Phase Change-Induced Magnetic Switching through Metal–Insulator Transition in VO2/TbFeCo Films

Abstract

:1. Introduction

2. Materials and Methods

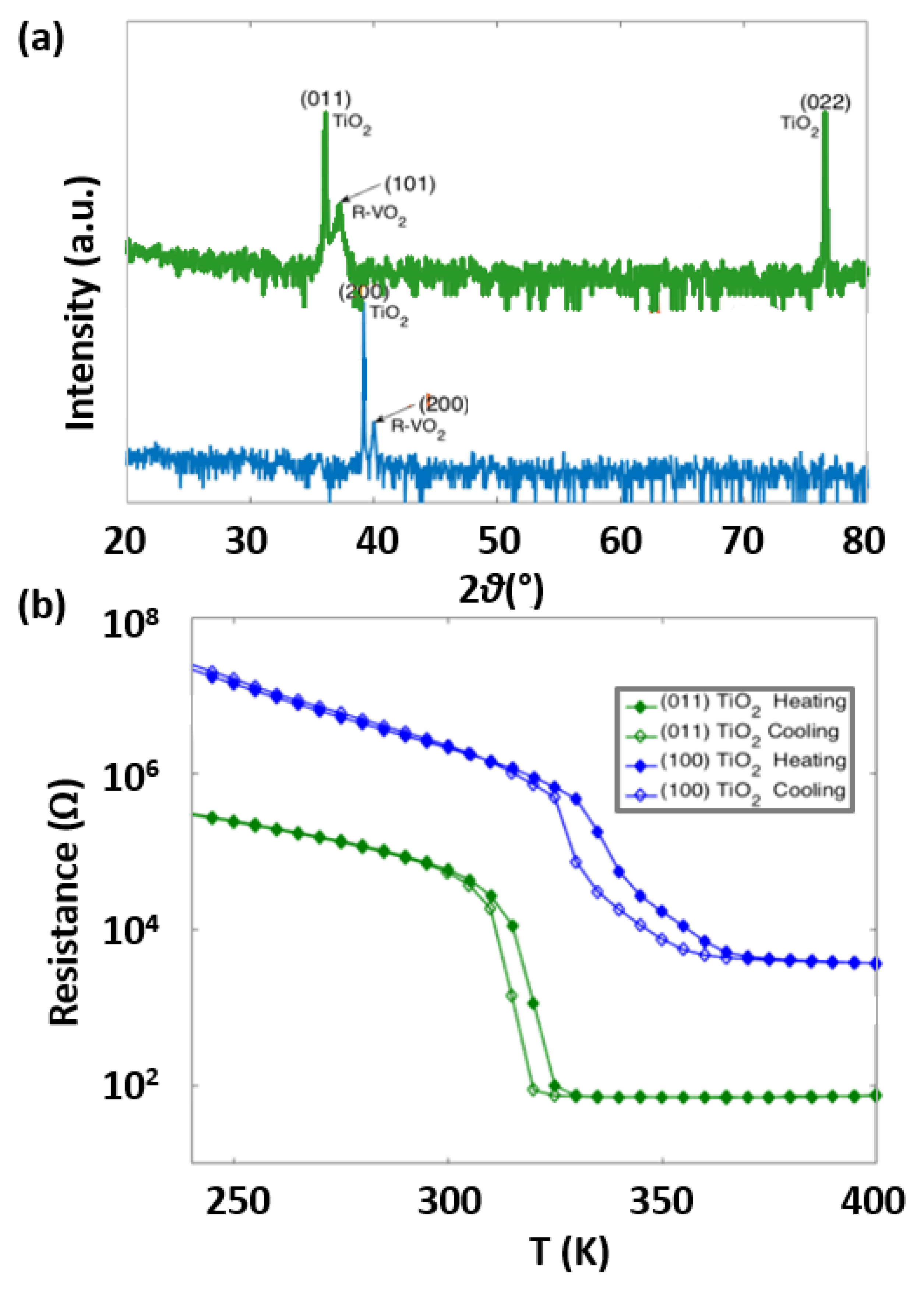

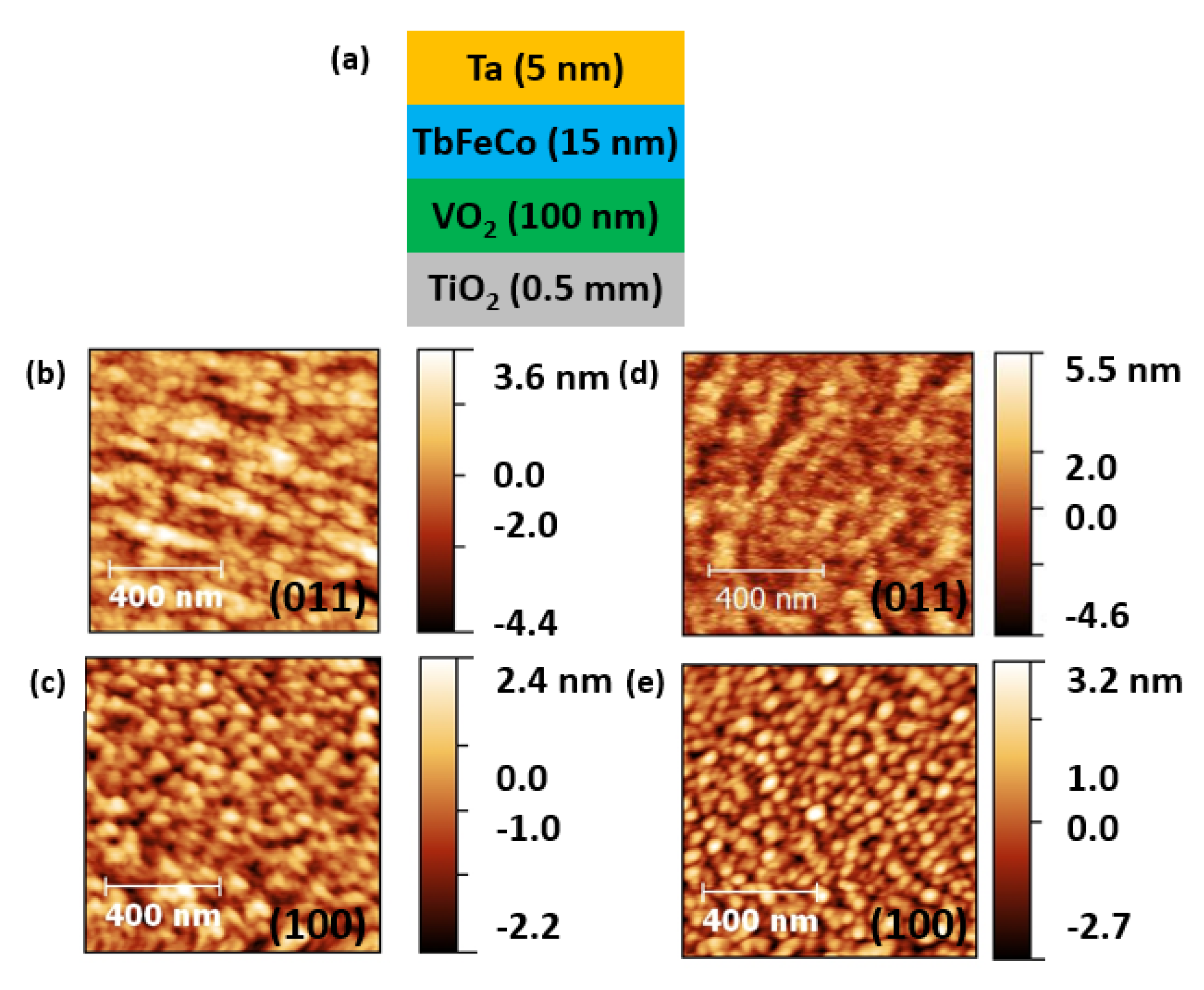

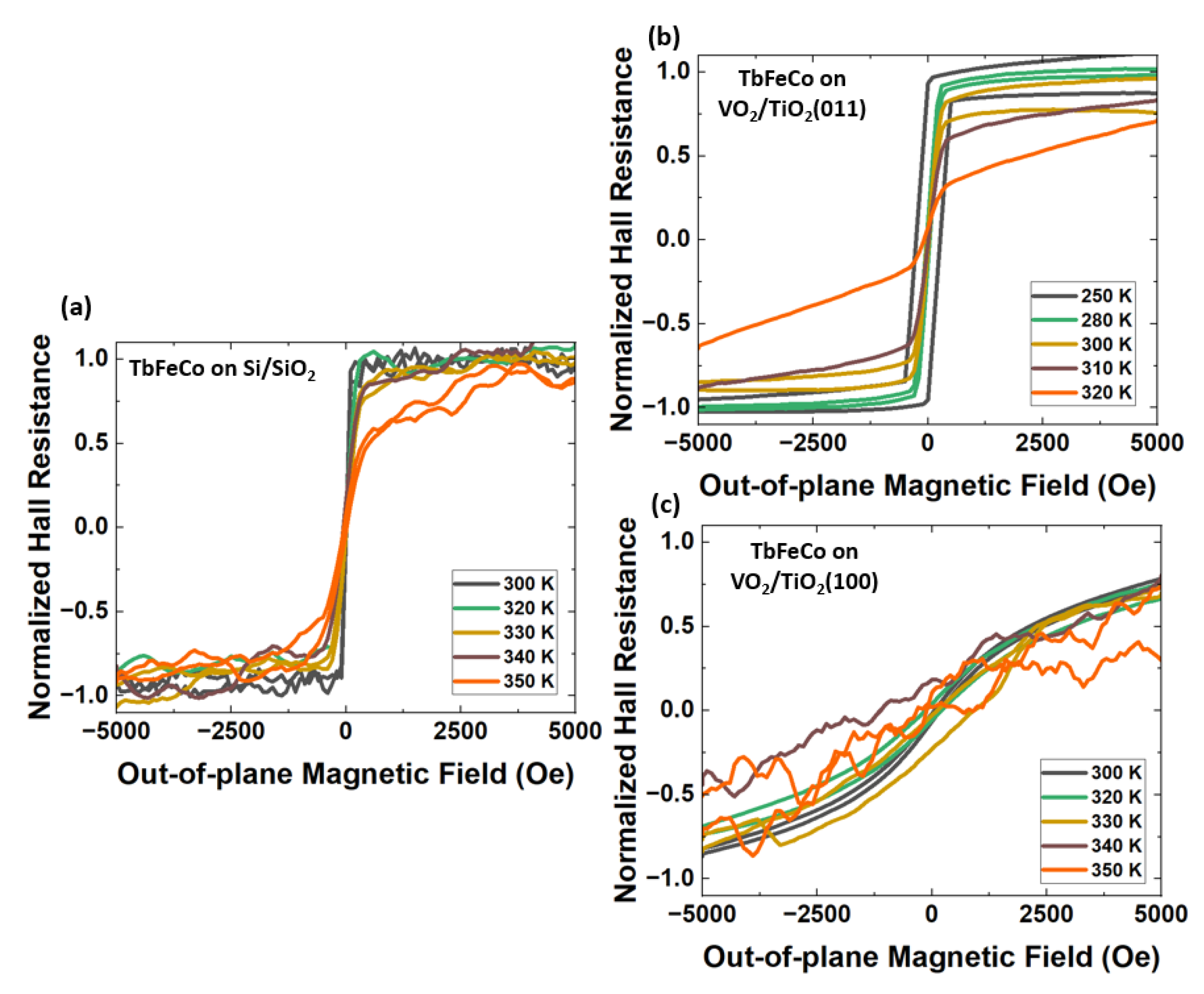

3. Results and Discussions

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Žutić, I.; Fabian, J.; Das Sarma, S. Spintronics: Fundamentals and applications. Rev. Mod. Phys. 2004, 76, 323–410. [Google Scholar] [CrossRef]

- Dieny, B.; Prejbeanu, I.L.; Garello, K.; Gambardella, P.; Freitas, P.; Lehndorff, R.; Raberg, W.; Ebels, U.; Demokritov, S.O.; Akerman, J.; et al. Opportunities and challenges for spintronics in the microelectronics industry. Nat. Electron. 2020, 3, 446–459. [Google Scholar] [CrossRef]

