Molecular Dynamics Simulation Analysis of Damage and Expansion Process of Nanoindentation Single-Crystal 3C-SiC Carbide Specimens at Different Temperature

Abstract

1. Introduction

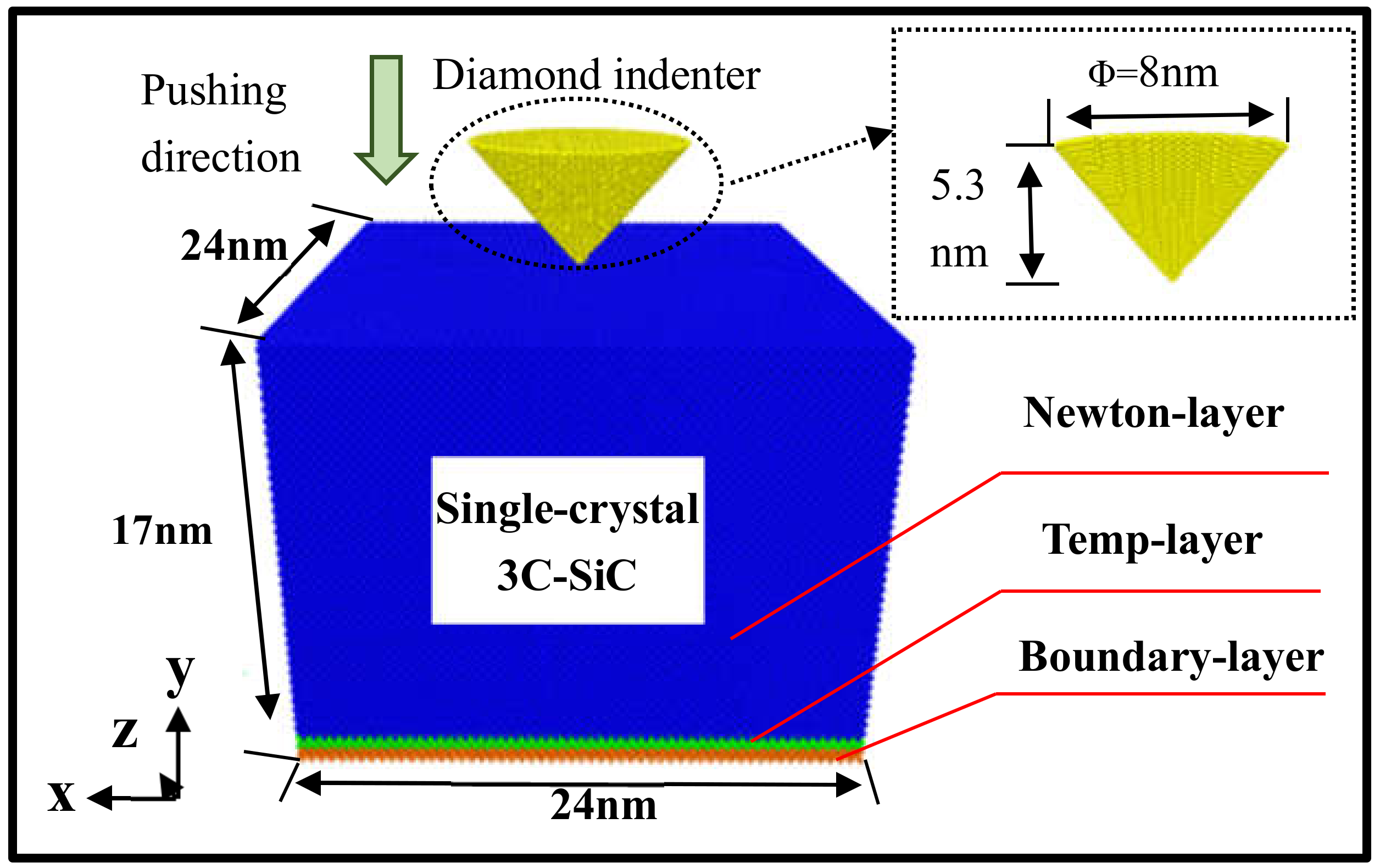

2. Model Building

