Wearable Electrospun Piezoelectric Mats Based on a PVDF Nanofiber–ZnO@ZnS Core–Shell Nanoparticles Composite for Power Generation

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of the Nanofiber Mat by Modified Electrospinning

2.3. Piezoelectric Device Fabrication

2.4. Materials Characterization

2.5. Device Characterization

3. Results and Discussion

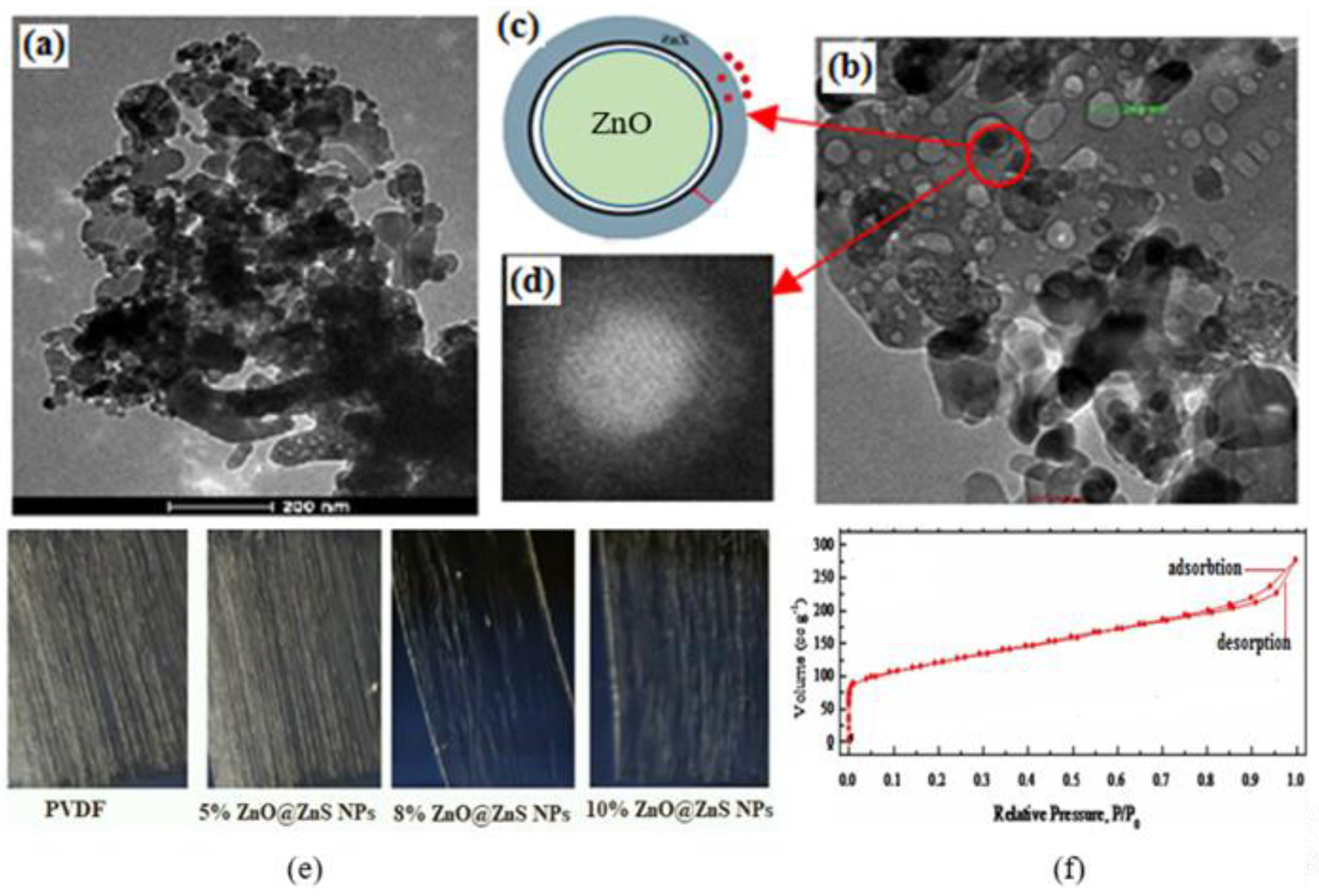

3.1. Characterization of the ZnO@ZnS Core–Shell Nanoparticles

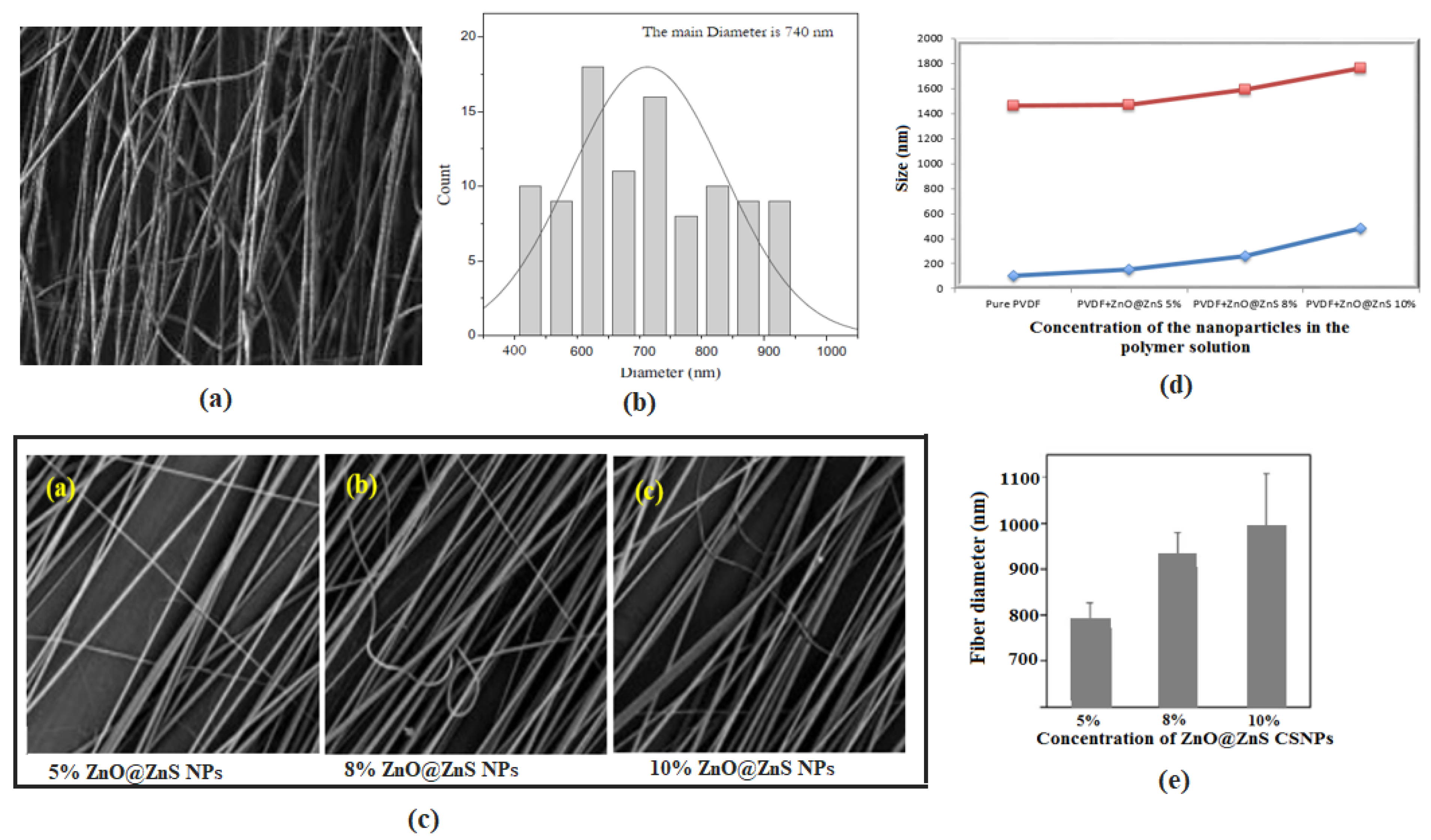

3.2. Morphology of the Fabricated Composite Nanofibers

