A Carbon Nanocomposite Material Used in the Physical Modelling of the Overburden Subsidence Process

Abstract

:1. Introduction

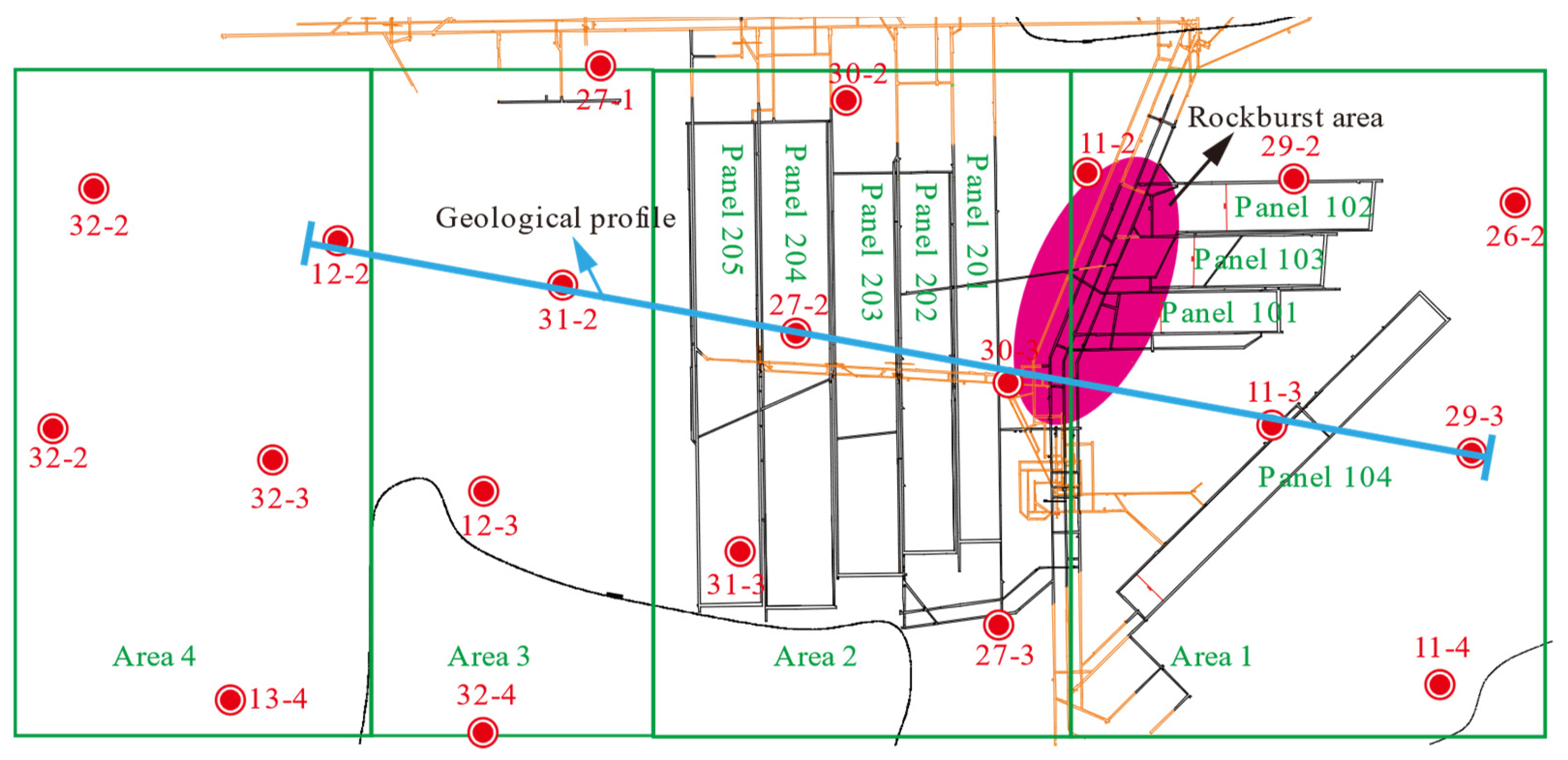

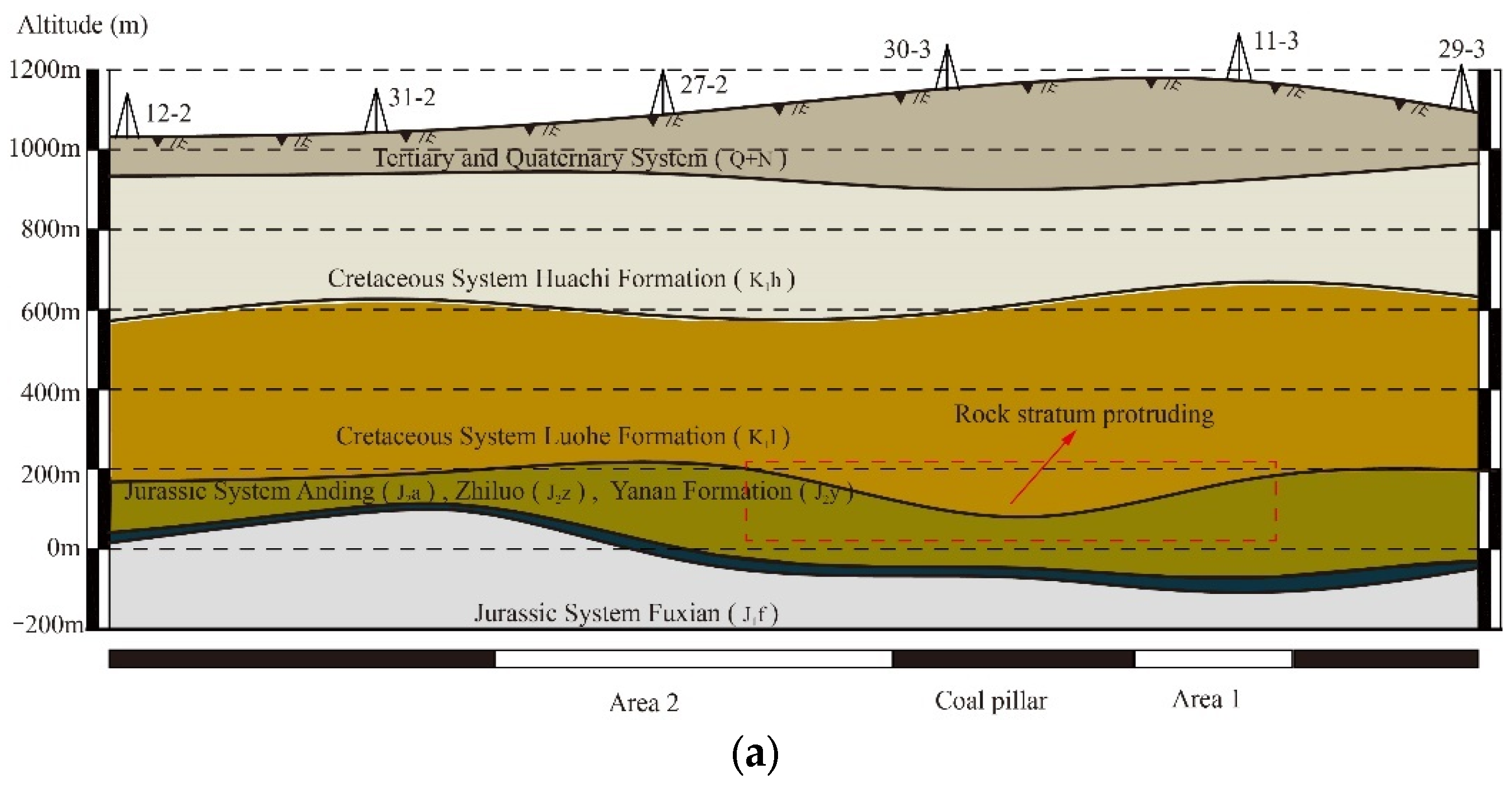

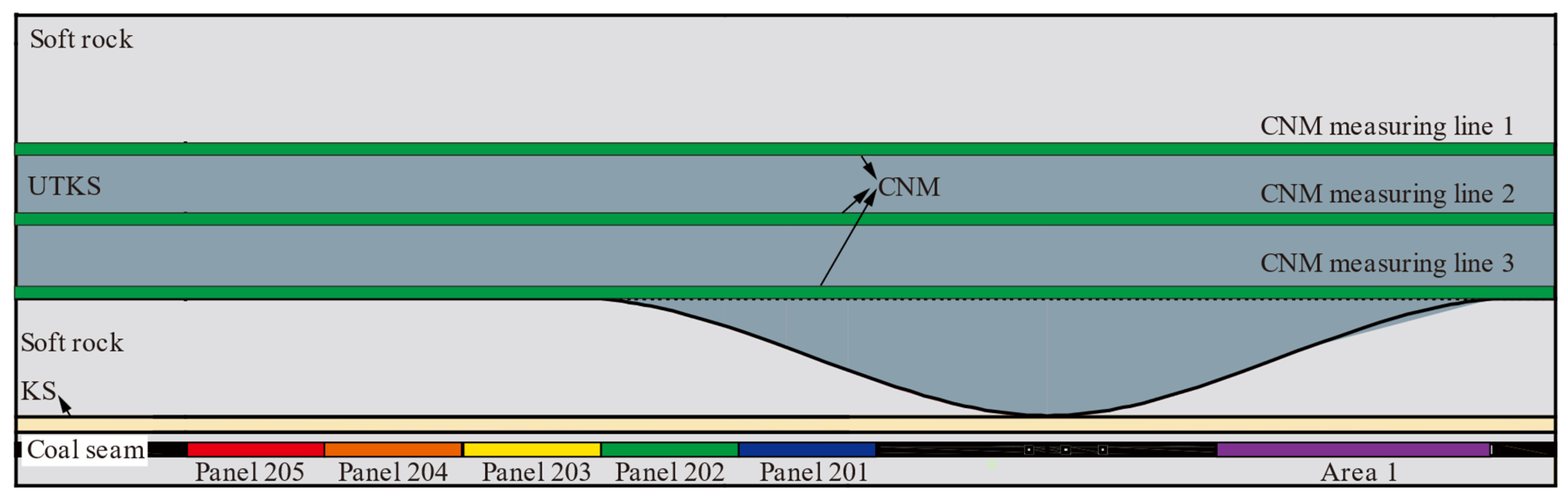

2. Geological Condition of the Study Mine

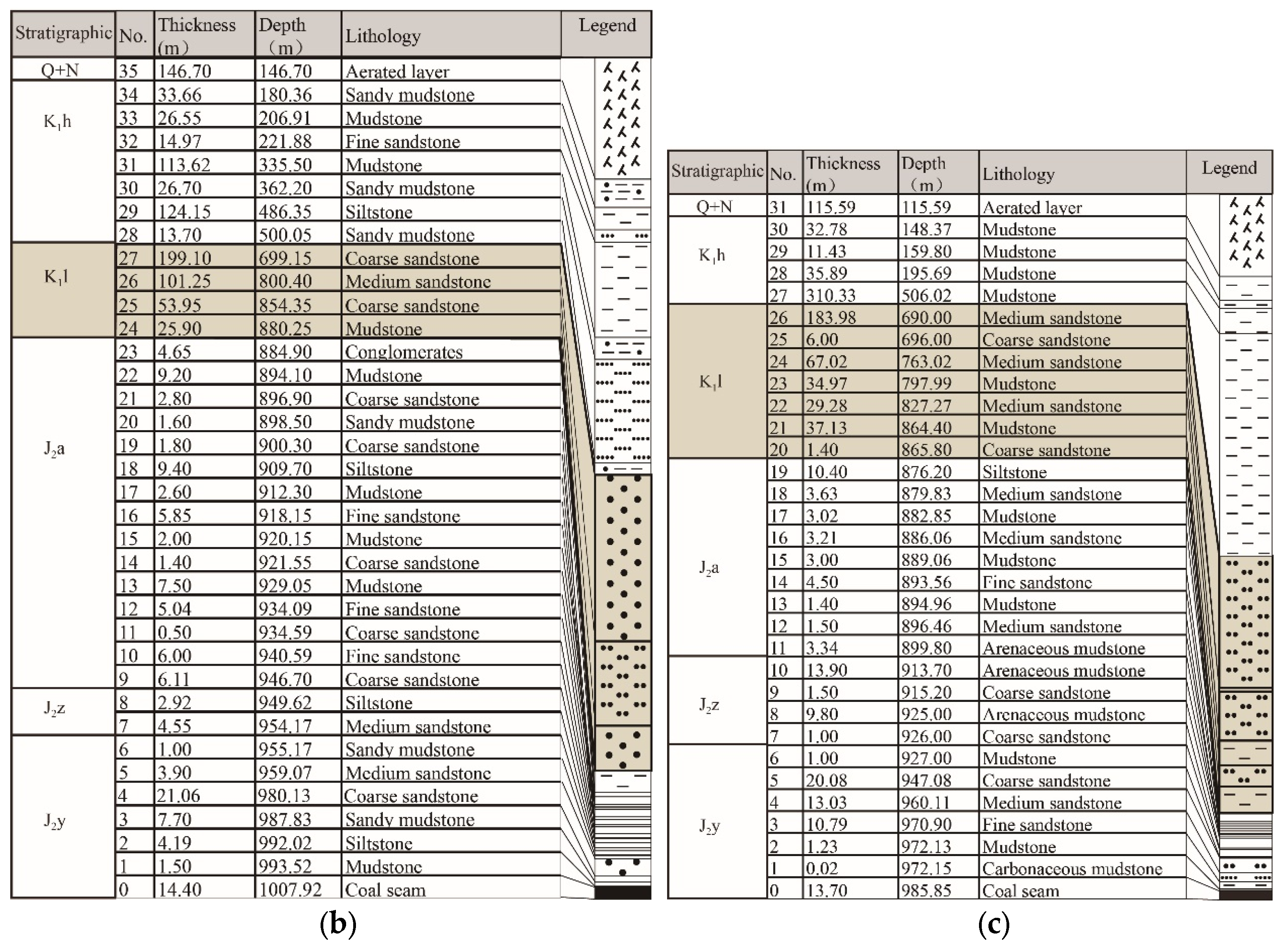

