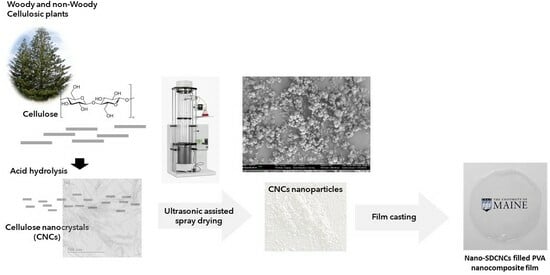

Characterization of CNC Nanoparticles Prepared via Ultrasonic-Assisted Spray Drying and Their Application in Composite Films

Abstract

:1. Introduction

2. Materials and Methods

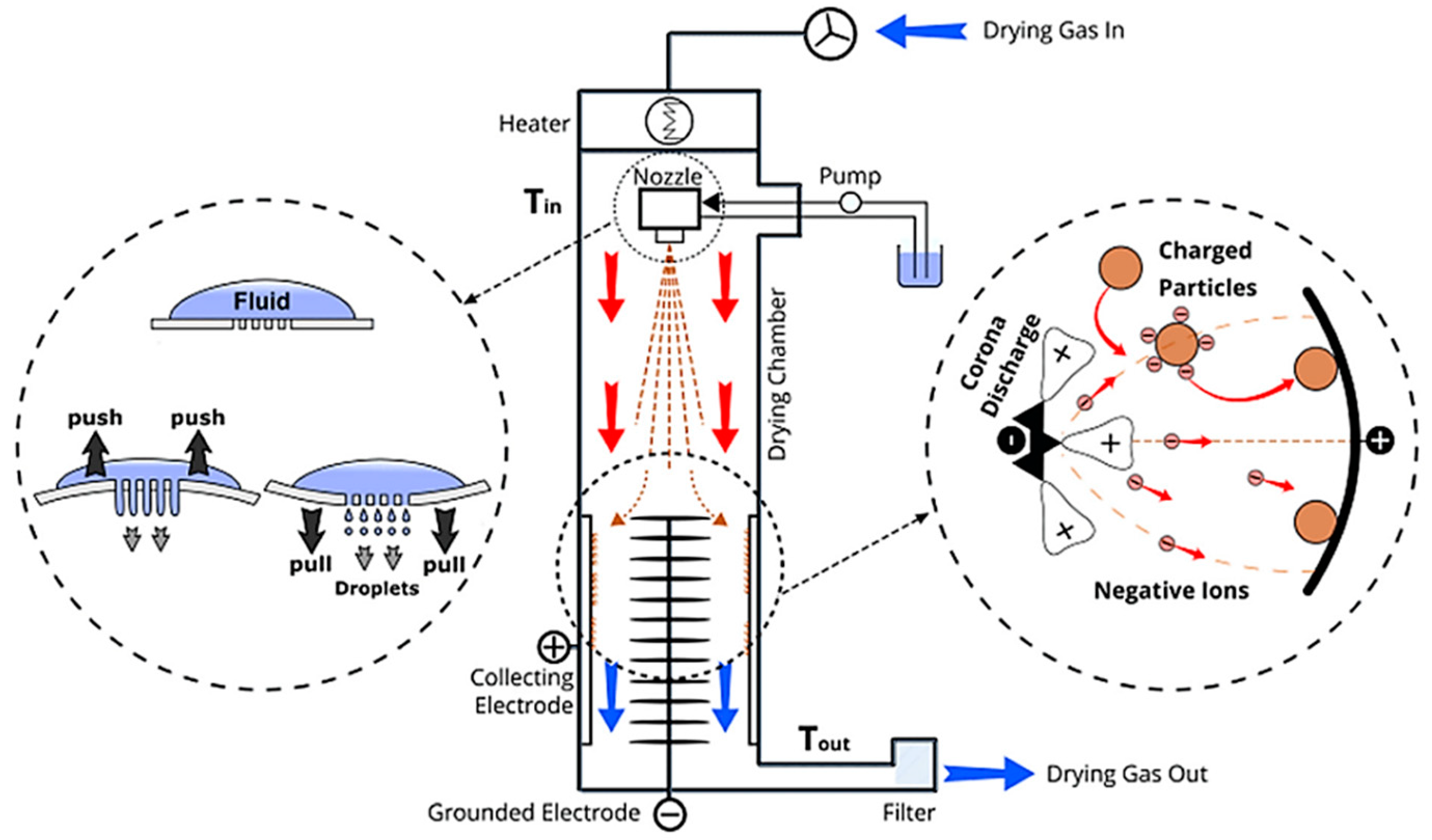

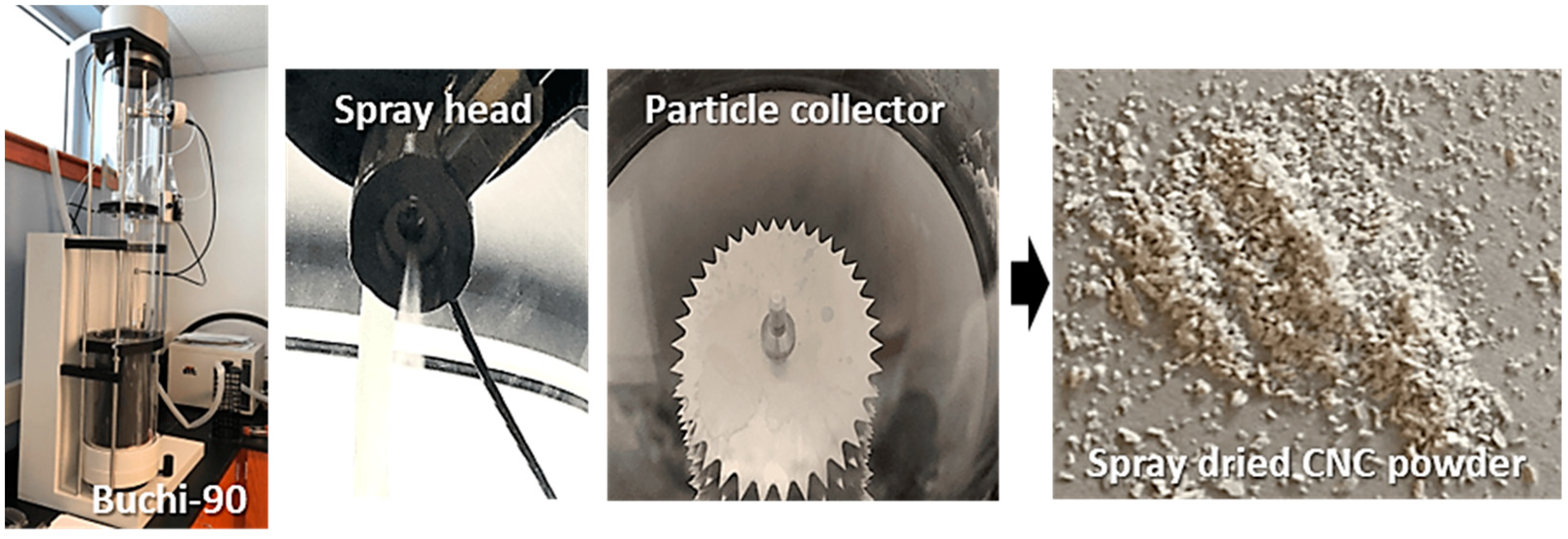

2.1. Spray Drying Conditions

2.2. Solvent Casting

2.3. Characteristics of Spray-Dried CNC Powders

2.4. Characteristics of PVA Nanocomposite Films

3. Results and Discussion

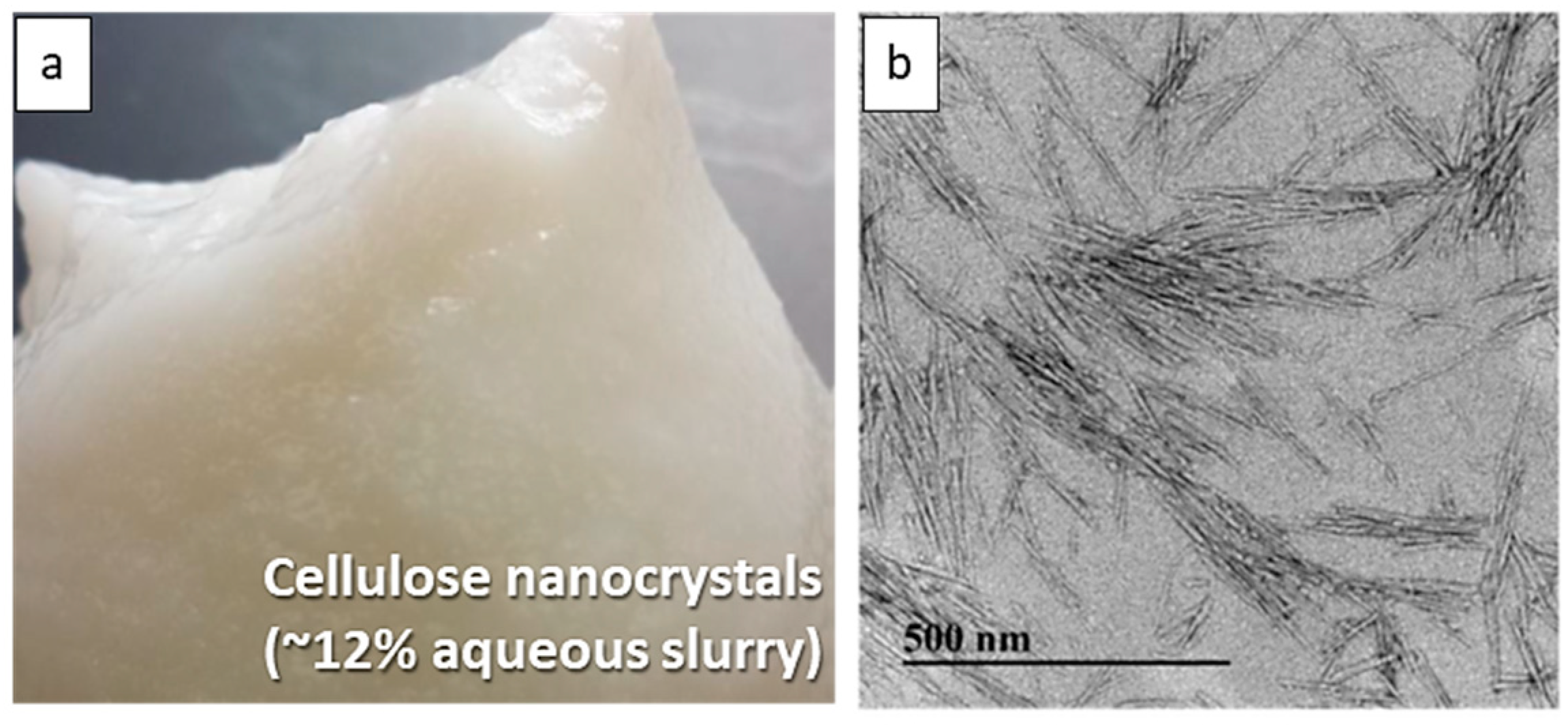

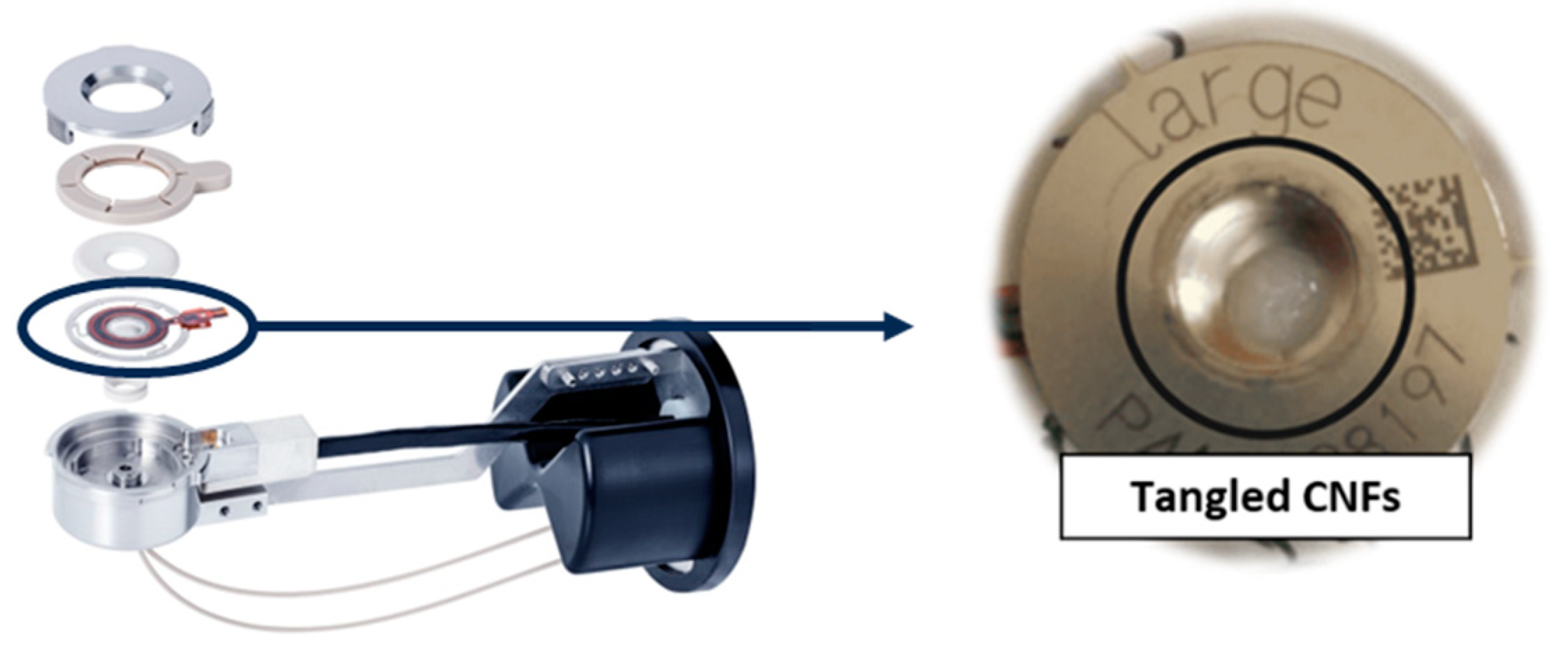

3.1. Feasibility of Spray Drying

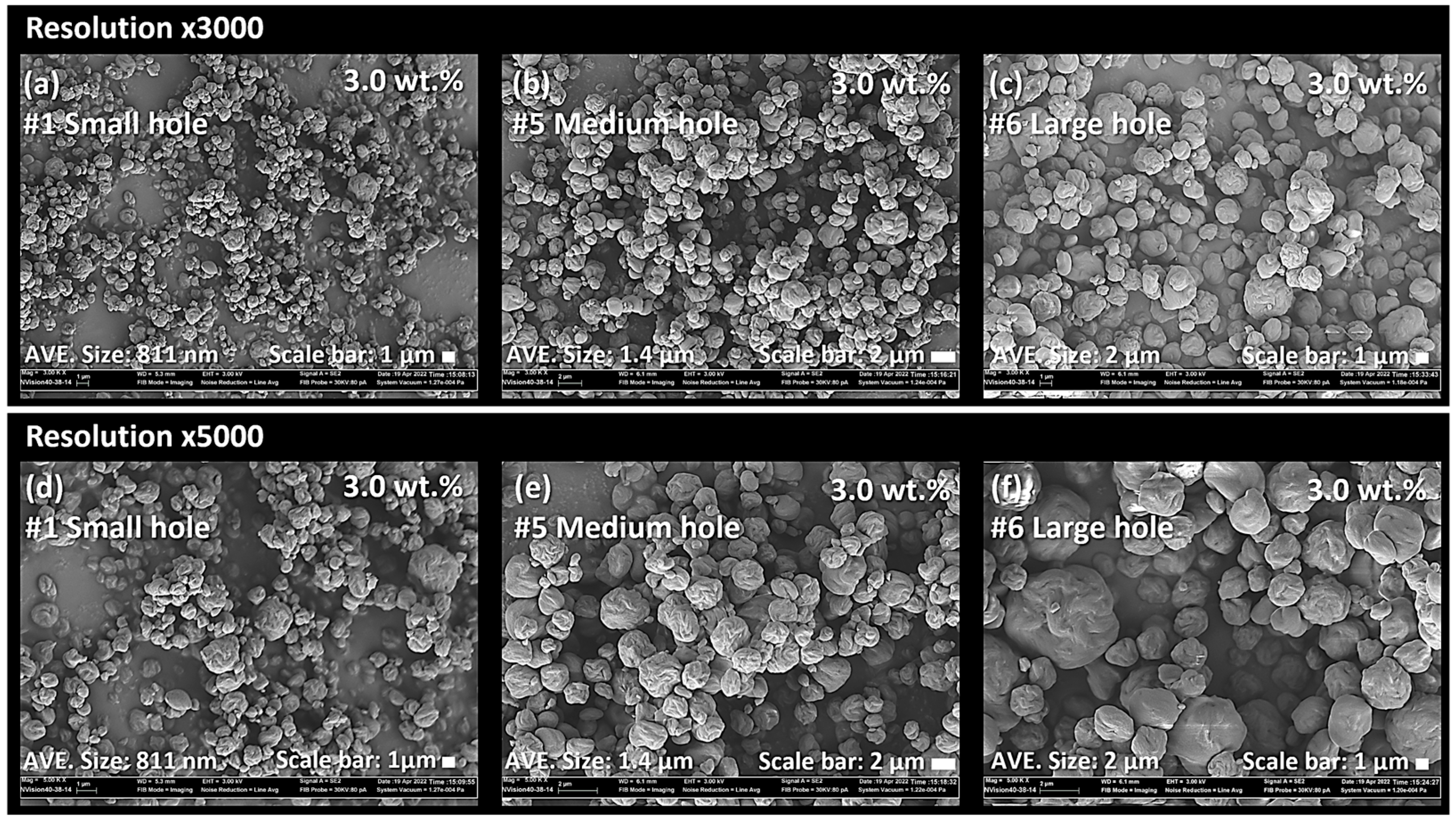

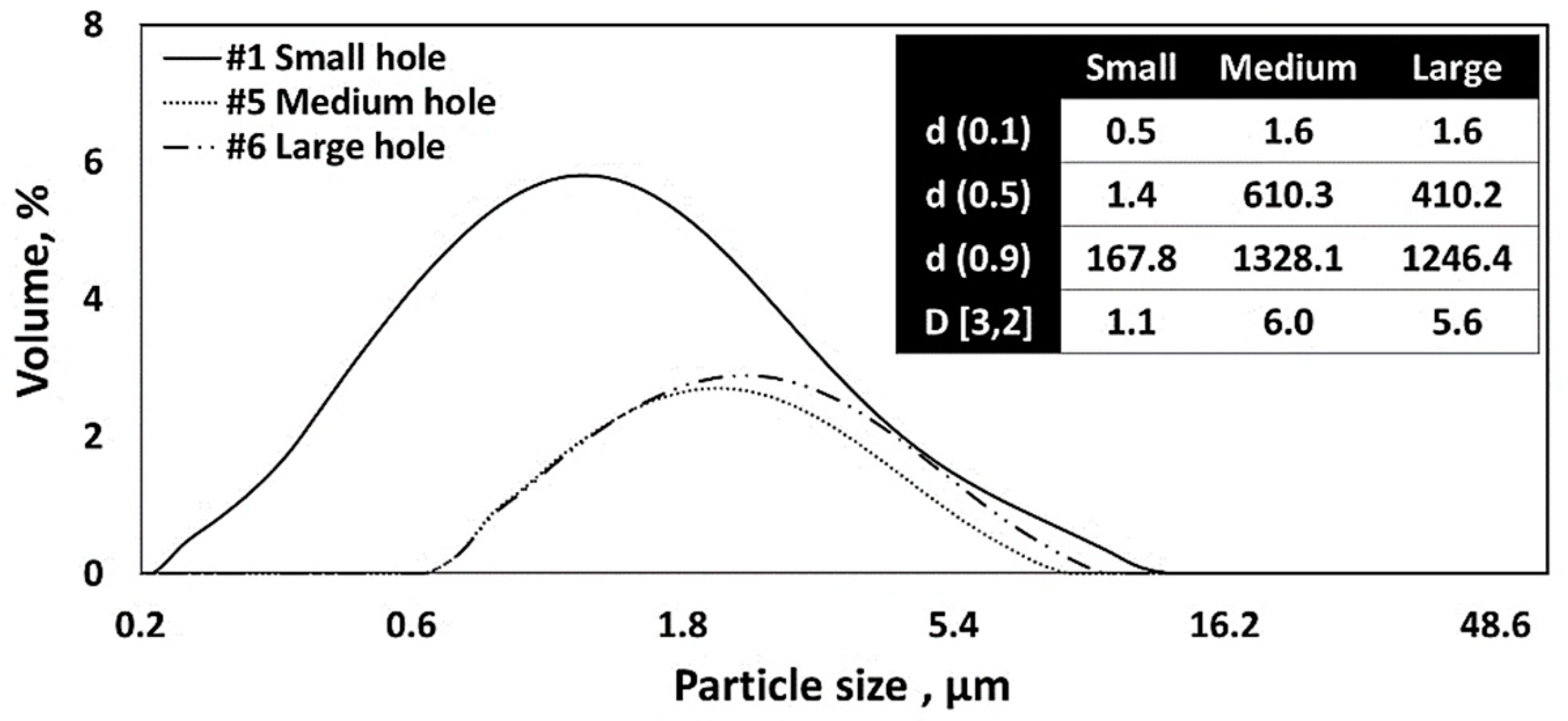

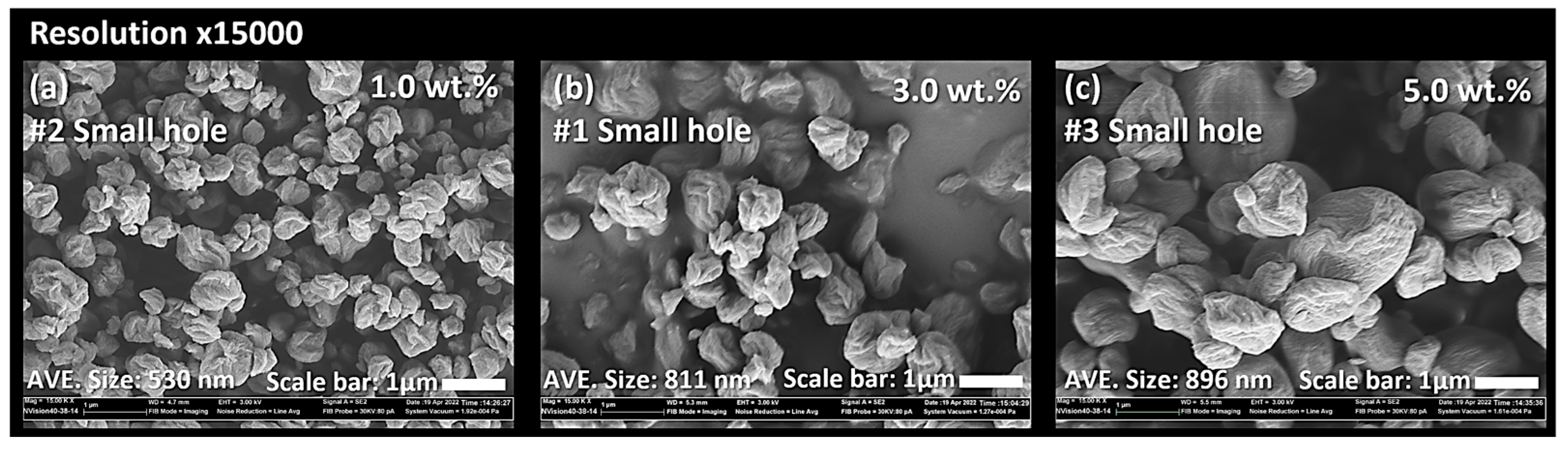

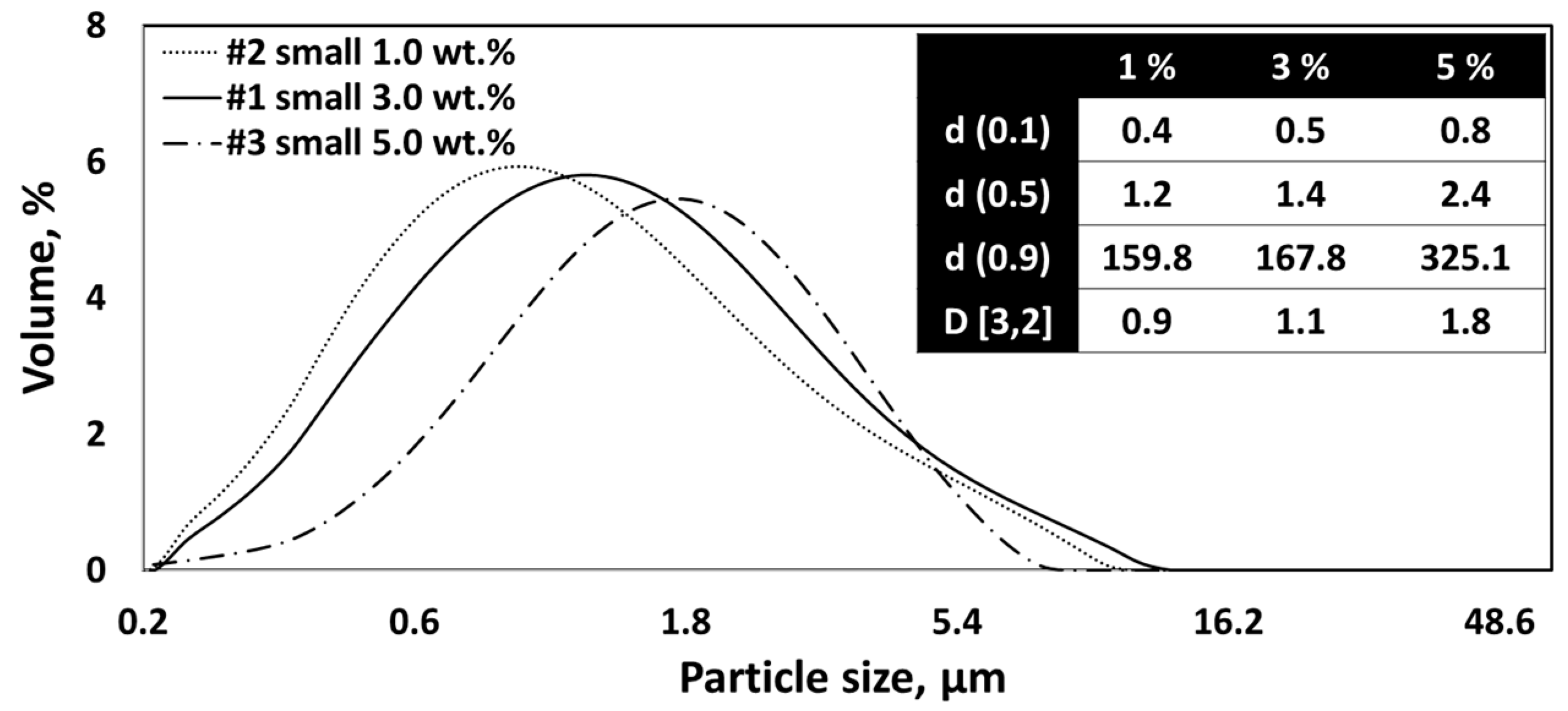

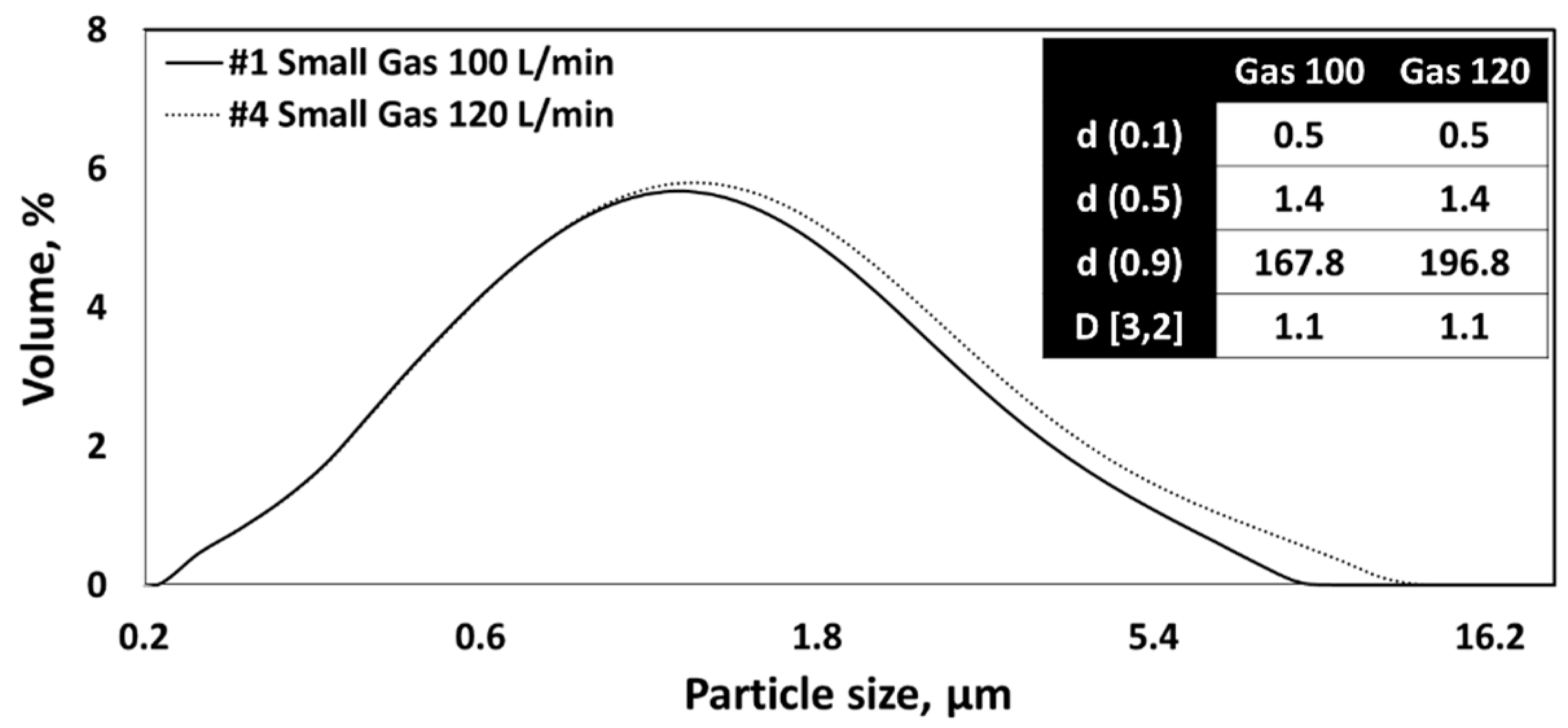

