Nanomechanics of Ultrathin Carbon Nanomembranes

Abstract

:1. Introduction

2. Materials and Methods

2.1. Synthesis of CNMs and CNM/PET Composites

2.2. Transfer of CNMs on Substrates for AFM Measurements

2.3. AFM Characterization

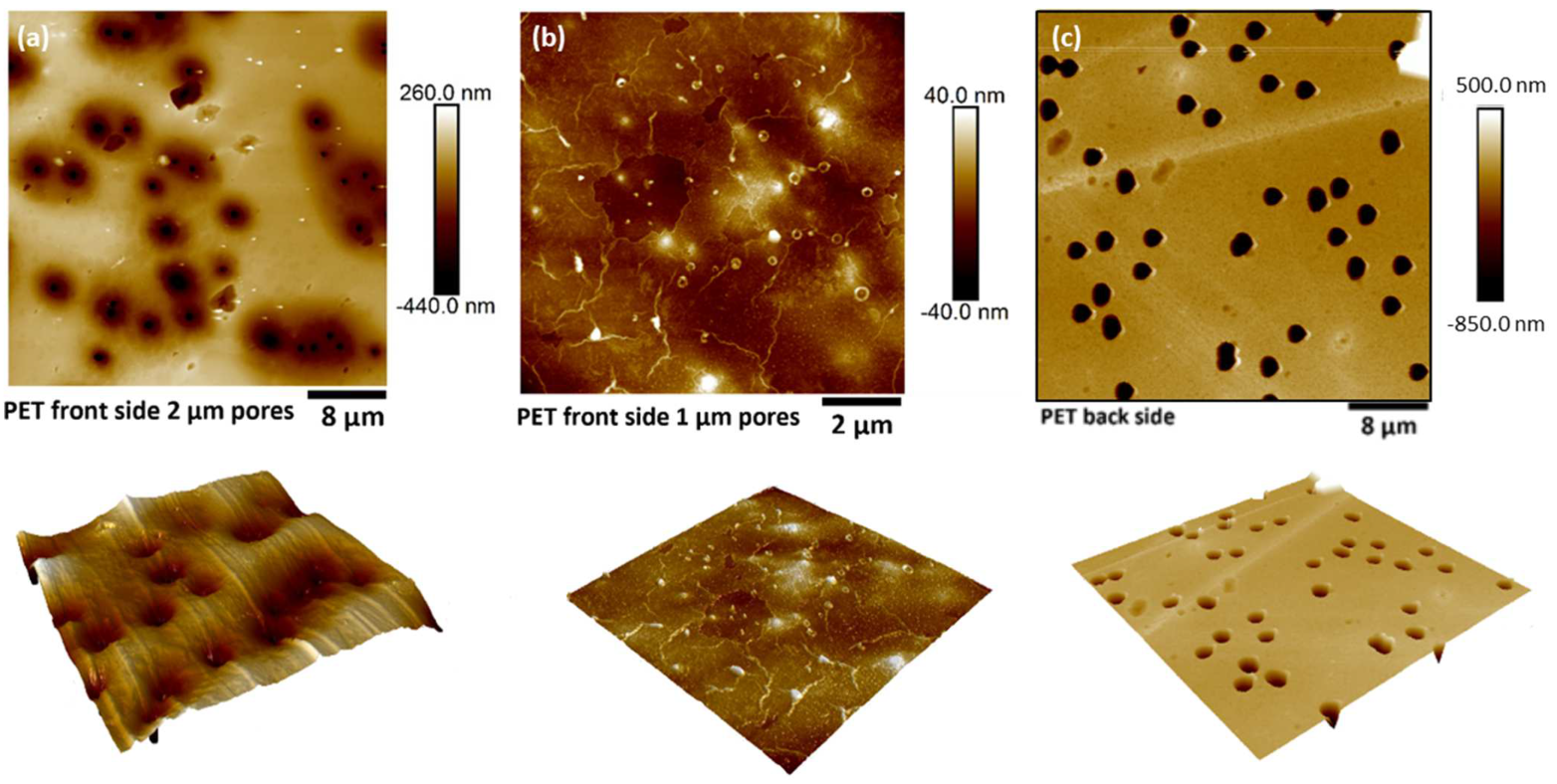

2.4. Composite Tensile Tests on Track-Etched Substrates

2.5. Thermogravimetric Analysis

3. Results and Discussion

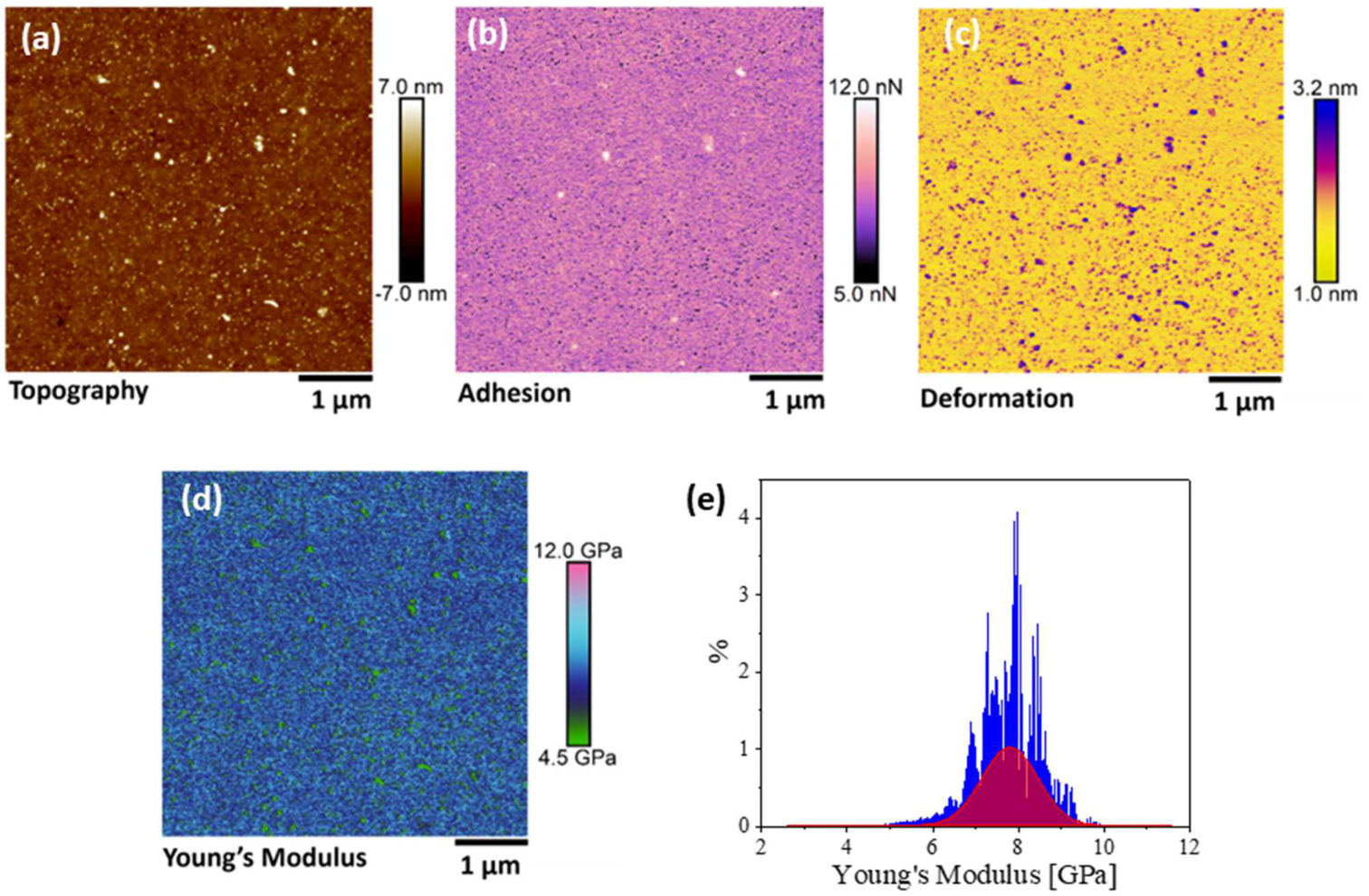

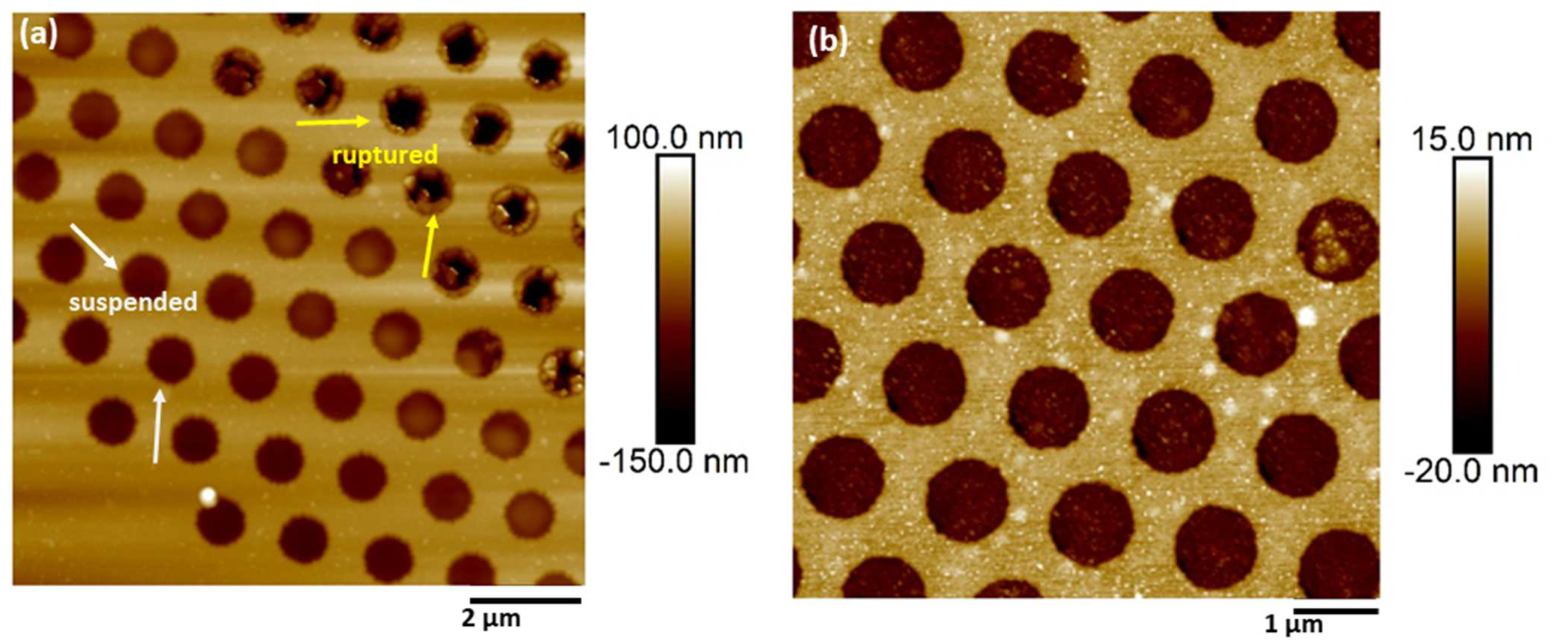

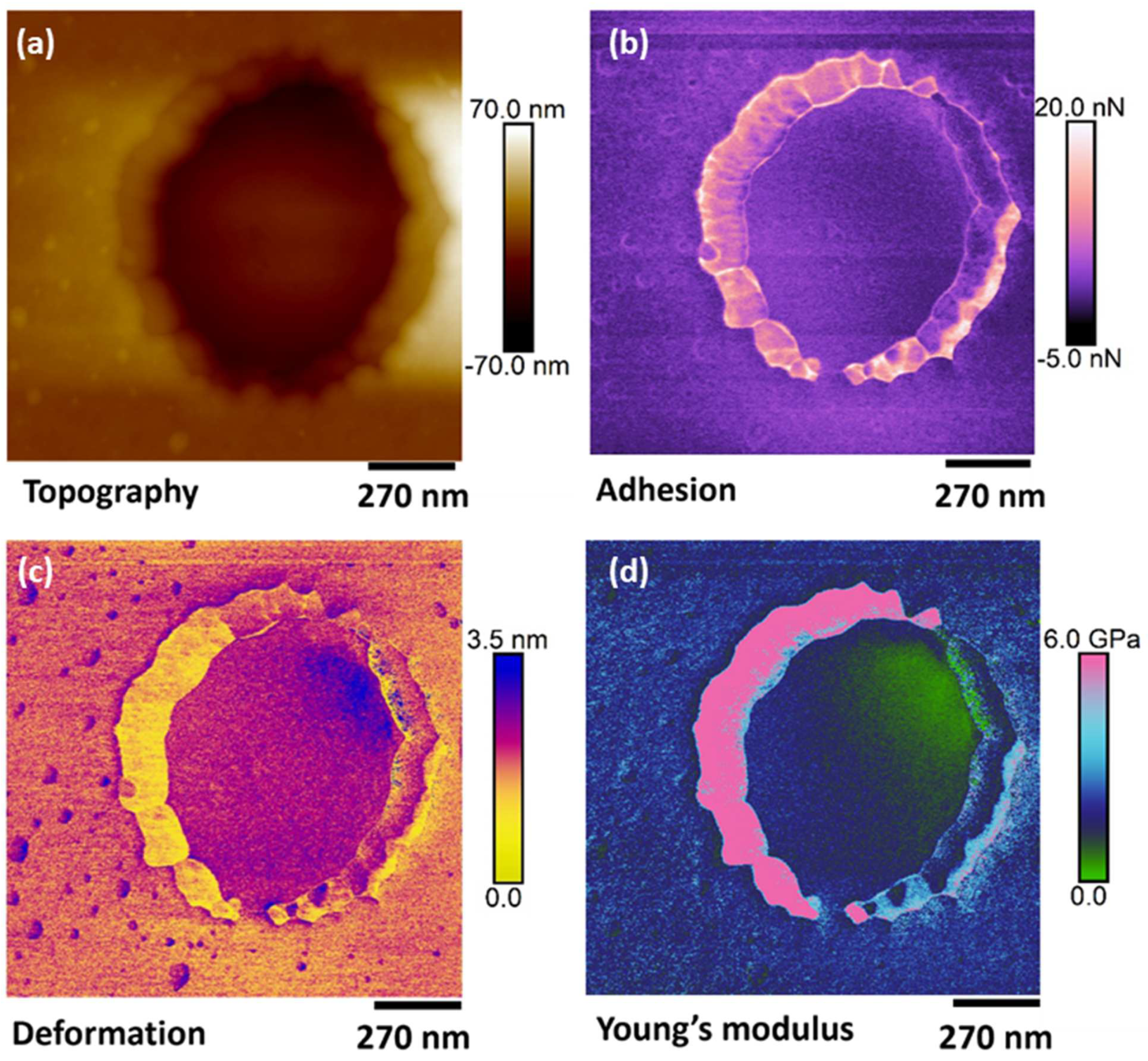

3.1. Mechanical Properties of CNMs

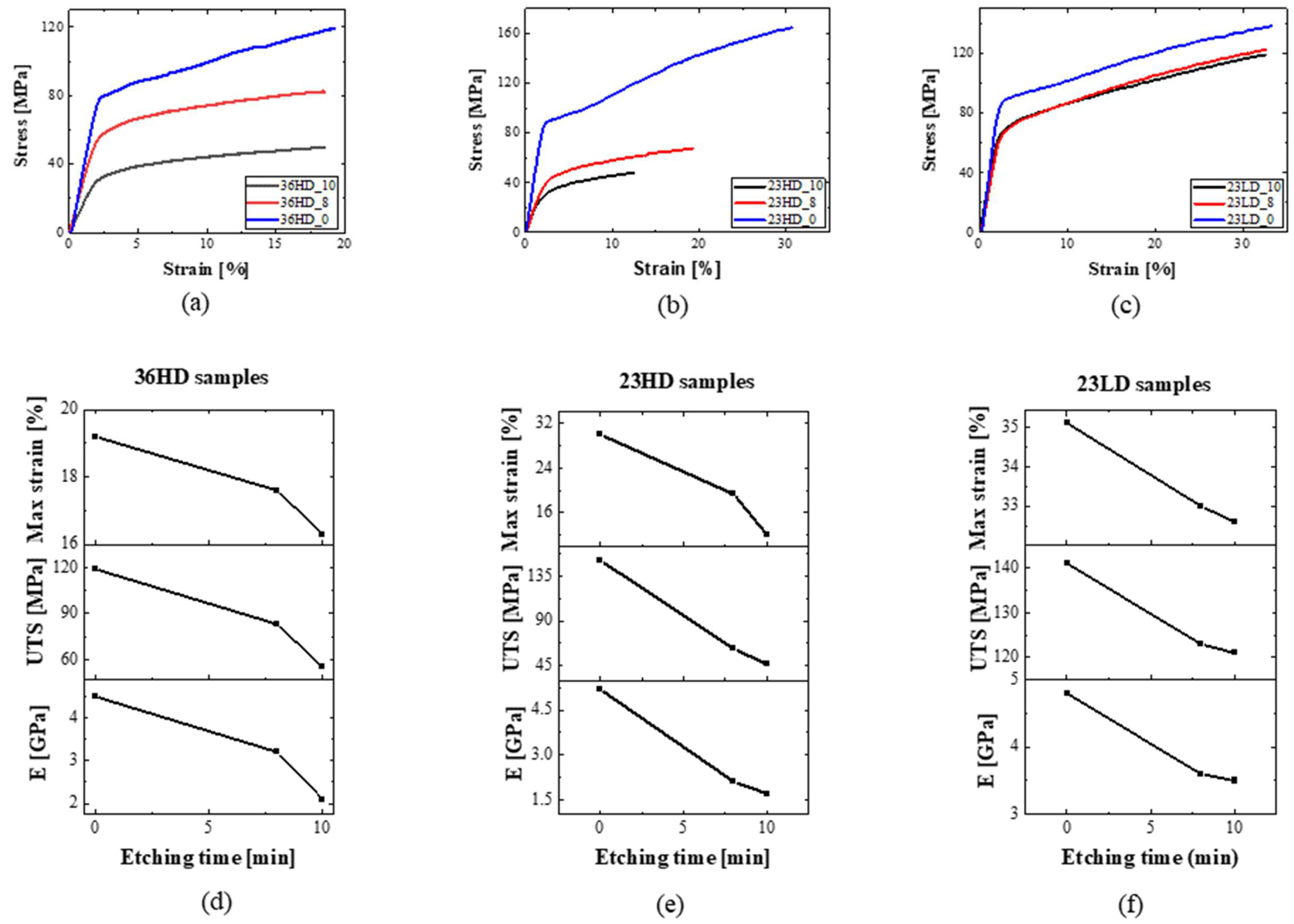

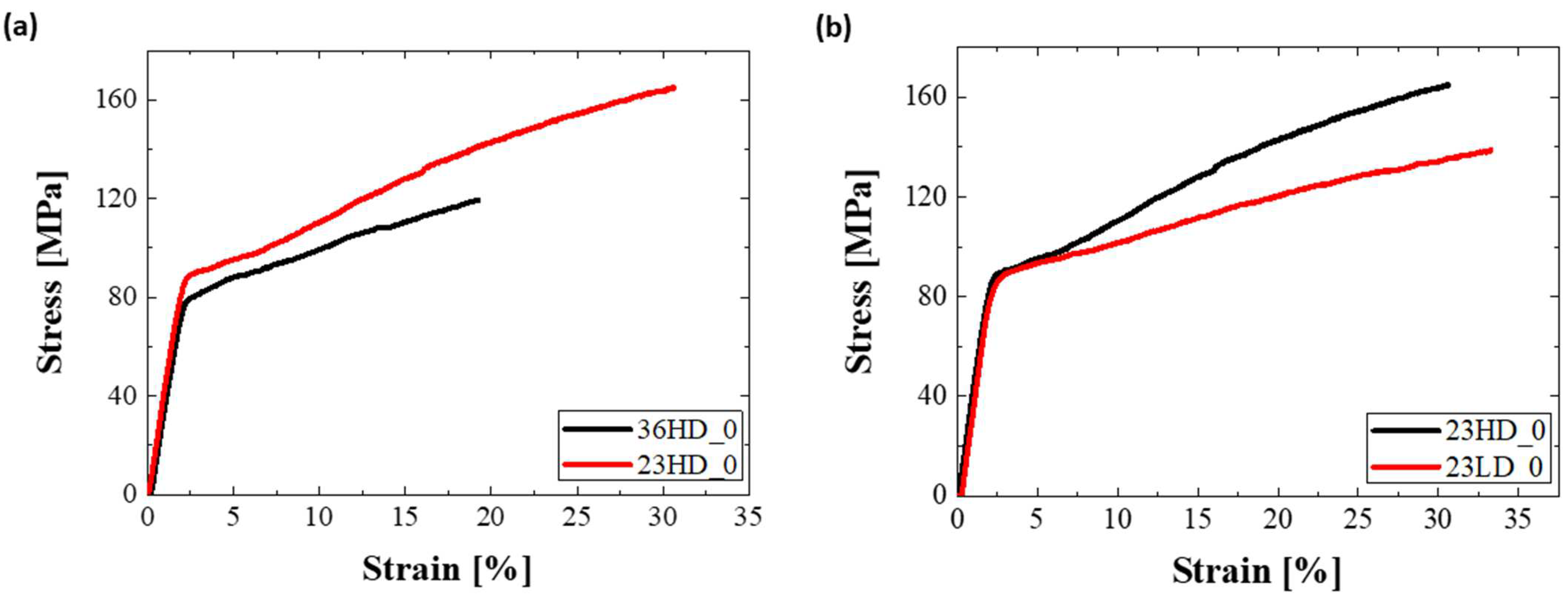