3. The Physical Model

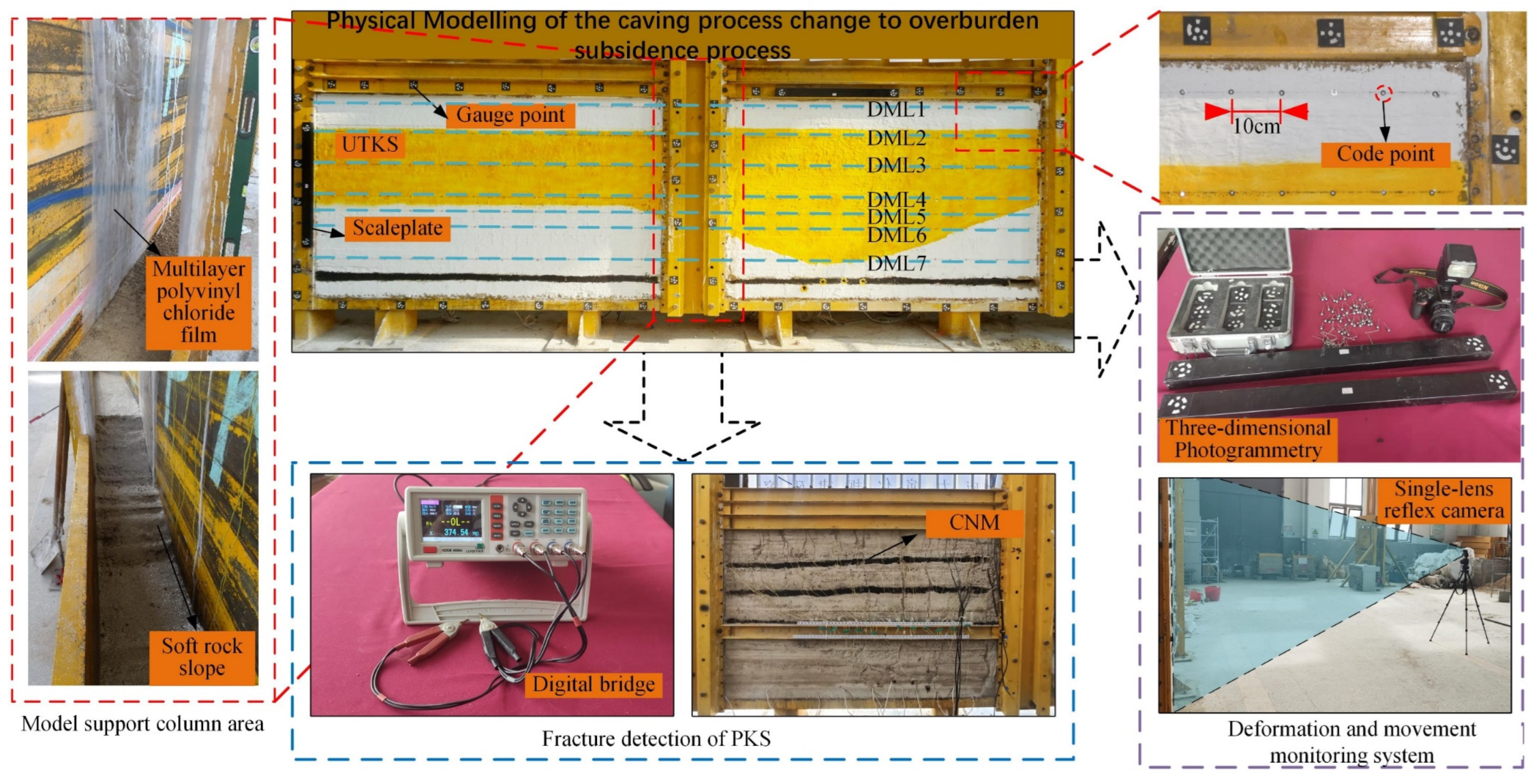

3.1. Experimental Scheme

3.2. The Conventional Monitoring System of Deformation

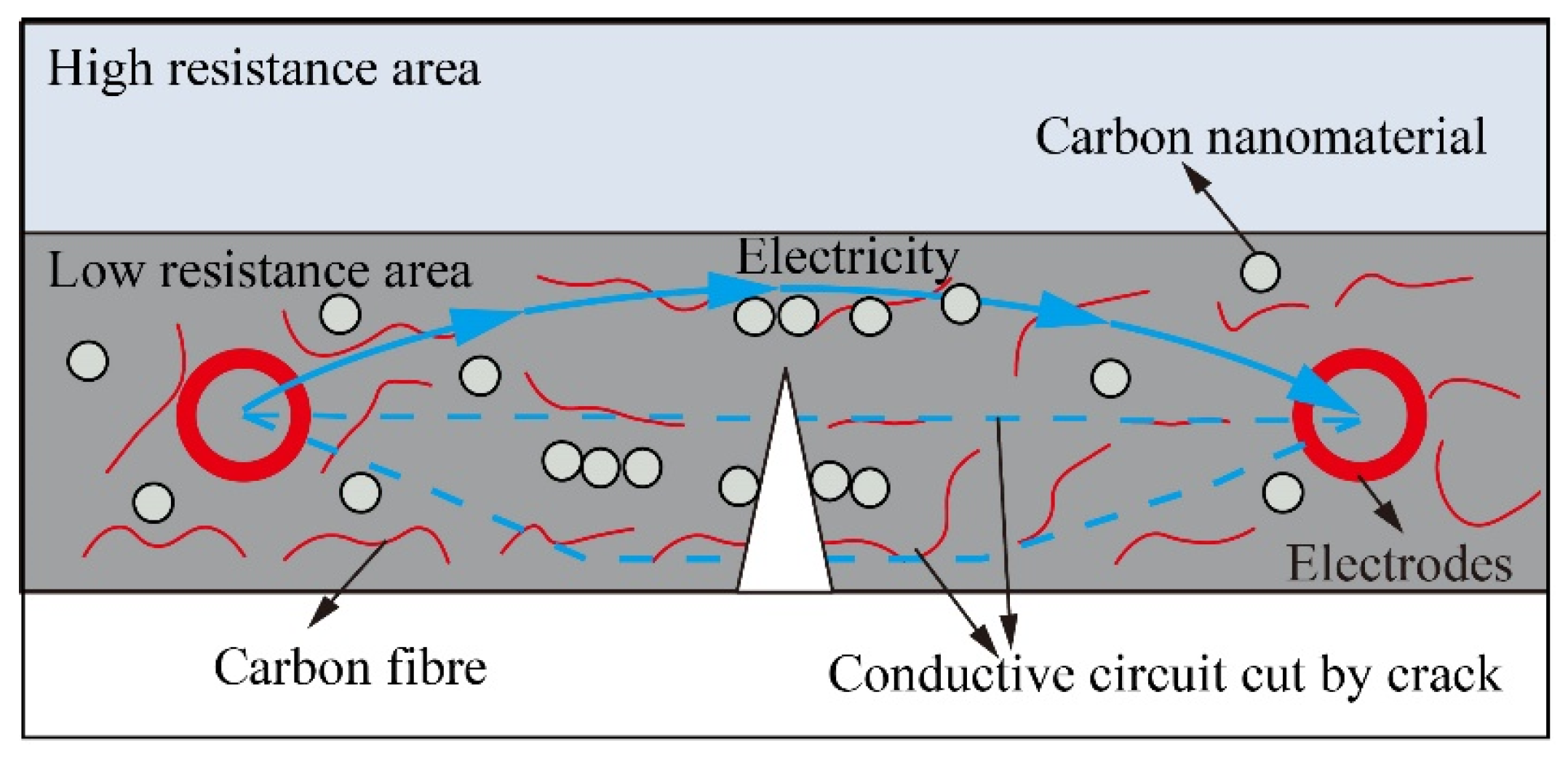

4. Using Carbon Nanocomposite Material (CNM) to Characterise Damage

4.1. Preparation of the CNM