3.2. Effects of Spray Drying Conditions on Particle Shapes and Sizes of Nano SDCNCs

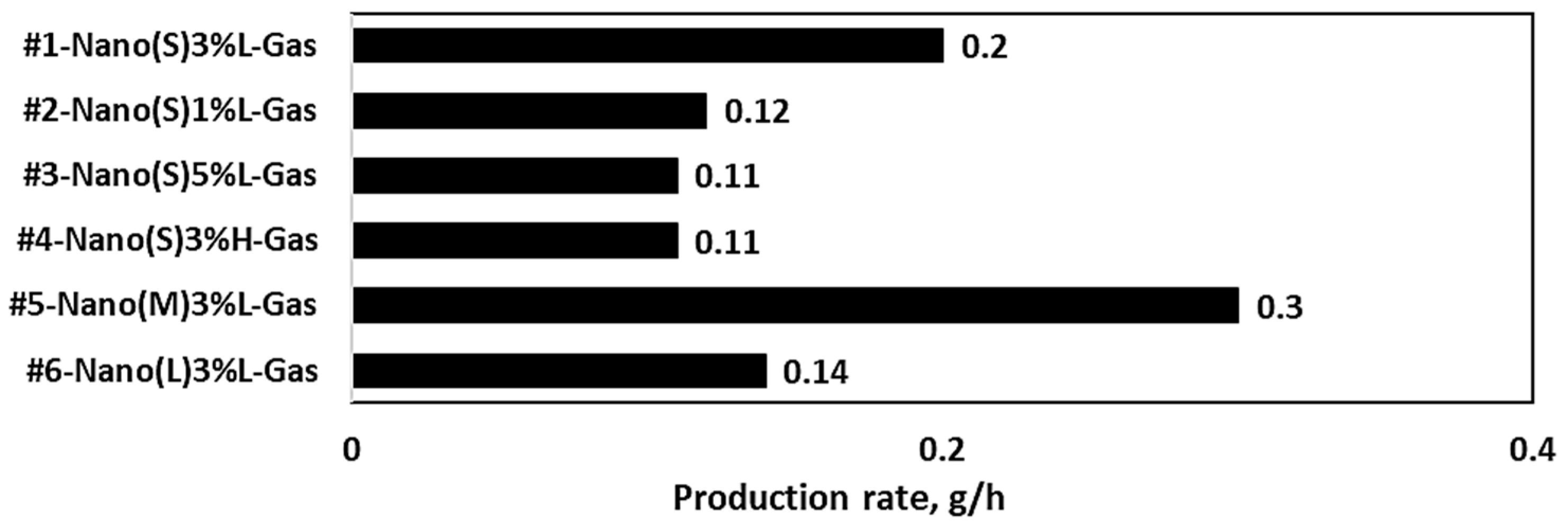

3.3. Effects of Spray Drying Conditions on Production Rates

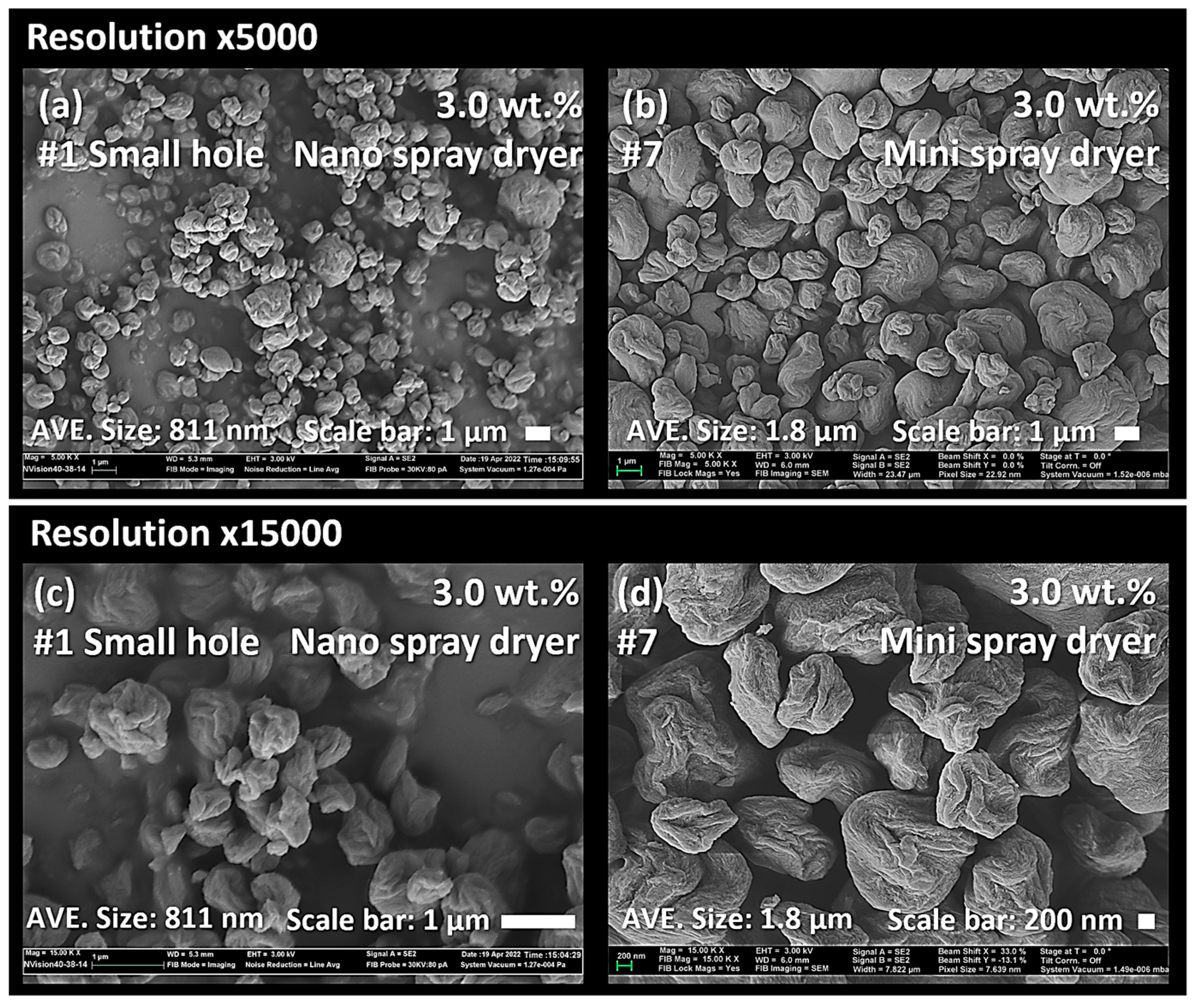

3.4. Nano Spray Dryer vs. Mini Spray Dryer

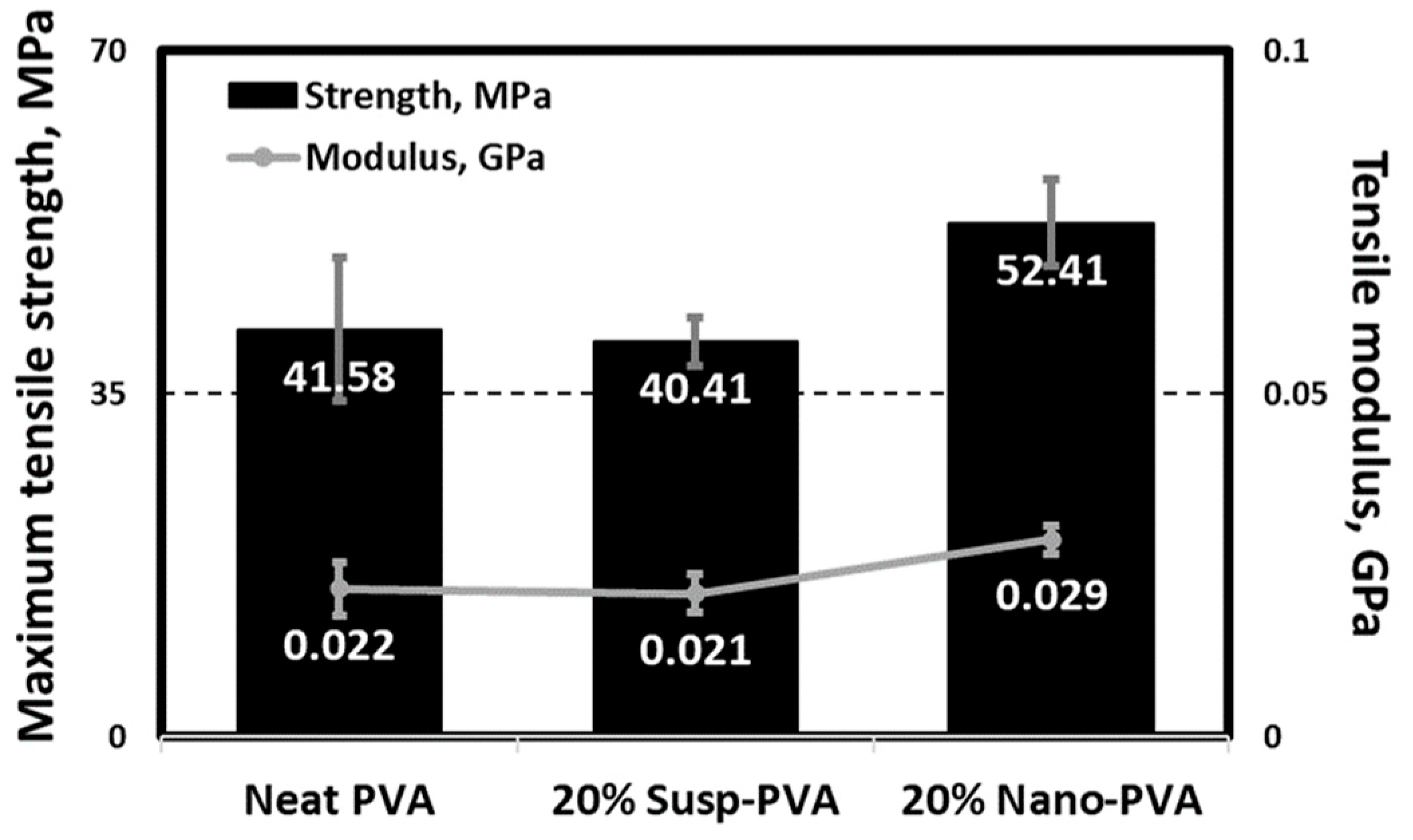

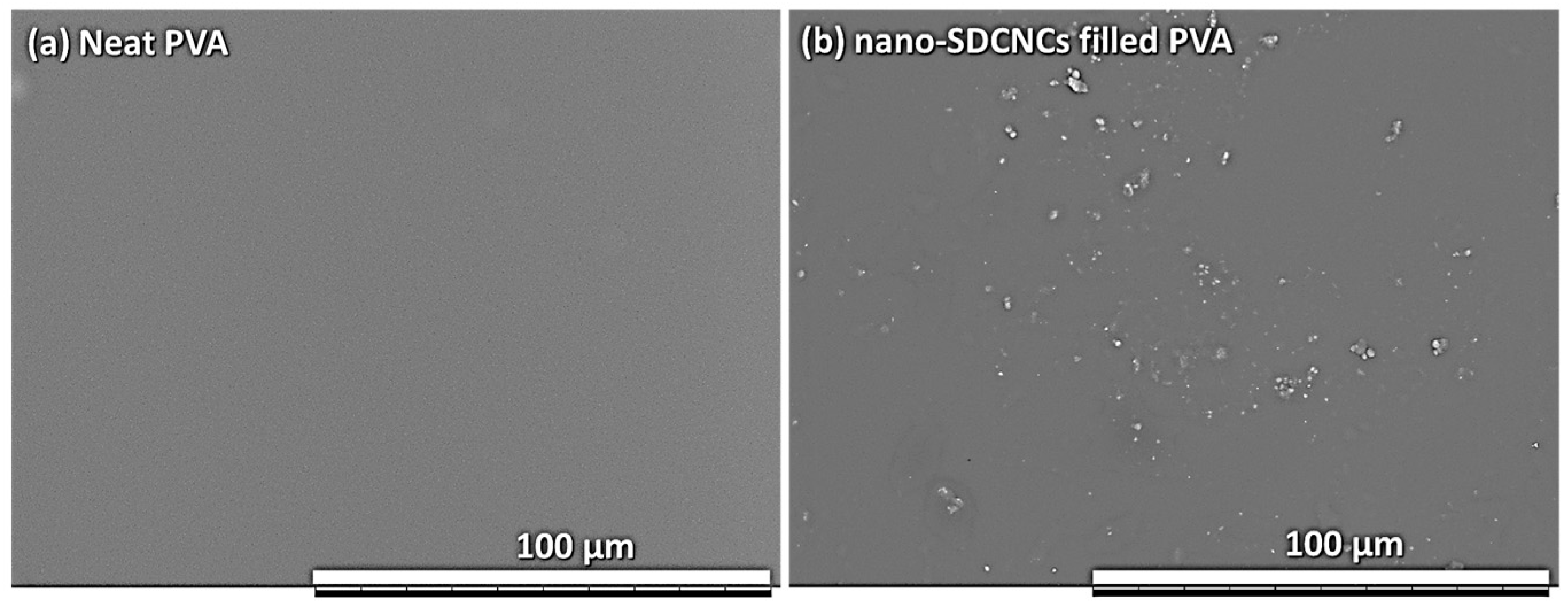

3.5. Optical, Physical, and Mechanical Properties of PVA Nanocomposite Films

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

References

- Shrotri, A.; Lambert, L.K.; Tanksale, A.; Beltramini, J. Mechanical depolymerisation of acidulated cellulose: Understanding the solubility of high molecular weight oligomers. Green Chem. 2013, 152, 761–2768. [Google Scholar] [CrossRef]