3.2. CNM-Composite Membrane Tensile Tests

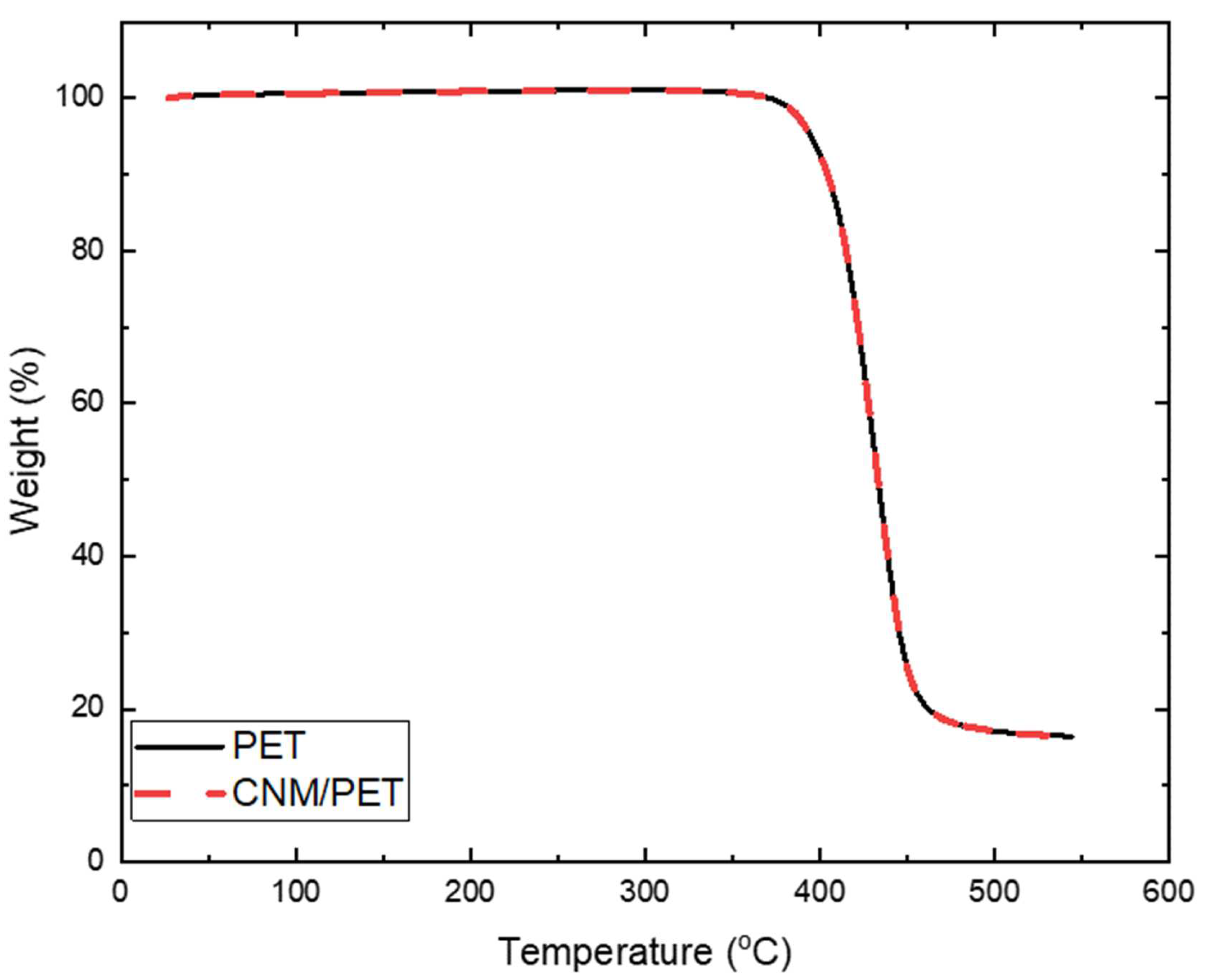

3.3. Thermogravimetry of CNMs/Substrates

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Gonzales, L.G.V.; Avila, F.F.G.; Torres, R.J.C.; Olivera, C.A.C.; Paredes, E.A.A. Scientometric study of drinking water treatments technologies: Present and future challenges. Cogent Eng. 2021, 8, 1929046. [Google Scholar] [CrossRef]

- Theerthagiri, J.; Lee, S.J.; Karuppasamy, K.; Arulmani, S.; Veeralakshmi, S.; Ashokkumar, M.; Choi, M.Y. Application of advanced materials in sonophotocatalytic processes for the remediation of environmental pollutants. J. Hazard. Mater. 2021, 412, 125245. [Google Scholar] [CrossRef] [PubMed]

