Abstract

In response to the issues of environment, climate, and human health coupled with the growing demand for energy due to increasing population and technological advancement, the concept of sustainable and renewable energy is presently receiving unprecedented attention. To achieve these feats, energy savings and efficiency are crucial in terms of the development of energy-efficient devices and thermal fluids. Limitations associated with the use of conventional thermal fluids led to the discovery of energy-efficient fluids called “nanofluids, which are established to be better than conventional thermal fluids. The current research progress on nanofluids has led to the development of the advanced nanofluids coined “hybrid nanofluids” (HNFs) found to possess superior thermal-optical properties than conventional thermal fluids and nanofluids. This paper experimentally explored the published works on the application of HNFs as thermal transport media in solar energy collectors and thermal energy storage. The performance of hybrid nano-coolants and nano-thermal energy storage materials has been critically reviewed based on the stability, types of hybrid nanoparticles (HNPs) and mixing ratios, types of base fluids, nano-size of HNPs, thermal and optical properties, flow, photothermal property, functionalization of HNPs, magnetic field intensity, and orientation, and φ, subject to solar and thermal energy storage applications. Various HNFs engaged in different applications were observed to save energy and increase efficiency. The HNF-based media performed better than the mono nanofluid counterparts with complementary performance when the mixing ratios were optimized. In line with these applications, further experimental studies coupled with the influence of magnetic and electric fields on their performances were research gaps to be filled in the future. Green HNPs and base fluids are future biomaterials for HNF formulation to provide sustainable, low-cost, and efficient thermal transport and energy storage media.

1. Introduction

The ever-growing global demand for energy can be linked to population explosion and economic and technological growth, which are the primary causative factors. As the major primary sources of energy, fossil fuels (coal, natural gas, and oil) consumption in various energy sectors (residential, industrial, transportation, etc.) of the global economy has led to the release of obnoxious gases and particulates into the atmosphere [1,2,3]. The aftermaths of these global actions are at present of serious concern in terms of environmental, climate, and health implications coupled with the attendant climate change and global warming. Collective efforts by most countries of the world toward ameliorating the consequences of global warming and climate change as championed by the United Nations (UN) birthed the Millennium Development Goals (2000–2015) and Sustainable Developments Goals (2015–2030). The Sustainable Development Goals (SDGs) have significantly oiled the global slogan “sustainability”, which is presently applicable to virtually all sectors of human endeavours. Sustainable manufacturing and sustainable energy are key components of the 17-point SDGs as reflected in SDG 12 and SDG 7, respectively, and are strongly connected to the nanotechnology revolution [4].

Prior to the advent of nanotechnology which spurred pioneering research in the field of heat transfer leading to the formulation of nanomaterials, such as nanofluids and nano-lubricants, cooling and lubrication of energy systems have been conducted using traditional thermal fluids (water, oil, ethylene glycol, thermal oil, transformer oil, air, etc.). For decades, studies have been performed using conventional thermal fluids in addition to surface area/volume ratio reduction, surface modification, miniaturization, and surface extension (fins) to improve heat transfer in thermal equipment. However, the thermal fluids and techniques have reached their practicable thresholds with little or no thermal improvement [5,6]. The state-of-the-art technologies in various sectors of the economy (power plants, electronics, communication, agriculture, industry, automobile, aviation, medicine, computing, space exploration, and power systems) are notable for the generation of high heat flux and have necessitated the speedy removal of such heat flux to avoid material failure culminating in system failure. These challenges call for a solution and energy-efficient fluids such as nanofluids appear to fit into this [7,8].

The low κ and coefficient of heat transfer of conventional thermal fluids led to an extensive search for energy-efficient fluids as pioneered by Maxwell [9], Ahuja [10], and Masuda et al. [11]. Behind these pioneering efforts was the intention to improve the κ and consequently the coefficient of heat transfer by adding micro-size and nano-size particles of metals and non-metals with higher κ into conventional thermal fluids. Finally, the deposition of the nano-size particles (SiO2, TiO2, and Al2O3) into water yielded higher κ compared with water [11]. The resulting energy-efficient fluids were coined “nanofluids” two and a half decades ago [12]. After 12 years of intensive studies on different types of nanofluids (NFs) in terms of various types of nanoparticles (NPs), diverse base fluids, and different thermal properties, as advanced thermal fluids in various applications, the innovative concept of combining two or more NPs at different mixing ratios (volume or mass) was introduced by Chopkar et al. [13] and Jana et al. [14]. The intention was to synergize the thermal properties of different NPs to formulate hybrid nanofluids (HNFs) with improved properties compared with mono nanofluids (MNFs).

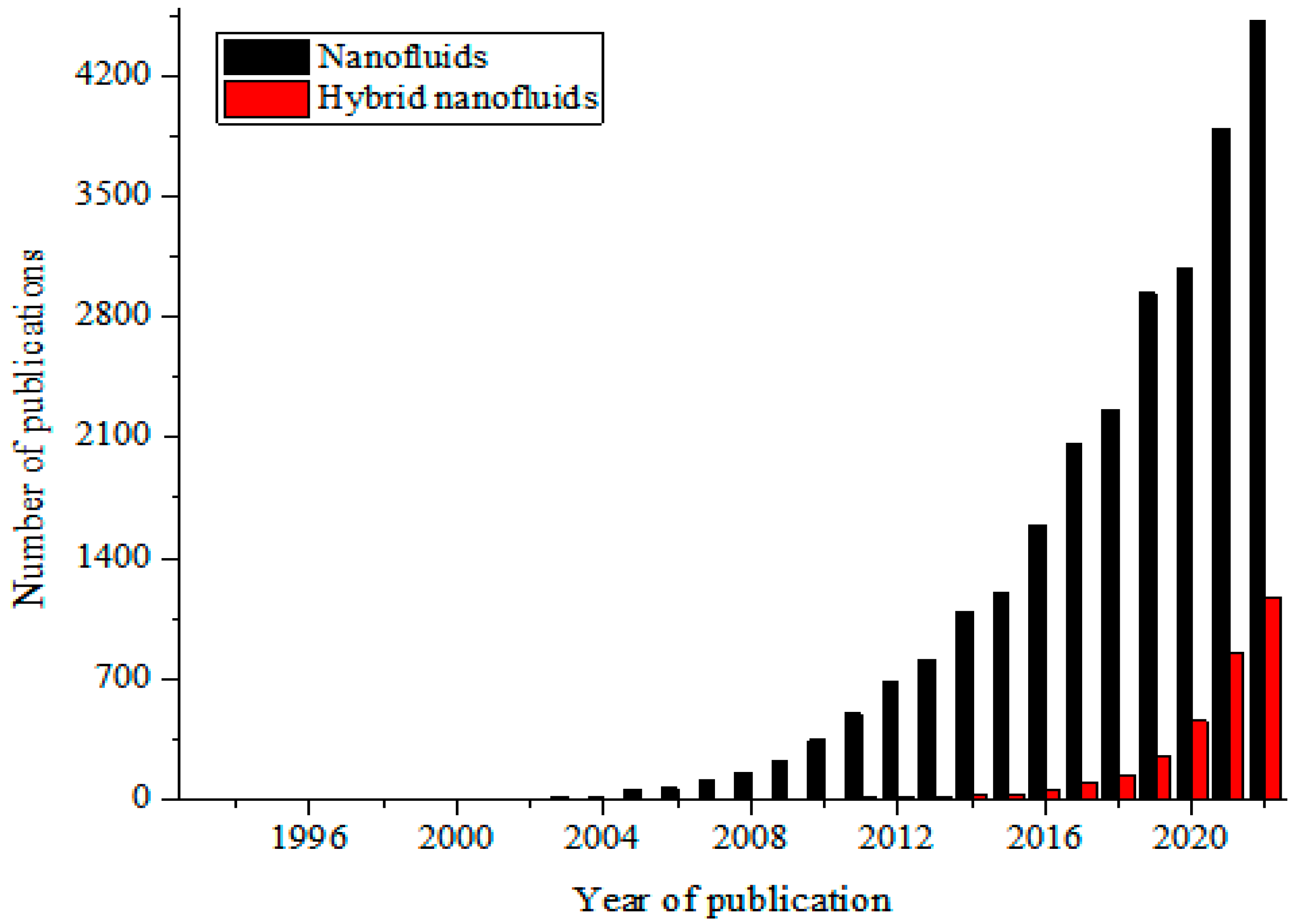

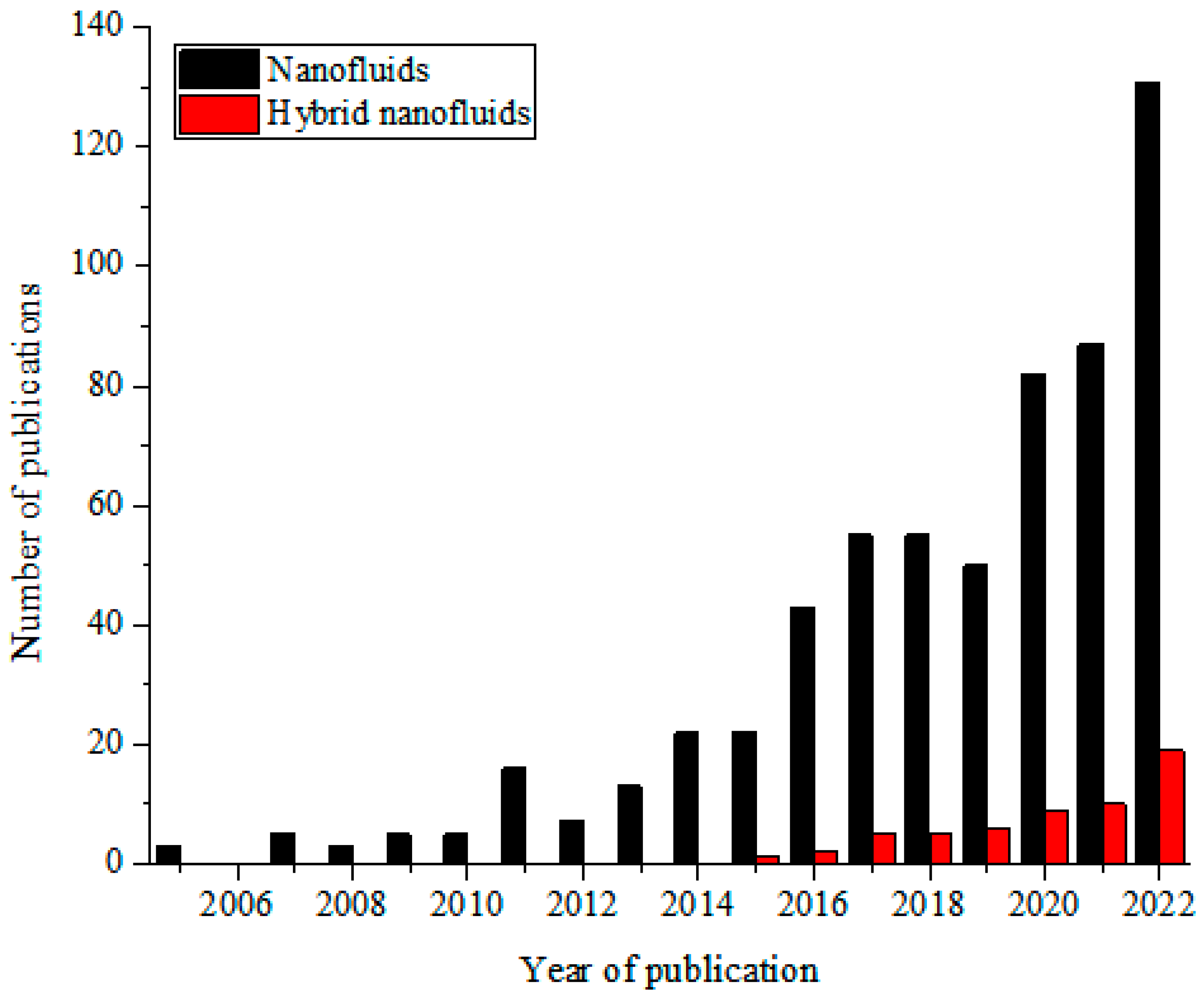

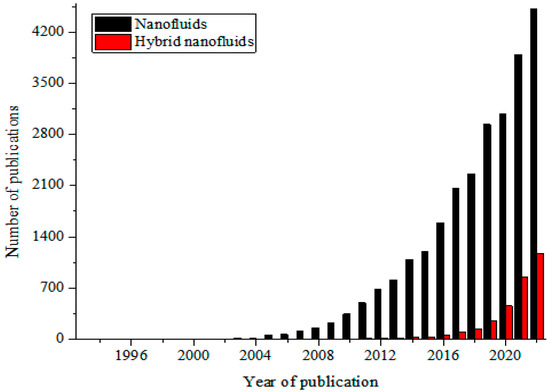

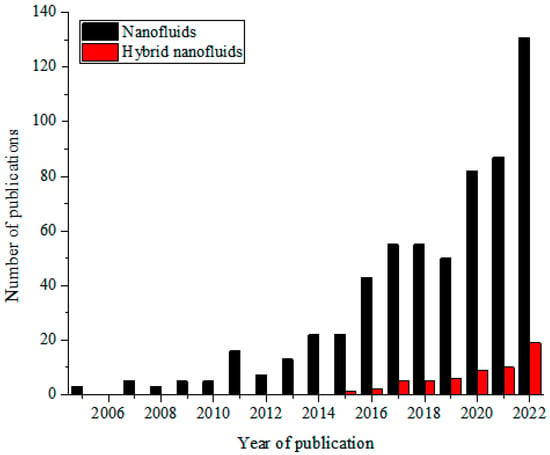

These MNFs are widely studied as nano-coolants (in thermal transporting equipment) [15,16,17,18,19,20,21,22,23,24,25,26], nano-lubricants (in moving and sliding parts of automobiles and machinery) [27,28,29], nano-based PCM (as energy storage materials) [30,31,32], nano-drilling mud [33,34,35], nano-CO2 absorbents [36,37,38], nano-water desalination and purification materials [39,40,41], nano-cutting fluids (in machining applications) [42,43,44], nano-oil recovery materials [45,46,47], nano-sensors [48,49,50], etc. The passive augmentation of the thermal properties of NFs via HNFs is presently receiving unprecedented attention with an increasing number of publications in this regard [13,14,51,52,53,54] but not as that of MNFs. Owing to the background that the HNFs offered higher thermal and convective properties compared to NFs, studies have been conducted on the various applications of HNFs similar to those of MNFs with increasingly growing publications in the open literature. In comparison to MNFs, studies are very scarce in some areas of applications of HNFs while some are witnessing an increasing number of publications in the public domain due to growing research interest. Generally, documentation on the applications of HNFs is still on the increase in the open literature. This observation is illustrated in Figure 1 (article publication trend on MNF and HNF studies) and Figure 2 (review paper publication trend on MNF and HNF studies).

Figure 1.

Temporal publication trend of articles on nanofluid and hybrid nanofluid studies (Source: SCOPUS (26 December 2022)).

Figure 2.

Temporal publication trend of review papers on nanofluid and hybrid nanofluid studies (Source: SCOPUS (26 December 2022)).

The deployment of HNFs as energy-efficient fluids in solar energy and thermal energy storage to improve energy efficiency, absorption of solar energy, and PTEC performance, and reduce exergetic efficiency, have been investigated by various authors. These studies, especially the solar energy application of HNFs as energy-efficient working fluids, have been carried out using theoretical, experimental, and numerical methods, with the majority conducted using the numerical technique. However, the experimental studies are of interest to this present work. An experimental exploration of the studies available in the open literature concerning the utilization of HNFs as nano-coolants and nano-phase change materials (PCMs) in solar energy and thermal energy storage, respectively, has been presented and discussed. The thermal and optical properties of different HNFs have been compiled and presented in this work.

