Processing and Characterization of UV Irradiated HDPE/POSS Fibers

Abstract

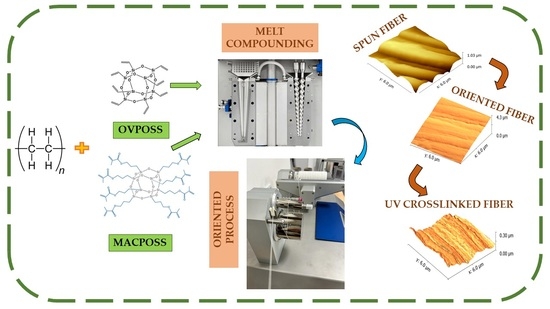

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Fiber Spinning and UV Cross-Linking

2.3. Characterization

2.3.1. Fourier Transform Infrared Spectroscopy Analyses

2.3.2. Gel Content Measurements

2.3.3. Mechanical Properties

2.3.4. Morphological Analyses

2.3.5. X-ray Diffraction Analyses

2.3.6. Thermal Analyses

3. Results and Discussions

3.1. Chemical Properties and Gel Content of Samples

3.2. Mechanical Properties

3.3. Morphology

3.4. Crystal Structure

3.5. Thermal Properties

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Roiron, C.; Lainé, E.; Grandidier, J.-C.; Garois, N.; Vix-Guterl, C. A review of the mechanical and physical properties of polyethylene fibers. Textiles 2021, 1, 86–151. [Google Scholar] [CrossRef]

- Penning, J.P.; Pras, H.E.; Pennings, A.J. Influence of chemical crosslinking on the creep behavior of ultra-high molecular weight polyethylene fibers. Colloid Polym. Sci. 1994, 272, 664–676. [Google Scholar] [CrossRef]

- Powell, A.K.; Craggs, G.; Ward, I.M. The structure and properties of oriented chain extended polyethylenes. J. Mater. Sci. 1990, 25, 3990–4000. [Google Scholar] [CrossRef]

- Perkins, W.G.; Porter, R.S. Solid-state deformation of polyethylene and nylon and its effects on their structure and morphology. J. Mater. Sci. 1977, 12, 2355–2388. [Google Scholar] [CrossRef]

- Sibson, A.G.; Ward, I.M.; Cole, B.N.; Parsons, B. Hydrostatic extrusion of linear polyethylene. J. Mater. Sci. 1974, 9, 1193. [Google Scholar]

- Pennings, A.J.; Schouteten, C.J.; Kiel, A.M. Hydrodynamically induced crystallization of polymers from solution.V.Tensile properties of fibrillar polyethylene crystals. J. Polym. Sci. Polym. Symp. 1972, 38, 167–192. [Google Scholar] [CrossRef]

- Smith, P.; Lemstra, P.J.; Kalb, B.; Pennings, A.J. Ultrahigh-strength polyethylene filaments by solution spinning and hot drawing. J. Polym. Bull. 1979, 1, 733–736. [Google Scholar] [CrossRef]

- Maghsoud, Z.; Moaddel, H. Gel spinning characteristics of ultra-high molecular weight polyethylene and study on fibre structure before drawing. Iran. Polym. J. 2007, 16, 363–373. [Google Scholar]

- Kanamoto, T.; Tsuruta, A.; Tanaka, K.; Takeda, M. Superdrawing of ultrahigh molecular weight polyethylene. 1. Effect of techniques on drawing of single crystal mats. Macromolecules 1988, 21, 470–477. [Google Scholar] [CrossRef]

- Andrews, J.M.; Ward, I.M. The cold-drawing of high density polyethylene. J. Mater. Sci. 1970, 5, 411–417. [Google Scholar] [CrossRef]

- Smith, P.; Lemstra, P.J. Ultra-high-strength polyethylene filaments by solution spinning/drawing. J. Mater. Sci. 1980, 15, 505–514. [Google Scholar] [CrossRef]

- Smith, P.; Lemstra, P.J. Ultrahigh-strength polyethylene filaments by solution spinning/drawing 2. Influence of solvent on the drawability. Macromol. Chem. 1979, 180, 2983–2986. [Google Scholar] [CrossRef]

