Field-Pulse-Induced Annealing of 2D Colloidal Polycrystals

Abstract

:1. Introduction

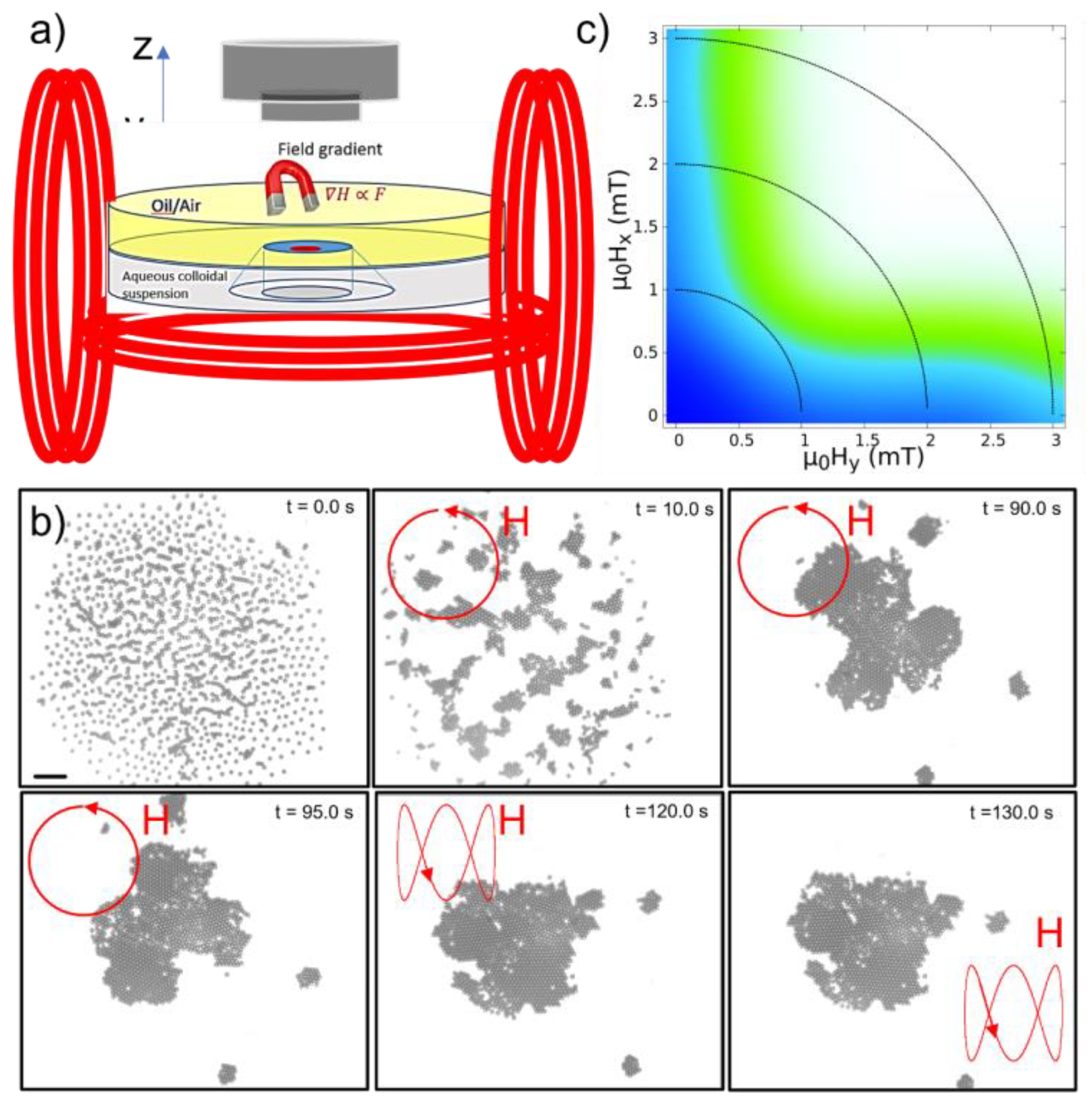

2. Materials and Methods

2.1. Magnetic Colloids

2.2. Adsorption at the Fluid Water/Decane Interface

2.3. Field Generation and System Monitorization

2.4. Formation of the Polycrystals

2.5. Pulse Effect

2.6. Degree of Alteration of the Order during the Annealing Process

2.7. Simulations

3. Results

3.1. Effect of the Pulse Duration

3.1.1. Small Polycrystals

3.1.2. Large Polycrystals

3.2. Simulations Results

4. Discussion

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Demirörs, A.F.; Pillai, P.P.; Kowalczyk, B.; Grzybowski, B.A. Colloidal assembly directed by virtual magnetic moulds. Nature 2013, 503, 99. [Google Scholar] [CrossRef] [PubMed]