- Wang, F.; Ouyang, D.; Zhou, Z.; Page, S.J.; Liu, D.; Zhao, X. Lignocellulosic biomass as sustainable feedstock and materials for power generation and energy storage. J. Energy Chem. 2021, 57, 247–280. [Google Scholar] [CrossRef]

- Lavrič, G.; Oberlintner, A.; Filipova, I.; Novak, U.; Likozar, B.; Brodnjak, U.V. Functional nanocellulose, alginate and chitosan nanocomposites designed as active film packaging materials. Polymers 2021, 13, 2523. [Google Scholar] [CrossRef] [PubMed]

- Wang, Q.; Zhao, X.; Zhu, J.Y. Kinetics of strong acid hydrolysis of a bleached kraft pulp for producing cellulose nanocrystals (CNCs). Ind. Eng. Chem. Res. 2014, 53, 11007–11014. [Google Scholar] [CrossRef]

- Jiang, F.; Esker, A.R.; Roman, M. Acid-catalyzed and solvolytic desulfation of H2SO4-hydrolyzed cellulose nanocrystals. Langmuir 2010, 26, 17919–17925. [Google Scholar] [CrossRef]

- Kumar, A.; Negi, Y.S.; Choudhary, V.; Bhardwaj, N.K. Characterization of cellulose nanocrystals produced by acid-hydrolysis from sugarcane bagasse as agro-waste. J. Mater. Chem. 2014, 2, 1–8. [Google Scholar] [CrossRef]

- Postek, M.T.; Vladár, A.; Dagata, J.; Farkas, N.; Ming, B.; Wagner, R.; Raman, A.; Moon, R.J.; Sabo, R.; Wegner, T.H. Development of the metrology and imaging of cellulose nanocrystals. Meas. Sci. Technol. 2010, 22, 024005. [Google Scholar] [CrossRef]

- Strojewski, D.; Krupa, A. Spray drying and nano spray drying as manufacturing methods or drug-loaded polymeric particles. Polim. Med. 2022, 52, 101–111. [Google Scholar] [CrossRef]

- Huang, L.X.; Mujumdar, A.S. The effect of rotary disk atomizer RPM on particle size distribution in a semi-industrial spray dryer. Dry. Technol. 2008, 26, 1319–1325. [Google Scholar] [CrossRef]

