Nanoscale Insights into the Mechanical Behavior of Interfacial Composite Structures between Calcium Silicate Hydrate/Calcium Hydroxide and Silica

Abstract

:1. Introduction

2. Computational Method

2.1. Simulation Model

2.2. Molecular Dynamics Modeling

2.3. Data Analysis

3. Results

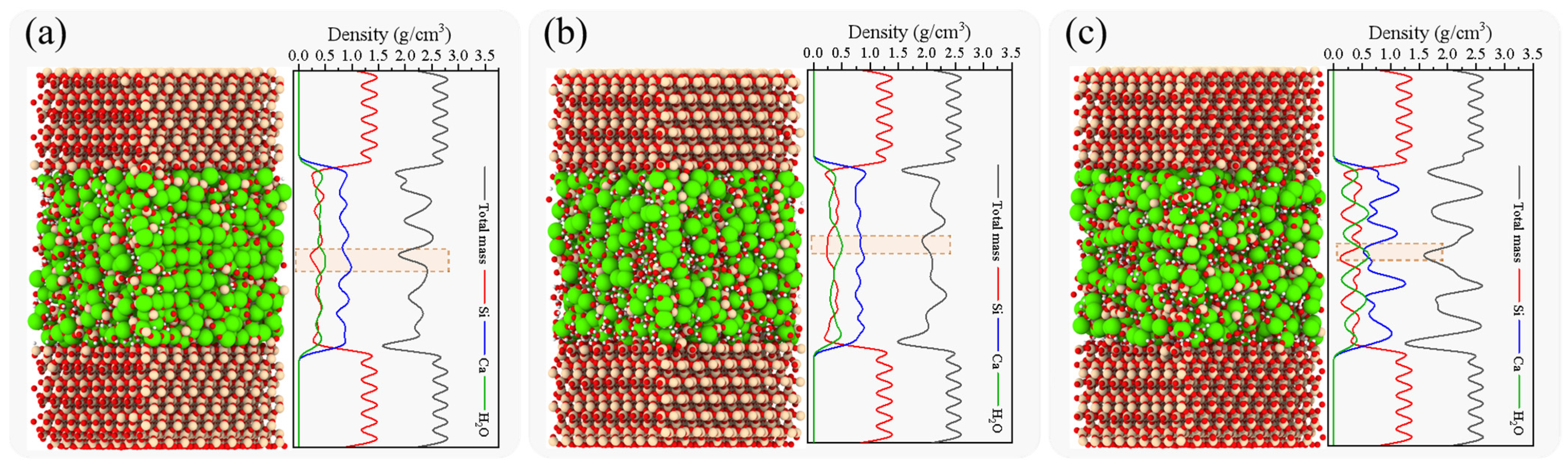

3.1. Density Profile

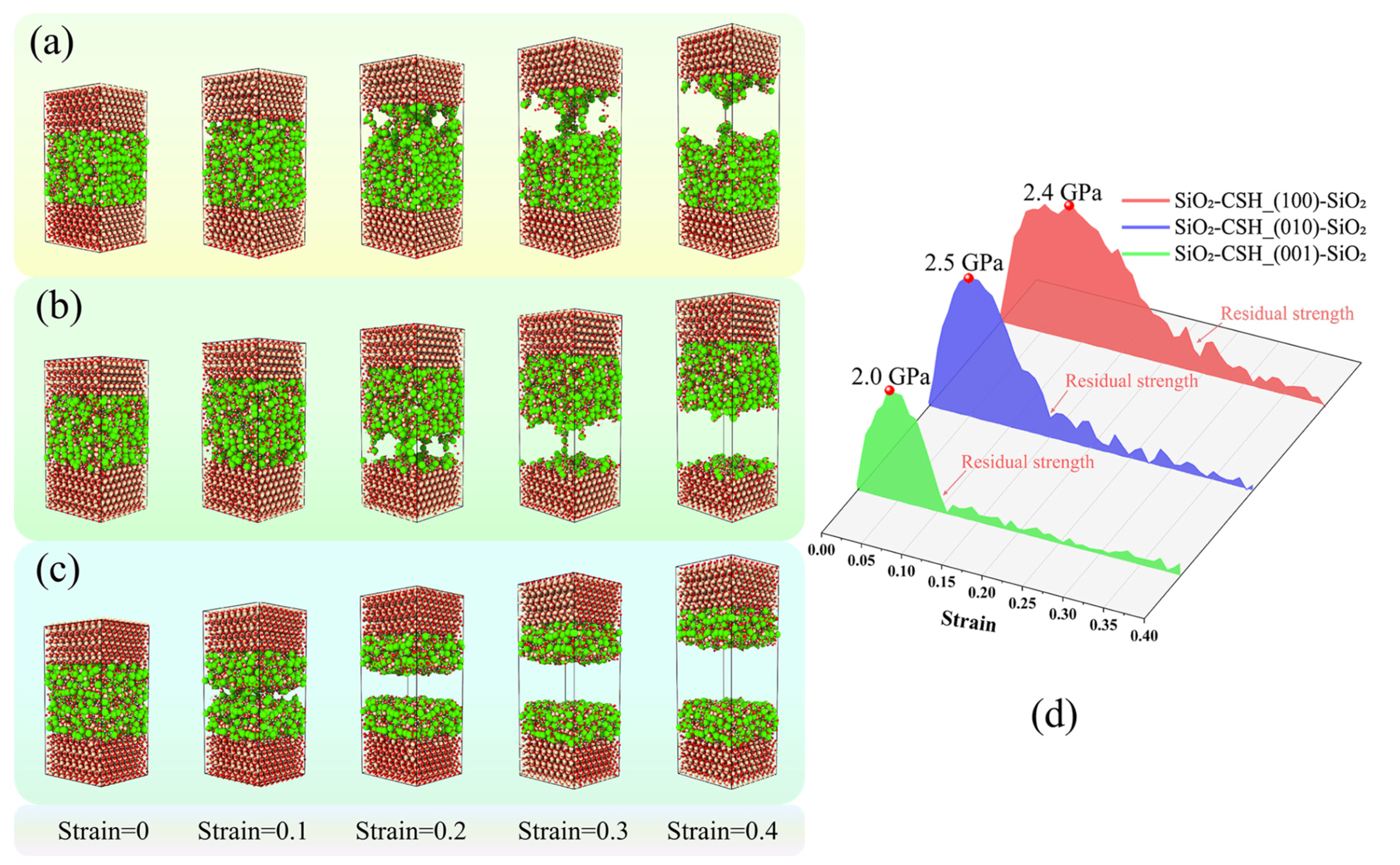

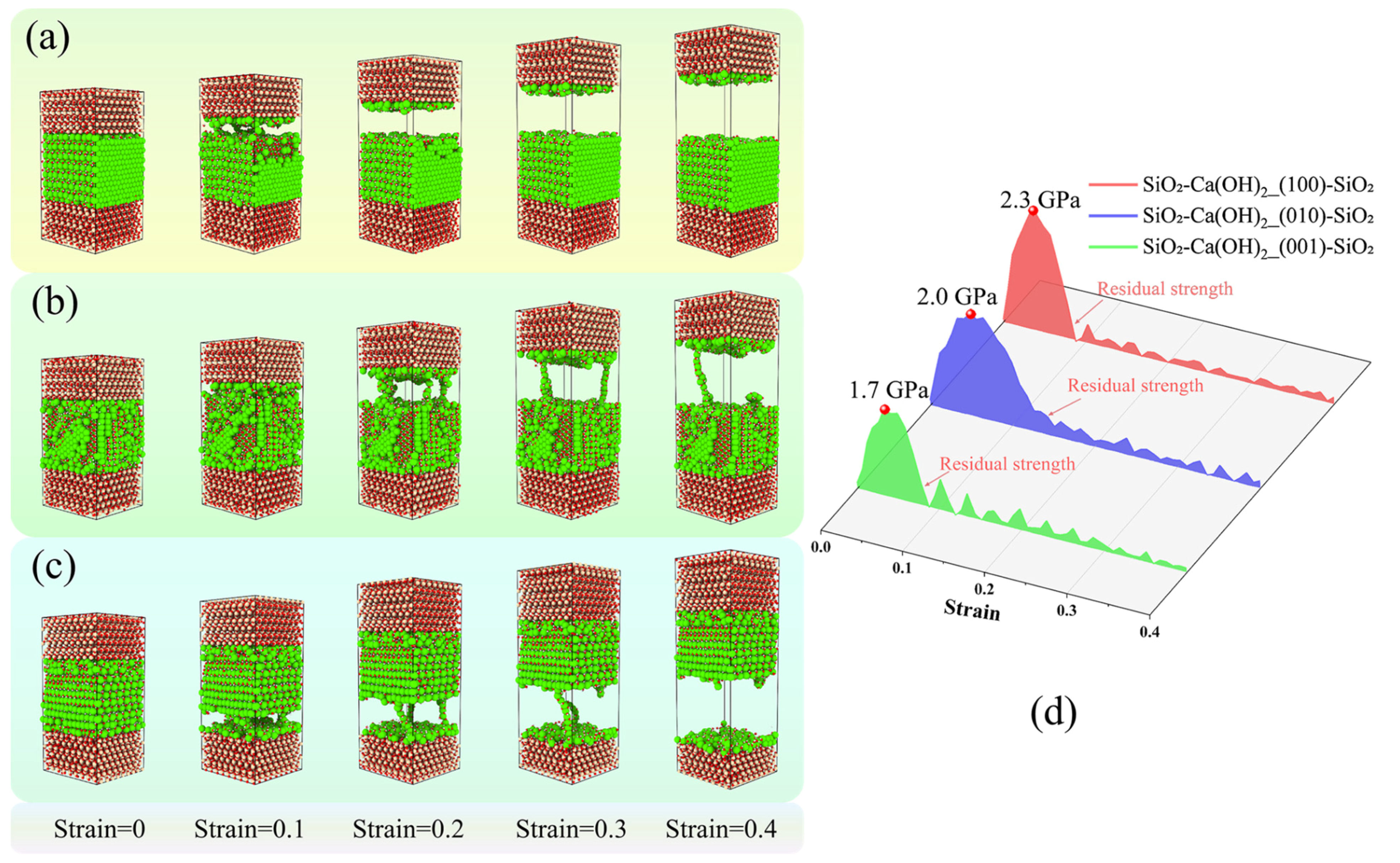

3.2. Nanomechanical Properties of Different Configurations

3.3. Influence of Strain Rate

4. Discussion

5. Conclusions

- 1.

- In interfacial composite structures of SiO2-CSH-SiO2 and SiO2-Ca(OH)2-SiO2, the interfacial zones (IZs) tended to have relatively lower densities than those of the bulk. Meanwhile, the anisotropy of the hydration products had almost no effect on the IZ being a low-density zone. For SiO2-CSH-SiO2, areas with elevated water densities in the bulk CSH also corresponded to lower overall densities.

- 2.