- van der Meer, B.; Filion, L.; Dijkstra, M. Fabricating large two-dimensional single colloidal crystals by doping with active particles. Soft Matter 2016, 12, 3406. [Google Scholar]

- Zahn, K.; Lenke, R.; Maret, G. Two-Stage Melting of Paramagnetic Colloidal Crystals in Two Dimensions. Phys. Rev. Lett. 1999, 82, 2721. [Google Scholar] [CrossRef] [Green Version]

- Yan, J.; Bae, S.C.; Granick, S. Rotating crystals of magnetic Janus colloids. Soft. Matter. 2015, 11, 147. [Google Scholar]

- Glotzer, S.C.; Solomon, M.J. Anisotropy of building blocks and their assembly into complex structures. Nat. Mater. 2007, 6, 557. [Google Scholar]

- Li, B.; Wang, F.; Zhou, D.; Peng, Y.; Ni, R.; Han, Y. Modes of surface premelting in colloidal crystals composed of attractive particles. Nature 2016, 531, 485. [Google Scholar] [CrossRef] [Green Version]

- Whitesides, G.M.; Grzybowski, B. Self-Assembly at All Scales. Science 2002, 295, 2418. [Google Scholar] [CrossRef] [Green Version]

- Li, B.; Zhou, D.; Han, Y. Assembly and phase transitions of colloidal crystals. Nat. Rev. Mater. 2016, 1, 15011. [Google Scholar] [CrossRef] [Green Version]

- Shipway, A.N.; Katz, E.; Willner, I. Nanoparticle Arrays on Surfaces for Electronic, Optical, and Sensor Applications. ChemPhysChem 2000, 1, 18. [Google Scholar] [CrossRef]

- Lu, Y.; Yin, Y.; Xia, Y. A Self-Assembly Approach to the Fabrication of Patterned, Two-Dimensional Arrays of Microlenses of Organic Polymers. Adv. Mater. 2001, 13, 34. [Google Scholar]

- Hochbaum, A.I.; Fan, R.; He, R.; Yang, P. Controlled Growth of Si Nanowire Arrays for Device Integration. Nano Lett. 2005, 5, 457. [Google Scholar] [CrossRef]

- Shah, A.A.; Schultz, B.; Zhang, W.; Glotzer, S.C.; Solomon, M.J. Actuation of shape-memory colloidal fibres of Janus ellipsoids. Nat. Mater. 2015, 14, 117. [Google Scholar]

- Martinez-Pedrero, F.; Tierno, P. Magnetic Propulsion of Self-Assembled Colloidal Carpets: Efficient Cargo Transport via a Conveyor-Belt Effect. Phys. Rev. Appl. 2015, 3, 051003. [Google Scholar] [CrossRef] [Green Version]

- Castriciano, M.A. Functional Nanostructures for Sensors, Optoelectronic Devices, and Drug Delivery. Nanomaterials 2020, 10, 1195. [Google Scholar] [CrossRef]

- Lobmeyer, D.M.; Biswal, S.L. Grain boundary dynamics driven by magnetically induced circulation at the void interface of 2D colloidal crystals. Sci. Adv. 2022, 8, eabn5715. [Google Scholar]

- Wang, Z.; Wang, F.; Peng, Y.; Zheng, Z.; Han, Y. Imaging the homogeneous nucleation during the melting of superheated colloidal crystals. Science 2012, 338, 87. [Google Scholar] [CrossRef]

- Peng, Y.; Wang, Z.; Alsayed, A.M.; Yodh, A.G.; Han, Y. Melting of Colloidal Crystal Films. Phys. Rev. Lett. 2010, 104, 205703. [Google Scholar] [CrossRef] [Green Version]

- Wei, Q.H.; Wu, X.L. Grain boundary dynamics under mechanical annealing in two-dimensional colloids. Phys. Rev. E 2004, 70, 020401. [Google Scholar]

- Irvine, W.T.M.; Hollingsworth, A.D.; Grier, D.G.; Chaikin, P.M. Dislocation reactions, grain boundaries, and irreversibility in two-dimensional lattices using topological tweezers. Proc. Natl. Acad. Sci. USA 2013, 110, 15544. [Google Scholar] [CrossRef] [Green Version]

- Li, W.; Peng, Y.; Zhang, Y.; Still, T.; Yodh, A.G.; Han, Y. Shear-assisted grain coarsening in colloidal polycrystals. Proc. Natl. Acad. Sci. USA 2020, 117, 24055. [Google Scholar] [CrossRef]

- Dosset, J.L. Practical Heat Treating: Basic Principles, 1st ed.; ASM International: Almere, Netherlands, 2021. [Google Scholar]

