolomeo, A. Black phosphorus unipolar transistor, memory, and photodetector. J. Mater. Sci. 2023, 58, 2689–2699. [Google Scholar] [CrossRef]

- Castellanos-Gomez, A. Black Phosphorus: Narrow Gap, Wide Applications. J. Phys. Chem. Lett. 2015, 6, 4280–4291. [Google Scholar] [CrossRef]

- Zhang, T.; Xie, H.; Xie, S.; Hu, A.; Liu, J.; Kang, J.; Hou, J.; Hao, Q.; Liu, H.; Ji, H. A Superior two-dimensional phosphorus flame retardant: Few-layer black phosphorus. Molecules 2023, 28, 5062. [Google Scholar] [CrossRef] [PubMed]

- De Volder, M.F.L.; Tawfick, S.H.; Baughman, R.H.; Hart, A.J. Carbon nanotubes: Present and future commercial applications. Science 2013, 339, 535–539. [Google Scholar] [CrossRef]

- Avouris, P.; Freitag, M.; Perebeinos, V. Carbon-nanotube photonics and optoelectronics. Nat. Photon. 2008, 2, 341–350. [Google Scholar] [CrossRef]

- Yang, L.; Wang, S.; Zeng, Q.; Zhang, Z.; Peng, L.-M. Carbon nanotube photoelectronic and photovoltaic devices and their applications in infrared detection. Small 2013, 9, 1225–1236. [Google Scholar] [CrossRef]

- Prechtel, L.; Song, L.; Manus, S.; Schuh, D.; Wegscheider, W.; Holleitner, A.W. Time-resolved picosecond photocurrents in contacted carbon nanotubes. Nano Lett. 2010, 11, 269–272. [Google Scholar] [CrossRef] [PubMed]

- Liu, X.; Chen, C.; Wei, L.; Hu, N.; Song, C.; Liao, C.; He, R.; Dong, X.; Wang, Y.; Liu, Q.; et al. A p-i-n junction diode based on locally doped carbon nanotube network. Sci. Rep. 2016, 6, 23319. [Google Scholar] [CrossRef] [PubMed]

- Dürkop, T.; Getty, S.A.; Cobas, E.; Fuhrer, M.S. Extraordinary mobility in semiconducting carbon nanotubes. Nano Lett. 2004, 4, 35–39. [Google Scholar] [CrossRef]

- Hou, C.; Yang, L.; Li, B.; Zhang, Q.; Li, Y.; Yue, Q.; Wang, Y.; Yang, Z.; Dong, L. Multilayer black phosphorus near-infrared photodetectors. Sensors 2018, 18, 1668. [Google Scholar] [CrossRef] [PubMed]

- Zeng, Q.; Wang, S.; Yang, L.; Wang, Z.; Pei, T.; Zhang, Z.; Peng, L.-M.; Zhou, W.; Liu, J.; Zhou, W.; et al. Carbon nanotube arrays based high-performance infrared photodetector [Invited]. Opt. Mater. Express 2012, 2, 839–848. [Google Scholar] [CrossRef]

- Rogalski, A. Infrared detectors: Status and trends. Prog. Quantum Electron. 2003, 27, 59–210. [Google Scholar] [CrossRef]

- Zhang, X.; Yan, C.; Hu, X.; Dong, Q.; Liu, Z.; Lv, W.; Zeng, C.; Su, R.; Wang, Y.; Sun, T.; et al. High performance mid-wave infrared photodetector based on graphene/black phosphorus heterojunction. Mater. Res. Express 2021, 8, 035602. [Google Scholar] [CrossRef]

- He, Z.; Wang, K.; Yan, C.; Wan, L.; Zhou, Q.; Zhang, T.; Ye, X.; Zhang, Y.; Shi, F.; Jiang, S.; et al. Controlled preparation and device application of sub-5 nm graphene nanoribbons and graphene nanoribbon/carbon nanotube intramolecular heterostructures. ACS Appl. Mater. Interfaces 2023, 15, 7148–7156. [Google Scholar] [CrossRef]

