Comparative Evaluation of TiO2 Nanoparticle Addition and Postcuring Time on the Flexural Properties and Hardness of Additively Fabricated Denture Base Resins

Abstract

:1. Introduction

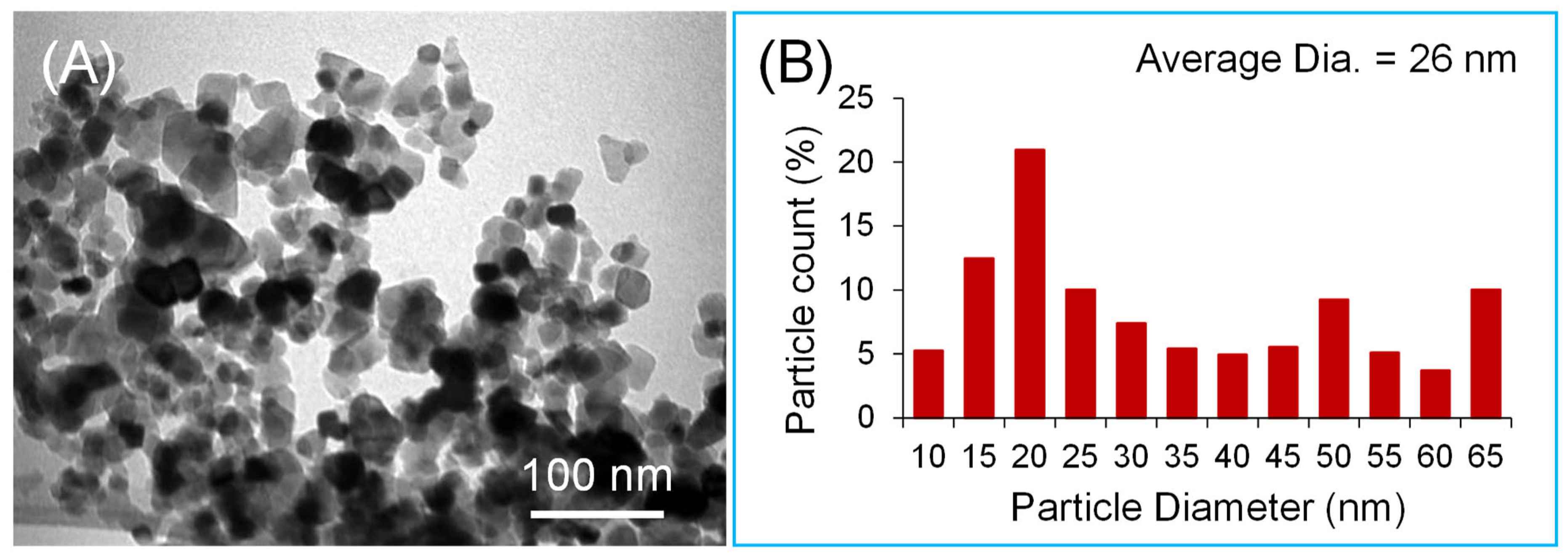

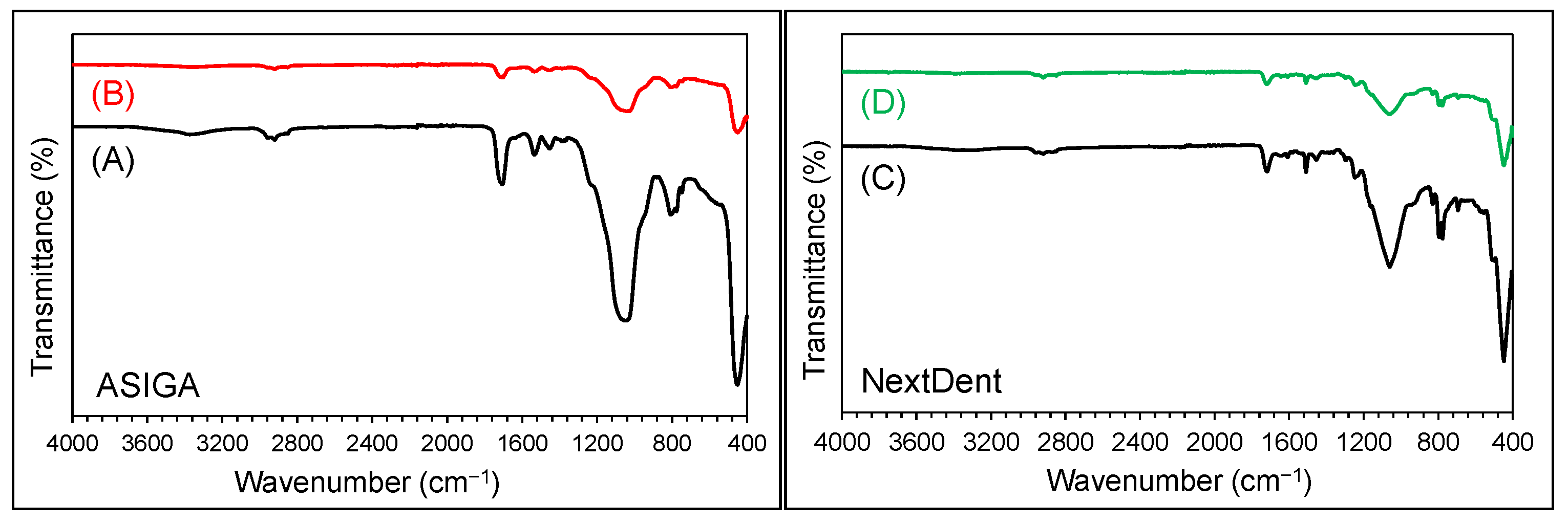

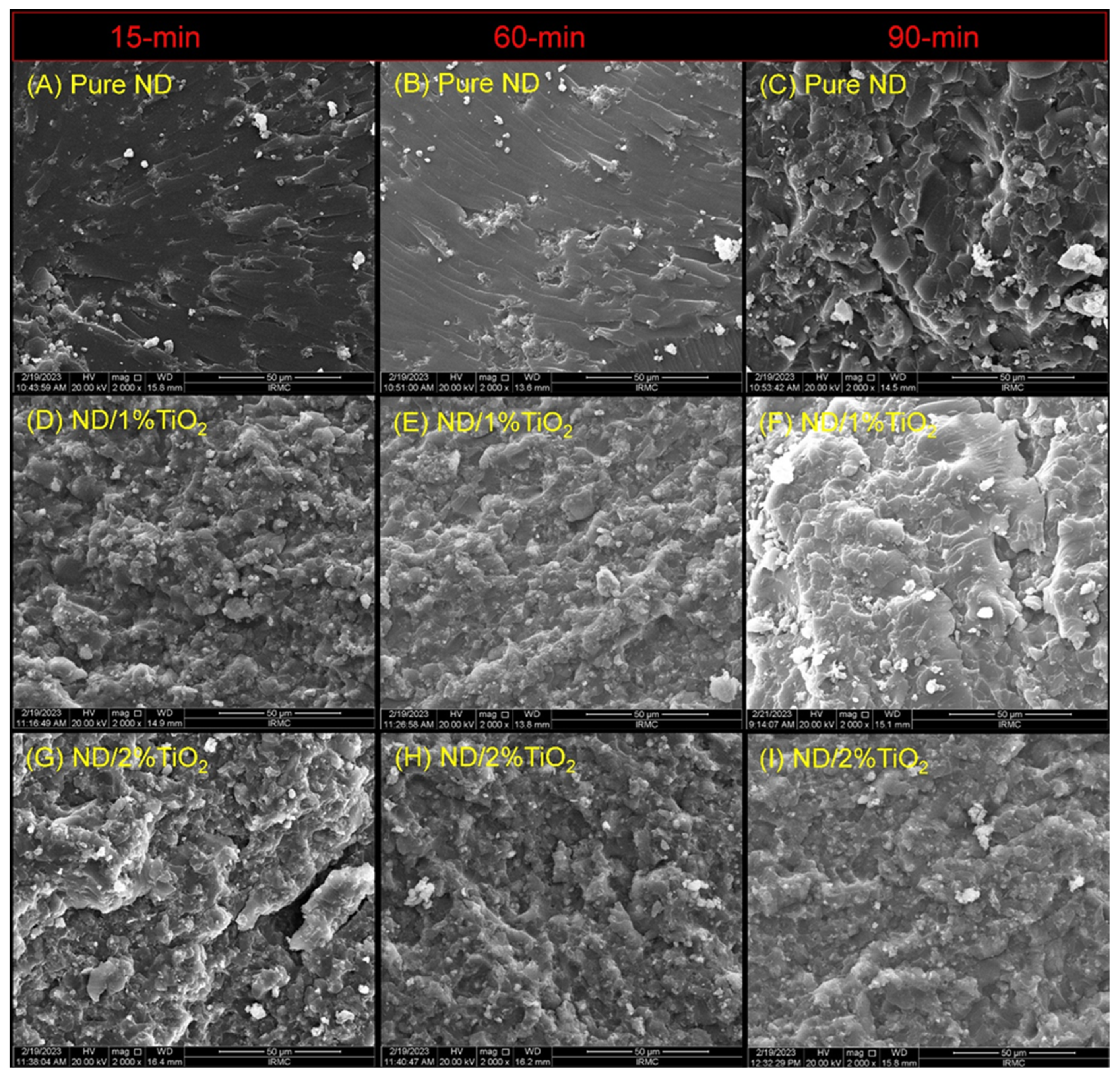

2. Materials and Methods

Statistical Analysis

3. Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Zeidan, A.A.E.L.; Sherif, A.F.; Baraka, Y.; Abualsaud, R.; Abdelrahim, R.A.; Gad, M.M.; Helal, M.A. Evaluation of the Effect of Different Construction Techniques of CAD-CAM Milled, 3D-Printed, and Polyamide Denture Base Resins on Flexural Strength: An In Vitro Comparative Study. J. Prosthodont. 2023, 32, 77–82. [Google Scholar] [CrossRef] [PubMed]

- Gokay, G.D.; Durkan, R.; Oyar, P. Evaluation of physical properties of polyamide and methacrylate based denture base resins polymerized by different techniques. Niger. J. Clin. Pract. 2021, 24, 1835–1840. [Google Scholar] [CrossRef] [PubMed]

- Gad, M.M.; Fouda, S.M. Current perspectives and the future of Candida albicans-associated denture stomatitis treatment. Dent. Med. Probl. 2020, 57, 95–102. [Google Scholar] [CrossRef] [PubMed]

- Alghazzawi, T.F. Advancements in CAD/CAM technology: Options for practical implementation. J. Prosthodont. Res. 2016, 60, 72–84. [Google Scholar] [CrossRef] [PubMed]