- Liu, G.P.; Jin, W.Q.; Xu, N.P. Two-Dimensional-Material Membranes: A New Family of High-Performance Separation Membranes. Angew. Chem. 2016, 55, 13384–13397. [Google Scholar] [CrossRef]

- Kim, S.; Wang, H.T.; Lee, Y.M. 2D Nanosheets and Their Composite Membranes for Water, Gas, and Ion Separation. Angew. Chem. 2019, 58, 17512–17527. [Google Scholar] [CrossRef] [Green Version]

- Liu, G.P.; Jin, W.Q.; Xu, N.P. Graphene-based membranes. Chem. Soc. Rev. 2015, 44, 5016–5030. [Google Scholar] [CrossRef] [PubMed]

- Kanaun, S. On the hydraulic fracture of poroelastic media. Int. J. Eng. Sci. 2020, 155, 103366. [Google Scholar] [CrossRef]

- Wang, C.; Park, M.J.; Yu, H.W.; Matsuyama, H.; Drioli, E.; Shon, H.K. Recent advances of nanocomposite membranes using layer-by-layer assembly. J. Membrane Sci. 2022, 661, 120926. [Google Scholar] [CrossRef]

- Norfarhana, A.S.; Ilyas, R.A.; Ngadi, N.; Sharma, S.; Sayed, M.M.; El-Shafay, A.S.; Nordin, A.H. Natural Fiber-Reinforced Thermoplastic ENR/PVC Composites as Potential Membrane Technology in Industrial Wastewater Treatment: A Review. Polymers 2022, 14, 2432. [Google Scholar] [CrossRef]

- HMTShirazi, R.; Mohammadi, T.; Asadi, A.A.; Tofighy, M.A. Electrospun nanofiber affinity membranes for water treatment applications: A review. J. Water Proc. Eng. 2022, 47, 102795. [Google Scholar] [CrossRef]