- Tian, X.-Q.; Wang, X.-R.; Wei, Y.-D.; Liu, L.; Gong, Z.-R.; Gu, J.; Du, Y.; Yakobson, B.I. Highly tunable electronic structures of phosphorene/carbon nanotube heterostructures through external electric field and atomic intercalation. Nano Lett. 2017, 17, 7995–8004. [Google Scholar] [CrossRef] [PubMed]

- Hu, B.; Zhang, T.; Wang, K.; Wang, L.; Zhang, Y.; Gao, S.; Ye, X.; Zhou, Q.; Jiang, S.; Li, X.; et al. Narrow directed black phosphorus nanoribbons produced by a reformative mechanical exfoliation approach. Small 2023, 19, e2207538. [Google Scholar] [CrossRef]

- Enlai, G.; Zhen, L.S.; Zhao, Q.; Buehler, M.J.; Qiao, F.X.; Xu, Z. Mechanical exfoliation of two-dimensional materials. J. Mech. Phys. Solids 2018, 115, 248–262. [Google Scholar] [CrossRef]

- Viscardi, L.; Intonti, K.; Kumar, A.; Faella, E.; Pelella, A.; Giubileo, F.; Sleziona, S.; Kharsah, O.; Schleberger, M.; Di Bartolomeo, A. Black phosphorus nanosheets in field effect transistors with Ni and NiCr contacts. Phys. Status Solidi 2023, 260, 2200537. [Google Scholar] [CrossRef]

- Telesio, F.; le Gal, G.; Serrano-Ruiz, M.; Prescimone, F.; Toffanin, S.; Peruzzini, M.; Heun, S. Ohmic contact engineering in few–layer black phosphorus: Approaching the quantum limit. Nanotechnology 2020, 31, 334002. [Google Scholar] [CrossRef]

- Liu, H.; Neal, A.T.; Zhu, Z.; Luo, Z.; Xu, X.; Tomanek, D.; Ye, P.D. Phosphorene: An unexplored 2D semiconductor with a high hole mobility. ACS Nano 2014, 8, 4033–4041. [Google Scholar] [CrossRef]

- Chen, C.; Lin, Y.; Zhou, W.; Gong, M.; He, Z.; Shi, F.; Li, X.; Wu, J.Z.; Lam, K.T.; Wang, J.N.; et al. Sub-10-nm graphene nanoribbons with atomically smooth edges from squashed carbon nanotubes. Nat. Electron. 2021, 4, 653–663. [Google Scholar] [CrossRef]

- Kim, J.S.; Jeon, P.J.; Lee, J.; Choi, K.; Lee, H.S.; Cho, Y.; Lee, Y.T.; Hwang, D.K.; Im, S. Dual gate black phosphorus field effect transistors on glass for NOR logic and organic light emitting diode switching. Nano Lett. 2015, 15, 5778–5783. [Google Scholar] [CrossRef]

- Chen, C.; Lu, Y.; Kong, E.S.; Zhang, Y.; Lee, S.-T. Nanowelded carbon-nanotube-based solar microcells. Small 2008, 4, 1313–1318. [Google Scholar] [CrossRef]

- Chen, C.; Jin, T.; Wei, L.; Li, Y.; Liu, X.; Wang, Y.; Zhang, L.; Liao, C.; Hu, N.; Song, C.; et al. High-work-function metal/carbon nanotube/low-work-function metal hybrid junction photovoltaic device. NPG Asia Mater. 2015, 7, e220. [Google Scholar] [CrossRef]

- Hou, C.; Li, B.; Li, Q.; Yang, L.; Wang, Y.; Yang, Z.; Dong, L. Plasmon-enhanced photovoltaic characteristics of black phosphorus-MoS2 heterojunction. IEEE Open J. Nanotechnol. 2021, 2, 41–51. [Google Scholar] [CrossRef]