- de Oliveira Limírio, J.P.J.; Gomes, J.M.L.; Alves Rezende, M.C.R.; Lemos, C.A.A.; Rosa, C.D.D.R.D.; Pellizzer, E.P. Mechanical properties of polymethyl methacrylate as a denture base: Conventional versus CAD-CAM resin—A systematic review and meta-analysis of in vitro studies. J. Prosthet. Dent. 2022, 128, 1221–1229. [Google Scholar] [CrossRef] [PubMed]

- Pagac, M.; Hajnys, J.; Ma, Q.-P.; Jancar, L.; Jansa, J.; Stefek, P.; Mesicek, J. A review of vat photopolymerization technology: Materials, applications, challenges, and future trends of 3D printing. Polymers 2021, 13, 598. [Google Scholar] [CrossRef] [PubMed]

- Abualsaud, R.; Gad, M.M. Flexural Strength of CAD/CAM Denture Base Materials: Systematic Review and Meta-Analysis of In-Vitro Studies. J. Int. Soc. Prev. Community Dent. 2022, 12, 160–170. [Google Scholar] [CrossRef]

- Dimitrova, M.; Corsalini, M.; Kazakova, R.; Vlahova, A.; Chuchulska, B.; Barile, G.; Capodiferro, S.; Kazakov, S. Comparison between conventional PMMA and 3D printed resins for denture bases: A narrative review. J. Compos. Sci. 2022, 6, 87. [Google Scholar] [CrossRef]

- Tian, Y.; Chen, C.; Xu, X.; Wang, J.; Hou, X.; Li, K.; Lu, X.; Shi, H.; Lee, E.-S.; Jiang, H.B. A review of 3D printing in dentistry: Technologies, affecting factors, and applications. Scanning 2021, 2021, 9950131. [Google Scholar] [CrossRef]

- Goodacre, B.J.; Goodacre, C.J. Additive manufacturing for complete denture fabrication: A narrative review. J. Prosthodont. 2022, 31 (Suppl. S1), 47–51. [Google Scholar] [CrossRef]

- Unkovskiy, A.; Schmidt, F.; Beuer, F.; Li, P.; Spintzyk, S.; Fernandez, P.K. Stereolithography vs. direct light processing for rapid manufacturing of complete denture bases: An in vitro accuracy analysis. J. Clin. Med. 2021, 10, 1070. [Google Scholar] [CrossRef] [PubMed]

- Lin, W.-S.; Harris, B.T.; Pellerito, J.; Morton, D. Fabrication of an interim complete removable dental prosthesis with an in-office digital light processing three-dimensional printer: A proof-of-concept technique. J. Prosthet. Dent. 2018, 120, 331–334. [Google Scholar] [CrossRef] [PubMed]

- Quan, H.; Zhang, T.; Xu, H.; Luo, S.; Nie, J.; Zhu, X. Photo-curing 3D printing technique and its challenges. Bioact. Mater. 2020, 5, 110–115. [Google Scholar] [CrossRef] [PubMed]

- Anadioti, E.; Musharbash, L.; Blatz, M.B.; Papavasiliou, G.; Kamposiora, P. 3D printed complete removable dental prostheses: A narrative review. BMC Oral Health 2020, 20, 343. [Google Scholar] [CrossRef]

- Aati, S.; Aneja, S.; Kassar, M.; Leung, R.; Nguyen, A.; Tran, S.; Shrestha, B.; Fawzy, A. Silver-loaded mesoporous silica nanoparticles enhanced the mechanical and antimicrobial properties of 3D printed denture base resin. J. Mech. Behav. Biomed. Mater. 2022, 134, 105421. [Google Scholar] [CrossRef] [PubMed]

- Gad, M.M.; Fouda, S.M.; Abualsaud, R.; Alshahrani, F.A.; Al-Thobity, A.M.; Khan, S.Q.; Akhtar, S.; Ateeq, I.S.; Helal, M.A.; Al-Harbi, F.A. Strength and Surface Properties of a 3D-Printed Denture Base Polymer. J. Prosthodont. 2022, 31, 412–418. [Google Scholar] [CrossRef] [PubMed]

- Choi, J.J.E.; Uy, C.E.; Plaksina, P.; Ramani, R.S.; Ganjigatti, R.; Waddell, J.N. Bond Strength of Denture Teeth to Heat-Cured, CAD/CAM and 3D Printed Denture Acrylics. J. Prosthodont. 2020, 29, 415–421. [Google Scholar] [CrossRef]

- Alzaid, M.; AlToraibily, F.; Al-Qarni, F.D.; Al-Thobity, A.M.; Akhtar, S.; Ali, S.; Al-Harbi, F.A.; Gad, M.M. The Effect of Salivary pH on the Flexural Strength and Surface Properties of CAD/CAM Denture Base Materials. Eur. J. Dent. 2023, 17, 234–241. [Google Scholar] [CrossRef]

- Gale, M.S.; Darvell, B.W. Thermal cycling procedures for laboratory testing of dental restorations. J. Dent. 1999, 27, 89–99. [Google Scholar] [CrossRef]

- Al-Qarni, F.D.; Gad, M.M. Printing Accuracy and Flexural Properties of Different 3D-Printed Denture Base Resins. Materials 2022, 15, 2410. [Google Scholar] [CrossRef]

- Alshaikh, A.A.; Khattar, A.; Almindil, I.A.; Alsaif, M.H.; Akhtar, S.; Khan, S.Q.; Gad, M.M. 3D-Printed Nanocomposite Denture-Base Resins: Effect of ZrO2 Nanoparticles on the Mechanical and Surface Properties In Vitro. Nanomaterials 2022, 12, 2451. [Google Scholar] [CrossRef]

