Evaluation of Mask Performances in Filtration and Comfort in Fabric Combinations

Abstract

:1. Introduction

2. Materials and Experimental Methods

2.1. Materials

2.2. Characterization

2.2.1. Filtration Properties

2.2.2. Fabric Texture and Microstructure

2.2.3. Fabric Thickness

2.2.4. Fiber Diameter

2.2.5. Average Pore Size

2.2.6. Fabric Hand

2.2.7. Water Vapor Transmission Rate (WVTR)

2.2.8. Air Permeability

3. Results and Discussion

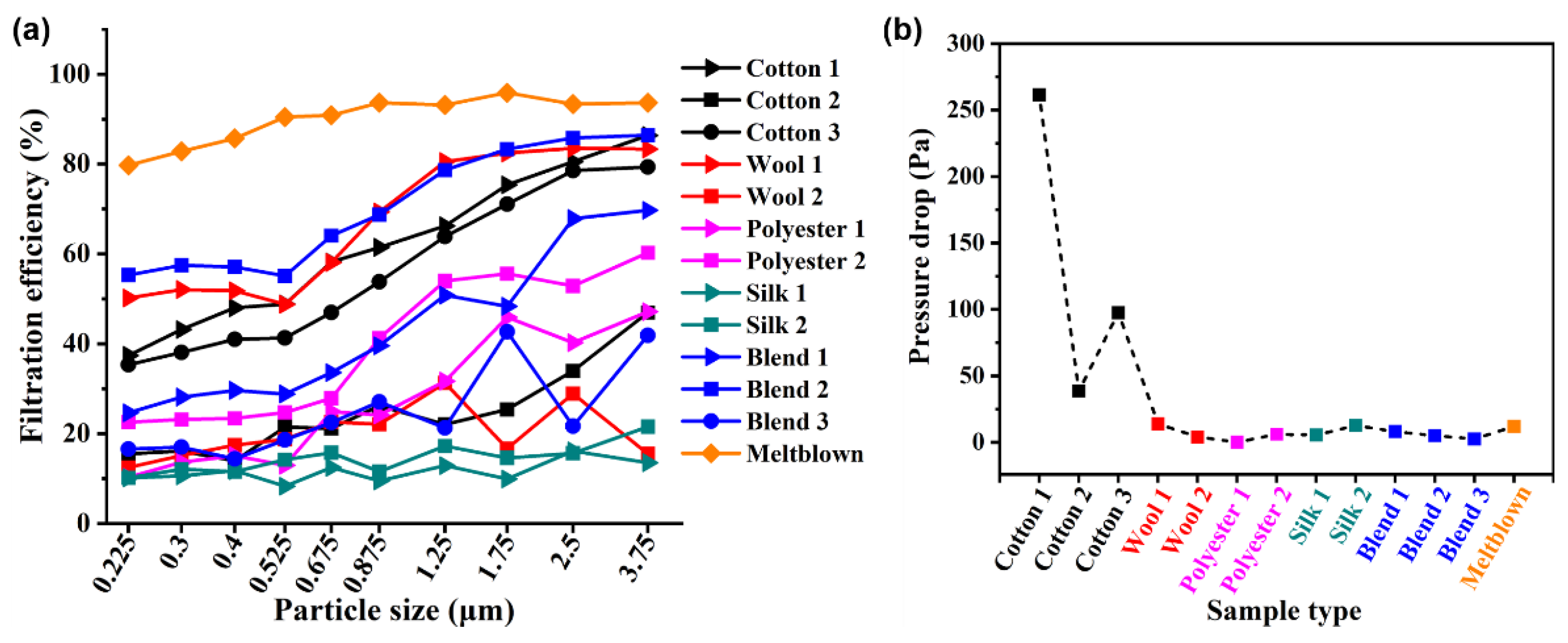

3.1. Fabric Comfort and Filtration Performances

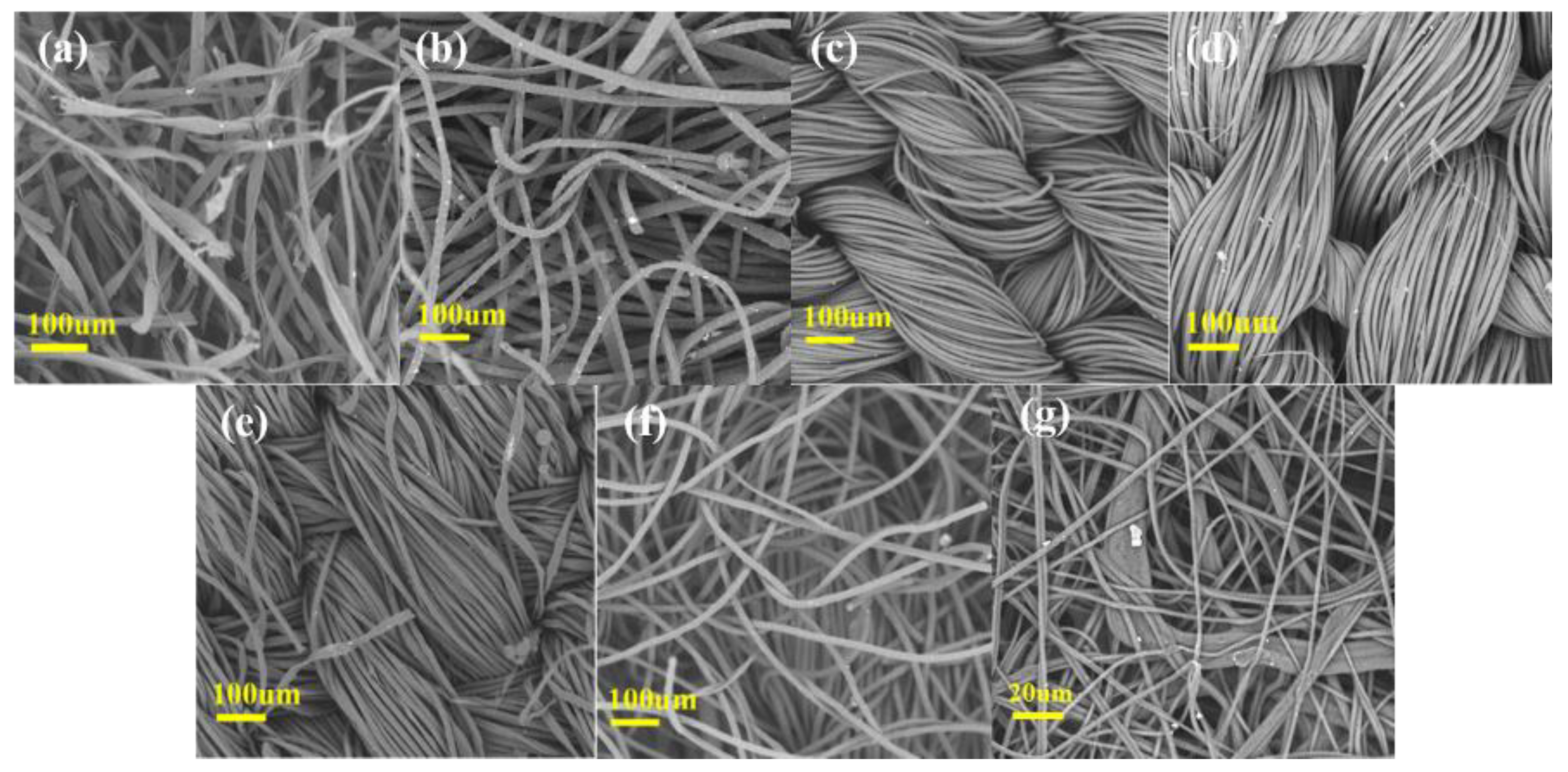

3.2. Influence of Surface Hairiness on Fabric Filtration Performance

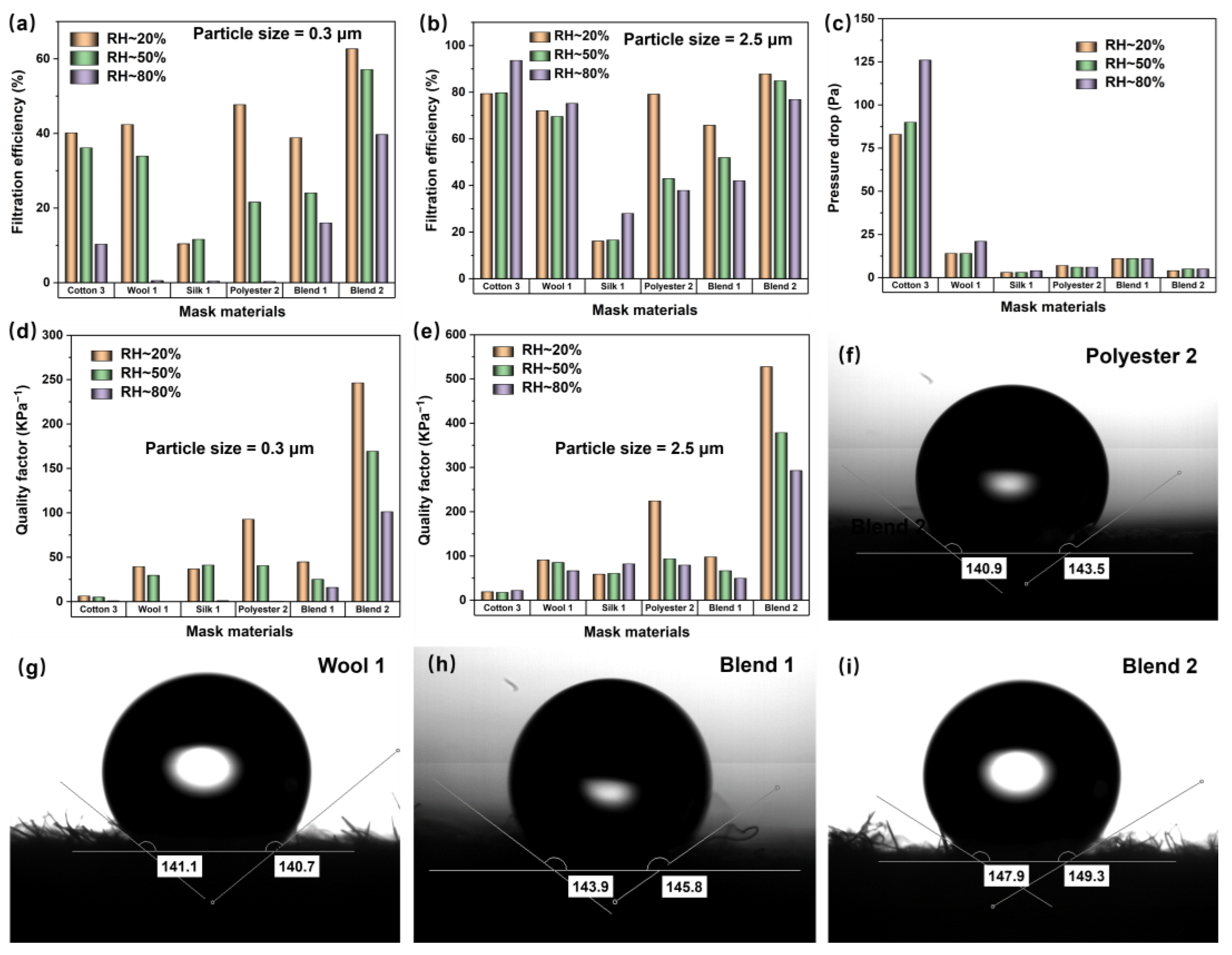

3.3. Influence of Ambient Humidity Effect on Fabric Filtration Efficiency

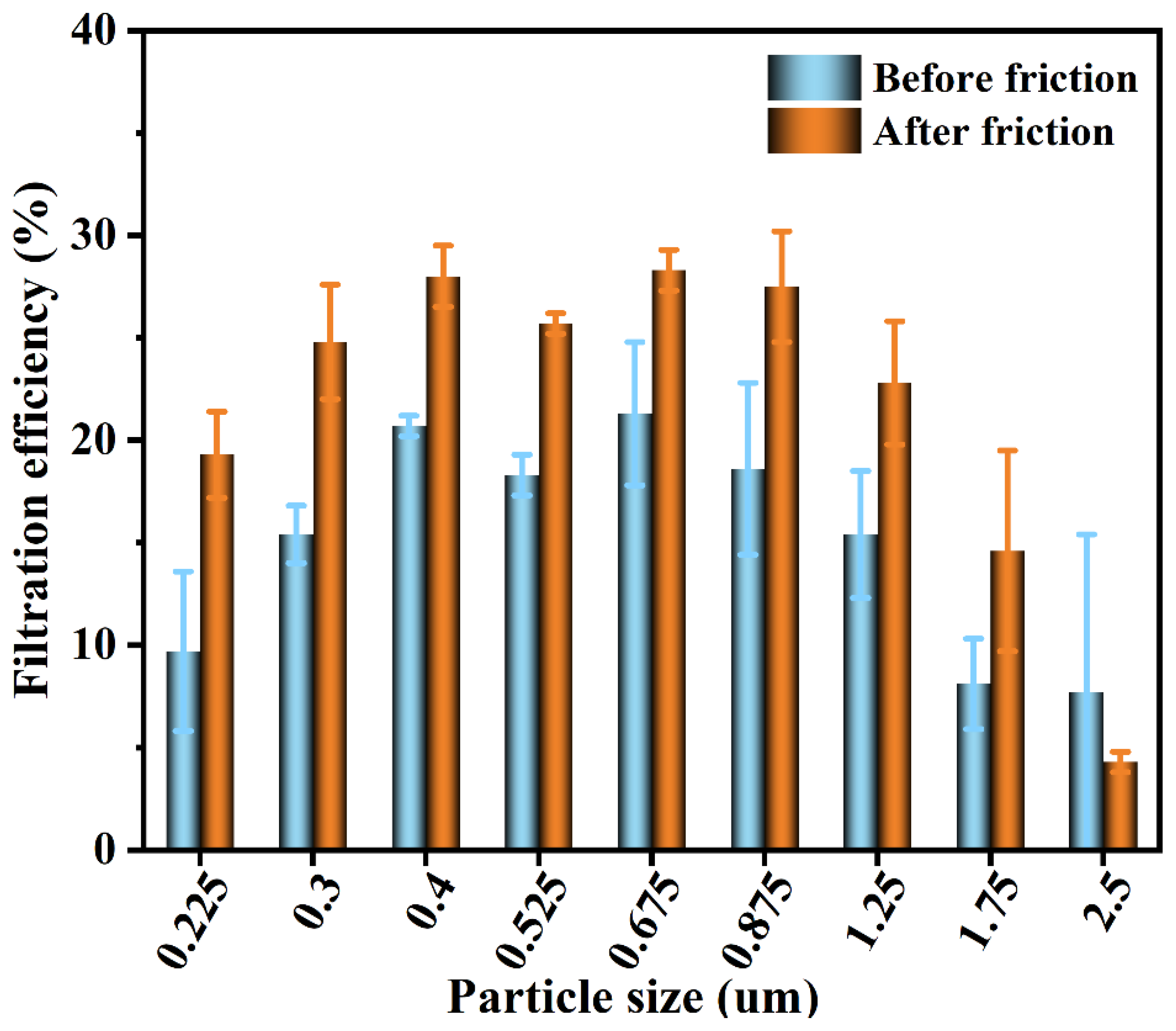