- Anagnostopoulos, G.; Androulidakis, C.; Koukaras, E.N.; Tsoukleri, G.; Polyzos, I.; Parthenios, J.; Papagelis, K.; Galiotis, C. Stress Transfer Mechanisms at the Submicron Level for Graphene/Polymer Systems. ACS Appl. Mater. Inter. 2015, 7, 4216–4223. [Google Scholar] [CrossRef]

- Turchanin, A.; Golzhauser, A. Carbon Nanomembranes. Adv. Mater. 2016, 28, 6075–6103. [Google Scholar] [CrossRef] [PubMed]

- Zhang, X.H.; Neumann, C.; Angelova, P.; Beyer, A.; Golzhauser, A. Tailoring the Mechanics of Ultrathin Carbon Nanomembranes by Molecular Design. Langmuir 2014, 30, 8221–8227. [Google Scholar] [CrossRef] [PubMed]

- Angelova, P.; Vieker, H.; Weber, N.E.; Matei, D.; Reimer, O.; Meier, I.; Kurasch, S.; Biskupek, J.; Lorbach, D.; Wunderlich, K.; et al. A Universal Scheme to Convert Aromatic Molecular Monolayers into Functional Carbon Nanomembranes. ACS Nano 2013, 7, 6489–6497. [Google Scholar] [CrossRef] [PubMed]

- Yang, Y.; Dementyev, P.; Biere, N.; Emmrich, D.; Stohmann, P.; Korzetz, R.; Zhang, X.H.; Beyer, A.; Koch, S.; Anselmetti, D.; et al. Rapid Water Permeation Through Carbon Nanomembranes with Sub-Nanometer Channels. ACS Nano 2018, 12, 4695–4701. [Google Scholar] [CrossRef] [PubMed]