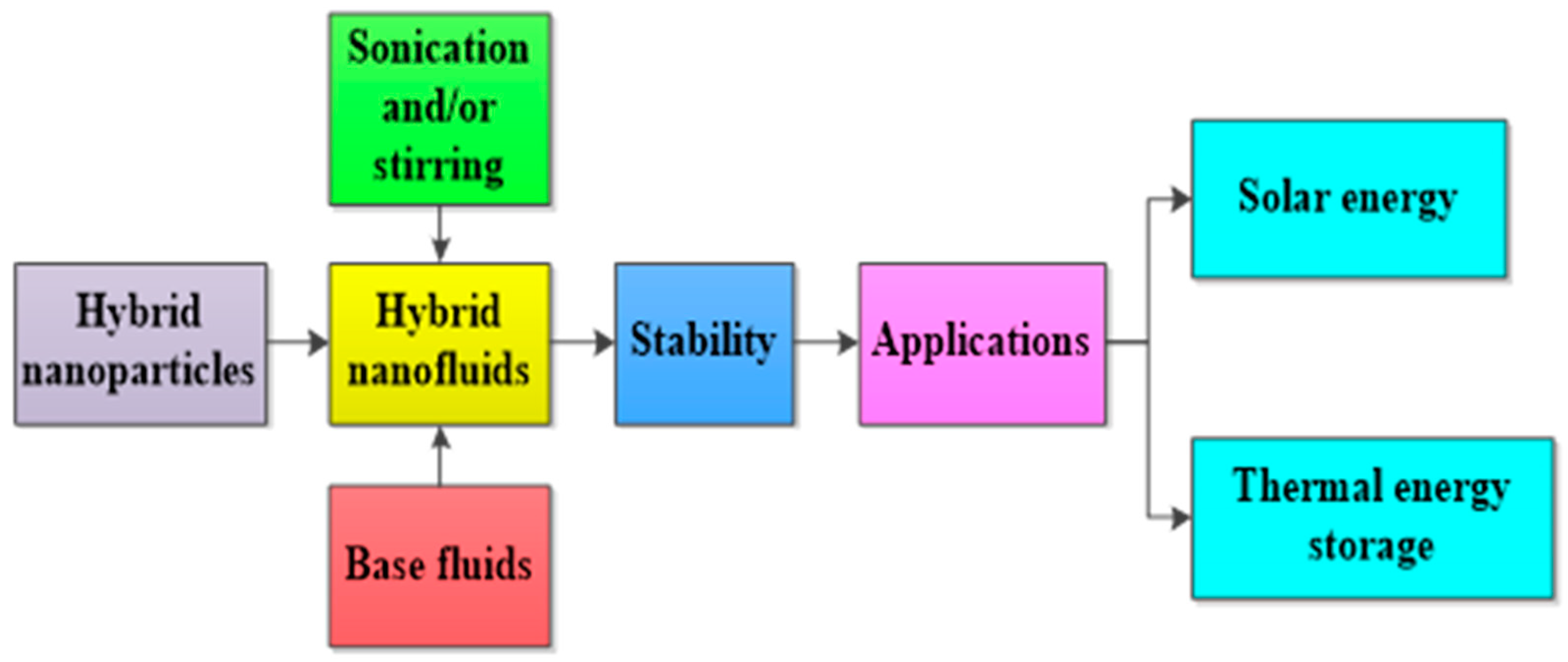

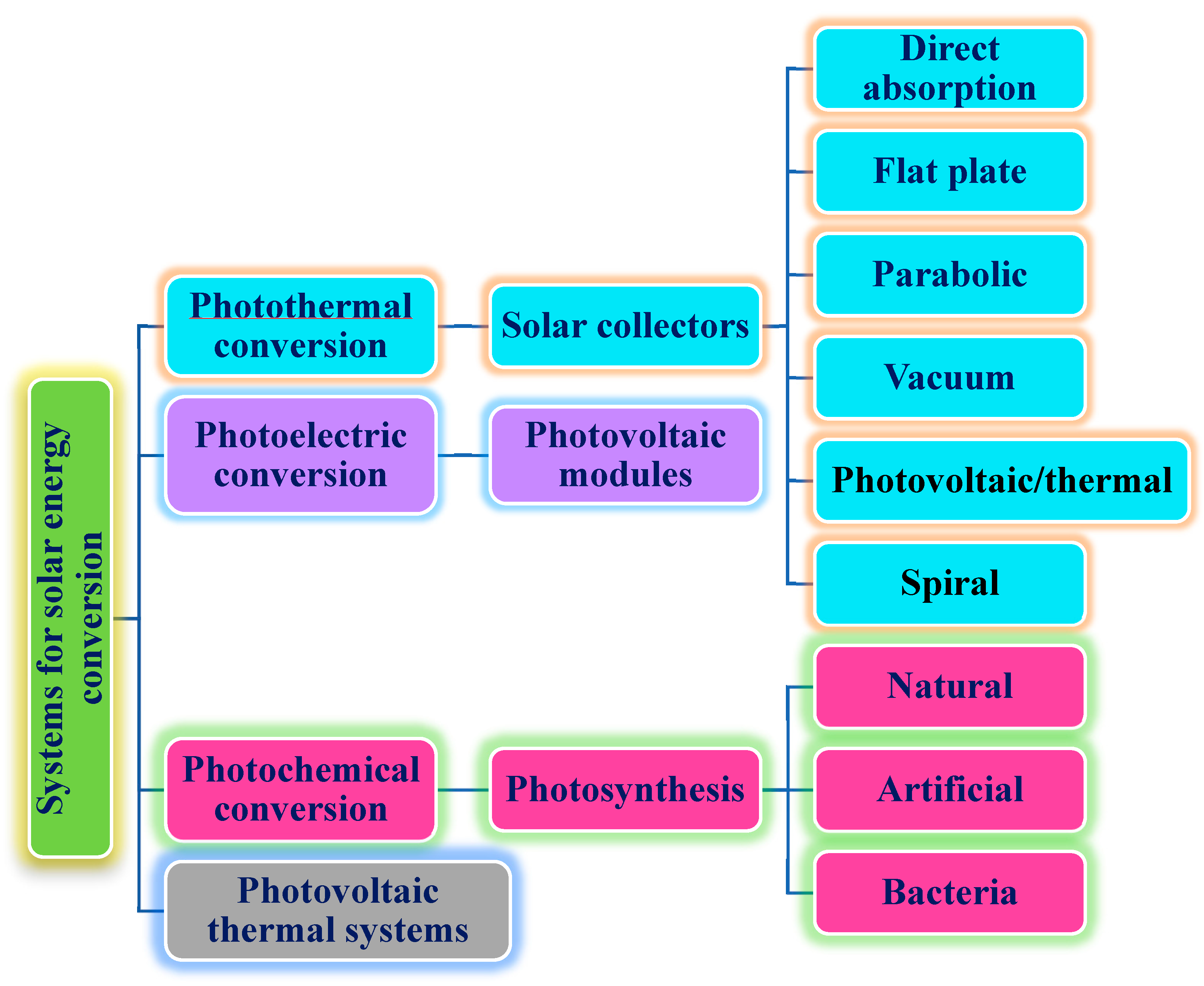

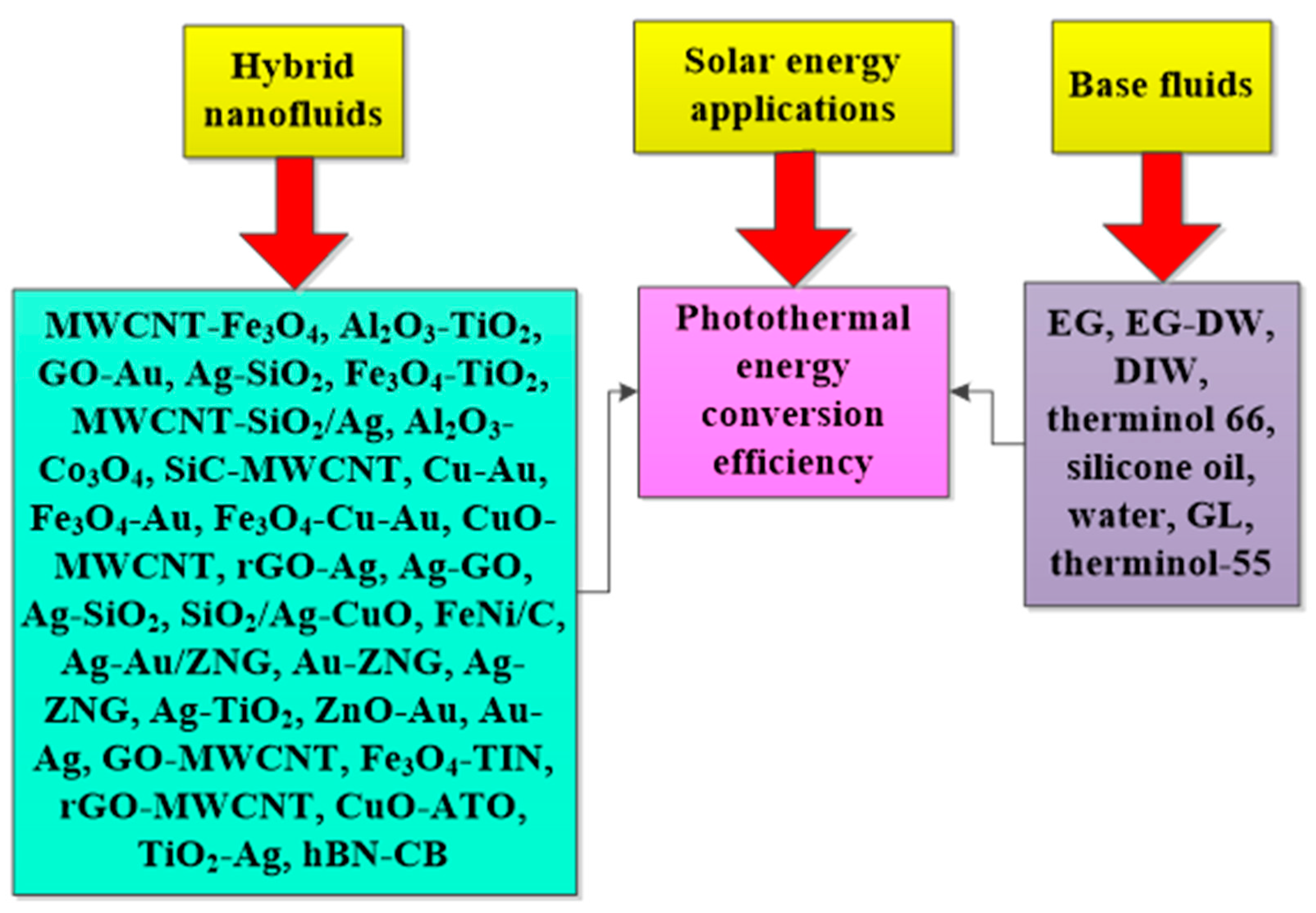

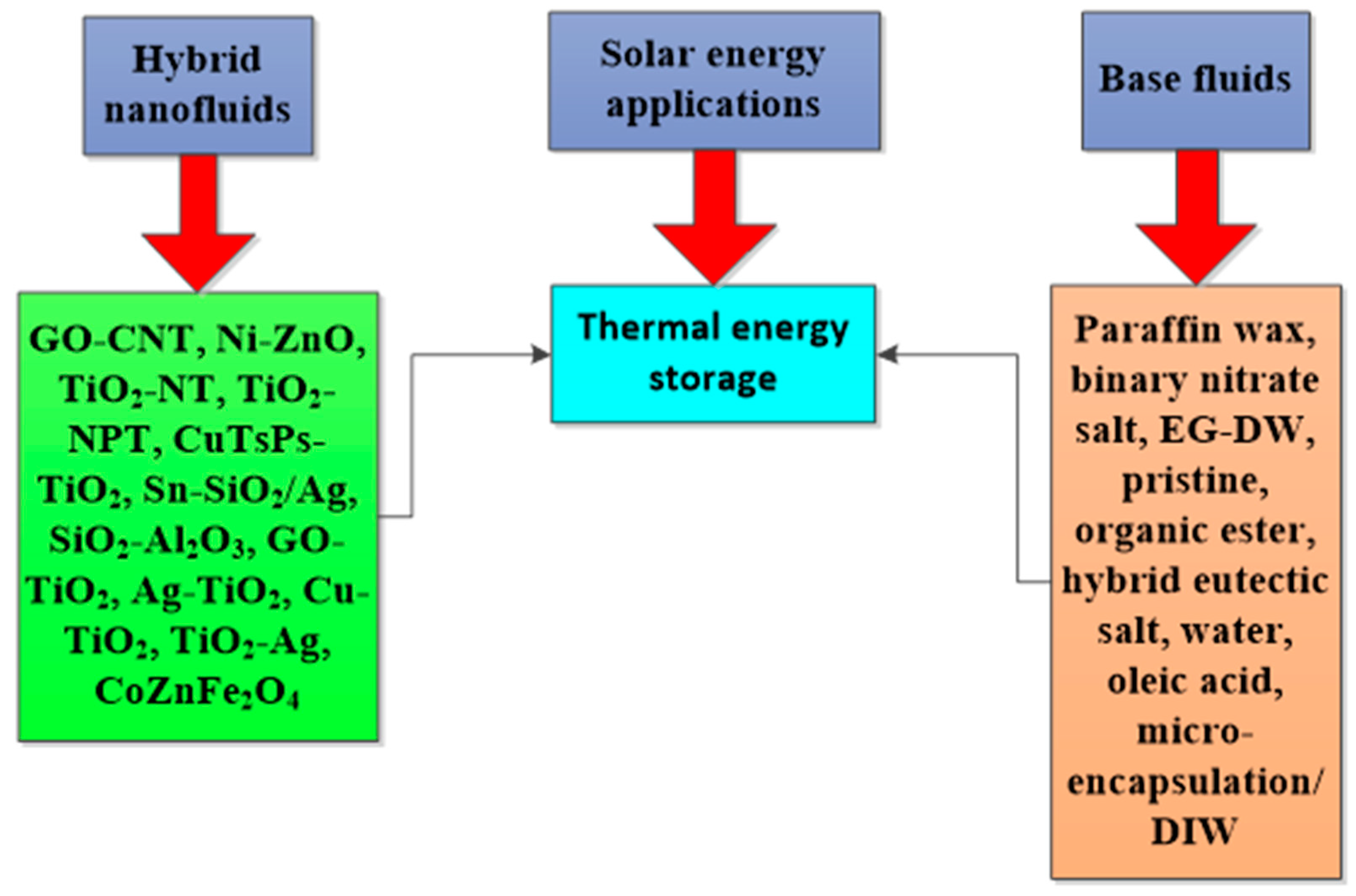

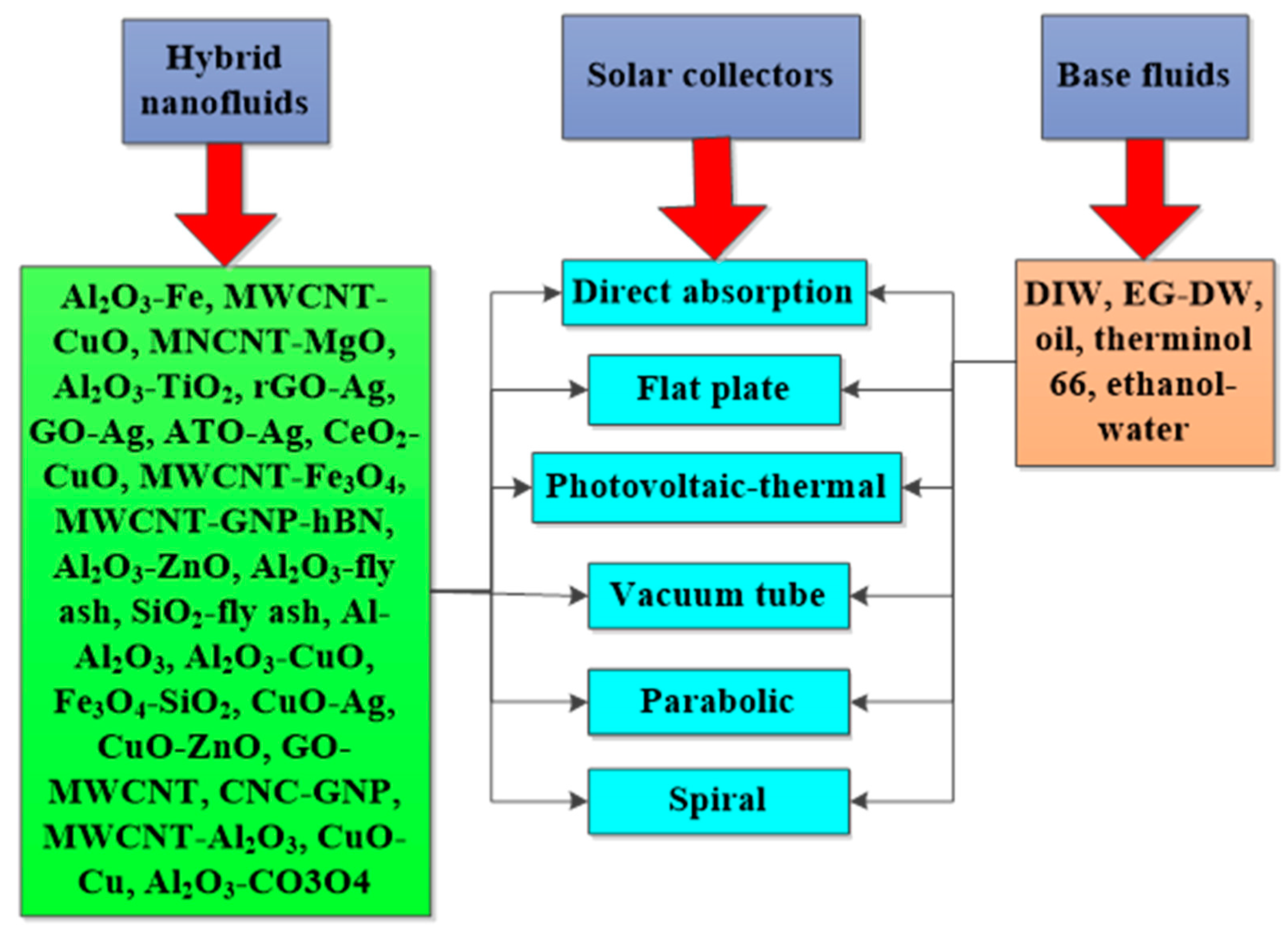

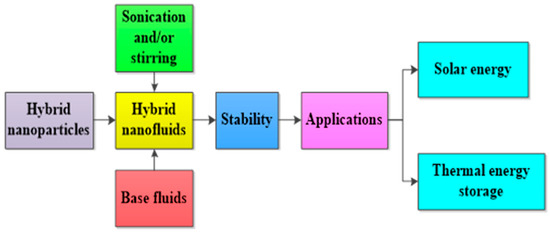

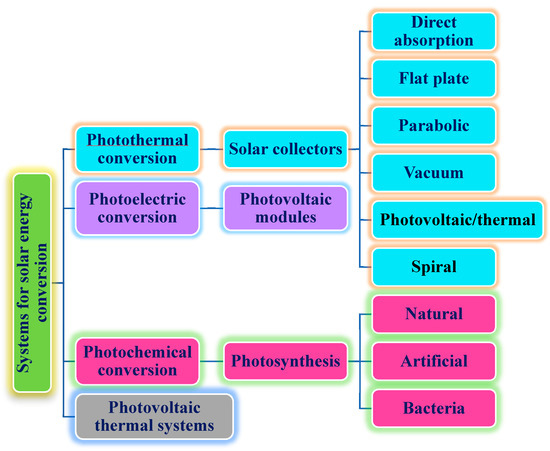

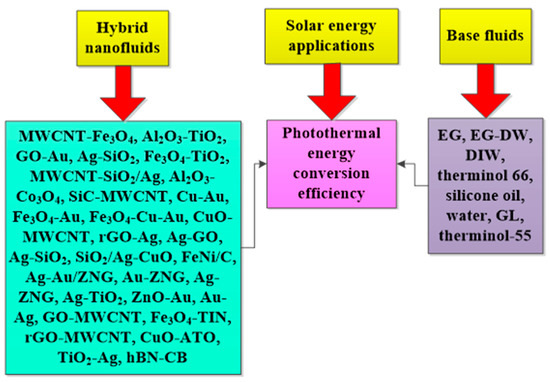

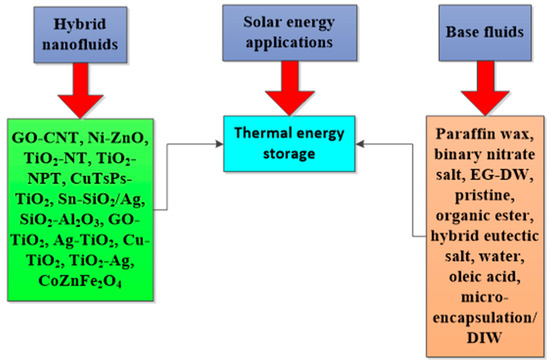

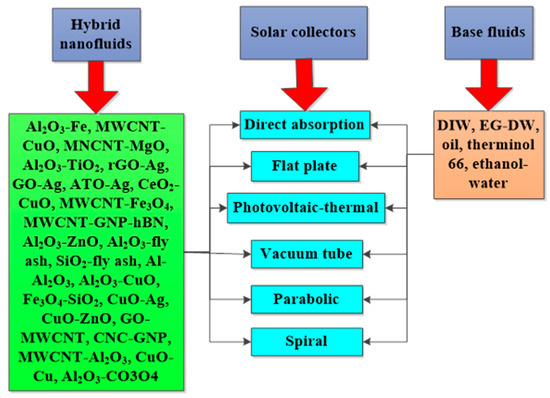

In addition, the PTEC and thermal energy storage characteristics of HNFs in relevant applications have been reviewed. Novel to this review is the special focus on the effect of mixing ratios of HNPs, nano-size of HNPs, types of base fluids and HNFs, magnetic field, flow conditions, and thermal and optical properties on various parameters relevant to the HNF applications. Amongst the key parameters are the energy and exergy efficiency of solar collectors for solar applications and latent heat of fusion, melting and freezing process temperature, and thermal stability for thermal energy storage applications. A schematic representation of this review work is given in Figure 3. The solar energy conversion and systems are presented in Figure 4. An increase in review papers on HNF studies has been observed (see Figure 2) but the majority of these papers are focused on HNF preparation, thermophysical properties, and stability. A few of these papers centred on hydrodynamic fluid flow and heat transfer in selected thermal systems. However, very scarce review papers have been published on solar applications of HNFs. The few existing ones fail to provide a distinct and in-depth understanding of the study approach (numerical and experimental), discussion on energy storage (which is complementary to solar applications), and effect of magnetic field on the performance of HNFs in solar applications. These research gaps in addition to the need to provide an update on the solar application of HNFs have prompted this work.

Figure 3.

A schematic presentation of this present work.

Figure 4.

Description of solar energy conversion and systems.

This paper is structured into six sections. Section 1 is the general introduction of the subject, focus, and objectives of this work while Section 2 addresses the PTEC efficiency of different working fluids engaged in solar energy applications. Section 3 deals with the exergetic and energetic performance of various HNFs in different types of solar collectors. The thermal energy storage performances of different types of hybrid-based PCMs and the effect of surface modification are discussed in Section 4. The challenge, future research, and conclusion are presented in Section 5 and Section 6, respectively.