3.4. Influence of Triboelectric Effect on Silk Filtration Efficiency

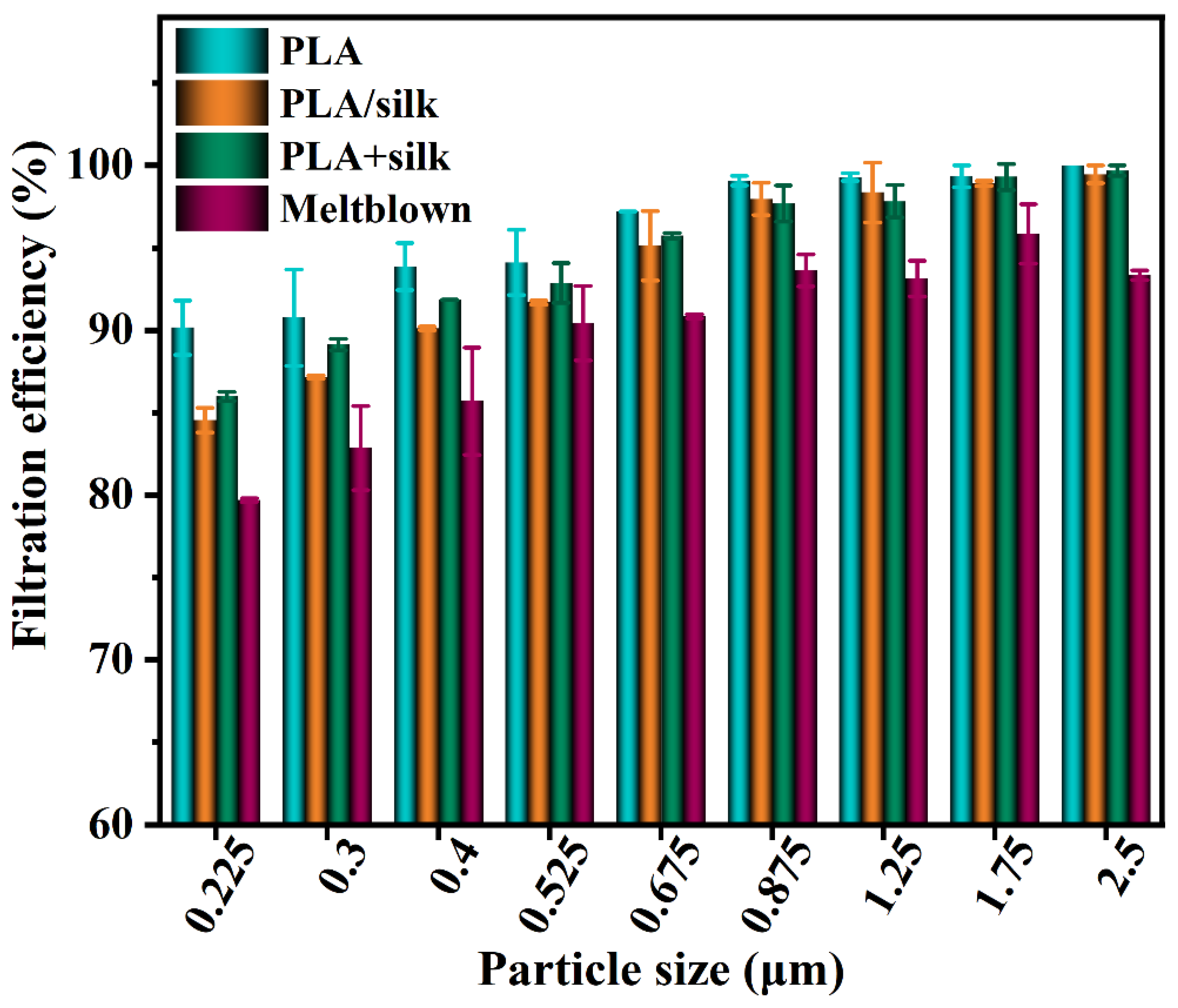

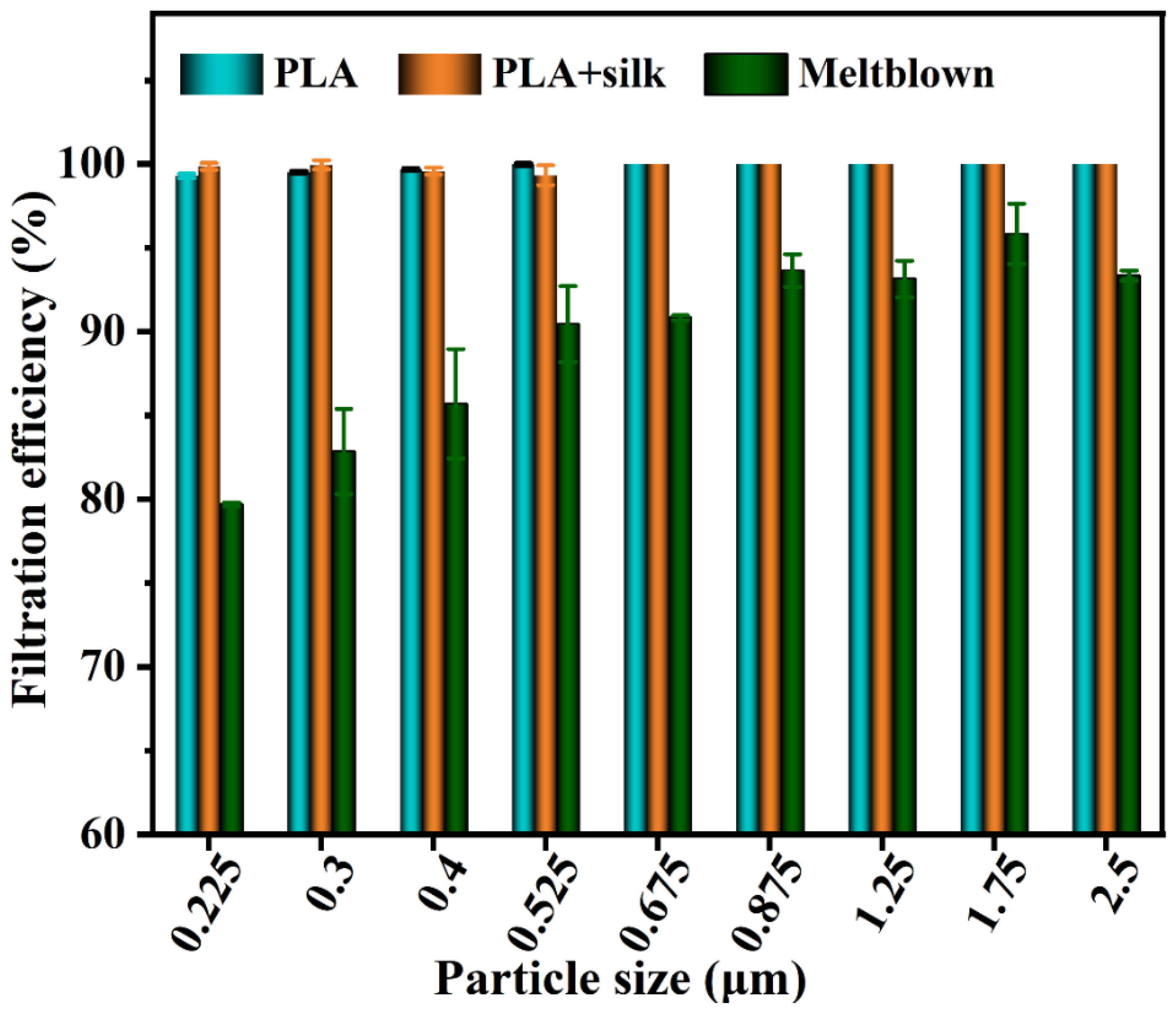

3.5. The Superimposing Effect of the Silk and PLA Nano-Fabric on Filtration Efficiency

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Stilianakis, Y.D.N.I. What aerosol physics tells us about airborne pathogen transmission. Aerosol Sci. Technol. 2020, 54, 639–643. [Google Scholar] [CrossRef]

- Aydin, O.; Emon, B.; Cheng, S.; Hong, L.; Chamorro, L.P.; Saif, M.T.A. Performance of fabrics for home-made masks against the spread of COVID-19 through droplets: A quantitative mechanistic study. Extrem. Mech. Lett. 2020, 40, 100924. [Google Scholar] [CrossRef] [PubMed]

- Wang, J.; Du, G. COVID-19 may transmit through aerosol. Ir. J. Med. Sci. 2020, 189, 1143–1144. [Google Scholar] [CrossRef] [Green Version]