- Deng, Y.; Luo, Z.; Conrad, N.J.; Liu, H.; Gong, Y.; Najmaei, S.; Ajayan, P.M.; Lou, J.; Xu, X.; Ye, P.D. Black Phosphorus–Monolayer MoS2 van der Waals Heterojunction p–n Diode. ACS Nano 2014, 8, 8292–8299. [Google Scholar] [CrossRef]

- Zhang, T.-F.; Li, Z.-P.; Wang, J.-Z.; Kong, W.-Y.; Wu, G.-A.; Zheng, Y.-Z.; Zhao, Y.-W.; Yao, E.-X.; Zhuang, N.-X.; Luo, L.-B. Broadband photodetector based on carbon nanotube thin film/single layer graphene Schottky junction. Sci. Rep. 2016, 6, 38569. [Google Scholar] [CrossRef] [PubMed]

- Lu, R.; Christianson, C.; Weintrub, B.; Wu, J.Z. High Photoresponse in Hybrid Graphene–Carbon Nanotube Infrared Detectors. ACS Appl. Mater. Interfaces 2013, 5, 11703–11707. [Google Scholar] [CrossRef] [PubMed]

- Amani, M.; Tan, C.; Zhang, G.; Zhao, C.; Bullock, J.; Song, X.; Kim, H.; Shrestha, V.R.; Gao, Y.; Crozier, K.B.; et al. Solution-Synthesized high-mobility tellurium nanoflakes for short-wave infrared photodetectors. ACS Nano 2018, 12, 7253–7263. [Google Scholar] [CrossRef] [PubMed]

| Photosensitive Material of the Device | D*/Jones | External η/% | Incident Wavelength/nm | Device Type | Source |

|---|---|---|---|---|---|

| 2D BP/SWCNT film heterostructure | 3.1 × 109 | 7.5 | 1550 | Photovoltaic | This work |

| BP nanoflake | 1.83 × 108 | / | 830 | Photoconductive | 17 |

| carbon nanotube (CNT) parallel array | 1.09 × 107 | 0.0156 | 785 | Photovoltaic | 18 |

| CNT thin film/graphene Schottky junction | 1.0 × 108 | / | 980 | Photovoltaic | 34 |

| graphene/multiwall CNT nanohybrid | 1.5 × 107 | / | 1300 | Photovoltaic | 35 |

| 2D tellurium (Te) | 2.0 × 109 | / | 1700 | Photoconductive | 36 |

| BP/MoS2 heterosturcture | / | 0.195 | 830 | Photovoltaic | 32 |

| Pd/CNT/Al junction | / | 5.0 (intrinsic η) | 1550 | Photovoltaic | 31 |

| Pd/CNT/Sc junction | / | 0.11 | 785 | Photovoltaic | 13 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Y.; Li, Q.; Ye, X.; Wang, L.; He, Z.; Zhang, T.; Wang, K.; Shi, F.; Yang, J.; Jiang, S.; et al. High-Performance Infrared Detectors Based on Black Phosphorus/Carbon Nanotube Heterojunctions. Nanomaterials 2023, 13, 2700. https://doi.org/10.3390/nano13192700

Zhang Y, Li Q, Ye X, Wang L, He Z, Zhang T, Wang K, Shi F, Yang J, Jiang S, et al. High-Performance Infrared Detectors Based on Black Phosphorus/Carbon Nanotube Heterojunctions. Nanomaterials. 2023; 13(19):2700. https://doi.org/10.3390/nano13192700

Chicago/Turabian StyleZhang, Yanming, Qichao Li, Xiaowo Ye, Long Wang, Zhiyan He, Teng Zhang, Kunchan Wang, Fangyuan Shi, Jingyun Yang, Shenghao Jiang, and et al. 2023. "High-Performance Infrared Detectors Based on Black Phosphorus/Carbon Nanotube Heterojunctions" Nanomaterials 13, no. 19: 2700. https://doi.org/10.3390/nano13192700