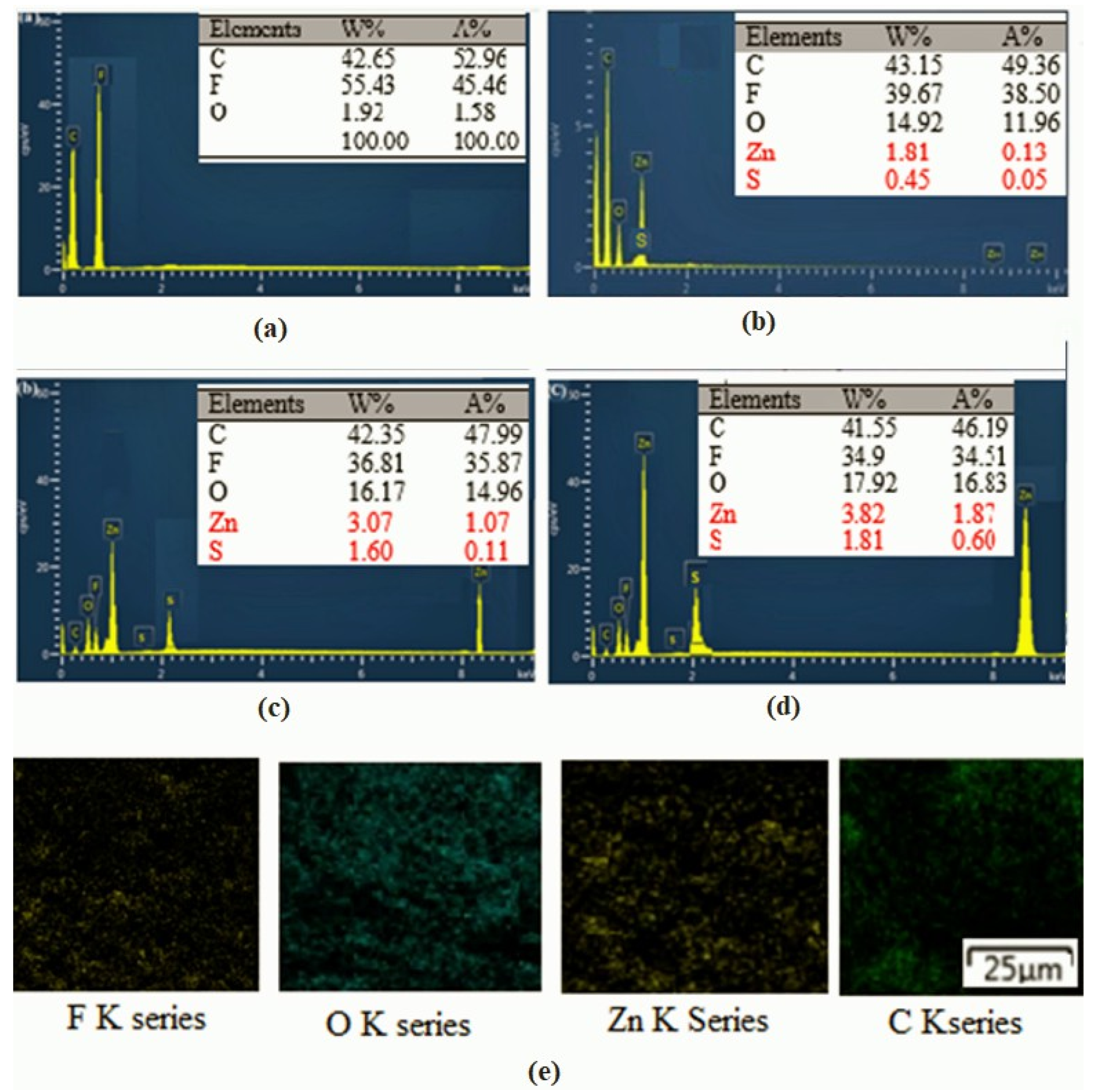

3.3. FTIR and EDS Analysis of the Composite Nanofibers

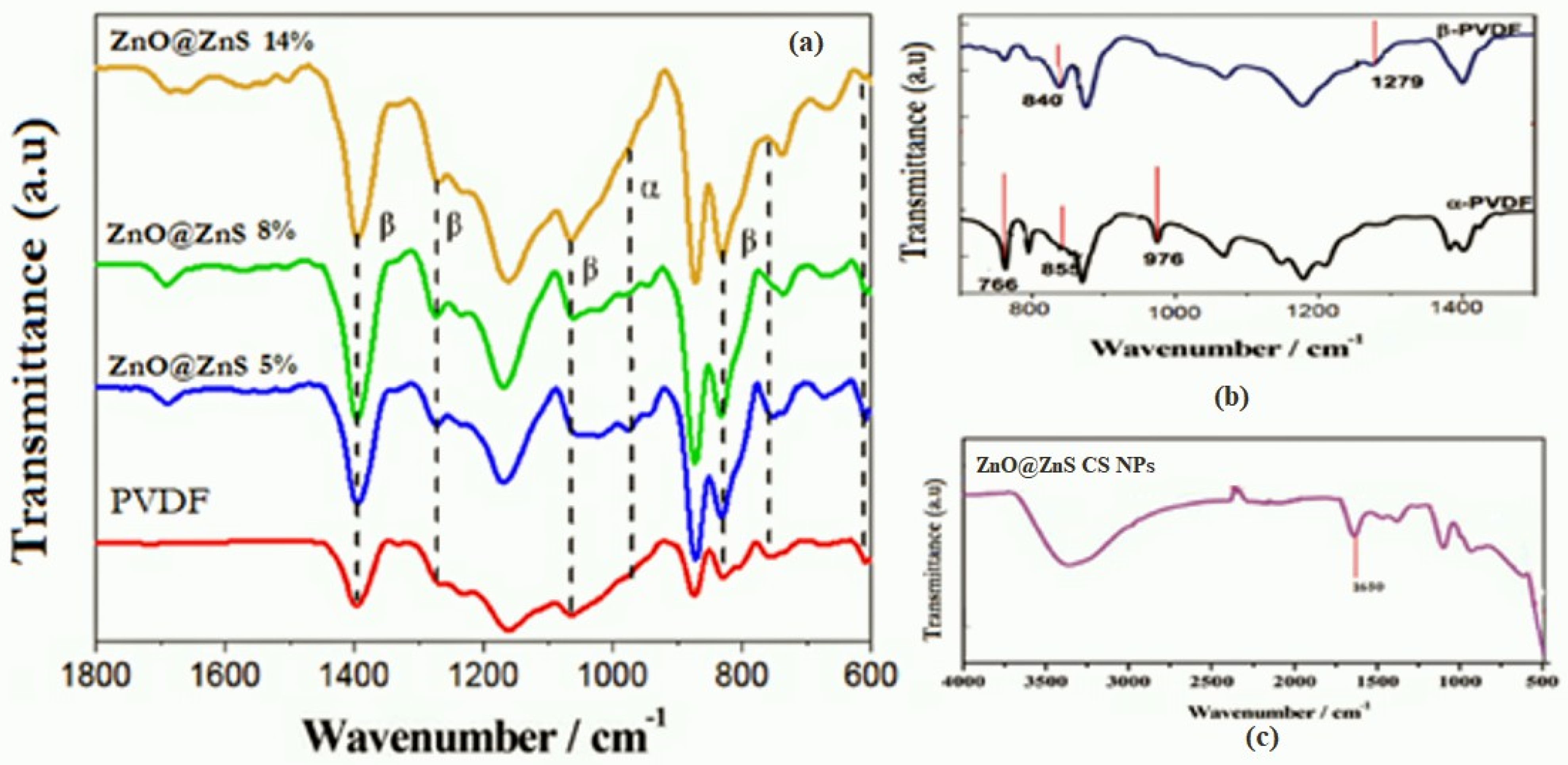

3.4. Crystalline Structure of the Composite Nanofibers

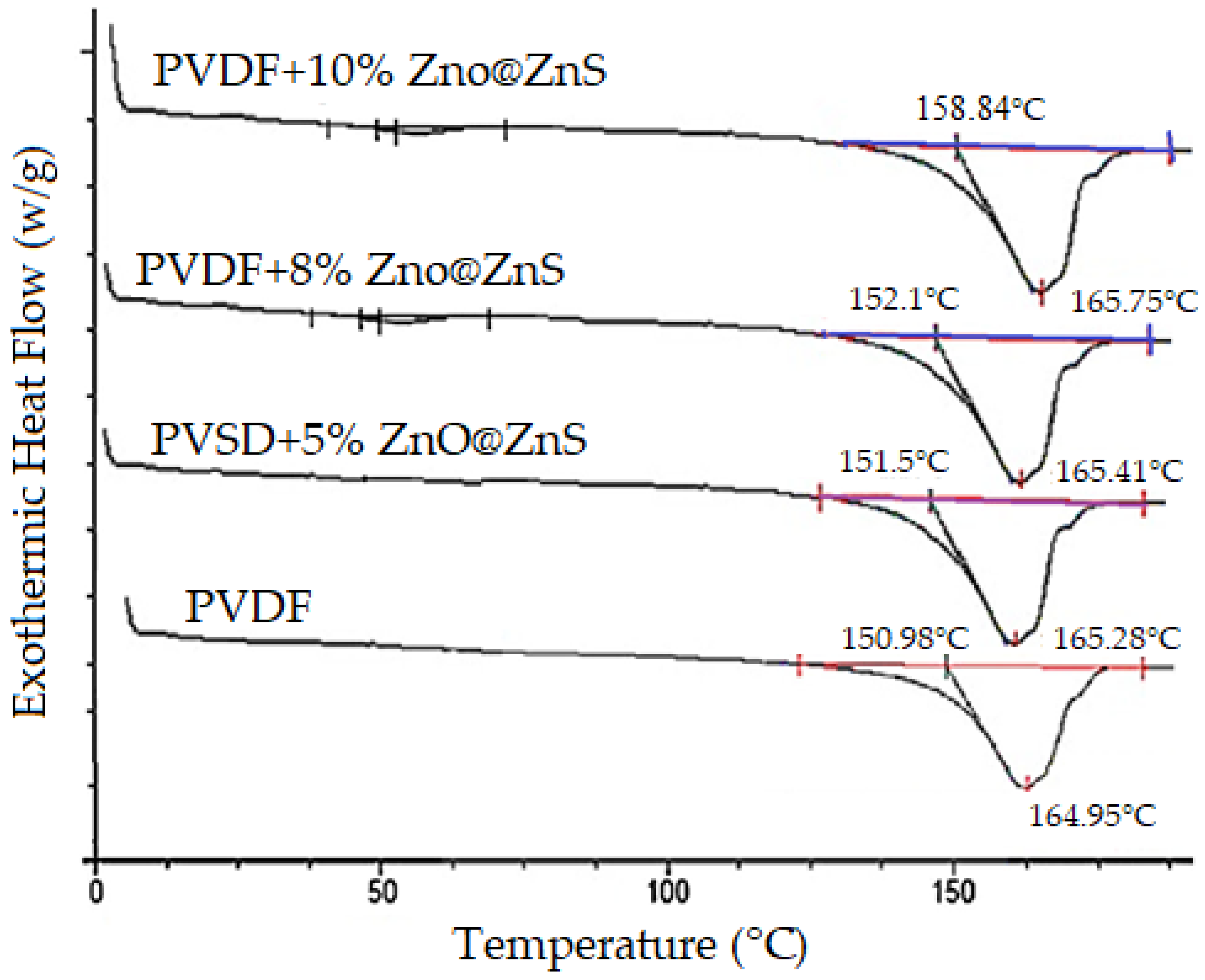

3.5. Mechanical and Thermal Properties of the Composite Nanofibers

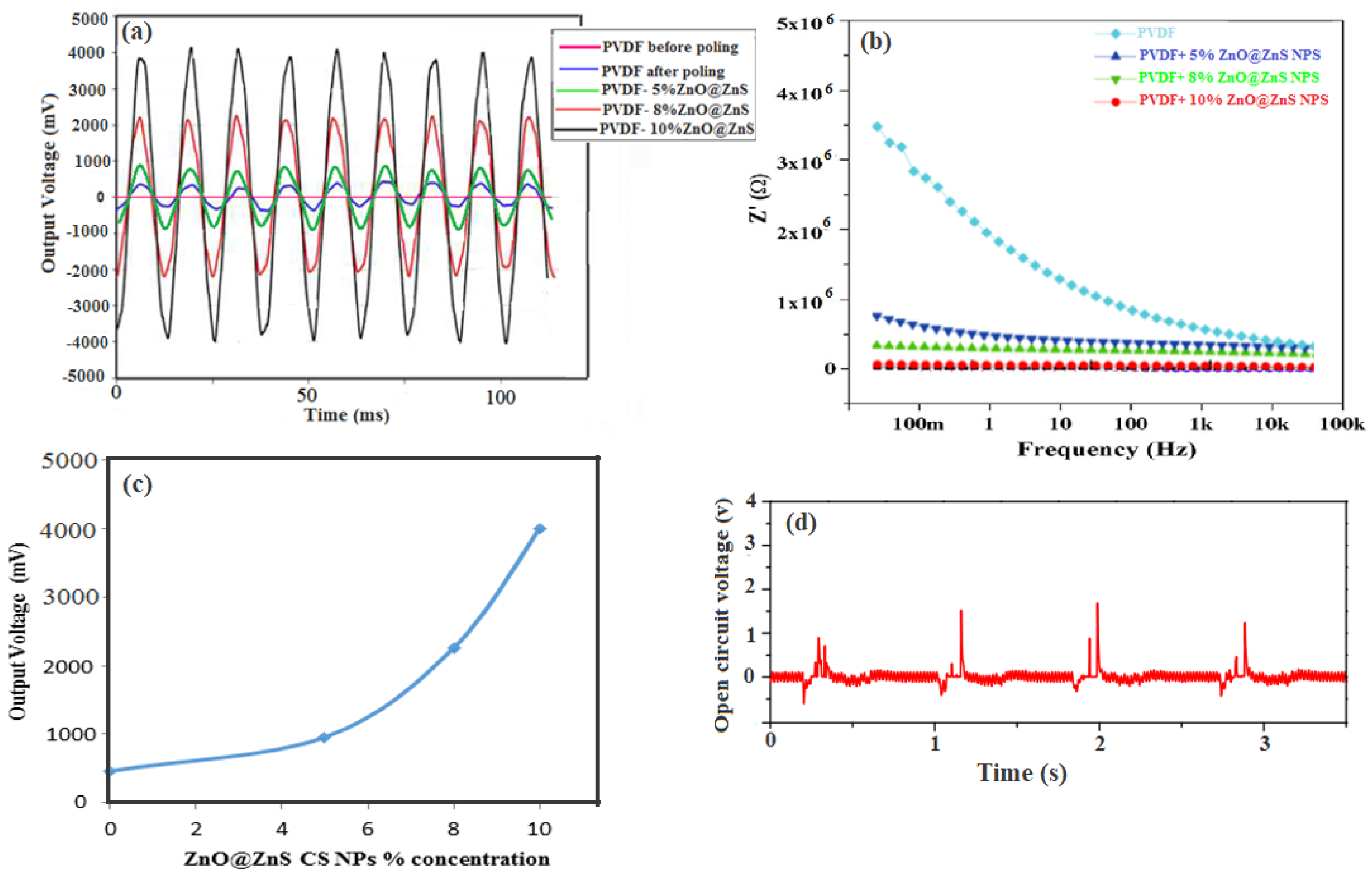

3.6. Impedance and Electrical Conductivity of the Nanogenerator Device

3.7. The Piezoelectric Response of the Nanogenerator Device

4. Implementation of the Nanogenerator Device