- Hamilton, J.; Lewis, T.; Farmer, L.; Richards, D. Universal visors as a key measure to stop nosocomial transmission of SARS-CoV-2. J. Hosp. Infect. 2021, 111, 200–201. [Google Scholar] [CrossRef]

- Farooq Azam, F.A. Zia Uddin A Review of the Fabrication Methods, Testing, and Performance of Face Masks. Int. J. Polym. Sci. 2022, 2022, 1–20. [Google Scholar] [CrossRef]

- Drouillard, K.G.; Tomkins, A.; Lackie, S.; Laengert, S.; Baker, A.; Clase, C.M.; De Lannoy, C.F.; Cavallo-Medved, D.; Porter, L.A.; Rudman, R.S. Fitted filtration efficiency and breathability of 2-ply cotton masks: Identification of cotton consumer categories acceptable for home-made cloth mask construction. PLoS ONE 2022, 17, e0264090. [Google Scholar] [CrossRef]

- Abd-Elsayed, A.; Karri, J. Utility of Substandard Face Mask Options for Health Care Workers During the COVID-19 Pandemic. Anesth. Analg. 2020, 131, 4–6. [Google Scholar] [CrossRef]

- Németh, E.; Albrecht, V.; Schubert, G.; Simon, F. Polymer tribo-electric charging: Dependence on thermodynamic surface properties and relative humidity. J. Electrost. 2003, 58, 3–16. [Google Scholar] [CrossRef]

- Rengasamy, S.; Eimer, B.; Shaffer, R.E. Simple respiratory protection–evaluation of the filtration performance of cloth masks and common fabric materials against 20–1000 nm size particles. Ann. Occup. Hyg. 2010, 54, 789–798. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zhao, M.; Liao, L.; Xiao, W.; Yu, X.; Wang, H.; Wang, Q.; Lin, Y.L.; Kilinc-Balci, F.S.; Price, A.; Chu, L.; et al. Household Materials Selection for Homemade Cloth Face Coverings and Their Filtration Efficiency Enhancement with Triboelectric Charging. Nano Lett. 2020, 20, 5544–5552. [Google Scholar] [CrossRef] [PubMed]

- Konda, A.; Prakash, A.; Moss, G.A.; Schmoldt, M.; Grant, G.D.; Guha, S. Aerosol Filtration Efficiency of Common Fabrics Used in Respiratory Cloth Masks. ACS Nano 2020, 14, 6339–6347. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zangmeister, C.D.; Radney, J.G.; Vicenzi, E.P.; Weaver, J.L. Filtration Efficiencies of Nanoscale Aerosol by Cloth Mask Materials Used to Slow the Spread of SARS-CoV-2. ACS Nano 2020, 14, 9188–9200. [Google Scholar] [CrossRef] [PubMed]

- Hao, W.; Xu, G.; Wang, Y. Factors influencing the filtration performance of homemade face masks. J. Occup. Environ. Hyg. 2021, 18, 128–138. [Google Scholar] [CrossRef] [PubMed]