- Smith, P.; Lemstra, P.J.; Booij, H.C. Ultradrawing of high-molecular-weight polyethylene cast from solution. II. Influence of initial polymer concentration. J. Polym. Sci. Part B Polym. Phys. 1981, 19, 877–888. [Google Scholar] [CrossRef]

- Shabani, E.; Gorga, R.E. Effect of the spin-line temperature profile on the mechanical properties of melt electrospun polyethylene fibers. J. Appl. Polym. Sci. 2021, 138, 50668. [Google Scholar] [CrossRef]

- Rein, D.M.; Shavit-Hadar, L.; Khalfin, L.R.; Cohen, L.Y.; Shuster, K.; Zussman, E. Electrospinning of ultrahigh-molecular-weight polyethylene nanofibers. J. Polym. Sci. Part B Polym. Phys. 2007, 45, 766–773. [Google Scholar] [CrossRef]

- Rajput, A.W.; Aleem, A.U.; Arain, F.A. An environmentally friendly process for the preparation of UHMWPE as-spun fibres. Int. J. Polym. Sci. 2014, 2014, 480149. [Google Scholar] [CrossRef]

- Wang, F.; Liu, L.; Xue, P.; Jia, M.; Wang, S.; Cai, J. The influence of formation temperatures on the crystal structure and mechanical properties of ultrahigh-molecular-weight polyethylene/high-density polyethylene blend fibers prepared by melt spinning. J. Ind. Text. 2020, 49, 1011–1035. [Google Scholar] [CrossRef]

- Chantrasakul, S.; Amornsakchai, T. High strength polyethylene fibers from high density polyethylene/organoclay composites. Polym. Eng. Sci. 2007, 47, 943–950. [Google Scholar] [CrossRef]

- Yeh, J.-T.; Wang, C.-K.; Yu, W.; Huang, K.-S. Ultradrawing and ultimate tensile properties of ultrahigh molecular weight polyethylene composite fibers filled with functionalized nanoalumina fillers. Polym. Eng. Sci. 2015, 55, 2205–2214. [Google Scholar] [CrossRef]

- Yeh, J.-T.; Wang, C.-K.; Hu, P.; Lai, Y.-C.; Huang, L.-K.; Tsai, F.-C. Ultradrawing properties of ultra high-molecular weight polyethylene/attapulgite fibers. Polym. Int. 2012, 61, 982–989. [Google Scholar] [CrossRef]

- Kuo, S.-W.; Chang, F.-C. POSS related polymer nanocomposites. Prog. Polym. Sci. 2011, 36, 1649–1696. [Google Scholar] [CrossRef]

- Li, G.; Wang, L.; Ni, H.; Pittman, C.U. Polyhedral oligomeric silsesquioxane (POSS) polymers and copolymers: A review. J. Inorg. Organomet. Polym. 2001, 11, 123–154. [Google Scholar] [CrossRef]

- Zhang, W.; Fu, B.X.; Seo, Y.; Schrag, E.; Hsiao, B.; Mather, P.T.; Yang, N.L.; Xu, D.; Ade, H.; Rafailovich, M.; et al. Effect of methyl methacrylate/polyhedral oligomeric silsesquioxane random copolymers in compatibilization of polystyrene and poly(methyl methacrylate) blends. Macromolecules 2002, 35, 8029–8038. [Google Scholar] [CrossRef]

- Sirin, H.; Turan, D.; Ozkoc, G.; Gurdag, S. POSS reinforced PET based composite fibers: “Effect of POSS type and loading level”. Compos. Part B Eng. 2013, 53, 395–403. [Google Scholar] [CrossRef]

- Jia, L.; Ma, J.; Gao, D.; Tait, W.R.T.; Sun, L. A star-shaped POSS-containing polymer for cleaner leather processing. J. Hazard. Mater. 2019, 361, 305–311. [Google Scholar] [CrossRef] [PubMed]

- Li, Z.; Kong, J.; Wang, F.K.; He, C. Polyhedral oligomeric silsesquioxanes (POSSs): An important building block for organic optoelectronic materials. J. Mater. Chem. C 2017, 5, 5283–5298. [Google Scholar] [CrossRef]