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ali, N.; Elmagd, A.A. Tunable emission of electro-spun ceramic ZnS: Cu: Co nanofibers for photonic applications: Structure and optical properties. J. Mater. Sci. Mater. Electron. 2021, 32, 3638–3648. [Google Scholar] [CrossRef]

- Shin, S.-H.; Kim, Y.-H.; Lee, M.H.; Jung, J.-Y.; Seol, J.H.; Nah, J. Lithium-Doped Zinc Oxide Nanowires–Polymer Composite for High Performance Flexible Piezoelectric Nanogenerator. ACS Nano 2014, 8, 10844–10850. [Google Scholar] [CrossRef] [PubMed]

- Elmessiry, K.S.; El-Aassar, M.R.; Nassr, A.B.A.A.; Kenawy, E.R.; Moharam, B.E.; Ali, N. Free-Standing Working Electrodes for Supercapacitors Based on Composite Polymer Nanofibers and Functionalized with Graphene Oxide. J. Electron. Mater. 2021, 50, 5599–5611. [Google Scholar] [CrossRef]

- Liao, Q.; Zhang, Z.; Zhang, X.; Mohr, M.; Zhang, Y.; Fecht, H.-J. Flexible piezoelectric nanogenerators based on a fiber/ZnO nanowires/paper hybrid structure for energy harvesting. Nano Res. 2014, 7, 917–928. [Google Scholar] [CrossRef]

- Ali, N.A.; Hussein, E.A. Characterization of functional electrospun polymeric nanofiber membranes. Int. J. Environ. Sci. Technol. 2019, 16, 8411–8422. [Google Scholar] [CrossRef]