2. Photothermal Performance of Hybrid Nanofluids

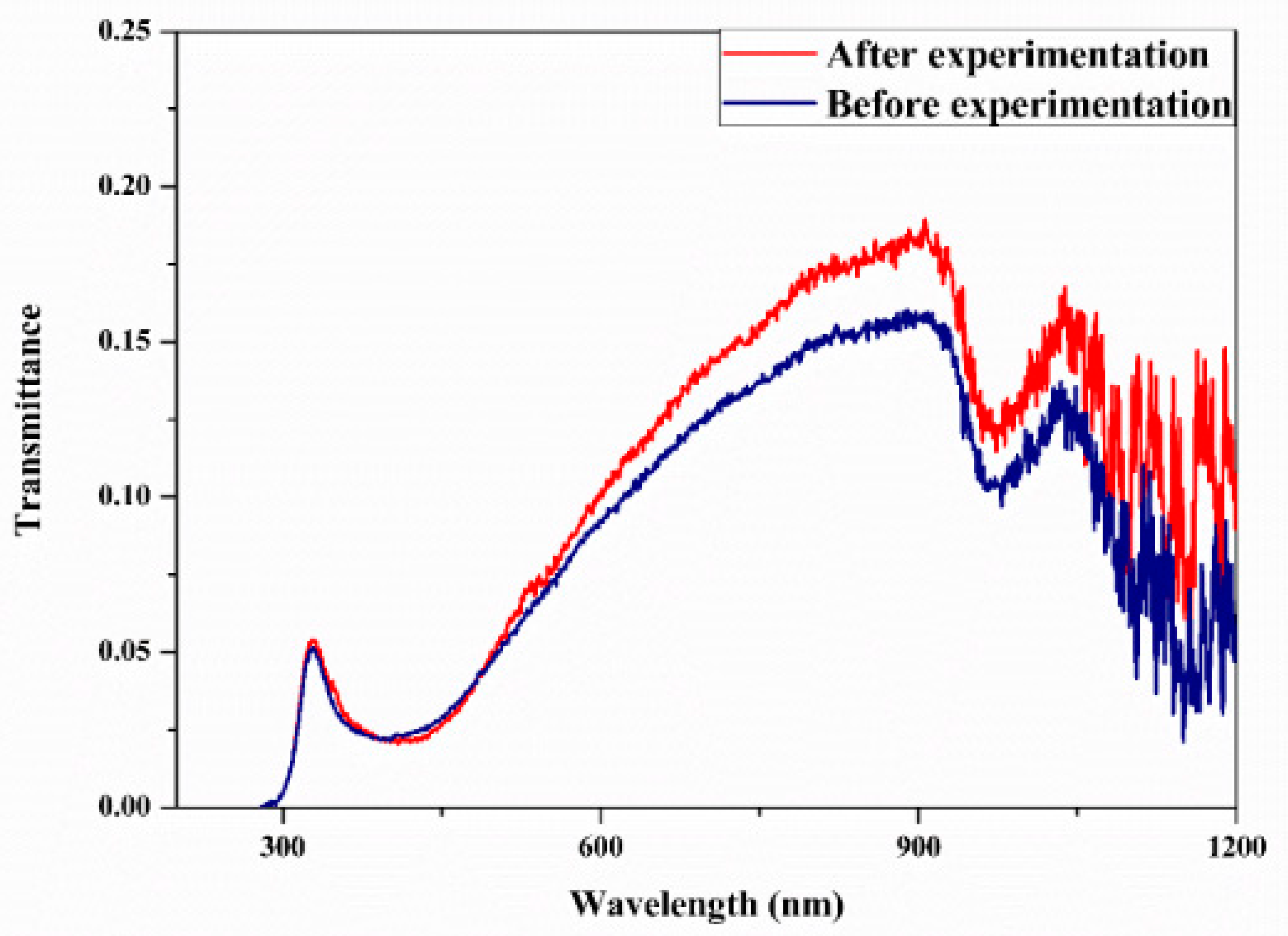

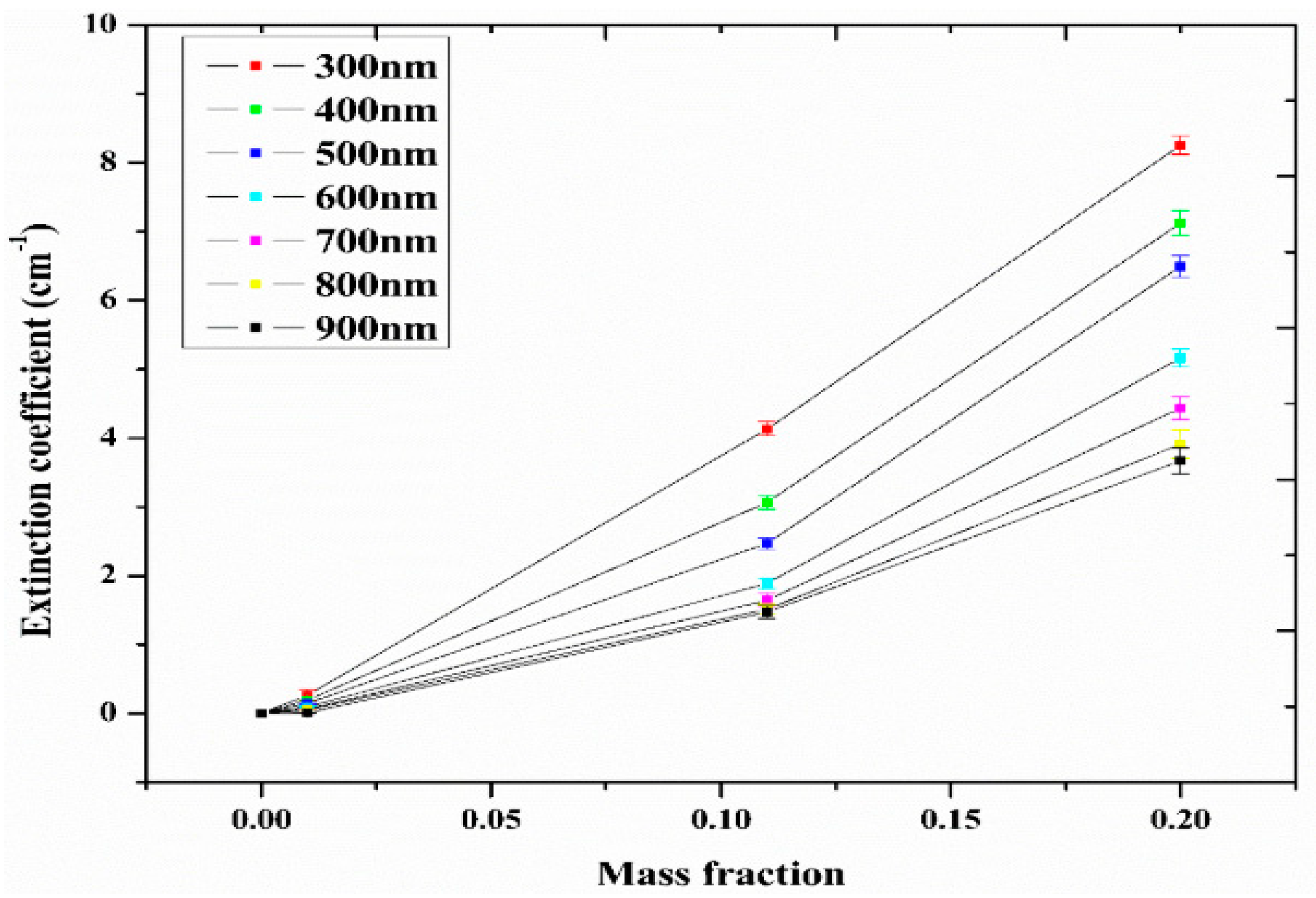

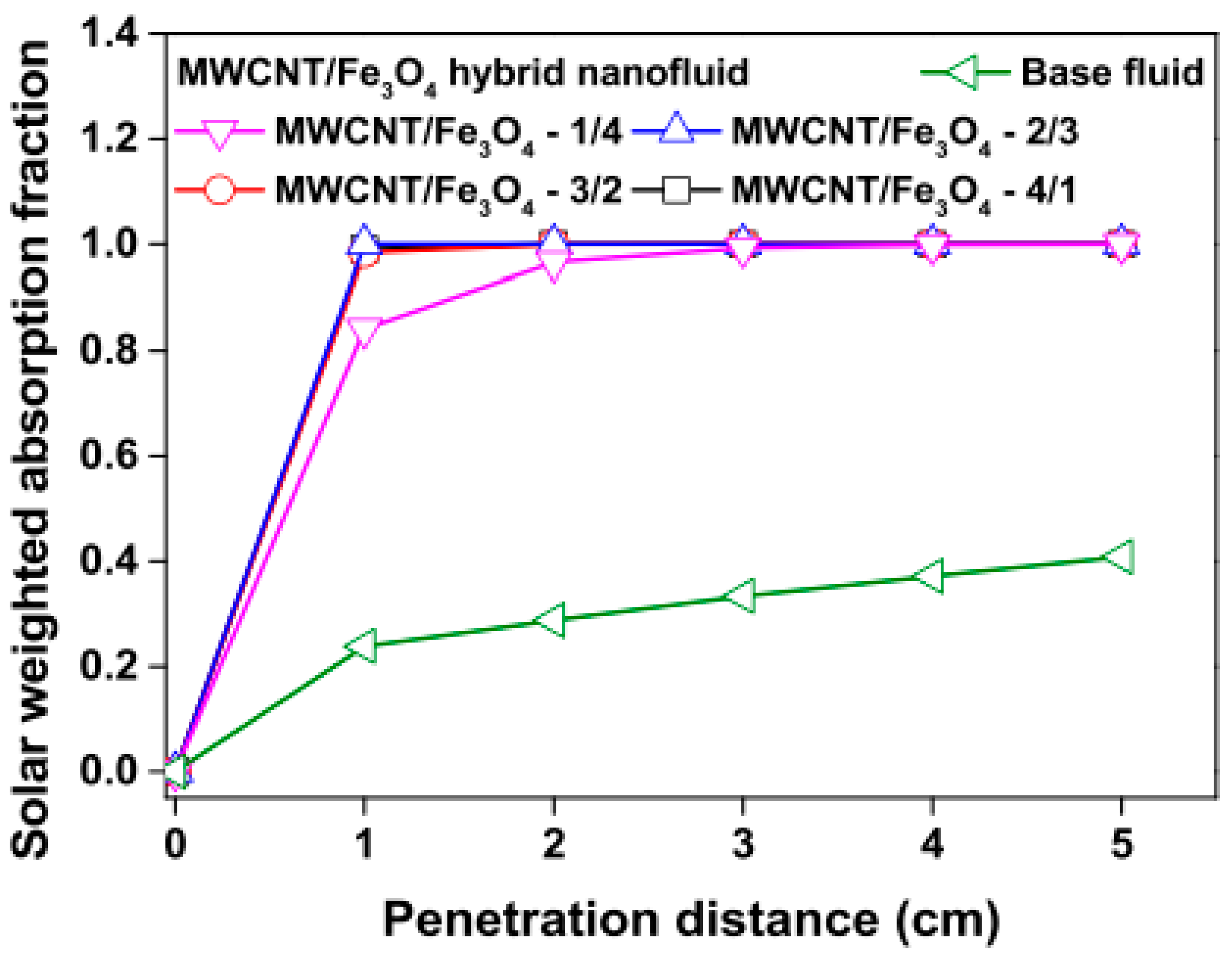

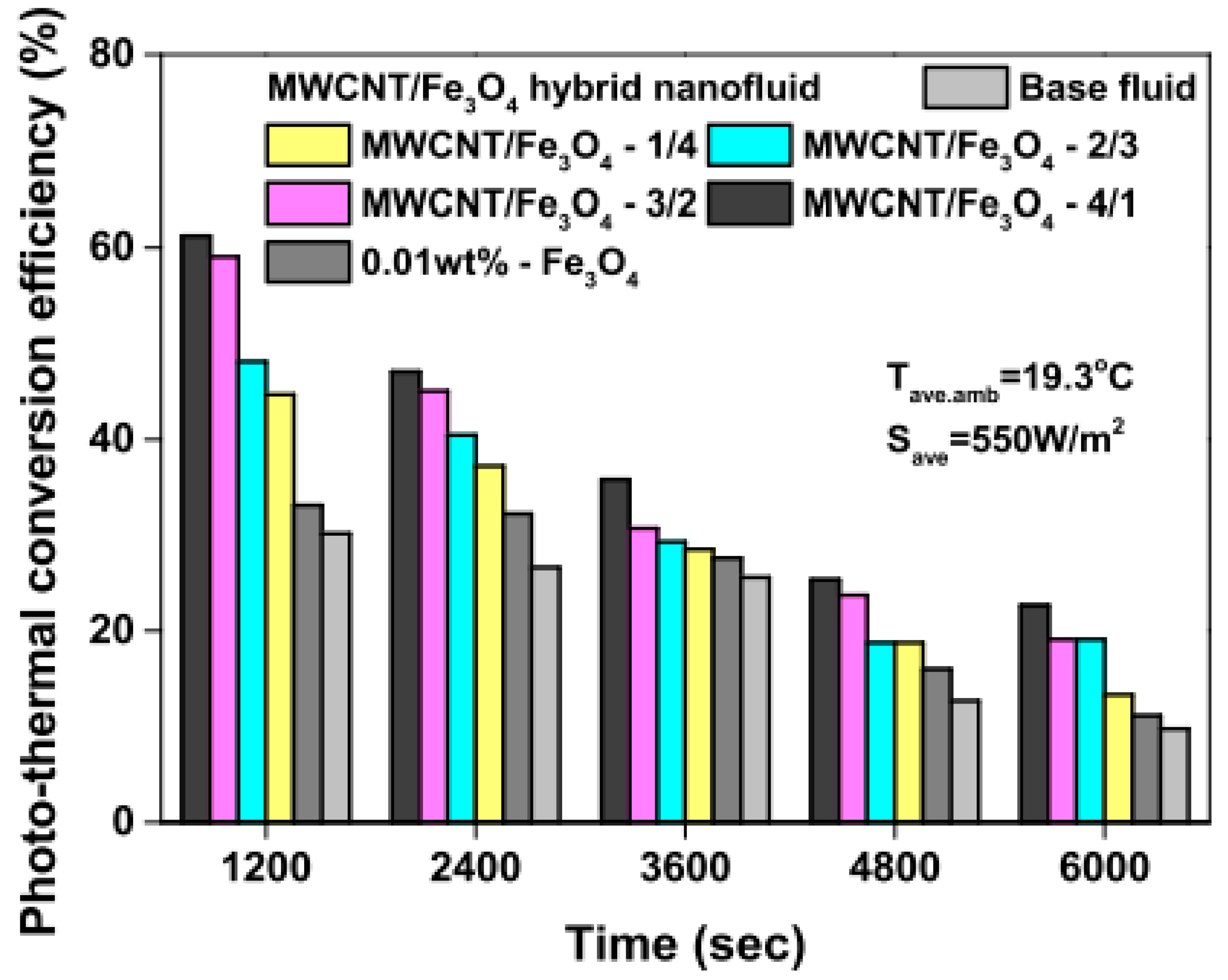

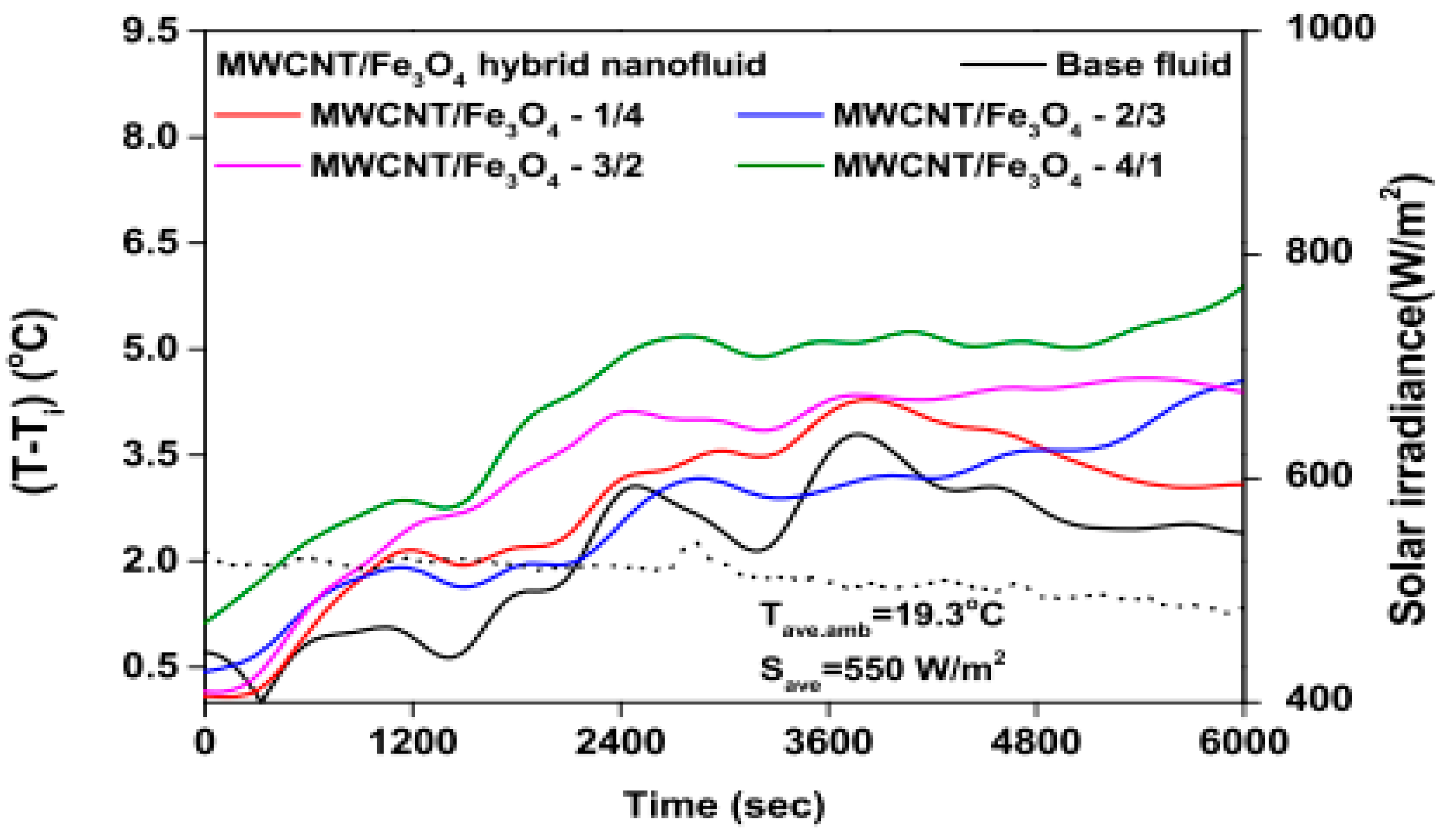

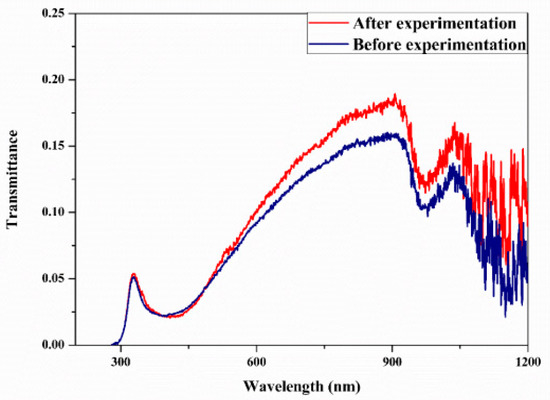

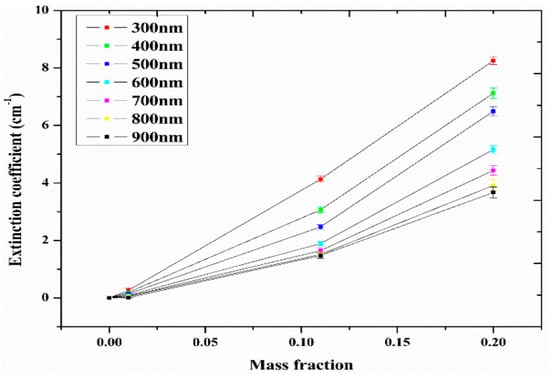

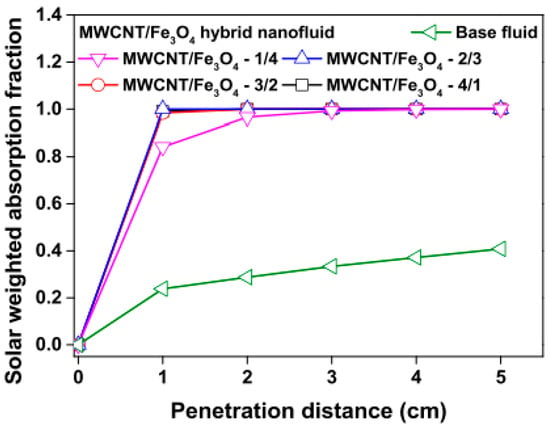

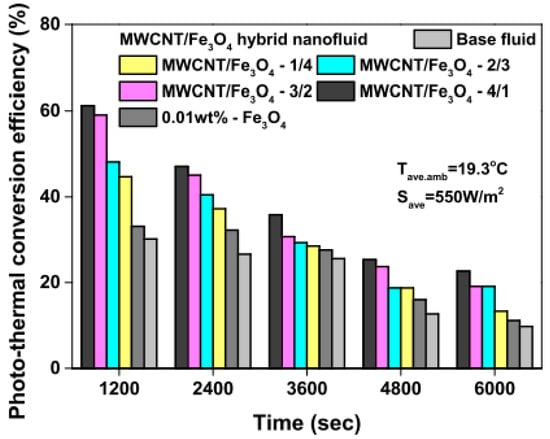

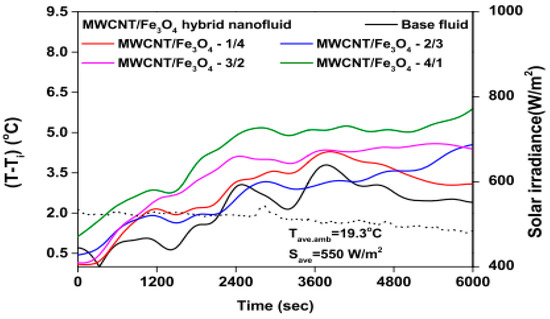

Studies on the thermal-optical properties (κ, μ, cp, rheology, transmittance, thermal diffusivity, sun intensity, absorbance, and extinction coefficient) of HNFs (with and without the influence magnetic field) at different volume/weight concentrations, temperatures, and shear rates (where applicable) as working fluids in solar energy applications are presented in Table 1. In addition, various NPs (with different nano-sizes) and base fluids (DW, EG, PG, vegetable oil, etc.) used in the formulation of HNFs at different mixing ratios and process strategies (1- or 2-step), along with the different stability tests (ZP, DLS, UV, visual, and pH) and surfactants (PVP, SDS, SHMP, gum Arabic, etc.) used to achieve stable HNFs (where engaged), are compiled in Table 1. Additionally, short remarks on the key findings from the various studies compiled in this regard were provided in the table. These papers were notable studies found in the open domain and were selected based on the different base fluids, HNPs, temperatures, nanoparticle size, surfactants, HNF processing strategies, mixing ratios, properties (thermal-optic), stability tests, and deployment of the magnetic field. In Figure 5, Figure 6, Figure 7 and Figure 8, the spectral transmittance, EC, SWEA fraction, and PTEC of different HNFs are presented. The transmittance of 0.2 vol% ATO-AG/DIW NF as a function of wavelength for DASC is presented in Figure 5. The wavelength is observed to be directly related to the transmittance of the HNF. Figure 6 presents the EC of ATO-AG/DIW NFs as a direct function of mass fraction and an indirect function of wavelength while Figure 7 shows the influence of penetration distance on SWEA for ATO-AG/DIW NFs. The effect of irradiance time on the PEC efficiency of MWCNT-Fe3O4 NFs is shown in Figure 8. The addition of different kinds of HNPs at various mixing ratios into diverse base fluids is known to produce different HNFs with varying thermal and optical properties [55,56,57,58]. This is because the individual base fluid and NPs have different absorption capacities (at different wavelengths) and thermal properties lending to synergetic effects on these properties. A shift in the wavelength range (visible and near-infrared) and the peak is mostly observed due to the mixing of different NPs [59,60,61,62]. For broadband absorption to be achieved, a combination of diverse absorption peak HNFs was engaged.

Figure 5.

Transmittance spectral analysis of optimized 0.2 vol% ATO-AG/DIW nanofluid (before and after the experiment) for DASC application (Adapted from Sreekumar et al. [63]).

Figure 6.

Extinction coefficient of ATO-Ag/DIW nanofluid as a function of mass fraction under varying wavelengths (Adapted from Sreekumar et al. [63]).

Figure 7.

Effect of increasing penetration distance on solar weighted absorption fraction of MWCNT/Fe3O4 nanofluids and base fluid (Adapted from Tong et al. [61]).

Figure 8.

Photothermal energy conversion efficiency of MWCNT/Fe3O4 nanofluids and base fluid with increasing irradiation (Adapted from Tong et al. [61]).

Table 2 gives a summary of the thermo-optical properties, formulation materials, process methods, and photothermal performances of different HNFs used as working fluids in solar energy applications. Details of the various HNPs (with different nano-sizes) and base fluids used to formulate HNFs at diverse volume/weight concentrations, mixing ratios, and process strategies are presented. Additionally, the various stability tests to monitor HNF homogeneity and the surfactants deployed to ensure HNF stability are compiled in Table 1. In addition, remarks on the important findings from the reviewed papers used to compile the table are included. These papers were notable studies carried out from 2015 to 2022 and based on the different base fluids, HNPs, nanoparticle sizes, surfactants, HNF process methods, mixing ratios, thermo-optical properties, photothermal performance, stability tests, and use of the magnetic field. The effects of volume fraction (0.002–0.15%) and core size (20 nm and 25 nm) of TiO2-Ag/DIW NFs as working fluids in a solar collector were explored by Xuan et al. [64]. The work was performed by exposing the test samples to the sun and the PTEC efficiency was estimated by substituting all applicable and measured parameters into an empirical equation. They reported that increasing the core size and volume fraction (to 0.1%) favored the improvement of the absorbed energy and consequently enhanced the temperature and PTEC efficiency of HNFs. With an increment of energy absorptance as the volume fraction increased and the temperature also increased as the solar radiation increased. Absorbed energy, temperature, and thermal efficiency of 57.89, 390.88, and 413.36 W/m2; 60.21 °C, 66.65 °C, and 66.93 °C; and 16.07%, 20.86%, and 20.9% were obtained for TiO2, Ag, and TiO2-Ag NFs, respectively, against temperature (57.52 °C) and thermal efficiency (15.52%) of DIW. Increasing the volume fraction from 0.005% to 0.01% enhanced energy absorbed from 0.76 to 0.93, with maximum temperature occurring at 0.01% concentration for TiO2-Ag NF.

Table 1.

Different HNPs, base fluids, surfactants, stability tests, process methods, and thermo-optical properties related to HNFs use in solar energy applications.

Table 1.

Different HNPs, base fluids, surfactants, stability tests, process methods, and thermo-optical properties related to HNFs use in solar energy applications.

| References | HNF (Mixing Ratio)/Base Fluid | φ | Temperature (°C) | Nano-Size (nm) | Stability (Tests, and Surfactants) | Properties | Result |

|---|---|---|---|---|---|---|---|