- Kriminski, S.; Caylor, C.L.; Nonato, M.C.; Finkelstein, K.D.; Thorne, R.E. Flash-cooling and annealing of protein crystals. Acta Crystallogr. Sect. D 2002, 58, 459. [Google Scholar] [CrossRef] [Green Version]

- Presenda, Á.; Salvador, M.D.; Vleugels, J.; Moreno, R.; Borrell, A. Fretting fatigue wear behavior of Y-TZP dental ceramics processed by non-conventional microwave sintering. J. Am. Ceram. Soc. 2017, 100, 1842. [Google Scholar] [CrossRef]

- Zhang, X.; Han, J.; Plombon, J.J.; Sutton, A.P.; Srolovitz, D.J.; Boland, J.J. Nanocrystalline copper films are never flat. Science 2017, 357, 397. [Google Scholar] [CrossRef] [Green Version]

- Crocker, J.C.; Grier, D.G. Methods of Digital Video Microscopy for Colloidal Studies. J. Colloid Interface Sci. 1996, 179, 298. [Google Scholar] [CrossRef] [Green Version]

- Ramananarivo, S.; Ducrot, E.; Palacci, J. Activity-controlled annealing of colloidal monolayers. Nat. Commun. 2019, 10, 3380. [Google Scholar]

- Tang, X.; Rupp, B.; Yang, Y.; Edwards, T.D.; Grover, M.A.; Bevan, M.A. Optimal Feedback Controlled Assembly of Perfect Crystals. ACS Nano 2016, 10, 6791. [Google Scholar] [CrossRef]

- Zhang, J.; Yang, J.; Zhang, Y.; Bevan, M.A. Controlling colloidal crystals via morphing energy landscapes and reinforcement learning. Sci. Adv. 2020, 6, eabd6716. [Google Scholar]

- Swan, J.W.; Bauer, J.L.; Liu, Y.; Furst, E.M. Directed colloidal self-assembly in toggled magnetic fields. Soft Matter 2014, 10, 1102. [Google Scholar] [CrossRef] [Green Version]

- Sherman, Z.M.; Swan, J.W. Dynamic, Directed Self-Assembly of Nanoparticles via Toggled Interactions. ACS Nano 2016, 10, 5260. [Google Scholar] [CrossRef]

- Sherman, Z.M.; Swan, J.W. Transmutable Colloidal Crystals and Active Phase Separation via Dynamic, Directed Self-Assembly with Toggled External Fields. ACS Nano 2019, 13, 764. [Google Scholar] [CrossRef]

- Kao, P.-K.; VanSaders, B.J.; Glotzer, S.C.; Solomon, M.J. Accelerated annealing of colloidal crystal monolayers by means of cyclically applied electric fields. Sci. Rep. 2021, 11, 11042. [Google Scholar]

- Bechinger, C.; Frey, E. Phase behaviour of colloids in confining geometry. J. Phys. Condens. Matter 2001, 13, R321. [Google Scholar] [CrossRef] [Green Version]

- Dash, J.G. History of the search for continuous melting. Rev. Mod. Phys. 1999, 71, 1737. [Google Scholar] [CrossRef]

- Du, D.; Doxastakis, M.; Hilou, E.; Biswal, S.L. Two-dimensional melting of colloids with long-range attractive interactions. Soft Matter 2017, 13, 1548. [Google Scholar] [CrossRef] [Green Version]

- Martínez-Pedrero, F.; Benet, J.; Rubio, J.E.F.; Sanz, E.; Rubio, R.G.; Ortega, F. Field-induced sublimation in perfect two-dimensional colloidal crystals. Phys. Rev. E 2014, 89, 012306. [Google Scholar]

- Martínez-Pedrero, F.; González-Banciella, A.; Camino, A.; Mateos-Maroto, A.; Ortega, F.; Rubio, R.G.; Pagonabarraga, I.; Calero, C. Static and Dynamic Self-Assembly of Pearl-Like-Chains of Magnetic Colloids Confined at Fluid Interfaces. Small 2021, 17, 2101188. [Google Scholar] [CrossRef]

- Helseth, L.E.; Wen, H.Z.; Hansen, R.W.; Johansen, T.H.; Heinig, P.; Fischer, T.M. Assembling and manipulating two-dimensional colloidal crystals with movable nanomagnets. Langmuir 2004, 20, 7323. [Google Scholar] [CrossRef]

- Martínez-Pedrero, F.; Ortega, F.; Codina, J.; Calero, C.; Rubio, R.G. Controlled disassembly of colloidal aggregates confined at fluid interfaces using magnetic dipolar interactions. J. Colloid Interface Sci. 2020, 560, 388. [Google Scholar] [CrossRef]

- Martínez-Pedrero, F.; Ortega, F.; Rubio, R.G.; Calero, C. Collective Transport of Magnetic Microparticles at a Fluid Interface through Dynamic Self-Assembled Lattices. Adv. Funct. Mater. 2020, 30, 2002206. [Google Scholar] [CrossRef]

