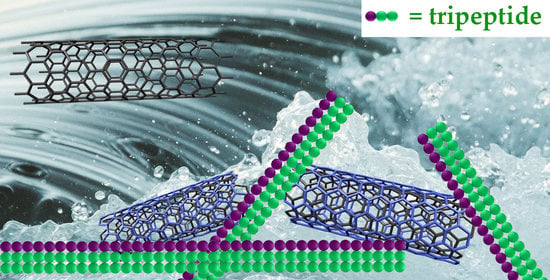

Hydrogels from a Self-Assembling Tripeptide and Carbon Nanotubes (CNTs): Comparison between Single-Walled and Double-Walled CNTs

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials and General Methods

2.2. DWCNT Production

2.3. DWCNT Oxidation

2.4. SWCNT Oxidation

2.5. L-Leu-D-Phe-D-Phe (Lff) Preparation

2.6. Thermogravimetric Analysis (TGA)

2.7. Visible-Near Infrared (Vis-NIR) Absorbance Spectroscopy

2.8. Raman Analysis

2.9. Transmission Electron Microscopy (TEM)

2.10. Fourier-Transformed Infrared (FT-IR) Spectroscopy

2.11. Self-Assembly into Nanocomposite Hydrogels

2.12. Oscillatory Rheology

3. Results and Discussion

3.1. SWCNT and DWCNT Characterization and Oxidation

3.2. Hydrogels with Self-Assembling Tripeptide and CNTs

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Darwish, M.S.A.; Mostafa, M.H.; Al-Harbi, L.M. Polymeric nanocomposites for environmental and industrial applications. Int. J. Mol. Sci. 2022, 23, 1023. [Google Scholar] [CrossRef]

- Huang, J.; Zhou, J.; Liu, M. Interphase in polymer nanocomposites. JACS Au 2022, 2, 280–291. [Google Scholar] [CrossRef] [PubMed]

- Malik, S.; Krasheninnikov, A.V.; Marchesan, S. Advances in nanocarbon composite materials. Beilstein J. Nanotechnol. 2018, 9, 20–21. [Google Scholar] [CrossRef] [Green Version]

- Melchionna, M.; Prato, M. Functionalizing carbon nanotubes: An indispensible step towards applications. ECS J. Solid State Sci. Technol. 2013, 2, M3040. [Google Scholar] [CrossRef]

- Marchesan, S.; Melchionna, M.; Prato, M. Wire up on carbon nanostructures! How to play a winning game. ACS Nano 2015, 9, 9441–9450. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Dhiman, N.; Ghosh, S.; Mishra, Y.K.; Tripathi, K.M. Prospects of nano-carbons as emerging catalysts for enzyme-mimetic applications. Mater. Adv. 2022, 3, 3101–3122. [Google Scholar] [CrossRef]

- Gerber, I.C.; Serp, P. A theory/experience description of support effects in carbon-supported catalysts. Chem. Rev. 2020, 120, 1250–1349. [Google Scholar] [CrossRef] [PubMed]

- Melchionna, M.; Prato, M.; Fornasiero, P. Mix and match metal oxides and nanocarbons for new photocatalytic frontiers. Catal. Today 2016, 277, 202–213. [Google Scholar] [CrossRef]

- Zhong, M.; Zhang, M.; Li, X. Carbon nanomaterials and their composites for supercapacitors. Carbon Energy 2022, 4, 950–985. [Google Scholar] [CrossRef]

- Karamveer, S.; Thakur, V.K.; Siwal, S.S. Synthesis and overview of carbon-based materials for high performance energy storage application: A review. Mater. Today Proc. 2022, 56, 9–17. [Google Scholar] [CrossRef]