- Hirohata, A.; Yamada, K.; Nakatani, Y.; Prejbeanu, I.L.; Diény, B.; Pirro, P.; Hillebrands, B. Review on spintronics: Principles and device applications. J. Magn. Magn. Mater. 2020, 509, 166711. [Google Scholar] [CrossRef]

- Puebla, J.; Kim, J.; Kondou, K.; Otani, Y. Spintronic devices for energy-efficient data storage and energy harvesting. Commun. Mater. 2020, 1, 24. [Google Scholar] [CrossRef]

- Barla, P.; Joshi, V.K.; Bhat, S. Spintronic devices: A promising alternative to CMOS devices. J. Comput. Electron. 2021, 20, 805–837. [Google Scholar] [CrossRef]

- Zhang, Y.; Feng, X.; Zheng, Z.; Zhang, Z.; Lin, K.; Sun, X.; Wang, G.; Wang, J.; Wei, J.; Vallobra, P.; et al. Ferrimagnets for spintronic devices: From materials to applications. Appl. Phys. Rev. 2023, 10, 011301. [Google Scholar] [CrossRef]

- El-Ghazaly, A.; Gorchon, J.; Wilson, R.B.; Pattabi, A.; Bokor, J. Progress towards ultrafast spintronics applications. J. Magn. Magn. Mater. 2020, 502, 166478. [Google Scholar] [CrossRef]

- Schubert, C.; Hassdenteufel, A.; Matthes, P.; Schmidt, J.; Helm, M.; Bratschitsch, R.; Albrecht, M. All-optical helicity dependent magnetic switching in an artificial zero moment magnet. Appl. Phys. Lett. 2014, 104, 082406. [Google Scholar] [CrossRef]

- Mangin, S.; Gottwald, M.; Lambert, C.H.; Steil, D.; Uhlíř, V.; Pang, L.; Hehn, M.; Alebrand, S.; Cinchetti, M.; Malinowski, G.; et al. Engineered materials for all-optical helicity-dependent magnetic switching. Nat. Mater. 2014, 13, 286–292. [Google Scholar] [CrossRef]

- Bukharaev, A.A.; Zvezdin, A.K.; Pyatakov, A.P.; Fetisov, Y.K. Straintronics: A new trend in micro- and nanoelectronics and materials science. Phys.-Uspekhi 2018, 61, 1175. [Google Scholar] [CrossRef]

- D’Souza, N.; Biswas, A.; Ahmad, H.; Fashami, M.S.; Al-Rashid, M.M.; Sampath, V.; Bhattacharya, D.; Abeed, M.A.; Atulasimha, J.; Bandyopadhyay, S. Energy-efficient switching of nanomagnets for computing: Straintronics and other methodologies. Nanotechnology 2018, 29, 442001. [Google Scholar] [CrossRef]

- Bandyopadhyay, S.; Atulasimha, J.; Barman, A. Magnetic straintronics: Manipulating the magnetization of magnetostrictive nanomagnets with strain for energy-efficient applications. Appl. Phys. Rev. 2021, 8, 041323. [Google Scholar] [CrossRef]

- Mott, N.F.; Friedman, L. Metal-Insulator Transitions in VO2, Ti2O3 and Ti2-xVxO3. Philos. Mag. 1974, 30, 389–402. [Google Scholar] [CrossRef]

- Zylbersztejn, A.; Mott, N.F. Metal-insulator transition in vanadium dioxide. Phys. Rev. B 1975, 11, 4383–4395. [Google Scholar] [CrossRef]

- Rini, M.; Cavalleri, A.; Schoenlein, R.W.; López, R.; Feldman, L.C.; Haglund, R.F.; Boatner, L.A.; Haynes, T.E. Photoinduced phase transition in VO2 nanocrystals: Ultrafast control of surface-plasmon resonance. Opt. Lett. 2005, 30, 558–560. [Google Scholar] [CrossRef] [PubMed]

- Dragoman, M.; Cismaru, A.; Hartnagel, H.; Plana, R. Reversible metal-semiconductor transitions for microwave switching applications. Appl. Phys. Lett. 2006, 88, 073503. [Google Scholar] [CrossRef]