- Bicer, E.; Demir, G.K.; Kodal, M.; Ozkoc, G. Crosslinked low-density polyethylene/polyhedral oligomeric silsesquioxanes composites: Effects of crosslinker concentration on the mechanical, thermal, rheological, and shape memory properties. J. Macromol. Sci. Part B 2021, 60, 999–1024. [Google Scholar] [CrossRef]

- Cozza, E.S.; Ma, Q.; Monticelli, O.; Cebe, P. Nanostructured nanofibers based on PBT and POSS: Effect of POSS on the alignment and macromolecular orientation of the nanofibers. Eur. Polym. J. 2013, 49, 33–40. [Google Scholar] [CrossRef]

- Tutak, M.; Dogan, M. Development of bio-active polypropylene fiber containing QA-POSS nanoparticles. Fibers Polym. 2015, 16, 2337–2342. [Google Scholar] [CrossRef]

- Boer, J.; Pennings, A.J. Crosslinking of ultra-high strength polyethylene fibers by means of γ -radiation. Polym. Bull. 1981, 5, 317–324. [Google Scholar] [CrossRef]

- Gao, C.; Li, S.; Song, H.; Xie, L. Radiation-induced crosslinking of ultra high molecular weight polyethylene fibers by means of electron beams. J. Appl. Polym. Sci. 2005, 98, 1761–1764. [Google Scholar] [CrossRef]

- Chodák, I. High modulus polyethylene fibres: Preparation, properties and modification by crosslinking. Prog. Polym. Sci. 1998, 23, 1409–1442. [Google Scholar] [CrossRef]

- ASTM D2765-16; American Society for Testing Materials; Standard Test Methods for Determination of Gel Content and Swell Ratio of Crosslinked Ethylene Plastics. ASTM International: West Conshohocken, PA, USA, 2016.

- Bandeira, B.; Lewis, E.L.V.; Barton, D.C.; Ward, I.M. The degree of crystalline orientation as a function of draw ratio in semicrystalline polymers: A new model based on the geometry of the crystalline chain slip mechanism. J. Mater. Sci. 2016, 51, 228–235. [Google Scholar] [CrossRef]

- Ellison, M.S.; Lopes, P.E.; Pennington, W.T. In-situ X-ray characterization of fiber structure during melt spinning. J. Eng. Fibers Fabr. 2008, 3, 10–21. [Google Scholar] [CrossRef]

- Monshi, A.; Foroughi, M.R.; Monshi, M.R. Modified Scherrer equation to estimate more accurately nano-crystallite size using XRD. World J. Nano Sci. Eng. 2012, 2, 154–160. [Google Scholar] [CrossRef]

- Wu, J.; Wu, Z.L.; Yang, H.; Zheng, Q. Crosslinking of low density polyethlyene with octavinyl polyhedral oligomeric silsesquioxane as the crosslinker. R. Soc. Chem. Adv. 2014, 4, 44030–44038. [Google Scholar] [CrossRef]

- Jabarin, S.A.; Lofgren, E.A. Photooxidative effects of properties and structure of high-density polyethylene. J. Apply Polym. Sci. 1994, 53, 411–423. [Google Scholar] [CrossRef]

- Tidjani, A. Comparison of formation of oxidation products during photo-oxidation of linear low density polyethylene under different natural and accelerated weathering conditions. Polym. Degrad. Stab. 2000, 68, 465–469. [Google Scholar] [CrossRef]

- David, C.; Trojan, M.; Daro, A.; Demarteau, W. Photodegradation of polyethylene: Comparison of various photoinitiators in natural weathering conditions. Polym. Degrad. Stab. 1992, 37, 233–245. [Google Scholar] [CrossRef]

- Ouyang, B.; Li, H.; Zhang, X.; Wang, S.; Li, J. The role of micro-structure changes on space charge distribution of XLPE dur-ing thermo-oxidative ageing. IEEE Trans. Dielectr. Electr. Insul. 2017, 24, 3849–3859. [Google Scholar] [CrossRef]

- Amin, A.-R. Synergistic effect of TNPP and carbon black in weathered XLPE materials. J. Polym. Environ. 2009, 17, 267. [Google Scholar] [CrossRef]