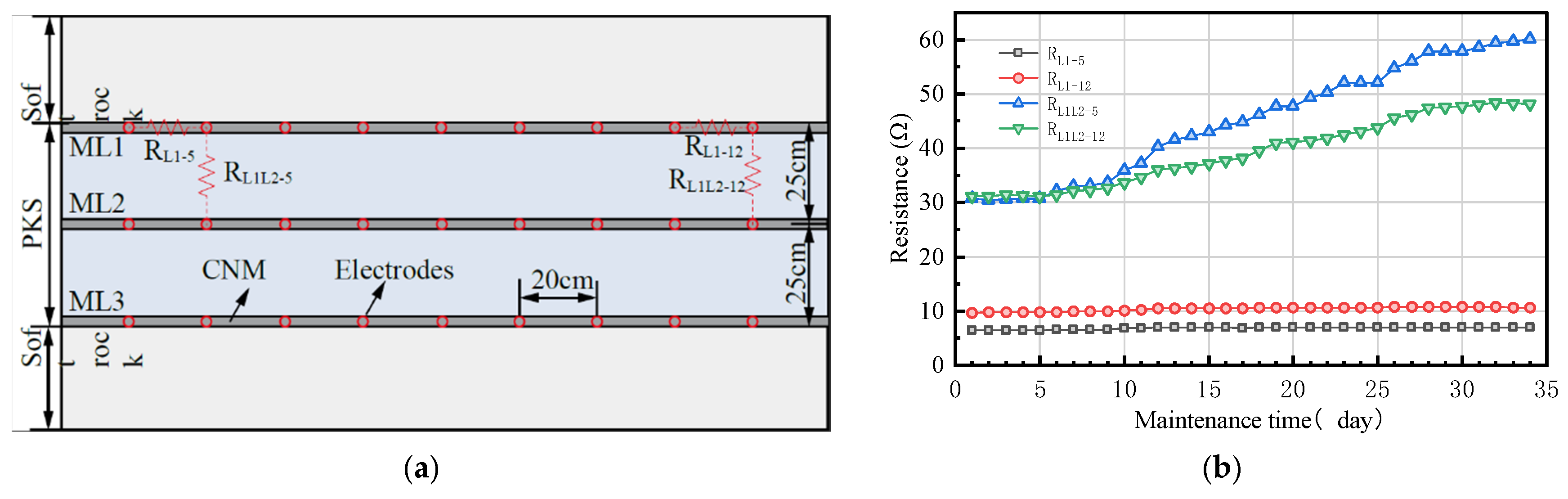

4.2. Resistance Change of CNM during Model Settlement

4.3. Using Resistance Change to Reflect Material Damage

5. Physical Simulation Results

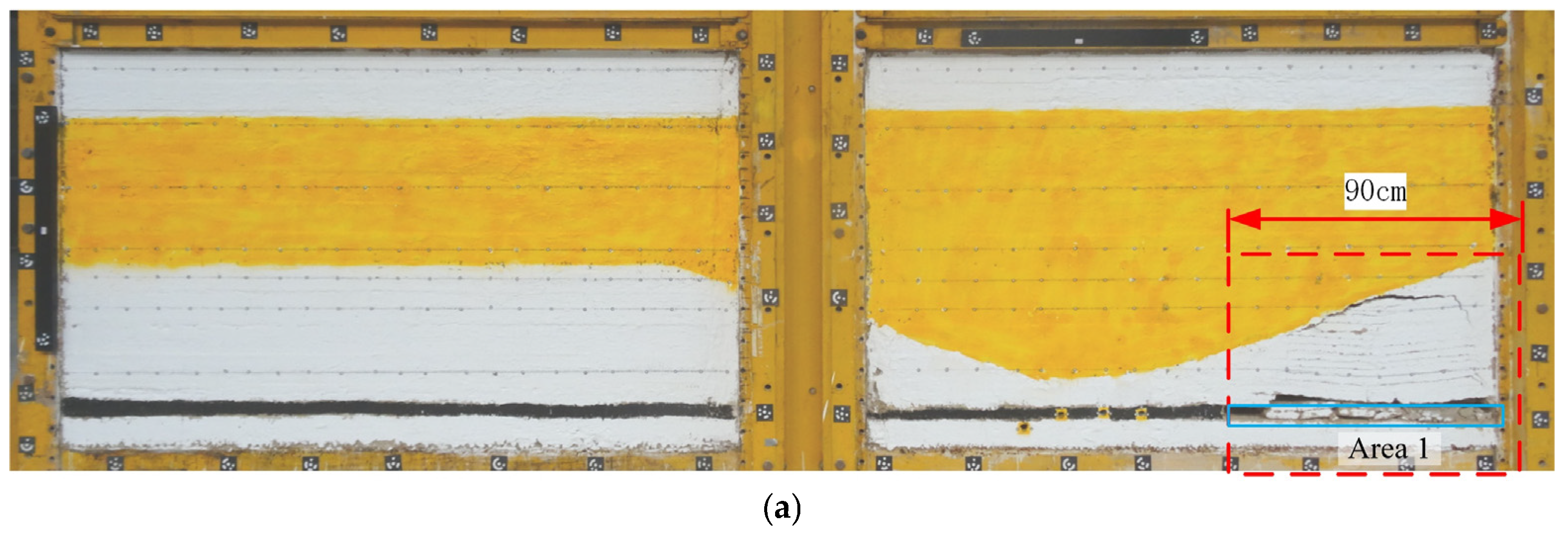

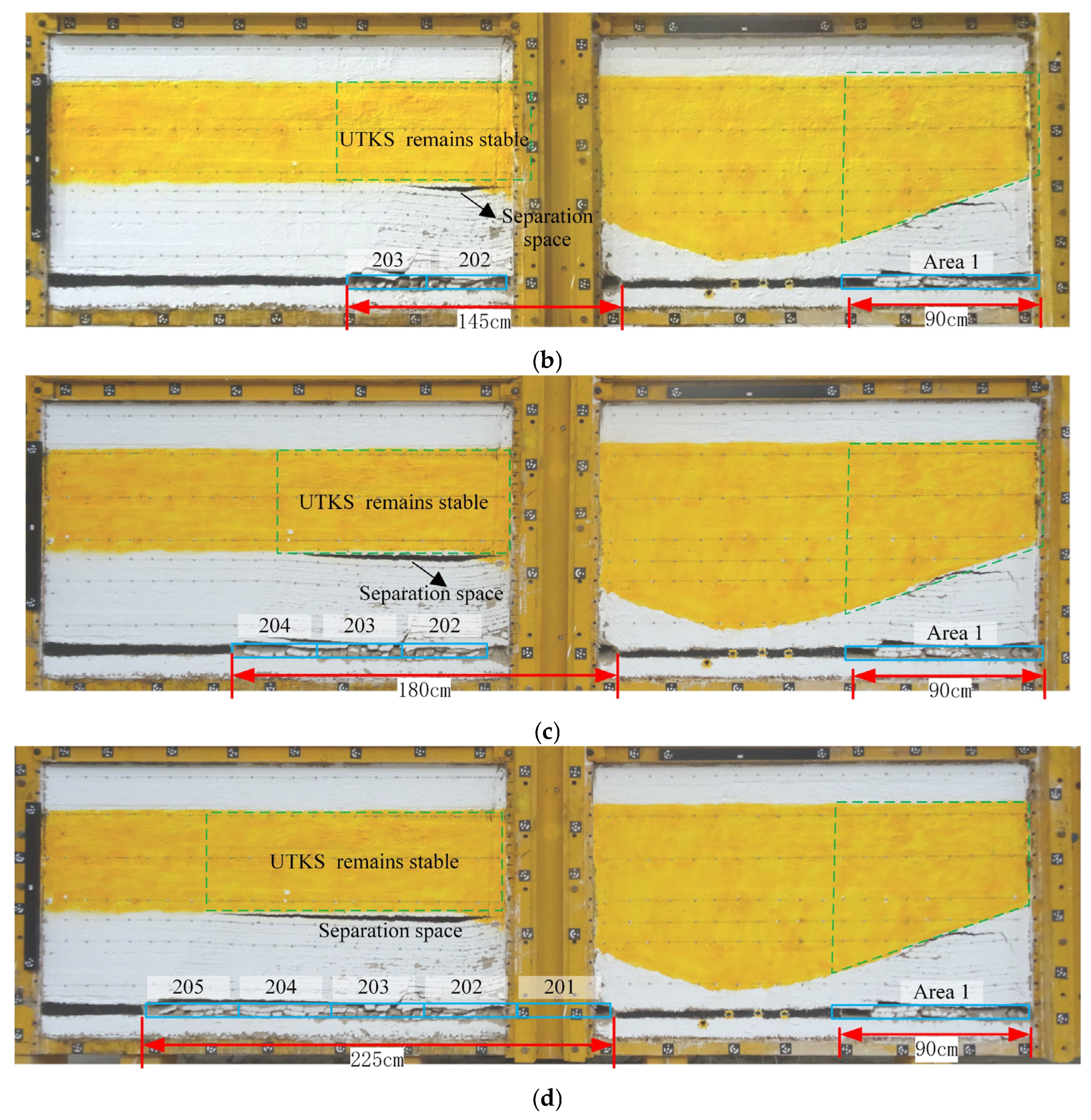

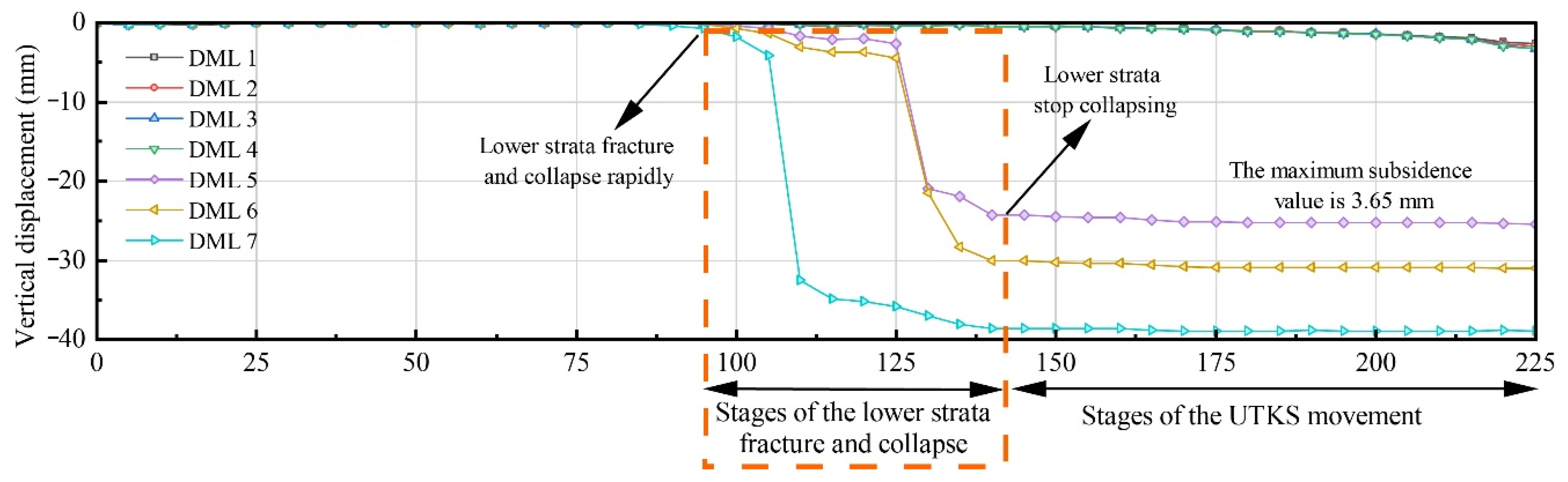

5.1. Overburden Subsidence Process