| Mechiri et al. [65] | Cu-Zn/ground nut (50:50, 75:25,25:75) | 0.1–0.5 vol% | 30–60 | 25 | ZP, surfactant, (2-step) | κ and μ | Highest κ and μ for Cu-Zn/oil (50:50). Newtonian flow for oil and HNFs. |

| Chandran et al. [66] | ZnO-paraffin wax /PG-DIW | 4–16 wt% (ZnO-paraffin) and 2 vol% wt% (HNFs) | 30 | ZnO–30-45 | (2-step) | κ and cp | Maximum enhancements of κ = 10.4%, cp = 18.7%, heat transfer = 13.54%, and coefficient of heat transfer = 15.37%. HNF with 10 wt% paraffin and 2 vol% ZnO yielded κ = 3.5%, cp = 5.1%, and coefficient of heat transfer = 15.37%. |

| Akilu et al. [67] | SiC-CuO/C/EG (8:2) | 0.8–3.13 wt% (0.25–0.99 vol%) | 25–80 | SiC-29, CuO/C-28.5, SiC-CuO/C -12-28 | ZP, DLS, Visual, PVP (2-step) | Rheology, κ, and μ. | At 3.13 wt% and 80 °C, κ and μ were enhanced by 19.3% and 205%, respectively, in comparison with EG. Newtonian behavior was observed for the HNFs at 50–250 s−1. |

| Ghafurian et al. [68] | MWCNT-GNP/seawater (50:50) | 0.001–0.04 wt% | sonication time (30–240) | GNP-40, MWCNT-20-30 | ZP, UV, pH, Gum Arabic (2-step) | Sun intensity, pH, absorbance. | At optimum sonication time of 120 min, the maximum solar evaporation efficiency (61.3%) and evaporation rate (2.89 kg/m2 h), and lowest average particle size were achieved when φ = 0.01 wt% and at the solar intensity of 3.6 suns. |

| Asadi et al. [69] | MgO-MWCNT/EO (80:20) | 0.25–2 wt% | 20–50 | MgO-30nm MWCNT-20-30nm | (2-step) | Κ | Maximum enhancement of 65% at 50 °C and φ = 2 wt%. |

| Gugulothu and Pasam [70] | CNT-MoS2/sesame oil (1:2) | 0.5–3 wt% | 20–50 | CNT-30 MoS2-30 | SDS (15%), Visual (2-step) | κ, μ, and cp | Maximum κ (28.31%), cp (10.98%), and μ were achieved at φ = 3 wt% as compared with sesame oil. |

| Kumar et al. [71] | ZnFe2O4/DW | 0.02–0.5 wt% | 30–80 | - | UV, Visual, CTAB (2-step) | κ and μ. | The highest κ was 11.8% for 0.5 wt at 80 °C. |

| Tong et al. [61] | MWCNT-Fe3O4/ EG-W (20:80) | 0.02 wt% | 20–50 | MW-10-20 Fe3O4-10 | ZP and V | κ | κ = 0.541 W/m°C (Fe3O4 @ 0.2 wt%) and κ = 0.562 W/m°C (MWCNT-Fe3O4 (80:20) @ 0.01 wt%) at 50 °C. |

| Ali et al. [72] | Al2O3-TiO2/5W-30 | 0.1 vol% (0.05% Al2O3 + 0.05% TiO2 + 1.9 wt% oleic) | - | Al2O3-8-12 TiO2-10 | Visual | κ and μ | κ was enhanced by 7–11% relative to the base oil. Non-Newtonian and pseudoplastic behavior were observed. |

| Mendari et al. [73] | Al2O3-CuO/EG-DW (50:50) and EG | 0.001% CuO and 0.04% Al2O3 | - | Al2O3-40 CuO-100 | UV, Visual, pH, SHMP (2-step) | EC, pH, and absorbance | Absorbency and EC of the Al2O3-CuO NFs were close to the sum of the individual NPs in the HNF. EC of EG-DW-based HNFs was higher than EG-based HNFs. |

| Mendari et al. [74] | CuO-Al2O3/DW | 0.001% CuO and 0.04% Al2O3 | - | Al2O3-40 CuO-100 | UV, Visual, pH, SHMP (2-step) | EC, pH, μ, and absorbance | Absorbency and EC of the Al2O3-CuO NFs were close to the sum of the individual NPs in the HNF. EC and absorbance improved with volume fraction. |

| Mendari et al. [75] | Al2O3-CuO/EG-DW (50:50) and DW | 0.001% CuO and 0.04% Al2O3 | - | Al2O3-40 CuO-100 | UV, Visual, pH, SHMP (2-step) | Absorbance and κ | Stability and κ of EG-DW and DW-based Al2O3-CuO NFs were strongly related to sonication time, pH, and surfactant mass fraction. The HNFs were stable at peak absorbance and κ values. |

| Mendari and Alemrajabi [76] | Al2O3-CuO/EG-DW (50:50), EG, and DW | 0.001% CuO and 0.04% Al2O3 | - | Al2O3-40 CuO-100 | UV, Visual, pH, SHMP (2-step) | EC and Absorbance | Absorbency and EC of the Al2O3-CuO NFs were close to the sum of the individual NPs in the HNF. EC of DW-based HNFs was higher than EG-DW and EG-based HNFs. |

| Shin et al. [77] | MWCNT-Fe3O4 (1:1)/EG-W (20:80 wt%) | 0.005–0.2 wt% | - | - | Visual (2-step) | B = 250–750 G, κ, | κ enhanced as φ and magnetic field intensity increased. Maximum κ of 0.562, 0.580, and 0.569 W/m °C for Fe3O4, MWCNT, and MWCNT/Fe3O4 NFs (absence of magnetic field) and 0.583 and 0.59 W/m°C for Fe3O4 and MWCNT/Fe3O4 NFs (under the magnetic intensity of 750 G), respectively, at φ = 0.2 wt% and 50 °C. |

| Harikrishnan et al. [78] | CuO-TiO2 (50:50)/paraffin | 0.25–1 wt% | - | CuO-TiO2- 21 | SDBS, Visual | κ, μ | κ and μ of CuO, TiO2, and CuO-TiO2 NF were enhanced by 51.5%, 32.3%, and 46.81%, and 7.76%, 4.85%, and 6.15%, respectively, at 60 °C. |

| Ali et al. [79] | Cu-GNP/EO (5W-30) | 0.03–0.6 wt% | - | Cu-10-20 GNP-5-10 μm | UV, Visual, Oleic (2 wt%) (2-step) | μ | μ of Cu-GNP/EO NFs enhanced with φ from 54.3–55.2 mm2/s and 9.4–10 mm2/s at 40 °C and 100 °C, respectively. |

| Ali et al. [80] | Al2O3-TiO2 (0.05:0.05 wt%)/5W-30 | 1.5–1.95 wt% and 0.05–0.5 wt% for OA | - | Al2O3- 8-12 TiO2- 10 | UV | μ | μ was 54.06, 54.01 and 51.62 mm2/s and 9.45, 9.42, and 9.23 mm2/s, for EO, EO + OA, and 0.1 wt% Al2O3-TiO2 NF at 40 °C and 100 °C, respectively. The viscosity index of 160, 160, and 163 were obtained for EO, EO + OA, and 0.1 wt% Al2O3-TiO2 NF, respectively. |

| Parameshwaran et al. [81] | Ag-TiO2/organic ester | 0.1–1.5 wt% | - | Ag-TiO2- 10-95 | - | μ and κ | With increasing φ, κ increased from 0.286 W/m K to 0.538 W/m K translating to 10–52% enhancement. μ was enhanced by 0.35–3.8% for the HNFs. Newtonian behavior was demonstrated by the HNFs, |

| Parameshwaran et al. [82] | Cu-TiO2/pristine | 0.02–0.1 wt% | - | - | PVP and ethanol (2-step) | κ | κ was augmented up to 0.08 wt% (0.1926 W/m K) translating to an enhancement of 5.53%. |

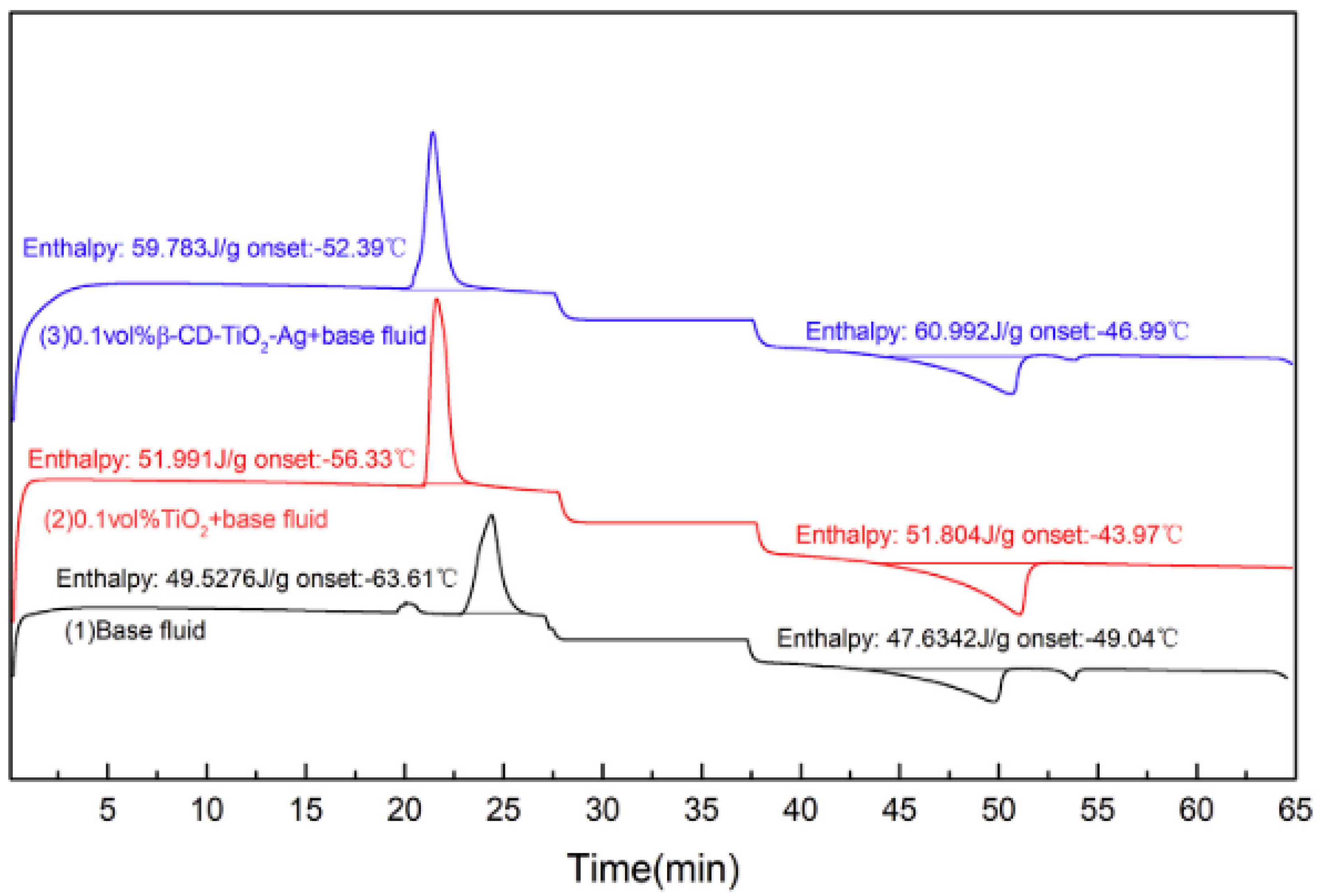

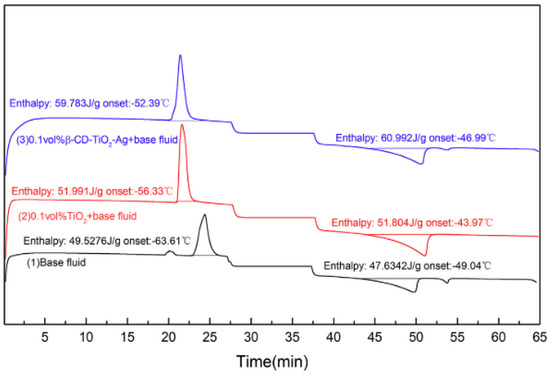

| Li et al. [83] | β-CD-TiO2-Ag/ EG-DIW (40:60) | 0.025–0.1 vol% | - | β-CD-TiO2-Ag–40-50 TiO2-Ag–40-50 TiO2 -25-30 | ZP | κ | κ enhanced as φ increased with an improvement of 24.58–42.17% for φ = 0.1 vol% at 20–50 °C. |

| Nithiyanantham et al. [84] | SiO2-Al2O3/binary nitrate salt (eutectic) | 1 wt% | - | SiO2-Al2O3–12, 14, 17 | - | μ, κ, thermal diffusivity | At temperatures of 250–400 °C, the thermal diffusivity, κ, and μ of 35-SiO2-Al2O3 nano-PCM were augmented by 7–14%, 11–19%, and 25–34%, respectively, compared with eutectic-based PCM. |

| Sundar et al. [85] | ND-Co3O4 (67:33)/DW | 0.05–0.15 wt% | 20–60 | - | Visual | μ and κ | For 0.05–0.15 wt% and at a temperature range of 20–60 C, the κ and μ were enhanced by 2.07–15.71% and 6.96–45.83% compared with DW. |