- Boukezzi, L.; Boubakeur, A.; Laurent, C.; Lallouani, M. Observations on structural changes under thermal ageing of cross-linked polyethylene used as power cables insulation. Iran. Polym. J. 2008, 17, 611. [Google Scholar]

- Kodal, M.; Wis, A.A.; Ozkoc, G. The mechanical, thermal and morphological properties of γ-irradiated PLA/TAIC and PLA/OvPOSS. Radiat. Phys. Chem. 2018, 153, 214–225. [Google Scholar] [CrossRef]

- Wang, Y.; Liu, F.; Xue, X. Morphology and properties of UV-curing epoxy acrylate coatings modified with Methacryl-POSS. Prog. Org. Coat. 2015, 78, 404–410. [Google Scholar] [CrossRef]

- Morgan, L.B. Crystallization phenomena in fibre-forming polymers. J. Appl. Chem. 1954, 4, 160. [Google Scholar] [CrossRef]

- Yao, F.; Wu, Q.; Lei, Y.; Xu, Y. Rice straw fiber-reinforced high-density polyethylene composite: Effect of fiber type and loading. Ind. Crops Prod. 2008, 28, 63–72. [Google Scholar] [CrossRef]

- Siddiqui, M.N.; Redhwi, H.H.; Younas, M.; Alghizzi, A.G.; Suliman, M.H.; Achilias, D.S. Effect of natural macromolecule filler on the properties of high-density polyethylene (HDPE). Macromol. Symp. 2018, 380, 1800072. [Google Scholar] [CrossRef]

- Zhu, B.; Liu, J.; Wang, T.; Han, M.; Valloppilly, S.; Xu, S.; Wang, X. Novel polyethylene fibers of very high thermal conductivity enabled by amorphous restructuring. ACS Omega 2017, 2, 3931–3944. [Google Scholar] [CrossRef] [PubMed]

- Yeh, J.-T.; Tsai, C.-C.; Wang, C.-K.; Shao, J.-W.; Xiao, M.-Z.; Chen, S.-c. Ultradrawing novel ultra-high molecular weight polyethylene fibers filled with bacterial cellulose nanofibers. Carbohydr. Polym. 2014, 101, 1–10. [Google Scholar] [CrossRef]

- Valadez-González, A.; Veleva, L. Mineral filler influence on the photo-oxidation mechanismdegradation of high density polyethylene. Part II: Natural exposure test. Polym. Degrad. Stab. 2004, 83, 139–148. [Google Scholar] [CrossRef]

- Gulmine, J.V.; Akcelrud, L. Correlations between structure and accelerated artificial ageing of XLPE. Eur. Polym. J. 2006, 42, 553–562. [Google Scholar] [CrossRef]

| Sample Name | HDPE Content (phr) | POSS Content (phr) |

|---|---|---|

| Pure HDPE | 100 | - |

| HDPE/4 OVPOSS | 100 | 4 |

| HDPE/4 MACPOSS | 100 | 4 |

| Sample Name | Tensile Strength (MPa) | Elongation at Break (%) | Modulus (GPa) | Energy at Break (J) | |