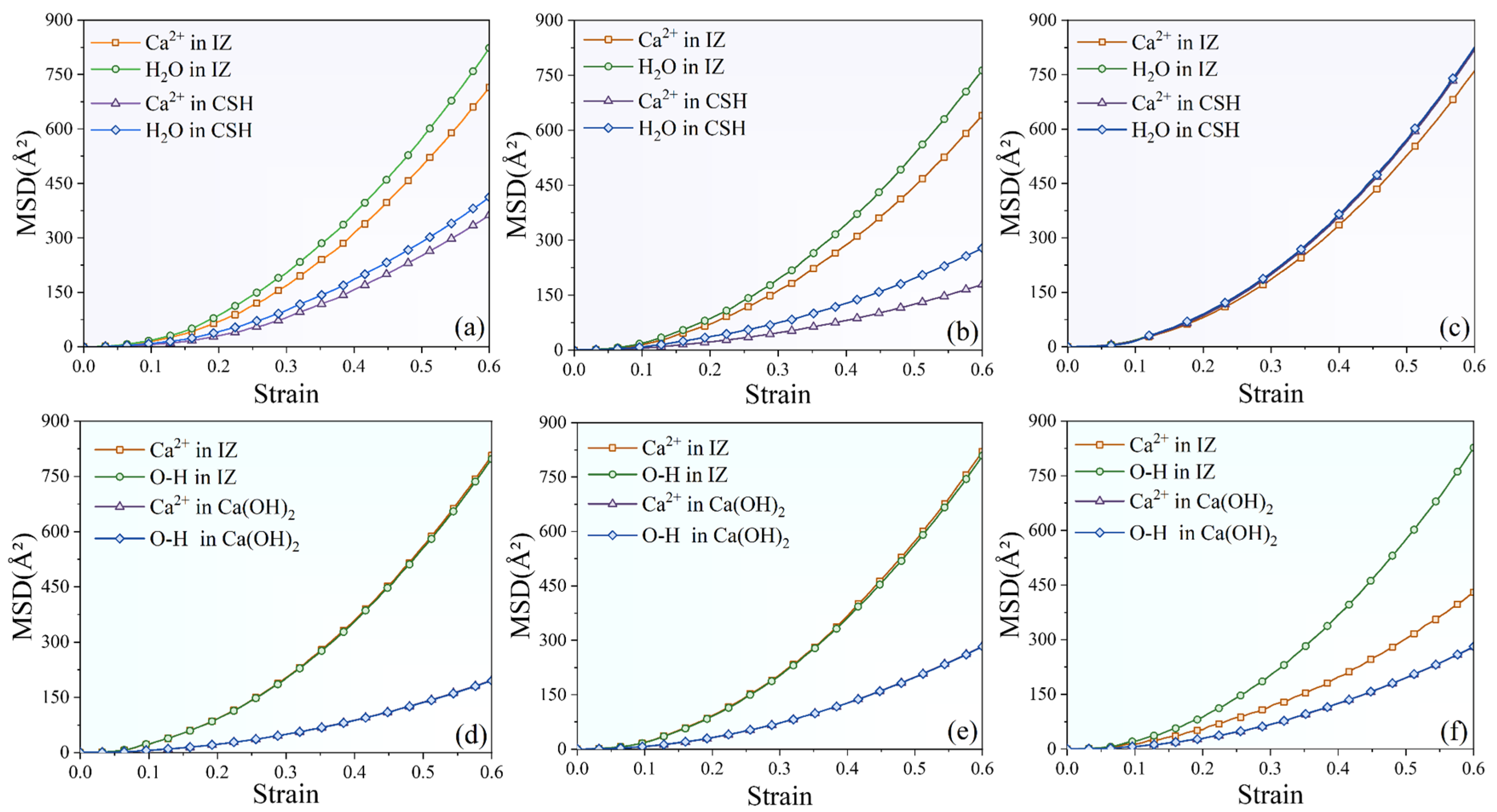

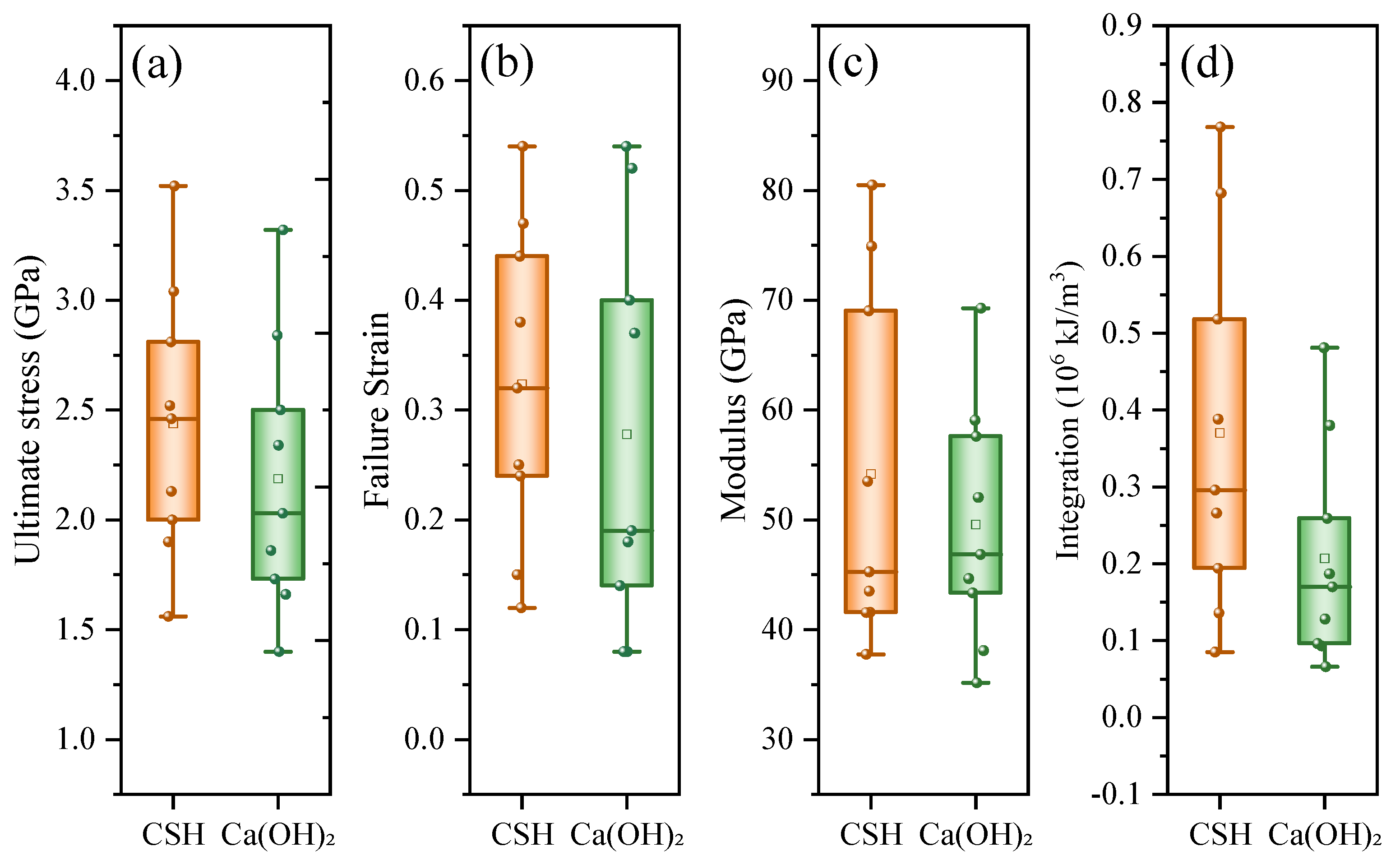

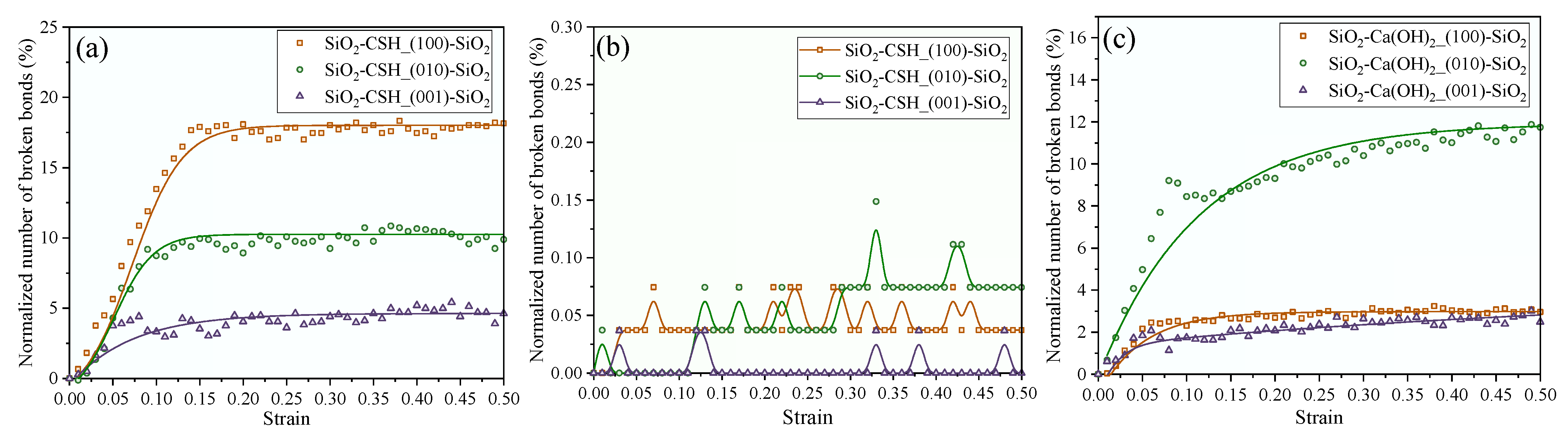

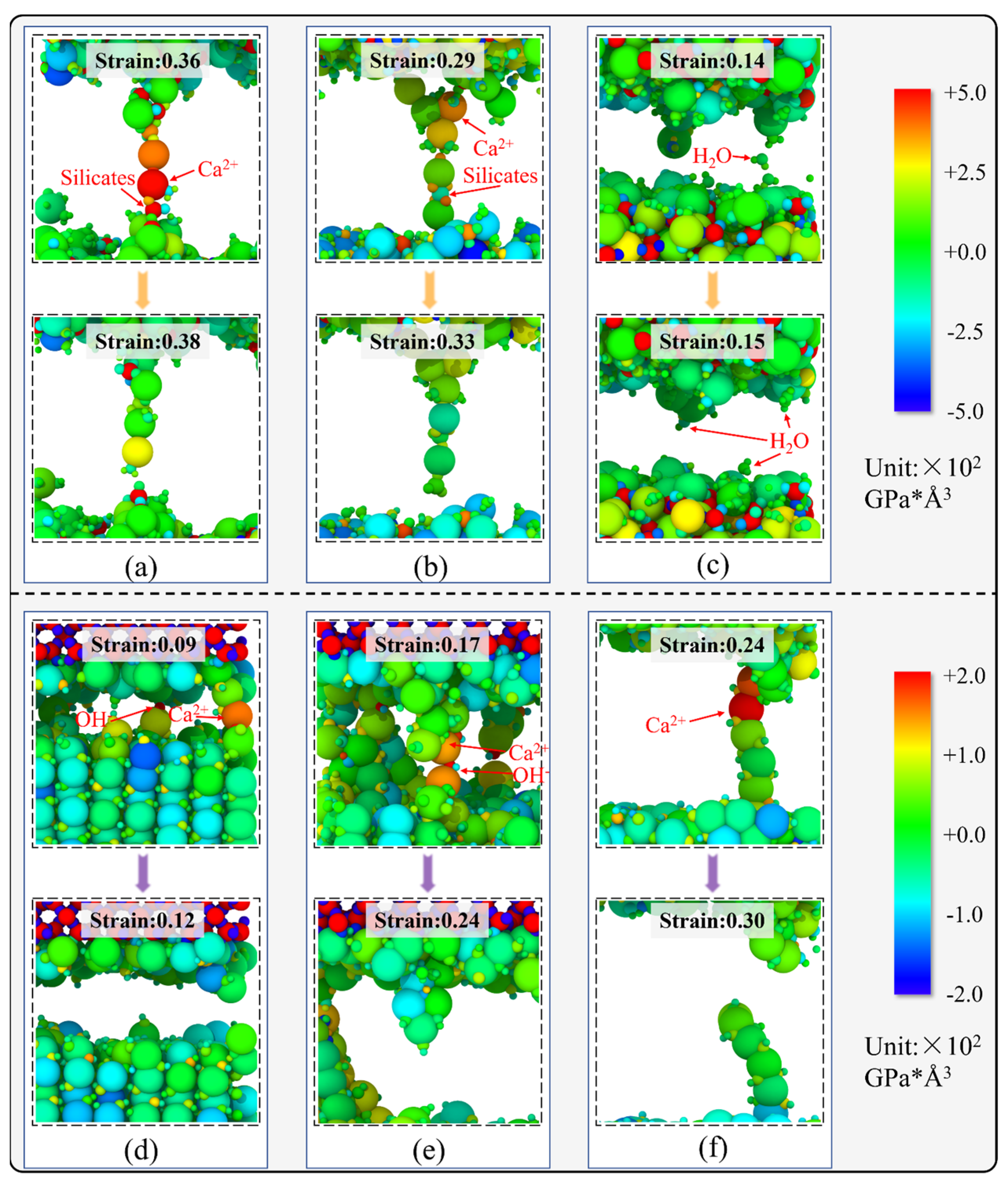

- Interfacial composite structures with different configurations, considering the anisotropy of CSH and Ca(OH)2, exhibited diverse nanomechanical behaviors in aspects of their ultimate strength, stress–strain relationship and fracture evaluation. The SiO2-CSH_(100)-SiO2 configuration exhibited fracturing within the water layer situated within the bulk of CSH, leading to diffusion rates of H2O molecules and Ca2+ ions in the interfacial zone (IZ) that were consistent with those observed in the bulk. In contrast, other interfacial composite structures fractured in proximity to the IZ, resulting in the significantly accelerated diffusion of H2O molecules/OH− ions and Ca2+ ions within the IZ compared to the bulk region.