- Helal, M.; Fadl-Alah, A.; Baraka, Y.; Gad, M.; Emam, A.-N. In-vitro Comparative Evaluation for the Surface Properties and Impact Strength of CAD/CAM Milled, 3D Printed, and Polyamide Denture Base Resins. J. Int. Soc. Prev. Community Dent. 2022, 12, 126–131. [Google Scholar] [CrossRef]

- Al-Dulaijan, Y.A.; Alsulaimi, L.; Alotaibi, R.; Alboainain, A.; Alalawi, H.; Alshehri, S.; Khan, S.Q.; Alsaloum, M.; AlRumaih, H.S.; Alhumaidan, A.A.; et al. Comparative Evaluation of Surface Roughness and Hardness of 3D Printed Resins. Materials 2022, 15, 6822. [Google Scholar] [CrossRef]

- Wang, E.; Yang, F.; Shen, X.; Li, Z.; Yang, X.; Zhang, X.; Peng, W. Investigation and Optimization of the Impact of Printing Orientation on Mechanical Properties of Resin Sample in the Low-Force Stereolithography Additive Manufacturing. Materials 2022, 15, 6743. [Google Scholar] [CrossRef] [PubMed]

- Dizon, J.R.C.; Gache, C.C.L.; Cascolan, H.M.S.; Cancino, L.T.; Advincula, R.C. Post-Processing of 3D-Printed Polymers. Technologies 2021, 9, 61. [Google Scholar] [CrossRef]

- Wang, X.; Jiang, M.; Zhou, Z.W.; Gou, J.H.; Hui, D. 3D printing of polymer matrix composites: A review and prospective. Compos. Part B Eng. 2017, 110, 442–458. [Google Scholar] [CrossRef]

- Kwan, J.; Kwan, N. Clinical Application of PEEK as a Provisional Fixed Dental Prosthesis Retained by Reciprocated Guide Surfaces of Healing Abutments During Dental Implant Treatment. Int. J. Oral Maxillofac. Implant. 2021, 36, 581–586. [Google Scholar] [CrossRef] [PubMed]

- Gad, M.M.; Abualsaud, R. Behavior of PMMA Denture Base Materials Containing Titanium Dioxide Nanoparticles: A Literature Review. Int. J. Biomater. 2019, 2019, 6190610. [Google Scholar] [CrossRef] [PubMed]

- Altarazi, A.; Haider, J.; Alhotan, A.; Silikas, N.; Devlin, H. 3D printed denture base material: The effect of incorporating TiO2 nanoparticles and artificial ageing on the physical and mechanical properties. Dent. Mater. 2023, 39, 1122–1136. [Google Scholar] [CrossRef]

- Pourhajibagher, M.; Bahador, A. Effects of incorporation of nanoparticles into dental acrylic resins on antimicrobial and physico-mechanical properties: A meta-analysis of in vitro studies. J. Oral Biol. Craniofac. Res. 2022, 12, 557–568. [Google Scholar] [CrossRef]

- Chen, S.-G.; Yang, J.; Jia, Y.-G.; Lu, B.; Ren, L. TiO2 and PEEK Reinforced 3D Printing PMMA Composite Resin for Dental Denture Base Applications. Nanomaterials 2019, 9, 1049. [Google Scholar] [CrossRef]

- Raj, V.; Bhat, V.; John, N.; Shetty, A.; Joseph, S.; Kuriakose, R.; Hameed, S. Assessment of Flexural Strength and Cytotoxicity of Heat Cure Denture Base Resin Modified with Titanium Dioxide Nanoparticles: An In Vitro Study. J. Contemp. Dent. Pract. 2021, 22, 1025–1029. [Google Scholar] [CrossRef]

- Heravi, F.; Ramezani, M.; Poosti, M.; Hosseini, M.; Shajiei, A.; Ahrari, F. In vitro cytotoxicity assessment of an orthodontic composite containing titanium-dioxide nanoparticles. J. Dent. Res. Dent. Clin. Dent. Prospect. 2013, 7, 192–198. [Google Scholar]

- Tsuji, M.; Ueda, T.; Sawaki, K.; Kawaguchi, M.; Sakurai, K. Biocompatibility of a titanium dioxide-coating method for denture base acrylic resin. Gerodontology 2016, 33, 539–544. [Google Scholar] [CrossRef]

- Liu, Y.; Chen, J.; Ning, L.; Sun, J.; Liu, L.; Zhao, K. Preparation and properties of nano-TiO2-modified photosensitive materials for 3D printing. e-Polymers 2022, 22, 686–695. [Google Scholar] [CrossRef]

- Totu, E.E.; Nechifor, A.C.; Nechifor, G.; Aboul-Enein, H.Y.; Cristache, C.M. Poly(methyl methacrylate) with TiO2 nanoparticles inclusion for stereolitographic complete denture manufacturing − the fututre in dental care for elderly edentulous patients? J. Dent. 2017, 59, 68–77. [Google Scholar] [CrossRef] [PubMed]

- Tandra, E.; Wahyuningtyas, E.; Sugiatno, E. The effect of nanoparticles TiO2 on the flexural strength of acrylic resin denture plate. Padjadjaran J. Dent. 2018, 30, 35. [Google Scholar] [CrossRef]

- Karci, M.; Demir, N.; Yazman, S. Evaluation of flexural strength of different denture base materials reinforced with different nanoparticles. J. Prosthodont. 2019, 28, 572–579. [Google Scholar] [CrossRef]