- Antonietti, M.; Bandosz, T.; Centi, G.; Costa, R.; Cruz-Silva, R.; Di, J.; Feng, X.; Frank, B.; Gebhardt, P.; Guld, D.M.; et al. Nanocarbon-Inorganic Hybrids: Next Generation Composites for Sustainable Energy Applications; Eder, D., Schlögl, R., Eds.; Walter de Gruyter GmbH & Co KG: Göttingen, Germany, 2014. [Google Scholar]

- Silva, M.R.F.; Lourenço, M.A.O.; Tobaldi, D.M.; da Silva, C.F.; Seabra, M.P.; Ferreira, P. Carbon-modified titanium oxide materials for photocatalytic water and air decontamination. Chem. Eng. J. 2020, 387, 124099. [Google Scholar] [CrossRef]

- Liao, Z.; Zi, Y.; Zhou, C.; Zeng, W.; Luo, W.; Zeng, H.; Xia, M.; Luo, Z. Recent advances in the synthesis, characterization, and application of carbon nanomaterials for the removal of endocrine-disrupting chemicals: A review. Int. J. Mol. Sci. 2022, 23, 13148. [Google Scholar] [CrossRef]

- Goyat, R.; Saharan, Y.; Singh, J.; Umar, A.; Akbar, S. Synthesis of graphene-based nanocomposites for environmental remediation applications: A review. Molecules 2022, 27, 6433. [Google Scholar] [CrossRef]

- Rivas-Sanchez, A.; Cruz-Cruz, A.; Gallareta-Olivares, G.; Gonzalez-Gonzalez, R.B.; Parra-Saldivar, R.; Iqbal, H.M.N. Carbon-based nanocomposite materials with multifunctional attributes for environmental remediation of emerging pollutants. Chemosphere 2022, 303, 135054. [Google Scholar] [CrossRef]

- Zhang, J.; Lin, G.; Vaidya, U.; Wang, H. Past, present and future prospective of global carbon fibre composite developments and applications. Compos. Part B 2023, 250, 110463. [Google Scholar] [CrossRef]

- Sun, T.; Zhang, X.; Qiu, B.; Zhang, H.; Zhang, C.; Zhou, J.; Heng, Z.; Xu, Z.; Liang, M.; Zou, H. Graphene oxide/polymer-based multi-scale reinforcement structures for enhanced interfacial properties of carbon fiber composites. ACS Appl. Nano Mater. 2022, 5, 10777–10785. [Google Scholar] [CrossRef]

- Niculescu, A.G.; Grumezescu, A.M. Novel tumor-targeting nanoparticles for cancer treatment—A review. Int. J. Mol. Sci. 2022, 23, 5253. [Google Scholar] [CrossRef] [PubMed]

- Marchesan, S.; Melchionna, M.; Prato, M. Carbon nanostructures for nanomedicine: Opportunities and challenges. Fuller. Nanotub. Carbon Nanostruct. 2014, 22, 190–195. [Google Scholar] [CrossRef]

- Ji, D.K.; Ménard-Moyon, C.; Bianco, A. Physically-triggered nanosystems based on two-dimensional materials for cancer theranostics. Adv. Drug Deliv. Rev. 2019, 138, 211–232. [Google Scholar] [CrossRef]

- Fusco, L.; Gazzi, A.; Peng, G.; Shin, Y.; Vranic, S.; Bedognetti, D.; Vitale, F.; Yilmazer, A.; Feng, X.; Fadeel, B.; et al. Graphene and other 2d materials: A multidisciplinary analysis to uncover the hidden potential as cancer theranostics. Theranostics 2020, 10, 5435–5488. [Google Scholar] [CrossRef]

- Kang, M.S.; Lee, H.; Jeong, S.J.; Eom, T.J.; Kim, J.; Han, D.W. State of the art in carbon nanomaterials for photoacoustic imaging. Biomedicines 2022, 10, 1374. [Google Scholar] [CrossRef]

- Kumar, N.; Chamoli, P.; Misra, M.; Manoj, M.K.; Sharma, A. Advanced metal and carbon nanostructures for medical, drug delivery and bio-imaging applications. Nanoscale 2022, 14, 3987–4017. [Google Scholar] [CrossRef]