Using DIW-based HNFs (Au (0.5–2.5 ppm) + Ag (0.15 and 0.5 ppm)) as thermal fluids, Chen et al. [86] studied the absorptance, SAR, and photo-thermal performance in DASCs. This work was carried out using simulated solar intensity and a theoretical model (based on energy balance) was developed to evaluate the PTEC efficiency. They observed that the temperature change of DIW-based Au (1.75 ppm) + Ag (0.15 ppm) NF was 15.61% and 8.98% higher than those of Ag (0.15 ppm) and Au (1.75 ppm) NFs, respectively. Increasing the concentration of Au in the DIW (45 °C) was noticed to improve the temperature of Au/DIW (2.5 ppm) NF (64 °C). The PTEC efficiency of 30.97%, 19.01%, and 11.90% was obtained for Au (1.75 ppm) + Ag (0.15 ppm), Au (1.75 ppm), and Ag (0.15 ppm) NFs respectively. The PTEC efficiency of the HNF translated to the sum of the individual efficiency of the MNFs. It was observed that the estimated (43.72 W/μL) and predicted SAR (43.81 W/μL) of Au (1.75 ppm) + Ag (0.15 ppm) NF based on the individual SAR values of Au (1.75 ppm) and Ag (0.15 ppm) NFs and PTEC performance of the HNF were almost equal. Carrillo-Torres et al. [87] studied the thermal stability and PTEC efficiency of Au-Ag NPs dispersed in water as thermal fluid in solar collectors. This experiment was conducted by exposing the test samples to laser light and the PTEC efficiency was calculated using the existing energy balance model. They reported that temperature change was enhanced as irradiation time, optical density, and heating profile increased. Using the HNF, maximum PTEC efficiency of 74.68% was obtained while a temperature of 20 °C was recorded after exposing the HNF to 15 min of irradiation. Furthermore, the HNF showed no significant change in optical properties after 12 h exposure to irradiation and 10 cycles of cooling/heating, thus, indicating thermal stability.

Chen et al. [88] examined the effect of mixing ratio (1:9–9:1) and φ (0.02–0.12 vol%) on the SWEA and PTEC efficiency of DIW-based CuO-ATO NFs in a solar collector. Alaboratory-based simulator was used in the experiment while the PTEC efficiency was evaluated based on the energy balance during the testing process. The temperature change, absorption coefficient, transmittance, SWEA fraction, and PTEC efficiency were noticed to be strongly related to the mixing ratio and φ of the HNFs. Increasing the solar radiation exposure of CuO-ATO NFs was noticed to increase temperature change until 7000 s, after which a decline was observed. At an optical distance of 1 cm, optimum absorption coefficient, transmittance, and SWEA fraction were attained with 0.12 vol% CuO-ATO (4:6) NF whereas optimum temperature change and thermal efficiency were reached using 0.1 vol% CuO-ATO (4:6) NF. Peak SWEA fraction, temperature change, and PTEC efficiency of 99.6%, 43.6 °C, and 92.5% were obtained for CuO-ATO NFs against 89.5%, 39.8 °C, and 81.3% and 89.8%, 39.6 °C, and 80.7% recorded for CuO and ATO NFs, respectively. Menbari et al. [75] deployed water and EG-W-based Al2O3-CuO NFs as working fluids in a DASC and examined the influence of base fluid type (water and EG-water), φ (0.002–0.008% (CuO) and 0.05–0.2% (Al2O3)), and volume flow rate (10–100 L/h) on the thermal efficiency. In addition, stability parameters (surfactant mass fraction, sonication time, and pH) on the absorbance and κ of the HNFs were measured. Their results demonstrated that stable HNFs were observed at high and low values of κ and absorbance. An increase in flow rate caused a reduction in temperature difference and outlet temperature while it enhanced inlet temperature and thermal efficiency. A rise in φ was demonstrated to improve temperature change, solar irradiation, and thermal efficiency. Both the solar irradiation and thermal efficiency of the collector were noticed to be higher for water-based HNFs than EG-water-based HNFs.

Khashan et al. [89] experimented the PTEC efficiency of DIW and DIW-kerosene-based Fe3O4-SiO2 NFs (1 mg/mL and 2 mg/mL) as thermal fluids in a solar collector. The test samples were exposed to irradiance via a solar similar and the estimation of the PTEC efficiency was carried out using the energy balance empirical equation. Results showed that after 10 min exposure of DIW, Fe3O4 (1 mg/mL), and Fe3O4-SiO2 (1 mg/mL) NFs to solar irradiation, the difference in temperature between the top and bottom surface of the collector was 1.4 °C, 2.7 °C, and 3.2 °C, respectively. After 65 min of irradiation, the surface temperature of DW and Fe3O4-SiO2 (1 mg/mL) NF increased by 9.2 °C and 12.7 °C, respectively. This was due to an increase in the absorption capacity of Fe3O4-SiO2 NF. At different collector heights and after 10 min of irradiation, PTEC efficiency of 10–17%, 27–83%, and 30–89% was obtained using DW, Fe3O4, and Fe3O4-SiO2, respectively. With 300 min of irradiation on the Fe3O4-SiO2 (1 mg/mL) NF + kerosene mixture, the part with kerosene alone and that with Fe3O4-SiO2 (1 mg/mL) NF recorded top and bottom temperatures of 50.7 °C and 47.8 °C and 57.3 °C and 55.5 °C, respectively. Additionally, after 5 min of irradiation, PTEC efficiency of 65.6%, 85.4%, and 98.5% was attained with DIW, kerosene + 2 mg/mL Fe3O4-SiO2 NF, and kerosene + 1 mg/mL Fe3O4-SiO2 (1 mg/mL) NF, respectively. The authors recommended similar future research using kerosene-based HNFs.

The utilization of DIW-based CuO-ZnO (70:30 and 50:50) NFs with φ = 0.001–0.01% as thermal fluids in solar collectors was investigated by Fang and Xuan [90] for their thermo-optical properties and PTEC efficiency. A simulated sunlight with an irradiance of 1000 W/m2 was used while a self-designed device was engaged to evaluate the PTEC efficiency. As transmittance is inversely proportional to absorbance, increasing φ was noticed to improve absorbance, κ, and EC for all the tested samples. Peak absorption and κ were observed for CuO and CuO-ZnO (70:30) NFs, respectively. At the optical depth of 1 cm and φ = 0.01%, maximum SWEA efficiency and temperatures of 99.47% and 71.62 °C (CuO/DIW NF), 98.67% and 72.65 °C (CuO-ZnO (70:30)/DIW NF), and 94.78% and 71.81 °C (CuO-ZnO (50:50)/DIW NF) were obtained, respectively. Maximum PTEC efficiency of 97.4% (30 °C) and 34.7% (70 °C) was reported for CuO-ZnO (70:30)/DIW NF. Yu and Xuan [91] examined the influence of volume fraction (0.015–0.025%) and mixing ratio (7:3 and 8:2) on the absorbance and PTEC efficiency of CuO-Ag/DIW NFs engaged as thermal fluids in a DASC. A solar simulator was used to provide irradiance and the PTEC efficiency was calculated using an existing and applicable equation. They reported that the absorbance of the CuO-Ag/DIW NFs was higher than those of CuO/DIW NFs and DIW and it improved with volume fraction increase. The HNFs with a mixing ratio of 7:3 were noticed to produce higher absorbance, temperature change, and PTEC efficiency than those of 8:2. As the concentration of the HNFs (with a mixing ratio of 7:3) and solar irradiation (till 7000 s) increased, temperature change and PTEC efficiency improved. At a volume fraction of 0.025% and irradiation of 7000 s, the highest temperature change and PTEC efficiency of 34.1 °C and 96.11%, respectively, were recorded using CuO-Ag (7:3)/DIW NF as a thermal fluid.

Hjerrild et al. [92] experimented with the stability, thermal treatment, and optical properties of GL-based Ag-SiO2 NF as a liquid optical filter applied in PV/T collectors. The test samples were exposed to concentrated UV irradiation. They found that the HNF was stable under medium thermal treatment (125 °C) and accelerated high UV irradiation (300–1500 nm) exposure. The Ag-SiO2/GL NF was noticed to be applicable in a PV/T collector with high temperature and electrical output. Additionally, the Ag-SiO2/GL NF was observed to considerably enhance light transmission in comparison with Ag-SiO2/W NF coupled with its low price and wide range of temperatures. Zhou et al. [60] studied the use of GO-Au/DIW NFs at φ = 0.1–0.3 mg/mL as thermal media for steam generation. A solar simulator was used as the light source while a self-built device was used to estimate the PTEC efficiency. They showed that 0.2 mg/mL-GO-Au/DIW NF was the best thermal fluid with the highest evaporation rate, enhancement factor, and PTEC efficiency of 1.34 kg/m2 h, 2.35, and 84.1%, respectively. The observed results were strongly linked to 0.2 mg/mL-GO-Au/DIW NF possessing the highest absorption characteristics. HNFs of GO-Au/DIW were demonstrated to be better than the MNFs of Au/DIW and GO-DIW as working fluids for solar steam generation. The solar steam generation efficiency of GO-Au/DIW NF (0.2 mg/mL) was 20% higher than GO/DIW NF. Using the same light illumination, the temperature of Au-GO/DIW (0.2 mg/mL) NF was found to be 8–10 °C higher than DIW. The authors stressed the potential application of GO-Au/DIW NFs to include power generation, seawater desalination, and sterilization of waste.

Zeng and Xuan [93] studied the κ and PTEC effectiveness of DIW-based MWCNT-SiO2/Ag NFs (0.001–0.1%) with mixing ratios of 4:1–1:4 as operating fluids in volumetric solar collectors. To measure the PTEC efficiency, a simulative volumetric solar thermal conversion device was used with the test samples opened to a solar simulator as the light source. They showed that the SWEA fractions of DIW-based MWCNT-SiO2/Ag NFs ranged from 71.4% to 74.5% with mixing ratios of 4:1 and 1:4 having the highest and lowest values. However, 73.2% and 69.1% were obtained for DIW-based MWCNT and SiO2/Ag NFs. On exposure to irradiation for 1 h, temperatures of 48.1–59.3 °C, 47.7–56.6 °C, and 48.6–62.3 °C were recorded for MWCNT, SiO2/Ag, and MWCNT-SiO2/Ag (with volume fractions of 0.001–0.1%) NFs, respectively, and 46.9 °C for DIW. The HNFs attained maximum PTEC efficiency of 97.6% and 42.7% at 35 °C and 70 °C, respectively. This indicated that the HNFs have higher PTEC efficiency than MNFs and that the PTEC efficiency was reduced with temperature increase. The obtained results were strongly connected to the higher κ and absorbance values recorded for the HNFs in comparison with MNFs and DIW. Shi et al. [59] studied the PTEC and purification capability of Fe3O4-TiO2/DIW NF with φ = 0.1 g/L in solar energy applications. The experiment exposed the HNFs to a solar simulator and the PTEC was evaluated using an empirical equation. The results proved that with increasing solar power intensities (1–10 suns), the thermal receiver efficiency was observed to reduce while the degradation and evaporation (at a steady-state) efficiency slowly increased. At 1 sun, maximum thermal receiver efficiency of 76.4% and degradation efficiency of 85% were recorded. A magnetic field was used to recover the HNPs of the HNF for purification purposes and this led to recovery efficiency of 47.4% and 94.0% with a magnetic field intensity of 25 mT and 100 mT, respectively. After 1200 s, total material recovery was achieved under magnetic field influence and no change in the material was observed in the absence of the magnetic field.

The possible manipulation of the thermal, optical, and photothermal properties of various NFs (TiN, Fe3O4, and Fe3O4-TiN with volume fractions of 0.005–0.04%) under diverse magnetic field strengths and orientations were investigated by Zeng and Xuan [94]. A simulative volumetric solar thermal conversion set up was used to measure the photo-thermal property of HNFs. They demonstrated that transmittance decreased with an increase in φ whereas the opposite was observed for absorbance. A rise in the temperature of the studied samples was noticed as solar irradiation time and φ increased. With 1 h solar irradiation time and volume fraction of 0.005%, the SWEA fraction and temperature (of studied NFs) increment order of Fe3O4-TiN > Fe3O4 > TiN was observed. The parallel configuration of the incident light and magnetic field direction was noticed to produce better results than the perpendicular case, except for the absorbance where further reduction was recorded. Under magnetic field exposure, the SWEA fraction, and temperature of Fe3O4-TiN and Fe3O4 NFs were reduced with increasing magnetic field strength. The obtained findings (under magnetic field influence) were due to the improvement of their κ values and this revealed the potential alteration of absorbance, absorbed solar energy, PTEC performance, and heat transfer of magnetic HNFs for solar applications.

Qu et al. [95] examined the optical properties and PTEC performance of CuO (0.01–0.25 wt%)-MWCNT (0.005–0.0015 wt%)/DIW NFs. Light from a solar simulator was beamed on the test samples for the photothermal property of the samples. The results proved that the transmittance decreased as the concentration of the HNFs increased but the EC enhanced with it. Using DIW-based 0.15 wt% CuO + 0.005 wt% MWCNT NF and at an optical penetration of 1 cm and solar radiation time of 45 min, the SWEA fractions of HNF were 99.2%. The highest terminal temperature surge (14.1 °C) was reached at the optimum mixing ratio of the HNFs and irradiation time of 45 min, in comparison with DIW. The use of HNFs, especially at the optimum mixing ratio yielded working fluids with better PTEC performance than MNFs (in this case DIW-based CuO and MWCNT NFs). The stability, optical, and thermal properties, and PTEC efficacy of DIW-based rGO, rGO-Ag (15), and rGO-Ag (30) NFs at varying concentrations (10–100 mg/L) as thermal fluids in a DASC, were examined by Mehrali et al. [96]. A solar simulator was engaged as a light source in the experiment. An evaluation of the PTEC efficiency was carried out using an established empirical equation. The absorbance, EC, and SWEA fraction of the MNF and HNFs were noticed to improve with concentration while the transmittance decreased with concentration. With an irradiation time of 2000 s, the highest change in temperature on the surface (top) of the collector was 24 °C, 27.4 °C, and 28.6 °C for rGO, rGO-Ag (15), and rGO-Ag (30) NFs, respectively. In addition, PTEC efficiency of 63.3% (at 80 mg/L), 78% (at 100 mg/L), and 77% (at 40 mg/L) was achieved with rGO, rGO-Ag (30), and rGO-Ag (15) NFs, respectively, at 1 sun irradiation and 2000 s irradiation time. The best candidate for DASC application based on cost was rGO-Ag (15) NF with 40 mg/L concentration and 20 mm collector height.

The PTEC performance, SAR, and cost of the deployment of DIW-based Au, Cu, carbon black, and Au-Cu NFs as thermal fluids in DASC were examined by Zeiny et al. [97]. Light was beamed on the test samples using a sun simulator while the PTEC efficiency was estimated using an empirical equation. They observed that increasing the irradiation time slightly increased the temperature of the studied samples while an increase in mass concentration moderately enhanced the temperature of the samples. The PTEC efficiency and enhancement were enhanced as the mass concentration of the MNFs and HNF increased but they decreased as irradiation time increased. Additionally, the SAR and cost of the MNFs reduced and increased with concentration increase, respectively. With PTEC efficiency of 125%, 72%, and 100% for carbon black (100 mg/L), Au (150 mg/L), and Cu (3000 mg/L) NFs, respectively, the HNFs did not show an increase in this parameter. Based on SAR and cost values, the carbon black NF appeared to be the best MNF. Bhalla et al. [98] experimented the PTEC characteristics of DIW-based Al2O3 (20–150 mg/L) + Co3O4 (20–80 mg/L) NFs in DASCs using surface absorption and blended NF absorption systems. An artificial light source was used to simulate solar irradiation. The effectiveness of these systems was performed under similar working conditions. The results proved that the HNFs have an SWEA fraction of over 80% at a penetration depth of 20 mm. The addition of different mass fractions of Co3O4/DIW NFs to various fixed mass fractions of Al2O3/DIW NFs showed an increase in the SWEA fraction. At an optimum mass fraction of 40 mg/L Al2O3 + 40 mg/L Co3O4 NF, the peak temperature rise was attained with the HNFs as thermal media. Under similar working conditions, the blended NF absorption system was observed to yield a higher temperature (5.4 °C) than the surface absorption system due to the deployment of HNFs, therefore, making them good candidates for DASC.

Silicone oil-based ZnO-Au NFs with φ = 0.1–1.0 mg/mL were deployed to examine the optical properties and PTEC performance under varying irradiation duration and intensities [99]. The tested HNFs were subjected to simulated solar radiation. PTEC efficiency was estimated using an empirical equation. Results proved that the transmittance of the studied sample decreased with φ while the EC was enhanced with φ. Increasing solar radiation time, φ, and height (from the bottom of the beaker) improved the temperature of the studied samples at a stirring rate of 1000 rpm. On exposure of the silicone oil-based ZnO-Au NFs (φ = 1.0 mg/mL) to 10 kW/m2 solar radiation for less than 1 h, the temperature was raised to around 125 °C. The PTEC efficiency of 36%, 49%, and 60% was obtained for ZnO-Au/silicone oil NFs with concentrations of 0.1, 0.5, and 1 mg/mL, respectively. In comparison with silicone oil (17%), PTEC efficiency improvement of 240% was achieved using 1 mg/mL ZnO-Au/silicone oil NF. Increasing the solar radiation intensity was observed to enhance the temperature of 1 mg/mL ZnO-Au/silicone oil NF. They demonstrated that ZnO-Au/silicone oil NFs were effective working fluids for application in DASCs.