- Harini, P.; Mohamed, K.; Padmanabhan, T. Effect of Titanium dioxide nanoparticles on the flexural strength of polymethylmethacrylate: An in vitro study. Indian J. Dent. Res. 2014, 25, 459–463. [Google Scholar] [CrossRef]

- Ahmed, M.A.; El-Shennawy, M.; Althomali, Y.M.; Omar, A.A. Effect of titanium dioxide nano particles incorporation on mechanical and physical properties on two different types of acrylic resin denture base. World J. Nano Sci. Eng. 2016, 6, 111–119. [Google Scholar] [CrossRef]

- Hamouda, I.M.; Beyari, M.M. Addition of glass fibers and titanium dioxide nanoparticles to the acrylic resin denture base material: Comparative study with the conventional and high impact types. Oral Health Dent. Manag. 2014, 13, 107–112. [Google Scholar]

- Cingesar, I.K.; Marković, M.-P.; Vrsaljko, D. Effect of post-processing conditions on polyacrylate materials used in stereolithography. Addit. Manuf. 2022, 55, 102813. [Google Scholar] [CrossRef]

- Altarazi, A.; Haider, J.; Alhotan, A.; Silikas, N.; Devlin, H. Assessing the physical and mechanical properties of 3D printed acrylic material for denture base application. Dent. Mater. 2022, 38, 1841–1854. [Google Scholar] [CrossRef]

- Bayarsaikhan, E.; Gu, H.; Hwangbo, N.-K.; Lim, J.-H.; Shim, J.-S.; Lee, K.-W.; Kim, J.-E. Influence of different postcuring parameters on mechanical properties and biocompatibility of 3D printed crown and bridge resin for temporary restorations. J. Mech. Behav. Biomed. Mater. 2022, 128, 105127. [Google Scholar] [CrossRef]

- AlQahtani, G.M.; AlSuhail, H.S.; Alqater, N.K.; AlTaisan, S.A.; Akhtar, S.; Khan, S.Q.; Gad, M.M. Polymethylmethacrylate Denture Base Layering as a New Approach for the Addition of Antifungal Agents. J. Prosthodont. 2023, 32, 298–308. [Google Scholar] [CrossRef]

- ISO 20795-1:2013; Dentistry—base polymers—Part 1: Denture base polymers. International Organization for Standardization (ISO): Vernier, Switzerland, 2021. Available online: https://www.iso.org/standard/62277.html (accessed on 30 October 2023).

- Gad, M.M.; Abualsaud, R.; Alqarawi, F.K.; Emam, A.-N.M.; Khan, S.Q.; Akhtar, S.; Mahrous, A.A.; Al-Harbi, F.A. Translucency of nanoparticle-reinforced PMMA denture base material: An in-vitro comparative study. Dent. Mater. J. 2021, 40, 972–978. [Google Scholar] [CrossRef] [PubMed]

- Taymour, N.; Fahmy, A.E.; Gepreel, M.A.H.; Kandil, S.; El-Fattah, A.A. Improved Mechanical Properties and Bioactivity of Silicate Based Bioceramics Reinforced Poly(ether-ether-ketone) Nanocomposites for Prosthetic Dental Implantology. Polymers 2022, 14, 1632. [Google Scholar] [CrossRef] [PubMed]

- Bayarsaikhan, E.; Lim, J.-H.; Shin, S.-H.; Park, K.-H.; Park, Y.-B.; Lee, J.-H.; Kim, J.-E. Effects of Postcuring Temperature on the Mechanical Properties and Biocompatibility of Three-Dimensional Printed Dental Resin Material. Polymers 2021, 13, 1180. [Google Scholar] [CrossRef] [PubMed]

- Aati, S.; Akram, Z.; Shrestha, B.; Patel, J.; Shih, B.; Shearston, K.; Ngo, H.; Fawzy, A. Effect of post-curing light exposure time on the physico–mechanical properties and cytotoxicity of 3D-printed denture base material. Dent. Mater. 2022, 38, 57–67. [Google Scholar] [CrossRef] [PubMed]

- Kim, D.; Shim, J.-S.; Lee, D.; Shin, S.-H.; Nam, N.-E.; Park, K.-H.; Shim, J.-S.; Kim, J.-E. Effects of Post-Curing Time on the Mechanical and Color Properties of Three-Dimensional Printed Crown and Bridge Materials. Polymers 2020, 12, 2762. [Google Scholar] [CrossRef] [PubMed]

- Chen, H.; Cheng, D.-H.; Huang, S.-C.; Lin, Y.-M. Comparison of flexural properties and cytotoxicity of interim materials printed from mono-LCD and DLP 3D printers. J. Prosthet. Dent. 2021, 126, 703–708. [Google Scholar] [CrossRef]

- Steyrer, B.; Neubauer, P.; Liska, R.; Stampfl, J. Visible Light Photoinitiator for 3D-Printing of Tough Methacrylate Resins. Materials 2017, 10, 1445. [Google Scholar] [CrossRef]

- Franz, A.; König, F.; Lucas, T.; Watts, D.C.; Schedle, A. Cytotoxic effects of dental bonding substances as a function of degree of conversion. Dent. Mater. 2009, 25, 232–239. [Google Scholar] [CrossRef]

- Azmy, E.; Al-Kholy, M.R.Z.; Al-Thobity, A.M.; Gad, M.M.; Helal, M.A. Comparative Effect of Incorporation of ZrO2, TiO2, and SiO2 Nanoparticles on the Strength and Surface Properties of PMMA Denture Base Material: An In Vitro Study. Int. J. Biomater. 2022, 2022, 5856545. [Google Scholar] [CrossRef]