- Speranza, G. Carbon nanomaterials: Synthesis, functionalization and sensing applications. Nanomaterials 2021, 11, 967. [Google Scholar] [CrossRef]

- Mondal, J.; An, J.M.; Surwase, S.S.; Chakraborty, K.; Sutradhar, S.C.; Hwang, J.; Lee, J.; Lee, Y.-K. Carbon nanotube and its derived nanomaterials based high performance biosensing platform. Biosensors 2022, 12, 731. [Google Scholar] [CrossRef] [PubMed]

- Fahmy, H.M.; Abu Serea, E.S.; Salah-Eldin, R.E.; Al-Hafiry, S.A.; Ali, M.K.; Shalan, A.E.; Lanceros-Mendez, S. Recent progress in graphene- and related carbon-nanomaterial-based electrochemical biosensors for early disease detection. ACS Biomater. Sci. Eng. 2022, 8, 964–1000. [Google Scholar] [CrossRef] [PubMed]

- Marchesan, S.; Bosi, S.; Alshatwi, A.; Prato, M. Carbon nanotubes for organ regeneration: An electrifying performance. Nano Today 2016, 11, 398–401. [Google Scholar] [CrossRef]

- Malik, S.; Ruddock, F.M.; Dowling, A.H.; Byrne, K.; Schmitt, W.; Khalakhan, I.; Nemoto, Y.; Guo, H.; Shrestha, L.K.; Ariga, K.; et al. Graphene composites with dental and biomedical applicability. Beilstein J. Nanotechnol. 2018, 9, 801–808. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Bellet, P.; Gasparotto, M.; Pressi, S.; Fortunato, A.; Scapin, G.; Mba, M.; Menna, E.; Filippini, F. Graphene-based scaffolds for regenerative medicine. Nanomaterials 2021, 11, 404. [Google Scholar] [CrossRef]

- Adorinni, S.; Rozhin, P.; Marchesan, S. Smart hydrogels meet carbon nanomaterials for new frontiers in medicine. Biomedicines 2021, 9, 570. [Google Scholar] [CrossRef]

- Llerena Zambrano, B.; Renz, A.F.; Ruff, T.; Lienemann, S.; Tybrandt, K.; Vörös, J.; Lee, J. Soft electronics based on stretchable and conductive nanocomposites for biomedical applications. Adv. Healthc. Mater. 2021, 10, e2001397. [Google Scholar] [CrossRef]

- Rani Aluri, E.; Gannon, E.; Singh, K.; Kolagatla, S.; Kowiorski, K.; Shingte, S.; McKiernan, E.; Moloney, C.; McGarry, K.; Jowett, L.; et al. Graphene oxide modulates inter-particle interactions in 3d printable soft nanocomposite hydrogels restoring magnetic hyperthermia responses. J. Colloid Interface Sci. 2022, 611, 533–544. [Google Scholar] [CrossRef] [PubMed]

- Shen, K.H.; Lu, C.H.; Kuo, C.Y.; Li, B.Y.; Yeh, Y.C. Smart near infrared-responsive nanocomposite hydrogels for therapeutics and diagnostics. J. Mater. Chem. B 2021, 9, 7100–7116. [Google Scholar] [CrossRef] [PubMed]

- Monks, P.; Wychowaniec, J.K.; McKiernan, E.; Clerkin, S.; Crean, J.; Rodriguez, B.J.; Reynaud, E.G.; Heise, A.; Brougham, D.F. Spatiotemporally resolved heat dissipation in 3D patterned magnetically responsive hydrogels. Small 2021, 17, 2004452. [Google Scholar] [CrossRef] [PubMed]