- Yang, Y.; Hillmann, R.; Qi, Y.B.; Korzetz, R.; Biere, N.; Emmrich, D.; Westphal, M.; Buker, B.; Hutten, A.; Beyer, A.; et al. Ultrahigh Ionic Exclusion through Carbon Nanomembranes. Adv. Mater. 2020, 32, 1907850. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Meyerbröker, N.; Angelova, P.; Schnieders, A.; Vieker, H. Carbon Nanomembranes on Porous Materials. International Patent Application WO 2019/228956 A1, 5 December 2019. [Google Scholar]

- Madauss, L.; Schumacher, J.; Ghosh, M.; Ochedowski, O.; Meyer, J.; Lebius, H.; Ban-d’Etat, B.; Toimil-Molares, M.E.; Trautmann, C.; Lammertink, R.G.H.; et al. Fabrication of nanoporous graphene/polymer composite membranes. Nanoscale 2017, 9, 10487–10493. [Google Scholar] [CrossRef]

- Stoltenberg, R.M.; Heise, S.E.; Sinton, S.W. Nanoporous membranes and methods for making the same. U.S. Patent 9,505,192 B2, 29 November 2016. [Google Scholar]

- Spohr, R.; Bethge, K. Ion Tracks and Microtechnology: Principles and Applications; Vieweg: Braunschweig, Germany, 1990; p. 272. [Google Scholar]

- Akinwande, D.; Brennan, C.J.; Bunch, J.S.; Egberts, P.; Felts, J.R.; Gao, H.J.; Huang, R.; Kim, J.S.; Li, T.; Li, Y.; et al. A review on mechanics and mechanical properties of 2D materials-Graphene and beyond. Extreme Mech. Lett. 2017, 13, 42–77. [Google Scholar] [CrossRef] [Green Version]

- Androulidakis, C.; Zhang, K.H.; Robertson, M.; Tawfick, S. Tailoring the mechanical properties of 2D materials and heterostructures. 2D Mater. 2018, 5, 032005. [Google Scholar] [CrossRef]

- Zhang, X.H.; Beyer, A. Mechanics of free-standing inorganic and molecular 2D materials. Nanoscale 2021, 13, 1443–1484. [Google Scholar] [CrossRef]

- Li, P.F.; Kang, Z.; Zhang, Z.; Liao, Q.L.; Rao, F.; Lu, Y.; Zhang, Y. In situ microscopy techniques for characterizing the mechanical properties and deformation behavior of two-dimensional (2D) materials. Mater. Today 2021, 51, 247–272. [Google Scholar] [CrossRef]

- Li, X.; Sun, M.; Shan, C.X.; Chen, Q.; Wei, X.L. Mechanical Properties of 2D Materials Studied by In Situ Microscopy Techniques. Adv. Mater. Interfaces 2018, 5, 1701246. [Google Scholar] [CrossRef]

- Angelova, P.; Schnieders, A. Method for manufacturing of a Carbon Nanomembrane. U.S. Patent 10,646,831 B2, 12 May 2020. [Google Scholar]

- Shearer, C.J.; Slattery, A.D.; Stapleton, A.J.; Shapter, J.G.; Gibson, C.T. Accurate thickness measurement of graphene. Nanotechnology 2016, 27, 125704. [Google Scholar] [CrossRef] [PubMed]

- Gölzhäuser, A.; Nottbohm, C.; Beyer, A. Beyer Method for transferring a nanolayer. U.S. Patent 8,377,243 B2, 19 February 2013. [Google Scholar]

- PeakForce QNM. Available online: https://www.bruker.com/en/products-and-solutions/microscopes/materials-afm/afm-modes/peakforce-qnm.html (accessed on 25 November 2022).

- Sader, J.E.; Borgani, R.; Gibson, C.T.; Haviland, D.B.; Higgins, M.J.; Kilpatrick, J.I.; Lu, J.N.; Mulvaney, P.; Shearer, C.J.; Slattery, A.D.; et al. A virtual instrument to standardise the calibration of atomic force microscope cantilevers. Rev. Sci. Instrum. 2016, 87, 093711. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Carbone, M.G.P.; Manikas, A.C.; Souli, I.; Pavlou, C.; Galiotis, C. Mosaic pattern formation in exfoliated graphene by mechanical deformation. Nat. Commun. 2019, 10, 1–7. [Google Scholar] [CrossRef] [Green Version]

- Castellanos-Gomez, A.; Poot, M.; Steele, G.A.; van der Zant, H.S.J.; Agrait, N.; Rubio-Bollinger, G. Elastic Properties of Freely Suspended MoS2 Nanosheets. Adv. Mater. 2012, 24, 772–775. [Google Scholar] [CrossRef] [Green Version]

- Lee, C.; Wei, X.D.; Kysar, J.W.; Hone, J. Measurement of the elastic properties and intrinsic strength of monolayer graphene. Science 2008, 321, 385–388. [Google Scholar] [CrossRef]

- Huang, M.H.; Meng, L.J.; Li, B.B.; Niu, F.H.; Lv, Y.; Deng, Q.; Li, J. Fabrication of innovative forward osmosis membranes via multilayered interfacial polymerization on electrospun nanofibers. J. Appl. Polym. Sci. 2019, 136, 47247. [Google Scholar] [CrossRef]