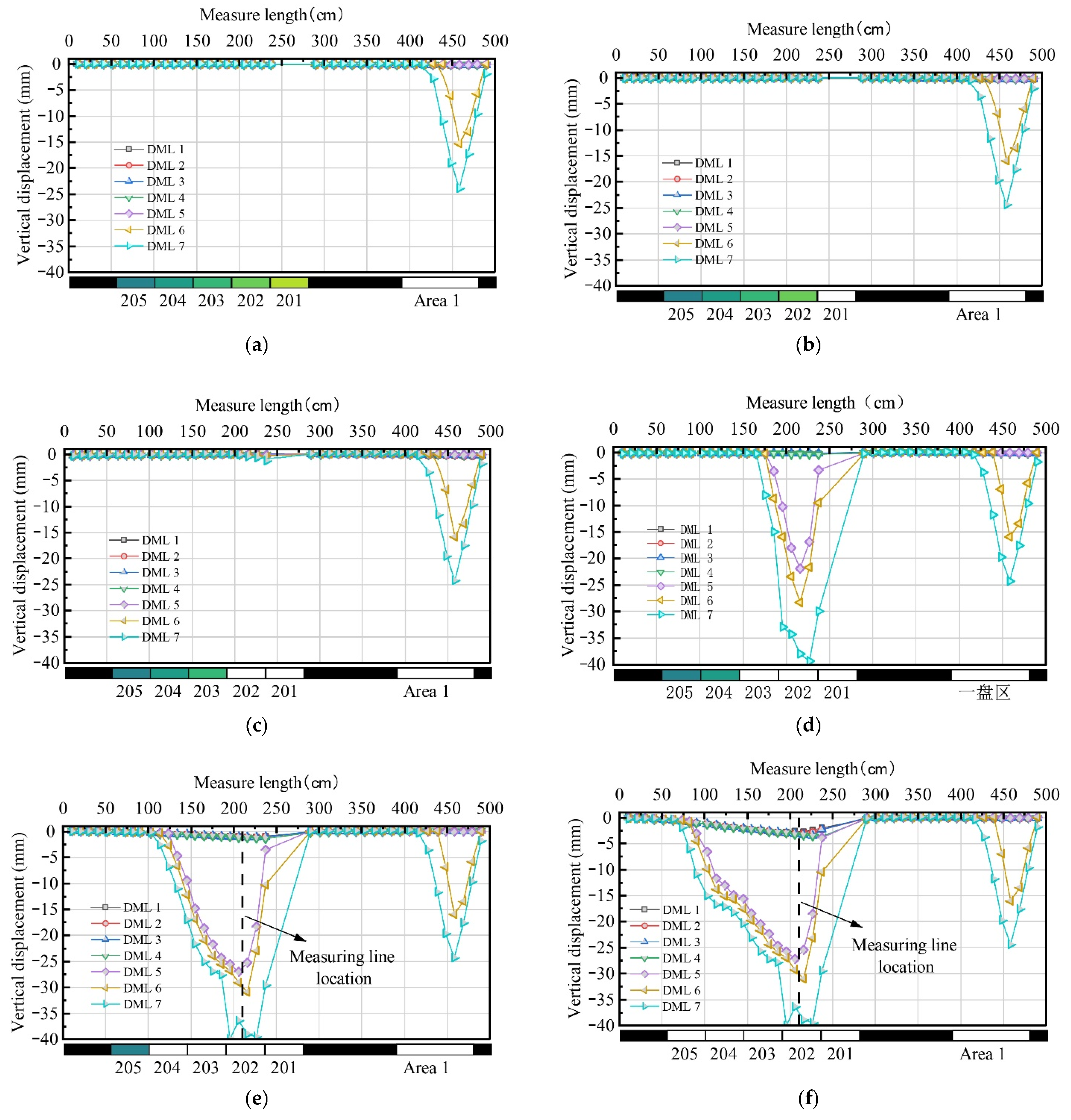

5.2. Deformation of the Overlying Strata on Different Levels

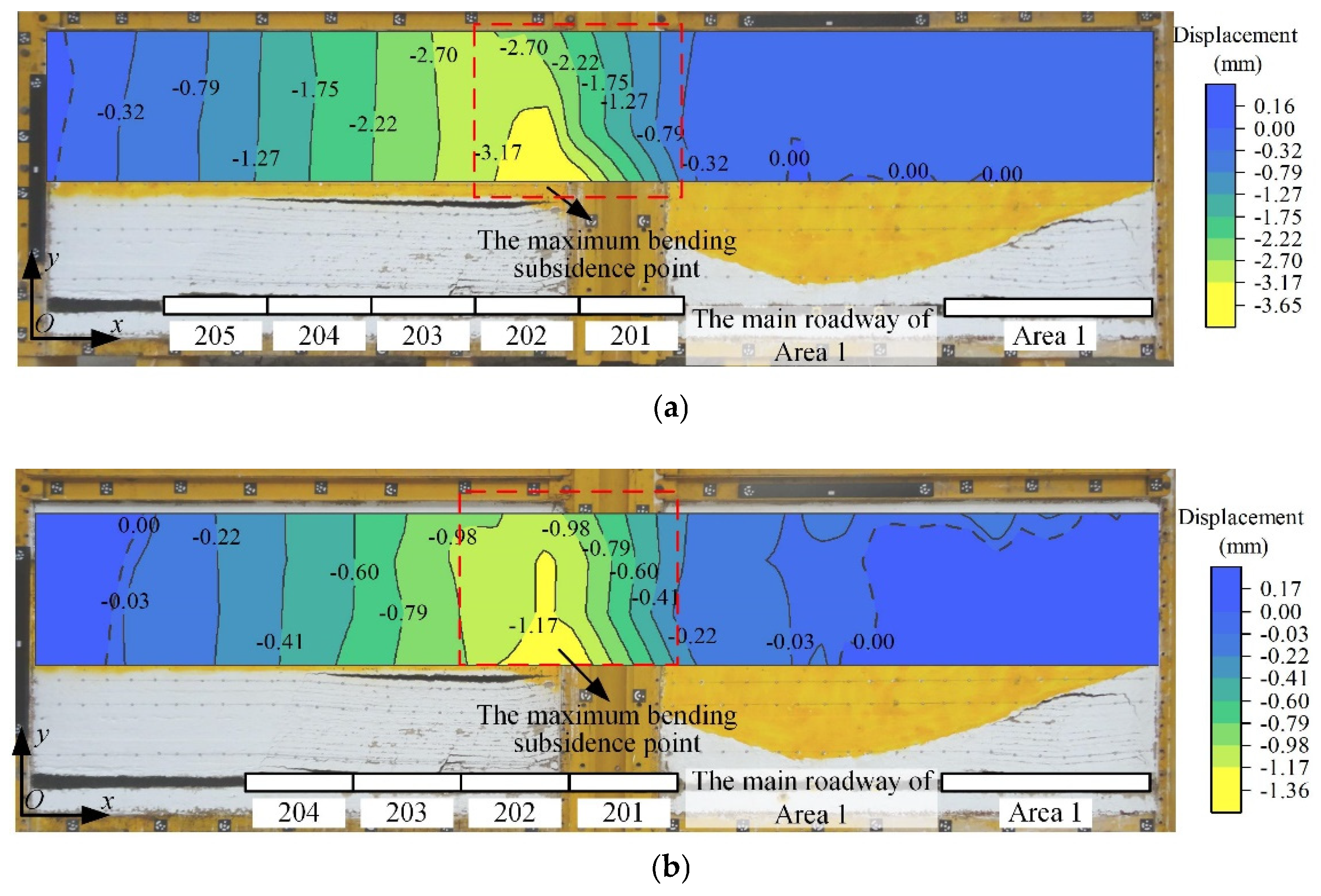

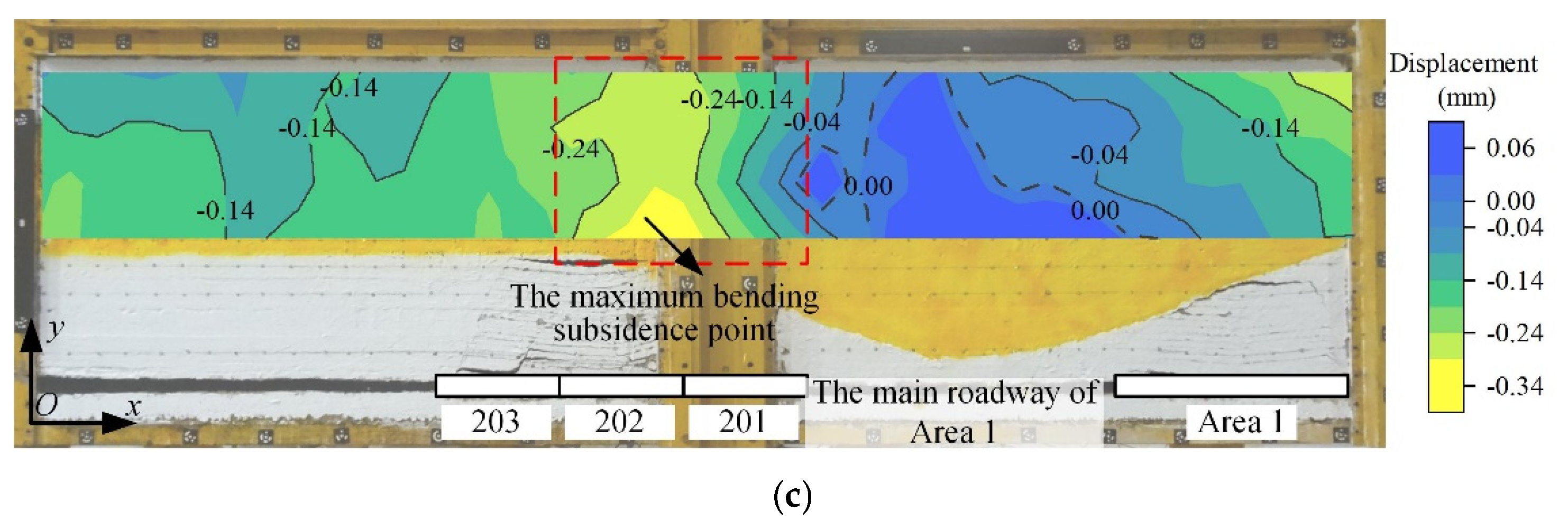

5.3. Deformation Distribution within the UTKS

5.4. Damage Distribution within the UTKS

6. Further Analysis with Analytical Models