- Marchesan, S.; Ballerini, L.; Prato, M. Nanomaterials for stimulating nerve growth. Science 2017, 356, 1010–1011. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Iglesias, D.; Bosi, S.; Melchionna, M.; Da Ros, T.; Marchesan, S. The glitter of carbon nanostructures in hybrid/composite hydrogels for medicinal use. Curr. Top. Med. Chem. 2016, 16, 1976–1989. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Hamley, I.W. Small bioactive peptides for biomaterials design and therapeutics. Chem. Rev. 2017, 117, 14015–14041. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- La Manna, S.; Di Natale, C.; Onesto, V.; Marasco, D. Self-assembling peptides: From design to biomedical applications. Int. J. Mol. Sci. 2021, 22, 12662. [Google Scholar] [CrossRef]

- Jervis, P.J.; Amorim, C.; Pereira, T.; Martins, J.A.; Ferreira, P.M.T. Dehydropeptide supramolecular hydrogels and nanostructures as potential peptidomimetic biomedical materials. Int. J. Mol. Sci. 2021, 22, 2528. [Google Scholar] [CrossRef] [PubMed]

- Uzunalli, G.; Guler, M.O. Peptide gels for controlled release of proteins. Ther. Deliv. 2020, 11, 193–211. [Google Scholar] [CrossRef]

- Ghosh, M.; Halperin-Sternfeld, M.; Adler-Abramovich, L. Bio mimicking of extracellular matrix. In Biological and Bio-Inspired Nanomaterials: Properties and Assembly Mechanisms; Perrett, S., Buell, A.K., Knowles, T.P.J., Eds.; Springer: Singapore, 2019; pp. 371–399. [Google Scholar]

- Adams, D.J. Dipeptide and tripeptide conjugates as low-molecular-weight hydrogelators. Macromol. Biosci. 2011, 11, 160–173. [Google Scholar] [CrossRef]

- Diaferia, C.; Rosa, E.; Morelli, G.; Accardo, A. Fmoc-diphenylalanine hydrogels: Optimization of preparation methods and structural insights. Pharmaceuticals 2022, 15, 1048. [Google Scholar] [CrossRef] [PubMed]

- Mayans, E.; Alemán, C. Revisiting the self-assembly of highly aromatic phenylalanine homopeptides. Molecules 2020, 25, 6037. [Google Scholar] [CrossRef] [PubMed]

- Brown, N.; Lei, J.; Zhan, C.; Shimon, L.J.W.; Adler-Abramovich, L.; Wei, G.; Gazit, E. Structural polymorphism in a self-assembled tri-aromatic peptide system. ACS Nano 2018, 12, 3253–3262. [Google Scholar] [CrossRef]

- Guilbaud-Chéreau, C.; Dinesh, B.; Wagner, L.; Chaloin, O.; Ménard-Moyon, C.; Bianco, A. Aromatic dipeptide homologue-based hydrogels for photocontrolled drug release. Nanomaterials 2022, 12, 1643. [Google Scholar] [CrossRef] [PubMed]

- Ligorio, C.; Zhou, M.; Wychowaniec, J.K.; Zhu, X.; Bartlam, C.; Miller, A.F.; Vijayaraghavan, A.; Hoyland, J.A.; Saiani, A. Graphene oxide containing self-assembling peptide hybrid hydrogels as a potential 3d injectable cell delivery platform for intervertebral disc repair applications. Acta Biomater. 2019, 92, 92–103. [Google Scholar] [CrossRef] [PubMed]

- Dinesh, B.; Squillaci, M.A.; Ménard-Moyon, C.; Samorì, P.; Bianco, A. Self-assembly of diphenylalanine backbone homologues and their combination with functionalized carbon nanotubes. Nanoscale 2015, 7, 15873–15879. [Google Scholar] [CrossRef] [Green Version]

- Marchesan, S.; Waddington, L.; Easton, C.D.; Winkler, D.A.; Goodall, L.; Forsythe, J.; Hartley, P.G. Unzipping the role of chirality in nanoscale self-assembly of tripeptide hydrogels. Nanoscale 2012, 4, 6752–6760. [Google Scholar] [CrossRef]