- Shah, A.A.; Cho, Y.H.; Nam, S.E.; Park, A.; Park, Y.I.; Park, H. High performance thin-film nanocomposite forward osmosis membrane based on PVDF/bentonite nanofiber support. J. Ind. Eng. Chem. 2020, 86, 90–99. [Google Scholar] [CrossRef]

- Wang, K.; Abdalla, A.A.; Khaleel, M.A.; Hilal, N.; Khraisheh, M.K. Mechanical properties of water desalination and wastewater treatment membranes. Desalination 2017, 401, 190–205. [Google Scholar] [CrossRef] [Green Version]

- Lin, X.; Hong, J. Recent Advances in Robust Superwettable Membranes for Oil-Water Separation. Adv. Mater. Interfaces 2019, 6, 1900126. [Google Scholar] [CrossRef]

- Mousa, H.M.; Fahmy, H.S.; Ali, G.A.M.; Abdelhamid, H.N.; Ateia, M. Membranes for Oil/Water Separation: A Review. Adv. Mater. Interfaces 2022, 9, 2200577. [Google Scholar] [CrossRef]

- Manawi, Y.M.; Wang, K.; Kochkodan, V.; Johnson, D.J.; Atieh, M.A.; Khraisheh, M.K. Engineering the Surface and Mechanical Properties of Water Desalination Membranes Using Ultralong Carbon Nanotubes. Membranes 2018, 8, 106. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Wang, H.; Li, Z.X.; Liu, Y.Q.; Zhang, X.P.; Zhang, S.J. Degradation of poly(ethylene terephthalate) using ionic liquids. Green Chem. 2009, 11, 1568–1575. [Google Scholar] [CrossRef]

| Sample | Etching Time (min) | Thickness (μm) | Pore Density (cm−2) |

|---|---|---|---|

| 36HD_10 | 10 | 36 | 20 × 106 |

| 36HD_8 | 8 | 36 | 20 × 106 |

| 36HD_0 | 0 | 36 | 20 × 106 |

| 23HD_10 | 10 | 23 | 20 × 106 |

| 23HD_8 | 8 | 23 | 20 × 106 |

| 23HD_0 | 0 | 23 | 20 × 106 |

| 23LD_10 | 10 | 23 | 1.5 × 106 |

| 23LD_8 | 8 | 23 | 1.5 × 106 |

| 23LD_0 | 0 | 23 | 1.5 × 106 |

| Sample | Young’s Modulus (GPa) | Ultimate Strength (MPa) | Strain (%) |

|---|---|---|---|

| 36HD_10 | 2.1 ± 0.3 | 55 ± 8 | 16.3 ± 2.0 |

| 36HD_8 | 3.2 ± 0.6 | 83 ± 9 | 17.6 ± 2.5 |

| 36HD_0 | 4.5 ± 0.4 | 119 ± 11 | 19.2 ± 2.7 |

| 23HD_10 | 1.7 ± 0.3 | 46 ± 4 | 12.0 ± 2.0 |

| 23HD_8 | 2.1 ± 0.3 | 62 ± 12 | 19.3 ± 0.5 |

| 23HD_0 | 5.2 ± 0.7 | 159 ± 14 | 30.1 ± 1.5 |

| 23LD_10 | 3.5 ± 0.3 | 121 ± 8 | 32.6 ± 2.5 |

| 23LD_8 | 3.6 ± 0.7 | 123 ± 3 | 33.0 ± 1.7 |

| 23LD_0 | 4.8 ± 0.2 | 141 ± 12 | 35.1 ± 2.8 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dimitropoulos, M.; Trakakis, G.; Meyerbröker, N.; Gehra, R.; Angelova, P.; Schnieders, A.; Pavlou, C.; Kostaras, C.; Galiotis, C.; Dassios, K. Nanomechanics of Ultrathin Carbon Nanomembranes. Nanomaterials 2023, 13, 267. https://doi.org/10.3390/nano13020267

Dimitropoulos M, Trakakis G, Meyerbröker N, Gehra R, Angelova P, Schnieders A, Pavlou C, Kostaras C, Galiotis C, Dassios K. Nanomechanics of Ultrathin Carbon Nanomembranes. Nanomaterials. 2023; 13(2):267. https://doi.org/10.3390/nano13020267

Chicago/Turabian StyleDimitropoulos, Marinos, George Trakakis, Nikolaus Meyerbröker, Raphael Gehra, Polina Angelova, Albert Schnieders, Christos Pavlou, Christos Kostaras, Costas Galiotis, and Konstantinos Dassios. 2023. "Nanomechanics of Ultrathin Carbon Nanomembranes" Nanomaterials 13, no. 2: 267. https://doi.org/10.3390/nano13020267

APA StyleDimitropoulos, M., Trakakis, G., Meyerbröker, N., Gehra, R., Angelova, P., Schnieders, A., Pavlou, C., Kostaras, C., Galiotis, C., & Dassios, K. (2023). Nanomechanics of Ultrathin Carbon Nanomembranes. Nanomaterials, 13(2), 267. https://doi.org/10.3390/nano13020267