- Whiley, H.; Keerthirathne, T.P.; Nisar, M.A.; White, M.A.F.; Ross, K.E. Viral Filtration Efficiency of Fabric Masks Compared with Surgical and N95 Masks. Pathogens 2020, 9, 762. [Google Scholar] [CrossRef] [PubMed]

- Bar-On, Y.M.; Flamholz, A.; Phillips, R.; Milo, R. SARS-CoV-2 (COVID-19) by the numbers. eLife 2020, 9, e57309. [Google Scholar] [CrossRef] [Green Version]

- Liu, Y.; Ning, Z.; Chen, Y.; Guo, M.; Liu, Y.; Gali, N.K.; Sun, L.; Duan, Y.; Cai, J.; Westerdahl, D.; et al. Aerodynamic analysis of SARS-CoV-2 in two Wuhan hospitals. Nature 2020, 582, 557–560. [Google Scholar] [CrossRef]

- Xiao, H.; Xie, W.; Chen, G. Study on filtration performance and mechanism of melt-blown polypropylene electret web used as air filter material against challenge aerosols with different chemical properties. J. Funct. Mater. 2013, 44, 936–939. [Google Scholar]

- Rengasamy, S.; Eimer, B.C. Total inward leakage of nanoparticles through filtering facepiece respirators. Ann. Occup. Hyg. 2011, 55, 253–263. [Google Scholar] [CrossRef] [Green Version]

- Oner, E.; Seckin, A.C.; Egeli, D.; Seckin, M. Investigation of the Thermal Comfort Properties of Masks Used during the COVID-19 Pandemic. Int. J. Environ. Res. Public Health 2022, 19, 11275. [Google Scholar] [CrossRef]

- Maduna, L.; Patnaik, A.; Mvubu, M.; Hunter, L. Optimization of air permeability of spunlaced filter fabrics using the Box–Behnken experimental design. J. Ind. Text. 2019, 50, 675–691. [Google Scholar] [CrossRef]

- Yan, Y.X.; Lou, L.J.; Tao, J.W.; Jin, Z.M. Fabric Materials and Sportswear Anti-drag Performance Relationship. Adv. Mater Res.. 2013, 821–822, 305. [Google Scholar] [CrossRef]

- Chauhan, V.K.; Singh, J.P.; Debnath, S. Investigation on filtration properties of polyester needle-punched dust filter. J. Text. Inst. 2020, 111, 897–905. [Google Scholar] [CrossRef]

- Podgórski, A.; Bałazy, A.; Gradoń, L. Application of nanofibers to improve the filtration efficiency of the most penetrating aerosol particles in fibrous filters. Chem. Eng. Sci. 2006, 61, 6804–6815. [Google Scholar] [CrossRef]

- Wetterling, J.; Mattsson, T.; Theliander, H. Effects of surface structure on the filtration properties of microcrystalline cellulose. Sep. Purif. Technol. 2014, 136, 1–9. [Google Scholar] [CrossRef]

- Das, D.; Thakur, R.; Pradhan, A.K. Optimization of corona discharge process using Box-Behnken design of experiments. J. Electrost. 2012, 70, 469–473. [Google Scholar] [CrossRef]

- Thakur, R.; Das, D.; Das, A. Optimization of charge storage in corona-charged fibrous electrets. J. Text. Inst. 2014, 105, 676–684. [Google Scholar] [CrossRef]

- Xu, C.; Zi, Y.; Wang, A.C.; Zou, H.; Dai, Y.; He, X.; Wang, P.; Wang, Y.C.; Feng, P.; Li, D.; et al. On the Electron-Transfer Mechanism in the Contact-Electrification Effect. Adv. Mater. 2018, 30, e1706790. [Google Scholar] [CrossRef]

- Gericke, A.; Venkataraman, M.; Militky, J.; Steyn, H.; Vermaas, J. Unmasking the Mask: Investigating the Role of Physical Properties in the Efficacy of Fabric Masks to Prevent the Spread of the COVID-19 Virus. Materials 2021, 14, 7756. [Google Scholar] [CrossRef]

- Gao, D.Y.; Zhao, R.H.; Yang, X.; Chen, F.X.; Ning, X. Bicomponent PLA Nanofiber Nonwovens as Highly Efficient Filtration Media for Particulate Pollutants and Pathogens. Membranes 2021, 11, 819. [Google Scholar] [CrossRef]

- Zhao, R.H.; He, H.W.; Cai, M.; Miao, D.G.; Yuan, D.; Ming, J.F.; Wang, N.; Ning, X. Nano-Crystalline Sandwich Formed in Polylactic Acid Fibers. Macromol. Rapid Commun. 2019, 40, e1900492. [Google Scholar] [CrossRef]

- Faisal, M.; Saeki, T.; Tsuji, H.; Daimon, H.; Fujie, K. Depolymerization of poly (L-lactic acid) under hydrothermal conditions. Asian J. Chem. 2007, 19, 1714–1722. [Google Scholar]