2.1. Molecular Dynamics Model of Single Crystal 3C-SiC Indentation Process

2.2. Interatomic Potential Function

3. Numerical Solution Process

4. Results and Analysis

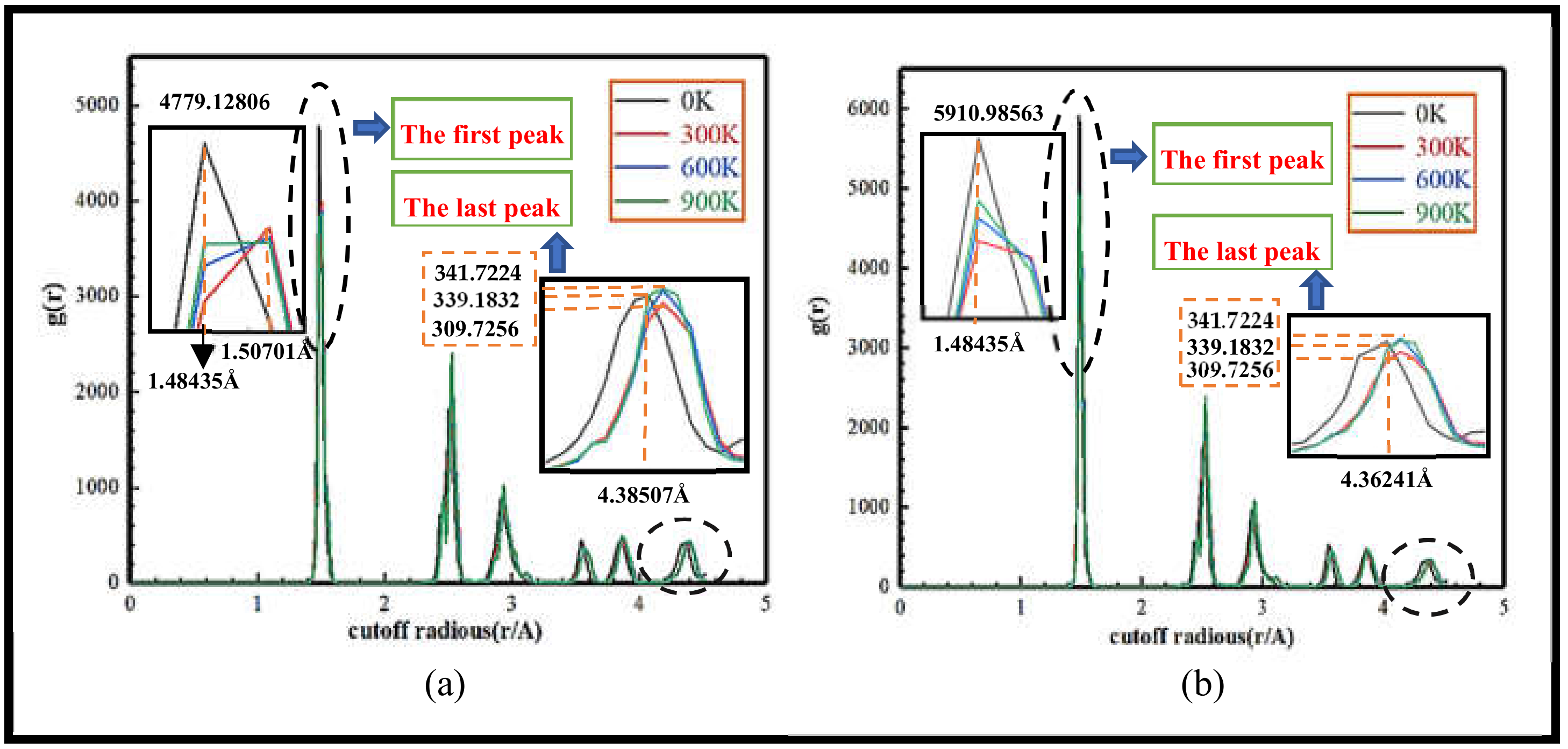

4.1. Single Crystal 3C-SiC Temperature Effect Analysis