- 3.

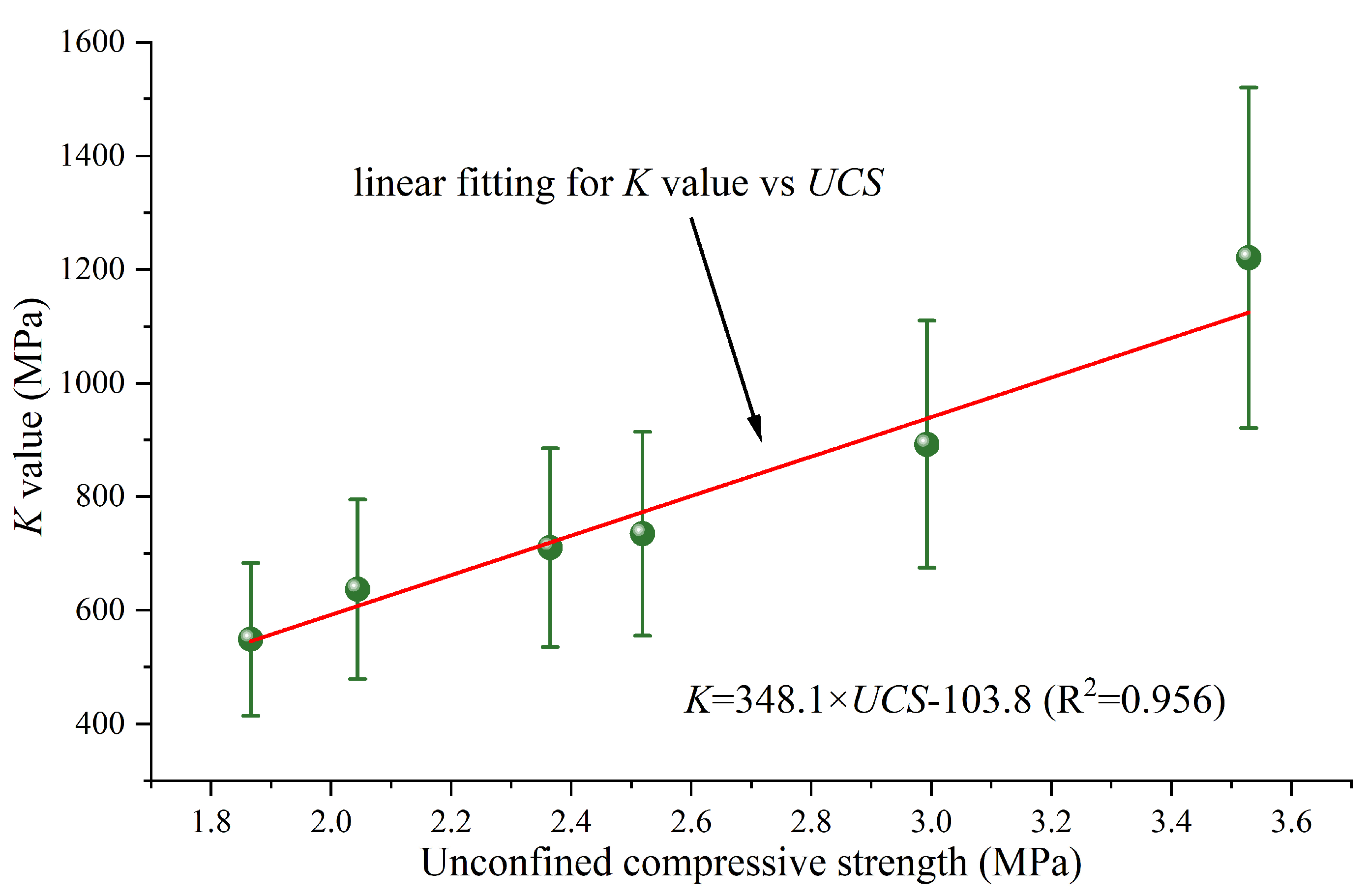

- For all configurations of the interfacial composite structures, a higher strain rate contributed to a higher ultimate strength and a more prolonged decline in the residual strength. In terms of the evolution of fractures, a relatively high strain rate (0.08 ps−1) induced concurrent fractures at both interfaces of the composite structures and also resulted in more atomic chains to provide a bridging effect as opposed to a lower strain rate (0.0008 ps−1).

- 4.