- Yang, P.; Zhao, H.; Yang, Y.; Zhao, P.; Zhao, X.; Yang, L. Fabrication of N, P-codoped Mo2C/carbon nanofibers via electrospinning as electrocatalyst for hydrogen evolution reaction. ES Mater. Manuf. 2020, 7, 34–39. [Google Scholar] [CrossRef]

- Ramakrishna, S. An Introduction to Electrospinning and Nanofibers; World scientific: Singapore, 2005. [Google Scholar]

- Li, D.; Wang, Y.; Xia, Y. Electrospinning of Polymeric and Ceramic Nanofibers as Uniaxially Aligned Arrays. Nano Lett. 2003, 3, 1167–1171. [Google Scholar] [CrossRef]

- Lu, H.; Liu, Y.; Gou, J.; Leng, J.; Du, S. Synergistic effect of carbon nanofiber and carbon nanopaper on shape memory polymer composite. Appl. Phys. Lett. 2010, 96, 084102. [Google Scholar] [CrossRef]

- Pusty, M.; Sharma, A.; Sinha, L.; Chaudhary, A.; Shirage, P. Comparative Study with a Unique Arrangement to Tap Piezoelectric Output to Realize a Self Poled PVDF Based Nanocomposite for Energy Harvesting Applications. ChemistrySelect 2017, 2, 2774–2782. [Google Scholar] [CrossRef]

- Liu, Z.H.; Pan, C.T.; Lin, L.W.; Huang, J.C.; Ou, Z.Y. Direct-write PVDF nonwoven fiber fabric energy harvesters via the hollow cylindrical near-field electrospinning process. Smart Mater. Struct. 2013, 23, 025003. [Google Scholar] [CrossRef]

- Shin, K.; Kim, D.; Park, H.; Sim, M.; Jang, H.; Sohn, J.; Jang, J.E. Artificial tactile sensor with pin-type module for depth profile and surface topography detection. IEEE Trans. Ind. Electron. 2019, 67, 637–646. [Google Scholar] [CrossRef]

- Huang, C.-T.; Tang, C.-F.; Lee, M.-C.; Chang, S.-H. Parametric design of yarn-based piezoresistive sensors for smart textiles. Sens. Actuators A Phys. 2008, 148, 10–15. [Google Scholar] [CrossRef]

- Hu, F.; Cai, Q.; Liao, F.; Shao, M.; Lee, S.-T. Recent Advancements in Nanogenerators for Energy Harvesting. Small 2015, 11, 5611–5628. [Google Scholar] [CrossRef]

- Yu, H.; Huang, T.; Lu, M.; Mao, M.; Zhang, Q.; Wang, H. Enhanced power output of an electrospun PVDF/MWCNTs-based nanogenerator by tuning its conductivity. Nanotechnology 2013, 24, 405401. [Google Scholar] [CrossRef]

- Al-Saygh, A.; Ponnamma, D.; Almaadeed, M.A.; Vijayan, P.P.; Karim, A.; Hassan, M.K. Flexible Pressure Sensor Based on PVDF Nanocomposites Containing Reduced Graphene Oxide-Titania Hybrid Nanolayers. Polymers 2017, 9, 33. [Google Scholar] [CrossRef]

- Fang, J.; Wang, X.; Lin, T. Power generation from randomly oriented electrospun nanofiber membranes. Adv. Mater. Res. 2012, 479–481, 340–343. [Google Scholar] [CrossRef]

- Tang, S.L.P. Recent developments in flexible wearable electronics for monitoring applications. Trans. Inst. Meas. Control 2009, 29, 283–300. [Google Scholar] [CrossRef]

- Kumar, R.S.; Sarathi, T.; Venkataraman, K.; Bhattacharyya, A. Enhanced piezoelectric properties of polyvinylidene fluoride nanofibers using carbon nanofiber and electrical poling. Mater. Lett. 2019, 255, 126515. [Google Scholar] [CrossRef]

- Han, G.; Su, Y.F.; Ma, S.; Nantung, T.; Lu, N. In Situ Rheological Properties Monitoring of Cementitious Materials through the Piezoelectric-based Electromechanical Impedance (EMI) Approach. Eng. Sci. 2021, 16, 259–268. [Google Scholar] [CrossRef]

- Lin, Y.; Song, J.; Ding, Y.; Lu, S.; Wang, Z.L. Alternating the output of a CdS nanowire nanogenerator by a white-light-stimulated optoelectronic effect. Adv. Mater. 2008, 20, 3127–3130. [Google Scholar] [CrossRef]

- Huang, C.; Song, J.; Lee, W.; Ding, Y.; Gao, Z.; Hao, Y.; Chen, L.; Wang, Z.L. GaN nanowire arrays for high-output nanogenerators. J. Am. Chem. Soc. 2010, 132, 4766–4771. [Google Scholar] [CrossRef]

- Huang, C.; Song, J.; Tsai, C.; Lee, W.; Lien, D.; Gao, Z.; Hao, Y.; Chen, L.; Wang, Z.L. Single-InN-nanowire nanogenerator with up to 1 V Output Voltage. Adv. Mater. 2010, 22, 4008–4013. [Google Scholar] [CrossRef]

- Wang, Z.L.; Song, J. Piezoelectric nanogenerators based on zinc oxide nanowire arrays. Science 2006, 312, 242–246. [Google Scholar] [CrossRef]

- Li, Z.; Zhu, G.; Yang, R.; Wang, A.C.; Wang, Z.L. Muscle-driven in vivo nanogenerator. Adv. Mater. 2010, 22, 2534–2537. [Google Scholar] [CrossRef]

- Shen, G.; Di Chen, A.; Lee, C.J. Hierarchical Saw-like ZnO Nanobelt/ZnS Nanowire Heterostructures Induced by Polar Sur-faces. J. Phys. Chem. B 2006, 110, 15689–15693. [Google Scholar] [CrossRef]

- Yan, J.; Fang, X.; Zhang, L.; Bando, Y.; Gautam, U.K.; Dierre, B.; Sekiguchi, T.; Golberg, D. Structure and Cathodoluminescence of Individual ZnS/ZnO Biaxial Nanobelt Heterostructures. Nano Lett. 2008, 8, 2794–2799. [Google Scholar] [CrossRef]

- Wang, Z.L. Nanopiezotronics. Adv. Mater. 2007, 19, 889–892. [Google Scholar] [CrossRef]