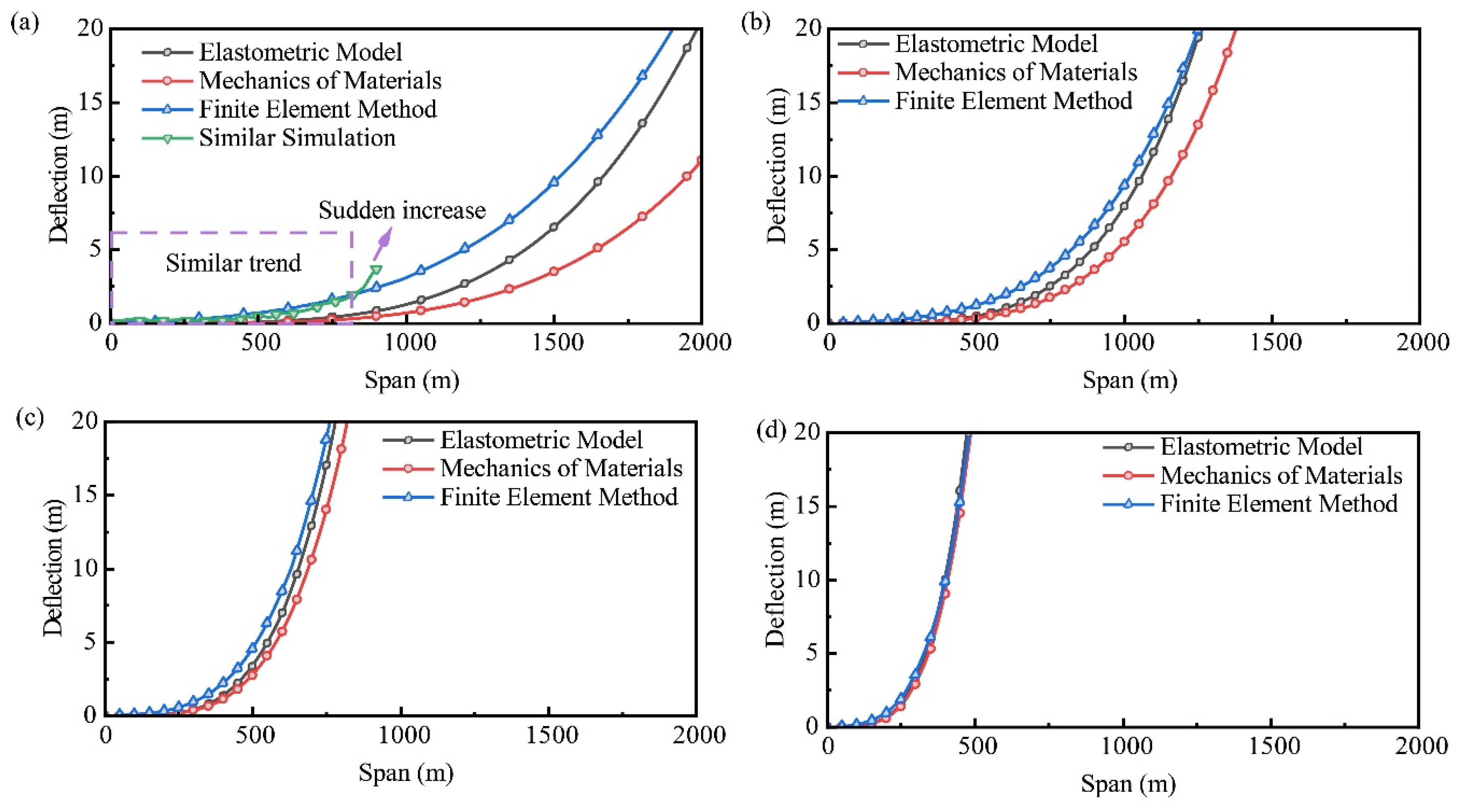

6.1. Influence of UTKS Thickness and Span on Its Deformation

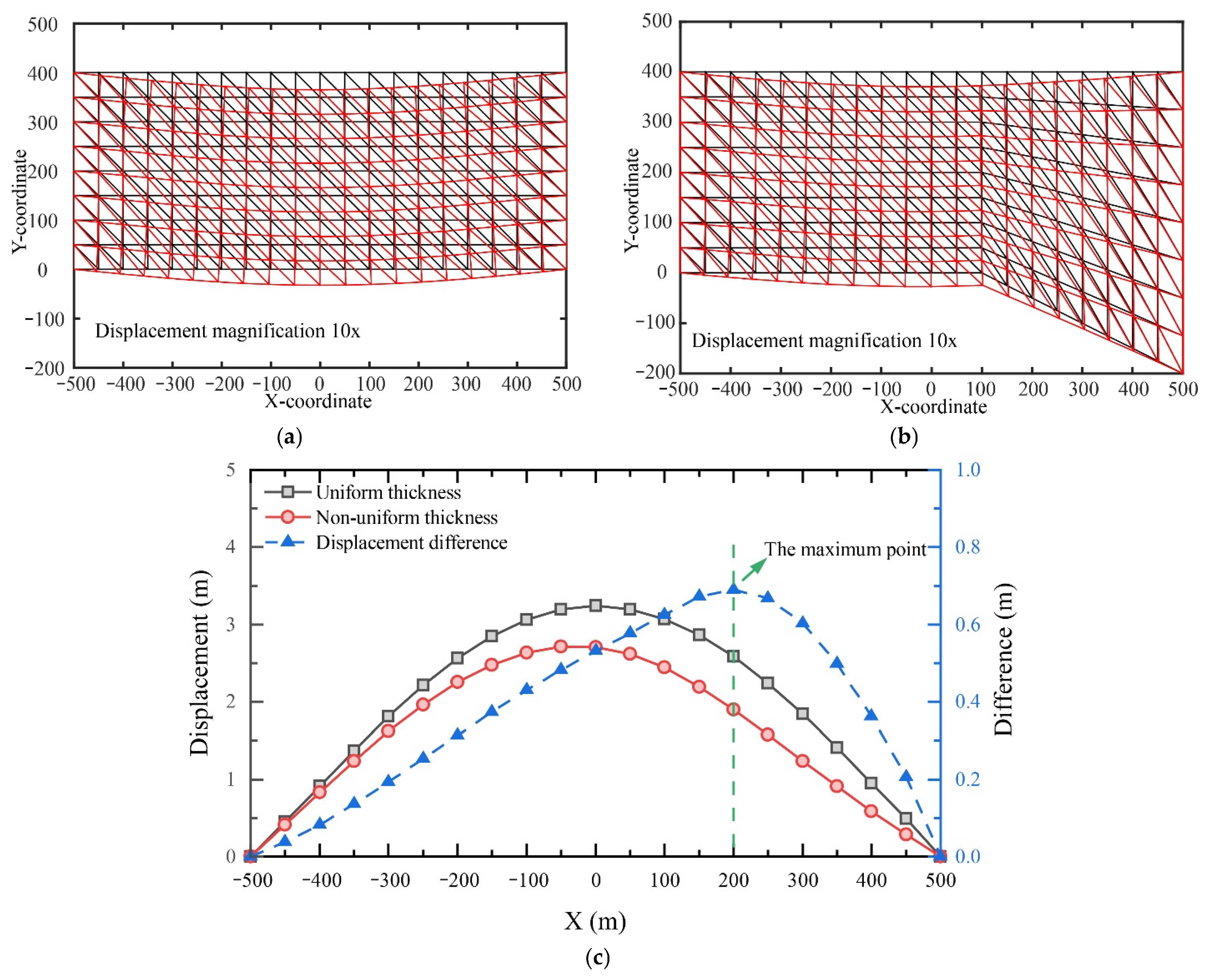

6.2. The Influence of Varying Thickness on Deformation

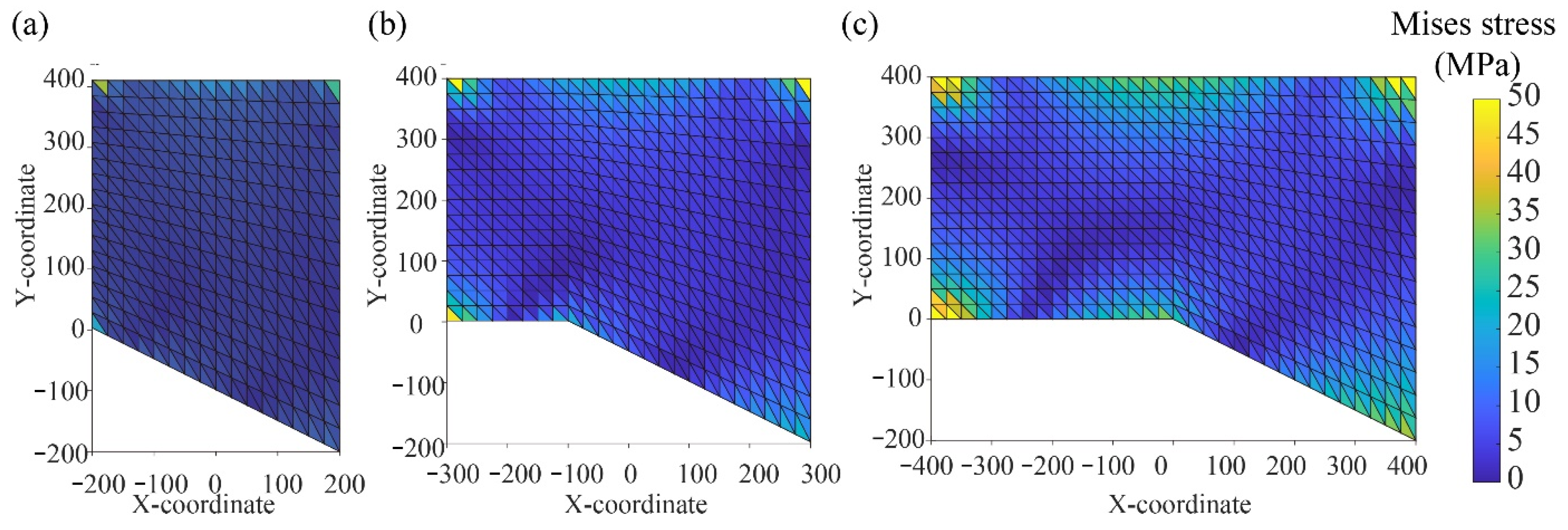

6.3. The Influence of Changing Thickness on the Location of UTKS Damage

7. Conclusions

- The 200–400 m thick sandstone layer remains stable after a cumulative excavation width of 900 m. The stability prevents the upward propagation of strata failure, resulting in significant bedding separation underneath the sandstone layer and a minor surface subsidence of only 0.072% of the excavation thickness.