- Pai, E.; Nayak, A.; Hallikerimath, R.; Ruttonji, Z.; Astagi, P.; Pokale, S. Comparison of titanium dioxide nanoparticles and silver nanoparticles for flexural strength once incorporated in heat-cure acrylic denture base resin: An in vitro Study. J. Indian Prosthodont. Soc. 2023, 23, 127–134. [Google Scholar] [CrossRef] [PubMed]

- Abdelraouf, R.M.; Bayoumi, R.E.; Hamdy, T.M. Influence of Incorporating 5% Weight Titanium Oxide Nanoparticles on Flexural Strength, Micro-Hardness, Surface Roughness and Water Sorption of Dental Self-Cured Acrylic Resin. Polymers 2022, 14, 3767. [Google Scholar] [CrossRef] [PubMed]

- Jindal, P.; Juneja, M.; Bajaj, D.; Siena, F.L.; Breedon, P. Effects of post-curing conditions on mechanical properties of 3D printed clear dental aligners. Rapid Prototyp. J. 2020, 26, 1337–1344. [Google Scholar] [CrossRef]

- Aromaa, M.K.; Vallittu, P.K. Delayed post-curing stage and oxygen inhibition of free-radical polymerization of dimethacrylate resin. Dent. Mater. 2018, 34, 1247–1252. [Google Scholar] [CrossRef]

- Lee, E.-H.; Ahn, J.-S.; Lim, Y.-J.; Kwon, H.-B.; Kim, M.-J. Effect of post-curing time on the color stability and related properties of a tooth-colored 3D-printed resin material. J. Mech. Behav. Biomed. Mater. 2022, 126, 104993. [Google Scholar] [CrossRef] [PubMed]

- Monzón, M.; Ortega, Z.; Hernández, A.; Paz, R.; Ortega, F. Anisotropy of Photopolymer Parts Made by Digital Light Processing. Materials 2017, 10, 64. [Google Scholar] [CrossRef]

- Hague, R.; Mansour, S.; Saleh, N.; Harris, R. Materials analysis of stereolithography resins for use in Rapid Manufacturing. J. Mater. Sci. 2004, 39, 2457–2464. [Google Scholar] [CrossRef]

- Al-Dwairi, Z.N.; Ebrahim, A.A.A.H.; Baba, N.Z. A Comparison of the Surface and Mechanical Properties of 3D Printable Denture-Base Resin Material and Conventional Polymethylmethacrylate (PMMA). J. Prosthodont. 2023, 32, 40–48. [Google Scholar] [CrossRef] [PubMed]

- Momper, R.; Landeta, A.I.; Yang, L.; Halim, H.; Therien-Aubin, H.; Bodenschatz, E.; Landfester, K.; Riedinger, A. Plasmonic and Semiconductor Nanoparticles Interfere with Stereolithographic 3D Printing. ACS Appl. Mater. Interfaces 2020, 12, 50834–50843. [Google Scholar] [CrossRef] [PubMed]

- Naji, S.A.; Behroozibakhsh, M.; Kashi, T.S.J.; Eslami, H.; Masaeli, R.; Mahgoli, H.; Tahriri, M.; Lahiji, M.G.; Rakhshan, V. Effects of incorporation of 2.5 and 5 wt% TiO2 nanotubes on fracture toughness, flexural strength, and microhardness of denture base poly methyl methacrylate (PMMA). J. Adv. Prosthodont. 2018, 10, 113–121. [Google Scholar] [CrossRef] [PubMed]

- Alhotan, A.; Yates, J.; Zidan, S.; Haider, J.; Silikas, N. Flexural Strength and Hardness of Filler-Reinforced PMMA Targeted for Denture Base Application. Materials 2021, 14, 2659. [Google Scholar] [CrossRef]

- Lin, C.-H.; Lin, Y.-M.; Lai, Y.-L.; Lee, S.-Y. Mechanical properties, accuracy, and cytotoxicity of UV-polymerized 3D printing resins composed of Bis-EMA, UDMA, and TEGDMA. J. Prosthet. Dent. 2020, 123, 349–354. [Google Scholar] [CrossRef]

- Reymus, M.; Fabritius, R.; Keßler, A.; Hickel, R.; Edelhoff, D.; Stawarczyk, B. Fracture load of 3D-printed fixed dental prostheses compared with milled and conventionally fabricated ones: The impact of resin material, build direction, post-curing, and artificial aging—An in vitro study. Clin. Oral Investig. 2020, 24, 701–710. [Google Scholar] [CrossRef]

- Hanon, M.M.; Zsidai, L. Tribological and mechanical properties investigation of 3D printed polymers using DLP technique. In Proceedings of the 2nd International Conference on Materials Engineering & Science (IConMEAS 2019), Baghdad, Iraq, 25–29 September 2019; AIP Publishing: New York, NY, USA; Volume 2213, p. 020205. [Google Scholar]

| (ASIGA) | NextDent | |

|---|---|---|

| Materials/Brand name | DentaBASE ASIGA, Erfurt, Germany | Denture 3D+ NextDent B.V., Soesterberg, The Netherlands |

| Composition | Ethoxylated bisphenol A dimethacrylate 7,7,9 (or 7,9,9)-trimethyl-4,13-dioxo-3,14-dioxa-5,12-diazahexadecane-1,16-diyl bismethacrylate 2- hydroxyethyl methacrylate silicon dioxide diphenyl (2,4,6-trimethylbenzoyl) phosphine oxide titanium dioxide | Ester-based monomer; Bisacylphosphine oxide (BAPO) phenylbis (2,4,6-trimethylbenzoyl)-phosphine oxide (Omnirad 819) |