- Kim, H.T.; Chae, B.G.; Youn, D.H.; Maeng, S.L.; Kim, G.; Kang, K.Y.; Lim, Y.S. Mechanism and observation of Mott transition in VO2-based two- and three-terminal devices. New J. Phys. 2004, 6, 52. [Google Scholar] [CrossRef]

- Kim, H.T.; Chae, B.G.; Youn, D.H.; Kim, G.; Kang, K.Y.; Lee, S.J.; Kim, K.; Lim, Y.S. Raman study of electric-field-induced first-order metal–insulator transition in VO2-based devices. Appl. Phys. Lett. 2005, 86, 242101. [Google Scholar] [CrossRef]

- Strelcov, E.; Lilach, Y.; Kolmakov, A. Gas Sensor Based on Metal-Insulator Transition in VO2 Nanowire Thermistor. Nano Lett. 2009, 9, 2322–2326. [Google Scholar] [CrossRef]

- Morin, F.J. Oxides Which Show a Metal-to-Insulator Transition at the Neel Temperature. Phys. Rev. Lett. 1959, 3, 34–36. [Google Scholar] [CrossRef]

- Atkin, J.M.; Berweger, S.; Chavez, E.K.; Raschke, M.B.; Cao, J.; Fan, W.; Wu, J. Strain and temperature dependence of the insulating phases of VO2 near the metal–insulator transition. Phys. Rev. B 2012, 85, 020101. [Google Scholar] [CrossRef]

- Park, J.H.; Coy, J.M.; Kasirga, T.S.; Huang, C.; Fei, Z.; Hunter, S.; Cobden, D.H. Measurement of a solid-state triple point at the metal—insulator transition in VO2. Nature 2013, 500, 431–434. [Google Scholar] [CrossRef] [PubMed]

- Abreu, E.; Liu, M.; Lu, J.; West, K.G.; Kittiwatanakul, S.; Yin, W.; Wolf, S.A.; Averitt, R.D. THz spectroscopy of VO2 epitaxial films: Controlling the anisotropic properties through strain engineering. New J. Phys. 2012, 14, 083026. [Google Scholar] [CrossRef]

- Liu, M.; Hwang, H.Y.; Tao, H.; Strikwerda, A.C.; Fan, K.; Keiser, G.R.; Sternbach, A.J.; West, K.G.; Kittiwatanakul, S.; Lu, J.; et al. Terahertz-field-induced insulator-to-metal transition in vanadium dioxide metamaterial. Nature 2012, 487, 345–348. [Google Scholar] [CrossRef] [PubMed]

- Kittiwatanakul, S.; Wolf, S.A.; Lu, J. Large epitaxial bi-axial strain induces a Mott-like phase transition in VO2. Appl. Phys. Lett. 2014, 105, 073112. [Google Scholar] [CrossRef]

- Laverock, J.; Kittiwatanakul, S.; Zakharov, A.A.; Niu, Y.R.; Chen, B.; Wolf, S.A.; Lu, J.W.; Smith, K.E. Direct Observation of Decoupled Structural and Electronic Transitions and an Ambient Pressure Monocliniclike Metallic Phase of VO2. Phys. Rev. Lett. 2014, 113, 216402. [Google Scholar] [CrossRef] [PubMed]

- de la Venta, J.; Wang, S.; Ramirez, J.G.; Schuller, I.K. Control of magnetism across metal to insulator transitions. Appl. Phys. Lett. 2013, 102, 122404. [Google Scholar] [CrossRef]

- de la Venta, J.; Wang, S.; Saerbeck, T.; Ramírez, J.G.; Valmianski, I.; Schuller, I.K. Coercivity enhancement in V2O3/Ni bilayers driven by nanoscale phase coexistence. Appl. Phys. Lett. 2014, 104, 062410. [Google Scholar] [CrossRef]

- Nkosi, S.; Lafane, S.; Masina, B.; Ndwandwe, O. The control of magnetism near metal-to-insulator transitions of VO2 nano-belts. J. Alloys Compd. 2016, 689, 313–317. [Google Scholar] [CrossRef]

- Nakayama, M.; Kai, T.; Shimomura, N.; Amano, M.; Kitagawa, E.; Nagase, T.; Yoshikawa, M.; Kishi, T.; Ikegawa, S.; Yoda, H. Spin transfer switching in TbCoFe\CoFeB\MgO\CoFeB\TbCoFe magnetic tunnel junctions with perpendicular magnetic anisotropy. J. Appl. Phys. 2008, 103, 07A710. [Google Scholar] [CrossRef]