Using EG-based FeNi/C NFs with concentrations of 5–50 ppm, Wang et al. [100] investigated their optical properties and PTEC performance under forced convection flow conditions in the absence and presence of a rotating magnetic field (50 mT). The HNFs were exposed to simulated solar radiation as the PTEC efficiency was evaluated using an equation. Results revealed that an increase in concentration led to the enhancement of EC and SWEA fraction and a reduction in transmittance for the studied samples. At an optical depth of 1 cm, absorbed energy was observed to appreciate with an increase in concentration and irradiation time. With solar irradiation time of 3600 s, the FeNi/C-EG NFs recorded absorbed energy of 1024.9 J, 1088.3 J, 1036.4 J, and 1022.4 J (without magnetic field) and 1069.9 J, 1233.6 J, 1269.2 J, and 1254.8 J (with the magnetic field) at 5 ppm, 15 ppm, 25 ppm, and 50 ppm, respectively, in comparison with EG (872 J). In addition, PTEC efficiency of 47.4%, 50.4%, 47.9%, and 47.3% (without magnetic field) and 49.5%, 57.1%, 58.7%, and 58.1% (magnetic field) was obtained for FeNi/C-EG NFs at 5 ppm, 15 ppm, 25 ppm, and 50 ppm, respectively, as compared with EG (40.4%). The magnetic field manipulation of the magnetic FeNi/C-EG NFs as working fluids in a DASC appears to improve its PTEC efficiency. Gulzar et al. [101] investigated the doping of a high-temperature thermal fluid (therminol-55) with Al2O3, TiO2, and Al2O3-TiO2 NPs as working fluids for concentrated solar collectors. To estimate the photothermal energy conversion, the test samples were subjected to simulated solar radiation as a light source. The MNFs and HNFs were formulated at weight concentrations of 0.05–0.5 wt% and subsequently studied the increase in heat gain, temperature, and temperature enhancement. Results demonstrated that due to higher absorption, maximum PTEC (heat gain) was observed with the HNFs followed by Al2O3 and TiO2 NFs. Though TiO2 NFs yielded the highest absorbance, Al2O3-TiO2 and Al2O3 NFs showed maximum temperatures of 158.6 °C and 152.9 °C, respectively, compared with 149.6 °C for TiO2 NFs and 125.8 °C for therminol-55. With the same irradiation time of 5000 s, a peak temperature improvement of 34 °C was noticed with 0.5 wt% Al2O3-TiO2/therminol-55 NF. For both Al2O3 and TiO2 NFs, increasing the weight concentration was observed to increase the maximum temperature enhancement.

Jin et al. [102] examined the SWEA capacity and PTEC performance of different DIW-based MNFs (Cu, Au, and Fe3O4) and HNFs (Cu-Au, Fe3O4-Au, Fe3O4-Cu, and Fe3O4-Cu-Au with equal volume fractions) as working fluids in DASC. The tested HNFs were subjected to a simulated light source and the PTEC efficiency was estimated using an equation. They showed that with an irradiation time of 300 s, the temperatures of water-based Cu, Au, Fe3O4, Cu-Au, and Fe3O4-Au NFs were 30.36 °C, 30.89 °C, 29.74 °C, 31.2 °C, and 30.47 °C, respectively. Additionally, at 1.5 cm optical depth, the PTEC efficiency of Cu, Au, Fe3O4, Cu-Au, Fe3O4-Au, Fe3O4-Cu, and Fe3O4-Cu-Au NFs was 75.4%, 76.2%, 61.2%, 80.2%, 70.7%, 76.9%, and 75.5%, respectively. It was observed that the PTEC efficiency of the HNFs enhanced as φ increased with optimum values achieved using Cu-Au (Au–0.52 volume fraction) and Fe3O4-Cu (Cu–0.46 volume fraction) NFs. Using DIW-based SiO2/Ag-CuO NF as a working fluid in a DASC, Joseph et al. [103] examined the thermo-optical properties and PTEC performance. Tested samples of HNFs were exposed to sunlight and the PTEC was calculated using an existing equation. The formulation of a stable SiO2/Ag-CuO NF was optimized via the mass fractions of CuO NPs, SiO2/Ag NPs, SDS (as a surfactant), relative κ, and SWEA fraction. Their results showed optimal values of 864.7 mg/L for CuO NPs, 206.3 mg/L for SiO2/Ag NPs, and 1996.2 mg/L for SDS to produce good relative κ (1.234) and SWEA fraction (82.8%). Using the HNF, a peak temperature of 45.7 °C was recorded against 38.8 °C for DIW. Additionally, the SiO2/Ag-CuO NF absorbed maximum energy of 1942.6 J while that of DIW was 1239 J. They proposed a mathematical model for the estimation of relative κ and SWEA fraction as dependent on mass fractions of CuO, SDS, and SiO2/Ag.

Table 2.

Photothermal performance of HNFs with different HNPs, mixing ratios, optical properties, surfactants, process methods, and stability tests.

Table 2.

Photothermal performance of HNFs with different HNPs, mixing ratios, optical properties, surfactants, process methods, and stability tests.

| References | HNF (Mix)/Base Fluid | φ | Optical | Nano-Size (nm) | Stability | Result |

|---|---|---|---|---|---|---|

| Tong et al. [61] | MWCNT-Fe3O4 (20:80–80:20)/EG-W (20:80) | 0.01 wt% (25°) | Absorbance, transmittance, and κ | MW-10–20 Fe3O4-10 | UV, ZP, and Visual (2-step) | SWEA fraction and PTEC efficiency of the HNFs were higher than the Fe3O4 NF. |

| Gulzar et al. [101] | Al2O3-TiO2 (60:40)/Therminol-55 | 0.05–0.5 wt% | Absorbance and transmittance | Al2O3-<80 TiO2-15–25 | Visual (72-D), UV, Oleic (2-step) | At the same irradiation time of 5000 s, the highest temperature improvement (34 °C) was noticed with 0.5 wt% Al2O3-TiO2/therminol-55 NF. |

| Zhou et al. [60] | GO-Au/DW | 0.1–0.3 mg/mL | Absorbance and transmittance | - | UV, ZP, glucose-functionalized (2-step) | The 0.2 mg/mL-GO-Au/DIW NF was the best thermal fluid with peak evaporation rate, enhancement factor, and PTEC efficiency of 1.34 kg/m2 h, 2.35, and 84.1%, respectively. |

| Hjerrild et al. [92] | Ag-SiO2/GL | Absorbance and transmittance | - | UV | Ag-SiO2/GL NF was noticed to be stable under medium-temperature thermal treatment and accelerated high UV irradiation exposure. Ag-SiO2/GL NF is better than Ag-SiO2/W NF in a PV/T collector with high temperature and electrical output. | |

| Shi et al. [59] | Fe3O4-TiO2/DIW | Absorbance and transmittance | Fe3O4-TiO2-50 | UV | The highest thermal receiver efficiency of 76.4% and degradation efficiency of 85% were recorded at 1 sun. Increasing magnetic field intensity enhanced degradation efficiency from 47% (25 mT) to 94% (100 mT). | |

| Zeng and Xuan [93] | MWCNT-SiO2/Ag (4:1–1:4)/DIW | 0.001–0.1% | Absorbance, transmittance, and κ | MWCNT-8–15 | UV, ZP, CTAB | Maximum PTEC efficiency of 97.6% was achieved using HNFs, making them better thermal fluids than MNFs. This was due to the high κ and absorbance values of HNFs. |

| Bhalla et al. [98] | Al2O3-Co3O4/DIW | Al2O3 (20–150 mg/L) Co3O4 (20–80 mg/L) | Absorbance and transmittance | Al2O3-13 Co3O4-10–30 | Triton X-100 (2-step) | The optimum mass fraction of 40 mg/L Al2O3 + 40 mg/L Co3O4 NF yielded the highest temperature rise. Under similar working conditions, the blended NF absorption system was noticed to yield a higher temperature (5.4 °C) than the surface absorption system. |

| Li et al. [104] | SiC-MWCNT (8:2)/EG | 0.01–1 wt% | Absorbance and transmittance | SiC-40 MWCNT-20 | ZP, UV, PVP, (2-step) | The SWEA fraction of 0.5 wt% SiC-MWCNT/EG NF was 99.9% at a penetration distance of 1 cm. With an irradiation time of 10 min, the peak PTEC efficiency was 97.3% using SiC-MWCNT/EG NF with φ = 1 wt%, which was 48.6% more than that of EG. |

| Jin et al. [102] | Cu-Au, Fe3O4-Au, Fe3O4-Cu (1:1), and Fe3O4-Cu-Au (1:1:1)/DIW | 0.06–1 vol% | Absorbance and transmittance | Cu-60–80 | UV | The PTEC efficiency of Cu, Au, Fe3O4, Cu-Au, Fe3O4-Au, Fe3O4-Cu, and Fe3O4-Cu-Au NFs was 75.4%, 76.2%, 61.2%, 80.2%, 70.7%, 76.9%, and 75.5%, respectively, at 1.5 cm optical depth. |

| Qu et al. [95] | CuO-MWCNT/DIW | 0.0015 wt% and 0.005 wt% (MWCNT), 0.01–0.25 wt% (CuO) | Extinction coefficient, absorbance, and transmittance. | MWCNT->50 | UV | Using DIW-based 0.15 wt% CuO + 0.005 wt% MWCNT NF and at an optical distance of 1 cm and irradiation time of 45 min, the SWEA fractions of HNF was 99.2%. The HNFs have improved PTEC efficiency better MNFs. |

| Mehrali et al. [96] | rGO-Ag/DIW | 10–100 mg/L | Extinction coefficient, absorbance, transmittance, κ, and μ. | Ag-25–45 | UV | The PTEC efficiency of 63.3% (80 mg/L), 78% (100 mg/L), and 77% (40 mg/L) was achieved with rGO, rGO-Ag (30), and rGO-Ag (15) NFs, respectively, at 1 sun irradiation intensity and 2000 s irradiation time. The rGO-Ag (15) NF was the best thermal fluid at a collector height of 2 cm. |

| Campus et al. [105] | Au, Ags, Agc, Cu, GOh, GOl, and Ag-GOl/water | 40 and 100 mg/L | Extinction coefficient, absorbance, transmittance, and κ | Au-20, Ags-60, Agc-40–120, Cu-10–100, and Ag-Gol-18 | UV | Under natural solar irradiation (high flux) of 600 s, a higher influence of the NPs shapes on the temperature difference and PTEC efficiency for NFs and HNFs was observed in comparison with artificial irradiation of 1 sun for 3000 s. |

| Kimpton et al. [62] | Ag, SiO2, and Ag-SiO2/W | - | Absorbance and optical density | - | UV (1-step) | The highest temperature and enhancement of 44.1 °C and 102% and 41.7 °C and 91% were observed for Ag and Ag-SiO2 NFs in comparison with water (21.8 °C), respectively. The PTEC efficiency of Ag-SiO2 and Ag NFs was around three-fold more than that of SiO2 NF. |

| Joseph et al. [103] | SiO2/Ag-CuO/DIW | - | κ | CuO-<50 | UV, ZP, SDS (2-step) | Optimal values of 206.3 mg/L, 864.7 mg/L, and 1996.2 mg/L for SiO2/Ag, CuO, and SDS produced good relative thermal conductivity (1.234) and SWEA fraction (82.8%). With the HNF, a peak temperature of 45.7 °C was recorded against 38.8 °C for DIW. |

| Zeiny et al. [97] | Au-Cu (1:1)/DIW | Absorbance | - | UV, DLS, ZP, | With PTEC efficiency of 125%, 72%, and 100% for carbon black (100 mg/L), Au (150 mg/L), and Cu (3000 mg/L) NFs, respectively, the HNFs showed no increase in this variable. Subject to SAR and cost results, the carbon black NF was a suitable thermal fluid. | |

| Wang et al. [100] | FeNi/C (2.19:2.41:95.4)/EG | 5–50 mg/L | Extinction coefficient, absorbance, transmittance, and B = 50 mT. | FeNi/C-8-10 | UV, Visual (2-step) | With solar irradiation time of 3600 s, PTEC efficiency of 47.3–50.4% (without magnetic field) and 49.5–58.7% (magnetic field) for EG-based FeNi/C NFs at 5–50 ppm, as compared with EG (40.4%). |

| Zhu et al. [106] | Ag-Au-ZNG, Au-ZNG, Ag-ZNG/EG | 10–100 ppm | Extinction coefficient, absorbance, and transmittance. | - | UV (2-step) | At an optical depth of 1 cm, concentration of 100 ppm, and solar irradiation of 3000 s, maximum temperature rise, SWEA fraction, and PTEC efficiency of 58.6 °C, 97.1%, and 74.35% were obtained for Ag-Au/ZNGs NF, respectively. |

| He et al. [107] | Ag-TiO2/EG-W | 50–200 ppm | Extinction coefficient, absorbance, and transmittance. | Ag-TiO2-23.6 TiO2-2 | UV | The PTEC efficiency of Ag-TiO2 NF (at 200 ppm) and EG-W (60:40) was 39.9% and 78.1%, respectively, while the PV efficiency was 5.6% for Ag-TiO2 NF. The overall PTEC efficiency of Ag-TiO2 NF was 83.7% (200 ppm) whereas 54.1% was recorded for EG-W (60:40). |

| Wang et al. [99] | ZnO-Au/silicone oil | 0.1–1 mg/mL | Extinction coefficient, absorbance, transmittance, and cp. | Au-13.3, ZnO-0.08 μm | UV (2-step) | The PTEC efficiency of 36%, 49%, and 60% was obtained for ZnO-Au/silicone oil NFs with concentrations of 0.1, 0.5, and 1 mg/mL, respectively. PTEC efficiency improvement of 240% was attained with 1 mg/mL ZnO-Au/silicone oil NF. |

| Chen et al. [86] | Au-Ag/DIW | Au (0.5–2.5 ppm) + Ag (0.15 ppm and 0.5 ppm) | Absorbance. | Au-10 Ag-30 | UV | The PTEC efficiency for Au (1.75 ppm) + Ag (0.15 ppm), Au (1.75 ppm), and Ag (0.15 ppm) NFs was 30.97%, 19.01%, and 11.90% was obtained respectively. |

| Zeng and Xuan [94] | Fe3O4-TIN/DIW | 0.005–0.04% | Extinction coefficient, absorbance, magnetization, and transmittance. | Fe3O4-100 TIN-15 | UV, Visual | With 1 h solar irradiation and volume fraction of 0.005%, the SWEA fraction and temperature of NFs increased in the order of Fe3O4-TiN > Fe3O4 > TiN. The parallel orientation of incident light and magnetic field direction was noticed to produce better results than the perpendicular case, except for the absorbance. |

| Carrillo-Torres et al. [87] | Au-Ag | - | - | - | DLS | For the HNF, maximum photothermal efficiency of 74.68% was obtained while a temperature of 20 °C was recorded after exposing the sample to 15 min of irradiation. |

| Shende and Sundara, [108] | rGO-MWCNT/DIW and EG | - | κ | - | UV, PEG: SLS (2:1), | The thermal and optical properties of rGO-MWNT NF were observed to be enhanced compared with DIW and EG. |

| Chen et al. [88] | CuO-ATO (1:9–9:1)/DIW | 0.02–0.12 vol% | - | - | UV, ZP, pH, sodium citrate (2-step) | Maximum SWEA fraction, temperature change, and PTEC efficiency of 99.6%, 43.6 °C, and 92.5%; 89.5%, 39.8 °C, and 81.3%; and 89.8%, 39.6 °C, and 80.7% were recorded for CuO-ATO, CuO, and ATO NFs, respectively. |

| Xuan et al. [64] | TiO2-Ag/DIW | 0.002–0.15% | - | TiO2-30 Ag-20 | (2-step) | Absorbed energy, temperature, and thermal efficiency of 57.89, 390.88, and 413.36 W/m2; 60.21 °C, 66.65 °C, and 66.93 °C; and 16.07%, 20.86%, and 20.9% were obtained for TiO2, Ag, and TiO2-Ag NFs, respectively. |

| Shin et al. [77] | MWCNT-Fe3O4 (1:1)/EG-W (20:80 wt%) | 0.005–0.2 wt% | Transmittance, B = 250–750 G, and κ | - | Visual (2-step) | The temperature and PTEC efficiency of 0.2 wt% MWCNT-Fe3O4 NF was 45 °C and 32% (without magnetic field) and 60 °C and 45% (with the magnetic field of 750 G). Under 750 G magnetic intensity, the total stored energy of 0.2 wt% MWCNT/Fe3O4 NF was enhanced by 61.5%. |

| Li et al. [104] | SiC-MWCNT (80:20)/EG | 0.01–1 wt% | Extinction coefficient, absorbance, and transmittance. | SiC- 40 MWCNT- 20 | ZP, UV, Visual, PVP-K30, (2-step) | At a maximum SWEA fraction of over 99.9%, the temperature difference of close to 110 °C, and PTEC efficiency of 97.3% were obtained with 1 wt% SiC-MWCNT/EG NF. |

Zhu et al. [106] examined the utilization of EG-based ZNGs, Au/, Ag/, and Ag-Au/ZNGs NFs (with concentrations of 10–100 ppm) as working fluids in DASC systems. With the use of a laboratory-built device, the PTEC efficiency was evaluated. A solar simulator was utilized as a source of light beamed on the tested samples. The optical properties and the PTEC capacity of the MNFs and HNFS were studied. With an increase in the concentration of the MNFs and HNFs, the SWEA fraction and EC were enhanced while the transmittance was reduced. This led to the improvement of PTEC efficiency with a rise in temperature, irradiation time, and concentration for all the studied samples due to the plasmonic effect and hybridization of HNPs. At an optical depth of 1 cm, a concentration of 100 ppm, and solar irradiation of 3000 s, SWEA fraction and PTEC efficiencies of 90.1%, 94.9%, 95.4%, and 97.1% and 69.25%, 70.35%, 72.41%, and 74.35% were obtained for ZNGs, Ag/, Au/ and Ag-Au/ZNGs NFs, respectively. The temperature of Ag/, Au/, and Ag-Au/ZNGs NFs were more than that of ZNGs, with Au/ZNGs NFs having the highest temperature (58.61 °C).

For a PV/T system, He et al. [107] examined the SWEA and PTEC performance of EG-W (60:40)-based Ag-TiO2 NFs with concentrations of 50–200 ppm as beam-splitter in a temperate region. A theoretical model based on energy balance was used to evaluate PTEC efficiency. A solar simulator was deployed as a light source to illuminate the test samples. The transmittance and absorbance were inversely and directly proportional to the concentration of the HNFs. After 35 min of exposure to solar radiation, the temperature of Ag-TiO2 NFs (200 ppm) was increased to 16.6 K. The current and power density were noticed to improve as voltage decreased and increased, respectively, while a reduction in concentration enhanced the current and power density of all the samples. The PTEC efficiency of Ag-TiO2 NF (at 200 ppm) and EG-W (60:40) was 39.9% and 78.1%, respectively, while the PV efficiency was 5.6% for Ag-TiO2 NF (at 200 ppm). The overall PTEC efficiency of Ag-TiO2 NF was 70.7%, 74.8%, and 83.7% at concentrations of 50, 100, and 200 ppm whereas 54.1% was recorded for EG-W (60:40). With higher merit functions of 1.89 (50 ppm), 1.91 (100 ppm), and 2.04 (200 ppm) for the HNF-based splitters compared with 1.64 for the base fluid, coupled with worth factor of 3 for Ag-TiO2 NF (at 200 ppm), the HNF-based splitter at the highest concentration appeared suitable for PV/T applications.