- Although the thick sandstone layer remains unbroken, it undergoes continuous deformation as excavation progresses. Minor deformation is observed in the first 540 m excavation, which then evidently increases. The maximum deformation was found in the middle part of the total excavation.

- The varying thickness of the thick sandstone layer shows a significant impact on the caving process and overall subsidence pattern. Both the physical and analytical models show that the thick rock layer experiences considerable damage in the thickness-changing region, emphasising the need for special attention to this area.

- To mitigate risks associated with the thick sandstone layer, it is recommended that the mine should control the cumulative excavation width within a critical limit in each mining area. The continuous monitoring and assessment of the behaviour of the thick layer are also essential.

- This study demonstrates that carbon nanocomposite materials’ high sensitivity to deformation and damage can be effectively tracked using RCR and ΔR values. The most pronounced damage, as indicated by the highest RCR values, occurs above Panels 201 and 202. Despite the uniformity in displacement data across different measurement lines, the combined use of RCR and ΔR offers a robust tool for evaluating damage evolution during excavation.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Dai, S.; Finkelman, R.B. Coal Geology in China: An Overview. Int. Geol. Rev. 2018, 60, 531–534. [Google Scholar] [CrossRef]

- Das, A.J.; Mandal, P.K.; Ghosh, N.; Singh, A.P.; Kumar, R.; Tewari, S.; Bhattacharjee, R. Evaluation of Energy Accumulation, Strain Burst Potential and Stability of Rock Mass during Underground Extraction of a Highly Stressed Coal Seam under Massive Strata-a Field Study. Eng. Geol. 2023, 322, 107178. [Google Scholar] [CrossRef]

- Khanal, M.; Qu, Q.; Zhu, Y.; Xie, J.; Zhu, W.; Hou, T.; Song, S. Characterization of Overburden Deformation and Subsidence Behavior in a Kilometer Deep Longwall Mine. Minerals 2022, 12, 543. [Google Scholar] [CrossRef]

- Han, H.; Xu, J.; Wang, X.; Xie, J.; Xing, Y. Surface Subsidence Prediction Method for Coal Mines with Ultrathick and Hard Stratum. Adv. Civ. Eng. 2019, 2019, 3714381. [Google Scholar] [CrossRef]

- Hu, Q.; Cui, X.; Liu, W.; Feng, R.; Ma, T.; Li, C. Quantitative and Dynamic Predictive Model for Mining-Induced Movement and Deformation of Overlying Strata. Eng. Geol. 2022, 311, 106876. [Google Scholar] [CrossRef]

- Zhou, K.; Dou, L.; Li, X.; Song, S.; Cao, J.; Jinzheng, B.; Ma, X. Coal Burst and Mining-Induced Stress Evolution in a Deep Isolated Main Entry Area—A Case Study. Eng. Fail. Anal. 2022, 137, 106289. [Google Scholar] [CrossRef]

- Zhou, K.; Dou, L.; Gong, S.; Li, J.; Zhang, J.; Cao, J. Study of Rock Burst Risk Evolution in Front of Deep Longwall Panel Based on Passive Seismic Velocity Tomography. Geofluids 2020, 2020, e8888413. [Google Scholar] [CrossRef]

- Niranjan, B.R.; Patil, S.S. Analysis of RC Deep Beam by Finite Element Method. Int. J. Mod. Eng. Res. 2012, 2, 4664–4667. [Google Scholar]

- Ramirez, J.; French, C.; Adebar, P.; Bonacci, J.; Collins, M.; Darwin, D.; Dilger, W.; Gogate, A.; Hawkins, N.; Hsu, T.; et al. Recent Approaches to Shear Design of Structural Concrete. J. Struct. Eng. 1998, 124, 1375–1417. [Google Scholar] [CrossRef]

- Wang, P.; Jiang, J.; Zhang, P.; Wu, Q. Breaking Process and Mining Stress Evolution Characteristics of a High-Position Hard and Thick Stratum. Int. J. Min. Sci. Technol. 2016, 26, 563–569. [Google Scholar] [CrossRef]

- Ning, J.; Wang, J.; Jiang, L.; Jiang, N.; Liu, X.; Jiang, J. Fracture Analysis of Double-Layer Hard and Thick Roof and the Controlling Effect on Strata Behavior: A Case Study. Eng. Fail. Anal. 2017, 81, 117–134. [Google Scholar] [CrossRef]

- Guoxiang, C.; Linming, D.; Xing, X. Research on Prevention of Rock Burst with Relieving Shot in Roof. In Proceedings of the 2012 International Symposium on Safety Science and Technology, Nanjing, China, 23–26 October 2012; Changgen, F., Shengcai, L., Eds.; Elsevier Science Bv: Amsterdam, The Netherlands, 2012; Volume 45, pp. 904–909. [Google Scholar]

- Singh, R.P.; Yadav, R.N. Prediction of Subsidence Due to Coal Mining in Raniganj Coalfield, West Bengal, India. Eng. Geol. 1995, 39, 103–111. [Google Scholar] [CrossRef]

- Peng, J.; Chen, L.; Huang, Q.; Men, Y.; Fan, W.; Yan, J. Physical Simulation of Ground Fissures Triggered by Underground Fault Activity. Eng. Geol. 2013, 155, 19–30. [Google Scholar] [CrossRef]

- Heydarnoori, V.; Khosravi, M.H.; Bahaaddini, M. Physical Modelling of Caving Propagation Process and Damage Profile Ahead of the Cave-Back. J. Min. Environ. 2020, 11, 1047–1058. [Google Scholar] [CrossRef]

- Yoo, D.Y.; You, I.; Zi, G.; Lee, S.-J. Effects of Carbon Nanomaterial Type and Amount on Self-Sensing Capacity of Cement Paste. Measurement 2019, 134, 750–761. [Google Scholar] [CrossRef]

- Parveen, S.; Rana, S.; Fangueiro, R. A Review on Nanomaterial Dispersion, Microstructure, and Mechanical Properties of Carbon Nanotube and Nanofiber Reinforced Cementitious Composites. J. Nanomater. 2013, 2013, 710175. [Google Scholar] [CrossRef]

- He, F.; Biolzi, L.; Carvelli, V.; Monteiro, P. Digital Imaging Monitoring of Fracture Processes in Hybrid Steel Fiber Reinforced Concrete. Compos. Struct. 2022, 298, 116005. [Google Scholar] [CrossRef]

- Choi, J.-I.; Nguyen, H.H.; Park, S.-E.; Ranade, R.; Lee, B.Y. Effects of Fiber Hybridization on Mechanical Properties and Autogenous Healing of Alkali-Activated Slag-Based Composites. Constr. Build. Mater. 2021, 310, 125280. [Google Scholar] [CrossRef]

- Wu, C.; Leung, C.; Li, V. Derivation of Crack Bridging Stresses in Engineered Cementitious Composites under Combined Opening and Shear Displacements. Cem. Concr. Res. 2018, 107, 253–263. [Google Scholar] [CrossRef]

- Dinesh, A.; Sudharsan, S.T.; Haribala, S. Self-Sensing Cement-Based Sensor with Carbon Nanotube: Fabrication and Properties—A Review. Mater. Today Proc. 2021, 46, 5801–5807. [Google Scholar] [CrossRef]

- Kanagasundaram, K.; Solaiyan, E. Smart Cement-Sensor Composite: The Evolution of Nanomaterial in Developing Sensor for Structural Integrity. Struct. Concr. 2023, 24, 6297–6337. [Google Scholar] [CrossRef]

- Wong, I.S.-Y. Effects of Ultra-Low Concentrations of Nanomaterials on the Piezoresistivity of Cementitious Composites; University of California: Davis, CA, USA, 2015; ISBN 978-1-321-80773-8. [Google Scholar]

- Zhu, W.; Xu, J.; Li, Y. Mechanism of the Dynamic Pressure Caused by the Instability of Upper Chamber Coal Pillars in Shendong Coalfield, China. Geosci. J. 2017, 21, 729–741. [Google Scholar] [CrossRef]

- Luo, T.; Pan, X.; Sun, Q.; Liu, F.; Hua, C.; Yi, Y. A Study on Damage of Steel Fiber Reinforced Concrete (SFRC) under Uniaxial Compression Based on the Electrical Resistivity Method. Mater. Struct. 2022, 55, 173. [Google Scholar] [CrossRef]