- Vargiu, A.V.; Iglesias, D.; Styan, K.E.; Waddington, L.J.; Easton, C.D.; Marchesan, S. Design of a hydrophobic tripeptide that self-assembles into amphiphilic superstructures forming a hydrogel biomaterial. Chem. Commun. 2016, 52, 5912–5915. [Google Scholar] [CrossRef]

- Iglesias, D.; Melle-Franco, M.; Kurbasic, M.; Melchionna, M.; Abrami, M.; Grassi, M.; Prato, M.; Marchesan, S. Oxidized nanocarbons-tripeptide supramolecular hydrogels: Shape matters! ACS Nano 2018, 12, 5530–5538. [Google Scholar] [CrossRef]

- Marin, D.; Bartkowski, M.; Kralj, S.; Rosetti, B.; D’Andrea, P.; Adorinni, S.; Marchesan, S.; Giordani, S. Supramolecular hydrogels from a tripeptide and carbon nano-onions for biological applications. Nanomaterials 2023, 13, 172. [Google Scholar] [CrossRef]

- Cringoli, M.C.; Kralj, S.; Kurbasic, M.; Urban, M.; Marchesan, S. Luminescent supramolecular hydrogels from a tripeptide and nitrogen-doped carbon nanodots. Beilstein J. Nanotechnol. 2017, 8, 1553–1562. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Flahaut, E.; Bacsa, R.; Peigney, A.; Laurent, C. Gram-scale CCVD synthesis of double-walled carbon nanotubes. Chem. Commun. 2003, 1442–1443. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Bortolamiol, T.; Lukanov, P.; Galibert, A.-M.; Soula, B.; Lonchambon, P.; Datas, L.; Flahaut, E. Double-walled carbon nanotubes: Quantitative purification assessment, balance between purification and degradation and solution filling as an evidence of opening. Carbon 2014, 78, 79–90. [Google Scholar] [CrossRef] [Green Version]

- Bouilly, D.; Cabana, J.; Meunier, F.; Desjardins-Carrière, M.; Lapointe, F.; Gagnon, P.; Larouche, F.L.; Adam, E.; Paillet, M.; Martel, R. Wall-selective probing of double-walled carbon nanotubes using covalent functionalization. ACS Nano 2011, 5, 4927–4934. [Google Scholar] [CrossRef] [PubMed]

- Singh, P.; Campidelli, S.; Giordani, S.; Bonifazi, D.; Bianco, A.; Prato, M. Organic functionalisation and characterisation of single-walled carbon nanotubes. Chem. Soc. Rev. 2009, 38, 2214–2230. [Google Scholar] [CrossRef]

- Dresselhaus, M.S.; Jorio, A.; Souza Filho, A.G.; Saito, R. Defect characterization in graphene and carbon nanotubes using Raman spectroscopy. Mater. Sci. Poland 2010, 368, 5355–5377. [Google Scholar] [CrossRef] [Green Version]

- Osswald, S.; Flahaut, E.; Gogotsi, Y. In situ raman spectroscopy study of oxidation of double- and single-wall carbon nanotubes. Chem. Mater. 2006, 18, 1525–1533. [Google Scholar] [CrossRef]

- Costa, S.; Borowiak-Palen, E.; Kruszynska, M.; Bachmatiuk, A.; Kalenczuk, R. Characterization of carbon nanotubes by Raman spectroscopy. Mater. Sci. Poland 2008, 26, 433–441. [Google Scholar]

- Bantignies, J.L.; Sauvajol, J.L.; Rahmani, A.; Flahaut, E. Infrared-active phonons in carbon nanotubes. Phys. Rev. B 2006, 74, 195425. [Google Scholar] [CrossRef] [Green Version]

- Branca, C.; Frusteri, F.; Magazù, V.; Mangione, A. Characterization of carbon nanotubes by tem and infrared spectroscopy. J. Phys. Chem. B 2004, 108, 3469–3473. [Google Scholar] [CrossRef]