- Lu, M.Y.; Song, J.; Lu, M.P.; Lee, C.Y.; Chen, L.J.; Wang, Z.L. ZnO−ZnS heterojunction and ZnS nanowire arrays for electricity generation. ACS Nano 2009, 3, 357–362. [Google Scholar] [CrossRef]

- Wu, X.; Jiang, P.; Ding, Y.; Cai, W.; Xie, S.; Wang, Z.L. Mismatch Strain Induced Formation of ZnO/ZnS Heterostructured Rings. Adv. Mater. 2007, 19, 2319–2323. [Google Scholar] [CrossRef]

- Fan, J.; Shavel, A.; Zamani, R.; Fabrega, C.; Rousset, J.; Haller, S.; Cabot, A. Control of the doping concentration, morphology and optoelectronic properties of vertically aligned chlorine-doped ZnO nanowires. Acta Mater. 2011, 59, 6790–6800. [Google Scholar] [CrossRef]

- Sadollahkhani, A.; Kazeminezhad, I.; Lu, J.; Nur, O.; Hultman, L.; Willander, M. Synthesis, structural characterization and photo-catalytic application of ZnO@ ZnS core–shell nanoparticles. RSC Adv. 2014, 4, 36940–36950. [Google Scholar] [CrossRef]

- Cheng, H.; Lu, Z.; Gao, Q.; Zuo, Y.; Liu, X.; Guo, Z.; Liu, C.; Shen, C. PVDF-Ni/PE-CNTs Composite Foams with Co-Continuous Structure for Electromagnetic Interference Shielding and Photo-Electro-Thermal Properties. Eng. Sci. 2021, 16, 331–340. [Google Scholar] [CrossRef]

- Klinge, U.; Klosterhalfen, B.; Öttinger, A.; Junge, K.; Schumpelick, V. PVDF as a new polymer for the construction of surgical meshes. Biomaterials 2002, 23, 3487–3493. [Google Scholar] [CrossRef]

- Gao, C.; Deng, W.; Pan, F.; Feng, X.; Li, Y. Superhydrophobic Electrospun PVDF Membranes with Silanization and Fluorosilanization Co-functionalized CNTs for Improved Direct Contact Membrane Distillation. Eng. Sci. 2020, 9, 35–43. [Google Scholar] [CrossRef]

- Trevino, J.E.; Mohan, S.; Salinas, A.E.; Cueva, E.; Lozano, K. Piezoelectric properties of PVDF-conjugated polymer nanofibers. J. Appl. Polym. Sci. 2021, 138, 50665. [Google Scholar] [CrossRef]

- Sengupta, D.; Kottapalli, A.G.P.; Chen, S.H.; Miao, J.M.; Kwok, C.Y.; Triantafyllou, M.S.; Warkiani, M.E.; Asadnia, M. Characterization of single polyvinylidene fluoride (PVDF) nanofiber for flow sensing applications. AIP Adv. 2017, 7, 105205. [Google Scholar] [CrossRef]

- Marzani, A.; Testoni, N.; De Marchi, L.; Messina, M.; Monaco, E.; Apicella, A. An open database for benchmarking guided waves structural health monitoring algorithms on a composite full-scale outer wing demonstrator. Struct. Health Monit. 2019, 19, 1524–1541. [Google Scholar] [CrossRef]

- Soliman, M.; Kochhar, A.; Abdelsalam, H.; Pop, F.V.; Vidal-Alvarez, G.; Weldon, J.; Piazza, G.; Parames, J. An 18 nW-47/-40 dBm sensitivity 3/100 kbps MEMS-assisted CMOS wake-up receiver. IEEE Trans. Circuits Syst. I Regul. Pap. 2019, 66, 4439–4447. [Google Scholar] [CrossRef]

- Lee, J.-E.; Eom, Y.; Shin, Y.-E.; Hwang, S.-H.; Ko, H.-H.; Chae, H.G. Effect of Interfacial Interaction on the Conformational Variation of Poly(vinylidene fluoride) (PVDF) Chains in PVDF/Graphene Oxide (GO) Nanocomposite Fibers and Corresponding Mechanical Properties. ACS Appl. Mater. Interfaces 2019, 11, 13665–13675. [Google Scholar] [CrossRef]

- Ribeiro, C.; Correia, D.M.; Ribeiro, S.; Sencadas, V.; Botelho, G.; Lanceros-Meńdez, S. Piezoelectric Poly(vinylidene fluoride) Micro-Structure and Poling State in Active Tissue Engineering. Eng. Life Sci. 2015, 15, 351–356. [Google Scholar] [CrossRef]

- Li, L.; Zhang, M.; Rong, M.; Ruan, W. Studies on the transformation process of PVDF from α to β phase by stretching. RSC Adv. 2014, 4, 3938–3943. [Google Scholar] [CrossRef]

- Hansen, B.J.; Liu, Y.; Yang, R.; Wang, Z.L. Hybrid nanogenerator for concurrently harvesting biomechanical and biochemical energy. ACS Nano 2010, 4, 3647–3652. [Google Scholar] [CrossRef] [PubMed]

- Cherumannil Karumuthil, S.; Prabha Rajeev, S.; Valiyaneerilakkal, U.; Athiyanathil, S.; Varghese, S. Electrospun Poly(vinylidene fluoride-trifluoroethylene)-Based Polymer Nanocomposite Fibers for Piezoelectric Nanogenerators. ACS Appl. Mater. Interfaces 2019, 11, 40180–40188. [Google Scholar] [CrossRef] [PubMed]

- Chang, C.; Tran, V.H.; Wang, J.; Fuh, Y.-K.; Lin, L. Direct-Write Piezoelectric Polymeric Nanogenerator with High Energy Conversion Efficiency. Nano Lett. 2010, 10, 726–731. [Google Scholar] [CrossRef]

- Pu, J.; Yan, X.; Jiang, Y.; Chang, C.; Lin, L. Piezoelectric actuation of direct-write electrospun fibers. Actuators A Phys. 2010, 164, 131–136. [Google Scholar] [CrossRef]

- Jia, N.; Xing, Q.; Xia, G.; Sun, J.; Song, R.; Huang, W. Enhanced β-crystalline phase in poly(vinylidene fluoride) films by polydopamine-coated BaTiO3 nanoparticles. Mater. Lett. 2015, 139, 212–215. [Google Scholar] [CrossRef]