- Helseth, L.E. Self-assembly of colloidal pyramids in magnetic fields. Langmuir 2005, 21, 7276. [Google Scholar] [CrossRef]

- Martín-Roca, J.; Jiménez, M.; Ortega, F.; Calero, C.; Valeriani, C.; Rubio, R.G.; Martínez-Pedrero, F. Rotating Micro-Spheres for adsorption monitoring at a fluid interface. J. Colloid Interface Sci. 2022, 614, 378. [Google Scholar] [CrossRef]

- Helgesen, G.; Pieranski, P.; Skjeltorp, A.T. Nonlinear phenomena in systems of magnetic holes. Phys. Rev. Lett. 1990, 64, 1425. [Google Scholar] [CrossRef]

- Osterman, N.; Poberaj, I.; Dobnikar, J.; Frenkel, D.; Ziherl, P.; Babić, D. Field-Induced Self-Assembly of Suspended Colloidal Membranes. Phys. Rev. Lett. 2009, 103, 228301. [Google Scholar] [CrossRef] [Green Version]

- Allen, M.P.; Allen, M.P.; Tildesley, D.J.; Tildesley, D.J. Computer Simulation of Liquids; Clarendon Press: Oxford, England, 1989. [Google Scholar]

- Ermak, D.L.; Mccammon, J.A. Brownian dynamics with hydrodynamic interactions. J. Chem. Phys. 1978, 69, 1352. [Google Scholar] [CrossRef]

- Schaertl, W.; Sillescu, H. Brownian dynamics of polydisperse colloidal hard spheres: Equilibrium structures and random close packings. J. Stat. Phys. 1994, 77, 1007. [Google Scholar] [CrossRef]

- Yung, K.W.; Landecker, P.B.; Villani, D.D. An Analytic Solution for the Force Between Two Magnetic Dipoles. Magn. Electr. Sep. 1998, 9, 079537. [Google Scholar]

- Toxvaerd, S.; Heilmann, O.J.; Dyre, J.C. Energy conservation in molecular dynamics simulations of classical systems. J. Chem. Phys. 2012, 136, 224106. [Google Scholar] [CrossRef] [Green Version]

- Cullity, B.D.; Graham, C.D. Introduction to Magnetic Materials; Wiley: Hoboken, NJ, USA, 2011. [Google Scholar]

- Nishinaga, T. Handbook of Crystal Growth 2E; Elsevier: Amsterdam, The Netherlands, 2015. [Google Scholar]

- Liu, M.; Shi, J.; Li, Y.; Zhou, X.; Ma, D.; Qi, Y.; Zhang, Y.; Liu, Z. Temperature-Triggered Sulfur Vacancy Evolution in Monolayer MoS2/Graphene Heterostructures. Small 2017, 13, 1602967. [Google Scholar] [CrossRef]

- Sinclair, R.; Ponce, F.A.; Yamashita, T.; Smith, D.J.; Camps, R.A.; Freeman, L.A.; Erasmus, S.J.; Nixon, W.C.; Smith, K.C.A.; Catto, C.J.D. Dynamic observation of defect annealing in CdTe at lattice resolution. Nature 1982, 298, 127. [Google Scholar] [CrossRef]

- Deng, S.; Li, R.; Park, J.-E.; Guan, J.; Choo, P.; Hu, J.; Smeets, P.J.M.; Odom, T.W. Ultranarrow plasmon resonances from annealed nanoparticle lattices. Proc. Natl. Acad. Sci. USA 2020, 117, 23380. [Google Scholar] [CrossRef]

- Yasui, K.; Kato, K. Oriented Attachment of Cubic or Spherical BaTiO3 Nanocrystals by van der Waals Torque. J. Phys. Chem. C 2015, 119, 24597. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Martín-Roca, J.; Horcajo-Fernández, M.; Valeriani, C.; Gámez, F.; Martínez-Pedrero, F. Field-Pulse-Induced Annealing of 2D Colloidal Polycrystals. Nanomaterials 2023, 13, 397. https://doi.org/10.3390/nano13030397

Martín-Roca J, Horcajo-Fernández M, Valeriani C, Gámez F, Martínez-Pedrero F. Field-Pulse-Induced Annealing of 2D Colloidal Polycrystals. Nanomaterials. 2023; 13(3):397. https://doi.org/10.3390/nano13030397

Chicago/Turabian StyleMartín-Roca, José, Manuel Horcajo-Fernández, Chantal Valeriani, Francisco Gámez, and Fernando Martínez-Pedrero. 2023. "Field-Pulse-Induced Annealing of 2D Colloidal Polycrystals" Nanomaterials 13, no. 3: 397. https://doi.org/10.3390/nano13030397