- Brozena, A.H.; Moskowitz, J.; Shao, B.; Deng, S.; Liao, H.; Gaskell, K.J.; Wang, Y. Outer wall selectively oxidized, water-soluble double-walled carbon nanotubes. J. Am. Chem. Soc. 2010, 132, 3932–3938. [Google Scholar] [CrossRef] [PubMed]

- Green, A.A.; Hersam, M.C. Properties and application of double-walled carbon nanotubes sorted by outer-wall electronic type. ACS Nano 2011, 5, 1459–1467. [Google Scholar] [CrossRef] [PubMed]

- Barrejón, M.; Zummo, F.; Mikhalchan, A.; Vilatela, J.J.; Fontanini, M.; Scaini, D.; Ballerini, L.; Prato, M. Tegylated double-walled carbon nanotubes as platforms to engineer neuronal networks. ACS Appl. Mater. Interfaces 2023, 15, 77–90. [Google Scholar] [CrossRef] [PubMed]

| p-DWCNTs | ox-DWCNTs | ||

|---|---|---|---|

| ω (cm−1) | d (nm) | ω (cm−1) | d (nm) |

| 150 | 1.6 | - | - |

| 161 | 1.5 | 161 | 1.5 |

| 168, 175 | 1.4 | 168, 175 | 1.4 |

| 204 | 1.2 | 203 | 1.2 |

| 209 | 1.1 | 211 | 1.1 |

| 227, 235 | 1.0 | 238 | 1.0 |

| 251, 261, 268, 275 | 0.9 | 267 | 0.9 |

| 310 | 0.7 | 310 | 0.7 |

| Hydrogel Material | CNT Loading (mg/mL) | G’ (kPa) | G” (kPa) | Gel Rupture (Pa) |

|---|---|---|---|---|

| Peptide hydrogel [51] | 0 | 2.0 ± 0.2 | 0.1 ± 0.0 | 70 ± 14 |

| + ox-DWCNTs | 0.1 | 38 ± 5.5 | 1.0 ± 0.1 | 72 ± 11 |

| + ox-DWCNTs | 1.0 | 38 ± 2.8 | 1.0 ± 0.1 | 110 ± 19 |

| + ox-SWCNTs | 0.1 | 8.2 ± 2.4 | 0.3 ± 0.1 | 63 ± 6.7 |

| + ox-SWCNTs | 1.0 | 7.6 ± 2.8 | 0.4 ± 0.1 | 45 ± 23 |

| + ox-MWCNTs [51] | 0.1 | 3.0 ± 1.0 | 0.1 ± 0.0 | 110 |

| + ox-MWCNTs [51] | 1.0 | 6.1 ± 2.0 | 0.2 ± 0.1 | 250 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rozhin, P.; Kralj, S.; Soula, B.; Marchesan, S.; Flahaut, E. Hydrogels from a Self-Assembling Tripeptide and Carbon Nanotubes (CNTs): Comparison between Single-Walled and Double-Walled CNTs. Nanomaterials 2023, 13, 847. https://doi.org/10.3390/nano13050847

Rozhin P, Kralj S, Soula B, Marchesan S, Flahaut E. Hydrogels from a Self-Assembling Tripeptide and Carbon Nanotubes (CNTs): Comparison between Single-Walled and Double-Walled CNTs. Nanomaterials. 2023; 13(5):847. https://doi.org/10.3390/nano13050847

Chicago/Turabian StyleRozhin, Petr, Slavko Kralj, Brigitte Soula, Silvia Marchesan, and Emmanuel Flahaut. 2023. "Hydrogels from a Self-Assembling Tripeptide and Carbon Nanotubes (CNTs): Comparison between Single-Walled and Double-Walled CNTs" Nanomaterials 13, no. 5: 847. https://doi.org/10.3390/nano13050847