- Xi, Y.; Song, J.; Xu, S.; Yang, R.; Gao, Z.; Hu, C.; Wang, Z.L. Growth of ZnO nanotube arrays and nanotube based piezoelectric nanogenerators. J. Mater. Chem. 2009, 19, 9260–9264. [Google Scholar] [CrossRef]

- Bae, S.; Kahya, O.; Sharma, B.K.; Kwon, J.; Cho, H.J.; Özyilmaz, B.; Ahn, J. Graphene-P (VDF-TrFE) multilayer film for flexible applications. ACS Nano 2013, 7, 3130–3138. [Google Scholar] [CrossRef]

- Meyers, F.N.; Loh, K.J.; Dodds, J.S.; Baltazar, A. Active sensing and damage detection using piezoelectric zinc oxide-based nanocomposites. Nanotechnology 2013, 24, 185501. [Google Scholar] [CrossRef]

- Parangusan, H.; Ponnamma, D.; Al-Maadeed, M.A.A. Stretchable Electrospun PVDF-HFP/Co-ZnO Nanofibers as Piezo-electric Nanogenerators. Sci. Rep. 2018, 8, 754. [Google Scholar] [CrossRef]

- Sorayani Bafqi, M.S.; Bagherzadeh, R.; Latifi, M. Fabrication of Composite PVDF-ZnO Nanofiber Mats by Electrospinning for Energy Scavenging Application with Enhanced Efficiency. J. Polym. Res. 2015, 22, 130. [Google Scholar] [CrossRef]

- Fakhri, P.; Amini, B.; Bagherzadeh, R.; Kashfi, M.; Latifi, M.; Yavari, N.; Asadi Kani, S.; Kong, L. Flexible Hybrid Structure Piezoelectric Nanogenerator Based on ZnO Nanorod/PVDF Nano-fibers with Improved Output. RSC Adv. 2019, 9, 10117–10123. [Google Scholar] [CrossRef] [PubMed]

- Kottapalli, A.G.P.; Shen, Z.; Asadnia, M.; Tian, S.; Tao, K.; Miao, J.; Triantafyllou, M.S. Polymer MEMS sensor for flow monitoring in biomedical device applications. In Proceedings of the 2017 IEEE 30th International Conference on Micro Electro Mechanical Systems (MEMS), Las Vegas, NV, USA, 22–26 January 2017; pp. 632–635. [Google Scholar] [CrossRef]

- Bhavanasi, V.; Kumar, V.; Parida, K.; Wang, J.; Lee, P.S. Enhanced piezoelectric energy harvesting performance of flexible PVDF-TrFE bilayer films with graphene oxide. ACS Appl. Mat. Interfaces 2016, 13, 521–529. [Google Scholar] [CrossRef] [PubMed]

- Jalili, R.; Morshed, M.; Ravandi, S.A.H. Fundamental parameters affecting electrospinning of PAN nanofibers as uniaxially aligned fibers. J. Appl. Polym. Sci. 2006, 101, 4350–4357. [Google Scholar] [CrossRef]

- Tsai, Y.S.; Chou, T.W.; Xu, C.Y.; Huang, W.C.; Lin, C.F.; Wu, Y.S.; Lin, Y.S.; Chen, H. ZnO/ZnS core-shell nanostructures for hydrogen gas sensing performances. Ceram. Int. 2019, 45, 17751–17757. [Google Scholar] [CrossRef]

- Azimi, B.; Milazzo, M.; Lazzeri, A.; Berrettini, S.; Uddin, M.J.; Qin, Z.; Buehler, M.J.; Danti, S. Electrospinning Piezoelectric Fibers for Biocompatible Devices. Adv. Healthc. Mater. 2020, 9, 1901287. [Google Scholar] [CrossRef]

- Yee, W.; Kotaki, M.; Liu, Y.; Lu, X. Morphology, polymorphism behavior and molecular orientation of electrospun poly(vinylidene fluoride) nanofibers. Polymer 2007, 48, 512–521. [Google Scholar] [CrossRef]

- Alam, M.M.; Mandal, D. Native cellulose microfiber-based hybrid piezoelectric generator for mechanical energy harvesting utility. ACS Appl. Mater. Interfaces 2016, 8, 1555–1558. [Google Scholar] [CrossRef]

- Satapathy, S.; Pawar, S.; Gupta, P.K.; Varma, K.B.R. Effect of annealing on the phase transition in poly(vinylidene fluoride) films prepared using polar solvent. Bull. Mater. Sci. 2011, 34, 727. [Google Scholar] [CrossRef]

- Persano, L.; Dagdeviren, C.; Su, Y.; Zhang, Y.; Girardo, S.; Pisignano, D.; Huang, Y.; Rogers, J.A. High performance piezoelectric devices based on aligned arrays of nanofibers of poly(vinylidene fluoride-co-trifluoroethylene). Nat. Commun. 2013, 4, 1633. [Google Scholar] [CrossRef]

- Kabir, E.; Khatun, M.; Nasrin, L.; Raihan, M.J.; Rahman, M. Pure β-phase formation in polyvinylidene fluoride (PVDF)-carbon nanotube composites. Journal of Physics D: Appl. Phys. 2017, 50, 163002. [Google Scholar] [CrossRef]

- Sharma, M.; Madras, G.; Bose, S. Process induced electroactive β-polymorph in PVDF: Effect on dielectric and ferroelectric properties. Phys. Chem. Chem. Phys. 2014, 16, 14792–14799. [Google Scholar] [CrossRef] [PubMed]

- Cardoso, V.F.; Minas, G.; Costa, C.M.; Tavares, C.J.; Lanceros-Mendez, S. Micro and Nanofilms of Poly(vinylidene fluoride) with Controlled Thickness, Morphology and Electroactive Crystalline Phase for Sensor and Actuator Applications. Smart Mater. Struct. 2011, 20, 087002. [Google Scholar] [CrossRef]

- Lazarraga, M.G.; Mandal, S.; Ibanez, J.; Amarilla, J.M.; Rojo, J.M. LiMn2O4-based composites processed by a chemical-route: Microstructural, electrical, electrochemical, and mechanical characterization. J. Power Sources 2003, 115, 315–322. [Google Scholar] [CrossRef]

- Doumit, N.; Poulin-Vittrant, G. Effect of the Dielectric and Mechanical Properties of the Polymer Matrix on ZnO Nanowire-Based Composite Nanogenerators Performance. Adv. Theory Simul. 2020, 3, 2000128. [Google Scholar] [CrossRef]