- Yang, J.Z.; Li, F.; Lu, G.B.; Lu, Y.B.; Song, C.B.; Zhou, R.; Wu, S.H. Electrospun Biodegradable Poly(L-lactic acid) Nanofiber Membranes as Highly Porous Oil Sorbent Nanomaterials. Nanomaterials 2022, 12, 12. [Google Scholar] [CrossRef] [PubMed]

| Fabric Code | Composition | Weaving Pattern | Thickness (mm) | Fiber Diameter (µm) | Average Aperture (µm) | Gram Weight (g/m2) |

|---|---|---|---|---|---|---|

| Cotton 1 | 100% Cotton |  | 0.422 | 14.16 | 7.19 | 253.00 |

| Cotton 2 | 100% Cotton |  | 0.380 | 12.31 | 24.28 | 207.58 |

| Cotton 3 | 100% Cotton |  | 1.200 | 16.80 | 13.15 | 366.50 |

| Wool 1 | 100% Wool |  | 1.200 | 21.04 | 36.61 | 382.08 |

| Wool 2 | 100% Wool |  | 0.891 | 17.31 | 74.23 | 259.92 |

| Polyester 1 | 100% Polyester |  | 0.658 | 13.50 | 136.14 | 306.25 |

| Polyester 2 | 100% Polyester |  | 0.387 | 9.61 | 68.38 | 178.83 |

| Silk 1 | 100% Silk |  | 0.443 | 12.13 | 77.93 | 182.00 |

| Silk 2 | 100% Silk |  | 0.256 | 10.93 | 37.09 | 129.25 |

| Blend 1 | 30% Cotton/70% Polyester |  | 0.304 | 11.54 | 33.57 | 136.17 |

| Blend 2 | 20% Wool/80% Polyester |  | 1.578 | 16.10 | 46.27 | 490.08 |

| Blend 3 | 5% Wool/20% Spandex /75% Polyester |  | 0.613 | 12.75 | 80.20 | 218.75 |

| Melt-blown | 100% Polypropylene |  | 0.166 | 2.42 | 16.59 | 21.33 |

| Sample | Drape | Wrinkle Recover Rate (%) | Stretch (Trial) | Resilience Score | Softness Score | Smoothness Score |

|---|---|---|---|---|---|---|

| Cotton 1 | 32.18 | 64.28 | 0.09 | 53.78 | 45.41 | 57.09 |

| Cotton 2 | 29.42 | 66.26 | 0.19 | 49.8 | 48.01 | 48.63 |

| Cotton 3 | 12.69 | 69.58 | 0.24 | 40.69 | 63.32 | 48.49 |

| Wool 1 | 19.43 | 80.79 | 0.43 | 51.06 | 59.8 | 48.05 |

| Wool 2 | 22.33 | 75.02 | 0.5 | 57.85 | 56.44 | 52.54 |

| Polyester 1 | 13.13 | 94.13 | 0.26 | 42.6 | 60.85 | 44.47 |

| Polyester 2 | 16.27 | 95.94 | 0.3 | 32.43 | 63.81 | 46.79 |

| Silk 1 | 36.67 | 79.47 | 0.55 | 67.45 | 69.03 | 68.14 |

| Silk 2 | 14.55 | 81.4 | 0.33 | 30.5 | 64.13 | 45.69 |

| Blend1 | 8.13 | 96.8 | 0.74 | 22.1 | 75.72 | 59.23 |

| Blend2 | 21.84 | 79.57 | 0.42 | 54.56 | 57.94 | 47.69 |

| Blend3 | 14.4 | 89.59 | 0.18 | 29.05 | 60.65 | 49.46 |

| Melt-blown | 11.94 | 78.65 | 0.32 | 28.78 | 59.84 | 55.48 |

| Sample Type | Filtration Efficiency (%) | Pressure Drop (Pa) | Air Permeability (mm/s) | Product | Q (kPa−1) | Moisture Permeability (g/m2·h) | ||