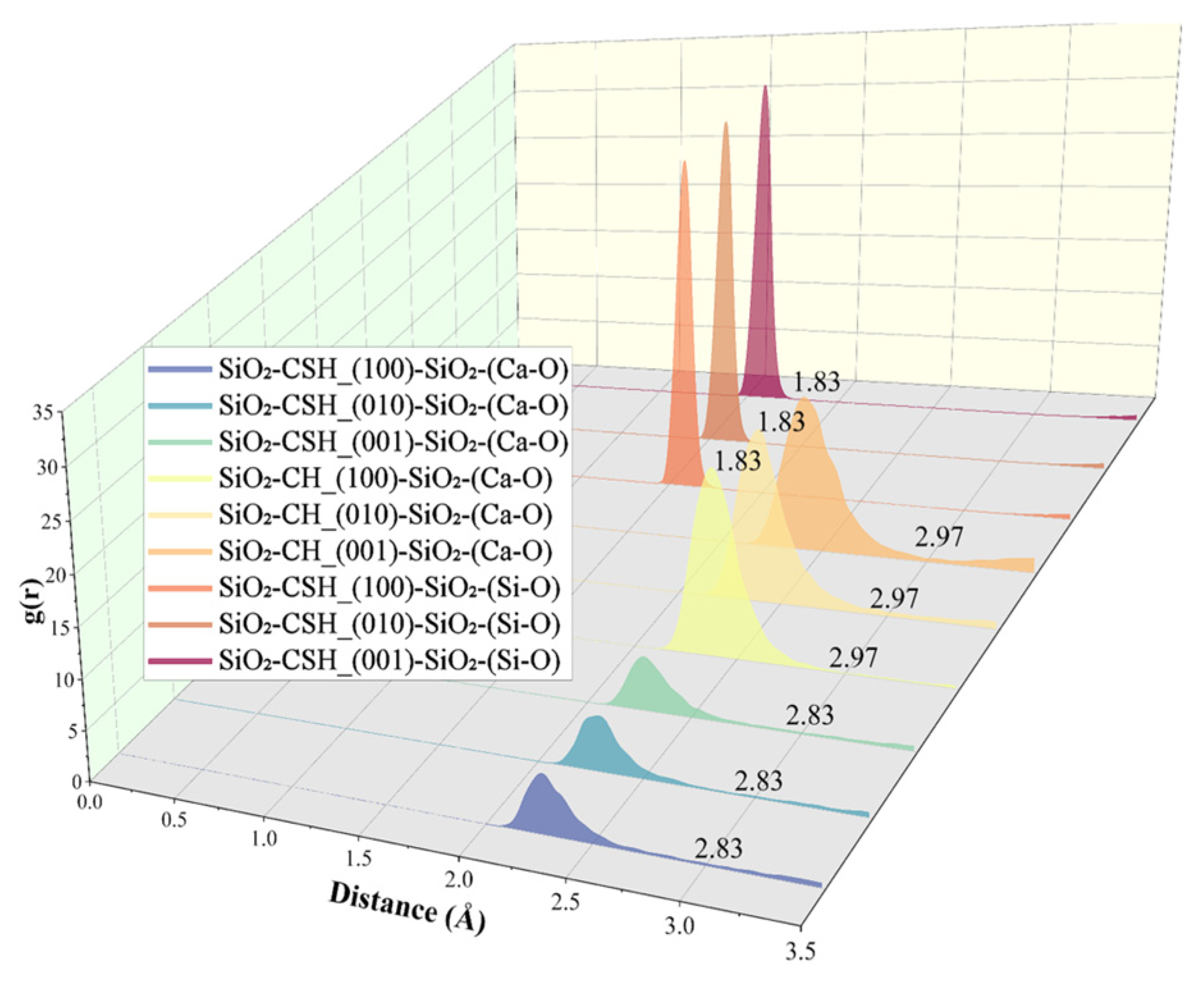

- In the interfacial composite structures, both CSH and Ca(OH)2 exhibited the rupturing of the Ca-O bond as the primary atomic pair during the tensile process, which can also be reflected by the broken characteristics of the atomic chain in the per-atom stress map. The plastic damage characteristics of the interfacial composite structures and the energy consumption during the tensile process can be effectively assessed by analyzing the normalized number of broken Ca-O bonds.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Appendix A

| Hydration Product | Strain Rate | Plane | Ultimate Stress (GPa) | Failure Strain | Modulus (GPa) | Integration (106 kJ/m3) |

|---|---|---|---|---|---|---|

| CSH | 0.08 | (100) | 3.04 | 0.54 | 74.92 | 0.768 |

| (010) | 3.52 | 0.47 | 80.49 | 0.682 | ||

| (001) | 2.81 | 0.44 | 69.04 | 0.518 | ||

| 0.008 | (100) | 2.46 | 0.38 | 45.26 | 0.388 | |

| (010) | 2.52 | 0.25 | 53.5 | 0.266 | ||

| (001) | 2.00 | 0.12 | 41.58 | 0.136 | ||

| 0.0008 | (100) | 1.90 | 0.32 | 41.55 | 0.296 | |

| (010) | 2.13 | 0.24 | 43.5 | 0.194 | ||

| (001) | 1.56 | 0.15 | 37.76 | 0.085 | ||

| Ca(OH)2 | 0.08 | (100) | 3.32 | 0.52 | 69.27 | 0.380 |

| (010) | 2.84 | 0.54 | 59.07 | 0.481 | ||

| (001) | 2.50 | 0.40 | 52.03 | 0.259 | ||

| 0.008 | (100) | 2.34 | 0.08 | 57.60 | 0.128 | |

| (010) | 2.03 | 0.19 | 46.84 | 0.187 | ||

| (001) | 1.73 | 0.08 | 43.34 | 0.093 | ||

| 0.0008 | (100) | 1.86 | 0.14 | 44.65 | 0.096 | |

| (010) | 1.66 | 0.37 | 38.10 | 0.170 | ||

| (001) | 1.40 | 0.18 | 35.16 | 0.066 |

References

- Bahmani, H.; Mostofinejad, D. Microstructure of Ultra-High-Performance Concrete (UHPC)—A Review Study. J. Build. Eng. 2022, 50, 104118. [Google Scholar] [CrossRef]

- Scrivener, K.L.; Juilland, P.; Monteiro, P.J.M. Advances in Understanding Hydration of Portland Cement. Cem. Concr. Res. 2015, 78, 38–56. [Google Scholar] [CrossRef]

- Schneider, M. The Cement Industry on the Way to a Low-Carbon Future. Cem. Concr. Res. 2019, 124, 105792. [Google Scholar] [CrossRef]

- Liu, L.; Deng, T.; Deng, Y.; Zhan, L.; Horpibulsuk, S.; Wang, Q. Stabilization Nature and Unified Strength Characterization for Cement-Based Stabilized Soils. Constr. Build. Mater. 2022, 336, 127544. [Google Scholar] [CrossRef]

- Cui, C.; Zhang, S.; Chapman, D.; Meng, K. Dynamic Impedance of a Floating Pile Embedded in Poro-Visco-Elastic Soils Subjected to Vertical Harmonic Loads. Geomech. Eng. 2018, 15, 793–803. [Google Scholar] [CrossRef]

- Jebli, M.; Jamin, F.; Malachanne, E.; Garcia-Diaz, E.; El Youssoufi, M.S. Experimental Characterization of Mechanical Properties of the Cement-Aggregate Interface in Concrete. Constr. Build. Mater. 2018, 161, 16–25. [Google Scholar] [CrossRef]

- Lin, D.; Wu, J.; Yan, P.; Chen, Y. Effect of Residual Mortar on Compressive Properties of Modeled Recycled Coarse Aggregate Concrete. Constr. Build. Mater. 2023, 402, 132511. [Google Scholar] [CrossRef]

- Wang, X.; Dong, S.; Li, Z.; Han, B.; Ou, J. Nanomechanical Characteristics of Interfacial Transition Zone in Nano-Engineered Concrete. Engineering 2022, 17, 99–109. [Google Scholar] [CrossRef]