4.2. Damage Analysis of Temperature Influence Indentation Loading Process

4.3. Dislocation Evolution and Extension Analysis

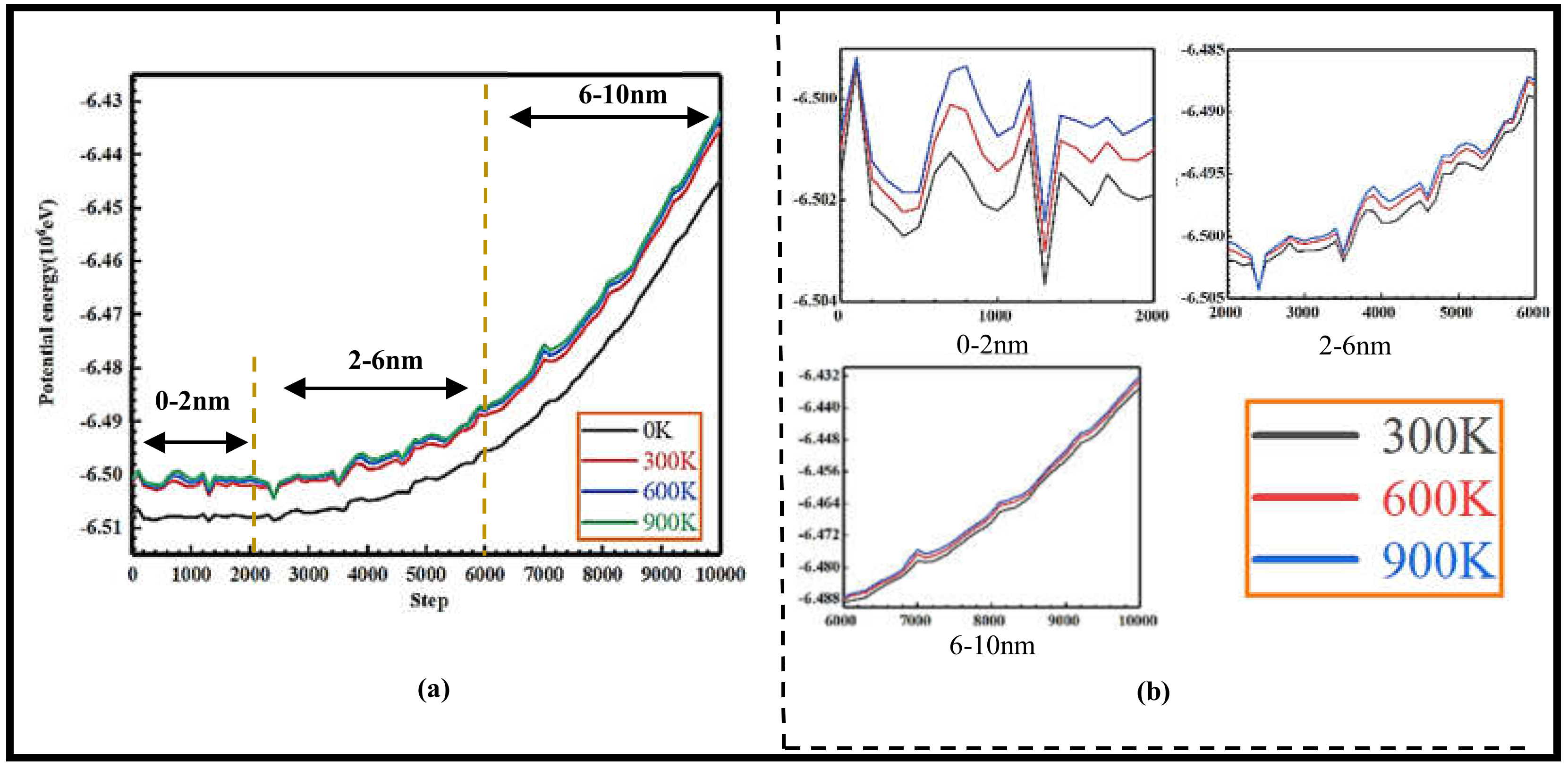

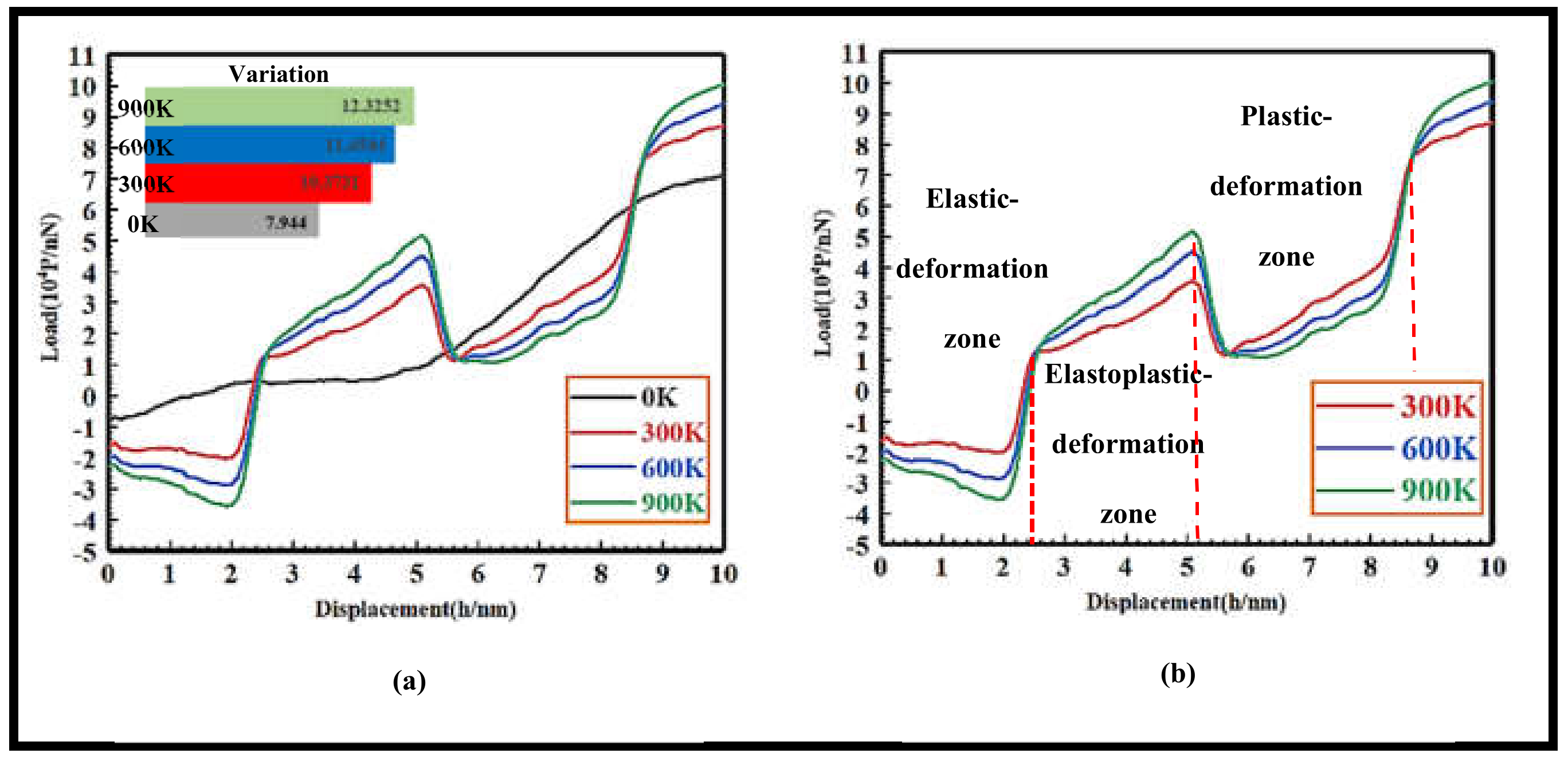

4.4. Potential Energy Change and Load Displacement Curve Analysis

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Wang, Y.; Zhou, P.; Zhao, Z. Preparation of Graphene Using 3C/4H-SiC Heterogeneous Epitaxial Films. Res. Prog. Solid State Electron. 2022, 42, 329–334. [Google Scholar]