- Shafaee, M.; Banitabaei, S.A.; Ashjaee, M.; Esfahanian, V. Effect of flow conditions on spray cone angle of a two-fluid atomizer. J. Mech. Sci. Technol. 2011, 25, 365–369. [Google Scholar] [CrossRef]

- Teunou, E.; Poncelet, D. Rotary disc atomisation for microencapsulation applications-prediction of the particle trajectories. J. Food Eng. 2005, 71, 345–353. [Google Scholar] [CrossRef]

- Woo, M.W.; Daud, W.R.W.; Tasirin, S.M.; Talib, M.Z.M. Optimization of the spray drying operating parameters-A quick trial-and-error method. Dry. Technol. 2007, 25, 1741–1747. [Google Scholar] [CrossRef]

- Chegini, G.R.; Bashiri, B.; Mesbahi, M.H. Comparison of pumped air characteristics from a rotary atomizer with three types of wheels. Exp. Tech. 2012, 36, 63–68. [Google Scholar] [CrossRef]

- Lukasiewicz, S.J. Spray-drying ceramic powders. J. Am. Ceram. 1989, 72, 617–624. [Google Scholar] [CrossRef]

- Parikh, D.M. Handbook of Pharmaceutical Granulation Technology; Drugs and the Pharmaceutical Sciences; Informa: London, UK, 2005; p. 81. [Google Scholar]

- Balderrama, C.I.P.; Porras, C.L.; Figueroa, Y.T.; Solis, V.E.; Salas, C.A.; Leos, M.Z. Encapsulation of active ingredients in food industry by spray-drying and nano spray-drying technologies. Processes 2020, 8, 889. [Google Scholar] [CrossRef]

- Schmid, K.; Arpagaus, C.; Friess, W. Evaluation of the nano spray dryer B-90 for pharmaceutical applications. Pharm. Dev. Technol. 2011, 16, 287–294. [Google Scholar] [CrossRef] [PubMed]

- Wang, B.; Friess, W. Spray drying of silica microparticles for sustained release application with a new sol-gel precursor. Int. J. Pharm. 2017, 532, 281–288. [Google Scholar] [CrossRef]