- Luo, Q.; Qin, T.; Chen, Z.; Pang, B.; Qu, J.; Gao, Z. The Influence of Moisture and Epoxy Bonding Agents on Interfacial Behavior between Normal Concrete Substrate and Ultrahigh Performance Concrete as a Repair Material: Experimental and Molecular Dynamics Study. Constr. Build. Mater. 2023, 372, 130779. [Google Scholar] [CrossRef]

- Im, S.; Liu, J.; Cho, S.; Moon, J.; Park, J.; Wi, K.; Seok, S.; Lim, S.; Bae, S. Quantitative Characterization of the Interfacial Transition Zone around Lightweight and Normal Aggregates in Cement Mortars at Different Water-to-Binder Ratios. Constr. Build. Mater. 2023, 400, 132584. [Google Scholar] [CrossRef]

- Guo, D.; Guo, M.; Xing, F.; Zhou, Y.; Huang, Z.; Cao, W. Using Limestone Calcined Clay Cement and Recycled Fine Aggregate to Make Ultra-High-Performance Concrete: Properties and Environmental Impact. Constr. Build. Mater. 2023, 394, 132026. [Google Scholar] [CrossRef]

- Xiao, J.; Li, W.; Sun, Z.; Lange, D.A.; Shah, S.P. Properties of Interfacial Transition Zones in Recycled Aggregate Concrete Tested by Nanoindentation. Cem. Concr. Compos. 2013, 37, 276–292. [Google Scholar] [CrossRef]

- Duque-Redondo, E.; Bonnaud, P.A.; Manzano, H. A Comprehensive Review of C-S-H Empirical and Computational Models, Their Applications, and Practical Aspects. Cem. Concr. Res. 2022, 156, 106784. [Google Scholar] [CrossRef]

- Barbhuiya, S.; Das, B.B. Molecular Dynamics Simulation in Concrete Research: A Systematic Review of Techniques, Models and Future Directions. J. Build. Eng. 2023, 76, 107267. [Google Scholar] [CrossRef]

- Al-Ostaz, A.; Wu, W.; Cheng, A.H.-D.; Song, C.R. A Molecular Dynamics and Microporomechanics Study on the Mechanical Properties of Major Constituents of Hydrated Cement. Compos. Part B Eng. 2010, 41, 543–549. [Google Scholar] [CrossRef]

- Xu, J.; Chen, X.; Yang, G.; Niu, X.; Chang, F.; Lacidogna, G. Review of Research on Micromechanical Properties of Cement-Based Materials Based on Molecular Dynamics Simulation. Constr. Build. Mater. 2021, 312, 125389. [Google Scholar] [CrossRef]

- Yaphary, Y.L.; Lau, D.; Sanchez, F.; Poon, C.S. Effects of Sodium/Calcium Cation Exchange on the Mechanical Properties of Calcium Silicate Hydrate (C-S-H). Constr. Build. Mater. 2020, 243, 118283. [Google Scholar] [CrossRef]

- Hou, D.; Zhu, Y.; Lu, Y.; Li, Z. Mechanical Properties of Calcium Silicate Hydrate (C–S–H) at Nano-Scale: A Molecular Dynamics Study. Mater. Chem. Phys. 2014, 146, 503–511. [Google Scholar] [CrossRef]

- Hou, D.; Li, Z. Large-Scale Simulation of Calcium Silicate Hydrate by Molecular Dynamics. Adv. Cem. Res. 2015, 27, 278–288. [Google Scholar] [CrossRef]

- Hou, D.; Ma, H.; Li, Z. Morphology of Calcium Silicate Hydrate (C-S-H) Gel: A Molecular Dynamic Study. Adv. Cem. Res. 2015, 27, 135–146. [Google Scholar] [CrossRef]

- Jin, S.; Li, J.; Xu, W.; Ding, Q. Heterogeneous Nature of Calcium Silicate Hydrate (C-S-H) Gel: A Molecular Dynamics Study. J. Wuhan Univ. Technol.-Mat. Sci. Edit. 2020, 35, 435–440. [Google Scholar] [CrossRef]

- Zhou, Y.; Tang, L.; Liu, J.; Miao, C. Interaction Mechanisms between Organic and Inorganic Phases in Calcium Silicate Hydrates/Poly(Vinyl Alcohol) Composites. Cem. Concr. Res. 2019, 125, 105891. [Google Scholar] [CrossRef]

- Sabet, A.B.; Hashemi, S.A.H.; Farokhzad, R.; Delnavaz, A. Synergic Effect of Defects on Carbon Nanoparticles under Interaction with Calcium Silicate Hydrate Composites. Appl. Surf. Sci. 2023, 622, 156712. [Google Scholar] [CrossRef]

- Hou, D.; Yang, Q.; Wang, P.; Jin, Z.; Wang, M.; Zhang, Y.; Wang, X. Unraveling Disadhesion Mechanism of Epoxy/CSH Interface under Aggressive Conditions. Cem. Concr. Res. 2021, 146, 106489. [Google Scholar] [CrossRef]

- Xu, J.; Chen, X.; Yu, B. Experimental and Simulation Study of Rubber/Cement Paste Interface Modified by Waste Paint and Silica in Two Stages. Constr. Build. Mater. 2023, 382, 131323. [Google Scholar] [CrossRef]

- Yu, Z.; Zhou, A.; Ning, W.; Tam, L. Molecular Insights into the Weakening Effect of Water on Cement/Epoxy Interface. Appl. Surf. Sci. 2021, 553, 149493. [Google Scholar] [CrossRef]

- Kai, M.-F.; Sanchez, F.; Hou, D.-S.; Dai, J.-G. Nanoscale Insights into the Interfacial Characteristics between Calcium Silicate Hydrate and Silica. Appl. Surf. Sci. 2023, 616, 156478. [Google Scholar] [CrossRef]

- Wu, H.; Pan, J.; Wang, J. Mechanical Properties of Interface between C–S–H and Silicon Dioxide: Molecular Dynamics Simulations. J. Mater. Res. Technol. 2022, 21, 3678–3685. [Google Scholar] [CrossRef]

- Zhou, Y.; Peng, Z.; Huang, J.; Ma, T.; Huang, X.; Miao, C. A Molecular Dynamics Study of Calcium Silicate Hydrates-Aggregate Interfacial Interactions and Influence of Moisture. J. Cent. South Univ. 2021, 28, 16–28. [Google Scholar] [CrossRef]