| Printer | ASIGA MAX™ | NextDent 5100 |

| Printing technology | DLP | SLA |

| Printing layer thickness | 50 µm | 50 µm |

| Printing orientation | 90 degrees | 90 degrees |

| Post-curing machine | ASIGA-Flash | LC-D Print Box |

| Post-curing time | 15 min, 60 min, and 90 min | 15 min, 60 min, and 90 min |

| Post-curing temperature | 60 °C | 60 °C |

| Properties | Materials | TNPs% | Time | p-Value | ||

|---|---|---|---|---|---|---|

| 15 min | 60 min | 90 min | ||||

| Flexural strength | ASIGA | 0% | 73.3 (2.6) | 81.1 (2.4) a | 87.3 (3.2) | 0.000 * |

| 1% | 76.0 (3.3) A | 81.5 (2.8) a,A | 91.4 (9.8) | 0.000 * | ||

| 2% | 77.7 (9.5) | 86.6 (2.9) A | 90.4 (2.9) A | 0.000 * | ||

| p-value | 0.281 | 0.000 * | 0.323 | |||

| NextDent | 0% | 72.3 (2.8) | 79.9 (2.6) | 85.2 (1.8) | 0.000 | |

| 1% | 78.1 (3.2) | 87.1 (1.6) a | 92.0 (2.4) a | 0.000 | ||

| 2% | 83.2 (4.3) A | 87.3 (3.4) a,A | 93.6 (4.1) a | 0.000 | ||

| p-value | 0.000 * | 0.000 * | 0.000 * | |||

| Elastic modulus | ASIGA | 0% | 3511.0 (132.5) | 3641.3 (220.9) | 3585.7 (156.6) a,b | 0.262 |

| 1% | 3534.6 (236.7) A,B | 3356.4 (260.8) A | 3637.9 (187.3) a,B | 0.035 * | ||

| 2% | 3406.8 (285.6) | 3583.2 (391.5) | 3356.4 (304.8) b | 0.290 | ||

| p-value | 0.421 | 0.10 | 0.022 * | |||

| NextDent | 0% | 3579.9 (399.6) a | 3726.1 (436.2) a | 3928.8 (509.7) | 0.239 | |

| 1% | 3548.6 (229.1) a | 4088.3 (187.6) b,A | 4243.6 (173.2) A | 0.000 * | ||

| 2% | 3181.0 (259.9) | 3779.9 (166.6) a,b | 4062.5 (92.9) | 0.000 * | ||

| p-value | 0.012 * | 0.020 * | 0.10 | |||

| Hardness | ASIGA | 0% | 15.2 (5.4) A | 16.8 (2.8) A,B | 19.7 (2.1) a,B | 0.038 * |

| 1% | 15.9 (2.2) | 15.3 (6.2) | 16.4 (6.4) a,b | 0.892 | ||

| 2% | 11.9 (3.4) | 12.4 (3.9) | 14.9 (2.5) b | 0.122 | ||

| p-value | 0.067 | 0.105 | 0.043 * | |||

| NextDent | 0% | 15.5 (4.9) A | 16.9 (3.9) A,B | 20.7 (3.7) B | 0.029 * | |

| 1% | 16.5 (5.7) | 18.8 (5.2) | 18.9 (4.4) | 0.516 | ||

| 2% | 16.6 (9.0) | 18.6 (6.4) | 18.5 (2.1) | 0.741 | ||

| p-value | 0.918 | 0.683 | 0.353 | |||

| Tested Properties | Source | Type III Sum of Squares | df | Mean Square | F | Sig. |

|---|---|---|---|---|---|---|

| Flexural strength | Corrected Model | 7087.190 a | 17 | 416.894 | 22.815 | <0.001 * |

| Intercept | 1,257,044.898 | 1 | 1,257,044.898 | 68,792.949 | <0.001 * | |

| time * concen | 55.998 21.409 197.040 105.164 | 4 2 2 4 | 14.000 | 0.766 | 0.549 | |

| time * resin concen * resin | 10.705 98.520 26.291 | 0.586 5.392 | 0.558 | |||

| 0.005 * | ||||||

| time * concen * resin | 1.439 | 0.224 | ||||

| Error | 2960.206 | 162 | 18.273 | |||

| Total | 1,267,092.293 | 180 | ||||

| Corrected Total | 10,047.395 | 179 | ||||

| a. R Squared = 0.705 (Adjusted R Squared = 0.674) | ||||||

| Elastic modulus | Corrected Model | 13,229,873.357 a | 17 | 778,227.845 | 9.940 | <0.001 * |

| Intercept | 2,401,859,264.539 | 1 | 2,401,859,264.5 | 30,676.787 | <0.001 * | |

| time * concen | 539,974.604 | 4 | 134,993.651 | 1.724 | 0.147 | |

| time * resin concen * resin | 2,767,384.066 | 2 | 1,383,692.03 | 17.673 4.322 | <0.001 * 0.015 * | |