|---|---|---|---|---|---|

| Spun | Pure HDPE | 24 ± 2 | 1007 ± 113 | 1.4 ± 0.1 | 0.315 ± 0.02 |

| HDPE/4 OVPOSS | 41 ± 4 | 797 ± 48 | 1.9 ± 0.2 | 0.335 ± 0.01 | |

| HDPE/4 MACPOSS | 25 ± 3 | 891 ± 133 | 1.5 ± 0.2 | 0.097 ± 0.03 | |

| Oriented | Pure HDPE | 265 ± 6 | 83 ± 23 | 1.5 ± 0.2 | 0.032 ± 0.01 |

| HDPE/4 OVPOSS | 279 ± 5 | 47 ± 8 | 2.4 ± 0.2 | 0.023 ± 0.02 | |

| HDPE/4 MACPOSS | 275 ± 3 | 64 ± 17 | 1.6 ± 0.2 | 0.024 ± 0.01 | |

| After UV | Pure HDPE | 264 ± 4 | 62 ± 14 | 2.2 ± 0.3 | 0.026 ± 0.03 |

| HDPE/4 OVPOSS | 293 ± 5 | 44 ± 20 | 2.8 ± 0.2 | 0.036 ± 0.04 | |

| HDPE/4 MACPOSS | 283 ± 2 | 63 ± 22 | 2.5 ± 0.2 | 0.030 ± 0.02 | |

| Sample Name | Average Fiber Diameters (µm) | ||

|---|---|---|---|

| Spun | Oriented | After UV | |

| Pure HDPE | 237 ± 22 | 92 ± 3 | 81 ± 19 |

| HDPE/4 OVPOSS | 237 ± 9 | 78 ± 8 | 78 ± 9 |

| HDPE/4 MACPOSS | 346 ± 27 | 93 ± 11 | 90 ± 11 |

| Sample Name | Crystallinity (%) | Crystal Thickness (nm) | ||||

| Spun | Oriented | After UV | Spun | Oriented | After UV | |

| Pure HDPE | 49 | 55 | 58 | 7.1 | 3.7 | 6.3 |

| HDPE/4 OVPOSS | 52 | 63 | 65 | 8.1 | 5.5 | 5.0 |

| HDPE/4 MACPOSS | 53 | 60 | 61 | 4.3 | 3.7 | 5.1 |

| Sample Name | Td,5 (°C) | Td,10 (°C) | Td,max (°C) | Residue Percentage (%) | |

|---|---|---|---|---|---|

| Spun | Pure HDPE | 445.6 | 456.7 | 473.7 | 2.6 |

| HDPE/4 OVPOSS | 450.8 | 456.7 | 475.2 | 3.7 | |

| HDPE/4 MACPOSS | 445.6 | 457.1 | 475.9 | 2.7 | |

| Oriented | Pure HDPE | 450.8 | 456.7 | 475.9 | 2.4 |

| HDPE/4 OVPOSS | 450.8 | 456.7 | 477.1 | 5.2 | |

| HDPE/4 MACPOSS | 450.8 | 456.7 | 478.7 | 4.8 | |

| After UV | Pure HDPE | 450.8 | 457.1 | 476.7 | 3.3 |

| HDPE/4 OVPOSS | 450.8 | 457.1 | 480.4 | 4.1 | |

| HDPE/4 MACPOSS | 450.8 | 456.7 | 478.8 | 4.1 | |

| Sample Name | Tm,onset (°C) | Tm,peak (°C) | Tm,endset (°C) | ΔHm (J/g) | Xc (%) | |

|---|---|---|---|---|---|---|

| Spun | Pure HDPE | 129 | 140 | 153 | 145.5 | 49.6 |

| HDPE/4 OVPOSS | 128 | 143 | 150 | 147.8 | 50.4 | |

| HDPE/4 MACPOSS | 127 | 146 | 148 | 154.4 | 52.7 | |

| Oriented | Pure HDPE | 132 | 142 | 150 | 158.5 | 56.3 |

| HDPE/4 OVPOSS | 130 | 140 | 149 | 172.4 | 60.6 | |

| HDPE/4 MACPOSS | 131 | 145 | 148 | 167.0 | 59.4 | |

| After UV | Pure HDPE | 130 | 139 | 150 | 159.8 | 54.5 |

| HDPE/4 OVPOSS | 131 | 141 | 152 | 169.4 | 60.2 | |

| HDPE/4 MACPOSS | 130 | 145 | 155 | 154.4 | 54.9 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Biçer, E.; Kodal, M.; Özkoç, G. Processing and Characterization of UV Irradiated HDPE/POSS Fibers. Nanomaterials 2023, 13, 3131. https://doi.org/10.3390/nano13243131

Biçer E, Kodal M, Özkoç G. Processing and Characterization of UV Irradiated HDPE/POSS Fibers. Nanomaterials. 2023; 13(24):3131. https://doi.org/10.3390/nano13243131

Chicago/Turabian StyleBiçer, Ezgi, Mehmet Kodal, and Güralp Özkoç. 2023. "Processing and Characterization of UV Irradiated HDPE/POSS Fibers" Nanomaterials 13, no. 24: 3131. https://doi.org/10.3390/nano13243131

APA StyleBiçer, E., Kodal, M., & Özkoç, G. (2023). Processing and Characterization of UV Irradiated HDPE/POSS Fibers. Nanomaterials, 13(24), 3131. https://doi.org/10.3390/nano13243131