|---|---|---|---|---|---|---|---|---|

| 0.3 um | 2.5 um | 0.3 μm | 2.5 μm | |||||

| Cotton3 X1 | 38.05 | 78.55 | 97.5 | 62.0 | 6045 | 4.9 | 15.8 | 206.1 |

| Cotton3 X2 | 56.4 | 94.2 | 174 | 34.5 | 6003 | 4.8 | 16.4 | - |

| Wool1 X1 | 52.1 | 83.5 | 14 | 340 | 4760 | 52.6 | 128.8 | 208.7 |

| Wool1 X2 | 73.8 | 97.9 | 33 | 164 | 5412 | 40.6 | 116.9 | - |

| Polyester2 X1 | 23.15 | 52.9 | 6 | 620 | 3720 | 43.9 | 125.5 | 235.3 |

| Polyester2 X2 | 31 | 69.7 | 19 | 264.7 | 5029.3 | 19.5 | 62.8 | - |

| Silk1 X1 | 10.6 | 16.15 | 5.5 | 1370 | 7535 | 20.4 | 32.0 | 210.9 |

| Silk1 X2 | 17.6 | 16.6 | 14.5 | 462.3 | 6703.35 | 13.4 | 12.5 | - |

| Blend1 X1 | 28.15 | 67.85 | 8 | 391 | 3128 | 41.3 | 141.8 | 175.6 |

| Blend1 X2 | 49 | 85 | 29 | 201.7 | 5849.3 | 23.2 | 65.4 | - |

| Blend2 X1 | 57.5 | 85.8 | 5 | 618.7 | 3093.5 | 171.1 | 390.1 | 264.5 |

| Blend2 X2 | 74.1 | 94.9 | 12 | 389 | 4668 | 112.6 | 248.2 | - |

| Melt-blown | 82.85 | 93.35 | 12 | 520.7 | 6248.4 | 146.9 | 225.9 | 162.5 |

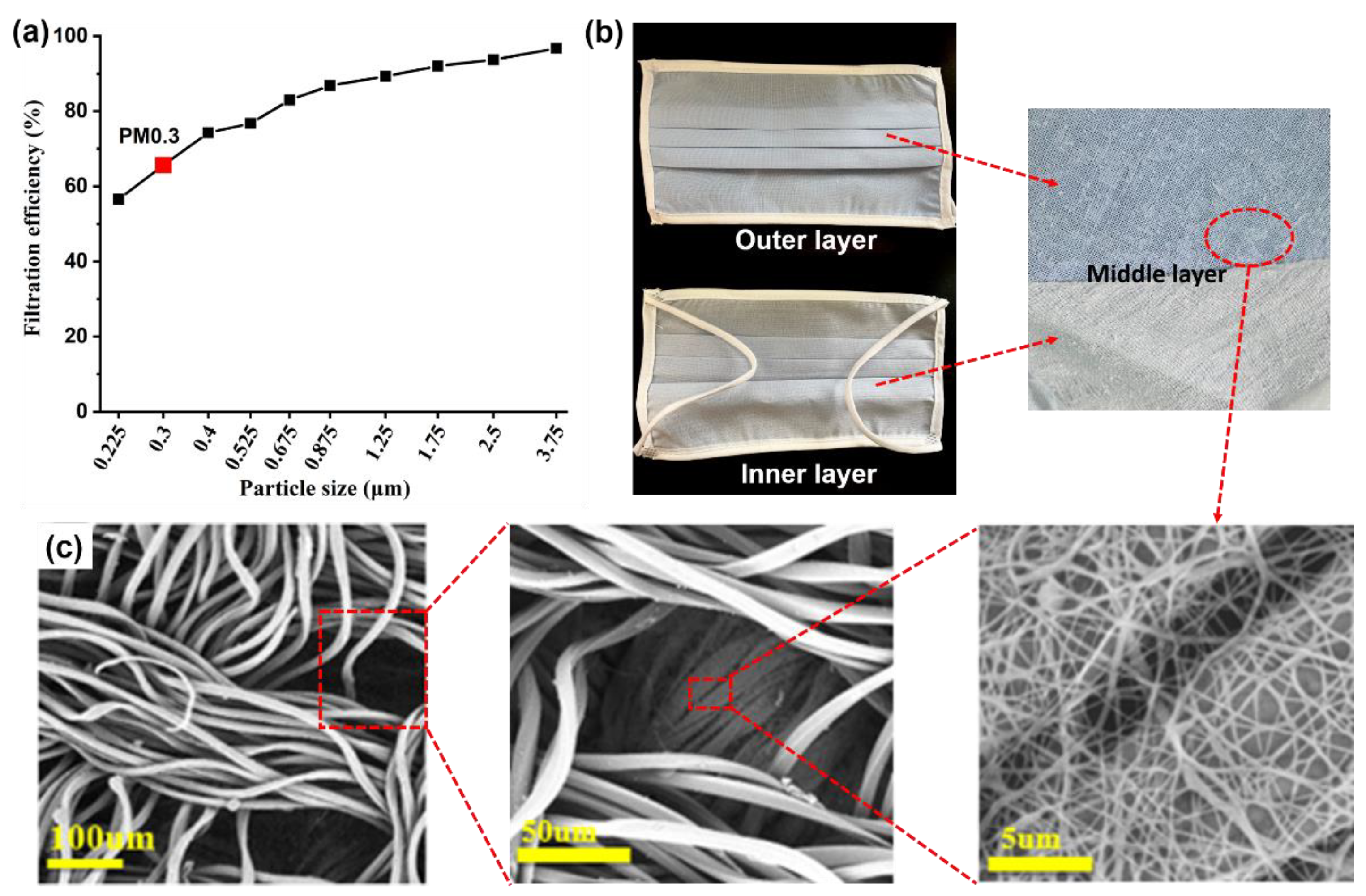

| Fiber Diameter (um) | Efficiency of Filtration (%) | Pressure Drop (Pa) | Gram Weight (g/m2) | Thickness (mm) | ||

|---|---|---|---|---|---|---|

| Outer Layer | Middle Layer | 0.3 um | 2.5 um | |||

| 12.52 | 0.15 | 65.7 | 93.7 | 30 | 99 | 0.31 |

| Sample | Initial Voltage (V) | Voltage after Attenuation (V) | Decay Rate (%) |

|---|---|---|---|

| 30 min PLA | 229 | 217 | 5 |

| 30 min PLA/silk | 1074 | 323 | 70 |

| 30 min PLA+silk | 1336 | 558 | 58 |

| 35 min PLA | 161 | 159 | 1 |

| 35 min PLA/silk | 1246 | 500 | 60 |

| 35 min PLA+silk | 1107 | 358 | 68 |

| silk | 864 | 33 | 96 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, J.; Zhao, R.; Zhao, Y.; Ning, X. Evaluation of Mask Performances in Filtration and Comfort in Fabric Combinations. Nanomaterials 2023, 13, 378. https://doi.org/10.3390/nano13030378

Wang J, Zhao R, Zhao Y, Ning X. Evaluation of Mask Performances in Filtration and Comfort in Fabric Combinations. Nanomaterials. 2023; 13(3):378. https://doi.org/10.3390/nano13030378

Chicago/Turabian StyleWang, Ji, Renhai Zhao, Yintao Zhao, and Xin Ning. 2023. "Evaluation of Mask Performances in Filtration and Comfort in Fabric Combinations" Nanomaterials 13, no. 3: 378. https://doi.org/10.3390/nano13030378