Campus et al. [105] studied the thermal and optical properties, and PTEC performance of water-based spherical (Au, Cu, and Ags), non-spherical (Agc, GOh, and GOl), and hybrid (GOl-Ag) NFs as working fluids in DASC. The influence of particle types and shapes, natural and artificial irradiation, irradiation time (600 s and 3000 s), and concentration (40 mg/L and 100 mg/L) on the PTEC efficiency were studied. They noticed that SWEA efficiency increased with a decrease in temperature while the temperature change increased with irradiation time. With 1 sun and irradiation of 3000 s, an order of GOl-Ag NF (91%) > GOl NF (73%) > GOh NF > Agc NF (71%) > Au NF (65%) > Cu NF (60%) > Ags NF (40%) was observed for the SWEA efficiency under different concentrations of 40 mg/L and 100 mg/L. The subjection of the MNFs and HNFs to natural solar irradiation (high flux) for 600 s resulted in a higher influence of the NPs shapes on the temperature difference and SWEA efficiency in comparison with artificial irradiation of 1 sun for 3000 s. This study showed that the GOl-Ag and Agc NFs were the most suitable thermal fluids as they have the highest SWEA efficiency. Recently, Tong et al. [61] examined the SWEA and transmittance characteristics and the PTEC efficiency of MWCNT-Fe3O4/W-EG (80:20) NFs at varying mixing ratios (80:20–20:80). Radiation of the sun was used as a light source and the PTEC efficiency was estimated using established equation. They showed that increasing the ratio of the MWCNT particle in the HNF caused an enhancement of the SWEA fraction and PTEC efficiency and a reduction in the transmittance characteristics. The highest transmittance (29%) was recorded for the HNF with a mixing ratio of 80:20 while 89% was observed for Fe3O4/W-EG (80:20) NF, all at 0.01 wt%. Thus, indicating that the MNF has a better transmittance property than the HNF. With higher thermal and optical properties of MWCNT-Fe3O4/W-EG NFs compared with Fe3O4/W-EG NFs, higher SWEA fraction (1–maximum), and PTEC efficiency were observed.

For the first time, an attempt was made by Kimpton et al. [62] to investigate the optical and stability properties and PTEC efficiency of water-based Ag, Ag-SiO2, and SiO2 NFs under natural and simulated solar exposure. Simulated sunlight was deployed as a light source in the experiment while the PTEC efficiency was estimated using the applicable existing equation. Results demonstrated the instability of Ag-SiO2 and Ag NFs on exposure to natural solar irradiation, with a higher tendency observed for Ag NF. With all the studied samples and under simulated solar irradiation, the temperature change rose as irradiation time increased. The highest temperature was observed with Ag NF (44.1 °C), followed by Ag-SiO2 NF (41.7 °C) and SiO2 (23.6 °C), with corresponding enhancements of 102%, 91%, and 8% in comparison with water (21.8 °C), respectively. The PTEC efficiency of Ag-SiO2 and Ag NFs was around three-fold more than that of SiO2 NF. The stability, optical properties, SWEA, and PTEC performance of therminol®66-based GO-MWCNT NFs (with φ = 10–150 ppm) as potential working fluids in a DASC under indoor and outdoor conditions were studied by Qu et al. [109]. Tested samples were subjected to simulated and real sunlight and the evaluation of the PTEC efficiency was calculated using an empirical equation. Similar to other studies, increasing φ enhanced EC and SWEA fraction and reduced the transmittance of the studied samples. Maximum temperature and PTEC efficiency were accomplished with HNF at an optimum concentration of 100 ppm. At an optical depth of 1.75 cm, a concentration of 150 ppm, and a solar radiation time of 45 min, 99% SWEA capacity was recorded. Under indoor and outdoor conditions, the temperature of 100 ppm-GO-MWCNT/therminol®66 NF was 94 °C and 153 °C and 11.6 °C and 97 °C higher than therminol®66, respectively.

The thermal-optical properties and the PTEC performance of EG-W (20:80)-based MWCNT-Fe3O4 (1:1) NFs with φ = 0.005–0.2 wt% as working fluids in a solar collector were studied by Shin et al. [77] under varying magnetic fields (250–750 G). Irradiation of the tested samples was carried out using solar simulation. Estimation of the PTEC efficiency was done using the established equation. Increasing the magnetic field was observed to enhance κ and temperature, and it reduced the PTEC efficiency of the HNFs. As the φ increased, κ, SWEA fraction, temperature, PTEC efficiency, and total stored energy were enhanced. On exposure to solar radiation of 560 W/m2 for 1 h and at an optical length of 1 cm, the temperature and PTEC efficiency of 0.2 wt% MWCNT-Fe3O4 NF were 45 °C and 32% (without magnetic field) and 60 °C and 45% (with a magnetic field of 750 G), respectively. On exposure of 0.2 wt% MWCNT-Fe3O4 NF to 20 min of solar radiation, the PTEC efficiency was 65% and 54% in the presence and absence of magnetic field intensity of 750 G, respectively. Under 750 G magnetic intensity, a peak total stored energy of 15 MJ was recorded for 0.2 wt% MWCNT/Fe3O4 NF, which translated to a 61.5% increment compared with the case of no magnetic field. This study showed an order of MWCNT > MWCNT-Fe3O4 > Fe3O4 for the PTEC efficiency and temperature due to the κ, transmittance, and SWEA efficiency of these MNFs and HNF. Li et al. [104] explored the stability, optical properties (EC and transmittance), and PTEC efficiency of SiC-MWCNT (8:2)/EG NFs with φ = 0.01–1 wt% as efficient working fluids in DASC. Tested HNFs were exposed to solar simulated light for the photothermal experiment, while the PTEC efficiency was evaluated using the established equation. The results revealed excellent stability and SWEA characteristics (200–1100 nm) for SiC-MWCNT/EG NFs as working fluids. Increasing the mass fraction of SiC-MWCNT/EG NF was noticed to enhance the EC, relative absorbance, solar irradiation, temperature difference, irradiation time, and PTEC performance but it reduced with transmittance. At an optical depth of 1 cm, the SWEA fraction of SiC-MWCNT/EG NF with φ = 0.5 wt% was 99.9%. The highest temperature difference for the HNFs was 32 °C above that of EG. With an irradiation time of 10 min, the peak PTEC efficiency (97.3%) was achieved using SiC-MWCNT/EG NF with φ = 1 wt%, which was 48.6% more than the value recorded when EG was used. The authors recommended the utilization of 0.5 wt% and 1 wt% SiC-MWCNT/EG NFs in DASC due to the PTEC performance.

Factors such as nano-size [88], types, shapes of NPs, concentration, Brownian motion, nano-layering, stability, optical properties (absorptivity and EC) and κ of HNPs, mixing ratios, magnetic field strength and orientation [77], types of base fluids have been shown to significantly influence the SWEA fractions, HNPs temperature rise [93], and consequently the PTEC efficiency of HNFs [94] as working fluids in solar energy application. Besides stability, nano-layering and Brownian motion are the two principal parameters that influence the thermal behavior of HNFs [101]. The solar-thermal properties of HNFs depend to a great extent on the relationship between the temperature change of HNFs and solar radiation time [104].

3. Solar Energy Application of Hybrid Nanofluids

The radiation of the sun releases solar energy which can be converted into heat and electricity. Outside of using photovoltaic cells to directly generate electricity from solar radiation, it is also practicable to harvest the same using steam generation, electric power generation, and thermal storage power technologies [95]. Solar collectors are engaged to absorb solar energy using different working fluids and the performance of the collectors is strongly connected to the optical and thermal properties of the working fluids. These optical properties include EC, absorptivity, transmissivity, scattering coefficient, SWEA, etc. [110]. PTEC is the most efficient of the solar energy harvesting methods of photothermal conversion, photochemical conversion, and photo-voltaic conversion [103]. The efficiency of solar collectors strongly depends on the thermophysical and optical properties of the HNFs used as working fluids, which are directly related to their PTEC performance [111]. The thermal properties, stability tests, and performances of various HNFs as working fluids for solar energy applications are presented in Table 3. Different HNPs (at varying mixing ratios and nano-sizes) and base fluids used to formulate the studied HNFs, and the characteristics of the various solar collectors used, are also included in Table 3. In addition, a summary of the key findings from the reviewed papers is presented in the table. Noteworthy works published between the inception of HNF studies and 2022 are reviewed in the compilation of Table 3.

Table 3.

Summary of stability tests, thermal properties, and performances of different HNFs, deployed in various solar collectors.