- Stanciu, C.D.; Kimel, A.V.; Hansteen, F.; Tsukamoto, A.; Itoh, A.; Kirilyuk, A.; Rasing, T. Ultrafast spin dynamics across compensation points in ferrimagnetic GdFeCo: The role of angular momentum compensation. Phys. Rev. B 2006, 73, 220402. [Google Scholar] [CrossRef]

- Radu, I.; Vahaplar, K.; Stamm, C.; Kachel, T.; Pontius, N.; Dürr, H.A.; Ostler, T.A.; Barker, J.; Evans, R.F.L.; Chantrell, R.W.; et al. Transient ferromagnetic-like state mediating ultrafast reversal of antiferromagnetically coupled spins. Nature 2011, 472, 205–208. [Google Scholar] [CrossRef] [PubMed]

- Hassdenteufel, A.; Hebler, B.; Schubert, C.; Liebig, A.; Teich, M.; Helm, M.; Aeschlimann, M.; Albrecht, M.; Bratschitsch, R. Thermally Assisted All-Optical Helicity Dependent Magnetic Switching in Amorphous Fe100-xTbx Alloy Films. Adv. Mater. 2013, 25, 3122–3128. [Google Scholar] [CrossRef] [PubMed]

- Woo, S.; Song, K.M.; Zhang, X.; Zhou, Y.; Ezawa, M.; Liu, X.; Finizio, S.; Raabe, J.; Lee, N.J.; Kim, S.I.; et al. Current-driven dynamics and inhibition of the skyrmion Hall effect of ferrimagnetic skyrmions in GdFeCo films. Nat. Commun. 2018, 9, 959. [Google Scholar] [CrossRef]

- Caretta, L.; Mann, M.; Büttner, F.; Ueda, K.; Pfau, B.; Günther, C.M.; Hessing, P.; Churikova, A.; Klose, C.; Schneider, M.; et al. Fast current-driven domain walls and small skyrmions in a compensated ferrimagnet. Nat. Nanotechnol. 2018, 13, 1154–1160. [Google Scholar] [CrossRef] [PubMed]

- Quessab, Y.; Xu, J.W.; Ma, C.T.; Zhou, W.; Riley, G.A.; Shaw, J.M.; Nembach, H.T.; Poon, S.J.; Kent, A.D. Tuning interfacial Dzyaloshinskii-Moriya interactions in thin amorphous ferrimagnetic alloys. Sci. Rep. 2020, 10, 7447. [Google Scholar] [CrossRef]

- Morshed, M.G.; Khoo, K.H.; Quessab, Y.; Xu, J.W.; Laskowski, R.; Balachandran, P.V.; Kent, A.D.; Ghosh, A.W. Tuning Dzyaloshinskii-Moriya interaction in ferrimagnetic GdCo: A first-principles approach. Phys. Rev. B 2021, 103, 174414. [Google Scholar] [CrossRef]

- Morshed, M.G.; Vakili, H.; Ghosh, A.W. Positional Stability of Skyrmions in a Racetrack Memory with Notched Geometry. Phys. Rev. Appl. 2022, 17, 064019. [Google Scholar] [CrossRef]

- Ding, M.; Poon, S.J. Tunable perpendicular magnetic anisotropy in GdFeCo amorphous films. J. Magn. Magn. Mater. 2013, 339, 51–55. [Google Scholar] [CrossRef]

- Anuniwat, N.; Ding, M.; Poon, S.J.; Wolf, S.A.; Lu, J. Strain-induced enhancement of coercivity in amorphous TbFeCo films. J. Appl. Phys. 2013, 113, 043905. [Google Scholar] [CrossRef]

- Hansen, P.; Clausen, C.; Much, G.; Rosenkranz, M.; Witter, K. Magnetic and magneto-optical properties of rare-earth transition-metal alloys containing Gd, Tb, Fe, Co. J. Appl. Phys. 1989, 66, 756–767. [Google Scholar] [CrossRef]