- Muñoz, J.A.; Avalos, M.; Bolmaro, R.E. Heterogeneity of Strain Path, Texture and Microstructure Evolution of AA6063-T6 Processed by Equal Channel Angular Sheet Extrusion (ECASE). J. Alloys Compd. 2018, 768, 349–357. [Google Scholar] [CrossRef]

- Cholker, A.K.; Tantray, M.A. Micro Carbon Fiber Based Concrete as a Strain-Damage Sensing Material. Mater. Today Proc. 2019, 19, 152–157. [Google Scholar] [CrossRef]

- De Souza, L.; Pimentel, M.; Milone, G.; Tristao, J.; Al-Tabbaa, A. Carbon Nanofibers Grown in CaO for Self-Sensing in Mortar. Materials 2022, 15, 4951. [Google Scholar] [CrossRef]

- Chuang, W.; Geng-sheng, J.; Bing-liang, L.; Lei, P.; Ying, F.; Ni, G.; Ke-zhi, L. Dispersion of Carbon Fibers and Conductivity of Carbon Fiber-Reinforced Cement-Based Composites. Ceram. Int. 2017, 43, 15122–15132. [Google Scholar] [CrossRef]

- Chen, B.; Liu, J. Damage in Carbon Fiber-Reinforced Concrete, Monitored by Both Electrical Resistance Measurement and Acoustic Emission Analysis. Constr. Build. Mater. 2008, 22, 2196–2201. [Google Scholar] [CrossRef]

- Cui, K.; Liang, K.; Chang, J.; Lau, D. Investigation of the Macro Performance, Mechanism, and Durability of Multiscale Steel Fiber Reinforced Low-Carbon Ecological UHPC. Constr. Build. Mater. 2022, 327, 126921. [Google Scholar] [CrossRef]

- Kamani, R.; Kamali Dolatabadi, M.; Asgharian Jeddi, A.A.; Nasrollahzadeh, K. Damage Detection of Carbon Fiber-Reinforced Concrete under Bending Test. J. Text. Polym. 2018, 6, 39–45. [Google Scholar]

- Kim, K.; Jo, M.-J. A Study on the Correlation between Coal Mining Subsidence and Underground Goaf-All Databases. Econ. Environ. Geol. 2008, 41, 1225–7281. [Google Scholar]

- Kryzia, K.; Majcherczyk, T.; Niedbalski, Z. Estimation of mining impact on surfacein relation to rock mass type. Gospod. Surowcami Miner. Miner. Resour. Manag. 2018, 34, 151–170. [Google Scholar] [CrossRef]

- Kattan, P.I. MATLAB Guide to Finite Elements: An Interactive Approach; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2010; ISBN 3-540-70698-4. [Google Scholar]

- Ning, S.; Zhu, W.; Xie, J.; Song, S.; Wang, X.; Yu, D.; Lou, J.; Xu, J. Influence of Stress Distribution in Coal Seams of Non-Uniform Extremely Thick Key Stratum and Disaster-Causing Mechanisms. Sci. Rep. 2022, 12, 14465. [Google Scholar] [CrossRef]

- Chiaia, B.; De Biagi, V.; Placidi, L. A Damaged Non-Homogeneous Timoshenko Beam Model for a Dam Subjected to Aging Effects. Math. Mech. Solids 2021, 26, 694–707. [Google Scholar] [CrossRef]

- Jiang, F.; Yu, W. Damage Analysis by Physically Nonlinear Composite Beam Theory. Compos. Struct. 2017, 182, 652–665. [Google Scholar] [CrossRef]

- Maleki, H.; Lawson, H. Analysis of Geomechanical Factors Affecting Rock Bursts in Sedimentary Rock Formations. In Proceedings of the Isrm European Rock Mechanics Symposium Eurock, Ostrava, Czech Republic, 20–22 June 2017; Konicek, P., Soucek, K., Konecny, P., Eds.; Elsevier: Amsterdam, The Netherlands, 2017; Volume 191, pp. 82–88. [Google Scholar]

- Goodno, B.J.; Gere, J.M. Mechanics of Materials; Cengage Learning: Boston, MA, USA, 2020; ISBN 0-357-37791-5. [Google Scholar]

- Lemaitre, J.; Chaboche, J.-L. Mechanics of Solid Materials; Cambridge University Press: Cambridge, UK, 1994; ISBN 0-521-47758-1. [Google Scholar]

- Mises, R. Mechanik Der Festen Körper Im Plastisch-Deformablen Zustand. Nachrichten Ges. Wiss. Göttingen Math. Phys. Kl. 1913, 1913, 582–592. [Google Scholar]

- Senthil, K.; Singhal, A.; Shailja, B. Damage Mechanism and Stress Response of Reinforced Concrete Slab under Blast Loading. Coupled Syst. Mech. 2019, 8, 315–338. [Google Scholar] [CrossRef]

- Tavoosi, M.; Sharifian, M.; Sharifian, M. A Hybrid Method to Update Stress for Perfect Von-Mises Plasticity Coupled with Lemaitre Damage Mechanics. Eng. Comput. 2020, 37, 705–729. [Google Scholar] [CrossRef]

| Stratigraphic Age | Lithology | Compressive Strength (MPa) | Tension Strength (MPa) | Young’s Modulus (GPa) | Poisson’s Ratio |

|---|---|---|---|---|---|

| Min–Max | Min–Max | Min–Max | Min–Max | ||

| Huachi formation (K1h) | Mudstone | 25.1–35.2 | 0.83–0.88 | 8.38 | 0.25 |

| Sandy mudstone | 23.8–79.9 | 0.79–3.19 | 9.12–16.02 | 0.20–0.26 | |

| Siltstone | 58.3–72.8 | 2.85–3.04 | 13.16 | 0.18 | |

| Fine sandstone | 40.6–56.1 | 2.71–3.22 | 13.95 | 0.2 | |

| Luohe formation (K1l) | Sandy mudstone | 58.2–68.9 | 2.14–2.20 | 11.04 | 0.19 |

| Siltstone | 44.4–79.0 | 1.60–4.49 | 12.08–19.12 | 0.18–0.22 | |

| Fine sandstone | 31.2–62.6 | 2.13–3.60 | 9.57–18.23 | 0.17–0.23 | |

| Medium sandstone | 25.8–42.6 | 0.67–2.05 | 9.36 | 0.24 | |

| Coarse sandstone | 38.2–44.3 | 1.09–1.22 | 10.21 | 0.2 | |

| Anding formation (J2a) | Sandy mudstone | 20.1–30.7 | 1.96–1.99 | 12.27 | 0.2 |

| Zhiluo formation (J2z) | Siltstone | 25.9–29.3 | 1.11–1.28 | 9.53 | 0.23 |

| Rock Stratum | Thickness/m | Laying Thickness/cm | Ratio Number | Sand/kg | Calcium Carbonate/kg | Gypsum/kg |

|---|---|---|---|---|---|---|

| Weak rock | 82.0 | 20.5 (2.0 cm each layer) | 673 | 516.6 | 60.2 | 28.8 |

| UTKS | 200.0–440.0 | 50.0–88.0 | 437 | 1553.6 | 116.5 | 271.9 |

| Weak rock | 100.0 | 38.5 (2.0 cm each layer) | 673 | 690.5 | 80.5 | 34.5 |

| Sub-key stratum | 20.0 | 5.0 | 455 | 126.0 | 7.5 | 17.6 |

| Weak rock | 14.0 | 3.5 | 673 | 88.2 | 10.2 | 4.4 |

| Coal seam | 16.0 | 4.0 | 773 | 100.8 | 10.1 | 4.3 |

| Weak rock | 40.0 | 10.0 (2.0 cm each layer) | 673 | 252.0 | 29.4 | 12.6 |

| Total | 1047.0 | 166.0 | 3327.7 | 314.4 | 374.1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xie, J.; Ning, S.; Qu, Q.; Zhu, W.; Zhao, B.; Xu, J. A Carbon Nanocomposite Material Used in the Physical Modelling of the Overburden Subsidence Process. Nanomaterials 2023, 13, 2962. https://doi.org/10.3390/nano13222962

Xie J, Ning S, Qu Q, Zhu W, Zhao B, Xu J. A Carbon Nanocomposite Material Used in the Physical Modelling of the Overburden Subsidence Process. Nanomaterials. 2023; 13(22):2962. https://doi.org/10.3390/nano13222962

Chicago/Turabian StyleXie, Jianlin, Shan Ning, Qingdong Qu, Weibing Zhu, Bozhi Zhao, and Jialin Xu. 2023. "A Carbon Nanocomposite Material Used in the Physical Modelling of the Overburden Subsidence Process" Nanomaterials 13, no. 22: 2962. https://doi.org/10.3390/nano13222962

APA StyleXie, J., Ning, S., Qu, Q., Zhu, W., Zhao, B., & Xu, J. (2023). A Carbon Nanocomposite Material Used in the Physical Modelling of the Overburden Subsidence Process. Nanomaterials, 13(22), 2962. https://doi.org/10.3390/nano13222962