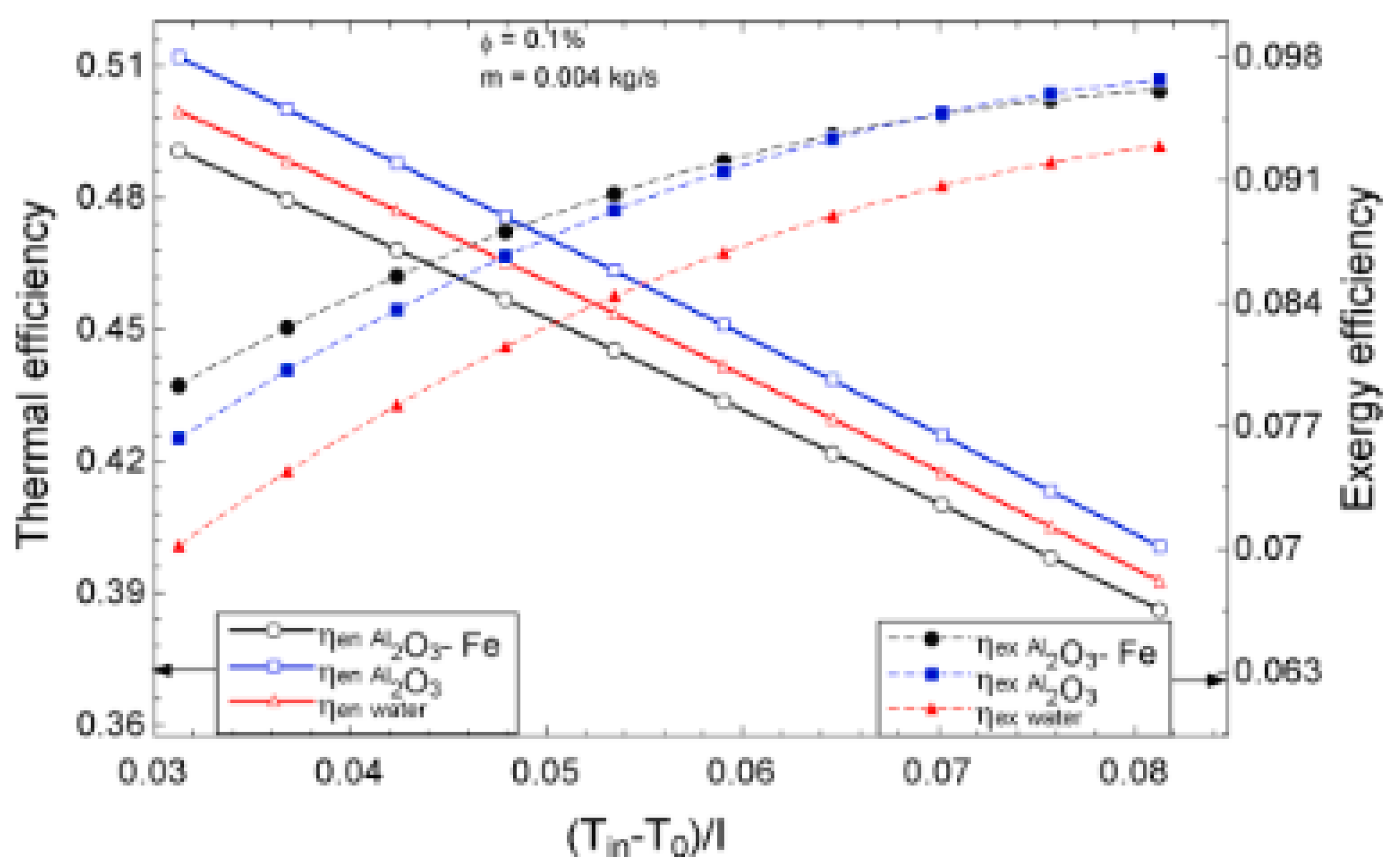

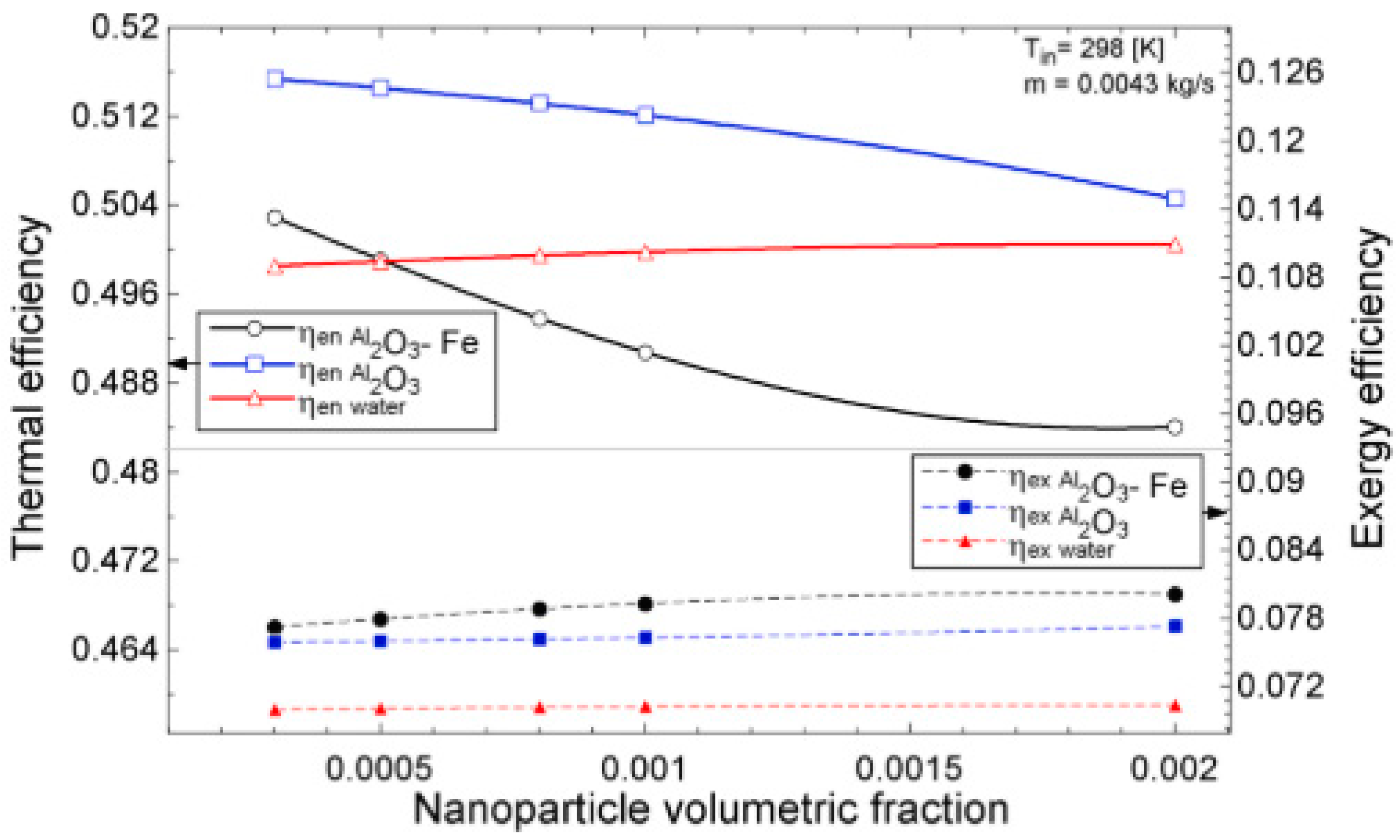

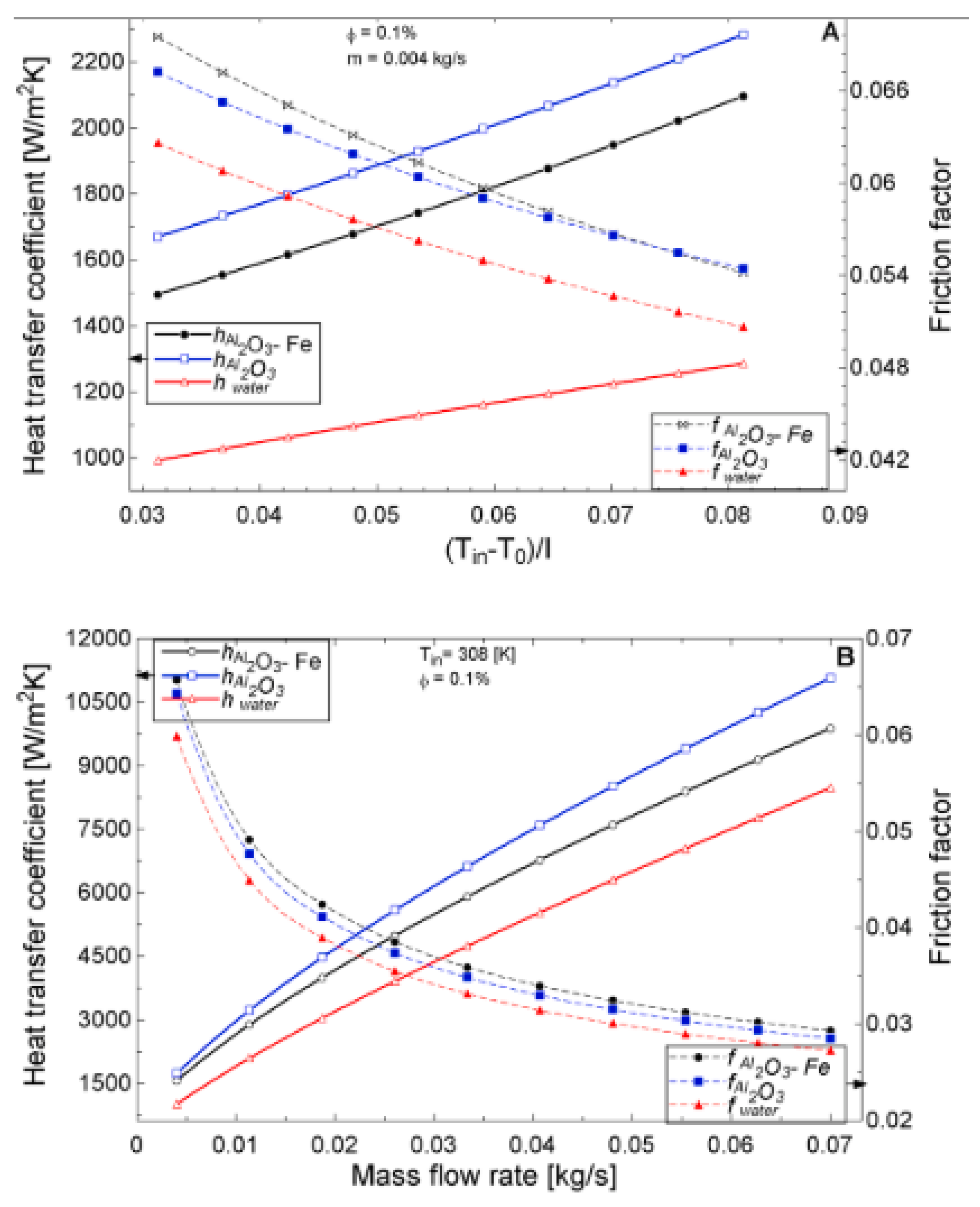

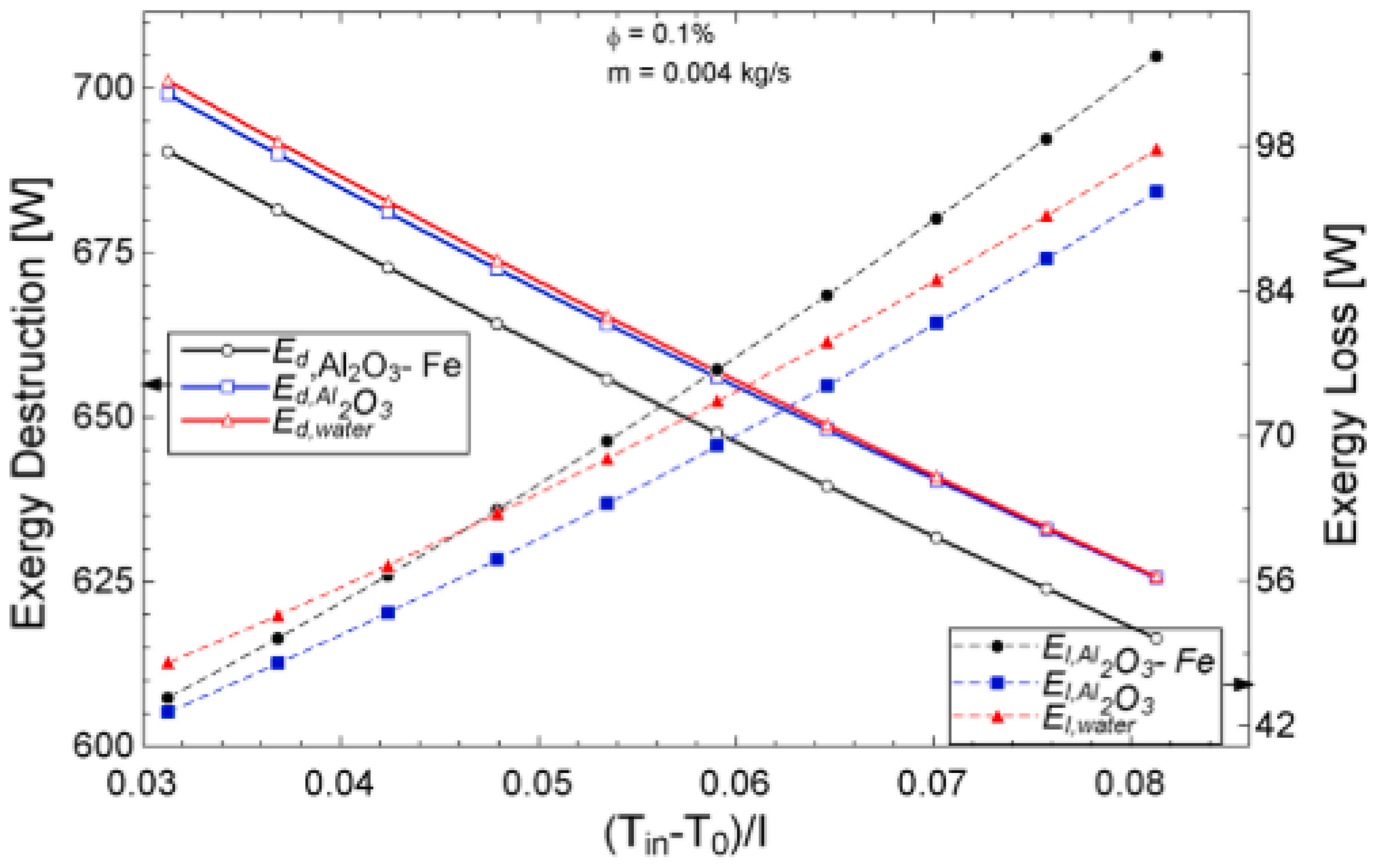

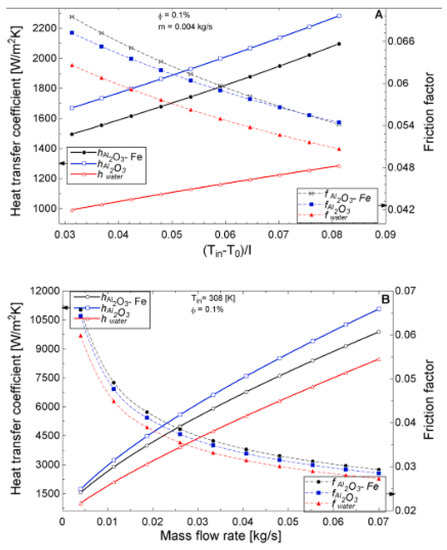

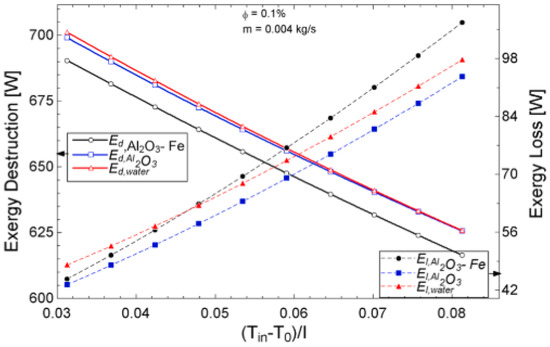

The temperature parameter and solar irradiance of HNFs of MWCNT-Fe3O4 (with varying mixing ratios) against increasing time of solar exposure are presented in Figure 9. Both solar irradiance and temperature parameter were improved as the exposure time increased with increasing amounts of MWCNT particles in the test samples found to cause this improvement. The energetic and exergetic efficiency of HNFs (MWCNT-Fe3O4) under varying temperatures and volume fractions as working fluids in an FPSC are provided in Figure 10 and Figure 11, respectively. Increasing temperature parameter was observed to reduce energetic efficiency and enhance exergetic efficiency. In Figure 12, the coefficient of heat transfer and friction factor of MWCNT-Fe3O4 nanofluids in an FPSC as functions of temperature parameters and mass flow rate is presented respectively while the exergy destruction and exergy loss of hybrid nanofluids in a solar collector under changing temperature parameters is illustrated in Figure 13. Further details of the study from which Figure 10, Figure 11, Figure 12 and Figure 13 are adapted are provided in paragraph three of Section 3.2.

Figure 9.

Temperature parameter and solar irradiance against increasing solar exposure duration for MWCNT/Fe3O4 nanofluids and base fluid (Adapted from Tong et al. [61]).

Figure 10.

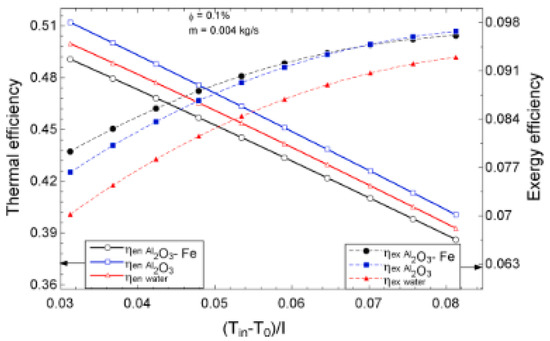

Thermal and exergetic efficiency performance of Al2O3-Fe nanofluid against temperature parameter for a flat plate collector application (Adapted from Okonkwo et al. [112]).

Figure 11.

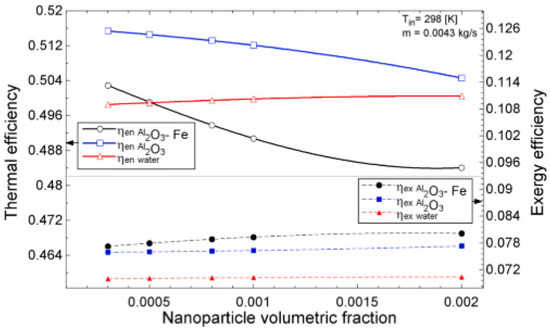

Thermal and exergetic efficiency performance of Al2O3-Fe and Al2O3 nanofluid and water against increasing volumetric fraction for a flat plate collector application (Adapted from Okonkwo et al. [112]).

Figure 12.

Coefficient of heat transfer coefficient and friction factor of 0.1% Al2O3-Fe and 0.1% Al2O3 nanofluid and water against varying mass flow rates at an inlet temperature of 308 K for a flat plate collector application (Adapted from Okonkwo et al. [112]). Heat transfer coefficient and friction factor performance as a function of (A) temperature (B) mass flow rate.

Figure 13.

Exergy destruction and exergy loss performance of Al2O3-Fe and Al2O3 nanofluid and water against increasing temperature parameters for a flat plate collector application (Adapted from Okonkwo et al. [112]).

3.1. Direct Absorption Solar Collectors

The influence of flow rate (20–100 cc/min) and mixing ratio (1:0–0:1) of DIW-based CeO2-CuO NFs (with φ = 0.1 vol%) on the thermal performance of a DASC was experimented in an outdoor and indoor environment under constant irradiation by Mohan and Sajeeb [116]. They showed that the thermal efficiency of the studied samples was enhanced as the flow rate increased while the same was improved as the mixing ratio of CuO NPs in the HNFs increased from 0.5 to 1.0 and as the CeO2 mixing ratio decreased from 1 to 0. In comparison with DIW and at a flow rate of 100 cc/min, the thermal efficiency of 13.8%, 18.1%, 24.3%, 24.9%, and 26.1% was obtained for the HNFs with mixing ratios of 1:0, 1:0.5, 1:1, 0.5:1, and 0:1, respectively. With the CeO2-CuO (1:1)/DIW NF, increasing the flow rate (20 to 100 cc/min) enhanced thermal efficiency by 16.5–51.5%. Additionally, at a flow rate of 100 cc/min, the thermal efficiency of CeO2-CuO/DIW NF was enhanced from 45.5% to 51.5%, when the mixing ratio of the HNF changed from 1:0 to 0.5:1. It was noticed that under indoor conditions, the thermal efficiency of all samples was improved as the flow rate increased with DIW-based CuO NF recording 35.4% thermal efficiency as the flow rate increased from 20 cc/min to 100 cc/min. It was observed that for the mixing ratios of 0:1, 1:1, and 0.5:1, the efficiency was almost the same.

Hong et al. [115] experimentally explored the efficiencies and solar vapor generation rates of HNFs (rGO + Ag, GO + Ag, rGO-Ag, and GO-Ag) with varying concentrations (0.113–1 mg/mL) under different light intensities (1–4 suns) as working fluids in different DASCs. The results showed that water mass loss increased as illumination time and concentration increased. Additionally, the relative efficiency and evaporation rate were observed to enhance with concentration increase. An order of rGO + Ag NFs > GO + Ag NFs > rGO-Ag NFs > GO-Ag NFs was noticed for the water mass loss, evaporation rate, and relative efficiency. At 3 suns, the relative efficiency ranges of 73.2–91.6%, 60.2–86.3%, 64.3–85.1%, and 54.1–79.9% were obtained for the GO + Ag, rGO + Ag, rGO-Ag, and GO-Ag NFs with concentrations of 1, 0.45, 0.225, and 0.1125 mg/mL, respectively. The elevated absorbance and plasmonic influence of the HNPs and high κ of graphene nanosheets were responsible for the obtained results. The future utilizations of rGO + Ag NF in applications such as desalination, power generation, and water treatment were recommended. Sreekumar et al. [63] investigated the thermal and exergy analysis of the deployment of DIW-ATO/Ag NF as a working fluid in a PTDASC. To formulate stable ATO-Ag/DIW NF, the mass fraction, surfactant mass fraction, and SWEA fraction were optimized. They reported an optimum mass fraction of 0.1% for ATO/Ag NF and surfactant with the corresponding SWEA of 90.1%. The results also demonstrated the enhancement of collector and exergy efficiency with an increase in temperature difference, irradiation intensity, and mass flow rate. At a mass flow rate of 0.022 kg/s and using the HNF, peak thermal efficiency due to a temperature surge of 12.6 °C was 63.5% while the highest exergy efficiency as a result of temperature difference of 8°C was 5.6%. Optical efficiency was noticed to improve as the angle of incidence decreased with a maximum value of 75% at 0°. Increasing the radiation penetration depth depreciated the transmittance of ATO-Ag/DIW NF while a rise in mass fraction enhanced its EC. This implied that the absorption of solar radiation can be achieved by either increasing the radiation penetration depth or mass fraction of the HNF. The authors proposed a mathematical model for the estimation of κ and SWEA fraction as dependent on mass fractions of ATO-Ag and SDS.

The influence of volume flow rate (1–5 L/h) and mixing ratio (0:100–100:0) of different HNFs (DW-based Al2O3-fly ash and SiO2-fly ash with φ = 2 vol%) employed as working fluids in a microchannel-based DASC on the energy and exergy performance was carried out by Thakur et al. [120]. The authors reported that increasing the volume flow rate enhanced thermal efficiency, pumping power, PEC, EGR, and exergy efficiency. The collector thermal and exergy efficiency was 72.82% and 59.23% and 73% and 68.09% for Al2O3-fly ash (80:20) and SiO2-fly ash (80:20) NFs, respectively. Higher pumping power of 30% and 33% than DW was obtained for Al2O3-fly ash (80:20) and SiO2-fly ash (80:20) NFs, respectively. In addition, at low flow rates, the Al2O3-fly ash (80:20) NF possessed a higher PEC (3.5) than SiO2-fly ash (80:20) NF with a PEC of 3.08. The Al2O3-fly ash (80:20) NF was observed to be a better working fluid compared with SiO2-fly ash (80:20) NF. This was because of the improved thermophysical properties of Al2O3-fly ash (80:20) NF relative to SiO2-fly ash (80:20) NF.

The collector performance of therminol®66-based GO-MWCNT NFs (with φ = 10–150 ppm) as potential working fluids in a DASC under indoor and outdoor conditions was studied by Qu et al. [109]. Under these conditions, the temperature of 100 ppm-GO-MWCNT/therminol®66 NF was 94 °C (indoor) and 153 °C (outdoor) compared with those of therminol®66 (11.6 °C and 97 °C). At irradiation times of 5 min and 45 min (under outdoor conditions), the collector efficiency using 100 ppm-GO-MWCNT/therminol®66 NF was 97% and 70%, respectively. The thermal stability of GO-MWCNT/therminol®66 NFs as determined prior to and after the experiments coupled with the obtained results emphasized the potential application of these thermal fluids for low-to-medium temperature in a DASC.

3.2. Flat Plate Solar Collectors

The influence of varying φ (0.5–2%) and thermal properties (ρ, κ, and μ) on the thermal efficiency of EG-W (75:25 wt%)-based Al2O3-CuO (70:30) NFs deployed as working fluids in an FPSC was investigated by Tahat and Benim [122]. They reported that a rise in the volume fraction led to the improvement of μ, ρ, κ, and thermal efficiency in comparison with water. Collector efficiency of 42–52% was obtained as the volume fraction increased from 0.5% to 2% when compared with water. The average improvement of the thermal efficiency for the FPSC relative to water was 45%. The improvement of h as κ increased for the HNFs resulted in thermal efficiency enhancement of the FPSC. Verma et al. [113] examined the effect of mass flow rate (0.01–0.05 kg/s), φ (0.25–2 vol%), solar intensity (380–1200 W/m2), and temperature parameter (0.0075–0.035) on the energetic and exergetic performance of MNFs (CuO/, MgO/, and MWCNT/DIW) and HNFs (MgO-MWCNT (80:20)/DIW and CuO-MWCNT (80:20)/DIW) in an FPSC. Results revealed that optimum values of 0.75–0.8 vol%, 800–900 W/m2, 298, and 0.025–0.03 kg/s were recorded for the φ, solar intensity, temperature parameter, and mass flow rate, respectively. Energetic efficiency was enhanced as φ, mass flow rate, and solar irradiation increased and as temperature parameter reduced. However, after the peak energetic efficiency was attained, increasing φ and mass flow led to a decrease in value, while with solar intensity, the energetic efficiency remained constant. Entropy generation and pumping power ratio were found to increase with φ. In comparison with DIW, the energetic and exergetic efficiency and entropy generation drop of 23.47%, 9.26%, 12.65%, 18.05%, and 20.52%; 29.8%, 12.3%, 17.1%, 23.4%, and 25.1%; and 65.52%, 45.57%, 48.16%, 56.86%, and 57.44% were obtained for the DIW-based MWCNT, MgO, CuO, CuO-MWCNT, and MgO-MWCNT NFs, respectively. With the MWCNT/DIW NFs having the highest κ and lowest viscosity followed by MgO-MWCNT NFs and then CuO-MWCNT NFs, the best working fluids followed a similar trend (MWCNT > MgO-MWCNT > CuO-MWCNT).

Farajzadeh et al. [123] explored the thermal efficiency of utilizing DIW-based Al2O3-TiO2 (1:1) NFs (with φ = 0.1 wt% and 0.2 wt%) in an FPSC under varying volume flow rates (1.5–2.5 L/min). The thermal efficiency of all the samples was noticed to reduce as the temperature parameter increased while the temperatures at the inlet, outlet, and tank increased as solar radiation increased. Maximum thermal efficiency was recorded with Al2O3-TiO2/DIW NF at a flow rate of 2 L/m and 0.2 wt% concentration. At 0.1 wt% and in comparison, with DIW, efficiencies of 19%, 21%, and 26% were obtained for TiO2/, Al2O3/, and Al2O3-TiO2/DIW NFs, respectively. Increasing the concentration of the HNF (from 0.1 wt% to 0.2 wt%) led to a 5% enhancement of the thermal efficiency of the collector. Additionally, at flow rates of 2.0 L/m and 2.5 L/m, the thermal efficiency was noticed to be 8% and 5% above that of the flow rate of 1.5 mL, respectively. The heat loss parameter of DIW was the highest whereas that of HNFs was the lowest. The authors stressed that using HNFs of Al2O3-TiO2/DIW reduced the cost coupled with the higher thermal efficiency of the collector.

Okonkwo et al. [112] experimented the deployment of water-based Al2O3 and Al2O3-Fe2O3 NFs as working fluids in an FPSC. The thermodynamic performance (first and second laws) and optimization (of mass flow rate, φ (0.05–0.2 vol%), and temperature) were carried out. Their results showed that the exergy and energy efficiency, h, f, exergy destruction, absorbed energy parameter, exergy loss, and generation strongly depended on φ, mass flow rate, and temperature parameter. Energy efficiency was observed to increase as mass flow increased and as φ and temperature parameter decreased whereas the reverse was the case with exergy efficiency. Using 0.1 vol%, the HNF enhanced exergetic efficiency by 6.9% against 5.7% for the MNF while the energy efficiency was augmented by 2.16% for the MNF and depreciated by 1.79 for the HNF, as compared with water. Of the useful exergy (1123 W) absorbed from the sun using the collector, 73% was used up in the collector with the destruction of 59% of the total exergy. The h was observed to enhance as the temperature and mass flow rate increased with the MNF (72%) recording the highest value followed by the HNF (56%) and water. The reverse was noticed for f as the HNF was slightly higher than the MNF. This finding was due to the higher nano-size, viscosity, and density of HNF in comparison with the MNF despite the higher κ value.

Under varying mass fluxes (420 kg/s m2 and 598 kg/s m2) and mixing volume concentrations, the efficiency of MWCNT (0.003 vol% and 0.005 vol%) + Fe3O4 (0.01 vol% and 0.015 vol%) NFs as working fluids was investigated in an FPSC [117]. They noticed that the collector efficiency was improved as the mass flux and MWCNT concentration increased and Fe3O4 concentration decreased. The efficiency of water was 62.7% while those of the HNFs ranged from 73.5% to 80.3% and this translated to 17.2–28.1% above that of water. The use of MWCNT (0.005 vol%) + Fe3O4 (0.01 vol%) NF was observed to produce maximum efficiency. Similarly, increasing the mass flux of water enhanced the efficiency of the collector by 6.5% whereas that of MWCNT (0.005 vol%) + Fe3O4 (0.01 vol%) NF was improved from 74.5% to 80.3%.