| 676,772.858 | 2 | 338,386.429 | ||||

| time * concen * resin | 1,116,207.931 | 4 | 279,051.983 | 3.564 | 0.008 * | |

| Error | 12,683,896.631 | 162 | 78,295.658 | |||

| Total | 2,427,773,034.527 | 180 | ||||

| Corrected Total | 25,913,769.988 | 179 | ||||

| a. R Squared = 0.511 (Adjusted R Squared = 0.459) | ||||||

| Hardness | Corrected Model | 921.092 a | 17 | 54.182 | 2.325 | 0.003 * |

| Intercept | 49,926.694 | 1 | 49,926.694 | 2142.394 | <0.001 * | |

| time * concen | 69.218 | 4 | 17.304 | 0.743 | 0.564 | |

| time * resin | 16.508 | 2 | 8.254 | 0.354 | 0.702 | |

| concen * resin | 145.005 | 2 | 72.502 | 3.111 | 0.047 * | |

| time * concen * resin | 26.349 | 4 | 6.587 | 0.283 | 0.889 | |

| Error | 3775.274 | 162 | 23.304 | |||

| Total | 54,623.060 | 180 | ||||

| Corrected Total | 4696.366 | 179 | Corrected Total | |||

| a. R Squared = 0.196 (Adjusted R Squared = 0.112) | ||||||

| Tested Properties | Concentration | Resin | Time | ||

|---|---|---|---|---|---|

| 15 min | 60 min | 90 min | |||

| Flexural strength | 0% | ASIGA | 73.34 (2.6) | 81.13 (2.4) | 87.3 (3.2) |

| NextDent | 72.34 (2.8) | 79.88 (2.6) | 85.2 (1.9) | ||

| P | 0.421 | 0.284 | 0.082 | ||

| 1% | ASIGA | 76.03 (3.29) | 81.49 (2.8) | 91.36 (9.7) | |

| NextDent | 78.08(3.2) | 87.1 (1.6) | 92.03 (2.4) | ||

| P | 0.721 | 0.000 * | 0.837 | ||

| 2% | ASIGA | 77.7 (9.5) | 86.6 (2.9) | 90.4 (2.9) | |

| NextDent | 83.3 (4.3) | 87.3 (3.4) | 93.6 (4.1) | ||

| P | 0.110 | 0.610 | 0.064 | ||

| Elastic Modulus | 0% | ASIGA | 3511.0 (132.5) | 3641.29 (220.9) | 3585.7 (156.6) |

| NextDent | 3579.9 (399.6) | 3726.13 (436.2) | 3928.8 (509.8) | ||

| P | 0.611 | 0.59 | 0.057 | ||

| 1% | ASIGA | 3534.56 (236.7) | 3356.47 (260.8) | 3637.8 (187.3) | |

| NextDent | 3548.58 (229.1) | 4088.35 (187.6) | 4243.6 (173.3) | ||

| P | 0.894 | <0.001 * | <0.001 * | ||

| 2% | ASIGA | 3406.8 (285.6) | 3583.2 (391.5) | 3356.3 (304.8) | |

| NextDent | 3181.0 (259.9) | 3779.9 (166.5) | 4062.5 (92.9) | ||

| P | 0.081 | 0.161 | 0.000 * | ||

| Hardness | 0% | ASIGA | 15.23 (5.4) | 16.48 (2.8) | 19.68 (2.1) |

| NextDent | 15.49 (4.9) | 16.95 (3.9) | 20.69 (3.7) | ||

| P | 0.912 | 0.943 | 0.464 | ||

| 1% | ASIGA | 15.9 (2.2) | 15.3 (6.2) | 16.4 (6.3) | |

| NextDent | 16.6 (5.7) | 18.8 (5.2) | 18.9 (4.5) | ||

| P | 0.757 | 0.186 | 0.320 | ||

| 2% | ASIGA | 11.9 (3.4) | 12.4 (3.9) | 14.9 (2.5) | |

| NextDent | 16.6 (9.0) | 18.6 (6.4) | 18.4 (2.1) | ||

| P | 0.143 | 0.017 * | 0.003 * | ||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

AlGhamdi, M.A.; Fouda, S.M.; Taymour, N.; Akhtar, S.; Khan, S.Q.; Ali, M.S.; Elakel, A.M.; Nassar, E.A.; Gad, M.M. Comparative Evaluation of TiO2 Nanoparticle Addition and Postcuring Time on the Flexural Properties and Hardness of Additively Fabricated Denture Base Resins. Nanomaterials 2023, 13, 3061. https://doi.org/10.3390/nano13233061

AlGhamdi MA, Fouda SM, Taymour N, Akhtar S, Khan SQ, Ali MS, Elakel AM, Nassar EA, Gad MM. Comparative Evaluation of TiO2 Nanoparticle Addition and Postcuring Time on the Flexural Properties and Hardness of Additively Fabricated Denture Base Resins. Nanomaterials. 2023; 13(23):3061. https://doi.org/10.3390/nano13233061

Chicago/Turabian StyleAlGhamdi, Maram A., Shaimaa M. Fouda, Noha Taymour, Sultan Akhtar, Soban Q. Khan, Mohamed S. Ali, Ahmed M. Elakel, Essam A. Nassar, and Mohammed M. Gad. 2023. "Comparative Evaluation of TiO2 Nanoparticle Addition and Postcuring Time on the Flexural Properties and Hardness of Additively Fabricated Denture Base Resins" Nanomaterials 13, no. 23: 3061. https://doi.org/10.3390/nano13233061

APA StyleAlGhamdi, M. A., Fouda, S. M., Taymour, N., Akhtar, S., Khan, S. Q., Ali, M. S., Elakel, A. M., Nassar, E. A., & Gad, M. M. (2023). Comparative Evaluation of TiO2 Nanoparticle Addition and Postcuring Time on the Flexural Properties and Hardness of Additively Fabricated Denture Base Resins. Nanomaterials, 13(23), 3061. https://doi.org/10.3390/nano13233061