- Wang, X.; Yang, T.; Hou, X.; Zheng, Y.; Wang, E.; Du, Z.; Cao, S.; Wang, H. Preparation of 2H/3C-SiC heterojunction nanowires from molten salt method with blue shift photoluminescence property. Ceram. Int. 2022, 48, 12971–12978. [Google Scholar] [CrossRef]

- Sameera, J.N.; Islam, M.A.; Islam, S.; Hossain, T.; Sobayel, M.K.; Akhtaruzzaman, M.; Amin, N.; Rashid, M.J. Cubic Silicon Carbide (3C-SiC) as a buffer layer for high efficiency and highly stable CdTe solar cell. Opt. Mater. 2022, 123, 111911. [Google Scholar] [CrossRef]

- Fan, T.; Liu, W.; Ruan, Z.; Cao, Y.; Ye, T.; Liu, J.; Zhong, F.; Tan, X.; Liang, H.; Chen, D.; et al. First-principies investigation of effects of defects on the physical properties of 3C-SiC under high temperatures and pressures. J. Mater. Res. Technol. 2022, 20, 3633–3645. [Google Scholar] [CrossRef]

- Daoud, S.; Bouarissa, N.; Rekab-Djabri, H.; Saini, P.K. Structural and Thermo-Physical Properties of 3C-SiC:High temperature and High-Pressure Effects. Silicon 2022, 14, 6299–6309. [Google Scholar] [CrossRef]

- Shinde, A.B.; Patil, S.; Patil, P.; Salunkhe, R.; Sande, R.; Pawar, S.; Patil, V. Dislocation and deformation analysis of Cu-Ni thin films during Nano-indentation using molecular dynamics simulation approach. Mater. Today Proc. 2022, 49, 1453–1461. [Google Scholar] [CrossRef]

- Wang, S.; He, X.; Yang, P.; Dou, Y. Dislocation Loop Formation in Refractory Metal under Nanoindentation Studied by Molecular Dynamics. At. Energy Sci. Technol. 2022, 56, 145–153. [Google Scholar]

- Li, R.; Wu, G.; Liang, K.; Wang, S.; Xue, L.; Sun, Y.; Dong, F.; Li, H.; Liu, S. Indenter radius effect on mechanical response of a-(11-20), c-(0001), and m-(-1100) plane GaN single crystals in nanoindentation: A molecular dynamics study. Mater. Sci. Semicond. Process. 2022, 145, 106648. [Google Scholar] [CrossRef]

- Huang, Y. Molecular dynamics of temperature influence of nanoindentation process. J. Syst. Simul. 2009, 21, 4454–4456. [Google Scholar]

- Sun, S.; Peng, X.; Xiang, H.; Huang, C.; Yang, B.; Gao, F.; Fu, T. Molecular dynamics simulation in single crystal 3C-SiC under nanoindentation:Formation of prismatic loops. Ceram. Int. 2017, 43, 16313–16318. [Google Scholar] [CrossRef]

- Zhao, L.; Alam, M.; Zhang, J.; Janisch, R.; Hartmaier, A. Amorphization-governed elasto-plastic deformation under nanoindentation in cubic (3C) silicon carbide. Ceram. Int. 2020, 46, 12470–12479. [Google Scholar] [CrossRef]

- Huseynov, E.M.; Naghiyev, T.G. Various thermal parameters investigation of 3C-SiC nanoparticles at the different heating rates. Appl. Phys. A 2022, 128, 115. [Google Scholar] [CrossRef]

- Li, Q.; Huang, C.; Liang, Y.; Fu, T.; Peng, T. Molecular Dynamics Simulation of Nanoindentation of Cu/Au Thin Films at Different Temperatures. J. Nanomater. 2016, 2016, 9265948. [Google Scholar] [CrossRef]

- Marinova, M.; Mantzari, A.; Beshkova, M.; Syväjärvi, M.; Yakimova, R.; Polychroniadis, E.K. The Influence of the Temperature Gradient on the Defect Structure of 3C-SiC Grown Heteroepitaxially on 6H-SiC by Sublimation Epitaxy. In Materials Science Forum; Trans Tech Publications, Ltd.: Bäch, Switzerland, 2010; Volume 907, pp. 645–648. [Google Scholar] [CrossRef]