- Kai, M.-F.; Dai, J.-G. Understanding Geopolymer Binder-Aggregate Interfacial Characteristics at Molecular Level. Cem. Concr. Res. 2021, 149, 106582. [Google Scholar] [CrossRef]

- Pellenq, R.J.-M.; Kushima, A.; Shahsavari, R.; Van Vliet, K.J.; Buehler, M.J.; Yip, S.; Ulm, F.-J. A Realistic Molecular Model of Cement Hydrates. Proc. Natl. Acad. Sci. USA 2009, 106, 16102–16107. [Google Scholar] [CrossRef]

- Abdolhosseini Qomi, M.J.; Krakowiak, K.J.; Bauchy, M.; Stewart, K.L.; Shahsavari, R.; Jagannathan, D.; Brommer, D.B.; Baronnet, A.; Buehler, M.J.; Yip, S.; et al. Combinatorial Molecular Optimization of Cement Hydrates. Nat. Commun. 2014, 5, 4960. [Google Scholar] [CrossRef] [PubMed]

- Yin, H.; Wang, X.; Qin, H.; Wang, S.; Cai, K. Nanoindentation Study of Calcium-Silicate-Hydrate Gel via Molecular Dynamics Simulations. Nanomaterials 2023, 13, 2578. [Google Scholar] [CrossRef] [PubMed]

- Allen, A.J.; Thomas, J.J.; Jennings, H.M. Composition and Density of Nanoscale Calcium–Silicate–Hydrate in Cement. Nat. Mater. 2007, 6, 311–316. [Google Scholar] [CrossRef] [PubMed]

- Kerisit, S.; Liu, C. Molecular Simulations of Water and Ion Diffusion in Nanosized Mineral Fractures. Environ. Sci. Technol. 2009, 43, 777–782. [Google Scholar] [CrossRef] [PubMed]

- Yang, H.; He, M.; Lu, C.; Gong, W. Deformation and Failure Processes of Kaolinite under Tension: Insights from Molecular Dynamics Simulations. Sci. China Phys. Mech. Astron. 2019, 62, 64612. [Google Scholar] [CrossRef]

- Wei, P.; Zheng, Y.-Y.; Xiong, Y.; Zhou, S.; Al-Zaoari, K.; Zaoui, A. Effect of Water Content and Structural Anisotropy on Tensile Mechanical Properties of Montmorillonite Using Molecular Dynamics. Appl. Clay Sci. 2022, 228, 106622. [Google Scholar] [CrossRef]

- Al-Muhit, B.; Sanchez, F. Nano-Engineering of the Mechanical Properties of Tobermorite 14 Å with Graphene via Molecular Dynamics Simulations. Constr. Build. Mater. 2020, 233, 117237. [Google Scholar] [CrossRef]

- Yoobanpot, N.; Jamsawang, P.; Poorahong, H.; Jongpradist, P.; Likitlersuang, S. Multiscale Laboratory Investigation of the Mechanical and Microstructural Properties of Dredged Sediments Stabilized with Cement and Fly Ash. Eng. Geol. 2020, 267, 105491. [Google Scholar] [CrossRef]

- Tahani, M.; Postek, E.; Sadowski, T. Investigating the Influence of Diffusion on the Cohesive Zone Model of the SiC/Al Composite Interface. Molecules 2023, 28, 6757. [Google Scholar] [CrossRef]

- Hosseini, E.; Zakertabrizi, M.; Korayem, A.H.; Xu, G. A Novel Method to Enhance the Interlayer Bonding of 3D Printing Concrete: An Experimental and Computational Investigation. Cem. Concr. Compos. 2019, 99, 112–119. [Google Scholar] [CrossRef]

- Dong, C.-Q.; Zhang, R.-J.; Zheng, J.-J.; Jiang, W.-H. Strength Behavior of Dredged Mud Slurry Treated Jointly by Cement, Metakaolin and Flocculant. Appl. Clay Sci. 2020, 193, 105676. [Google Scholar] [CrossRef]

- Deng, Y.; Wu, Z.; Liu, S.; Yue, X.; Zhu, L.; Chen, J.; Guan, Y. Influence of geopolymer on strength of cement-stabilized soils and its mechanism. Chin. J. Geotech. Eng. 2016, 38, 446–453. [Google Scholar] [CrossRef]

- Hou, D.; Zhao, T.; Wang, P.; Li, Z.; Zhang, J. Molecular Dynamics Study on the Mode I Fracture of Calcium Silicate Hydrate under Tensile Loading. Eng. Fract. Mech. 2014, 131, 557–569. [Google Scholar] [CrossRef]

- Zhang, T.; Yang, Y.-L.; Liu, S.-Y. A Shear Model for Solidified Soils Considering Conservation of Energy. Comput. Geotech. 2020, 120, 103439. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, J.; Zhang, Y.; Xue, D.; Cui, C.; Li, W.; Liu, F. Nanoscale Insights into the Mechanical Behavior of Interfacial Composite Structures between Calcium Silicate Hydrate/Calcium Hydroxide and Silica. Nanomaterials 2023, 13, 3059. https://doi.org/10.3390/nano13233059

Zhao J, Zhang Y, Xue D, Cui C, Li W, Liu F. Nanoscale Insights into the Mechanical Behavior of Interfacial Composite Structures between Calcium Silicate Hydrate/Calcium Hydroxide and Silica. Nanomaterials. 2023; 13(23):3059. https://doi.org/10.3390/nano13233059

Chicago/Turabian StyleZhao, Jiuye, Yuanhang Zhang, Dapeng Xue, Chunyi Cui, Wenzheng Li, and Fang Liu. 2023. "Nanoscale Insights into the Mechanical Behavior of Interfacial Composite Structures between Calcium Silicate Hydrate/Calcium Hydroxide and Silica" Nanomaterials 13, no. 23: 3059. https://doi.org/10.3390/nano13233059

APA StyleZhao, J., Zhang, Y., Xue, D., Cui, C., Li, W., & Liu, F. (2023). Nanoscale Insights into the Mechanical Behavior of Interfacial Composite Structures between Calcium Silicate Hydrate/Calcium Hydroxide and Silica. Nanomaterials, 13(23), 3059. https://doi.org/10.3390/nano13233059