- Jafari, S.M.; Arpagaus, C.; Cerqueira, M.A.; Samborska, K. Nano spray drying of food ingredients; materials, processing and applications. Trends Food Sci. 2021, 109, 632–646. [Google Scholar] [CrossRef]

- Arpagaus, C.; Collenberg, A.; Rütti, D.; Assadpour, E.; Jafari, S.M. Nano spray drying for encapsulation of pharmaceuticals. Int. J. Pharm. 2018, 546, 194–214. [Google Scholar] [CrossRef]

- Lee, S.H.; Heng, D.; Ng, W.K.; Chan, H.K.; Tan, R.B.H. Nano spray drying: A novel method for preparing protein nanoparticles for protein therapy. Int. J. Pharm. 2011, 403, 192–200. [Google Scholar] [CrossRef]

- Arpagaus, C.; John, P.; Collenberg, A.; Rütti, D. Nanocapsules formation by nano spray drying. In Nanoencapsulation Technologies for the Food and Nutraceutical Industries; Academic Press: Cambridge, MA, USA, 2017; pp. 346–401. [Google Scholar]

- Samborska, K.; Poozesh, S.; Barańska, A.; Sobulska, M.; Jedlińska, A.; Arpagaus, C.; Malekjani, N.; Jafari, S.M. Innovations in spray drying process for food and pharama industries. J. Food Eng. 2022, 321, 110960. [Google Scholar] [CrossRef]

- Jayaprakash, P.; Maudhuit, A.; Gaiani, C.; Desobry, S. Encapsulation of bioactive compounds using competitive emerging techniques: Electrospraying, nano spray drying, and electrostatic spray drying. J. Food Eng. 2023, 339, 111260. [Google Scholar] [CrossRef]

- Almansour, K.; Ali, R.; Alheibshy, F.; Almutairi, T.J.; Alshammari, R.F.; Alhajj, N.; Arpagaus, C.; Elsayed, M.M.A. Particle engineering by nano spray drying: Optimization of process parameters with hydroethanolic versus aqueous solutions. Pharmaceutics 2022, 14, 800. [Google Scholar] [CrossRef] [PubMed]

- Bürki, K.; Jeon, I.; Arpagaus, C.; Betz, G. New insights into respirable protein powder preparation using a nano spray dryer. Int. J. Pharm. 2011, 408, 248–256. [Google Scholar] [CrossRef]

- Arpagaus, C. Pharmaceutical particle engineering via nano spray drying-Process parameters and application examples on the laboratory-scale. Int. J. Med. Nano Res. 2018, 5, 026. [Google Scholar] [CrossRef]

- Khoramabadi, H.N.; Arefian, M.; Hojjati, M.; Tajzad, I.; Mokhtarzade, A.; Mazhar, M.; Jamavari, A. A review of polyvinyl alcohol/carboxymethyl cellulose (PVA/CMC) composites for various applications. J. Compos. Compd. 2020, 2, 69–76. [Google Scholar]

- Virtanen, S.; Vartianen, J.; Setala, H.; Tammelin, T.; Vuoti, S. Modified nanofibrillated cellulose-polyvinyl alcohol films with improved mechanical performance. RSC Adv. 2014, 4, 11343. [Google Scholar] [CrossRef]

- Rowe, A.A.; Tajvidi, M.; Gardner, D.J. Thermal stability of cellulose nanomaterials and their composites with polyvinyl alcohol (PVA). Therm. Anal. Calorim. 2016, 126, 1371–1386. [Google Scholar] [CrossRef]

- Lee, H.; You, J.; Jin, H.J.; Kwak, H.W. Chemical and physical reinforcement behavior of dialdehyde nanocellulose in PVA composite film: A comparison of nanofiber and nanocrystal. Carbohydr. Polym. 2020, 232, 115771. [Google Scholar] [CrossRef]

- Liu, C.; Shao, Z.; Wang, J.; Lu, C.; Wang, Z. Eco-friendly polyvinyl alcohol/cellulose nanofiber-Li+ composite separator for highperformance lithium-ion batteries. RSC Adv. 2016, 6, 97912. [Google Scholar] [CrossRef]

- Sathwane, M.; Chhajed, M.; Verma, C.; Gaikward, K.K.; Maji, P.K. Synergistic effect of hybrid hydroxylated boron nitride and cellulose nanocrystals for enhancing the thermal, mechanical, and hydrophobic properties of composite film. Polym. Compos. 2023, 44, 492–504. [Google Scholar] [CrossRef]

- Chen, C.; Sun, W.; Wang, L.; Tajvidi, M.; Wang, J.; Gardner, D.J. Transparent multifunctional cellulose nanocrystal films prepared using trivalent metal ion exchange for food packaging. ACS Sustain. Chem. Eng. 2022, 10, 9419–9430. [Google Scholar] [CrossRef]

- Chowdhury, R.A.; Rai, A.; Glynn, E.; Morgan, P.; Moore, A.L.; Youngblood, J.P. Superior, processing-dependent thermal conductivity of cellulose nanocrystal-poly(vinyl alcohol) composite films. Polymer 2019, 164, 17–25. [Google Scholar] [CrossRef]

- Popescu, M.C. Structure and sorption properties of CNC reinforced PVA films. Int. J. Biol. Macromol. 2017, 101, 783–790. [Google Scholar] [CrossRef] [PubMed]

- Tanpichai, S.; Oksman, K. Crosslinked poly(vinyl alcohol) composite films with cellulose nanocrystals: Mechanical and thermal properties. J. Appl. Polym. Sci. 2018, 135, 45710. [Google Scholar] [CrossRef]

- Sanders, J.E.; Wang, L.; Brinkley, G.; Garder, D.J. Production of nano-scale cellulose nanocrystal powder via electrospray drying (ESD) for sustainable composites. Cellulose 2023, 30, 6303–6315. [Google Scholar] [CrossRef]

- Linsinger, T.P.J.; Gerganova, T.; Kestens, V.; Got, J.C. Preparation and characterization of two polydisperse, non-spherical materials as certified reference materials for particle size distribution by static image analysis and laser diffraction. Powder Technol. 2019, 343, 652–661. [Google Scholar] [CrossRef]

- Bellino, I.; Bergougnoux, L.; Ripault, J.M.; Firpo, J.L. Particle size effects on an optical fiber sensor response. Powder Technol. 2001, 115, 68–74. [Google Scholar] [CrossRef]

- Ulusoy, U.; Kursun, I. Comparison of different 2D image analysis measurement techniques for the shape of talc particles produced by different media milling. Miner. Eng. 2011, 24, 91–97. [Google Scholar] [CrossRef]

- TAPPI T 402; Standard Conditioning and Testing Atmospheres for Paper, Board, Pulp Handsheets, and Related Products. TAPPI: Atlanta, GA, USA, 2008.

- TAPPI T 220; Physical Testing of Pulp Handsheets. TAPPI: Atlanta, GA, USA, 2016.

- Kelly, P.V.; Gardner, D.J.; Gramlich, W.M. Optimizing lignocellulosic nanofibril dimensions and morphology by mechanical refining for enhanced adhesion. Carbohydr. Polym. 2021, 273, 118566. [Google Scholar] [CrossRef]

- Product Specification of Cellulose Nanocrystals, CAS Number: 9004-34-6, Process Development Center, University of Maine. Available online: https://umaine.edu/pdc/wp-content/uploads/sites/398/2016/03/Specs-CNC.pdf (accessed on 10 October 2023).

- Product Brochure Nano Spray Dryer B-90 HP en. Available online: https://assets.buchi.com/image/upload/v1605802436/pdf/Operation-Manuals/OM_093261_B-90_en.pdf (accessed on 10 October 2023).