- Hebler, B.; Hassdenteufel, A.; Reinhardt, P.; Karl, H.; Albrecht, M. Ferrimagnetic Tb–Fe Alloy Thin Films: Composition and Thickness Dependence of Magnetic Properties and All-Optical Switching. Front. Mater. 2016, 3, 8. [Google Scholar] [CrossRef]

- West, K.G.; Lu, J.; Yu, J.; Kirkwood, D.; Chen, W.; Pei, Y.; Claassen, J.; Wolf, S.A. Growth and characterization of vanadium dioxide thin films prepared by reactive-biased target ion beam deposition. J. Vac. Sci. Technol. A 2008, 26, 133–139. [Google Scholar] [CrossRef]

- Ostler, T.A.; Evans, R.F.L.; Chantrell, R.W.; Atxitia, U.; Chubykalo-Fesenko, O.; Radu, I.; Abrudan, R.; Radu, F.; Tsukamoto, A.; Itoh, A.; et al. Crystallographically amorphous ferrimagnetic alloys: Comparing a localized atomistic spin model with experiments. Phys. Rev. B 2011, 84, 024407. [Google Scholar] [CrossRef]

- Gilbert, T. A Lagrangian Formulation of the Gyromagnetic Equation of the Magnetization Field. Phys. Rev. 1955, 100, 1243. [Google Scholar]

- Kittiwatanakul, S. Study of Metal-Insulator Transition in Strongly Correlated Vanadium Dioxide Thin Films. Ph.D. Thesis, University of Virginia, Charlottesville, VA, USA, 2014. [Google Scholar]

- Satoh, T.; Fukamichi, K.; Satoh, Y. Magnetic Properties and Thermal Expansion of Fe-Tb Amorphous Alloys. IEEE Transl. J. Magn. Jpn. 1985, 1, 796–797. [Google Scholar] [CrossRef]

- Lopez, R.; Boatner, L.A.; Haynes, T.E.; Haglund, R.F.J.; Feldman, L.C. Enhanced hysteresis in the semiconductor-to-metal phase transition of VO2 precipitates formed in SiO2 by ion implantation. Appl. Phys. Lett. 2001, 79, 3161–3163. [Google Scholar] [CrossRef]

| Parameter | Value |

|---|---|

| Fe Magnetic moment () | 2.22 |

| Tb Magnetic moment () | 9.34 |

| Fe-Fe Exchange Interaction (J) | 2.83 × 10 J |

| Tb-Tb Exchange Interaction (J) | 0.99 × 10 J |

| Fe-Tb Exchange Interaction (J) | −1.09 × 10 J |

| Anisotropy (K) | 1 × 10 J/m |

| Damping () | 0.05 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ma, C.T.; Kittiwatanakul, S.; Sittipongpittaya, A.; Wang, Y.; Morshed, M.G.; Ghosh, A.W.; Poon, S.J. Phase Change-Induced Magnetic Switching through Metal–Insulator Transition in VO2/TbFeCo Films. Nanomaterials 2023, 13, 2848. https://doi.org/10.3390/nano13212848

Ma CT, Kittiwatanakul S, Sittipongpittaya A, Wang Y, Morshed MG, Ghosh AW, Poon SJ. Phase Change-Induced Magnetic Switching through Metal–Insulator Transition in VO2/TbFeCo Films. Nanomaterials. 2023; 13(21):2848. https://doi.org/10.3390/nano13212848

Chicago/Turabian StyleMa, Chung T., Salinporn Kittiwatanakul, Apiprach Sittipongpittaya, Yuhan Wang, Md Golam Morshed, Avik W. Ghosh, and S. Joseph Poon. 2023. "Phase Change-Induced Magnetic Switching through Metal–Insulator Transition in VO2/TbFeCo Films" Nanomaterials 13, no. 21: 2848. https://doi.org/10.3390/nano13212848

APA StyleMa, C. T., Kittiwatanakul, S., Sittipongpittaya, A., Wang, Y., Morshed, M. G., Ghosh, A. W., & Poon, S. J. (2023). Phase Change-Induced Magnetic Switching through Metal–Insulator Transition in VO2/TbFeCo Films. Nanomaterials, 13(21), 2848. https://doi.org/10.3390/nano13212848