- Zhu, Q.; Hu, J.; Yang, J.; Zhou, H.; Dong, S. Strong SiC Porous Ceramic Obtain by Sintering of Reticulated Aligned SiC Nanowires. J. Inorg. Mater. 2021, 36, 547. [Google Scholar] [CrossRef]

- Tao, P.; Ye, F.; Gong, J.; Barrett, R.A.; Leen, S.B. A dislocation-based yield strength model for nano-indentation size effect. J. Mater. Des. Appl. 2021, 235, 1238–1247. [Google Scholar] [CrossRef]

- Long, J.; Chen, W. Effects of surface tension on the nanoindentation with a conical indenter. Acta Mech. 2017, 228, 3533–3542. [Google Scholar] [CrossRef]

- Xiong, L.; Jifen, W.; Huaqing, X.; Zhang, X. Effect of vacancy defects on thermal conductivity of single-layer graphene by molecular dynamics. Energy Storage Sci. Technol. 2022, 11, 1322. [Google Scholar]

- Alamri, A.; Wu, C.; Mishra, A.; Chen, L.; Li, Z.; Deshmukh, A.; Zhou, J.; Yassin, O.; Ramprasad, R.; Vashishta, P.; et al. Improving the Rodational Freedom of Polytherimide:Enhancement of the Dielectric Properties of a Commodity High-Temperature Polymer Using a Structral Defect. Chem. Mater. 2022, 34, 6553–6558. [Google Scholar] [CrossRef]

- Verlet, L. Computer ‘experiment’ on classical fluids. I. Thermodynamical properties of Lennard-Jones molecules. Health Phys. 1967, 22, 79–85. [Google Scholar] [CrossRef]

- Tian, J.; Feng, Q.; Zheng, J. Molecular dynamics simulation of irradiation swelling and acrystallization of monocrystalline cubic silicon carbide. Mater. Rev. 2022, 36, 20100248–5. [Google Scholar]

- Hunter, A.; Preston, D.L. Analytic model of dislocation density evolution in fcc polycrystals accounting for dislocation generation, storage, and dynamic recovery mechanisms. Int. J. Plast. 2022, 151, 103178. [Google Scholar] [CrossRef]

| The Relevant Parameter | Parameter Values |

|---|---|

| Simulated box size Number of atoms in simulated box | 24 nm × 27.5 nm × 24 nm 1,039,657 |

| Indenter diameter Height of the indenter Number of atoms in cone head | 8 nm 5.3 nm 24,409 |

| 3C-SiC Workpiece size | 24 nm × 17 nm × 24 nm |

| Indentation crystal Ensemble Pushing speed Depth of indentation Temperature Timestep | (010) (NPT) 20 m/s 10 nm 0 K, 300 K, 600 K, 900 K 1 fs |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ning, X.; Wu, N.; Zhong, M.; Wen, Y.; Li, B.; Jiang, Y. Molecular Dynamics Simulation Analysis of Damage and Expansion Process of Nanoindentation Single-Crystal 3C-SiC Carbide Specimens at Different Temperature. Nanomaterials 2023, 13, 235. https://doi.org/10.3390/nano13020235

Ning X, Wu N, Zhong M, Wen Y, Li B, Jiang Y. Molecular Dynamics Simulation Analysis of Damage and Expansion Process of Nanoindentation Single-Crystal 3C-SiC Carbide Specimens at Different Temperature. Nanomaterials. 2023; 13(2):235. https://doi.org/10.3390/nano13020235

Chicago/Turabian StyleNing, Xiang, Nanxing Wu, Mengjuan Zhong, Yuwei Wen, Bin Li, and Yi Jiang. 2023. "Molecular Dynamics Simulation Analysis of Damage and Expansion Process of Nanoindentation Single-Crystal 3C-SiC Carbide Specimens at Different Temperature" Nanomaterials 13, no. 2: 235. https://doi.org/10.3390/nano13020235

APA StyleNing, X., Wu, N., Zhong, M., Wen, Y., Li, B., & Jiang, Y. (2023). Molecular Dynamics Simulation Analysis of Damage and Expansion Process of Nanoindentation Single-Crystal 3C-SiC Carbide Specimens at Different Temperature. Nanomaterials, 13(2), 235. https://doi.org/10.3390/nano13020235