- Baba, K.; Nishida, K. Calpain inhibitor nanocrystals prepared using nano spray dryer B-90. Nanoscale Res. Lett. 2012, 7, 436. [Google Scholar] [CrossRef] [PubMed]

- Li, X.; Anton, N.; Arpagaus, C.; Belleteix, F.; Vandamme, T.F. Nanoparticles by spray drying using innovative new technology: The büchi nano spray dryer B-90. J. Control. Release 2010, 147, 304–310. [Google Scholar] [CrossRef] [PubMed]

- Littringer, E.M.; Zellnitz, S.; Hammernik, K.; Adamer, V.; Friedl, H.; Urbanetz, N.A. Spray drying of aqueous salbutamol sulfate solutions using the nano spray dryer B-90-The impact of process parameters on particle size. Dry. Technol. 2013, 31, 1346–1353. [Google Scholar] [CrossRef]

- Dafsari, R.A.; Lee, H.J.; Han, J.; Park, D.C.; Lee, J. Viscosity effect on the pressure swirl atomization of an alternative aviation fuel. Fuel 2019, 240, 179–191. [Google Scholar] [CrossRef]

- Broichsitter, M.B.; Strehlow, B.; Kissel, T. Direct fractionation of spray-dried polymeric microparticles by inertial impaction. Powder Technol. 2015, 286, 311–317. [Google Scholar] [CrossRef]

- Keshani, S.; Daud, W.R.W.; Nourouzi, M.M.; Namvar, F.; Ghasemi, M. Spray drying: An overview on wall deposition, process and modeling. J. Food Eng. 2015, 146, 152–162. [Google Scholar] [CrossRef]

- Wang, W.; Dufour, C.; Zhou, W. Impacts of spray-drying conditions on the physicochemical properties of soy sauce powders using maltodextrin as auxiliary drying carrier. CYTA J. Food 2015, 13, 548–555. [Google Scholar] [CrossRef]

- Peng, Y.; Gardner, D.J.; Han, Y.S. Drying cellulose nanofibrils: In search of a suitable method. Cellulose 2012, 19, 91–102. [Google Scholar] [CrossRef]

- Peng, Y.; Han, Y.S.; Gardner, D.J. Spray drying cellulose nanofibrils: Effect of drying process parameters on particle morphology and size distribution. Wood Fiber Sci. 2012, 44, 448–461. [Google Scholar]

- Hwang, S.; Walker, C.C.; Johnson, D.; Han, Y.; Gardner, D.J. Spray drying enzyme-treated cellulose nanofibrils. Polymers 2023, 15, 4086. [Google Scholar] [CrossRef]

- Wang, L.; Gardner, D.J.; Bousfield, D.W. Cellulose nanofibril-reinforced polypropylene composites for material extrusion: Rheological properties. Polym. Eng. Sci. 2018, 58, 793–801. [Google Scholar] [CrossRef]

- Fortunati, E.; Puglia, D.; Luzi, F.; Santulli, C.; Kenny, J.M.; Torre, L. Binary PVA bio-nanocomposites containing cellulose nanocrystals extracted from different natural sources: Part I. Carbohydr. Polym. 2013, 97, 825–836. [Google Scholar] [CrossRef] [PubMed]

- Fortunati, E.; Puglia, D.; Monti, M.; Santulli, C.; Maniruzzaman, M.; Kenny, J.M. Cellulose nanocrystals extracted from Okra fibers in PVA nanocomposites. J. Appl. Sci. 2013, 128, 3220–3230. [Google Scholar] [CrossRef]

- Lee, S.Y.; Mohan, D.J.; Kang, I.A.; Doh, G.H.; Lee, S.; Han, S.O. Nanocellulose reinforced PVA composite films: Effects of acid treatment and filler loading. Fibers Polym. 2009, 10, 77–82. [Google Scholar] [CrossRef]

- Song, M.; Yu, H.; Gu, J.; Ye, S.; Zhou, Y. Chemical cross-linked polyvinyl alcohol/cellulose nanocrystal composite films with high structural stability by spraying fenton reagent as initiator. Int. J. Biol. Macromol. 2018, 113, 171–178. [Google Scholar] [CrossRef]

- Ebrahimzadeh, S.; Ghanbarzadeh, B.; Hamishehkar, H. Physical properties of carboxymethyl cellulose based nano-biocomposites with graphene nano-platelets. Int. J. Biol. Macromol. 2016, 84, 16–23. [Google Scholar] [CrossRef]

- Bhawal, P.; Ganguly, S.; Das, T.K.; Mondal, S.; Choudhury, S.; Das, N.C. Superior electromagnetic interference shielding effectiveness and electro-mechanical properties of EMA-IRGO nanocomposites through the in-situ reduction of GO from melt blended EMA-GO composites. Compo. B Eng. 2018, 134, 46–60. [Google Scholar] [CrossRef]

- Peng, Y.; Gallegos, S.; Gardner, D.J.; Han, Y.; Cai, Z. Maleic anhydride polypropylene modified cellulose nanofibrils polypropylene nanocomposites with enhanced impact strength. Polym. Compos. 2016, 37, 782–793. [Google Scholar] [CrossRef]

- Wang, L.; Sanders, J.E.; Gardner, D.J.; Han, Y. Mechanisms contributing to mechanical property changes in composites of polypropylene reinforced with spray-dried cellulose nanofibrils. Cellulose 2018, 23, 439–448. [Google Scholar] [CrossRef]

- Achaby, M.E.I.; Miri, N.E.; Aboulkas, A.; Zahouily, M.; Bilal, E.; Barakat, A.; Solhy, A. Processing and properties of eco-friendly bio-nanocomposite films filled with cellulose nanocrystals from sugarcane bagasse. Int. J. Biol. Macromol. 2017, 96, 340–352. [Google Scholar] [CrossRef]

| No. | Nebulizer Hole Size, (µm) | Solid Contents, (wt.%) | Inlet Temperature, (°C) | Gas Flow Rate, (L/min) | Spray Intensity, (%) |

|---|---|---|---|---|---|

| 1 | small (4 µm) | 3 | 120 | 100 | 80 |

| 2 | small (4 µm) | 1 | 120 | 100 | 80 |

| 3 | small (4 µm) | 5 | 120 | 100 | 80 |

| 4 | small (4 µm) | 3 | 120 | 120 | 80 |

| 5 | medium (5.5 µm) | 3 | 120 | 100 | 80 |

| 6 | large (7 µm) | 3 | 120 | 100 | 80 |

| No. | Solid Contents, (wt.%) | Inlet Temperature, (°C) | Gas Flow Rate, (L/h) | Aspirator Rate, (%) | Pump Rate, (mL/min) |

|---|---|---|---|---|---|

| 7 | 3 | 175 | 540 | 100 | 8 |

| Composite Film | Drying Technique | PVA Contents, wt.% | Filler Contents, wt.% |

|---|---|---|---|

| Neat PVA | - | 100 | - |

| Nano SDCNCs filled PVA | Nano spray dryer | 80 | 20 |

| Mini SDCNCs filled PVA | Mini spray dryer | 80 | 20 |

| Feedstock | Drying Techniques | Average Particle Sizes | References |

|---|---|---|---|

| CNCs | Electrospray drying | 208 nm in length, 78 nm in width | Sanders et al., 2023 [38] |

| CNCs | Ultrasonic-assisted spray dryer | 530–896 nm in width | This study |

| CNCs | Two-fluid nozzle | CE diameter: 2.7–4.59 µm | This study Peng et al., 2012 [55] |

| CNFs | Two-fluid nozzle | CE diameter: 4.09–4.35 µm | Peng et al., 2012 [55] |

| CNFs | Pilot-scale rotary disk atomizer | CE diameter: 9.58–19 µm | Hwang et al., 2023 [56] Wang et al., 2018 [57] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hwang, S.; Han, Y.; Gardner, D.J. Characterization of CNC Nanoparticles Prepared via Ultrasonic-Assisted Spray Drying and Their Application in Composite Films. Nanomaterials 2023, 13, 2928. https://doi.org/10.3390/nano13222928

Hwang S, Han Y, Gardner DJ. Characterization of CNC Nanoparticles Prepared via Ultrasonic-Assisted Spray Drying and Their Application in Composite Films. Nanomaterials. 2023; 13(22):2928. https://doi.org/10.3390/nano13222928

Chicago/Turabian StyleHwang, Sungjun, Yousoo Han, and Douglas J. Gardner. 2023. "Characterization of CNC Nanoparticles Prepared via Ultrasonic-Assisted Spray Drying and Their Application in Composite Films" Nanomaterials 13, no. 22: 2928. https://doi.org/10.3390/nano13222928

APA StyleHwang, S., Han, Y., & Gardner, D. J. (2023). Characterization of CNC Nanoparticles Prepared via Ultrasonic-Assisted Spray Drying and Their Application in Composite Films. Nanomaterials, 13(22), 2928. https://doi.org/10.3390/nano13222928