- Ma, W.; Zhang, J.; Wang, X. Formation of poly(vinylidene fluoride) crystalline phases from tetrahydrofuran/N,N-dimethylformamide mixed solvent. J. Mater. Sci. 2008, 43, 398–401. [Google Scholar] [CrossRef]

- Choia, S.-S.; Lee, Y.S.; Joo, C.W.; Lee, S.G.; Park, J.K.; Hanc, K.-S. Electrospun PVDF nanofiber web as polymer electrolyte or separator. Electrochim. Acta 2004, 50, 339–343. [Google Scholar] [CrossRef]

- Parangusan, H.; Ponnamma, D.; AlMaadeed, M.A.A. Toward High Power Generating Piezoelectric Nanofibers: Influence of Particle Size and Surface Electrostatic Interaction of Ce-Fe2O3 and Ce-Co3O4 on PVDF. ACS Omega 2019, 4, 6312–6323. [Google Scholar] [CrossRef]

- Hu, X.; Yan, X.; Gong, L.; Wang, F.; Xu, Y.; Feng, L.; Zhang, D.; Jiang, Y. Improved Piezoelectric Sensing Performance of P(VDF-TrFE) Nanofibers by Utilizing BTO Nanoparticles and Penetrated Electrodes. ACS Appl. Mater. Interfaces 2019, 11, 7379–7386. [Google Scholar] [CrossRef]

- Park, S.-H.; Lee, H.B.; Yeon, S.M.; Park, J.; Lee, N.K. Flexible and Stretchable Piezoelectric Sensor with Thickness-Tunable Con-figuration of Electrospun Nanofiber Mat and Elastomeric Substrates. ACS Appl. Mater. Interfaces 2016, 8, 24773–24781. [Google Scholar] [CrossRef]

- Moghadam, B.H.; Hasanzadeh, M.; Simchi, A. Self-Powered Wearable Piezoelectric Sensors Based on Polymer Nanofiber–Metal–Organic Framework Nanoparticle Composites for Arterial Pulse Monitoring. ACS Appl. Nano Mater. 2020, 3, 8742–8752. [Google Scholar] [CrossRef]

- Lin, Z.H.; Yang, Y.; Wu, J.M.; Liu, Y.; Zhang, F.; Wang, Z.L. BaTiO3 nanotubes-based flexible and transparent nano-generators. J. Phys. Chem. Lett. 2012, 3, 3599–3604. [Google Scholar] [CrossRef] [PubMed]

- Maity, K.; Garain, S.; Henkel, K.; Schmeißer, D.; Mandal, D. Self-Powered Human-Health Monitoring through Aligned PVDF Nano-fibers Interfaced Skin-Interactive Piezoelectric Sensor. ACS Appl. Polym. Mater. 2020, 2, 862–878. [Google Scholar] [CrossRef]

| [email protected] NPs (wt %) | Fiber Diameter (nm) | β-Phase Content (%) | Mechanical Characteristics | ||

|---|---|---|---|---|---|

| Young’s Modulus (MPa) | Fracture Stress (MPa) | Elongation at Break (%) | |||

| 0 | 740 | 68 | 1640 ± 0.63 | 46 ± 0.59 | 6.1 |

| 5 | 790 | 75 | 1595 ± 0.37 | 41± 0.57 | 5.5 |

| 8 | 925 | 79 | 1507 ± 0.88 | 34± 0.49 | 4.9 |

| 10 | 1050 | 81 | 1413± 0.64 | 29± 0.31 | 4.6 |

| ZnO@ZnS Nps % | F(x) = P1 × X + P2 | R2 | Resistance Ω | |

|---|---|---|---|---|

| P1 | P2 | |||

| 0 | 2.425 × 108 (2.416 × 108, 2.476 × 108) | −24.69 (−23.47, −25.38) | 0.863 | 3.35 × 108 |

| 5 | 1.047 × 108 (1.025 × 108, 1.094 × 108) | −14.43 (−14.95, −13.424) | 0.975 | 0.15 × 108 |

| 8 | 4.196 × 107 (4.1263 × 107, 4.21 × 107) | −7.042 (−7.581, −6.649) | 0.969 | 5.9 × 107 |

| 10 | 5.028 × 106 (5.067 × 106, 5.311 × 106) | −5.004 (−5.621, −4.822) | 0.991 | 0.1 × 107 |

| Piezoelectric materials | Max wt % | With/without Poling | F(β)% | Max Output Voltage (V) | Ref. |

|---|---|---|---|---|---|

| PVDF | - | without | 7% | 0.028 | [6] |

| ZnO NWs/PVDF | - | with | 4% | 0.2 | [4] |

| PVDF/Carbon nanofiber | 0.5% (w/w) | with | 11% | 0.56 | [19] |

| PvDF + MWCNT | 5 wt % | without | - | 6 | [15] |

| titanium dioxide- rGO/PVDF | 2.5 wt % | with | 10% | 3.9 | [16] |

| 2.5 wt % | |||||

| Li doped ZnO NW-Polymer Composite | 3 wt % | with | 9% | 180 | [2] |

| Fe-fGO/PVDF | 5 wt % | without | 14% | 1.2 | [10] |

| Native Cellulose microfiber | 8 wt % | without | - | 30 | [60] |

| BaTiO3 nanotubes | with | - | 3.5 | [74] | |

| ZnO@ZnS CS NPs/PVDF | 10 wt % | with | 17% | 4.42 sensitivity of 0.153 V/N·mm3 | Present work |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ali, N.; Kenawy, E.-R.; Wadoud, A.A.; Elhadary, M.I. Wearable Electrospun Piezoelectric Mats Based on a PVDF Nanofiber–ZnO@ZnS Core–Shell Nanoparticles Composite for Power Generation. Nanomaterials 2023, 13, 2833. https://doi.org/10.3390/nano13212833

Ali N, Kenawy E-R, Wadoud AA, Elhadary MI. Wearable Electrospun Piezoelectric Mats Based on a PVDF Nanofiber–ZnO@ZnS Core–Shell Nanoparticles Composite for Power Generation. Nanomaterials. 2023; 13(21):2833. https://doi.org/10.3390/nano13212833

Chicago/Turabian StyleAli, Nehal, El-Refaie Kenawy, A. A. Wadoud, and M. I. Elhadary. 2023. "Wearable Electrospun Piezoelectric Mats Based on a PVDF Nanofiber–ZnO@ZnS Core–Shell Nanoparticles Composite for Power Generation" Nanomaterials 13, no. 21: 2833. https://doi.org/10.3390/nano13212833